Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Improve slotting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

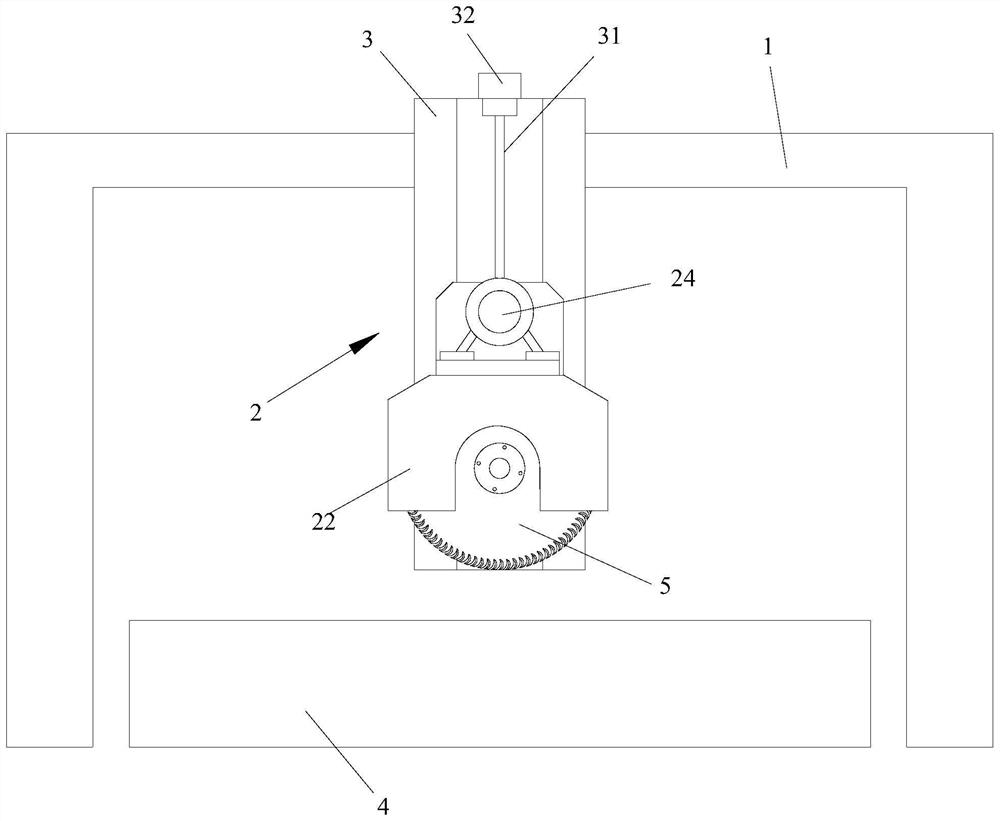

Wood board grooving device

ActiveCN103921322ASimple structureQuick slotting operationWood mortising machinesWood slotting machinesDrive motorWood plank

The invention relates to the technical field of wood board processing devices, in particular to a wood board grooving device which is simple in structure, capable of realizing quick grooving operation and good in grooving effect. The wood board grooving device comprises a rack, a supporting frame is arranged on one side of the rack, a positioning device is arranged on the supporting frame, linear sliding rails are arranged on the rack on one side of the supporting frame, a slidable supporting seat is arranged at the upper ends of the linear sliding rails, a supporting platform is arranged on the supporting seat through a lifting cylinder, a driving motor is arranged on the supporting platform, and a cutting wheel is arranged on the driving motor.

Owner:广东迈丹尼家居定制有限公司

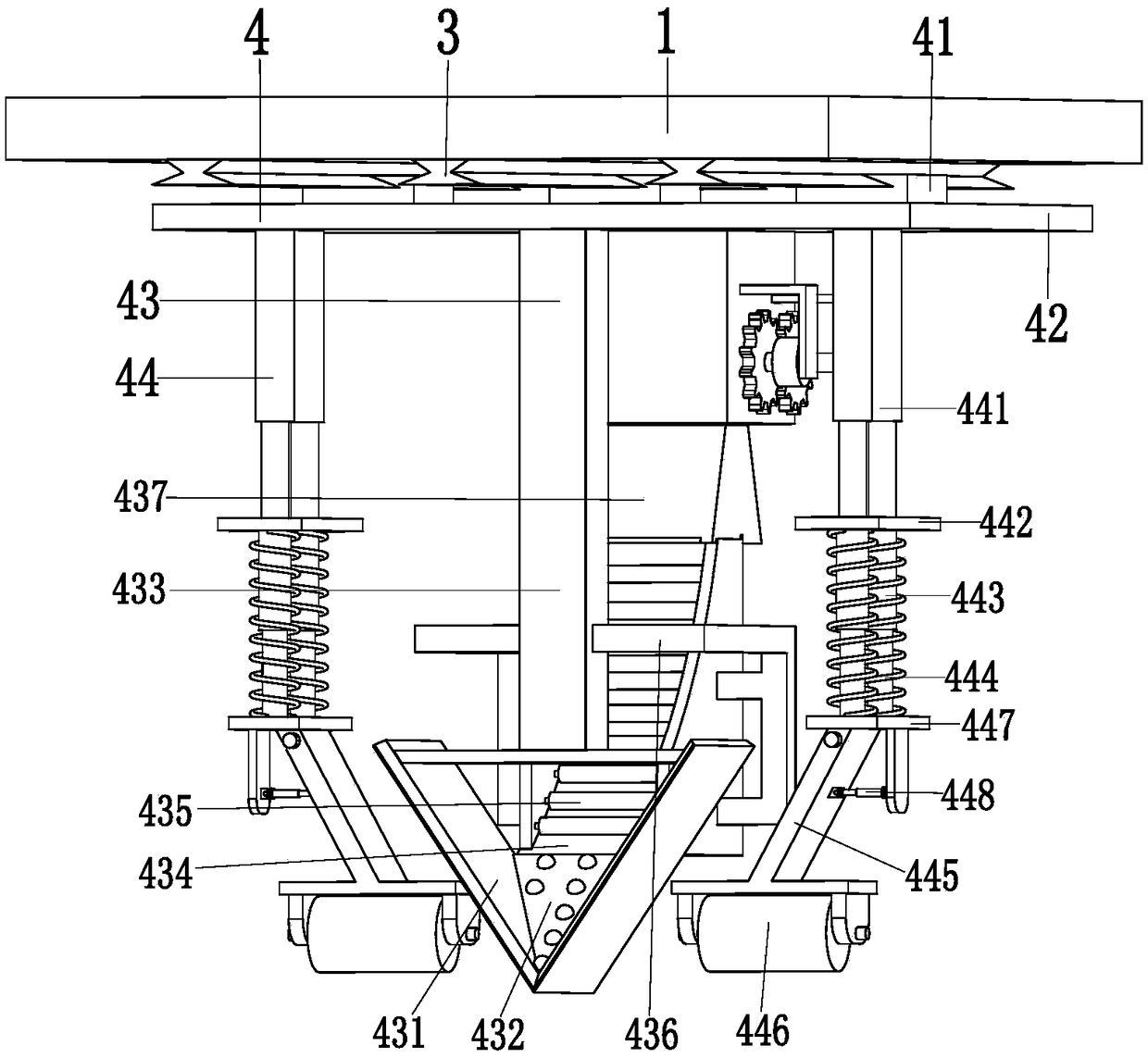

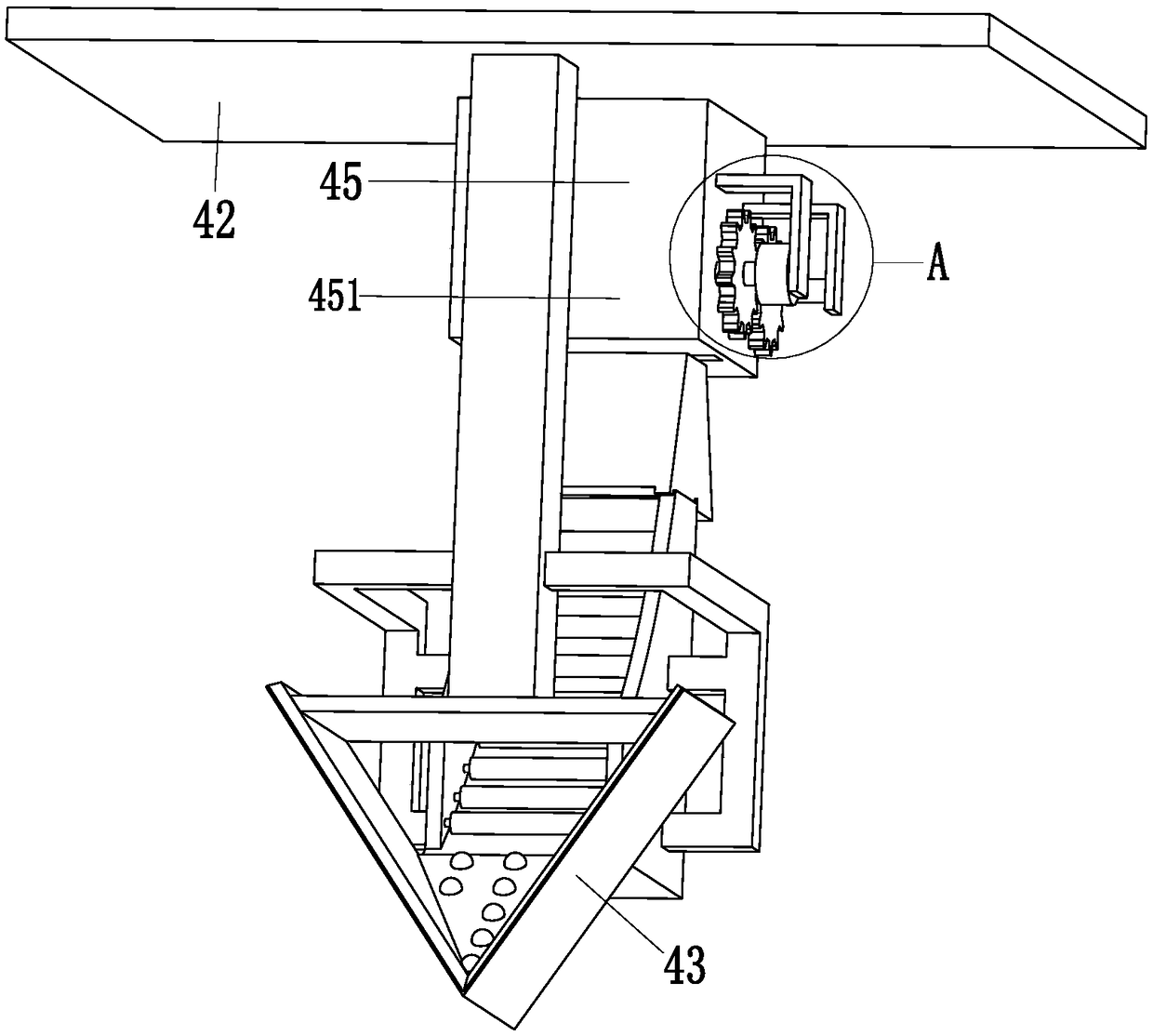

Cutting machine for PVC plastic floor

ActiveCN108656189AImprove slotting effectImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

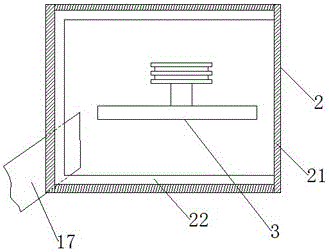

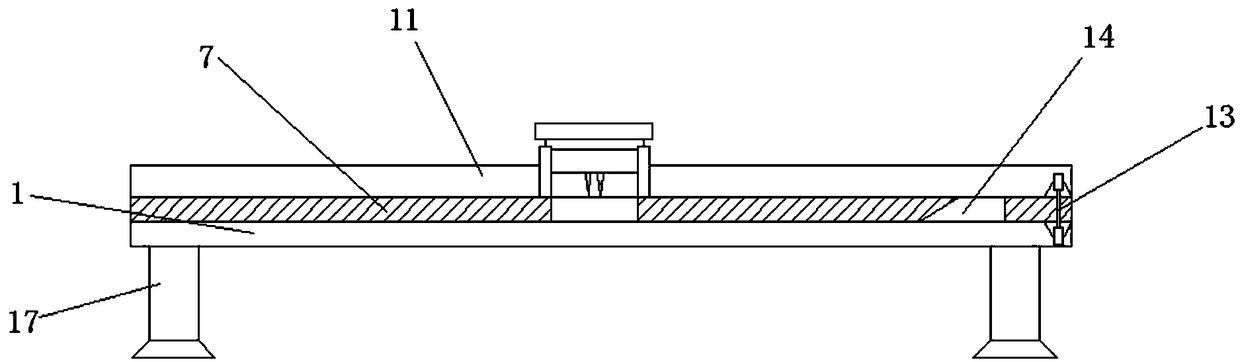

The invention relates to a cutting machine for a PVC plastic floor. The cutting machine comprises a supporting top plate, movable mechanisms, a movable electric sliding rail, a groove cutting device and a limiting device; the movable mechanisms are symmetrically installed on the outer side of the bottom of the supporting top plate; the movable electric sliding rail is installed on the lower end surface of the middle part of the supporting top plate; the groove cutting device is installed at the left end of the movable electric sliding rail; and the limiting device is installed at the right endof the movable electric sliding rail. The problems that the working efficiency is low when the plastic floor is slotted, the slotting effect of the plastic floor through manual work is poor, the plastic floor is required to be cut through the manual work before slotting, the cutting effect of the plastic floor is poor, the two sides of the plastic floor can not be rolled when the plastic floor isslotted, strip-shaped plastic through the slotting can not be automatically recovered, and the slotting position can not be limited when the plastic floor is slotted can be solved.

