Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve groove accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

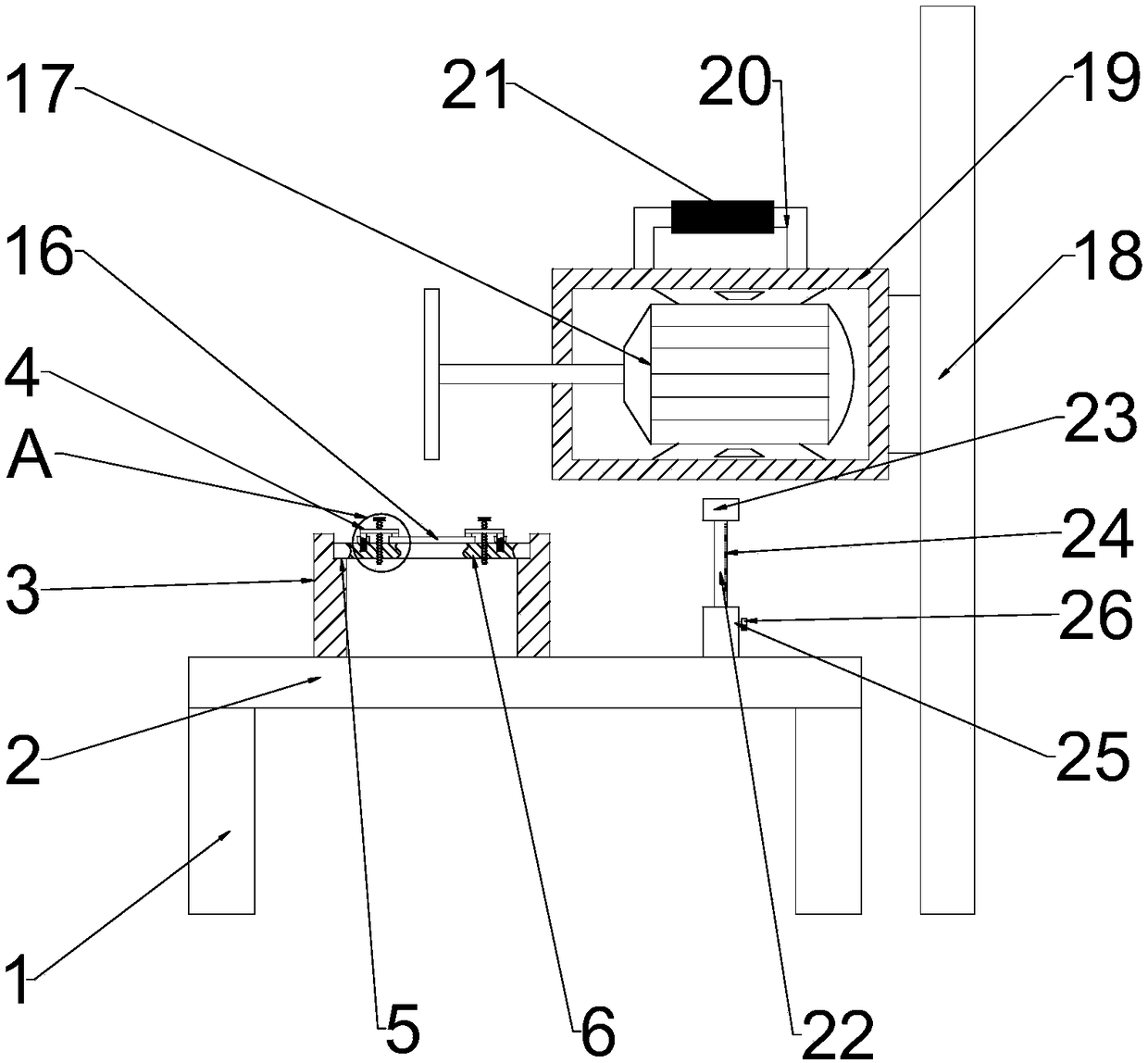

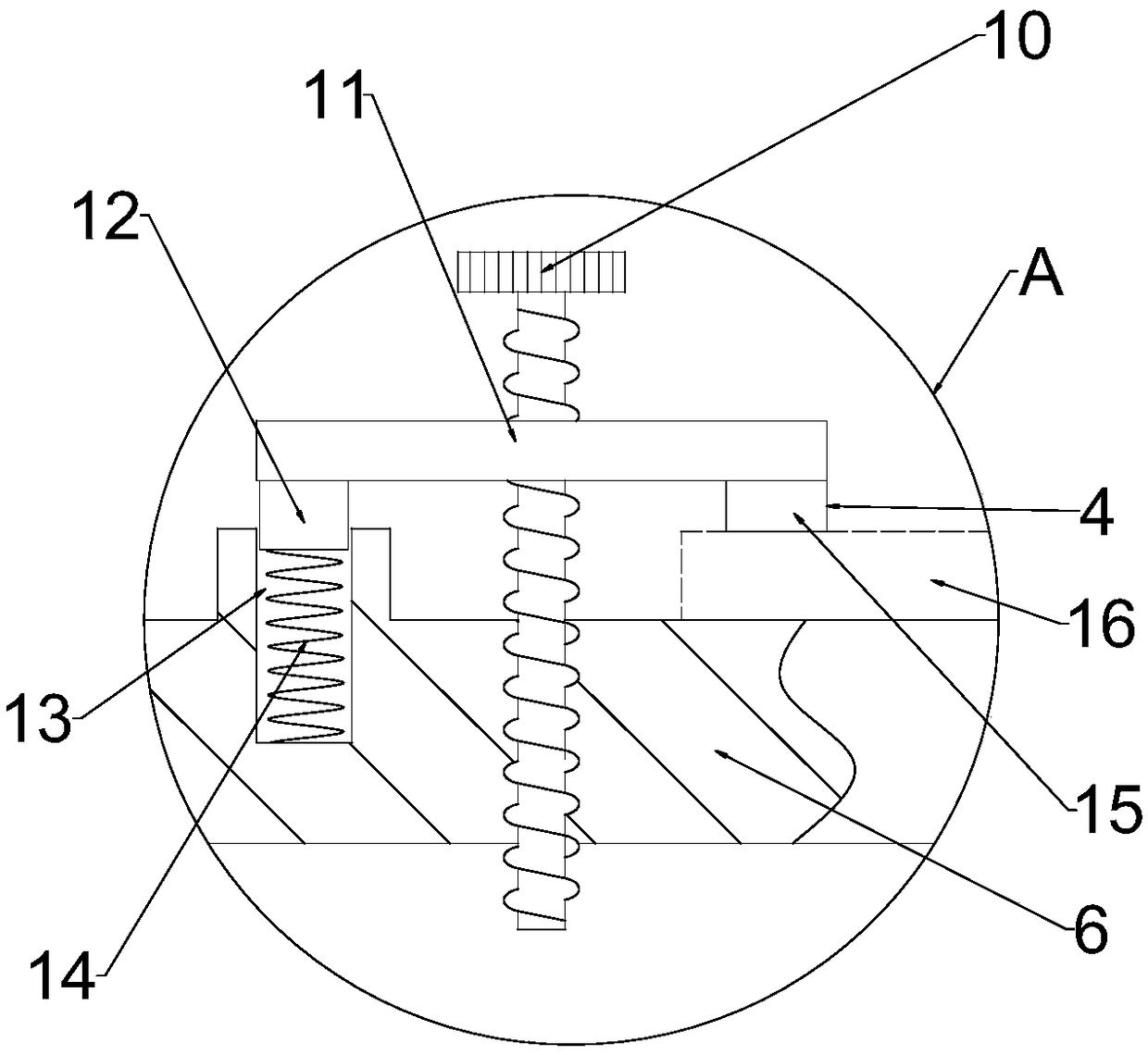

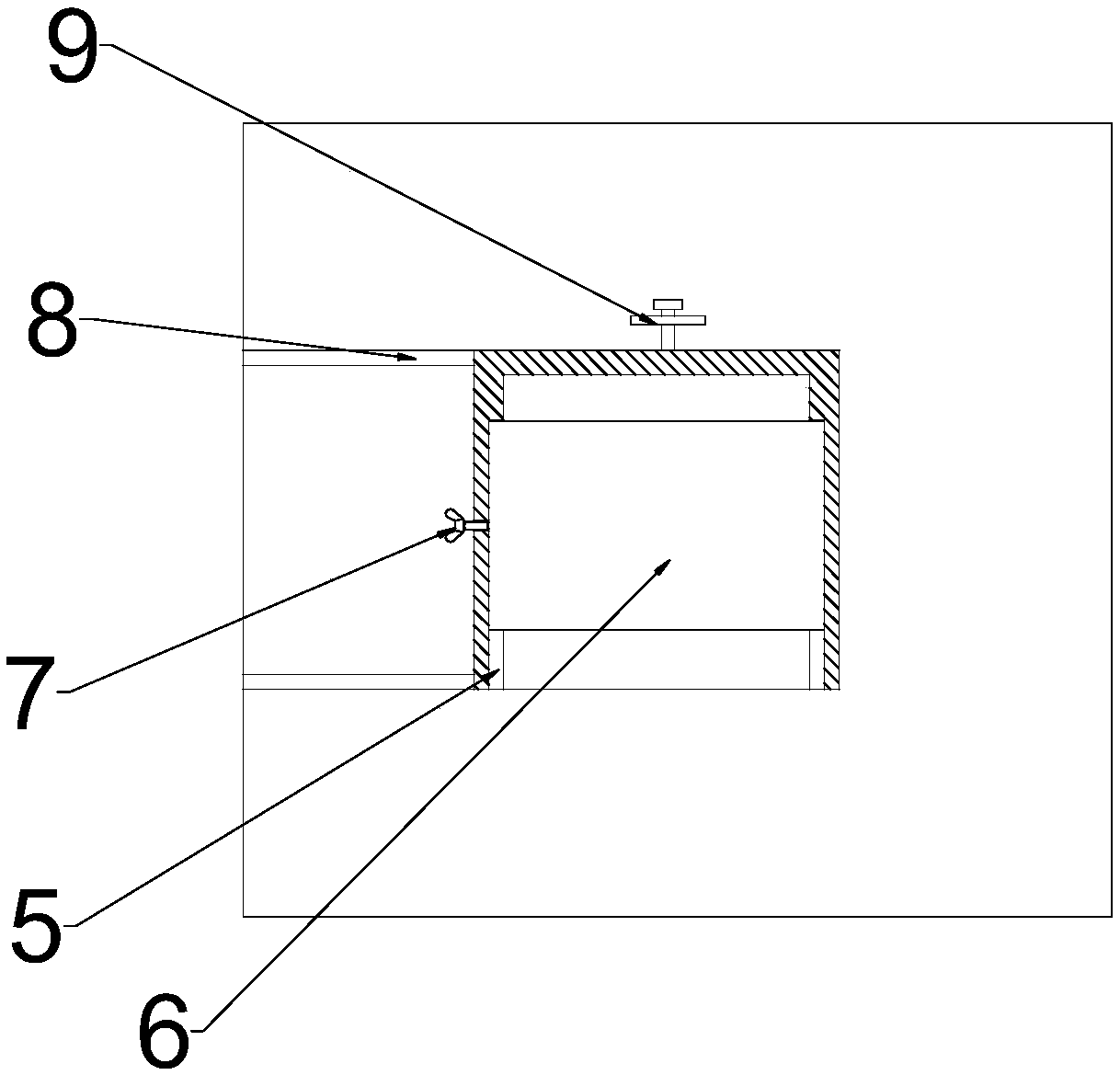

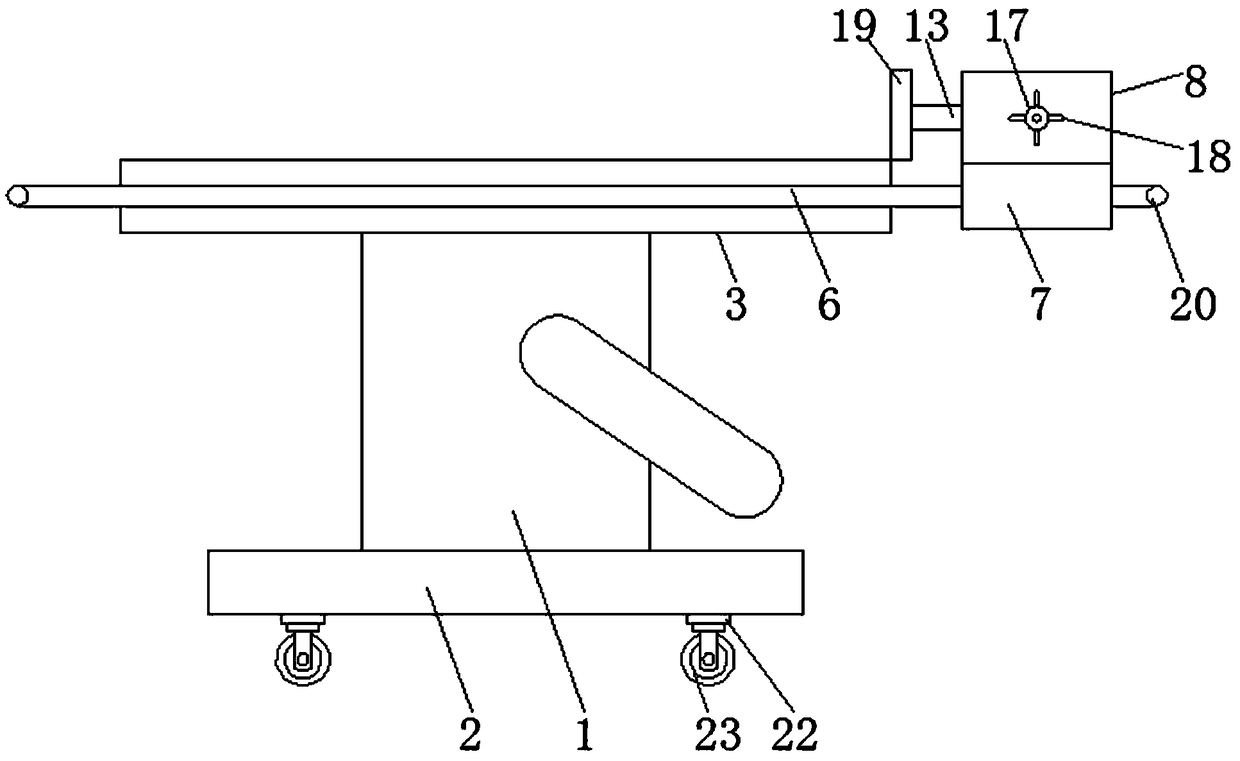

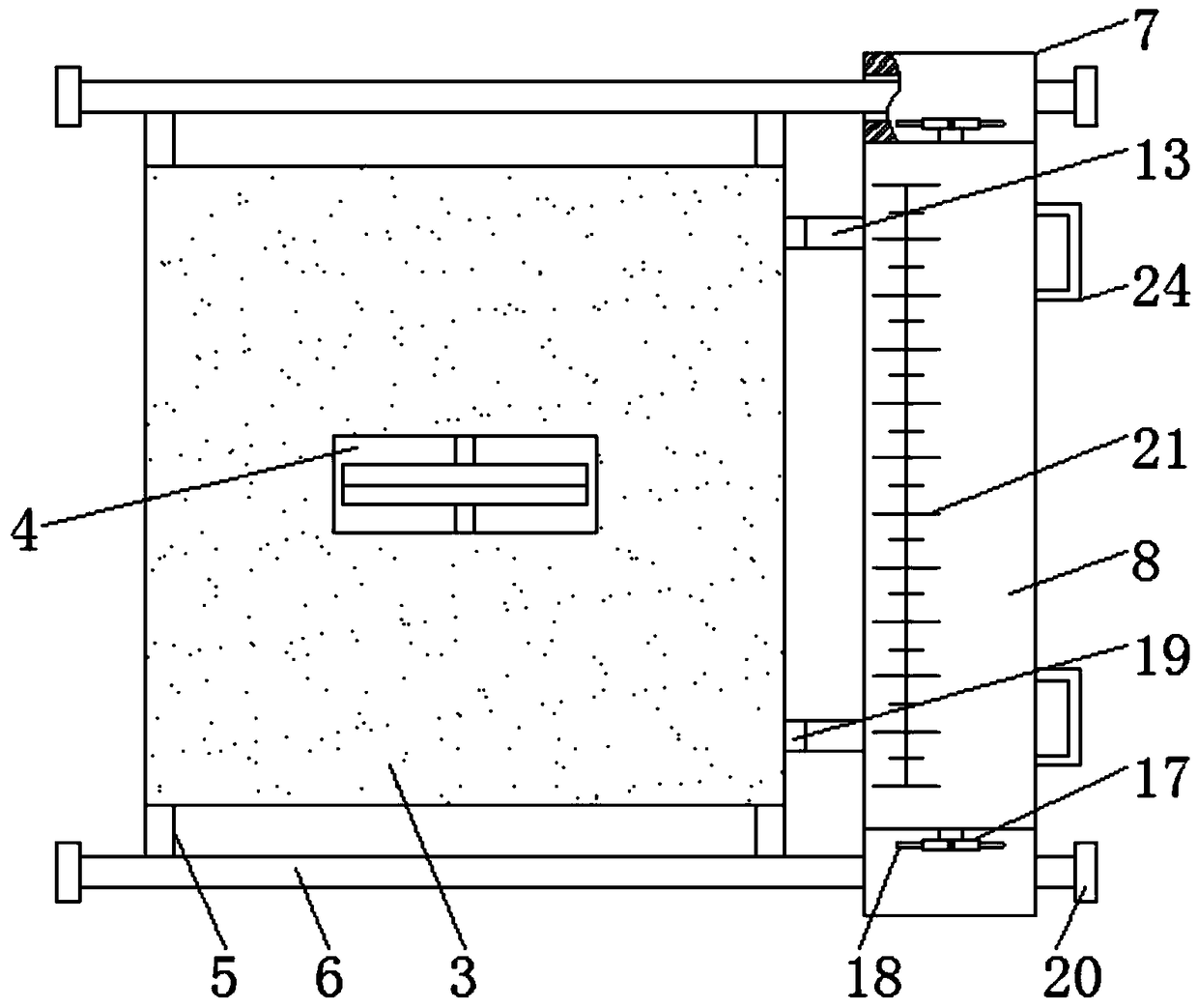

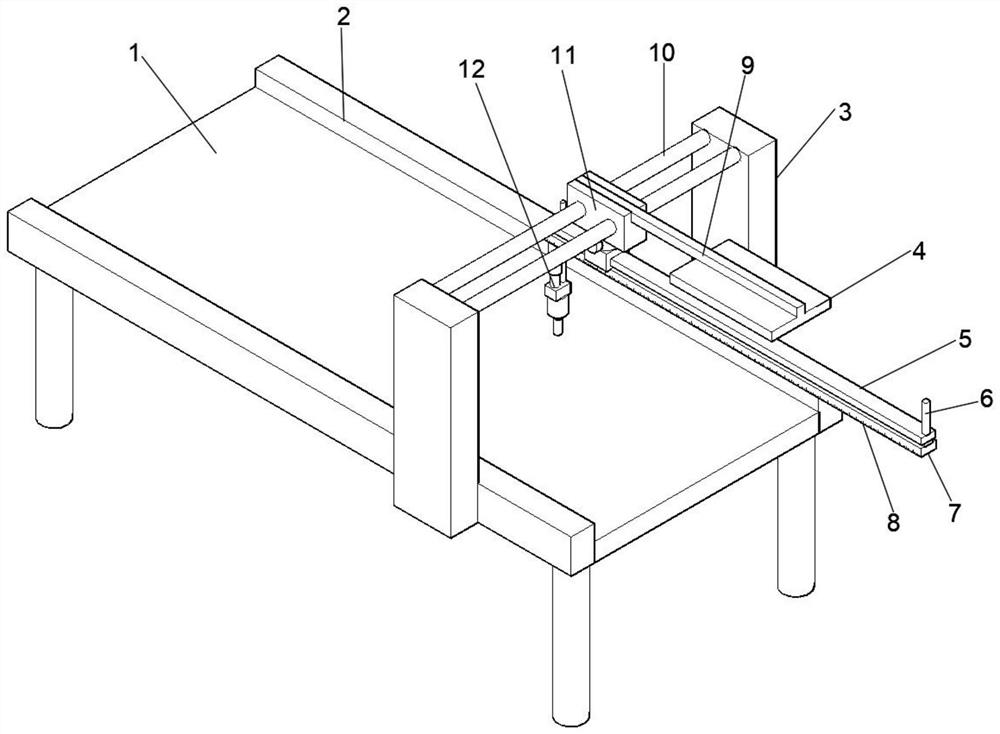

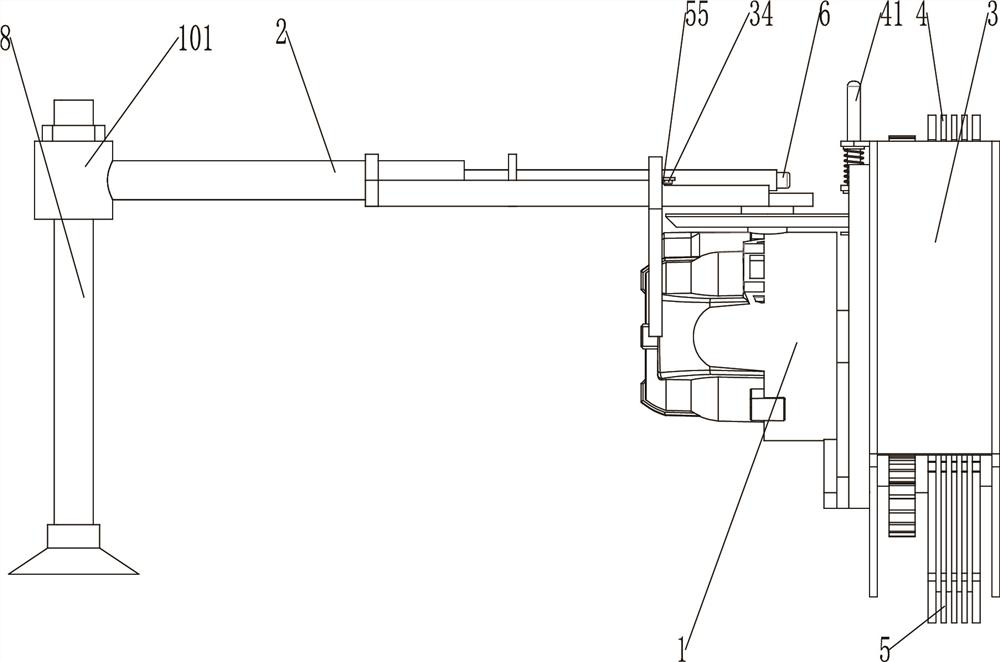

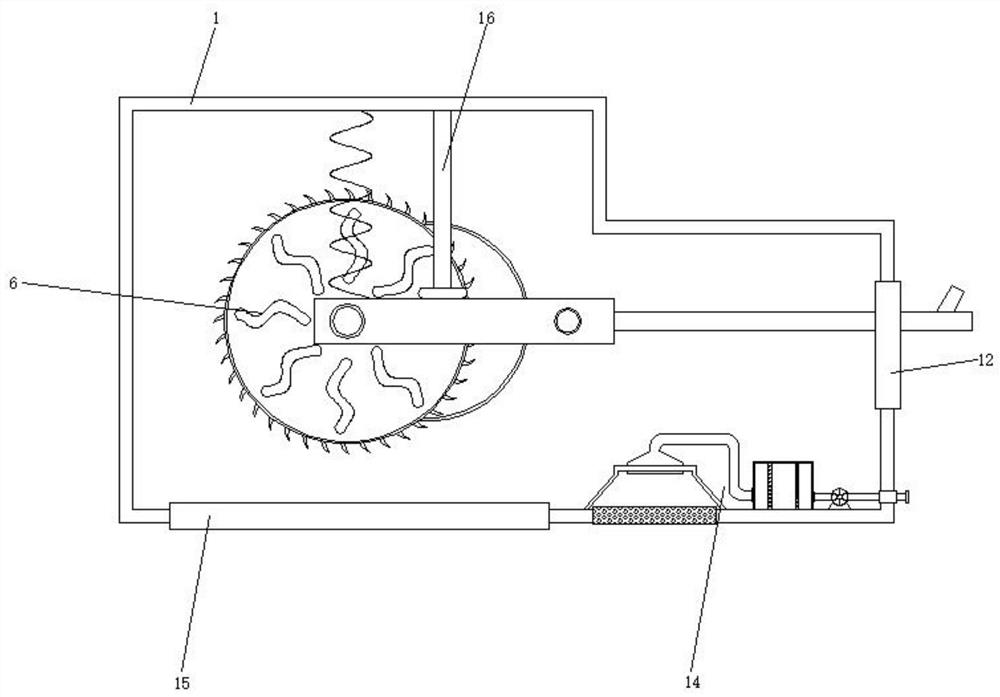

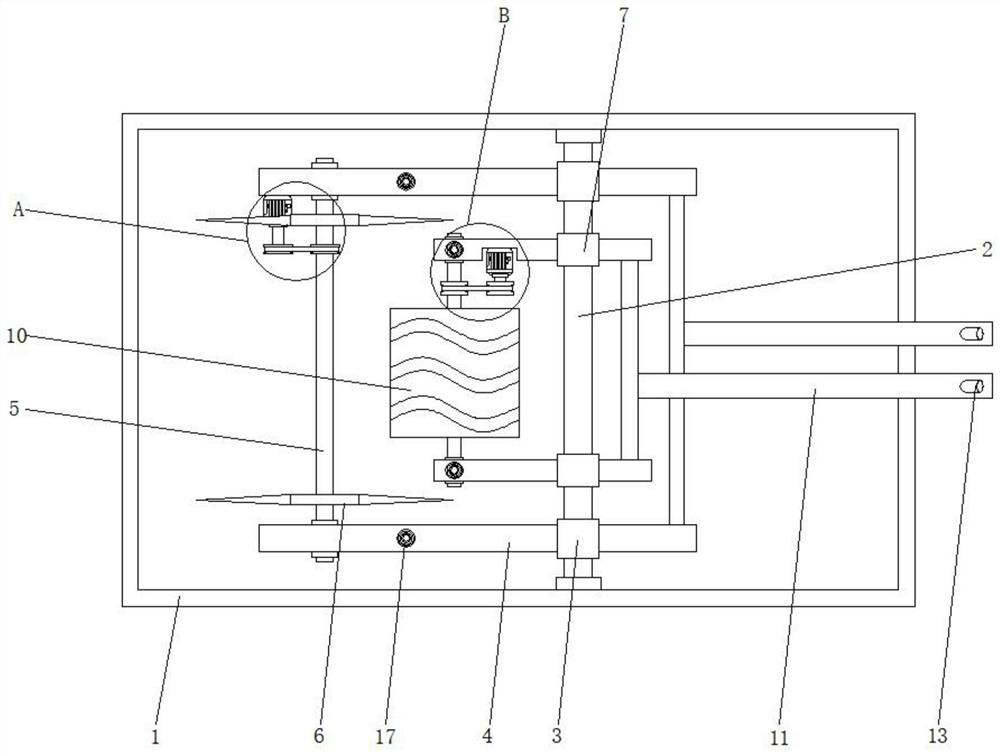

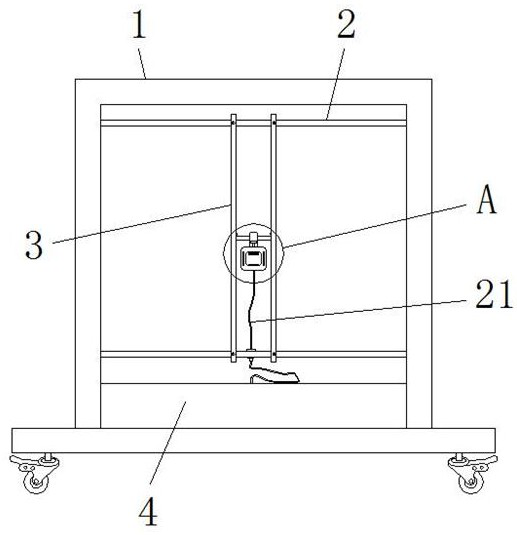

Automatic feeding type woodworking machine

ActiveCN110253682AImprove groove accuracyImprove securityFeeding devicesGripping devicesLocking mechanismPulp and paper industry