Owner:浙江奕科新材料股份有限公司

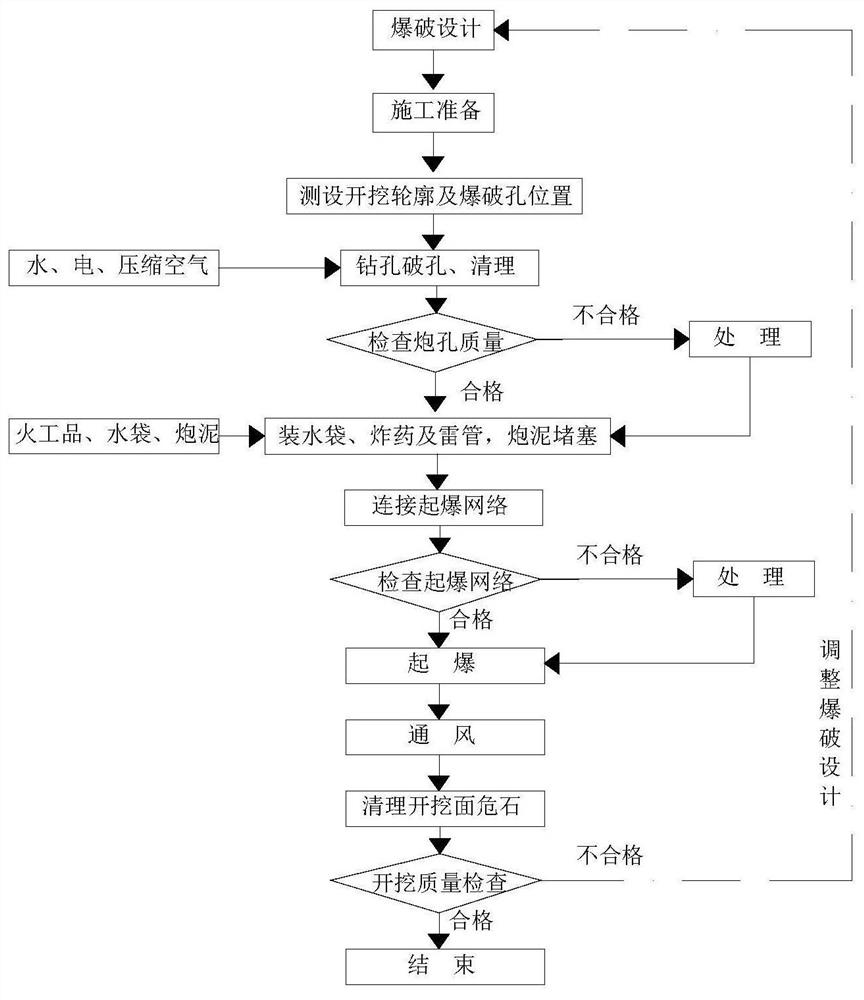

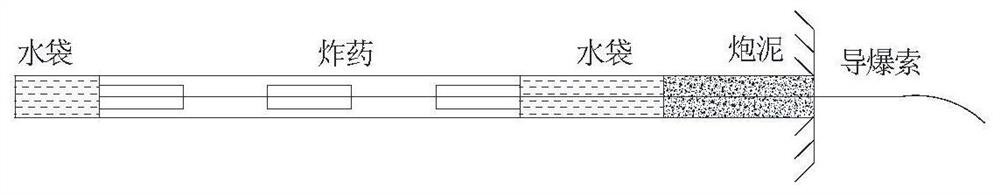

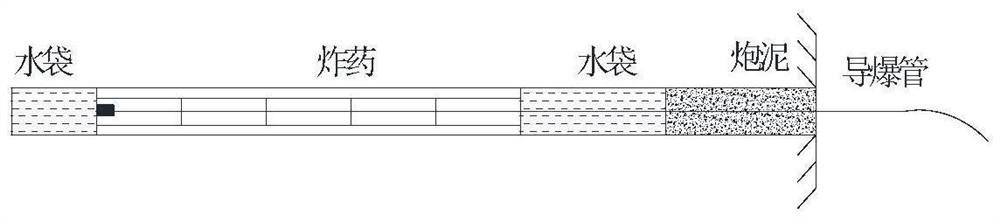

Sandy slate tunnel construction method

InactiveCN112066830AImprove slotting effectImprove working precisionBlastingDetonatorSocial benefits

The invention discloses a sandy slate tunnel construction method. The sandy slate tunnel construction method comprises the following steps: (1) measuring is performed; (2) leveling of a field is carried out; (3) hole distribution is performed; (4) hole drilling is performed; (5) charging is performed; (6) blast holes are blocked; (7) detonating network connection is performed: the detonator section and detonating network connection mode is executed according to a blasting design scheme; (8) safety alert is performed; (9) checking is performed after explosion; (10) blind shot treatment is carried out; (11) secondary crushing is performed; (12) water pressure smooth blasting control is performed; (13) dangerous rocks on the excavation surface are cleaned; and (14) the excavation quality is inspected, and if the excavation quality is qualified, the smooth blasting process is ended. By the method, the problems that the operation space is limited, and a good slotting effect is obtained through a small number of shot holes and the minimum explosive unit consumption can be solved, the purposes that the method is easy and convenient to operate, wide in application range and good in operation precision effect are finally achieved, the smooth blasting quality and the construction progress are effectively improved, and the construction cost is reduced. According to the method, the smoothblasting excavation technology of a sandy slate tunnel is perfected, the construction period is shortened, the construction cost is reduced, a good smooth blasting effect is achieved, and obvious economic benefits and social benefits are achieved.

Owner:GUANGDONG CONSTR CO LTD OF CHINA RAILWAY NO 3 ENG GRP CO LTD +1

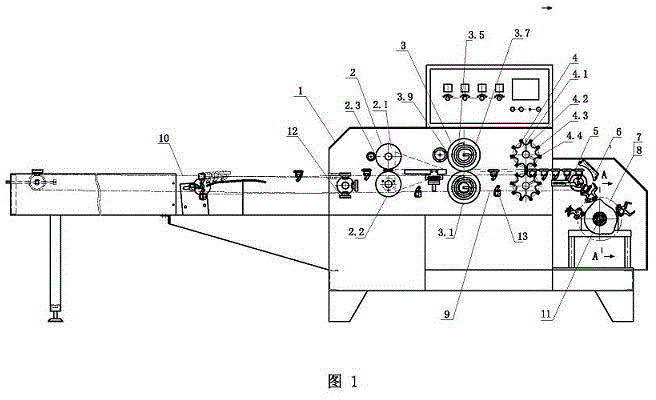

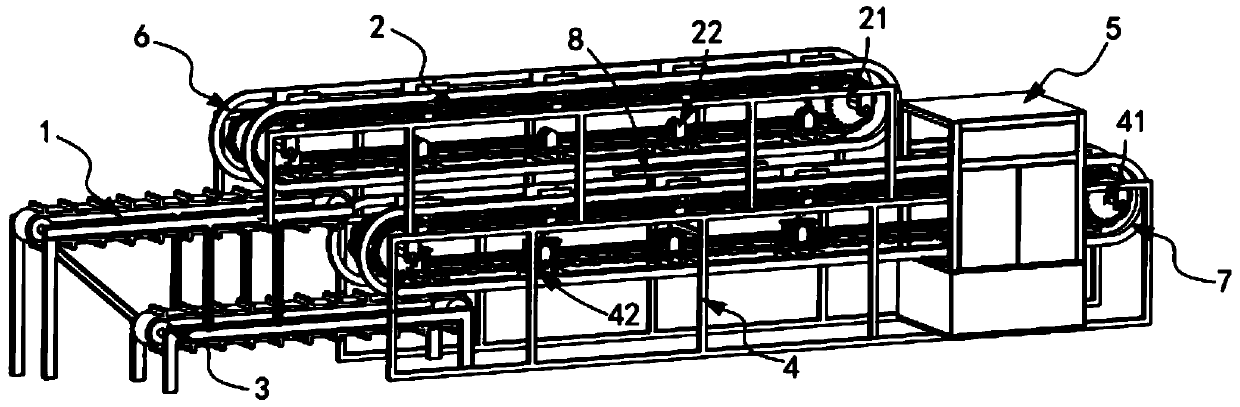

Twisting packing machine for special-shaped candy sticks

ActiveCN104627408AImprove sealingQuick compensationWrappingWrapper twisting/gatheringEngineeringFuselage

The invention discloses a twisting packing machine for special-shaped candy sticks. The twisting packing machine comprises a machine body, a conveying chain, a clamping chain, an upper paper feeding wheel, a lower paper feeding wheel and a transverse sealing and cutting device, and the upper paper feeding wheel and the lower paper feeding wheel are arranged in an oppositely rolling mode. A clamping arm disc and a twisting arm disc are coaxially arranged on the machine body, a plurality of pairs of inner clamping arms and outer clamping arms are evenly arranged on the disc face of the clamping arm disc, electric heating elements are arranged on the inner clamping arms, a plurality of pairs of twisting arms are arranged on the disc face of the twisting arm disc, the number of pairs of the twisting arms on the twisting arm disc is equal to the number of pairs of the inner clamping arms and outer clamping arms on the clamping arm disc, and the twisting arms on the twisting arm disc correspond to the inner clamping arms and outer clamping arms of the clamping arm disc one to one. According to the twisting packing machine for the special-shaped candy sticks, twisting packing can be carried out on candies in the continuous motion process, therefore, the defects due to the fact that only one pair of twisting arms is applied to be matched with an intermittent mechanism on an existing machine are overcome, and the advantages of being reasonable in structure, small in mechanical vibration, high in production speed and high in efficiency are achieved.