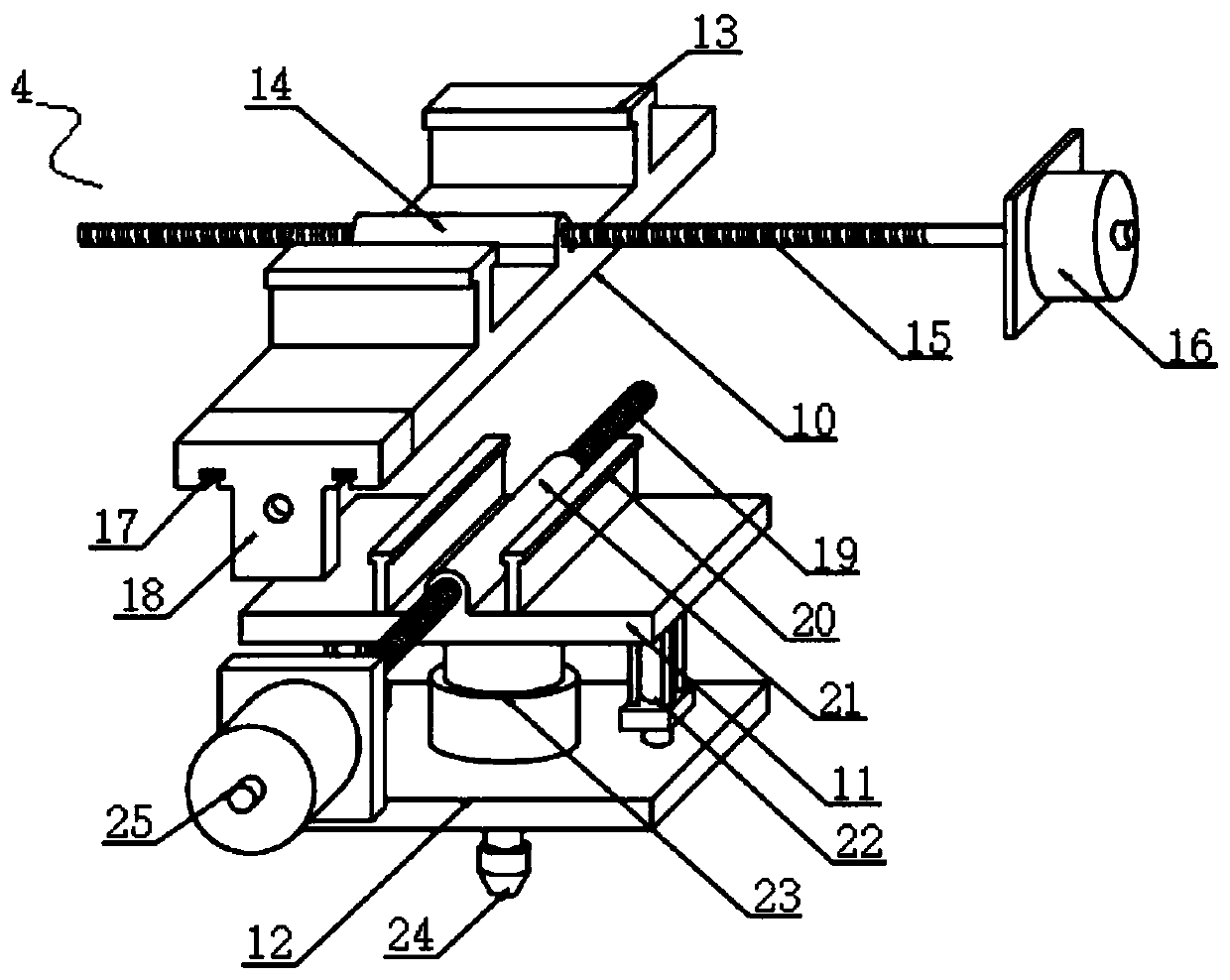

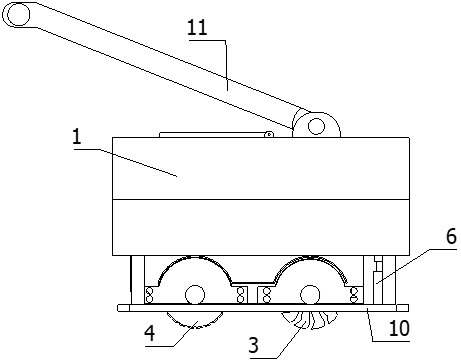

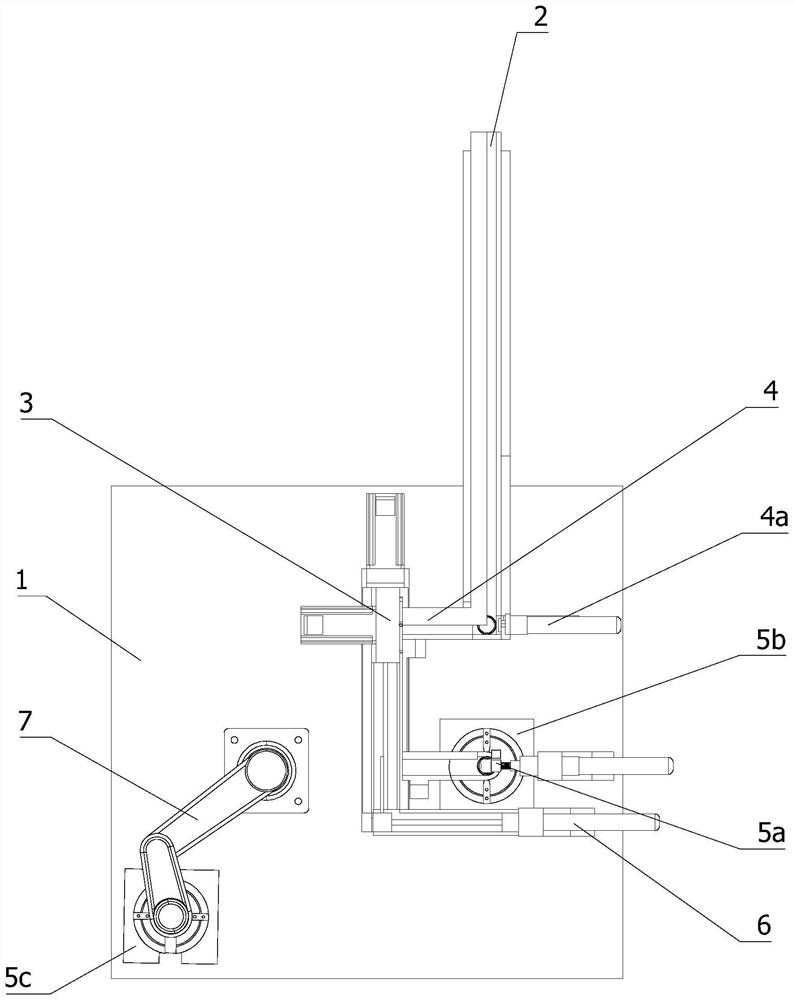

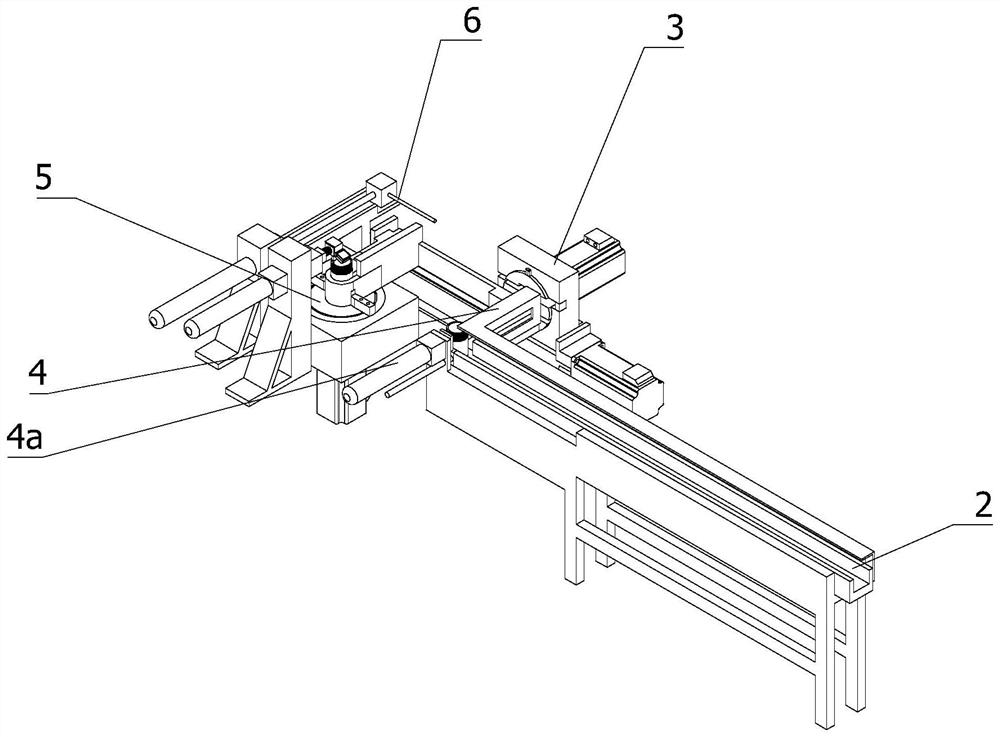

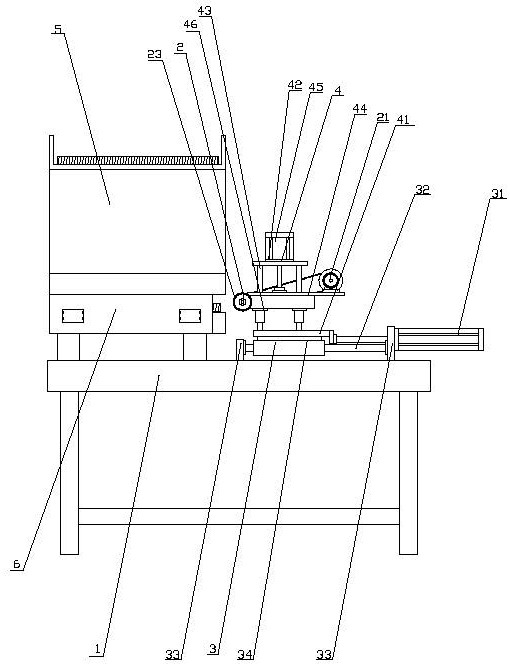

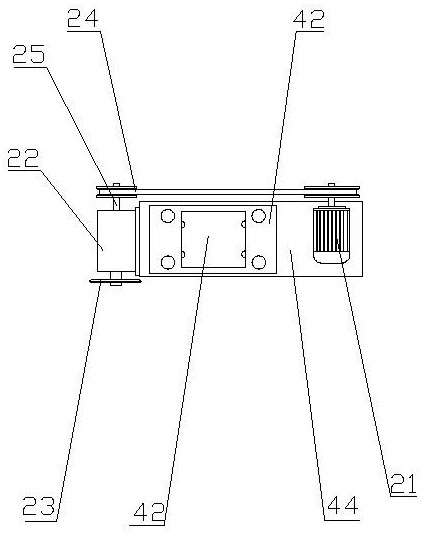

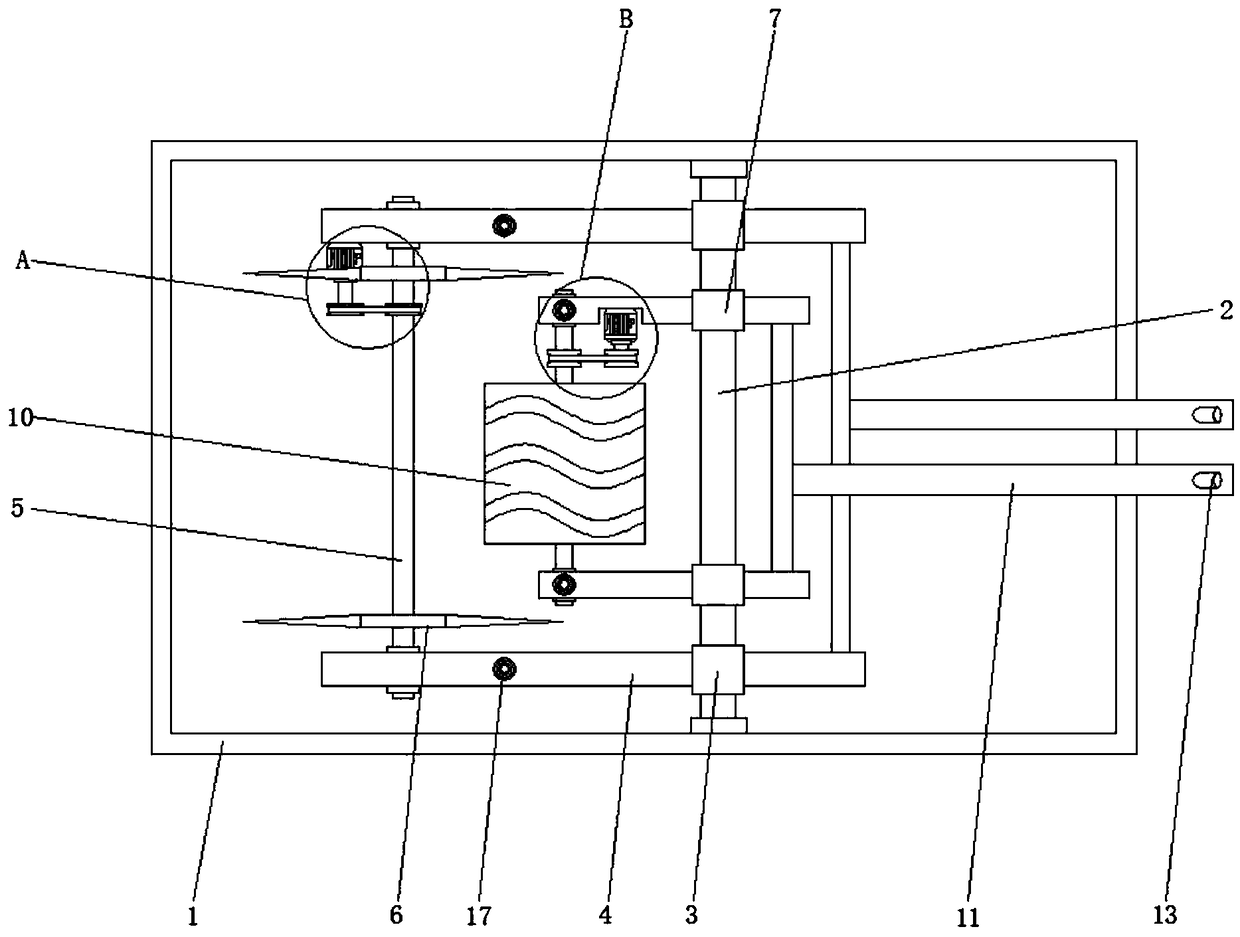

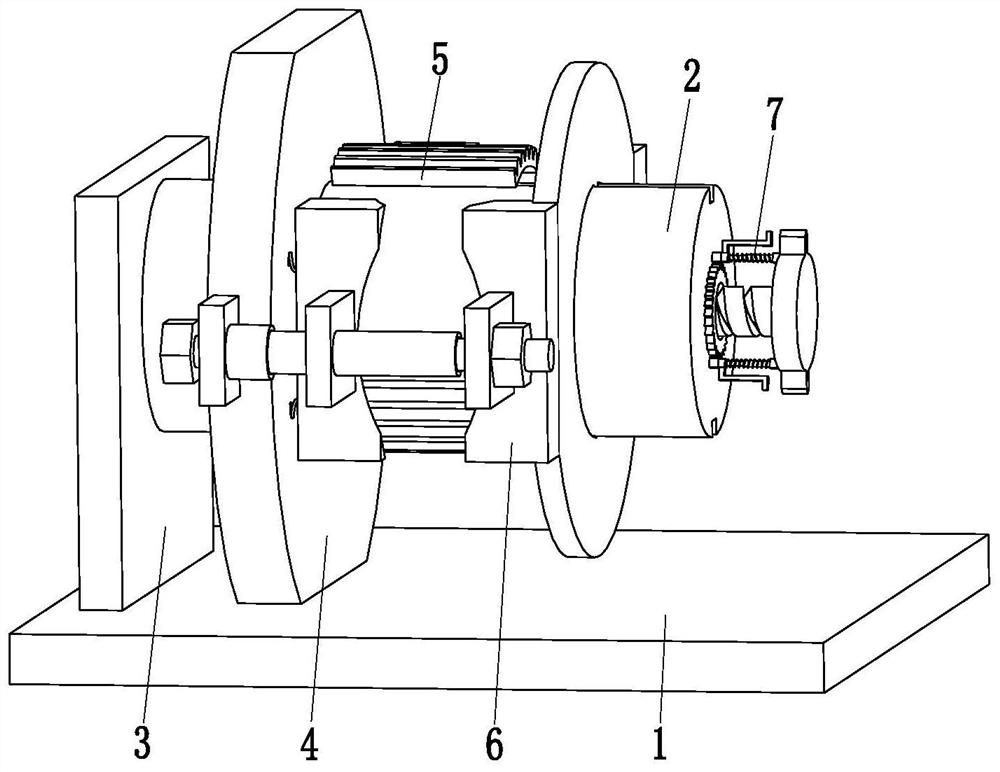

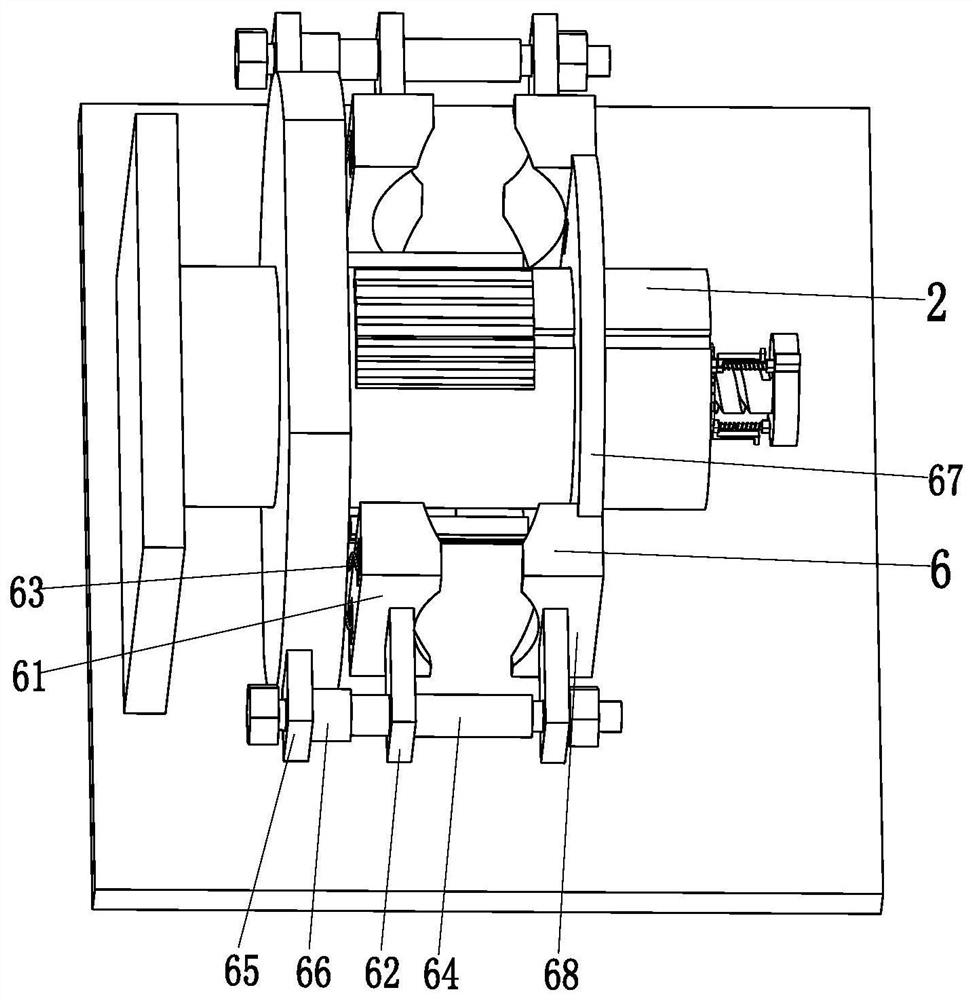

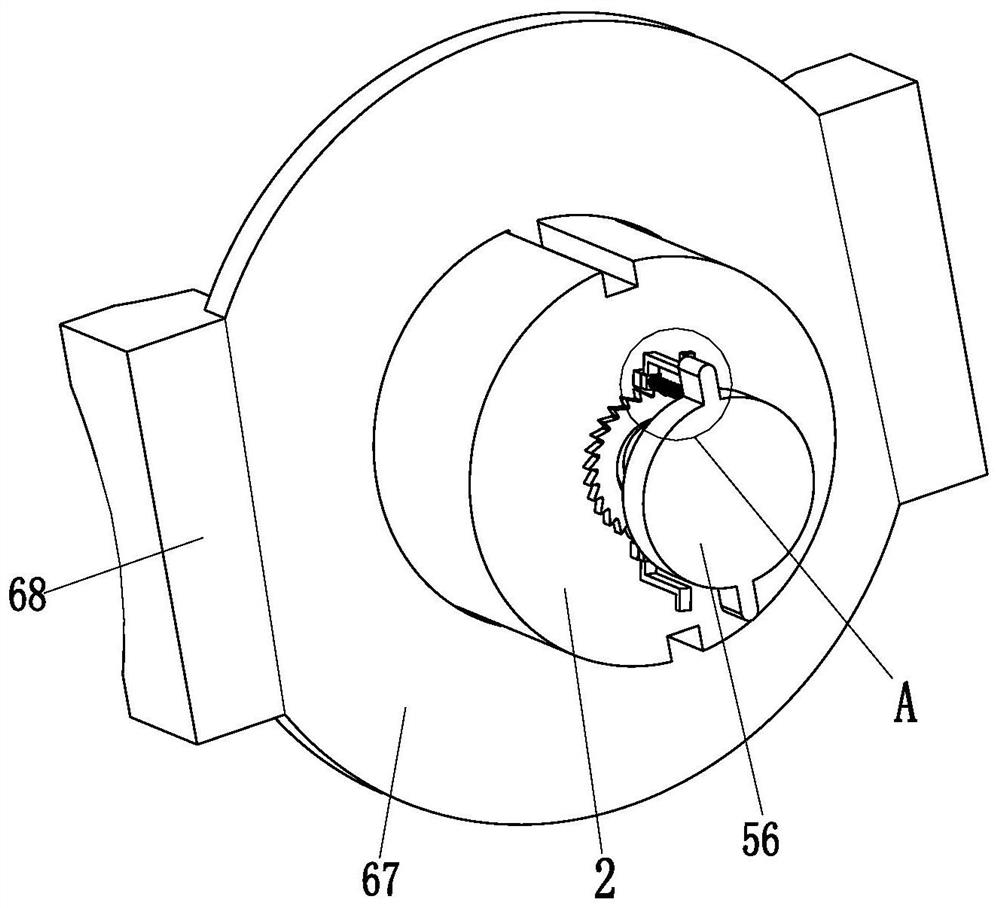

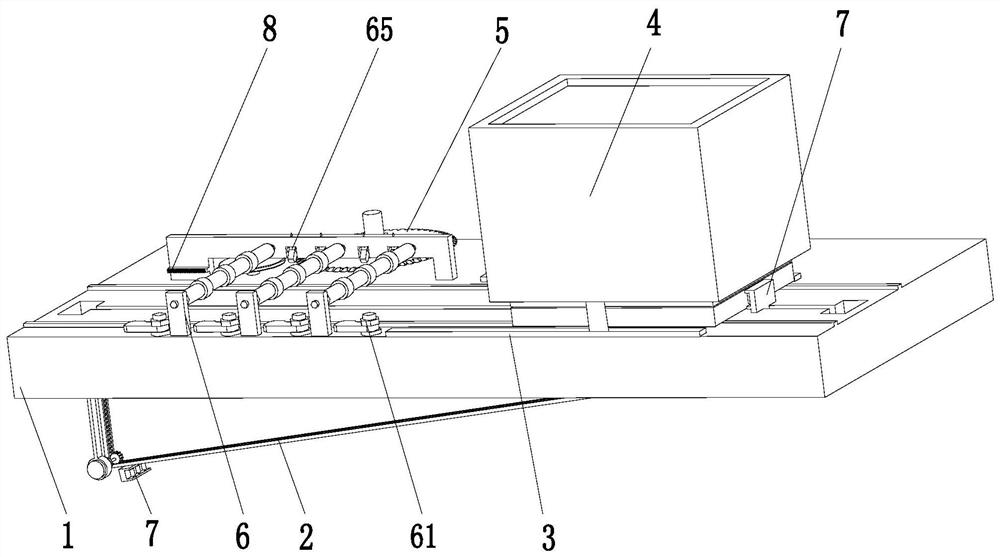

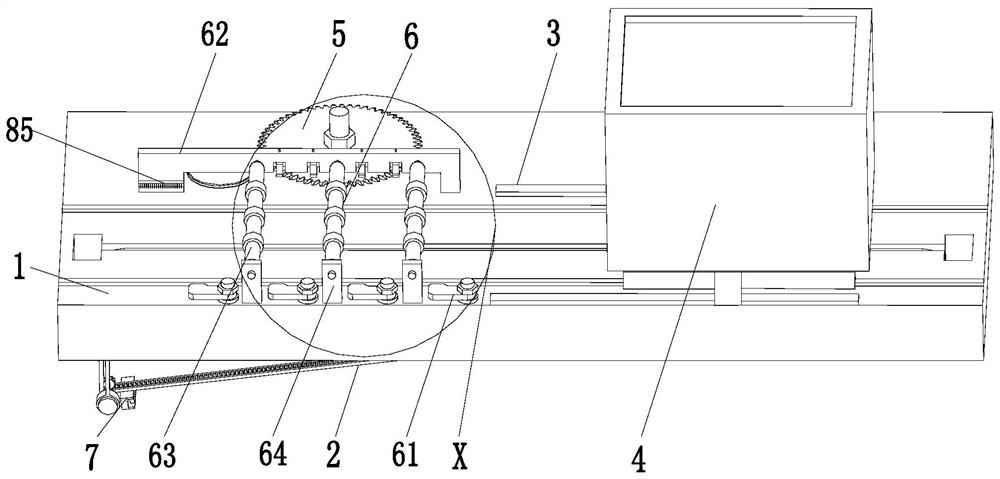

The invention relates to an automatic feeding type woodworking machine. The automatic feeding type woodworking machine comprises a sawing machine, locking mechanisms, a supporting vertical plate, a sliding seat, a rotating support, a supporting mechanism and a follow-up plate, wherein the locking mechanisms are connected to the left end and the right end of the sawing machine respectively, the follow-up plate is installed on the top of the locking mechanism located at the left end of the sawing machine, the supporting vertical plate is installed on the left end of the locking mechanism located at the right end of the sawing machine, and dovetail grooves are formed in the left side surface of the supporting vertical plate; and the right side surface of the sliding seat is connected with the dovetail grooves of the supporting vertical plate in a sliding fit manner, the sliding seat is of an L-shaped structure, the rotating support is arranged on the upper end surface of the middle of the sliding seat through a rotating shaft, and the supporting mechanism is arranged at the left end of the rotating support. According to the automatic feeding type woodworking machine, the problems that when the inclined grooves are formed in the existing wood, an inclined positioning plate cannot be intuitively adjusted, and the side surface of the wooden board is a non-smooth plane, so that when the wood slides along the positioning plate, the precision of the wooden board slotting is low, and the safety of holding wood by hand is poor can be solved.