Owner:JIANGSU FLYING DRAGON FOOD MACHINERY

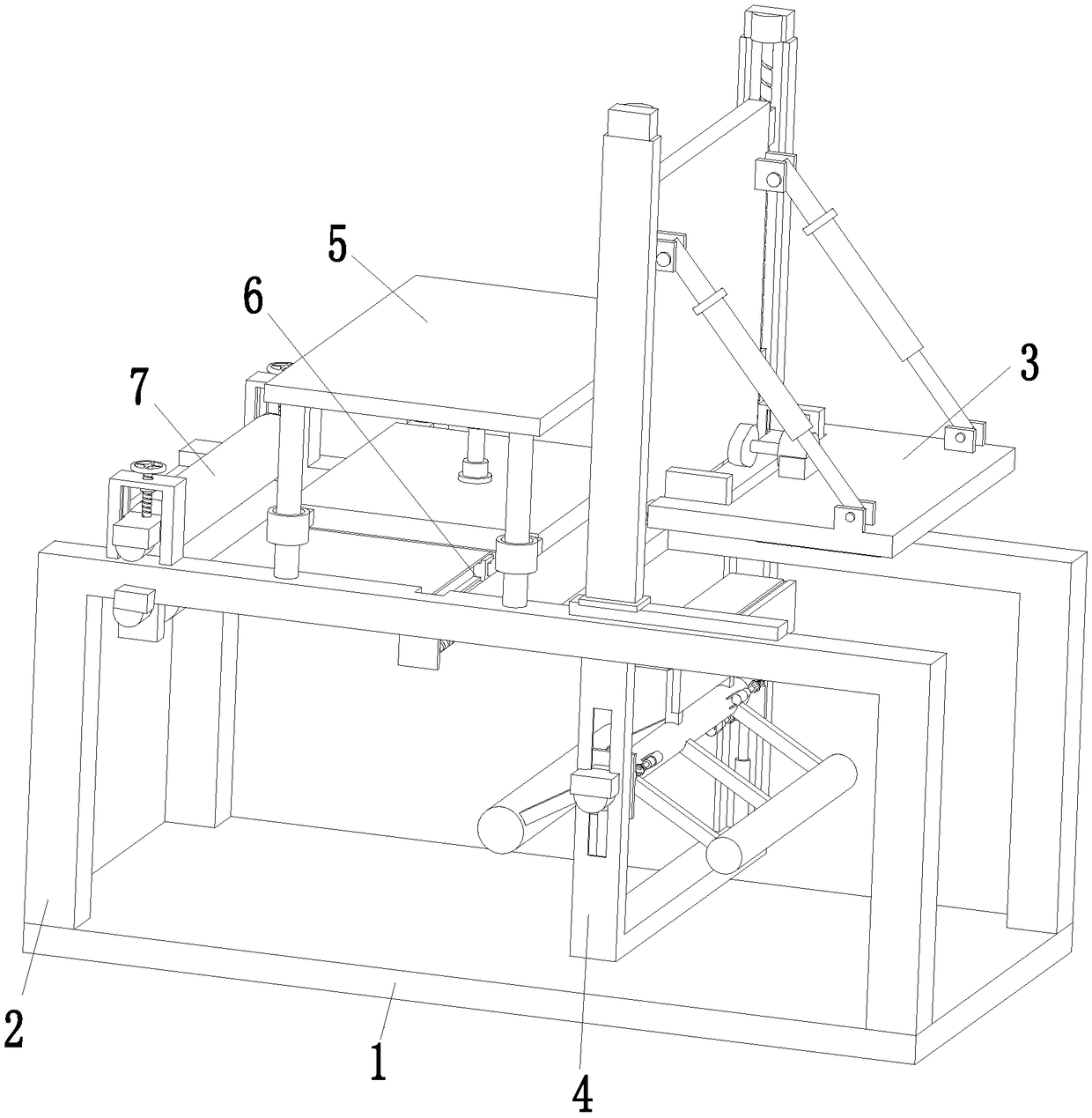

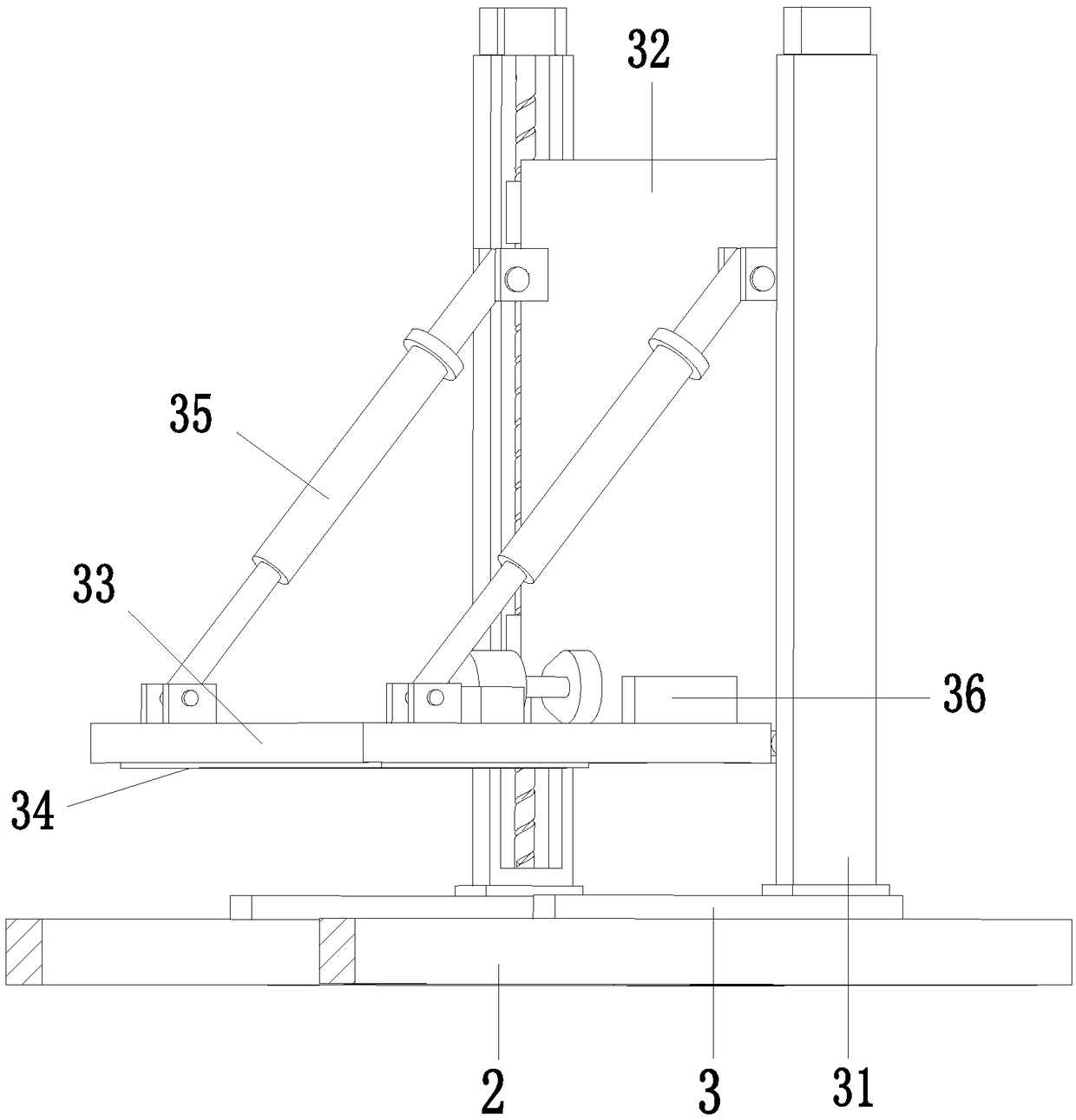

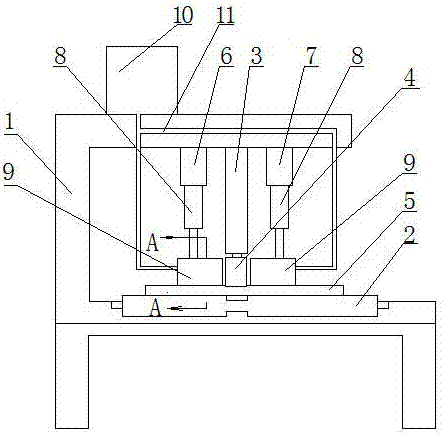

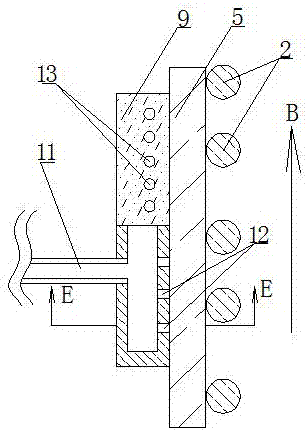

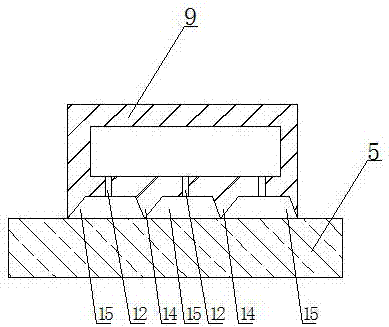

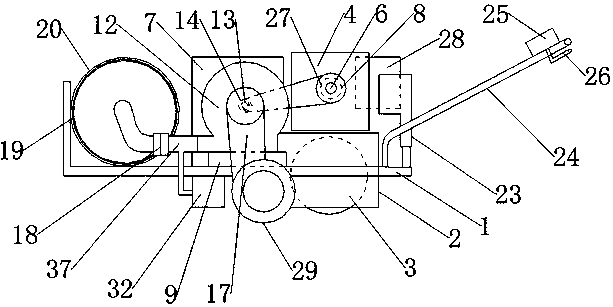

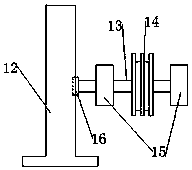

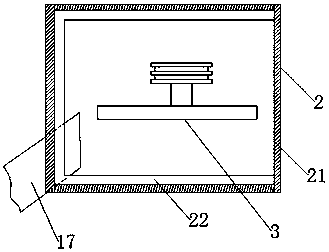

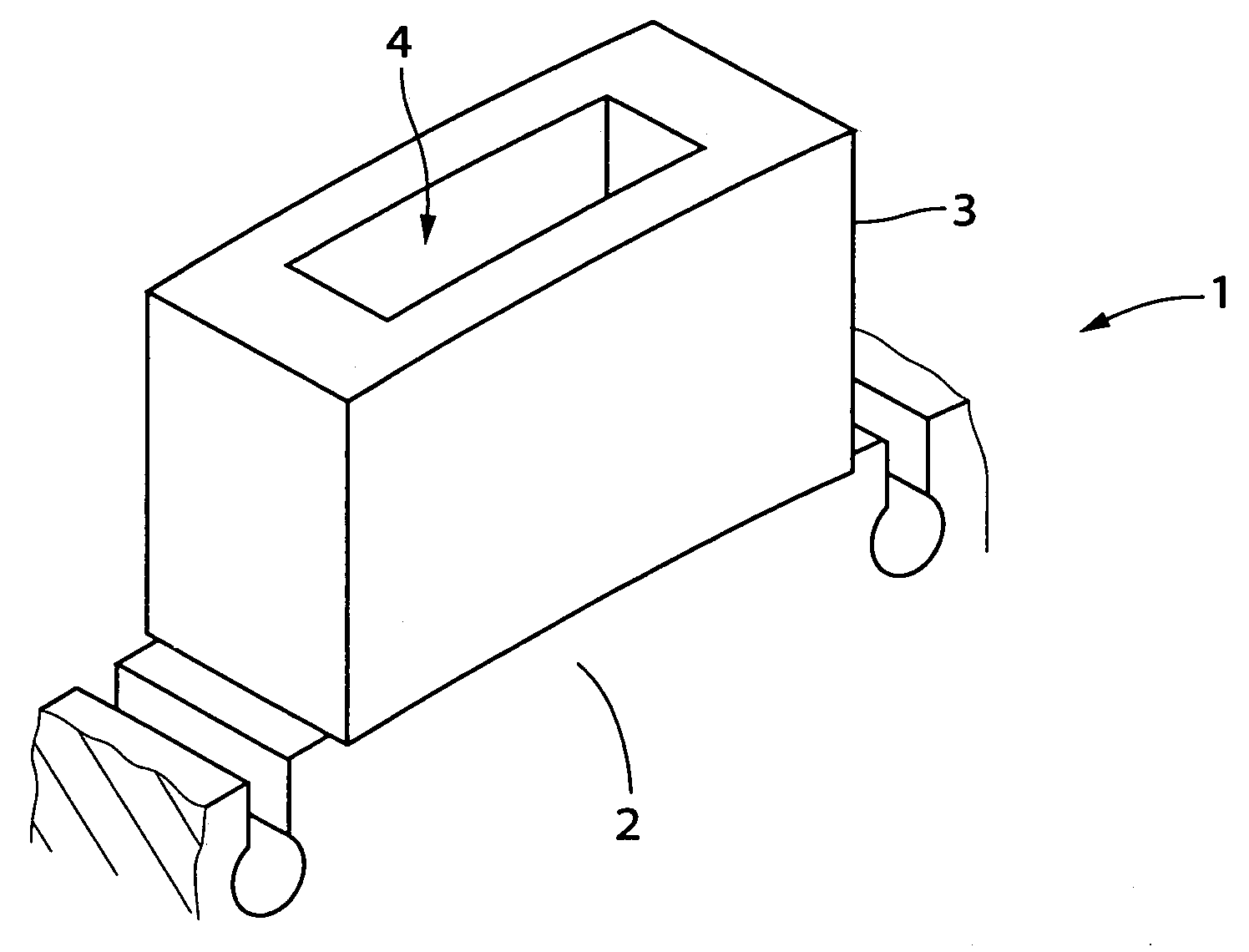

Intelligent bending machine for aluminum-plastic panel

The invention relates to an intelligent bending machine for an aluminum-plastic panel. The intelligent bending machine comprises a bottom plate, two U-shaped supporting frames, a bending device, a diedevice, a pressing device, a slotting device and a feeding device. The two U-shaped supporting frames are installed at the upper end of the bottom plate, the bending device is installed at the rightupper ends of the U-shaped supporting frames, the die device is installed at the right lower ends of the U-shaped supporting frames, the slotting device is installed in the middles of the U-shaped supporting frames, the pressing device is installed at the upper end of the slotting device, and the feeding device is installed at the left ends of the U-shaped supporting frames. By means of the intelligent bending machine, the problems that at present, aluminum-plastic panels are conveyed manually in the bending process of the aluminum-plastic panels, the manual conveying efficiency is low, the slotting depth can not be controlled in manual slotting, the manual bending effect is poor, the bending precision is low, the aluminum-plastic panels can not be accurately bent to have needed angles, arcs are not likely to be formed when arc bending is carried out on the aluminum-plastic panels, dies are not convenient to change and the like are solved.