Owner:珠海德驰科技有限公司

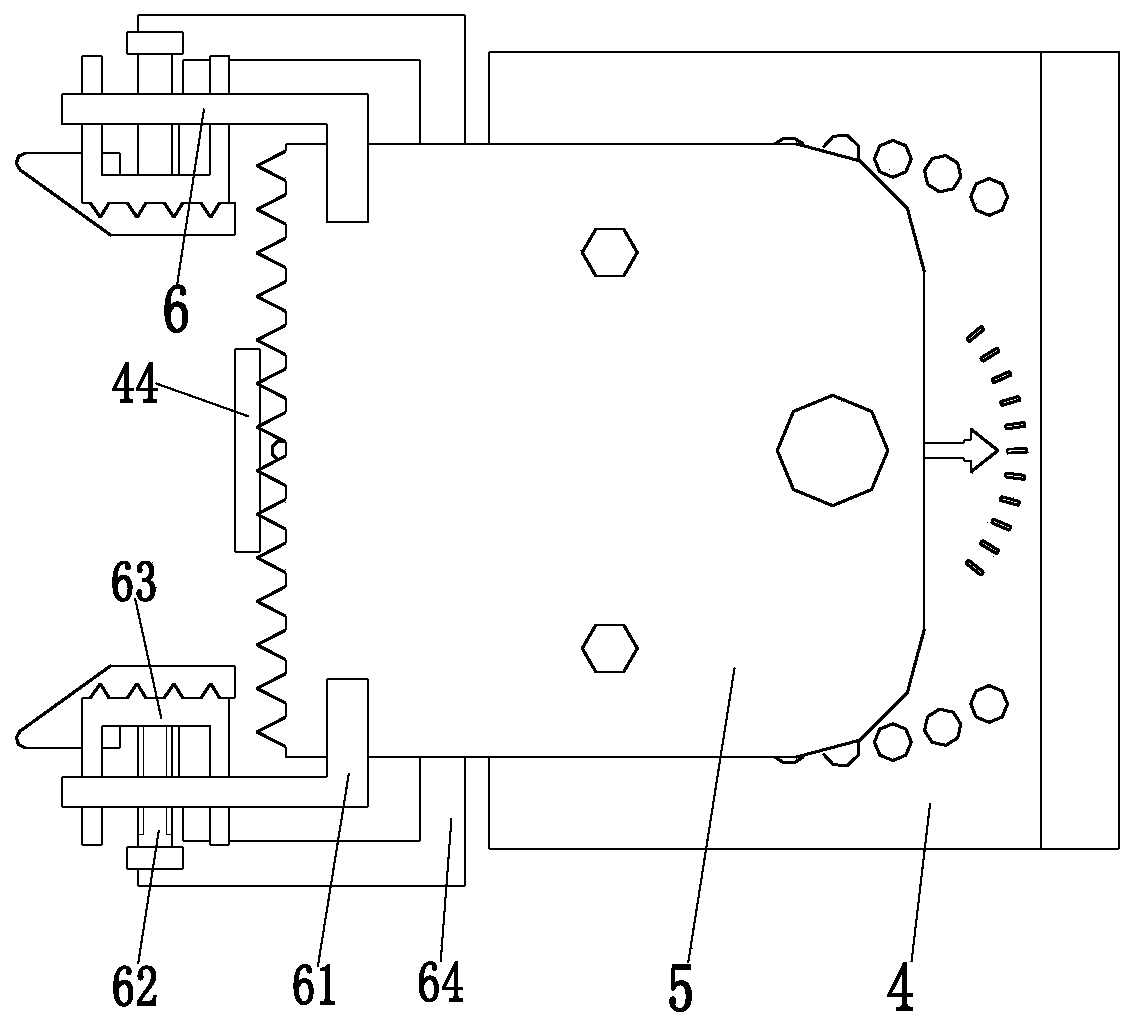

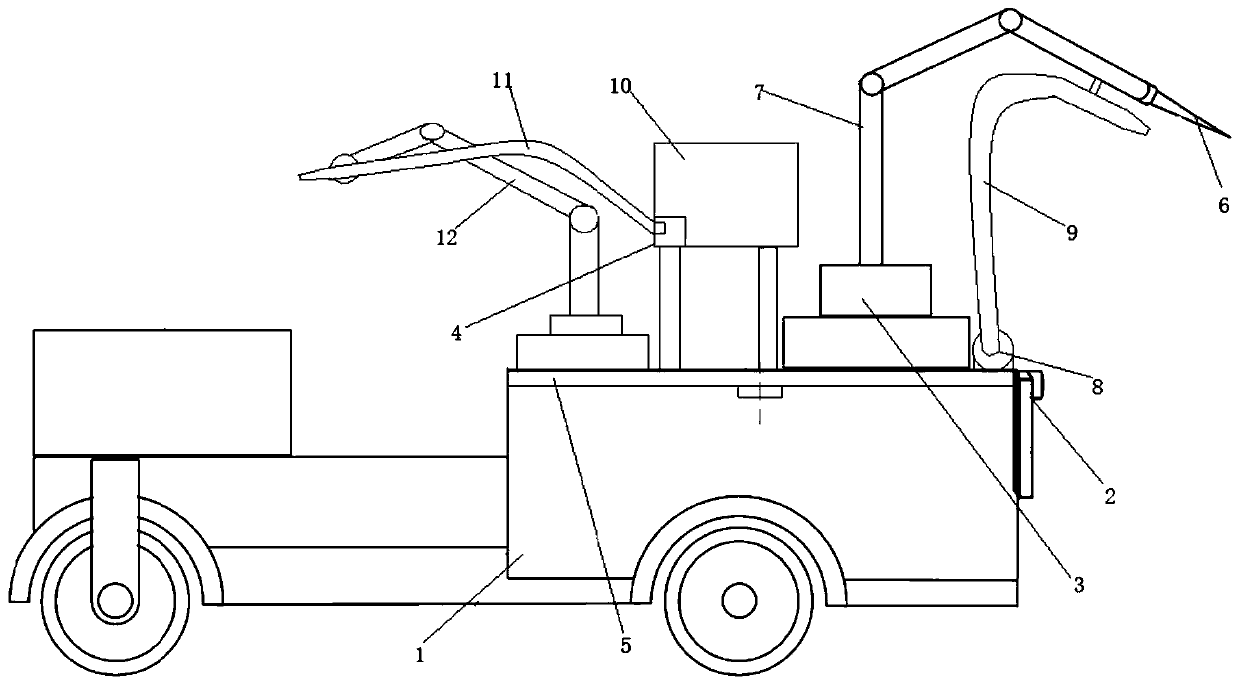

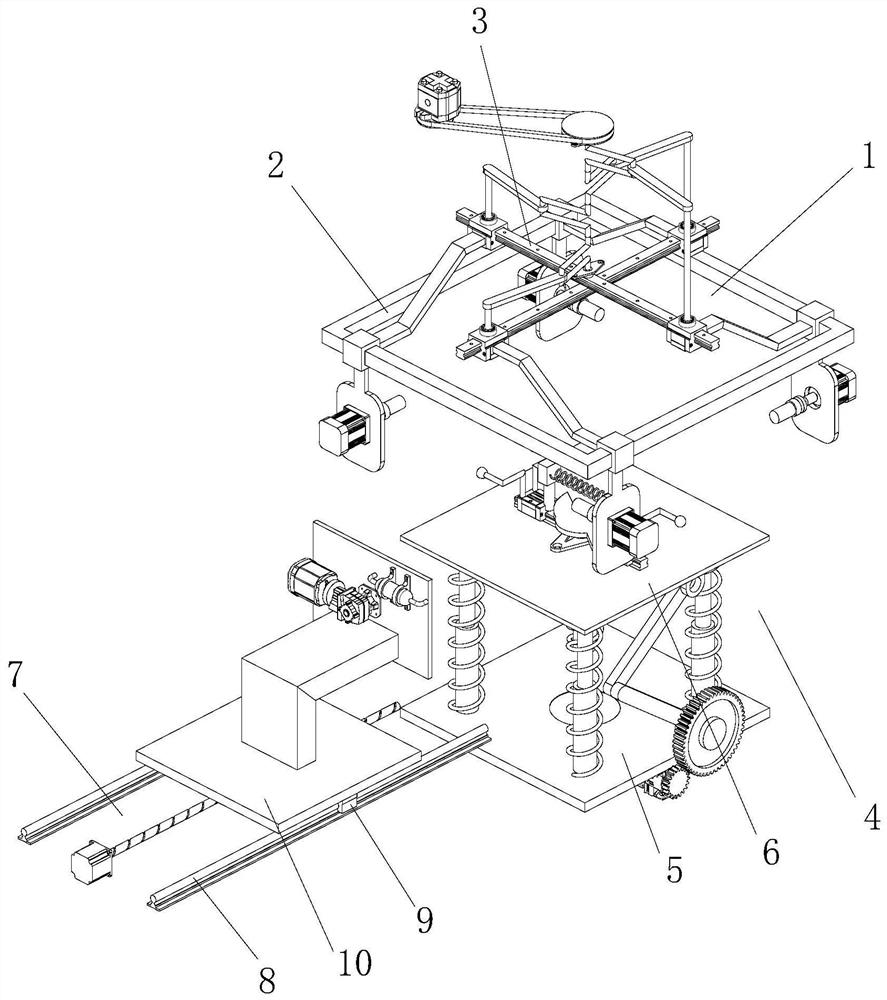

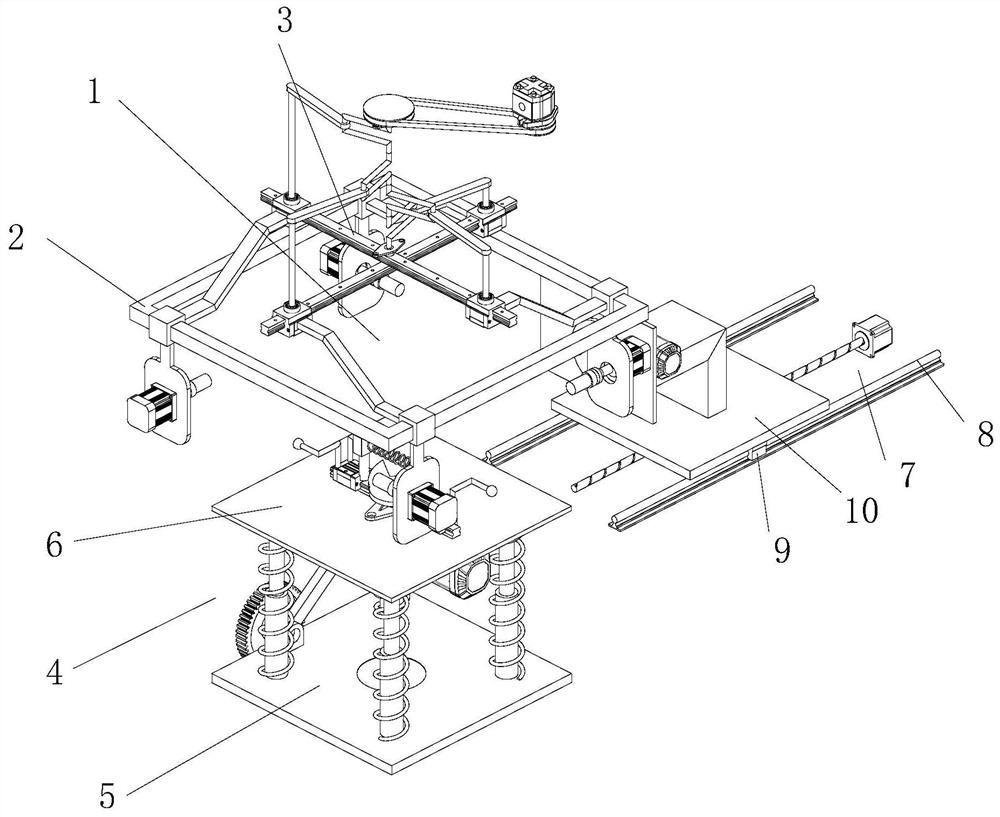

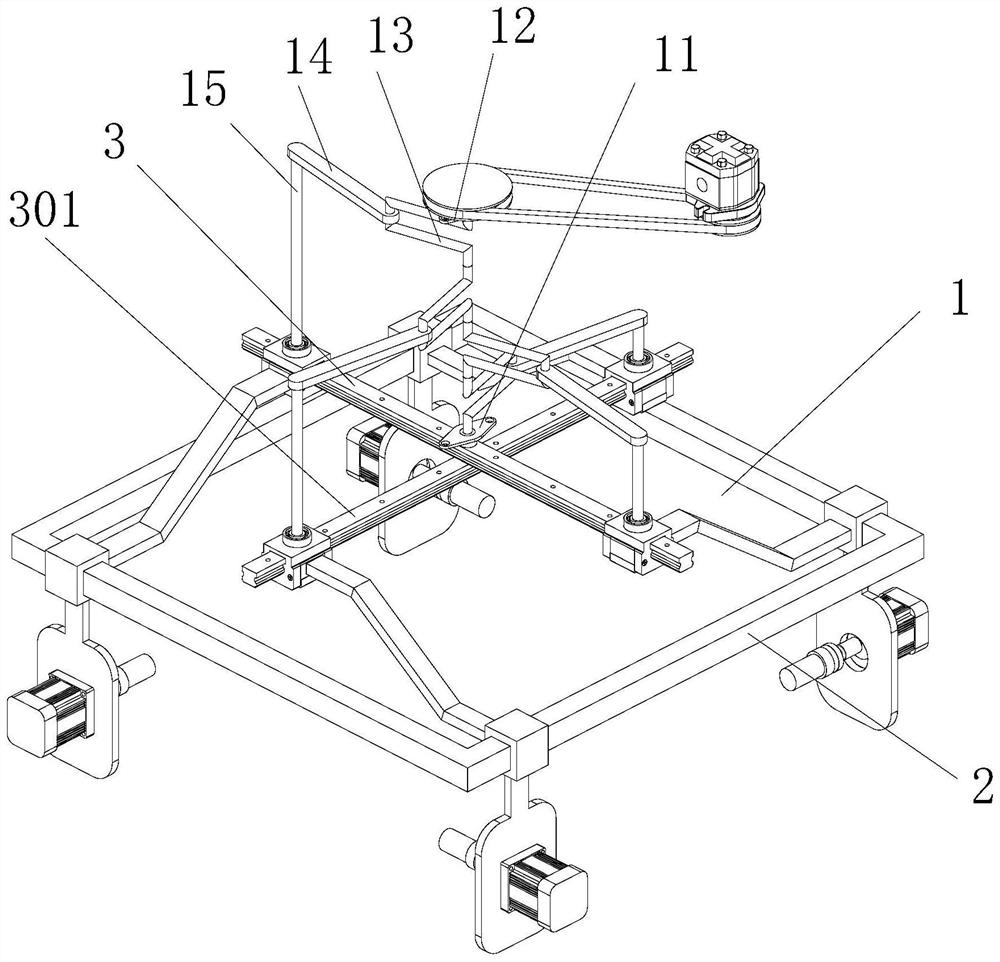

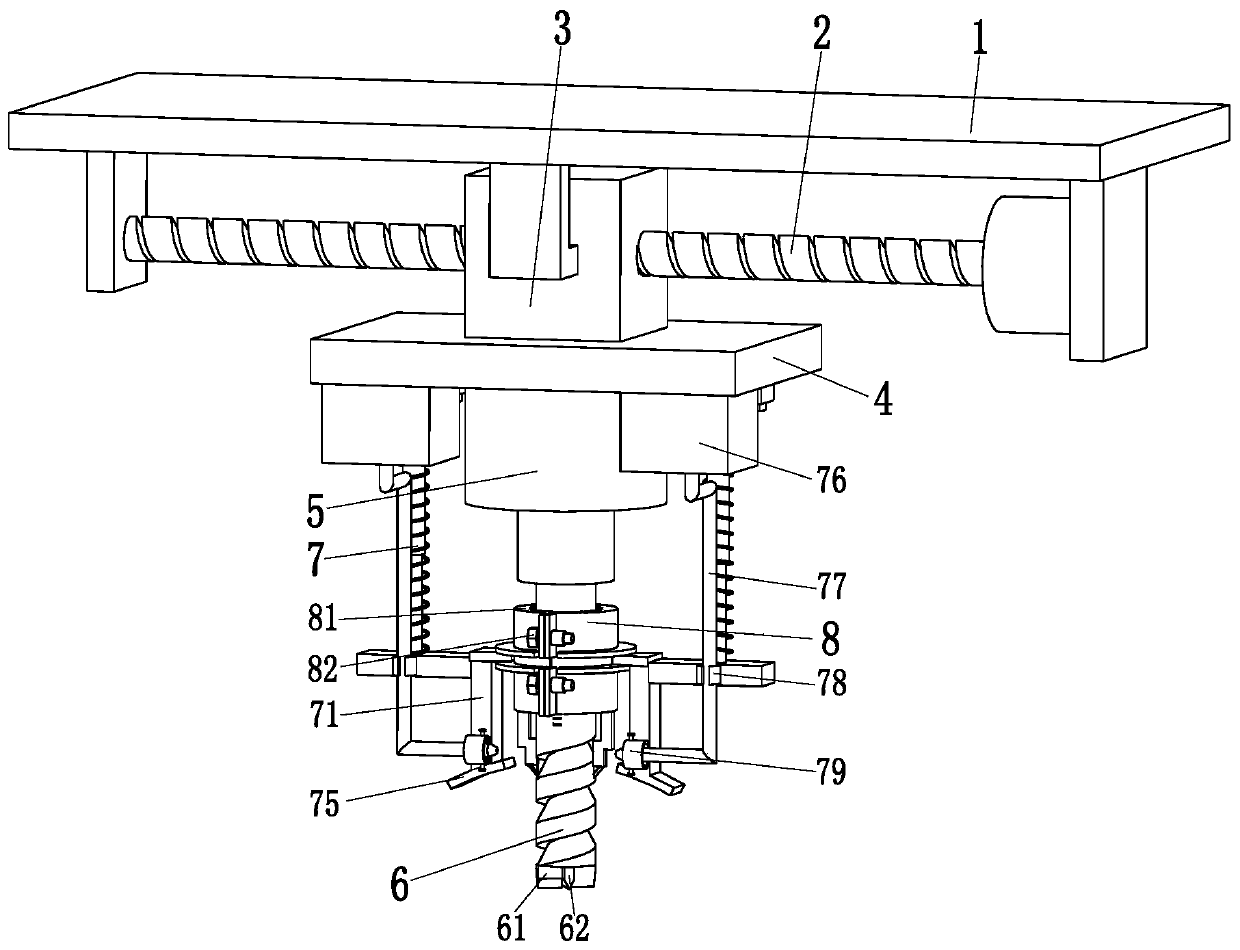

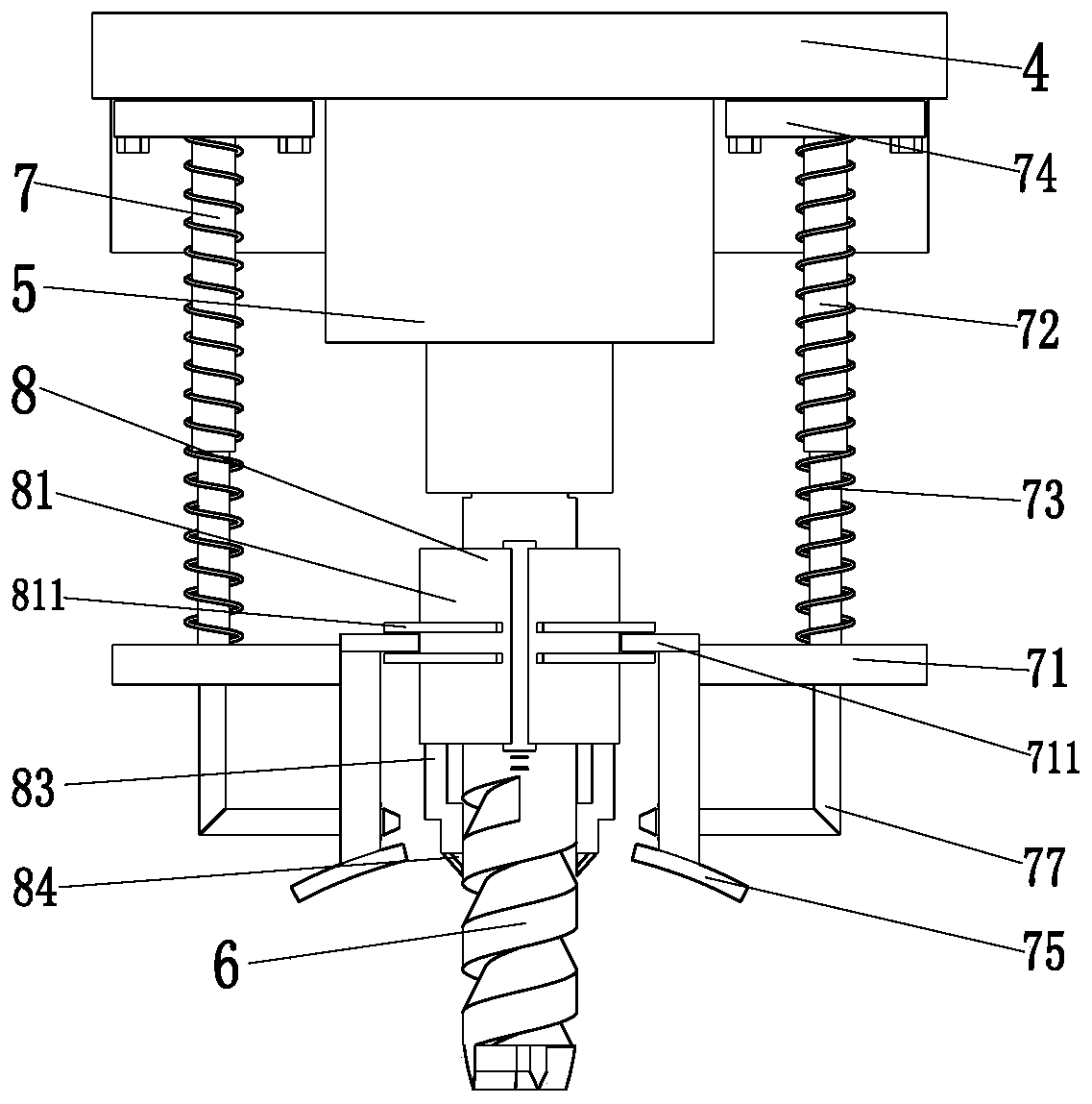

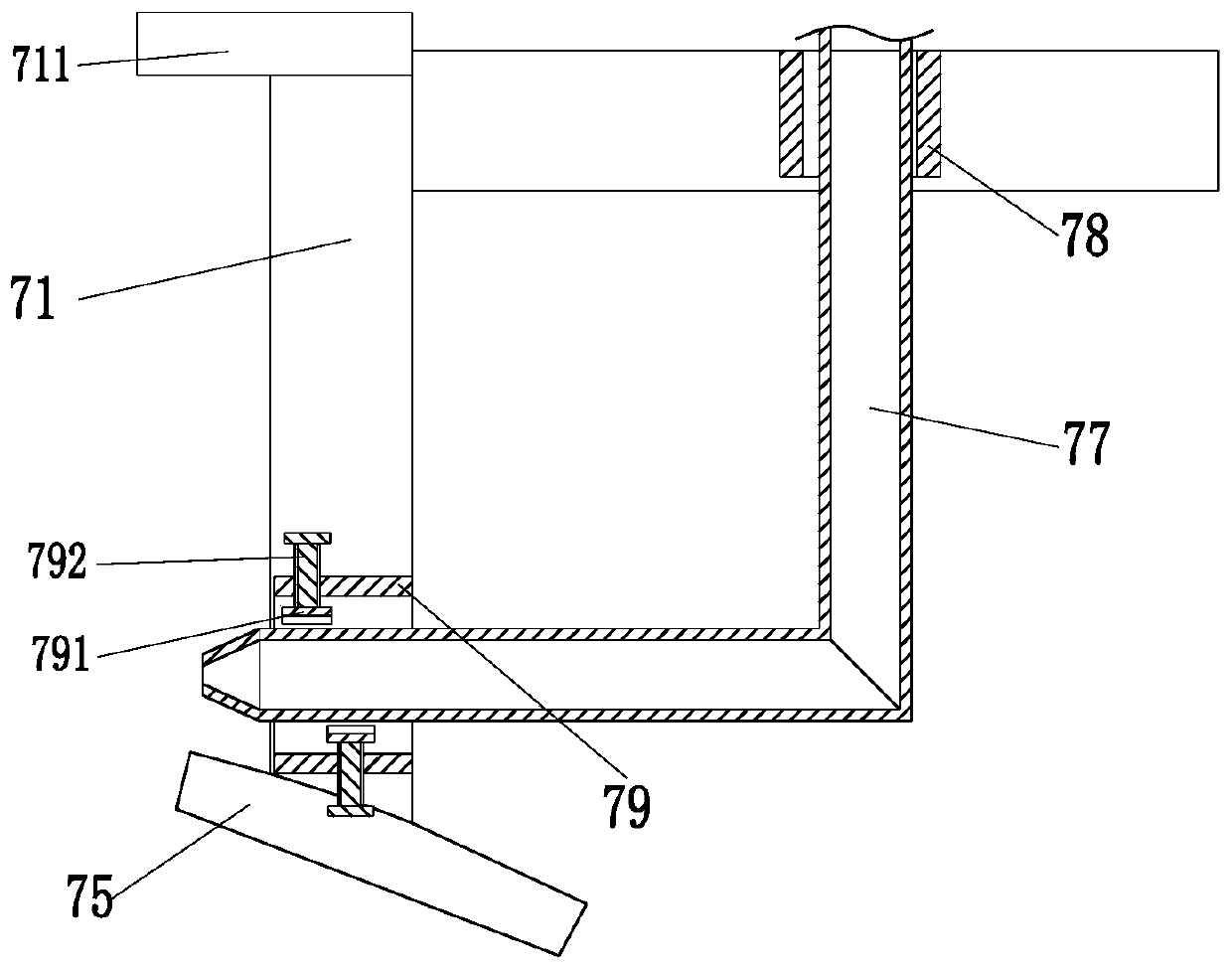

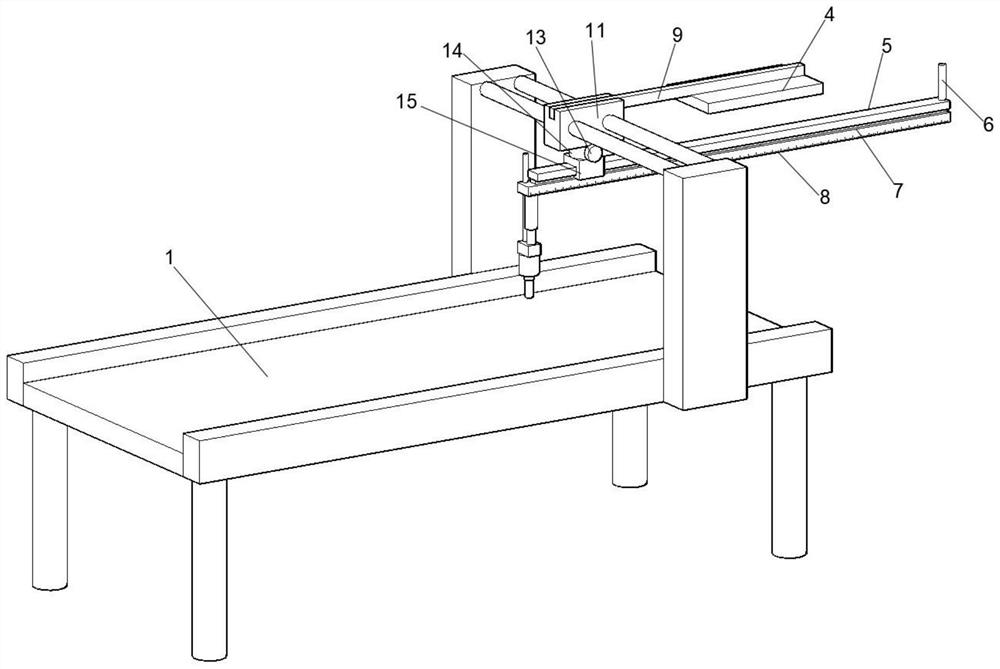

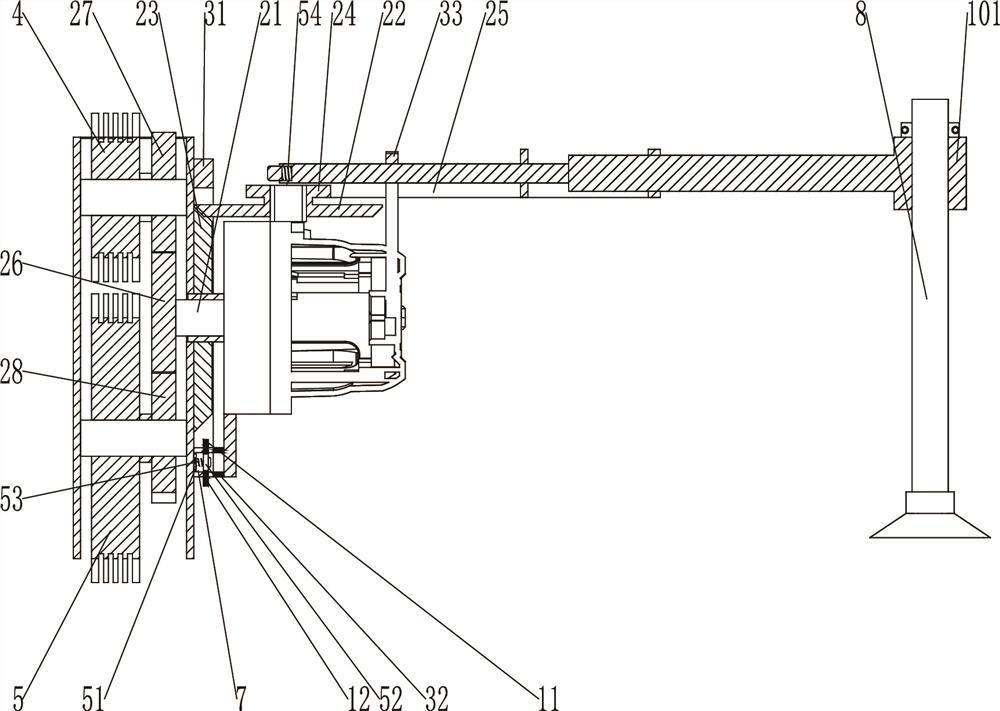

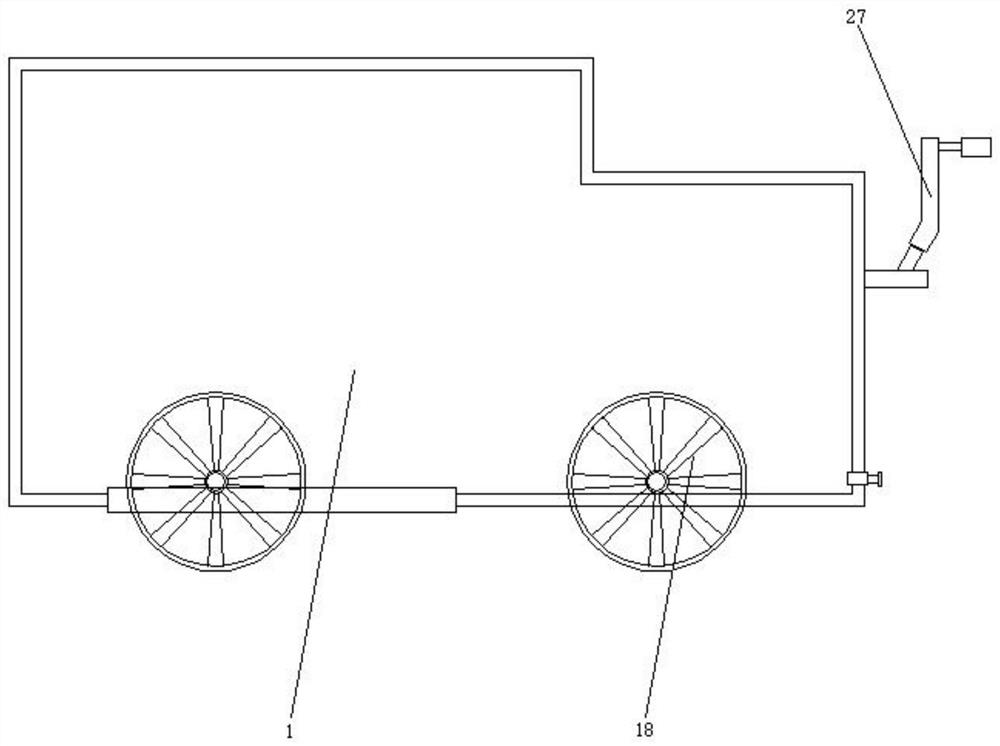

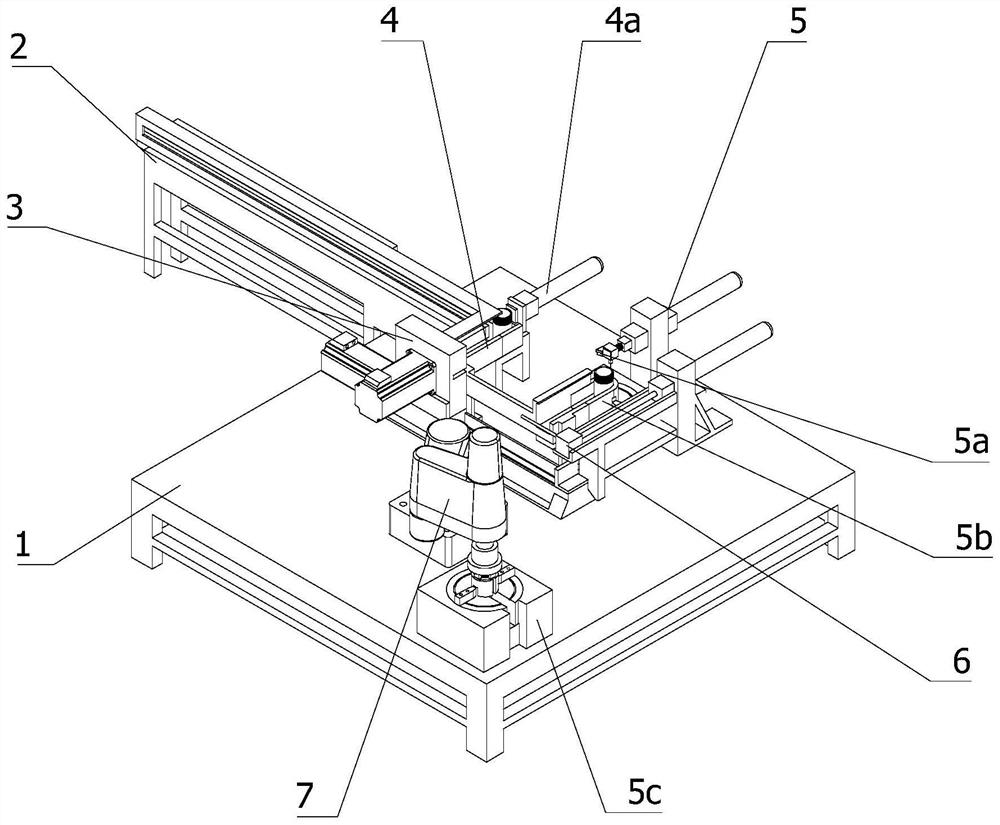

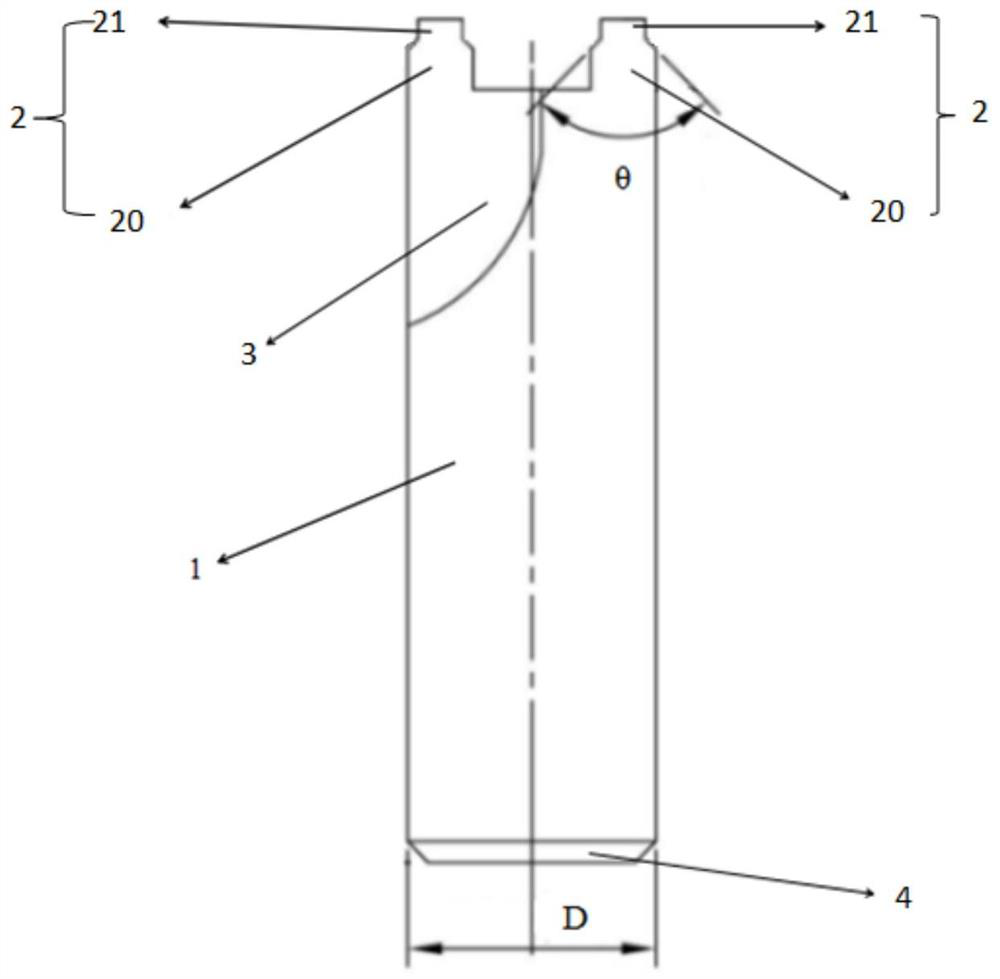

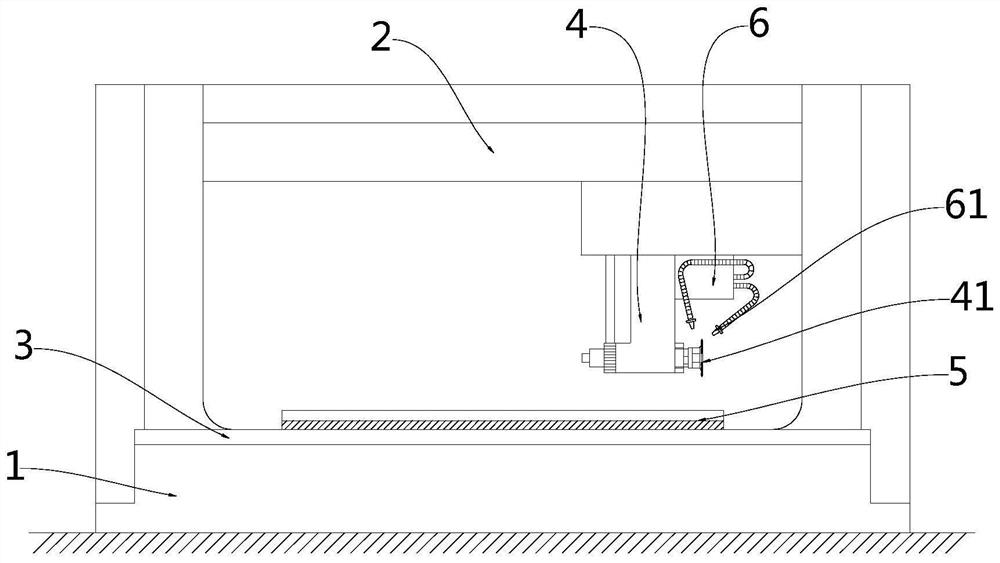

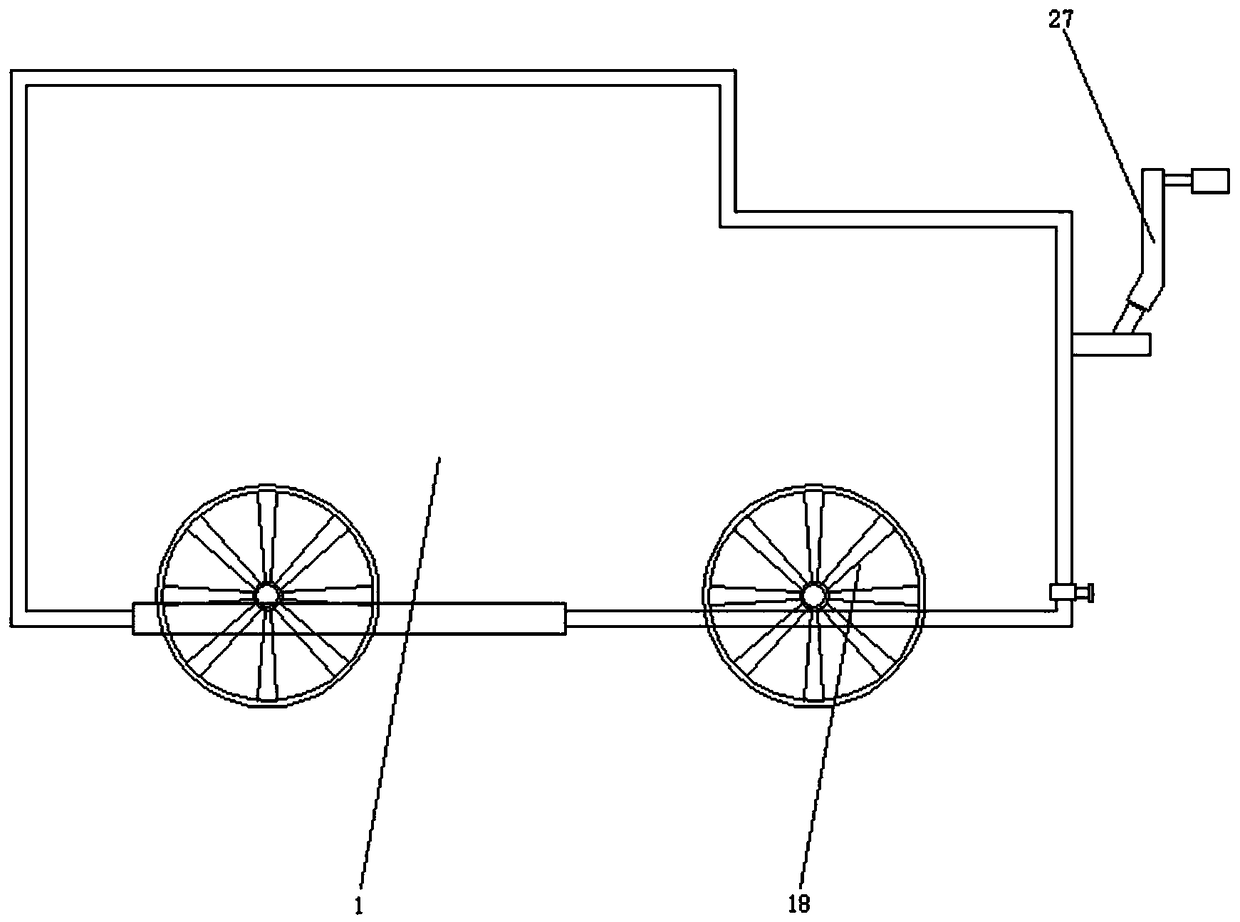

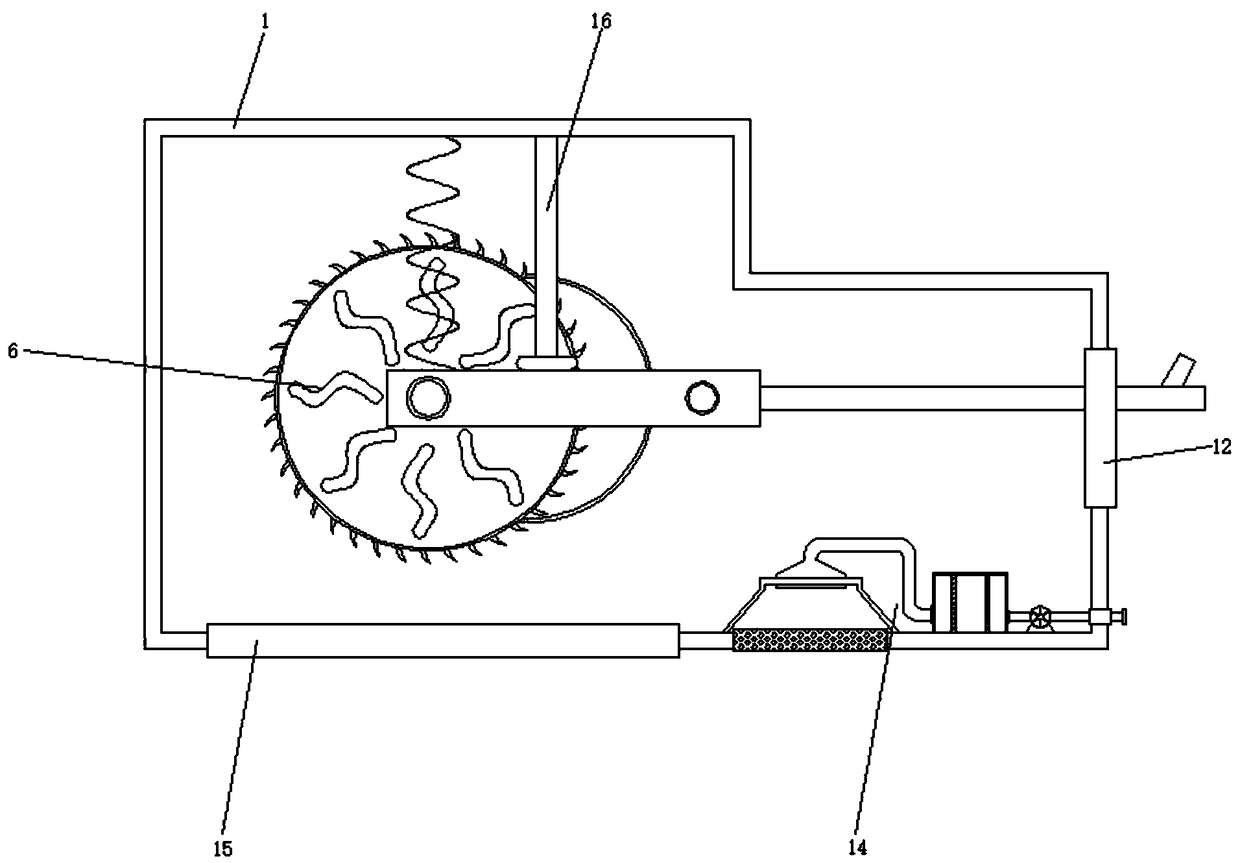

Highway asphalt pavement crack repairing apparatus and method

PendingCN111364338AChanging the Crack AngleFully filledRoads maintainenceArchitectural engineeringRepair material

The invention discloses a highway asphalt pavement crack repairing apparatus and method. The apparatus comprises a mobile device platform, and a crack slotting device and a repairing device which arearranged on the mobile device platform, and the crack slotting device and the repairing device are both rotationally fixed to the mobile device platform. A mechanical arm of the crack slotting deviceis used for controlling a taper twist drill to realize accurate positioning slotting of road cracks, and the slotting route can be consistent with the crack route, so excessive slotting is avoided, and the slotting precision is improved; and a repairing material heated by a preheating device in a repairing material tank is pumped into the formed slot time through a discharging pipe communicated with the repairing material tank, so the filling efficiency and the construction safety are improved. Automatic slotting, slot cleaning and crack pouring can be achieved, and compared with a traditionalprocess, the method of the invention is more efficient, safer and more reliable.

Owner:CHANGAN UNIV

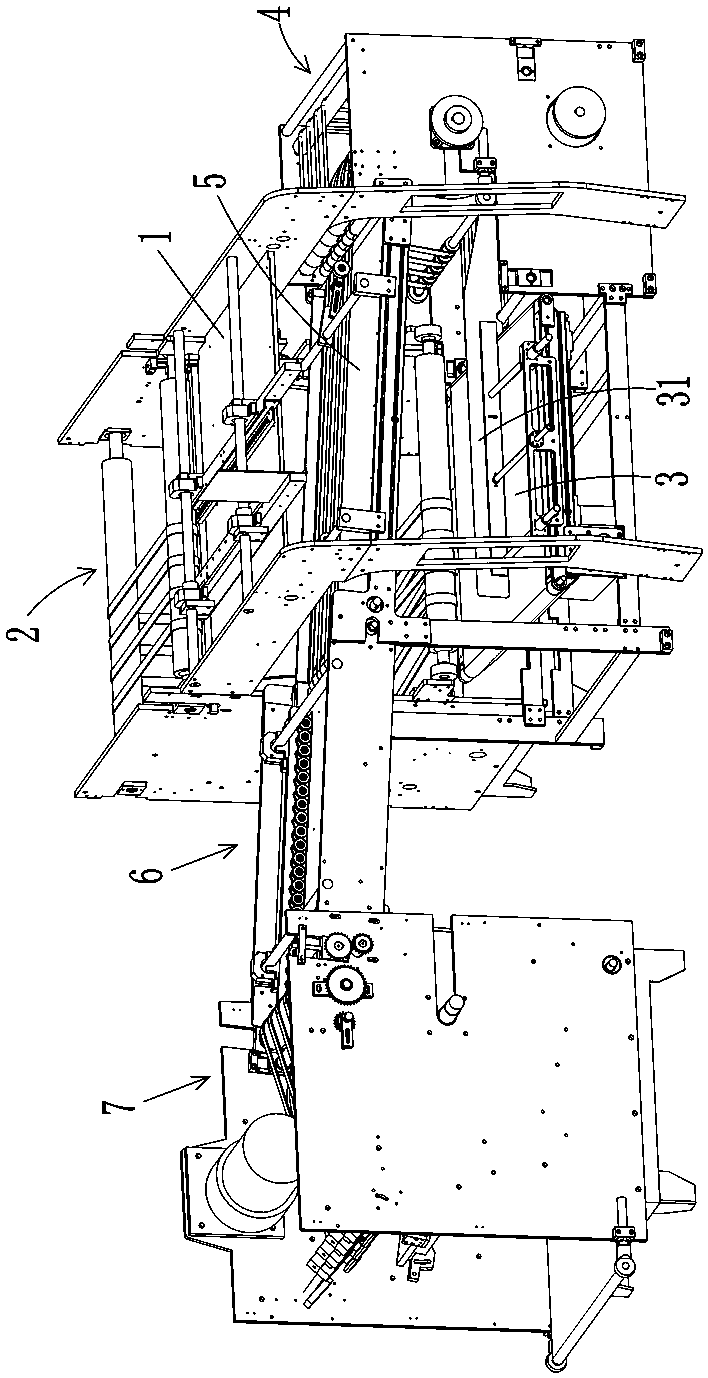

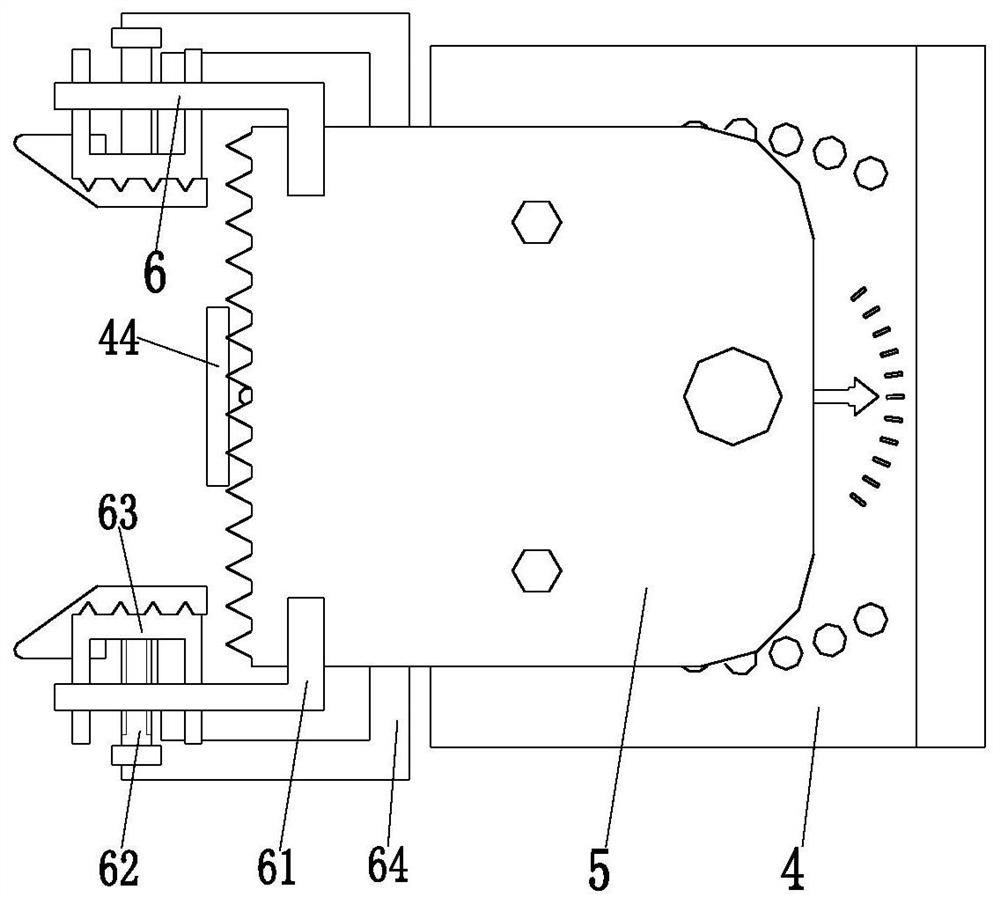

Paper carton slotting and die-cutting machine and slotting process thereof

InactiveCN105599351AIncrease productivityImprove stress resistancePaper-makingBox making operationsGear wheelCarton

The invention provides a paper carton slotting and die-cutting machine and slotting process thereof. The paper carton slotting and die-cutting machine is composed of a work bench, a plurality of embossing mechanisms and a slotting mechanism; the outer diameter of a cutter disk on a shaft gear of a cross cutting roll is reduced, the outer diameter of a cutting blade on the cutting disk is utilized as the linear velocity to slot paper cartons and achieve a paper guiding function at the same time, and different types of knife points are arranged on the cutting blade. Due to the fact that the outer diameter of the cutting blade on the cutting disk is utilized as the linear velocity to slot the paper cartons and achieve the paper guiding function, an original slotted portion is not damaged; thus, the producing efficiency of a paper carton factory is improved, the producing cost of a machinery manufacturer is reduced, the slotting accuracy is high, slotted openings are smooth and are not coarse, a second cutter has no jet angle, shaped paper carton slots are not damaged, the crushing resistance of the paper cartons is improved, all irregular-shaped slots can be achieved, and the paper cartons have the characteristics of being attractive in appearance and practical.