Owner:安徽坤源铝业有限公司

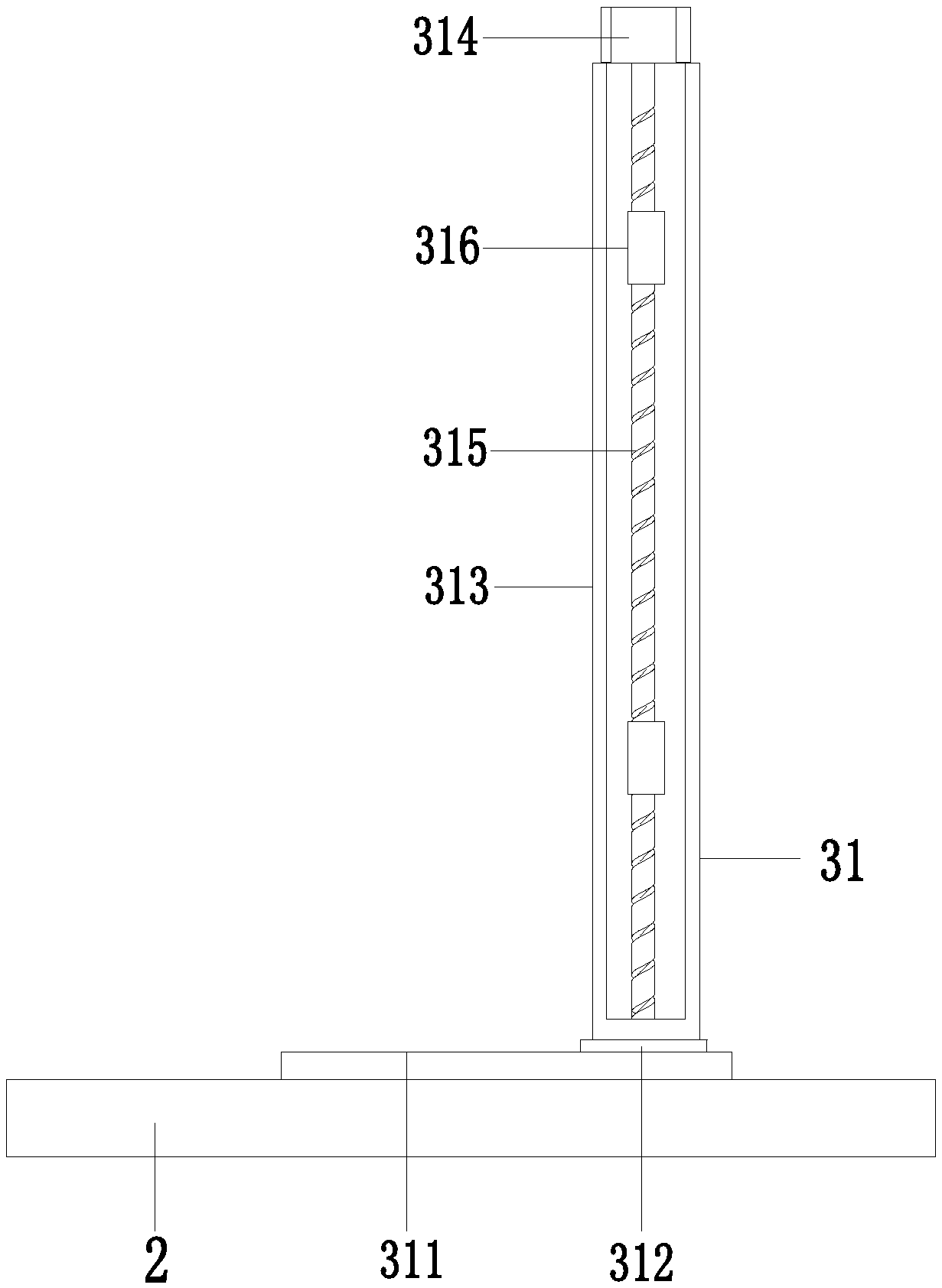

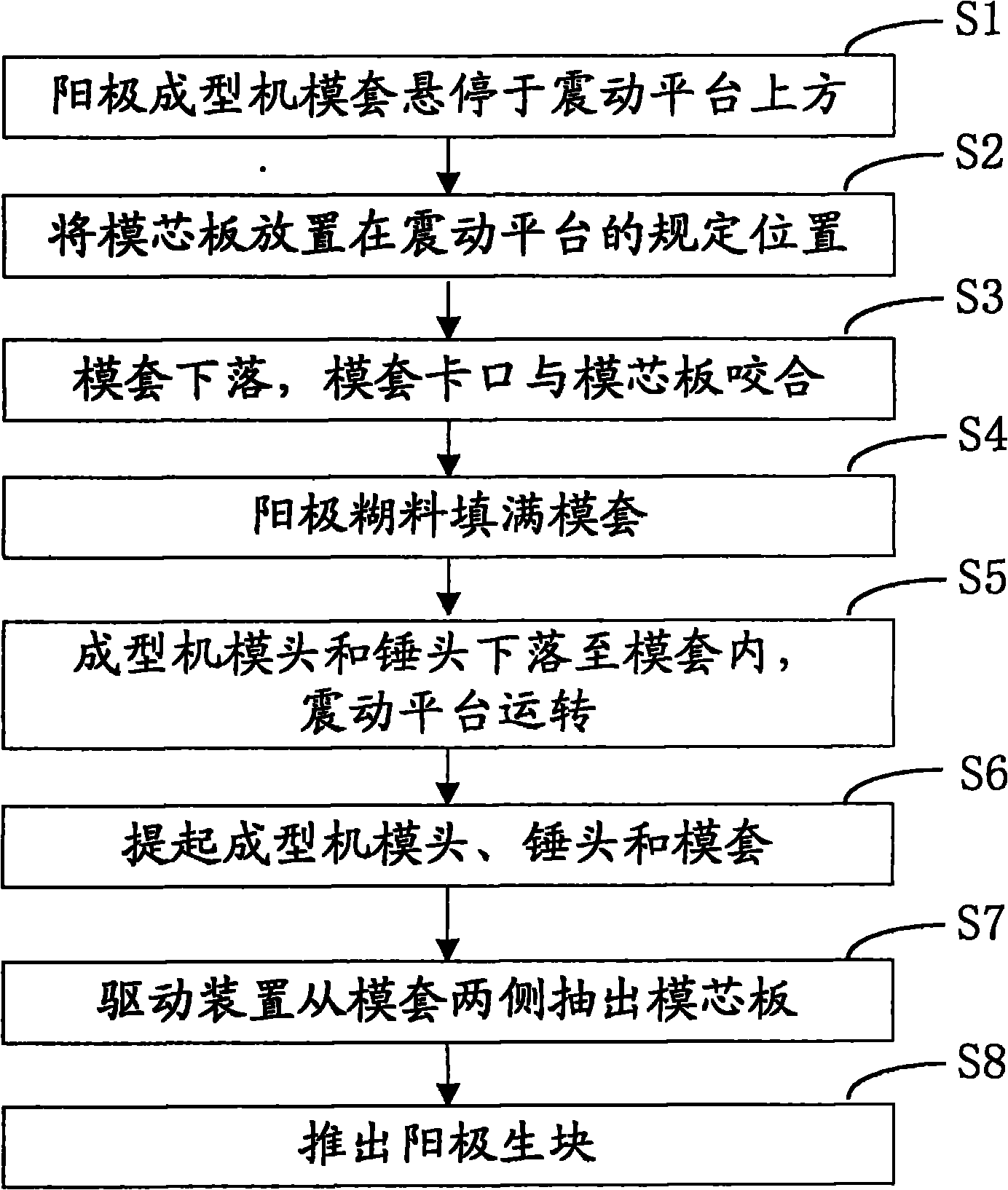

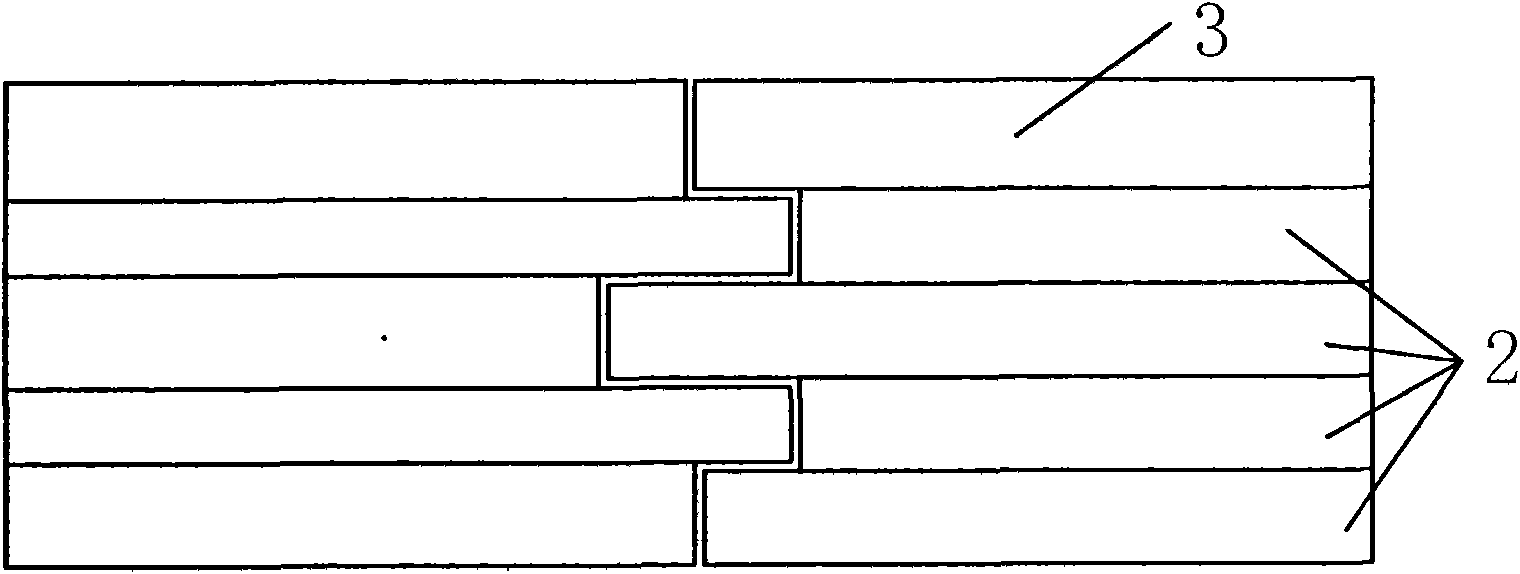

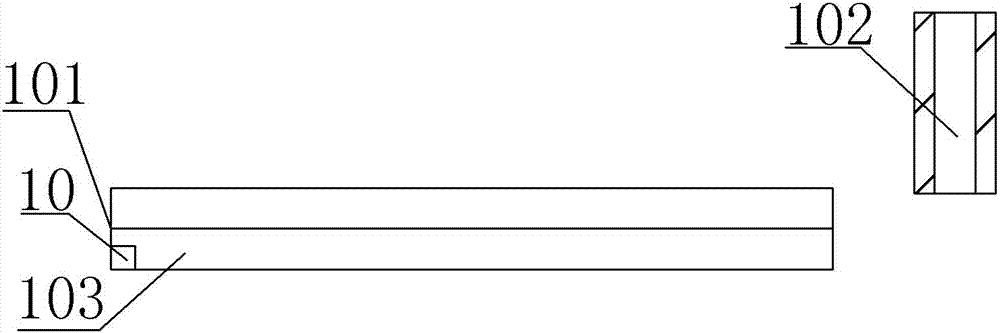

Method for slotting anode

InactiveCN101927526ALeave quicklyReduce overvoltageCeramic shaping apparatusAluminum industryMaterials science

The invention discloses a method for slotting an anode in the electrolytic aluminum industry. The technical scheme is that: the method comprises the following steps of: placing a die core plate consisting of a left part and a right part in an anode molding die sleeve; and after the anode is made into a block and molded, pulling the die core plate out from the two sides of the die sleeve by using a drive device. The slotting method has good effect, namely, irregularly-shaped slots of which middle parts are lower than tops at two ends can be reserved, and compared with straight slots, are more favorable for driving CO2 foams to quickly leave the bottom of the anode; and the slotting method also has the advantages of simple process, convenient use and raw material saving.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

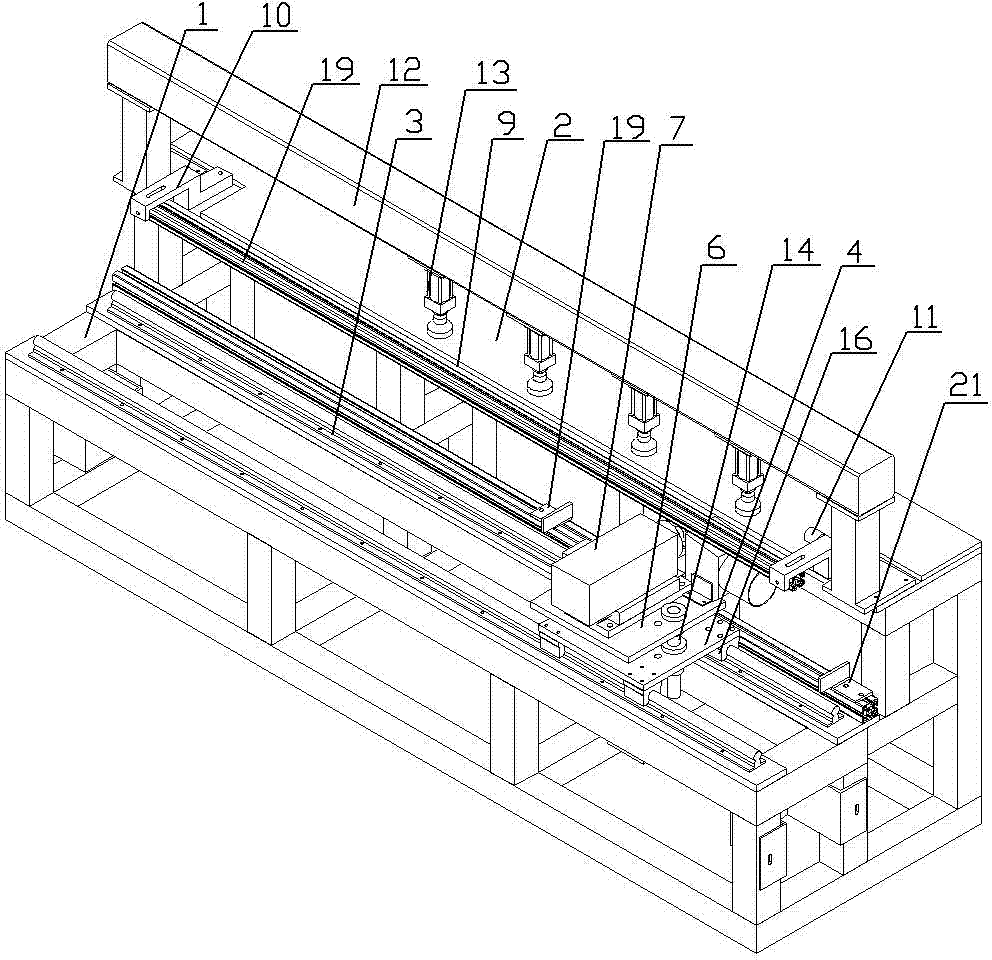