Owner:李峰

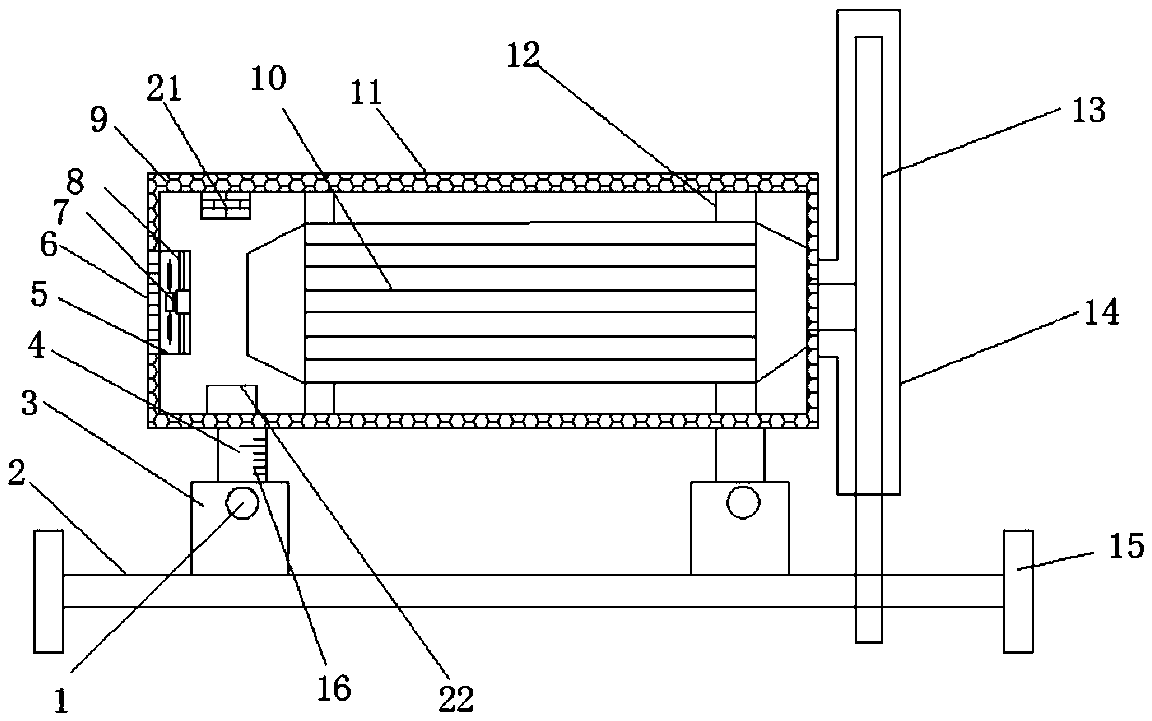

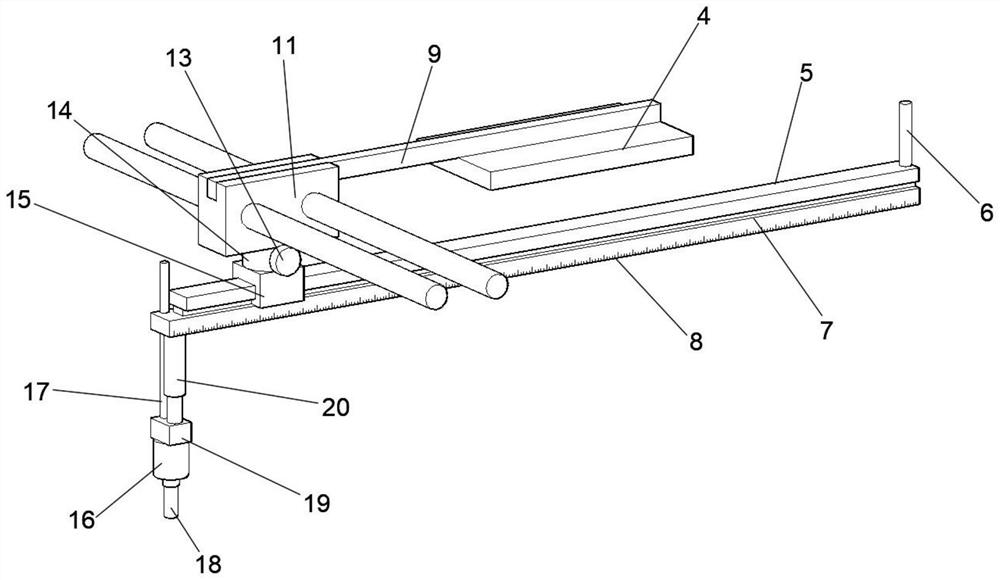

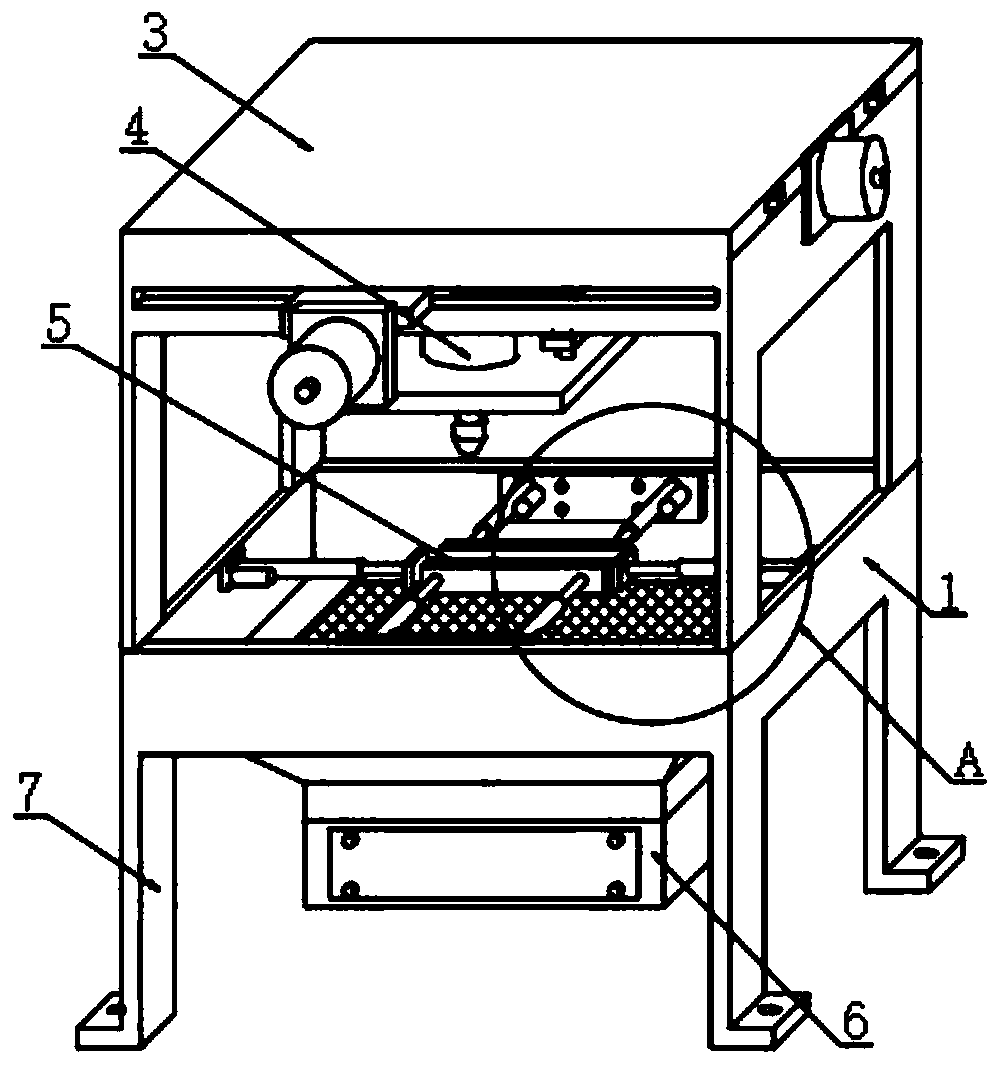

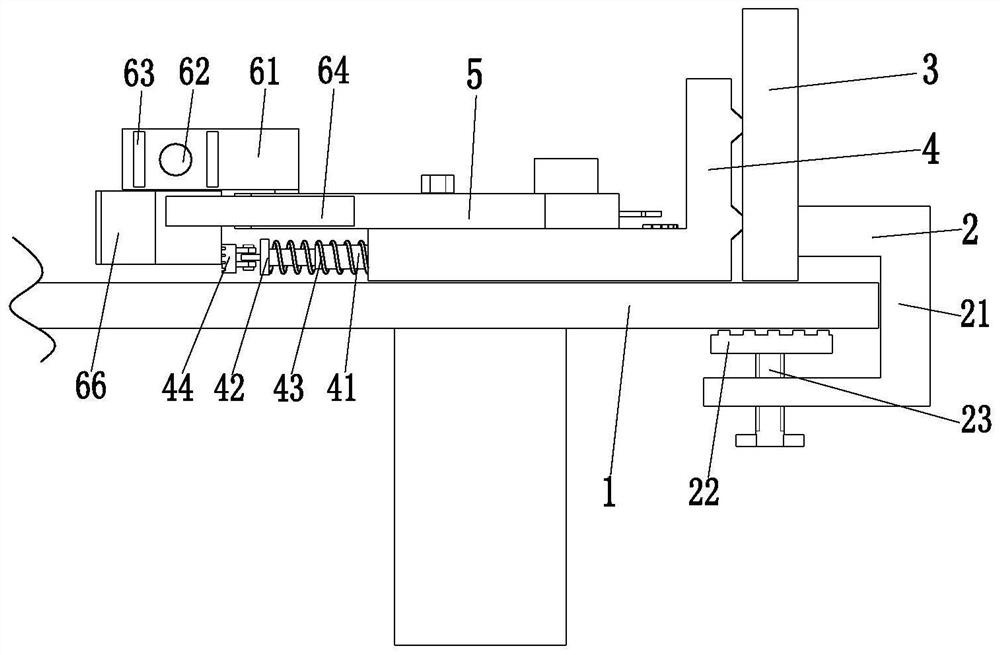

Mechanical part precise grooving device

InactiveCN109226898APrecise control of groove depthPracticalLarge fixed membersPositioning apparatusMechanical componentsControl engineering

The invention relates to the technical field of machining, in particular to a mechanical part precise grooving device which comprises a frame, a tabletop, a part and a grooving machine. A left slide groove and a right slide groove are machined in the upper end face of the tabletop. A fixed barrel is left-right slidingly installed in the left slide groove and the right slide groove and provided with a left fixing bolt and a right fixing bolt. A front slide groove and a rear slide groove are machined in the fixed barrel. A front slider and a rear slider are front-back slidingly installed in thefront slide groove and the rear slide groove. The front slider and the rear slider are fixed by the front fixing bolt and the rear fixing bolt. The part is fixed to the upper end face of the front slider and the upper end face of the rear slider through workpiece fastening mechanisms. The outer side of the grooving machine is sleeved with an installation barrel. The right side face of the installation barrel is vertically slidingly installed on a stand column. A limiting mechanism is arranged at the lower portion of the installation barrel. The mechanical part precise grooving device is simplein structure, low in cost, suitable for machining grooves with various shapes and extremely wide in application range, can precisely control the grooving depth and greatly improve the grooving efficiency and grooving precision, and has great significance in improving economic benefits for enterprises.

Owner:HENAN HUANQIU AVIATION EQUIP TECH CO LTD

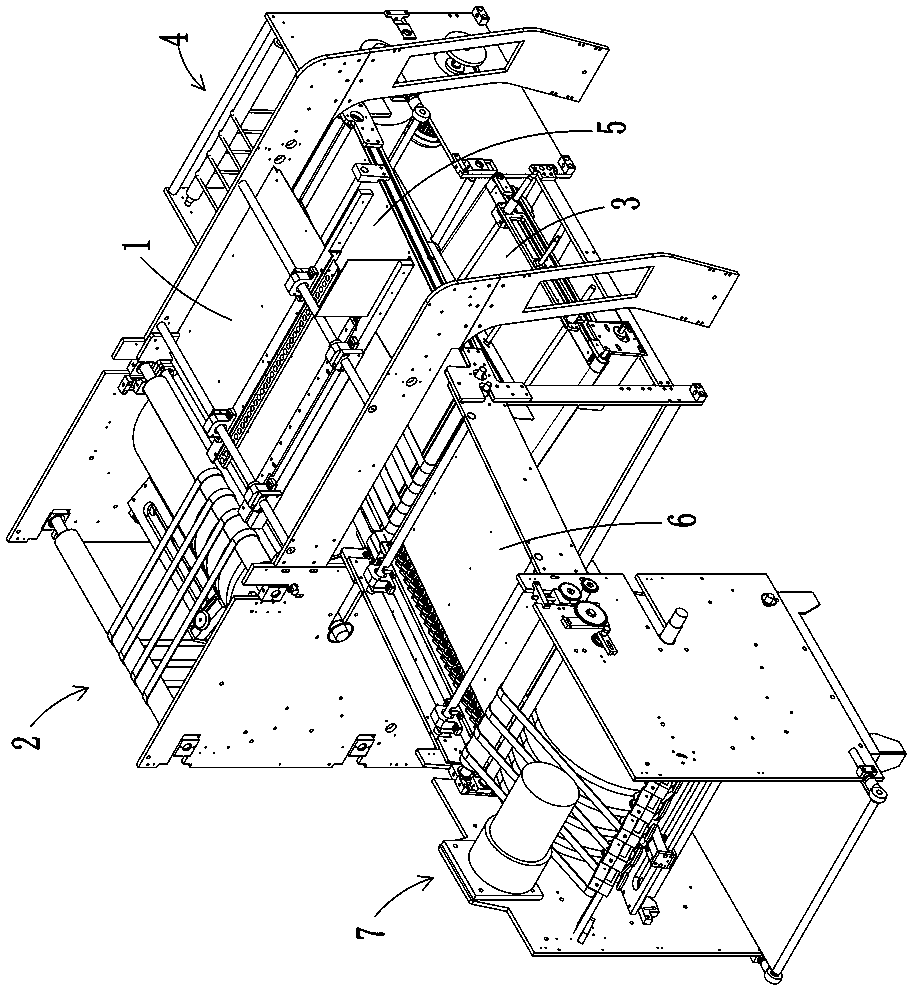

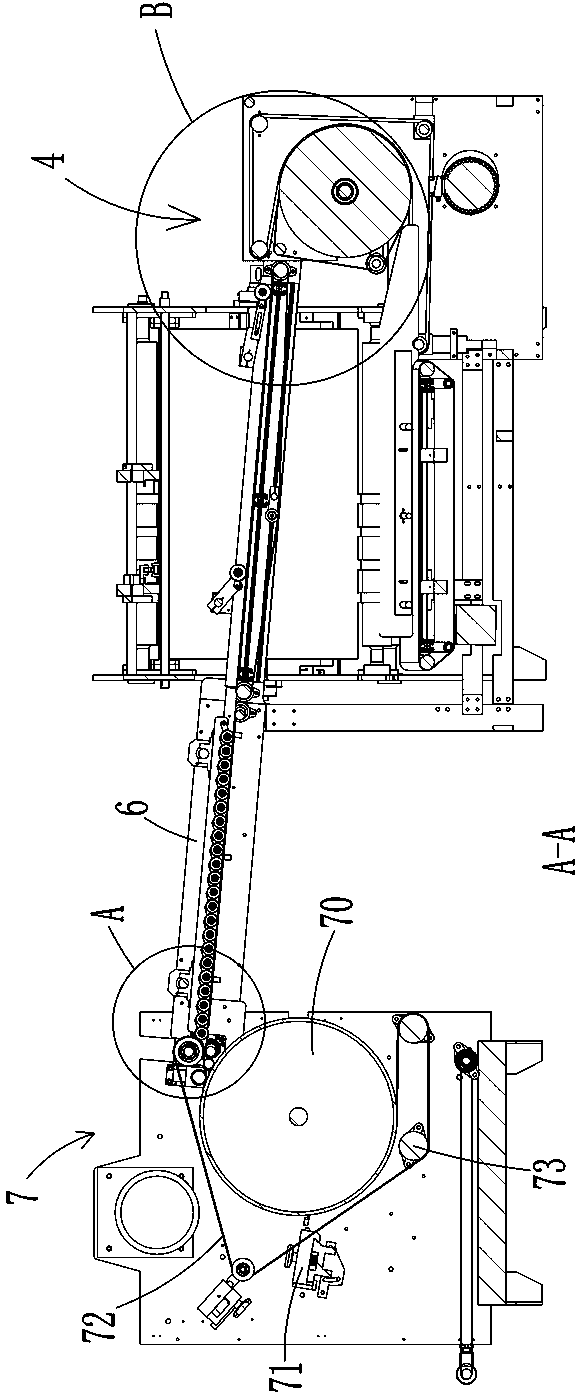

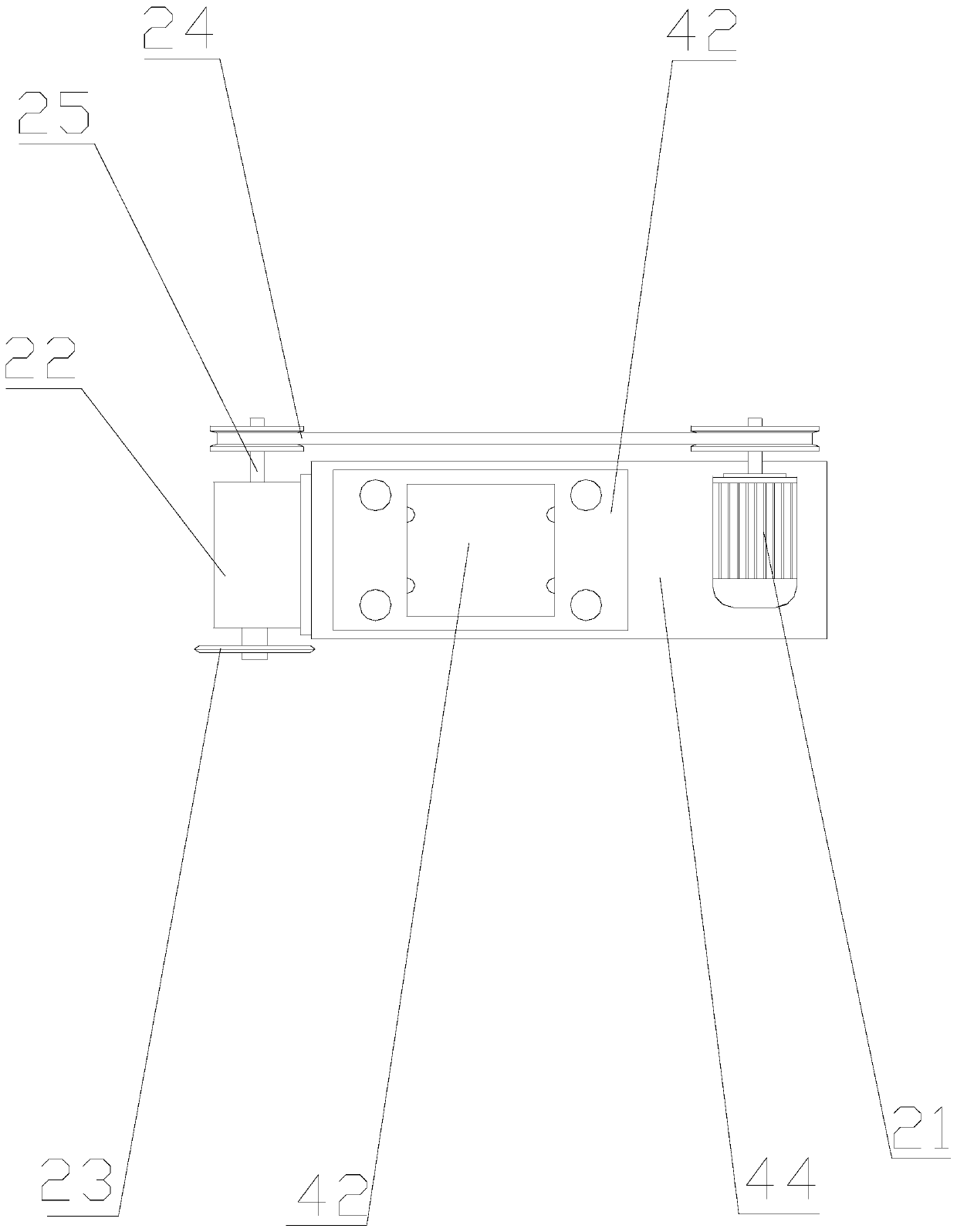

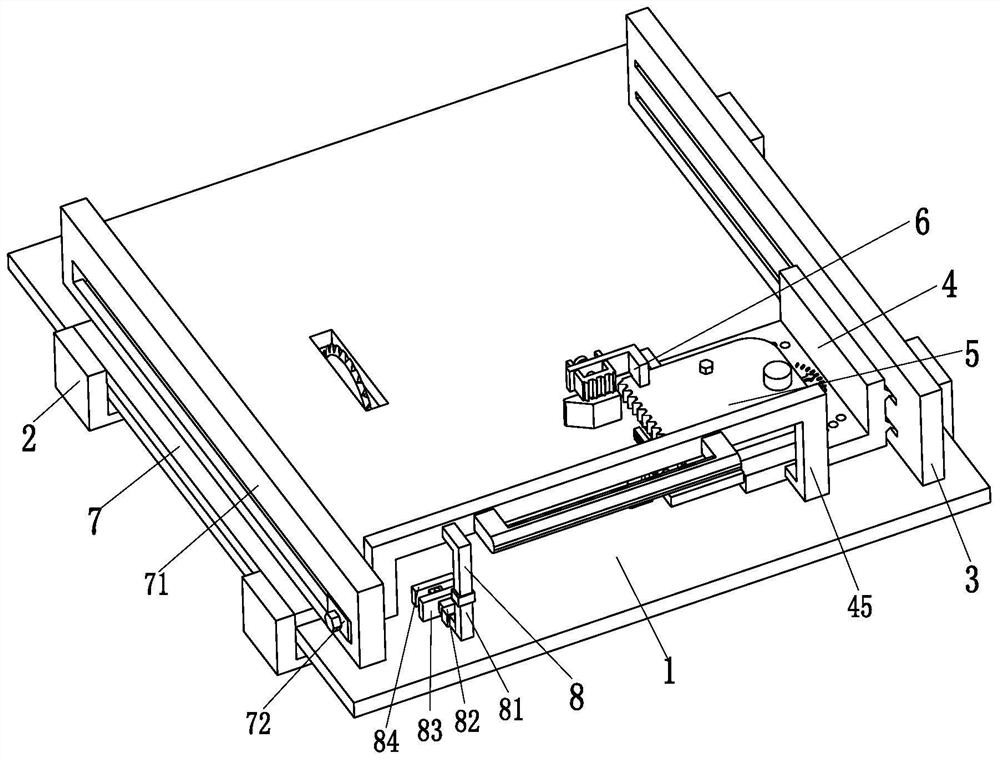

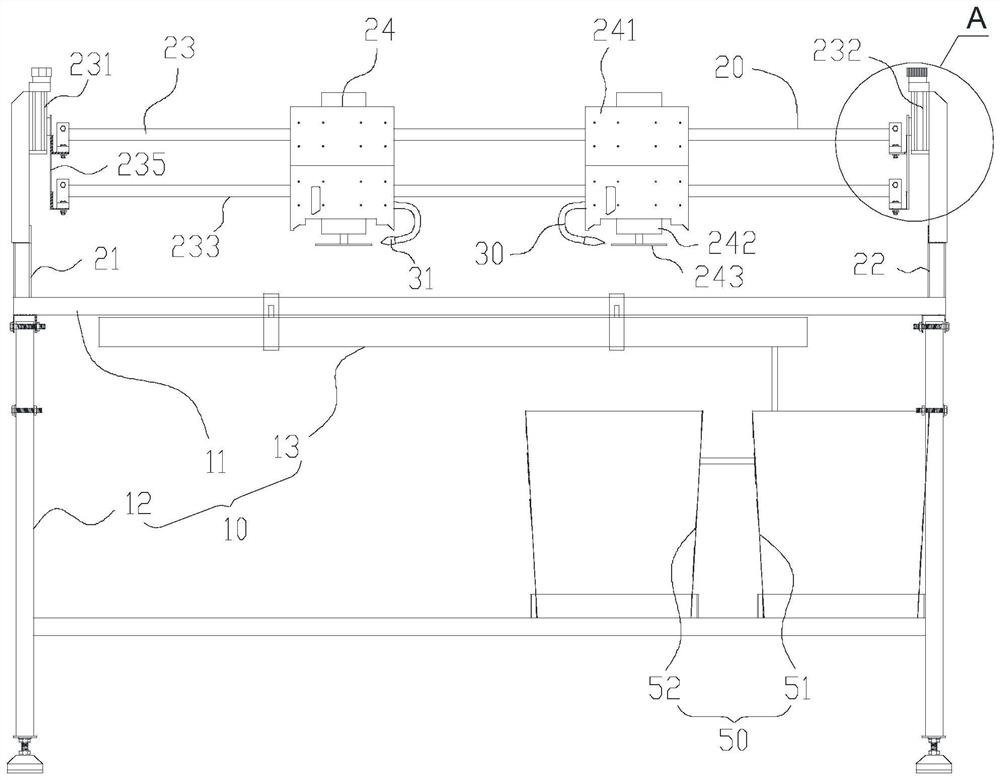

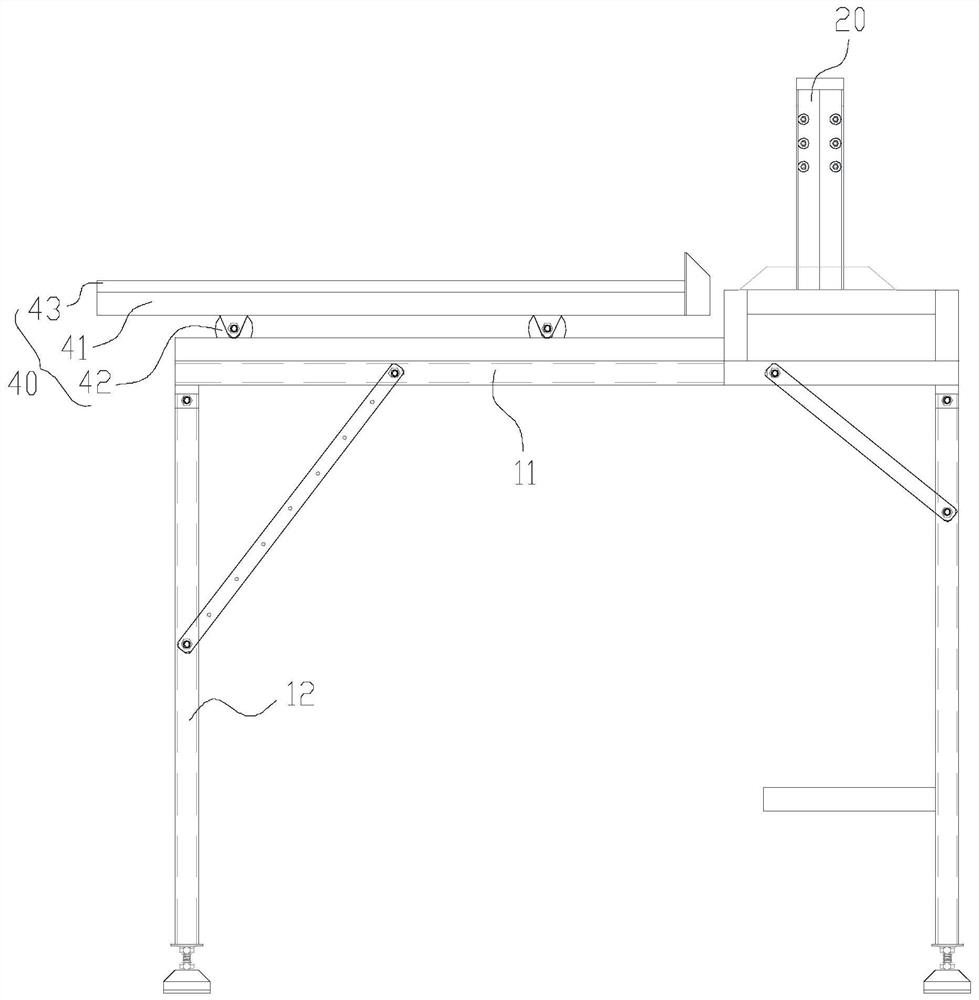

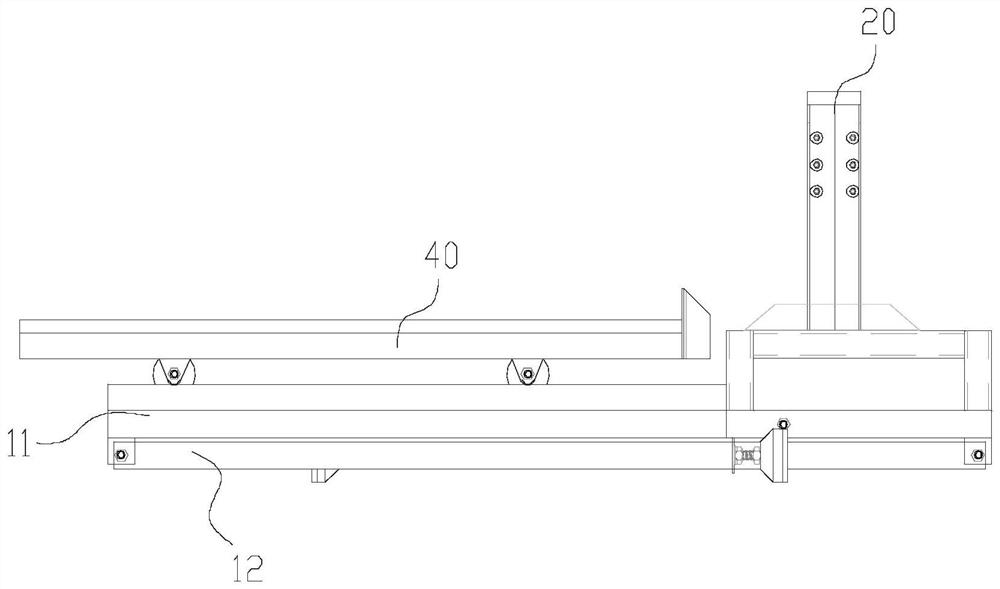

Novel bidirectional paper board grooving machine

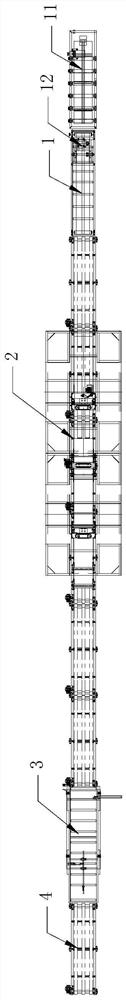

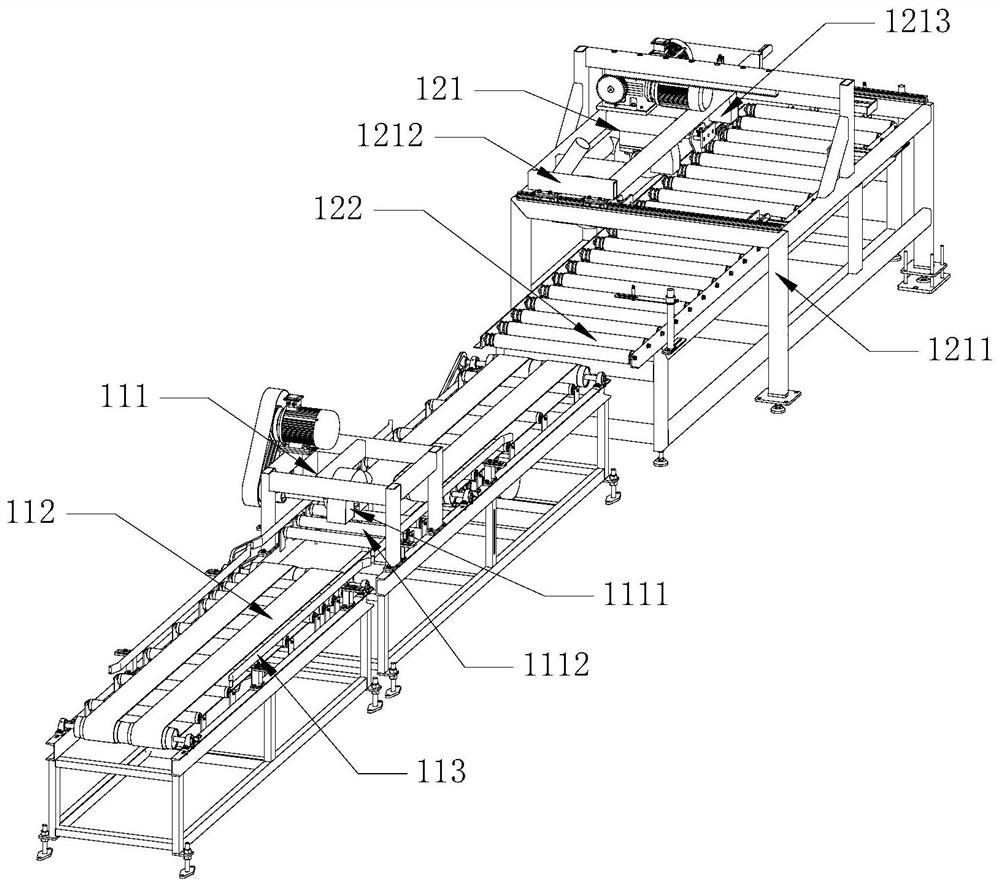

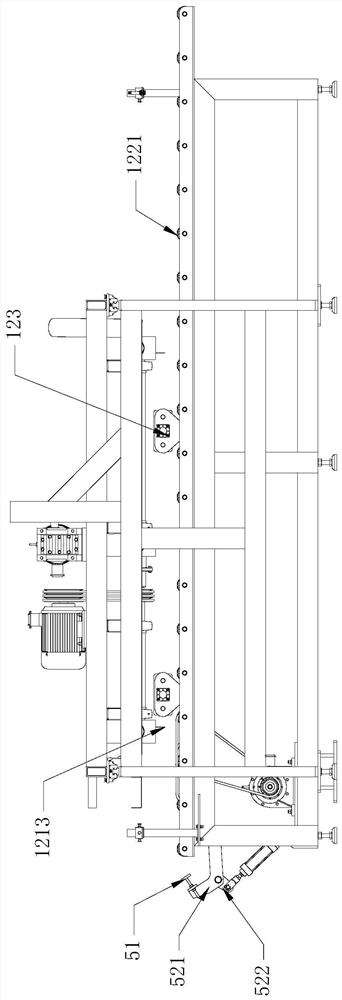

ActiveCN110435214AImprove groove accuracyGuaranteed to lastBox making operationsPaper-makingCardboardEngineering

The invention relates to a novel bidirectional paper board grooving machine capable of achieving complete deviation correction. The novel bidirectional paper board grooving machine comprises a feedingmechanism, a primary grooving mechanism and a secondary grooving mechanism, and is characterized in that the feeding end of the primary grooving mechanism is located at the upper end, and the discharging end of the primary grooving mechanism is located at the lower end; the feeding mechanism is in conveying connection with the feeding end of the primary grooving mechanism; the discharging end ofthe primary grooving mechanism in conveying connection with a lower feed mechanism; the conveying direction of the lower feed mechanism crosses with the discharging direction of the primary grooving mechanism; and a turnover feed mechanism is arranged on the discharging side of the lower feed mechanism. According to the novel bidirectional paper board grooving machine, enough stroke can be provided to achieve deviation correction, the grooving precision of secondary grooving of paper boards is higher, meanwhile, primary grooving and secondary grooving are the grooving manner of achieving conveying and grooving from top to bottom, and it is guaranteed that a grooving tool is durable.