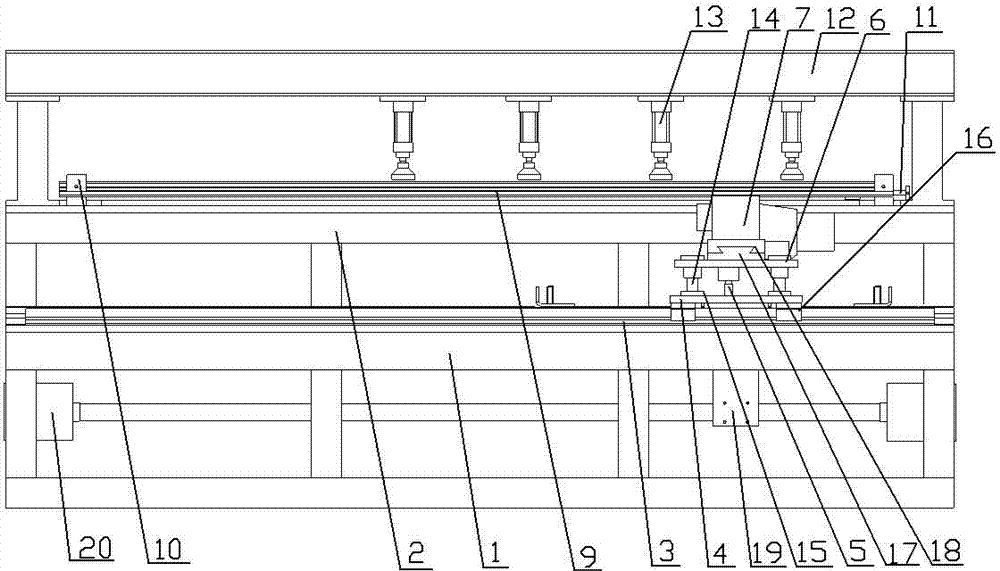

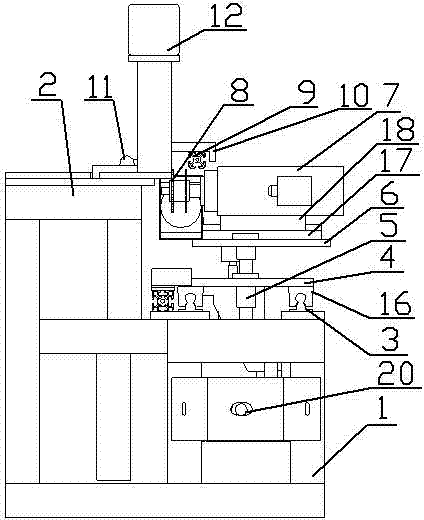

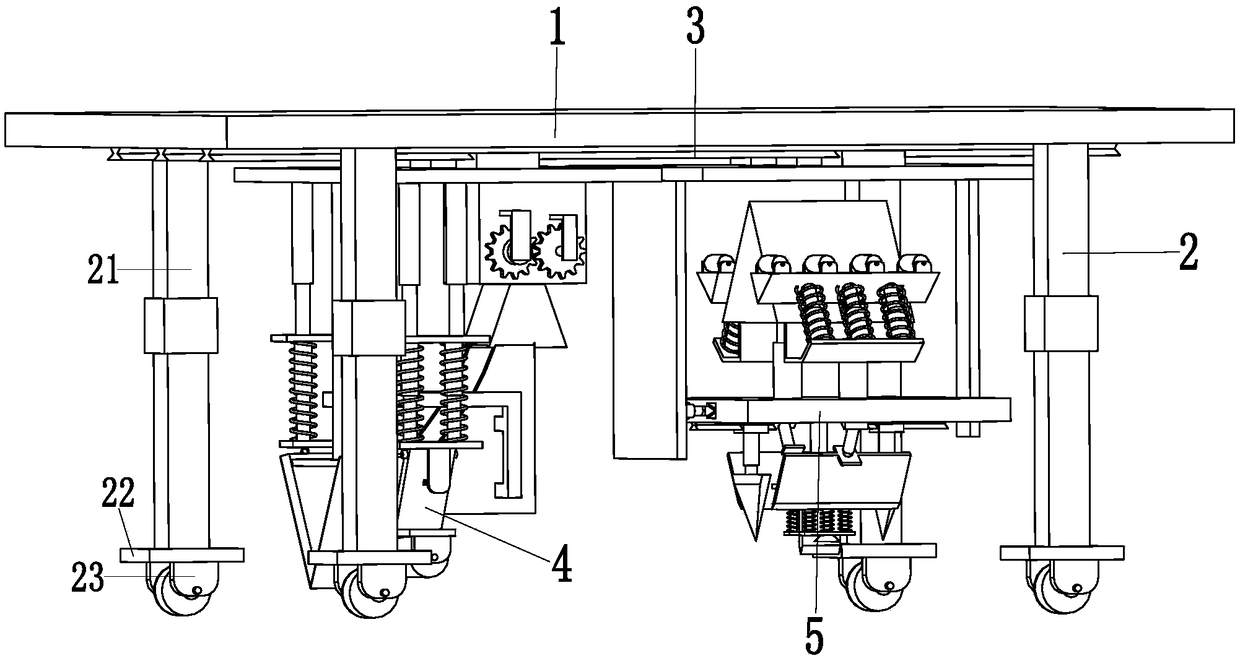

Wood board slotting equipment

InactiveCN107053383ASimple wayWon't distortWood mortising machinesWood slotting machinesEngineeringWood plank

The invention relates to the technical field of wood plate machining, in particular to wood board slotting equipment. The wood board slotting equipment comprises a rack, a locating device, a slotting device and a level device, wherein the locating device is mounted on one side of the rack; the locating device is provided with controllable cylinders and clamps; the controllable cylinders are arranged on the rack; the clamps are arranged at the left and right short ends of the rack; the slotting device is arranged on the other side of the rack; the slotting device comprises a supporting seat and a cutting wheel motor; the cutting wheel motor is placed above the supporting seat; a sliding rail is arranged below a supporting table; and a pressure sensor is arranged on the level device. The wood board slotting equipment can quickly locate a wood board and enable the wood board to be horizontally placed and also can guarantee stable slotting for the wood board.

Owner:CHONGQING YIJU DOOR

Grooving device for mounting building monitoring equipment

ActiveCN108214936AAvoid influenceExtended service lifeWorking accessoriesStone-like material working toolsEngineeringWater spray

The invention relates to a grooving device, in particular to a grooving device for mounting building monitoring equipment. The time and labor can be saved by the grooving device for mounting the building monitoring equipment, grooves can be neatly formed by the grooving device, and dust which appears during grooving can be cleaned up by the grooving device without influence on surrounding environments. The grooving device for mounting the building monitoring equipment comprises a vertical plate and the like. An opening is formed in the middle of the vertical plate, a frame is mounted in the middle of the right side surface of the vertical plate, a movable device is arranged in the frame, a cutting machine is connected onto the movable device, and a saw blade is connected onto the cutting machine and is positioned in the opening. The grooving device has the advantages that the appeared dust can be sucked away and cleaned up by a dust removal device without the influence on the surrounding environments; water can be sprayed on the saw blade by a water spraying device, accordingly, the saw blade can be cooled and is long in service life, the time and the labor can be saved by the grooving device, the grooves can be neatly formed by the grooving device, and the dust which appears during grooving can be cleaned up by the grooving device without the influence on the surrounding environments.

Owner:青岛明珠建设监理有限公司

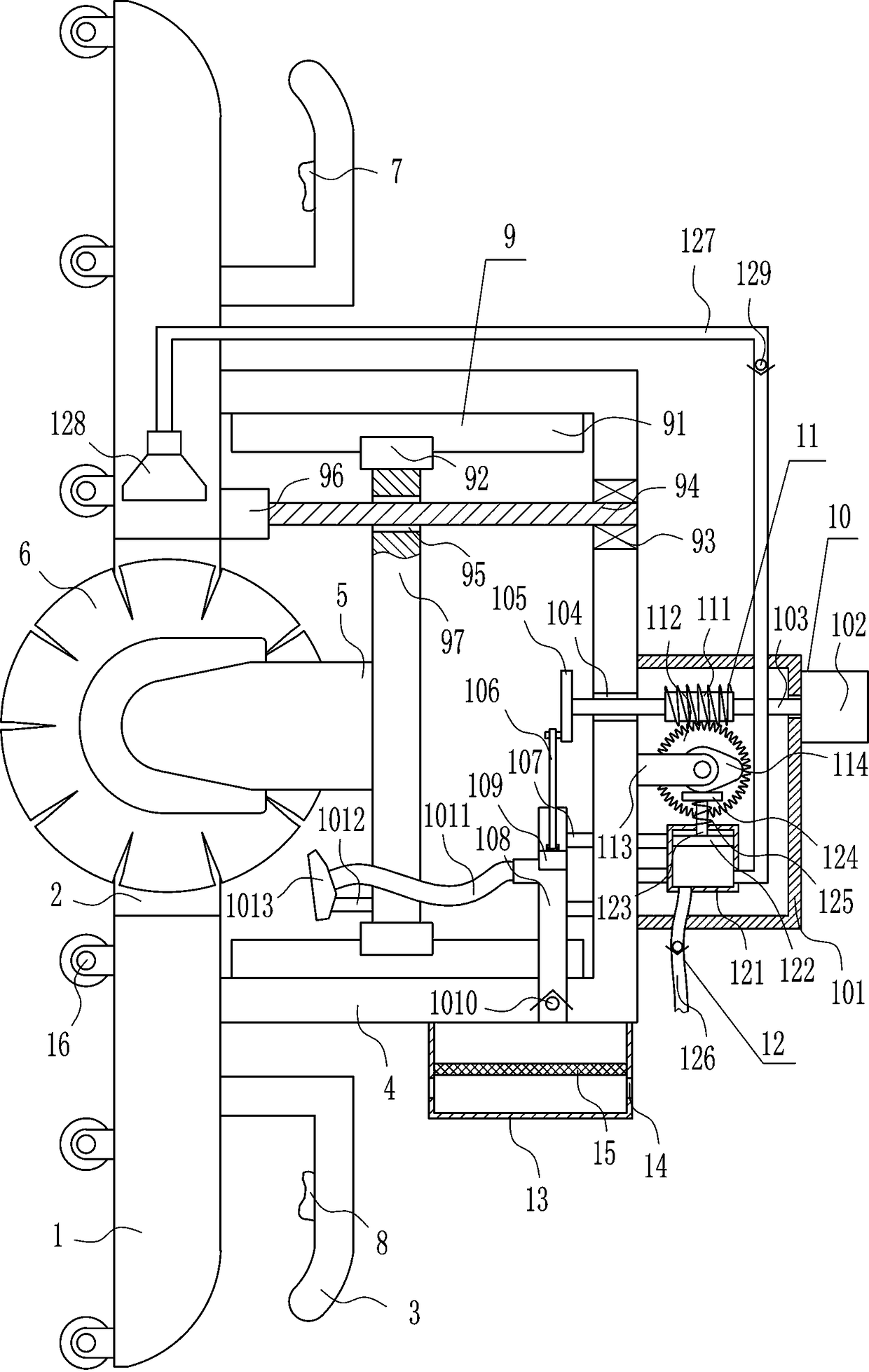

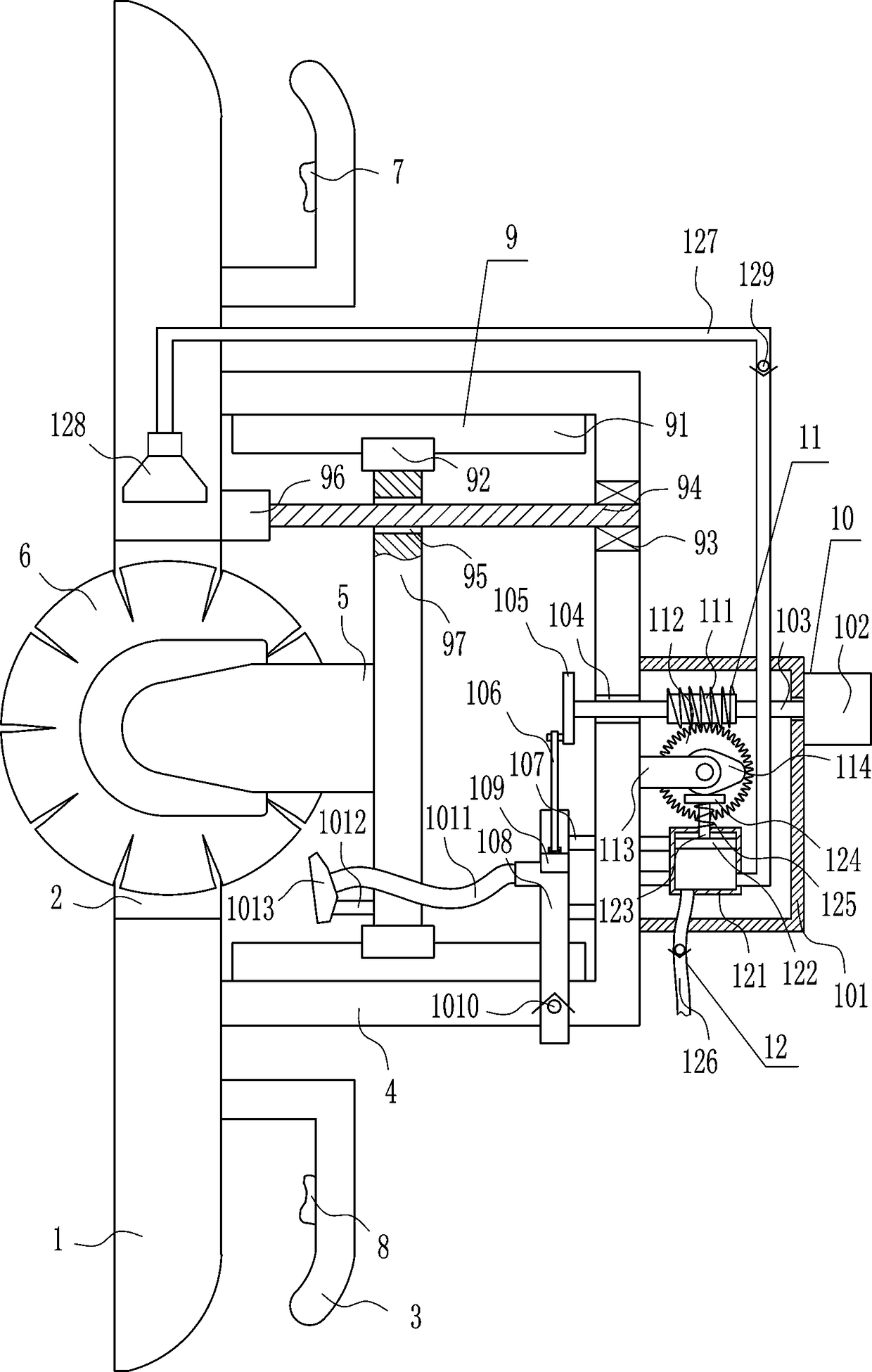

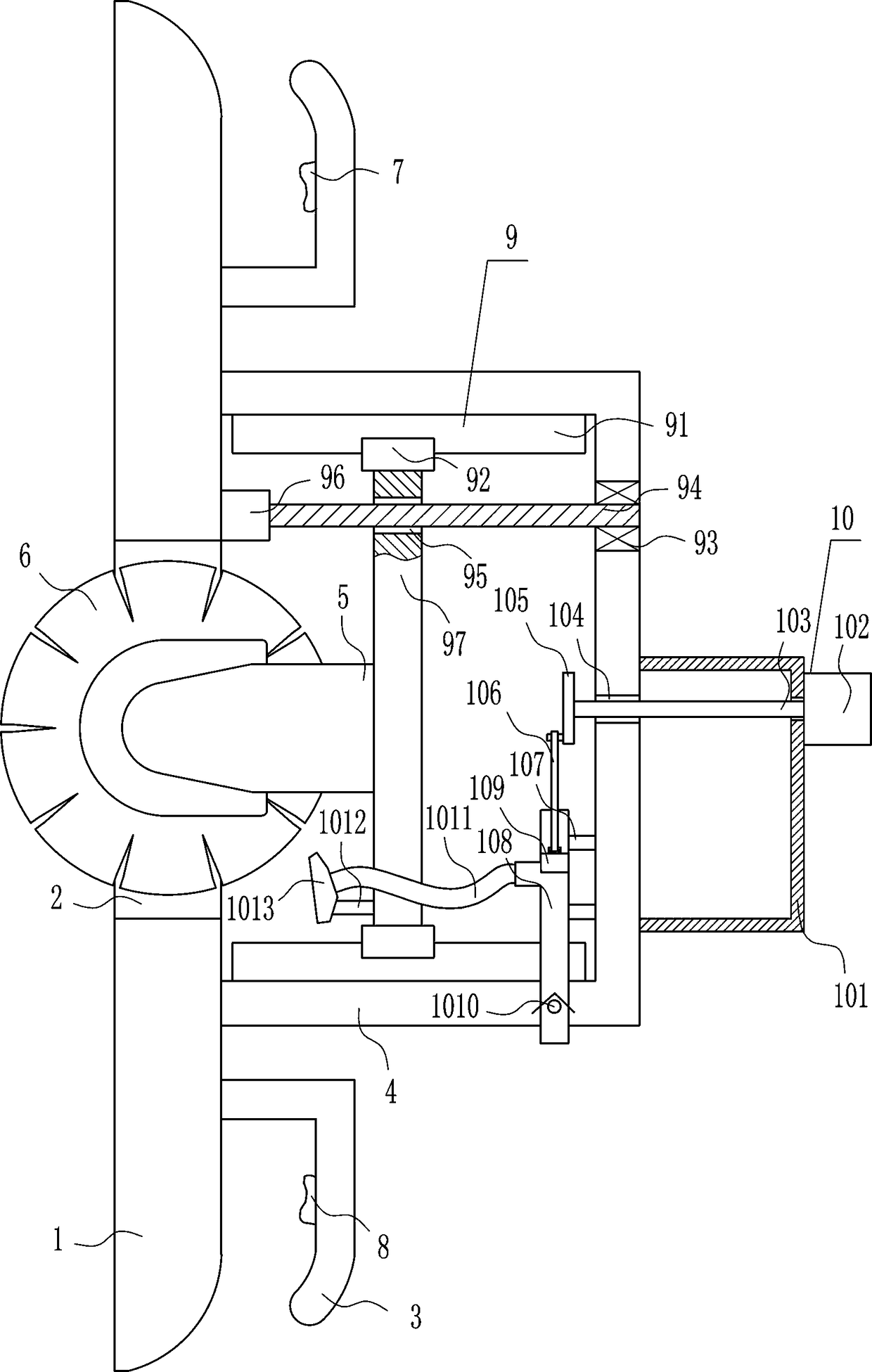

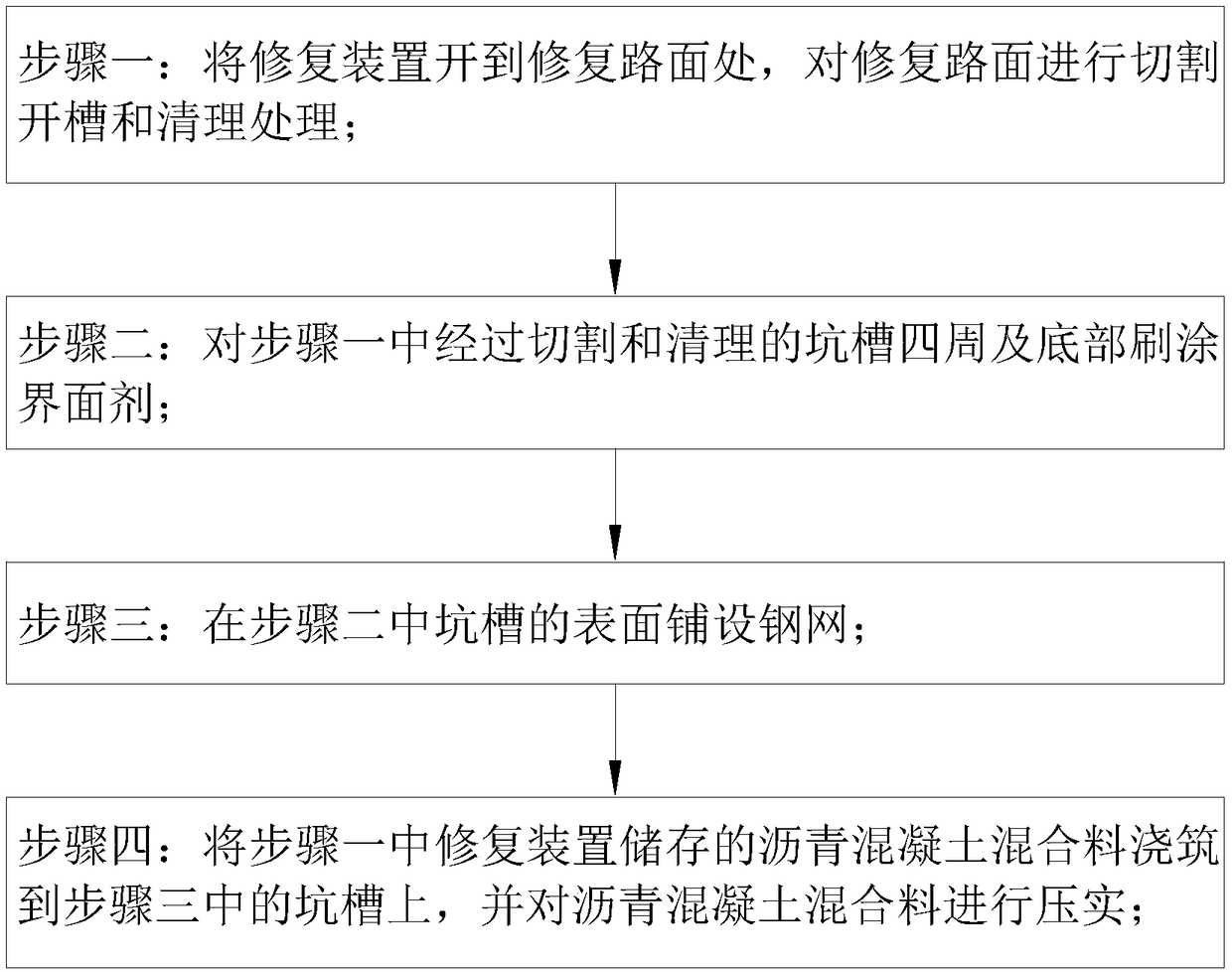

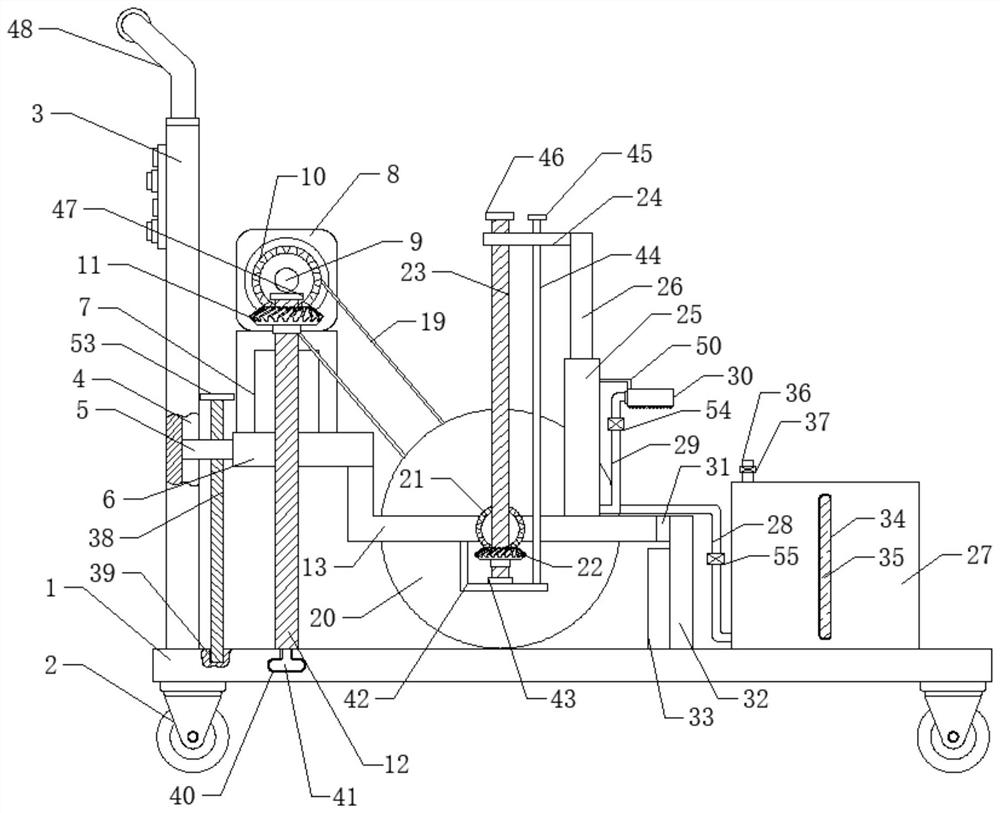

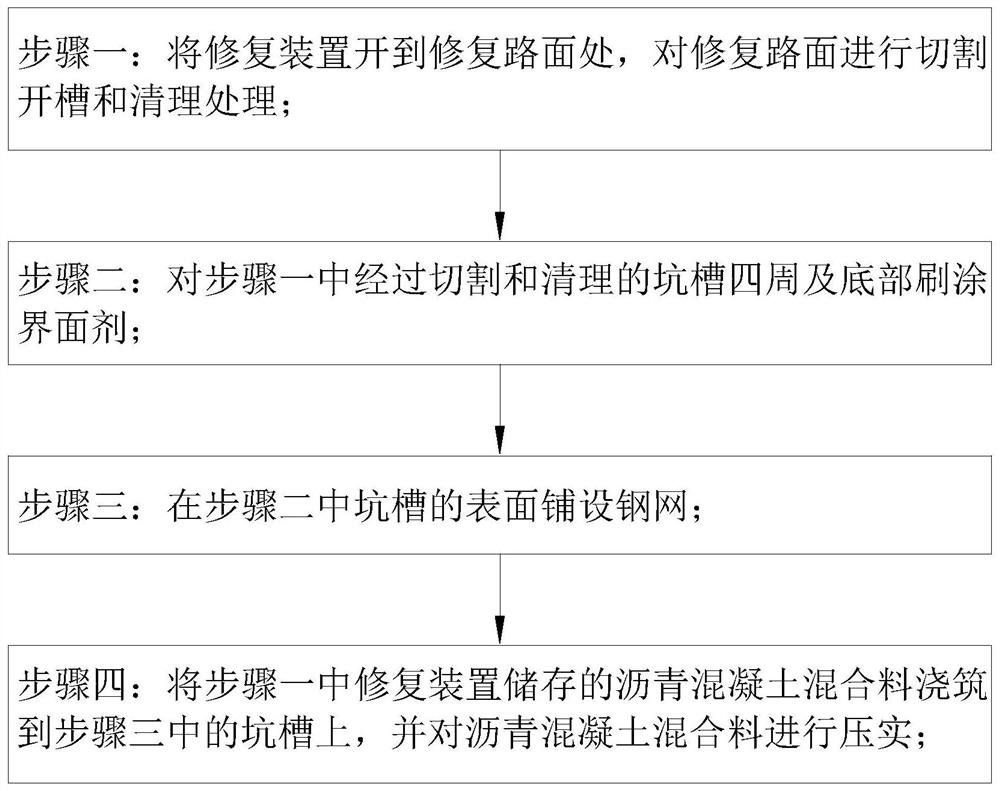

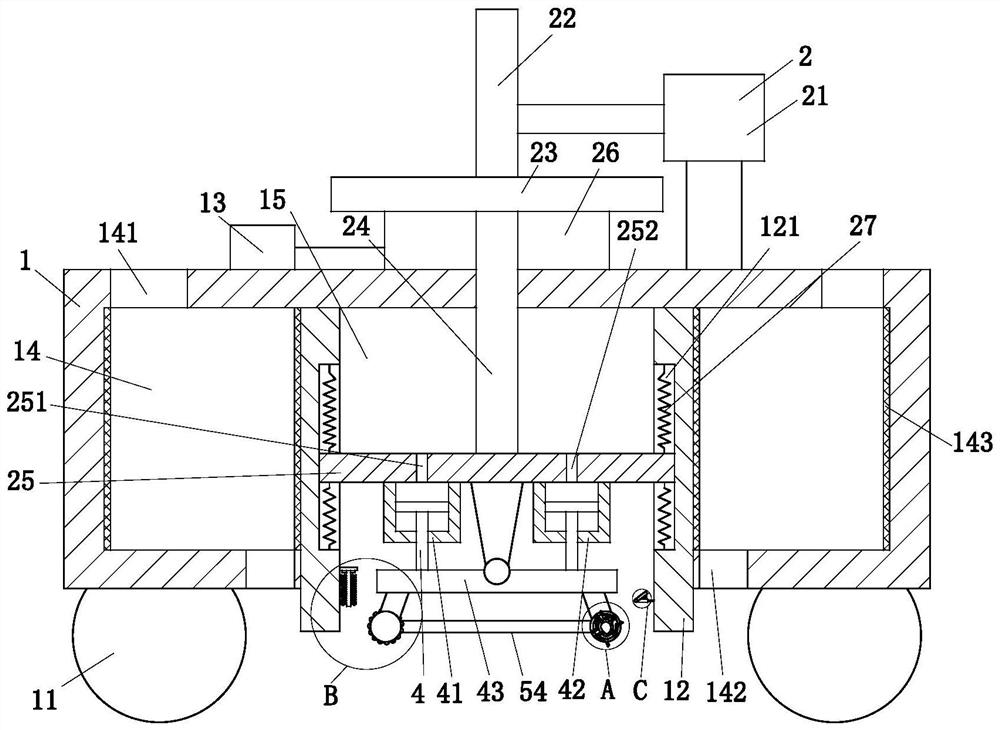

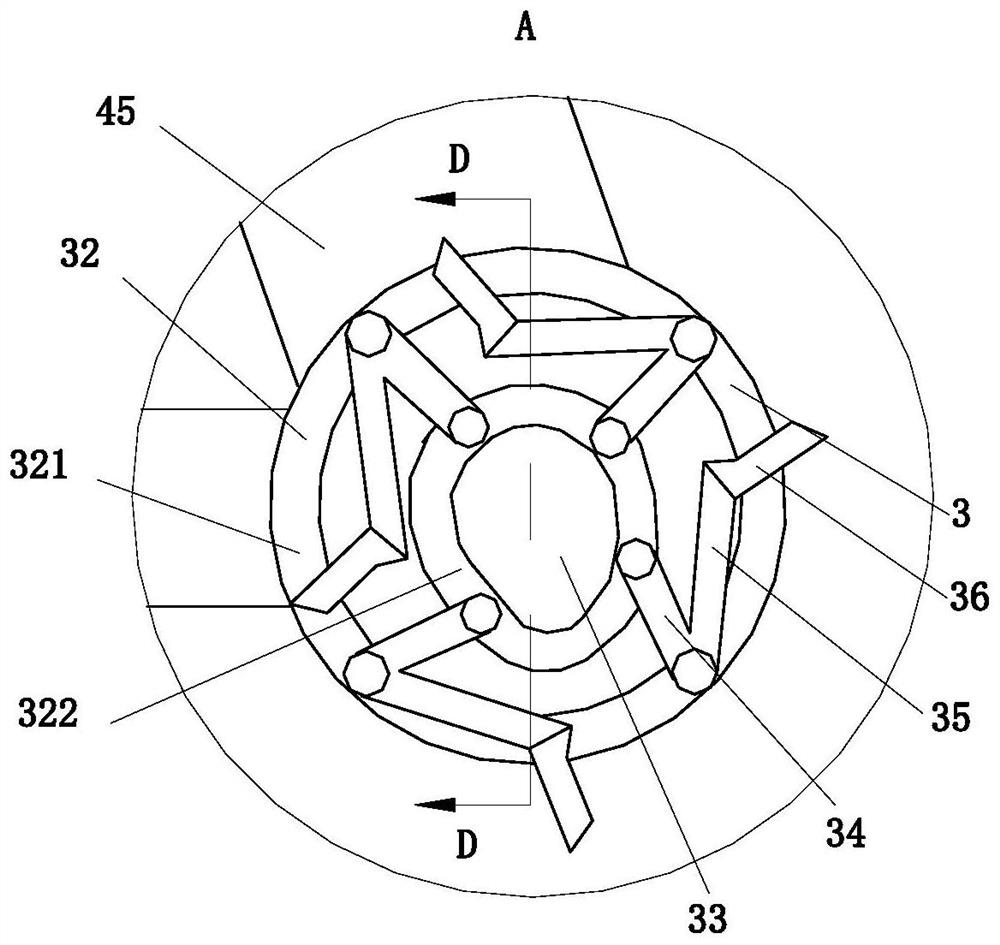

A method for repair damaged asphalt pavement

ActiveCN109082990AImprove securityExtended service lifeDispersed particle separationRoads maintainenceRoad surfaceEngineering

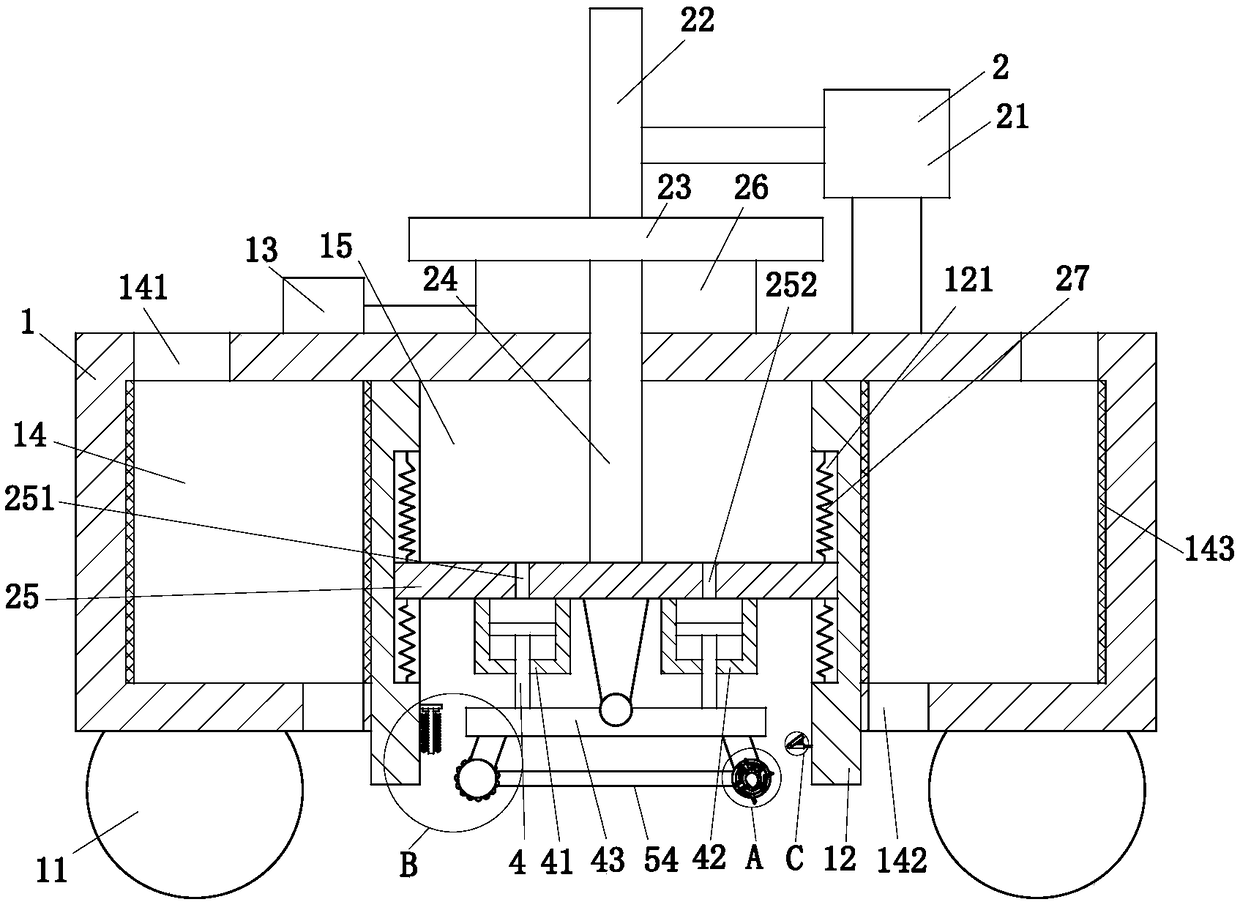