Owner:ZHEJIANG SAILI MACHINERY

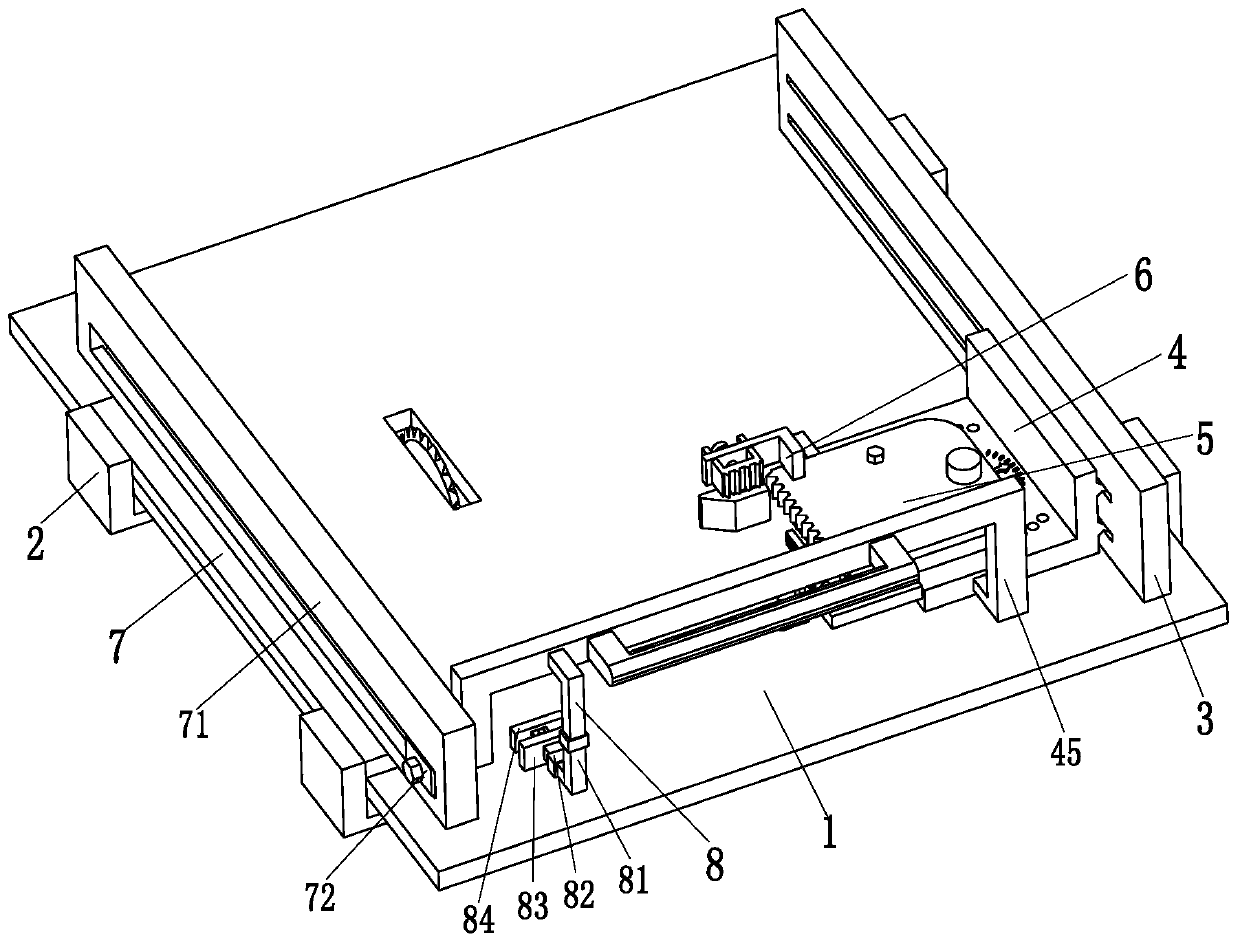

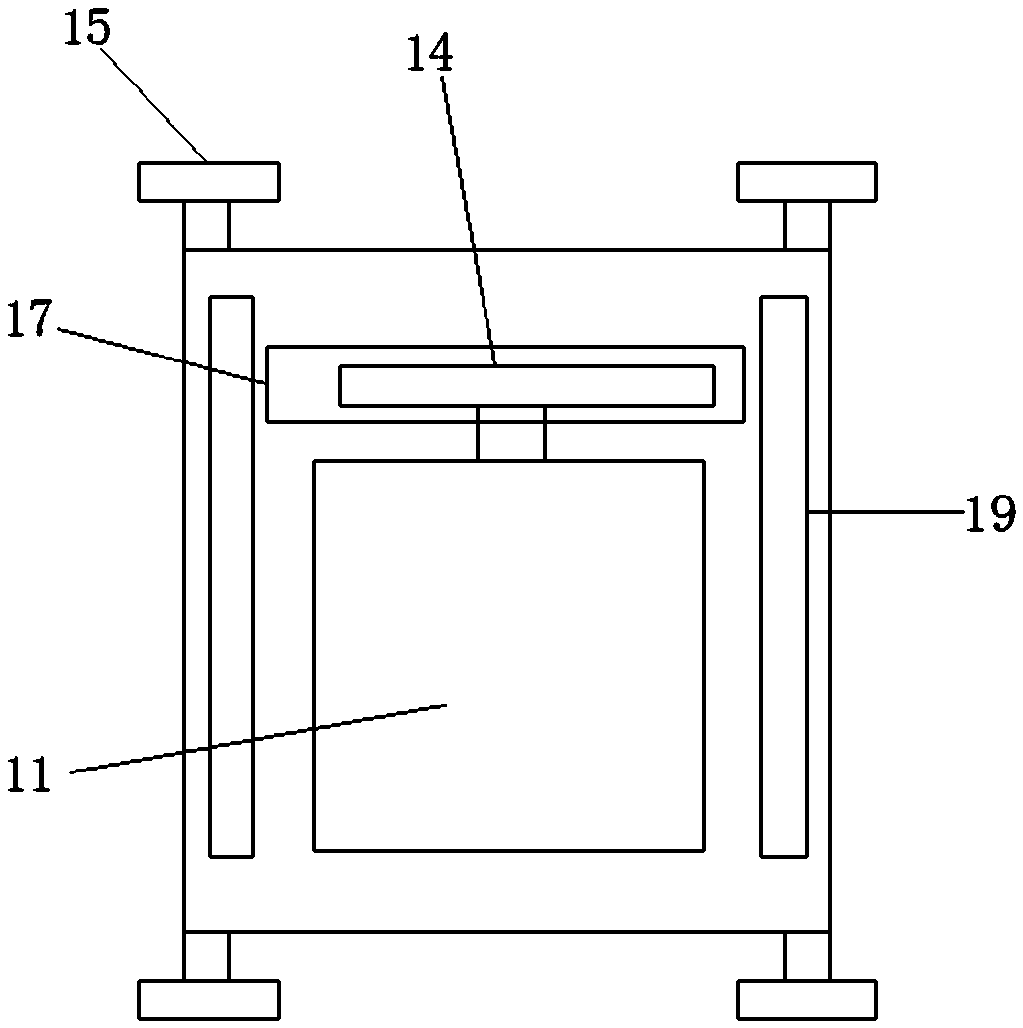

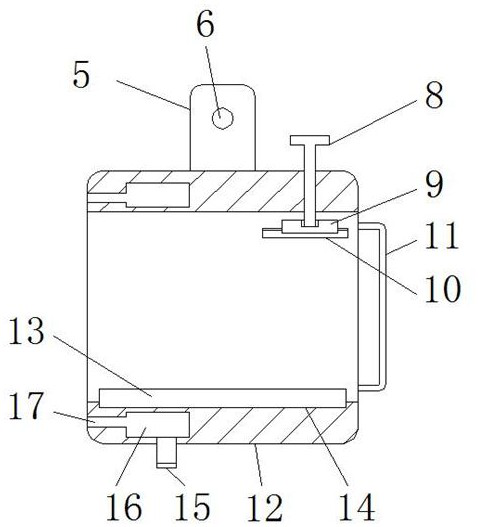

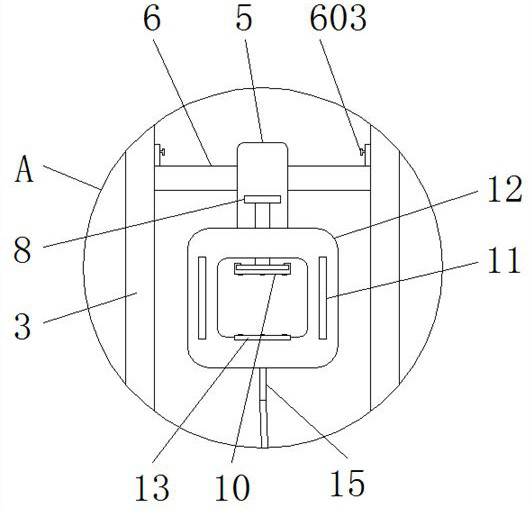

Grooving mechanism for plates

ActiveCN112454560ASave human effortImprove groove accuracyWood mortising machinesWood slotting machinesStructural engineeringMechanical engineering

The invention discloses a grooving mechanism for plates, and belongs to the field of plate processing. The grooving mechanism comprises a grooving assembly, the grooving assembly comprises a square frame, the square frame is fixedly installed relative to the ground, the cross section of the square frame is rectangular, four square sleeves are arranged on the square frame in a sleeving manner, thesquare sleeves are respectively arranged on four borders of the square frame, and the four square sleeves are respectively connected with the square frame in a sliding manner; and a first sliding guide rail and a second sliding guide rail are fixedly mounted above the square frame, and the second sliding guide rail is perpendicular to the first sliding guide rail. The grooving mechanism is high inplate grooving precision.

Owner:盐城兴展新材料科技有限公司

Portable grooving machine for building

PendingCN108748701AImprove groove accuracyExtended service lifeWorking accessoriesStone-like material working toolsEngineeringBolt connection

The invention discloses a portable grooving machine for a building. The portable grooving machine comprises a base; four first telescopic rods distributed at equal distances are connected to the top of the base through bolts; and cavities are formed in the first telescopic rods, second telescopic rods are inserted into the cavities, first through holes are formed in the tops of the first telescopic rods, fastening bolts are connected into the first through holes through threads, and a motor shell is connected to the tops of the second telescopic rods through bolts. According to the portable grooving machine for the building, by arranging the base, a rectangular notch, a grooving saw disc, the first telescopic rods, the second telescopic rods, the fastening bolts and scales, the first telescopic rods are extended and retracted, and the first telescopic rods are fixed to the second telescopic rods by screwing the fastening bolts; and the scales are engraved on the outer walls of the second telescopic rods, the depth that the grooving saw disc enters the rectangular notch can be controlled, thus the grooving depth is adjusted, the grooving depth does not needed to be controlled manually, and grooving precision is improved.

Owner:郑赛娇

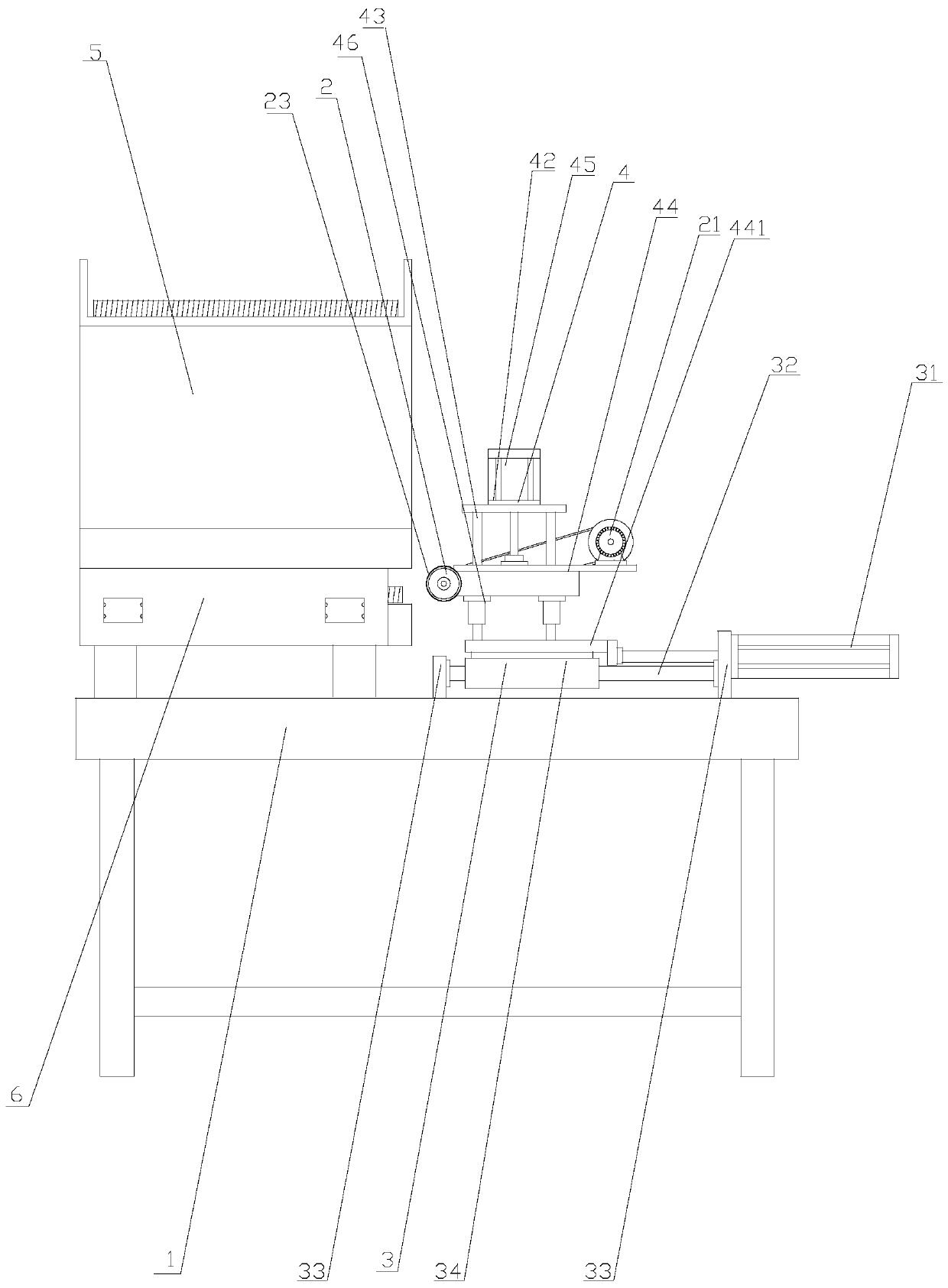

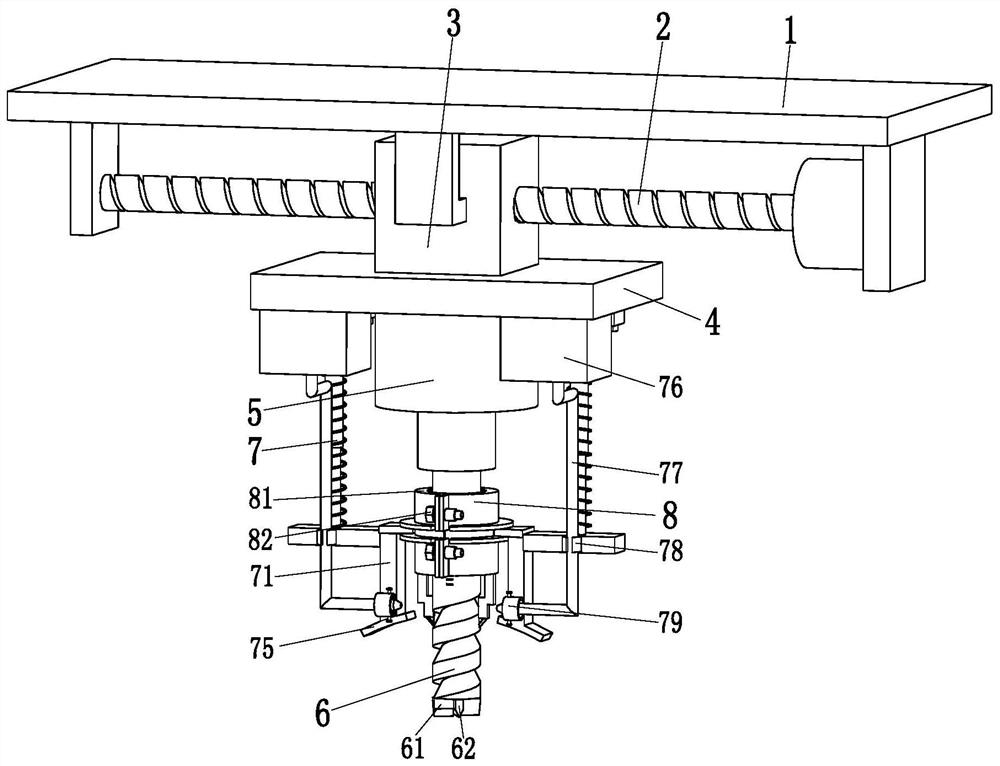

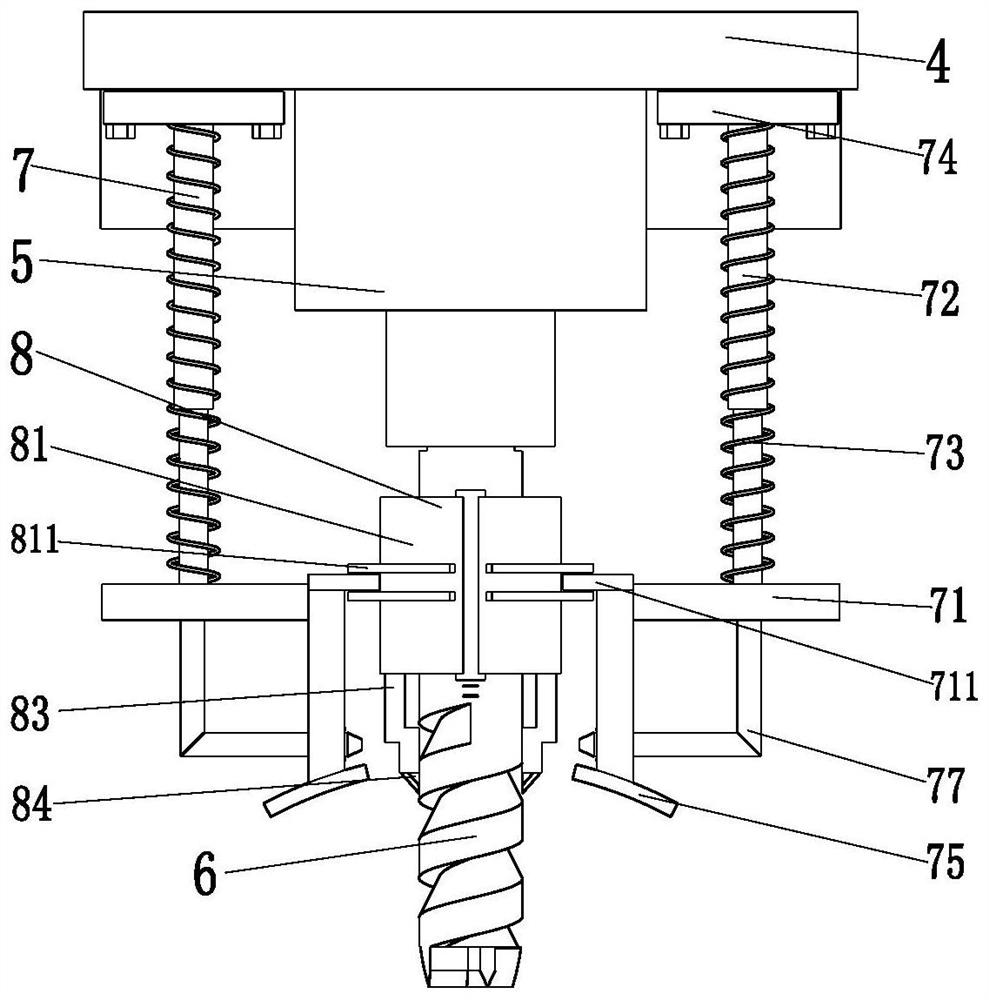

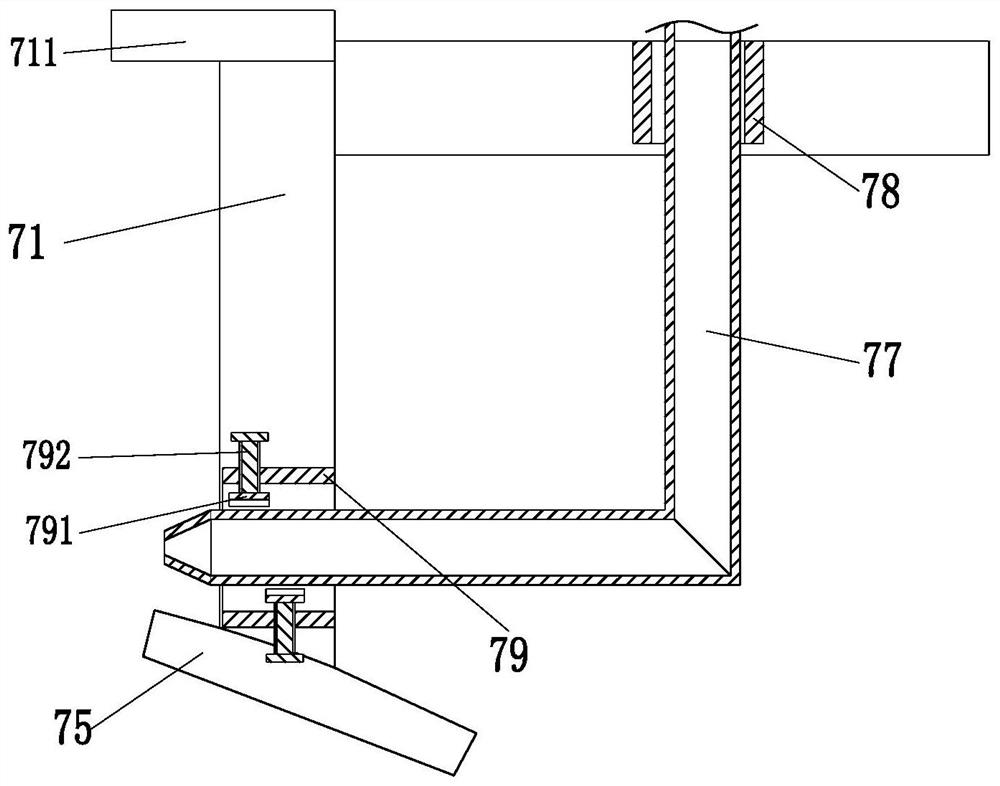

Slot milling machine for workpiece milling

ActiveCN110253061AImprove groove accuracyMilling cuttersOther manufacturing equipments/toolsMilling cutterEngineering

The invention relates to a slot milling machine for workpiece milling. The slot milling machine comprises a top plate, a moving screw rod, a moving sliding block, a hanger plate, a rotating motor, a milling cutter and position-limiting mechanisms, wherein the bottom of the top plate is provided with the moving screw rod, the moving sliding block is installed on the middle portion of the moving screw rod, the outer end of the moving sliding block is provided with a sliding rod, the upper end of the sliding rod on the moving sliding block is connected with the bottom of the top plate in a sliding fit manner, the hanger plate is installed on the bottom of the moving sliding block, the rotating motor is installed on the lower end face of the middle portion of the hanger plate through a motor sleeve and is provided with the milling cutter, the left and right two ends of the rotating motor are each distributed with one position-limiting mechanism, and the position-limiting mechanisms are installed on the bottom of the hanger plate. By means of the slot milling machine for the workpiece milling, the problems existing in slot milling performed on existing nylon shafts that the nylon shaft slot milling efficiency is low, the slot milling depth of the nylon shafts in the slot milling performed on the nylon shafts cannot be limited and the like due to chamfering treatment needs to be performed on slots slotted in the nylon shafts separately after the nylon shaft slot milling is finished can be solved.

Owner:海盐瑞扬新材料股份有限公司

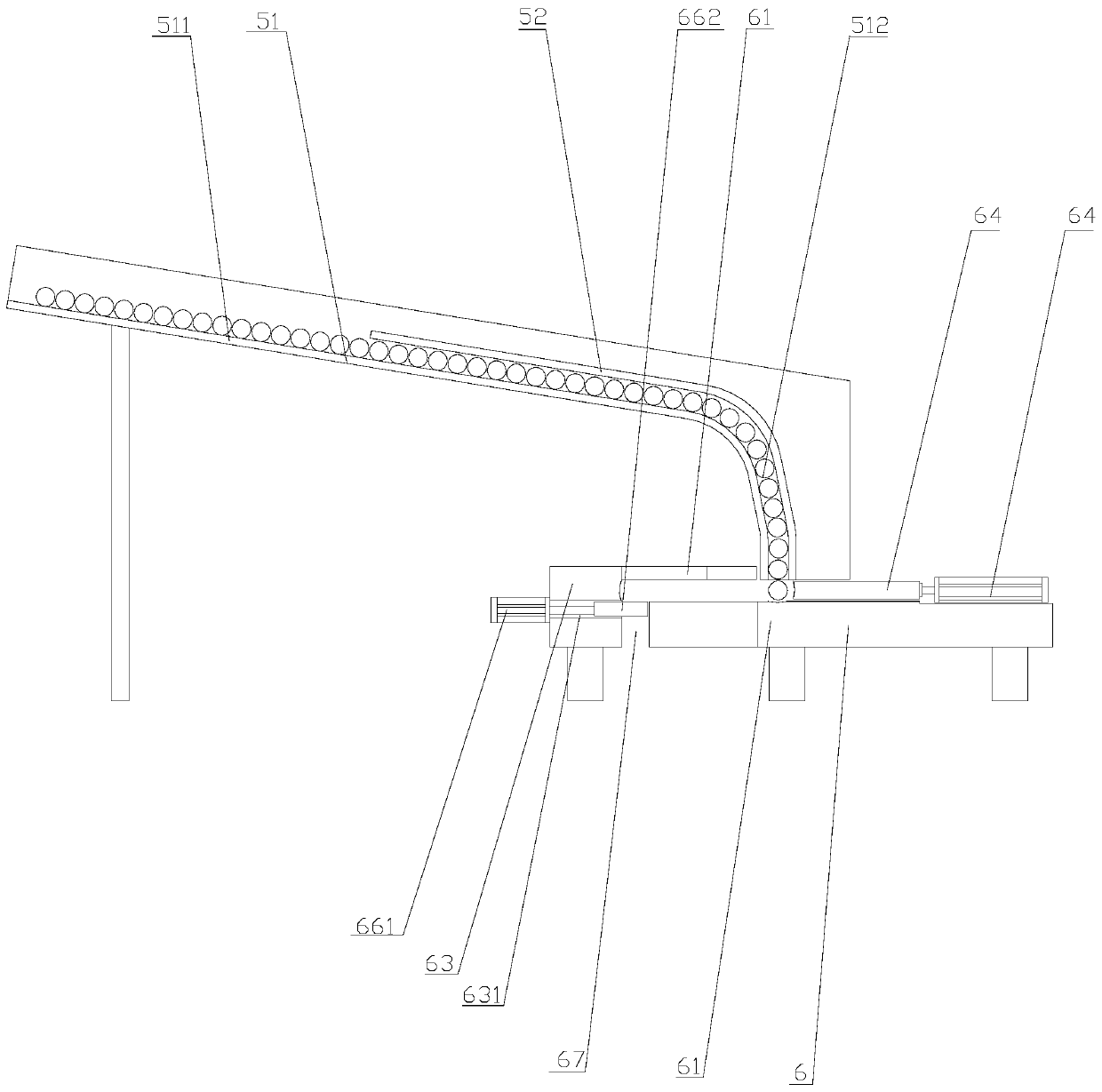

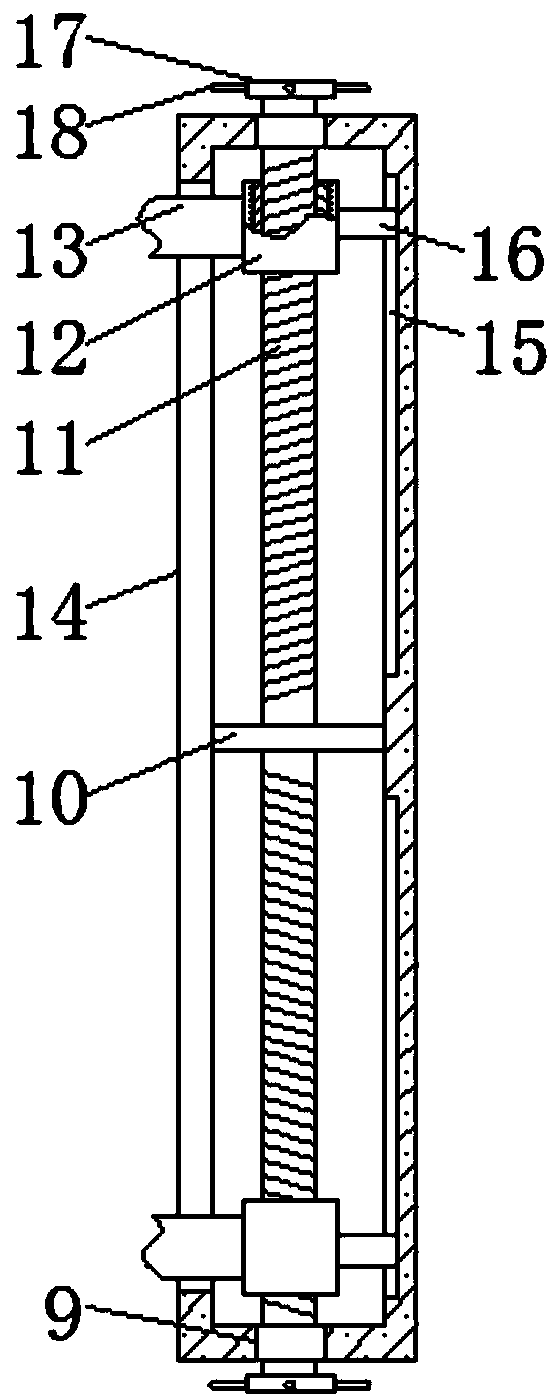

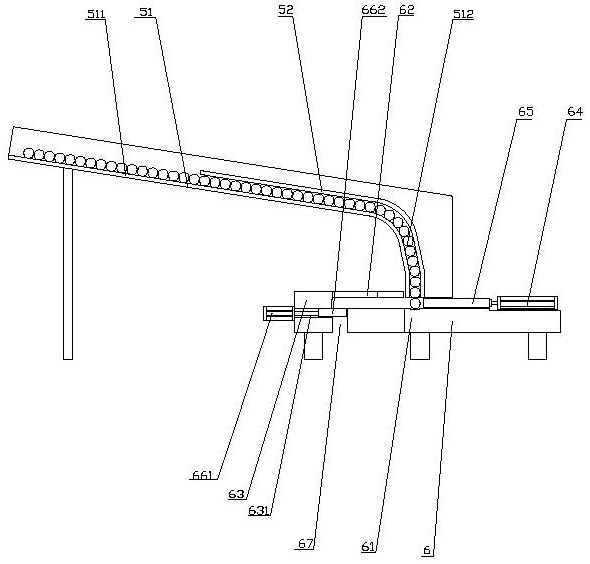

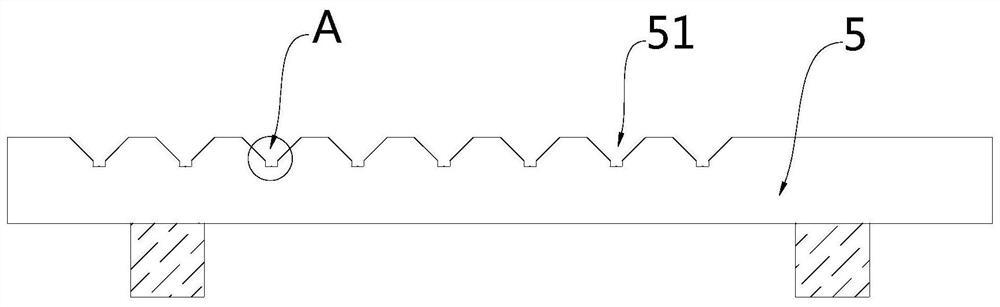

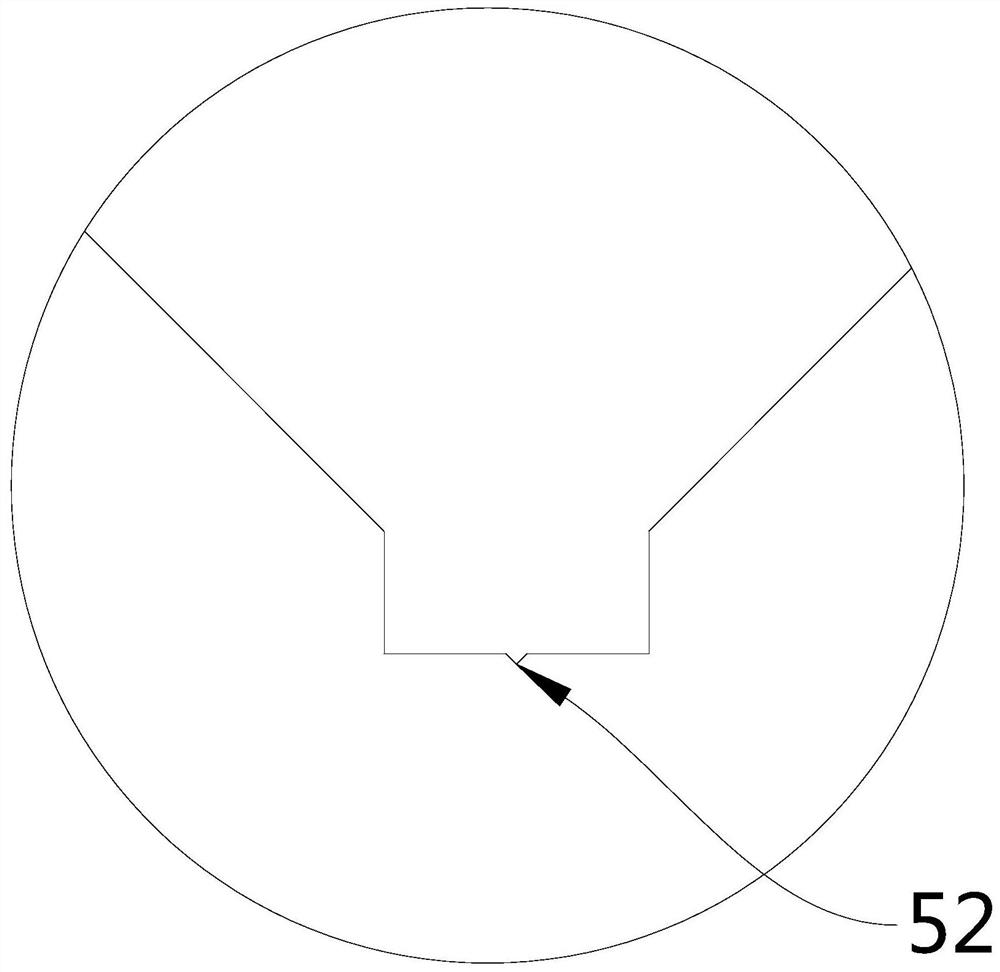

Threaded rod automatic feeding and automatic slotting device

ActiveCN110405582AImprove slotting efficiencyGood slotting efficiencyGrinding carriagesGrinding drivesEngineeringThreaded rod

The invention discloses a threaded rod automatic feeding and automatic slotting device comprising a rack, a slotting device, a slotting device traverse movement mechanism, a slotting device lifting device, a threaded rod feeding slot and an automatic feeding device; the upper end of the rack is transversely provided with the slotting device traverse movement mechanism, and the upper end of a moving portion of the slotting device traverse movement mechanism is provided with the slotting device lifting device. According to the threaded rod automatic feeding and automatic slotting device, the threaded rod feeding slot and the automatic feeding device are matched to achieve automatic feeding and automatic unloading of threaded rods, the threaded rod slotting efficiency is improved, the slotting quality is improved, and the labor intensity is reduced; the slotting device lifting device and the slotting device traverse movement mechanism drive the slotting device to move up and down and leftand right, the slotting device is more flexible, the threaded rod slotting efficiency is improved, and the threaded rod slotting accuracy is improved; and the slotting device lifting device drives the slotting device to slot a threaded rod from bottom to top or from top to bottom, and the threaded rod slotting quality is better, notches are neat, and the depths of the notches are the same.

Owner:HAIYAN HUILIAN GENERAL FITTING

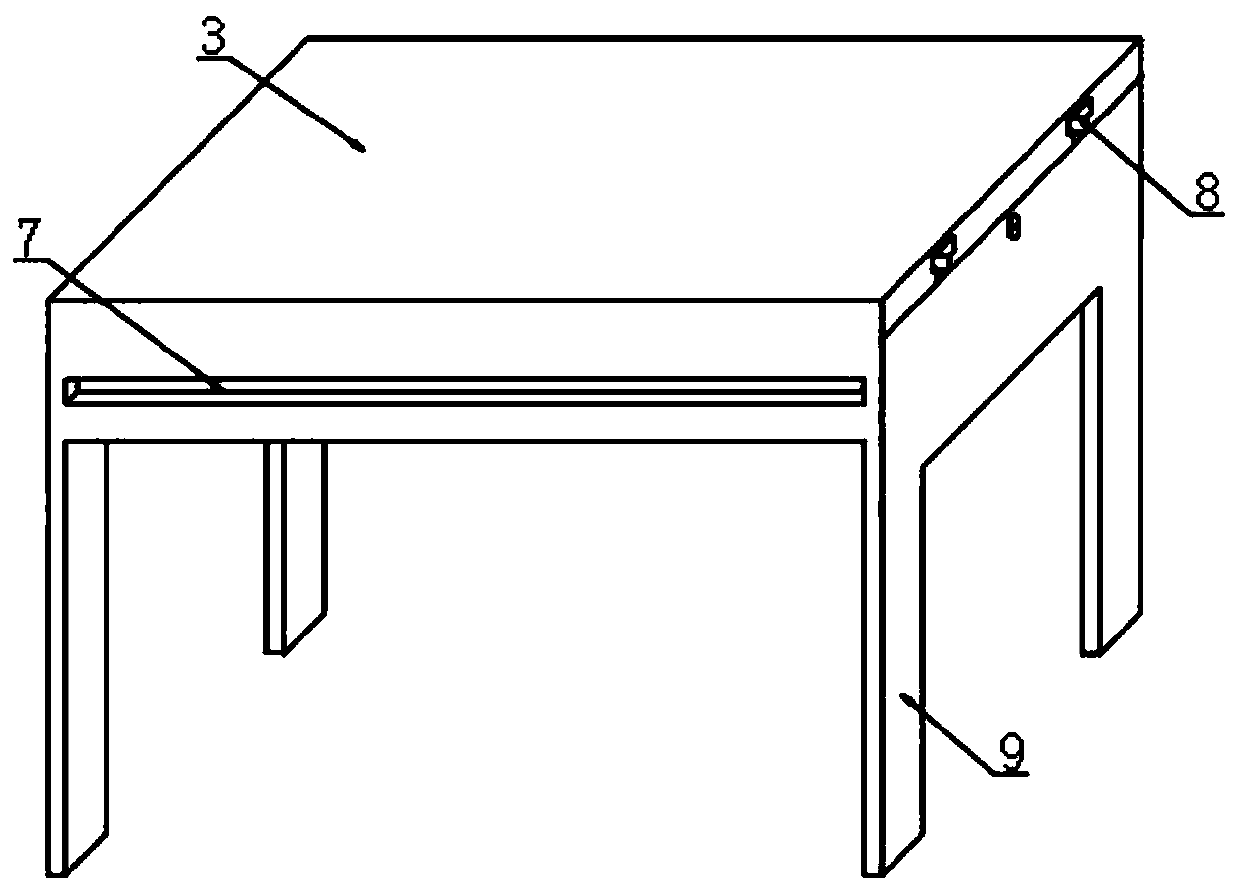

Grooving equipment for dining table top processing

InactiveCN108748464AImprove practicalityImprove slotting effectWood mortising machinesWood slotting machinesArchitectural engineeringMachine tool

The invention discloses grooving equipment for dining table top processing. The grooving equipment comprises a grooving equipment body. A base is fixedly connected with the bottom of the grooving equipment body. A machine tool body is fixedly connected with the top of the grooving equipment body. An equipment groove is formed in the center of the top of the machine tool body. Connecting rods are fixedly connected with the front side and the rear side of the machine tool body. Through coordinate application of a sliding rod, a sliding block, a shell, a bearing, a partition plate, a threaded rod, a threaded pipe, a fixing rod and a scale plate, the problems that when existing grooving equipment is used, dining table tops are often pushed manually to move on the surface of a machine tool andare liable to be deviated in the pushing process, consequently, the grooving effect is poor, and the grooving precision is low are solved, the grooving equipment for dining table top processing has the advantages of being good in table top fixing effect and high in grooving precision, and is convenient to operate, the effect of saving time and effort is achieved, and the practicability of the grooving equipment for dining table top processing is improved.

Owner:安吉木亦家具有限公司

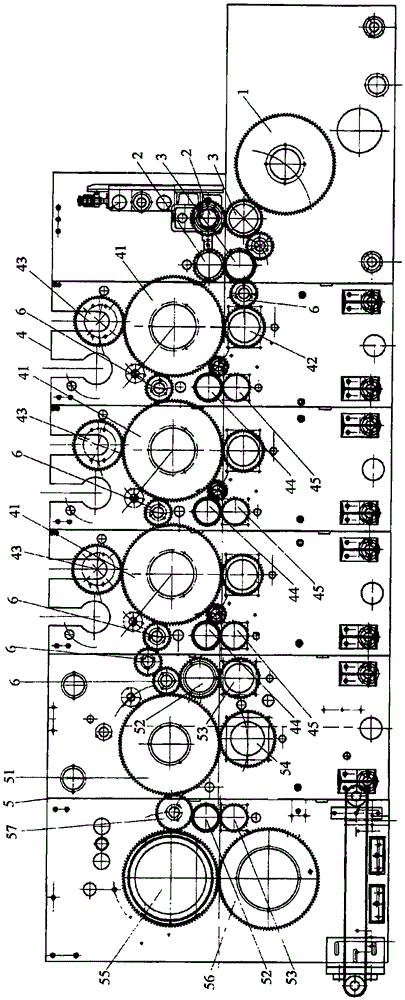

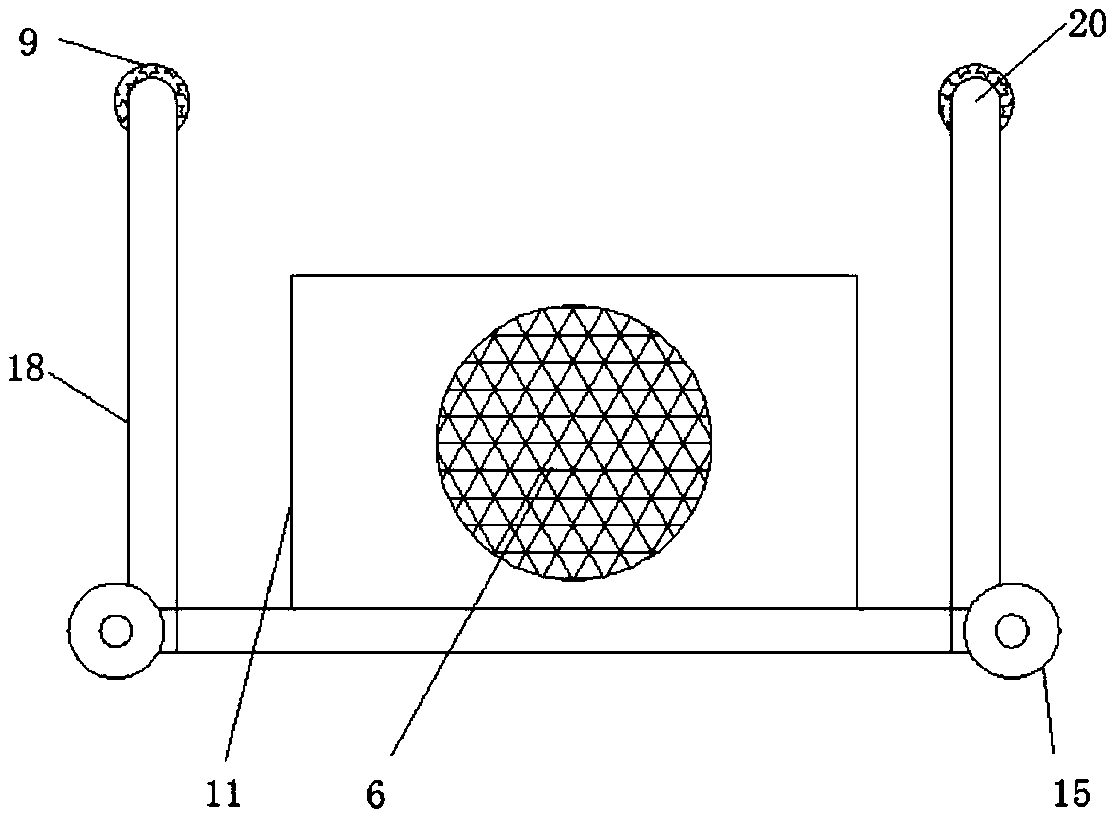

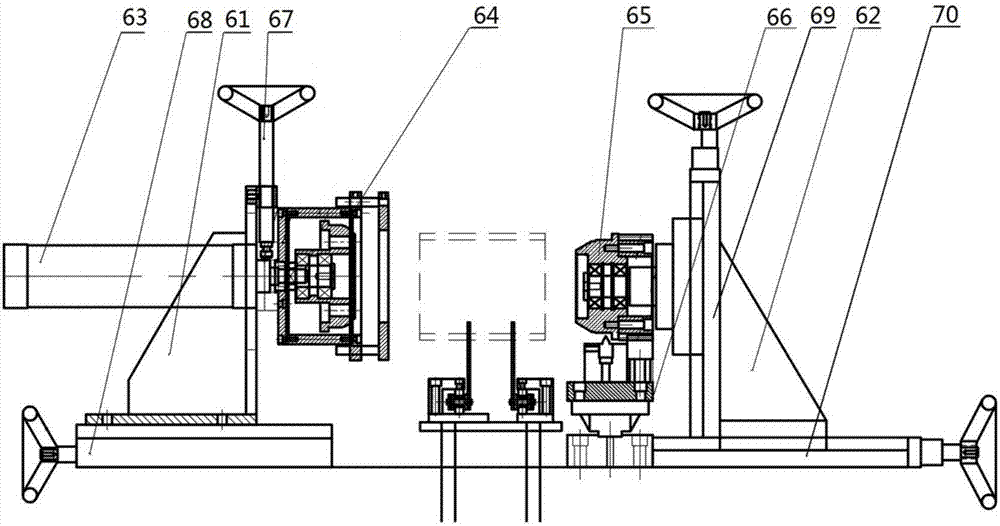

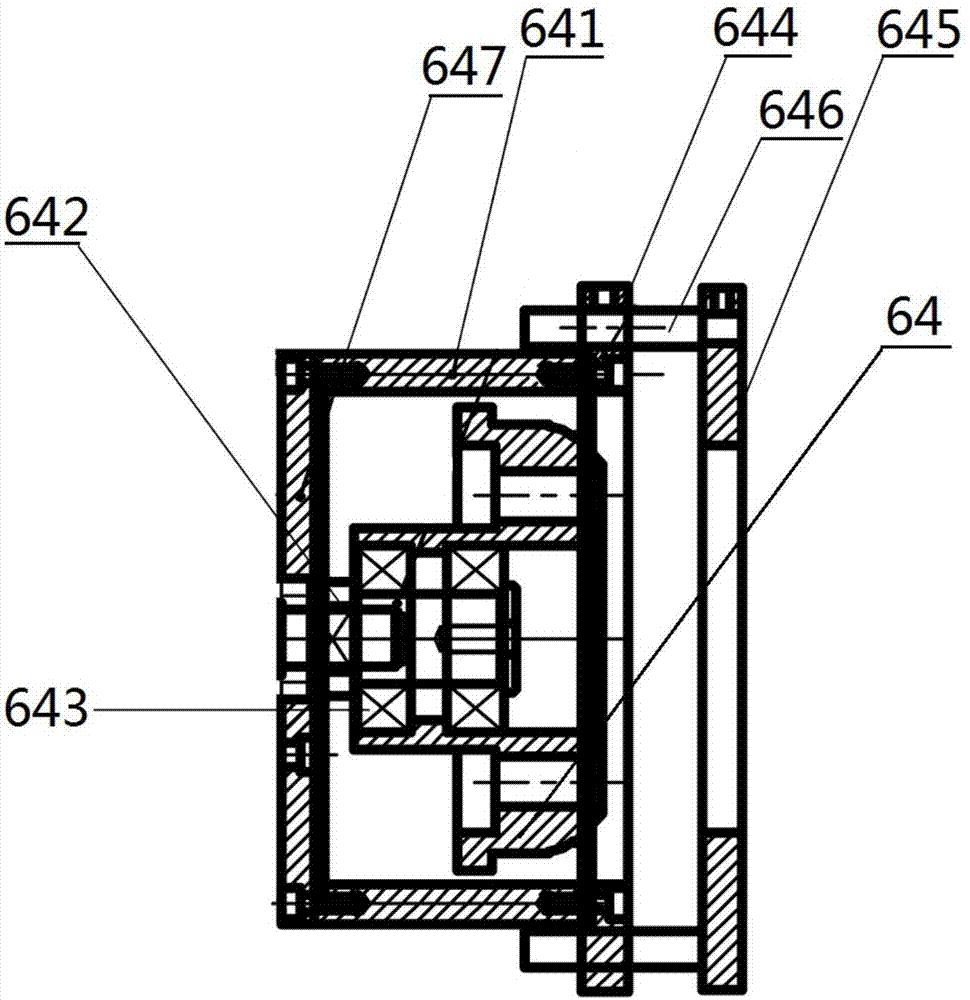

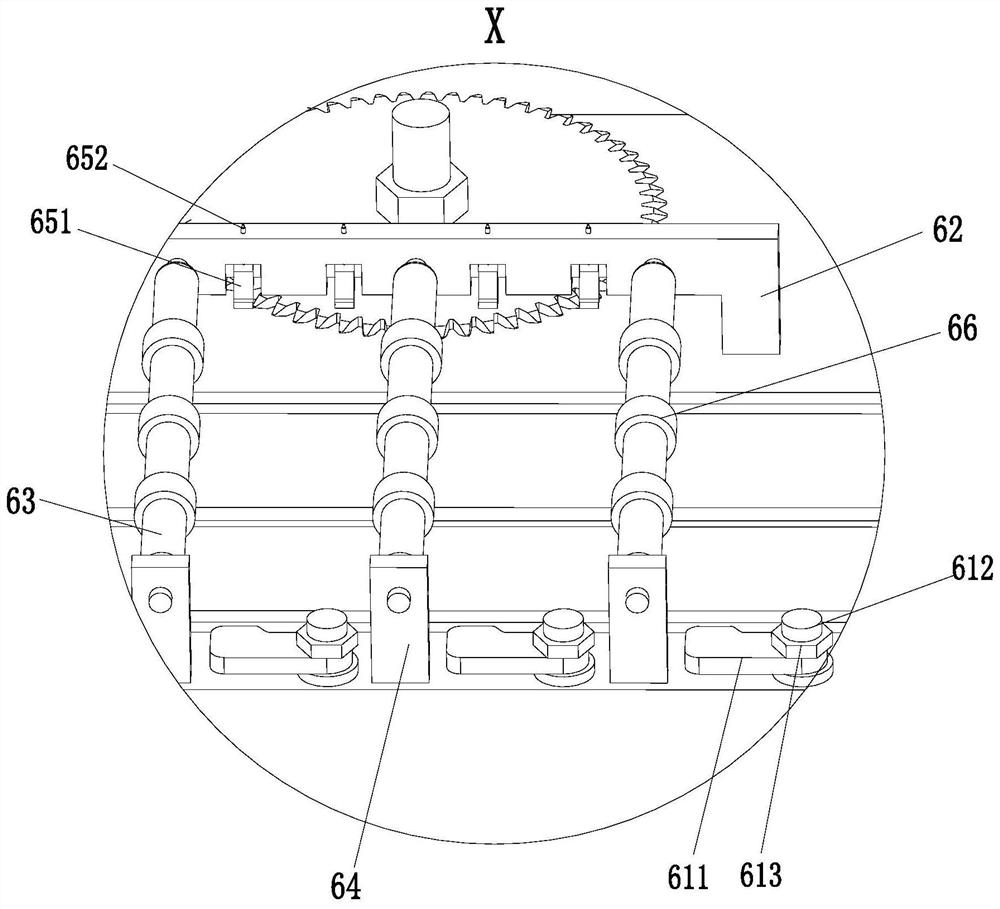

Paper tube shaping machine

InactiveCN107443207AStable clampingImprove groove accuracyGrinding machinesGrinding work supportsDevice formPulp and paper industry

The invention discloses a paper tube shaping machine. The paper tube shaping machine comprises a machine frame. A conveying device is arranged in the middle of the upper end of the machine frame. The conveying device comprises a conveying disc belt which is arranged along the center line of the upper end of the machine frame and can rotate around the machine frame, and a drive motor used for driving the conveying disc belt to rotate. Feeding devices, head grinding devices, polishing devices and slotting devices are sequentially arranged at the upper end of the machine frame from left to right along the two sides of the conveying disc belt. The three sets of the head grinding devices are arranged at the two sides of the conveying disc belt. The three sets of the polishing devices are arranged at the two sides of the conveying disc belt. The six slotting devices are arranged at the two sides of the conveying disc belt. Every three slotting devices form a group and the slotting devices comprise the first slotting devices and the second slotting devices. According to the paper tube shaping machine, due to arrangement of the six sets of the head grinding devices, production efficiency is made higher; through structural design of the better slotting devices, paper tubes can be clamped stably, slotting precision is high, and the phenomenon that the paper tube quality is affected due to unstable clamping is avoided; and two specifications of products can be produced by switching the slotting devices, and production cost is reduced.

Owner:TONGXIANG HENGYI PAPER PLASTIC

Multi-direction furniture plate grooving equipment

PendingCN114102772AMeet slotting needsEasy to makeWood mortising machinesWood slotting machinesElectric machineryStructural engineering

The invention discloses multi-direction furniture plate grooving equipment which comprises a machining table. A guide assembly and a grooving assembly are arranged on the machining table. The guiding assembly comprises a fixing frame, a first guiding rod is arranged at the bottom of the fixing frame, an adjusting block is slidably connected to the first guiding rod, a guiding frame is rotatably connected to the bottom of the adjusting block, and a mounting plate is transversely slidably connected to the bottom of the guiding frame. The grooving assembly comprises a driving motor, a grooving drill bit is mounted on a rotating shaft of the driving motor, an electric telescopic rod is mounted on the driving motor, and the other end of the electric telescopic rod is connected with the end of the mounting plate. By rotating one end of the mounting plate, the guide frame and the adjusting block on the mounting plate rotate, so that the grooving assembly located at the other end of the mounting plate is controlled to conduct arc-shaped grooving and multi-direction and multi-type grooving, and different grooving requirements are met.

Owner:安徽省徽派家私有限责任公司

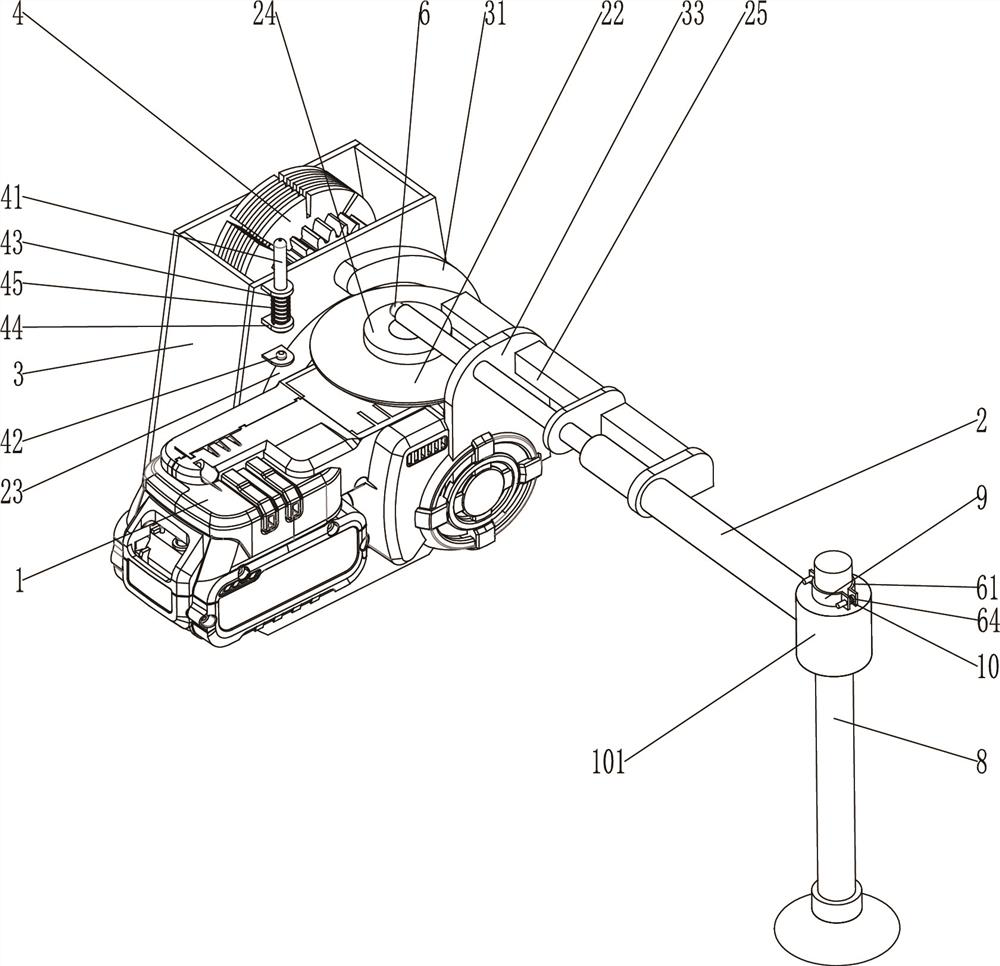

High-voltage brushless motor grooving machine

PendingCN114012911AImprove consistencyImprove slotting efficiencyWorking accessoriesStone-like material working toolsBrushless motorsStructural engineering

A high-voltage brushless motor grooving machine disclosed by the present invention comprises a grooving machine and an auxiliary rod, the grooving machine is provided with a rotatable housing, the housing is internally provided with a first cutting blade and a second cutting blade, the auxiliary rod is provided with a lock pin matched with the housing, the housing is provided with a lock hole matched with the lock pin, a first conducting rod and a second conducting rod which are matched with the lock pin are arranged on the lock hole, the auxiliary rod is arranged on a supporting rod in a sliding mode, a clamping block which is matched with the lock pin and used for clamping the supporting rod is arranged on the auxiliary rod, and a first electromagnet connected with the lock pin is arranged on the clamping block. According to the high-voltage brushless motor grooving machine provided by the invention, the cutting blade can be switched when an arc-shaped groove body is cut, so that the grooving efficiency and precision are improved, and meanwhile, the grooving stability and the grooving depth consistency are improved through cooperation with the auxiliary rod.

Owner:浙江精力工具有限公司

High-precision slotting device applied to production of automobile exhaust manifold

ActiveCN110977039AImprove groove accuracyHigh precisionPositioning apparatusMaintainance and safety accessoriesSlide plateMotronic

The invention discloses a high-precision slotting device applied to production of an automobile exhaust manifold and specifically relates to the technical field of production of automobile exhaust manifolds. The high-precision slotting device comprises a table face, wherein a top supporting component is welded on the upper surface of the table face; a slotting component is in slide connection to the inner lower surface of the top supporting component; a clamping component is installed inside the table face; supporting legs are welded on one side of the lower surface of the table face; a dust collection framework is welded on the lower surface of the table face in a through manner; a lifting plate is welded on one side of the lower surface of the top supporting component; a first slide groove is formed in the inner upper surface of the top supporting component; supporting legs are disposed on the front surface of the top supporting component; and a first slide plate is disposed on the upper end of the slotting component. The high-precision slotting device applied to production of the automobile exhaust manifold disclosed by the invention has the beneficial effects that slotting precision is high; a slotting position can be adjusted electrically; a high-strength clamping component is disposed; and a dust collection device is disposed.

Owner:HENAN FEILONG WUHU AUTOMOBILE PARTS

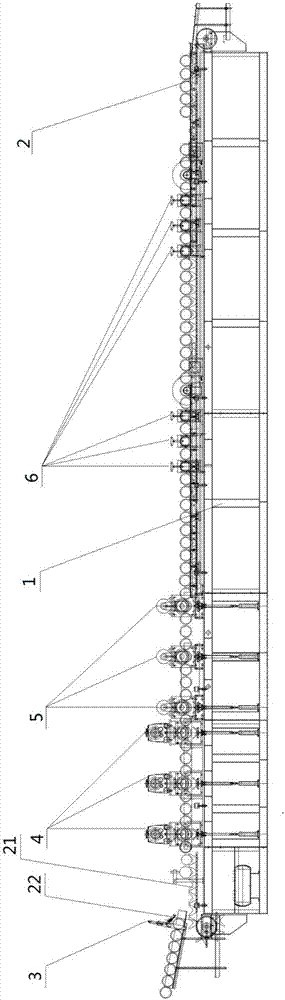

MPR fireproof and thermal insulation template production line

PendingCN111975856AImprove protectionAvoid damageMetal working apparatusProduction lineThermal insulation

This application provides a MPR fireproof and thermal insulation template production line. The production line comprises a conveyor line, wherein according to the conveying direction of the conveyor line, a slotting mechanism, a conveying material laying mechanism, a grid cloth cutting mechanism and a discharging mechanism are sequentially arranged on the conveyor line; the slotting mechanism comprises a first slotting part for axial slotting of a plate and a second slotting part for radial slotting of the plate, the first slotting part comprises a first slotting saw and a first transmission part, the first slotting saw is erected above the first transmission part, the second slotting part comprises a second slotting saw and a second transmission part, the second slotting part is erected above the second transmission part, and the first transmission part is connected to the conveying material laying mechanism through the second transmission part. In the application, the slotting mechanism is provided, and the slotted plate is directly transported to the conveying material laying mechanism for material laying. On the one hand, the plate is better protected and prevented from being damaged when it is slotted and then conveyed; and on the other hand, laying is carried out immediately after slotting, which improves the efficiency and quality of laying.

Owner:山东七星绿色建筑科技有限公司

Drilling machine for workpiece milling

ActiveCN110253061BImprove groove accuracyMilling cuttersOther manufacturing equipments/toolsMilling cutterElectric machine

Owner:海盐瑞扬新材料股份有限公司

Method for integrating positioning, slotting, rechecking and self-checking of barreling equipment

ActiveCN114393723AImprove processing efficiencyReduce fully automated processingUsing electrical meansWorking accessoriesCrystal orientationMechanical wear

The invention discloses a method for realizing the integration of positioning, slotting, rechecking and self-checking of barreling equipment, which comprises the following steps: S1, firstly, carrying out a 100 single crystal slotting step: automatically finding a corner angle on a single crystal machine to measure a peak value, rapidly rotating to a certain angle to slowly find a signal peak value, and carrying out the step S2; in the same method, the crystal orientation is rotated by a certain angle, four maximum peak points are measured, and grooving is performed after the original point position 110 of the maximum peak current position is 0 degree and the original point position 100 is 45 degrees plus the original point correction amount. According to the invention, the grooving precision is improved, the crystal orientation precision deterioration caused by mechanical wear is reduced, the grooving error rate is reduced, the full-automatic processing of the barreling machine can be realized, the barreling processing efficiency is greatly improved, and the recheck of the zero offset of the mechanical position after grooving can be realized. By means of the method, the barreling crystal bar slotting positioning time is greatly shortened, the slotting orientation precision is improved, the slotting error rate is reduced, and finally the silicon bar barreling machining efficiency is greatly improved.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD

A slotting device for an operating table

ActiveCN109483626BAvoid damageGuaranteed neatnessDispersed particle filtrationMetal working apparatusHobbingWorking environment

The invention discloses an operation table top grooving device and relates to the technical field of operation tables. The device comprises a supporting shell. The two ends of a cutting rotary shaft are symmetrically and fixedly connected with cutting knives correspondingly. The two ends located in the middle of a supporting rod are rotationally connected with slotted bearings correspondingly. Theslotted bearings are fixedly connected with a slotted supporting frame. The end, away from the supporting rod, of the slotted supporting frame is rotationally connected with a slotted rotary shaft. The middle of the slotted rotary shaft is fixedly connected with a slotted hobbing cutter. The right sides of a cutting supporting frame and the slotted supporting frame are fixedly connected with transmission connecting rods correspondingly. The ends, located outside the supporting shell, of the transmission connecting rods are fixedly connected with shifting sleeve columns correspondingly. The tops of the shifting sleeve columns are sleeved with manual shifting rods correspondingly. The right side of the bottom end of the interior of the supporting shell is fixedly connected with a dust collecting mechanism. According to the operation table top grooving device, the purposes that groove edge damage in the grooving process is avoided, the regularity of groove edges is guaranteed, the grooving precision is improved, the dust raising phenomenon in the construction process is avoided, and the working environment of workers is improved are achieved.

Owner:滁州市朝友精密制造有限公司

A slotting device for building interior decoration and its operating method

ActiveCN111421671BAvoid human manual controlsImprove groove accuracyWorking accessoriesStone-like material working toolsArchitectural engineeringStructural engineering

The present invention relates to the technical field related to construction machinery, in particular to a slotting device for building interior decoration, which includes an organism, a slotting assembly, a grinding assembly, a driving assembly, a dust collection assembly and a height adjustment assembly. The two output ends of the driving assembly are respectively It is connected with the slotting assembly and the grinding assembly. The slotting assembly includes a vertical slotting disc, which is rotatably mounted on the bottom of the machine body. The grinding assembly includes a vertical grinding disc. There is a dust-absorbing head, which is fixedly installed on the bottom of the machine body. The height adjustment assembly includes a bottom plate that can be lifted vertically. There are several slotted discs and grinding discs. The top of the machine body is hingedly provided with a push handle. The equipment shown improves the accuracy of slotting, reduces labor intensity, and can adjust the number and size of slotting disks according to requirements, which improves the practicability of the equipment. The dust suction component can collect the dust generated during slotting and grinding. The construction environment is protected.

Owner:安徽省凤阳县名城建筑安装有限责任公司

A self-feeding woodworking machine

ActiveCN110253682BImprove groove accuracyImprove securityFeeding devicesGripping devicesAgricultural engineeringWoodworking machine

The invention relates to an automatic feeding woodworking machine, which comprises a sawing machine, a locking mechanism, a supporting vertical plate, a sliding seat, a rotating support, a supporting mechanism and a follower plate. A locking mechanism is connected to the left and right ends of the sawing machine , a follower plate is installed on the top of the locking mechanism at the left end of the sawing machine, and a supporting vertical plate is installed on the left end of the locking mechanism at the right end of the sawing machine. The matching mode is connected with the dovetail groove supporting the vertical plate. The sliding seat is an L-shaped structure. A rotating support is installed on the upper end surface of the middle part of the sliding seat through a rotating shaft, and the supporting mechanism is installed on the left end of the rotating support. The invention can solve the problem that the inclined positioning board existing when the inclined groove is set up in the existing wood cannot be adjusted intuitively, and the side of the board is a non-smooth plane, and when the wood slides along the positioning board, the slotting precision of the wood board will be low, and manual handling will be caused. Poor wood security and other issues.

Owner:珠海德驰科技有限公司

A slotting device for building decoration that can improve slotting precision

ActiveCN110253767BHigh precisionEasy to useWorking accessoriesStone-like material working toolsBuilding renovationIndustrial engineering

The invention discloses a slotting device for building decoration which can improve the slotting precision, which comprises a support frame, a dust collection box, a bearing, a handle, a connecting pipe, a connecting channel, a dust suction port and a hose. The inside of the support frame A sliding rod is provided, and a supporting plate is arranged on the sliding rod, and a dust collection box is arranged under the supporting plate, a lifting groove is opened on the inner side of the supporting plate, and the inside of the lifting groove is connected with the supporting rod, and the supporting rod The middle part of the connecting block is connected with the connecting block, the second sliding block is arranged under the first sliding block, and the second sliding block is connected with the bottom end inside the fixed shell through the sliding groove, and the handle bolt is connected to the fixed shell The outer side of the support plate is provided with knobs on the upper and lower sides of the front side. The slotting device for building decoration which can improve the slotting precision can improve the slotting precision of the wall surface, and the slotting machine can be installed and removed from the fixed casing according to the slotting requirements, which is convenient for users to use.

Owner:上海美凯龙装饰工程集团有限公司

Grooving equipment for bearing adapter sleeve

ActiveCN114473054AImprove unityGuaranteed unityMeasurement/indication equipmentsEngineeringVisual perception

The invention relates to the field of bearing adapter sleeves, in particular to slotting equipment for bearing adapter sleeves, which comprises a vibration track arranged on a workbench, a conversion device arranged beside the output end of the vibration track, a pushing track arranged between the conversion device and the output end of the vibration track, a pushing air cylinder arranged on the vibration track, and a driving device arranged on the pushing air cylinder, a positioning detection device used for positioning the bearing adapter sleeve and detecting a thread starting point of the bearing adapter sleeve is further arranged beside the conversion device, the positioning detection device comprises a visual detection mechanism, a first clamp and a second clamp, and a material moving mechanism is arranged beside the first clamp; according to the bearing adapter sleeve grooving device, the first clamp, the second clamp and the visual detection mechanism are matched to position and clamp the bearing adapter sleeves, all the bearing adapter sleeves can be located at the same position in a unified mode during grooving, and the grooving precision of the bearing adapter sleeves is improved.

Owner:宁波斯立福精密工业有限公司

Forming cutter for sputtering target material sealing groove and grooving method of forming cutter

PendingCN114570990AGood diameter consistencyAvoid measurement errorsMilling cuttersMilling equipment detailsStructural engineeringMachining process

The invention relates to a forming cutter of a sputtering target material sealing groove and a grooving method of the forming cutter, the forming cutter comprises a cylindrical cutter bar, the end face of the cutter bar is provided with protrusions, the protrusions are distributed on an annular area with the central axis of the cutter bar as the center line, and a chip groove is formed between every two adjacent protrusions; the forming cutter is used for the grooving process of the O-shaped sealing groove of the sputtering target material, the rotating speed and the feeding amount of the forming cutter are controlled, various errors generated in the machining process can be effectively avoided, and therefore the consistency of the diameter of the O-shaped sealing groove can be kept, and the efficiency of the grooving process is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

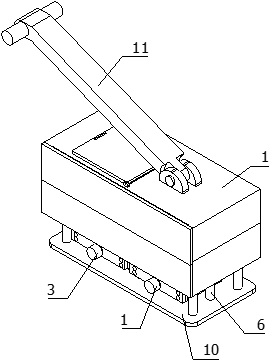

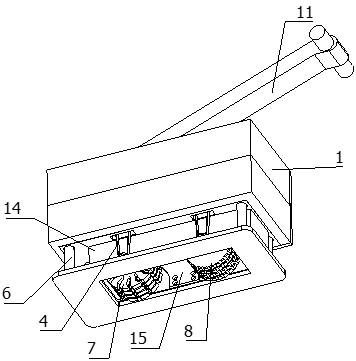

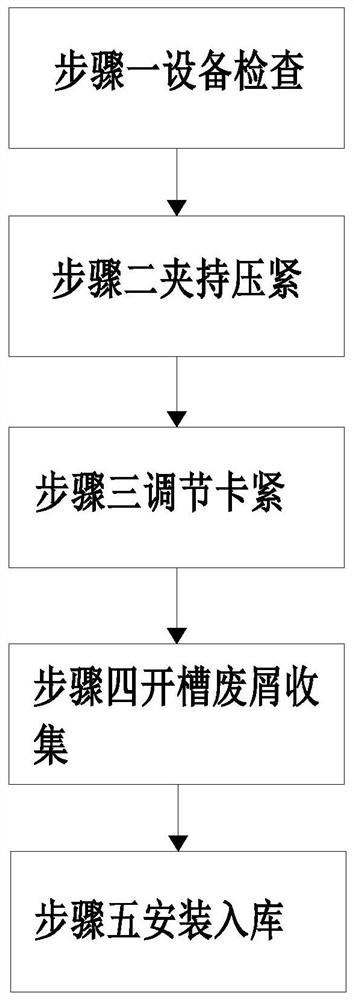

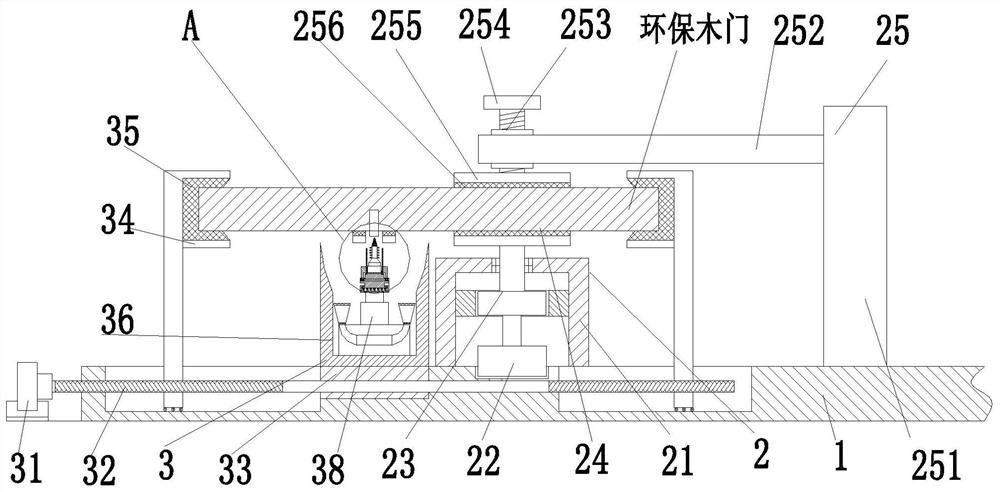

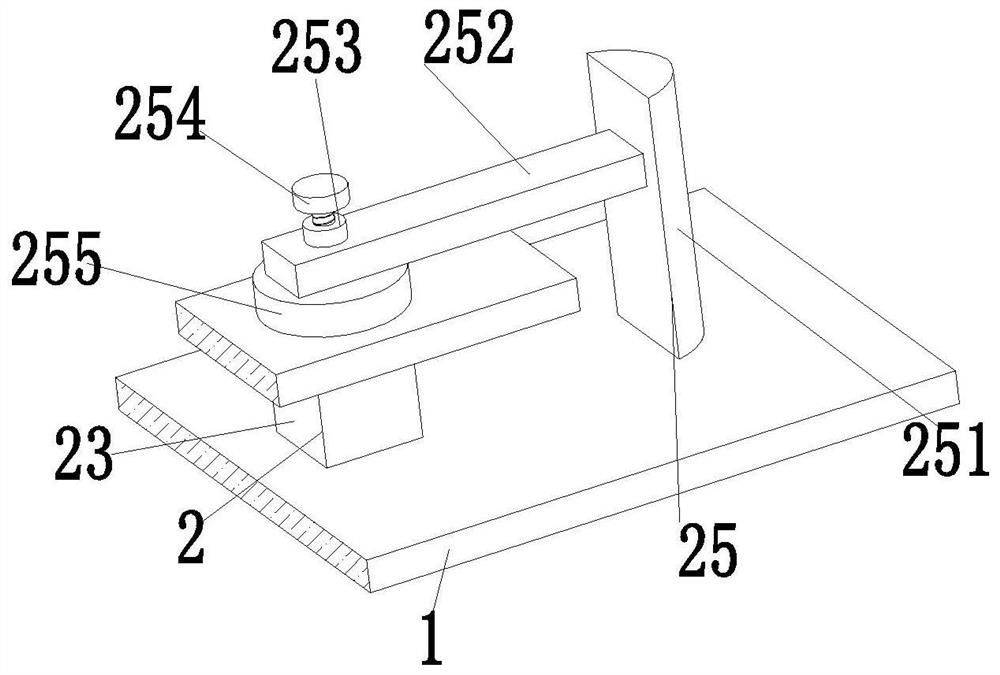

Installation method for light environment-friendly wooden door hardware

InactiveCN111730712AAffect cleanlinessAffect the working environmentWood mortising machinesBark-zones/chip/dust/waste removalWorking environmentStructural engineering

The invention relates to an installation method for light environment-friendly wooden door hardware. An auxiliary installation device is used in the method. The auxiliary installation device comprisesa bottom plate, a clamping and pressing device and a grooving device. The clamping and pressing device is installed at the middle portion of the upper end face of the bottom plate. A sliding groove is formed in the bottom plate. The grooving device is installed in the sliding groove in a sliding fit manner. The grooving device is located on the left side of the bottom plate. The installation method can solve the problems that an existing device cannot be used for stably clamping an environment-friendly wooden door, the grooving precision is poor, and the installation precision of the hardwareis affected; and the installation method can also solve the problems that when the existing device is used for conducting grooving on the environment-friendly wooden door, the wooden door cannot be clamped and fixed stably from four directions, waste wood bits generated in an open groove cannot be removed in time, the wood bits are likely to adhere to the interior of a wooden door groove, cleanliness of the wooden door is affected, meanwhile, the installation precision of the hardware of the environment-friendly wooden door is affected, environment pollution is likely to be caused by the waste wood bits, and the working environment of a workshop is affected.

Owner:郭娟

An automatic feeding and slotting device for tooth bars

ActiveCN110405582BImprove slotting efficiencyGood slotting efficiencyGrinding carriagesGrinding drivesStructural engineeringMoving parts

Owner:HAIYAN HUILIAN GENERAL FITTING

Grooving process of grooved rods for quartz long boats

ActiveCN110000943BEasy to fixReduce damage rateWorking accessoriesFine working devicesNumerical controlEngineering

The invention discloses a grooved bar slotting process for a long quartz boat, comprising the following steps: A. making a quartz round bar into a square bar; B. cutting both ends of the square bar to check the flatness, length and verticality of the square bar C. Embed several square rods on the upper surface of the graphite plate with equal number of parallel "V"-shaped grooves, pour the connection between the square rods and the "V"-shaped grooves with liquid wax, and cool the liquid wax to solidify the liquid wax. Complete the fixing of the square bar; D. Put the graphite plate on which the square bar is fixed with wax on the table of the CNC machine tool; E. Adjust the angle of the blade axis of the CNC machine tool and install the blade; F. Call the program of the CNC machine tool to open the square bar Grooving; G. After the grooving is completed, the bar is waxed and cleaned. The invention has the advantages of good positioning and fixing effect of the quartz square bar, high slotting precision, less damage during slotting, easy removal of the bar after slotting, simultaneous slotting of multiple square bars, and high slotting efficiency.

Owner:HUZHOU DONGKE ELECTRONICS QUARTZ

Operation table top grooving device

ActiveCN109483626AAvoid damageGuaranteed neatnessDispersed particle filtrationMetal working apparatusHobbingWorking environment

The invention discloses an operation table top grooving device and relates to the technical field of operation tables. The device comprises a supporting shell. The two ends of a cutting rotary shaft are symmetrically and fixedly connected with cutting knives correspondingly. The two ends located in the middle of a supporting rod are rotationally connected with slotted bearings correspondingly. Theslotted bearings are fixedly connected with a slotted supporting frame. The end, away from the supporting rod, of the slotted supporting frame is rotationally connected with a slotted rotary shaft. The middle of the slotted rotary shaft is fixedly connected with a slotted hobbing cutter. The right sides of a cutting supporting frame and the slotted supporting frame are fixedly connected with transmission connecting rods correspondingly. The ends, located outside the supporting shell, of the transmission connecting rods are fixedly connected with shifting sleeve columns correspondingly. The tops of the shifting sleeve columns are sleeved with manual shifting rods correspondingly. The right side of the bottom end of the interior of the supporting shell is fixedly connected with a dust collecting mechanism. According to the operation table top grooving device, the purposes that groove edge damage in the grooving process is avoided, the regularity of groove edges is guaranteed, the grooving precision is improved, the dust raising phenomenon in the construction process is avoided, and the working environment of workers is improved are achieved.

Owner:滁州市朝友精密制造有限公司

A ball valve ball arc incision processing equipment

ActiveCN110576323BImprove groove accuracyEasy to operatePositioning apparatusMetal-working holdersEngineeringPhysics

Owner:JIANG SU YAN DIAN FA MEN CO LTD

A plate slotting machine

ActiveCN110465863BImprove work efficiencyAvoid damageProfiling/shaping machinesWorking accessoriesTransmission beltWorking environment

The invention relates to a plate slotting machine, which comprises a bottom plate, a transmission belt, a guide block, a limit frame, a slotting mechanism, a limit device, a pushing mechanism and a grinding mechanism. The middle part of the bottom plate is provided with an H-shaped square groove, and the transmission belt is installed In the H-shaped square groove opened in the middle of the bottom plate, the guide blocks are symmetrically distributed on the front and rear sides of the H-shaped square groove of the bottom plate. The device is installed on the top left front side of the bottom plate, the slotting mechanism is installed on the top left rear side of the bottom plate, a pushing mechanism is installed on the right top and left bottom of the transmission belt, and the grinding mechanism is located on the left side of the slotting mechanism. On the side, the grinding mechanism is installed on the top left rear side of the bottom plate. The invention can solve the problems of low production efficiency, large dust in the working environment that damages workers' bodies, great safety hazards, poor slotting precision and poor slotting effect during manual slotting, and the like.

Owner:江苏融至新材料有限公司

Portable dust-free ceramic tile slotting device

InactiveCN111805769ARealize modular processingAvoid flying intoWorking accessoriesStone-like material working toolsStructural engineeringMachining

The invention discloses a portable dust-free ceramic tile slotting device. The portable dust-free ceramic tile slotting device comprises a rack, a slotting device, a movable platform and a dust-proofassembly, wherein the slotting device is detachably connected to the rack; the movable platform is slidably connected to the rack, and the slotting device is positioned in the sliding extension direction of the movable platform; and the dust-proof assembly is detachably connected to the rack and connected to the slotting device, and the dust-proof assembly sprays liquid in the cutting direction ofthe slotting device. The dust-proof assembly, the slotting device and the movable platform are all detachably connected to the rack, modular machining of all functional components is achieved, disassembly and assembly are convenient, the portable dust-free ceramic tile slotting device can be applied to a construction site, and operation is convenient. The movable platform is slidably connected tothe rack so as to place and push ceramic tiles to be close to and away from the slotting device, the slotting precision is high, and the safety is high. The dust-proof assembly is used for flushing dust generated in the ceramic tile slotting process, the dust is prevented from flying into air, and environmental protection, sanitation and less pollution are achieved.

Owner:百合盛华建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com