The invention belongs to the technical field of road construction, in particular to a method for repairing damaged asphalt pavement. The method adopts a repairing device which comprises a locomotive and a rolling wheel. The utility model also comprises a No. 1 plate, a driving unit, a cutting unit, a control unit and a No. 1 cleaning unit. The rolling roller is used for tamping the asphalt concrete mixture; The cutting unit is used for slotting the damaged part of the pavement; The No. 1 cleaning unit cleans the slotted road surface. On the one hand, the asphalt concrete mixture is completelypoured into the repairing notch, and the pavement is leveled by the rolling roller, so that the driving safety of the vehicle is improved; on the other hand, the asphalt concrete mixture is completelypoured into the repairing notch by the mutual cooperation of the cutting unit, the cleaning unit No. On the other hand, the dust in the pavement cutting is cleaned out of the notch to increase the bonding force between the asphalt concrete mixture and the notch, thus prolonging the service life of the highway pavement.

Owner:江苏雨梦建设有限公司

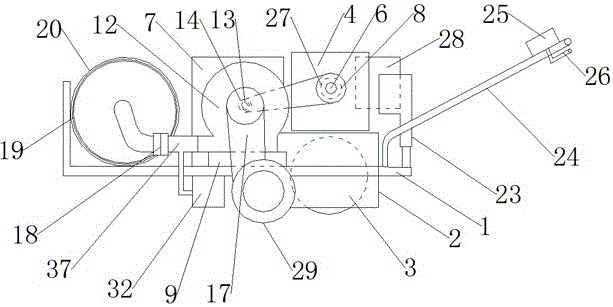

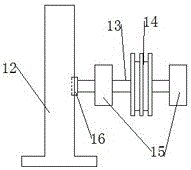

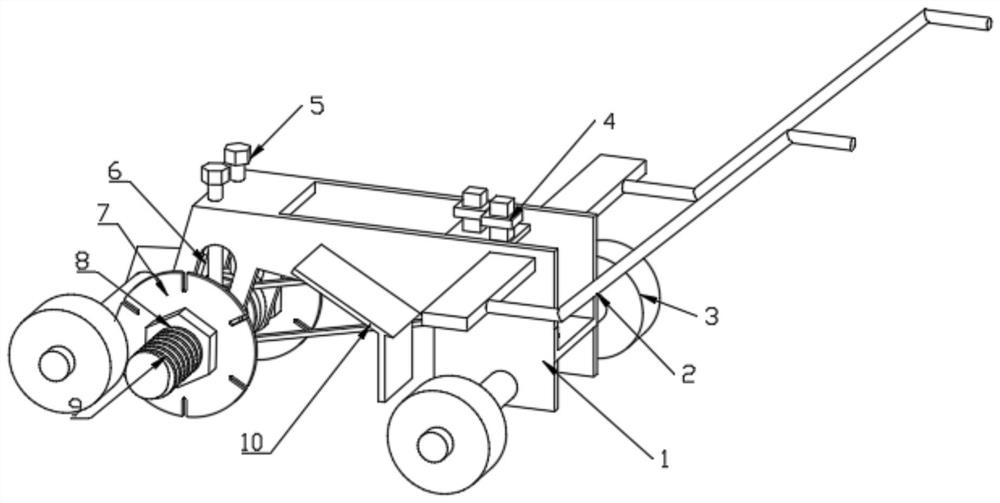

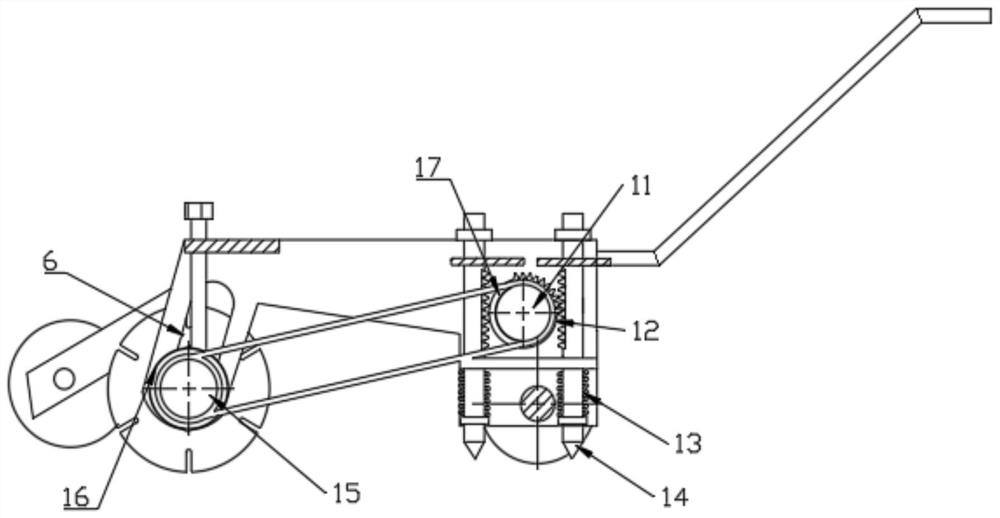

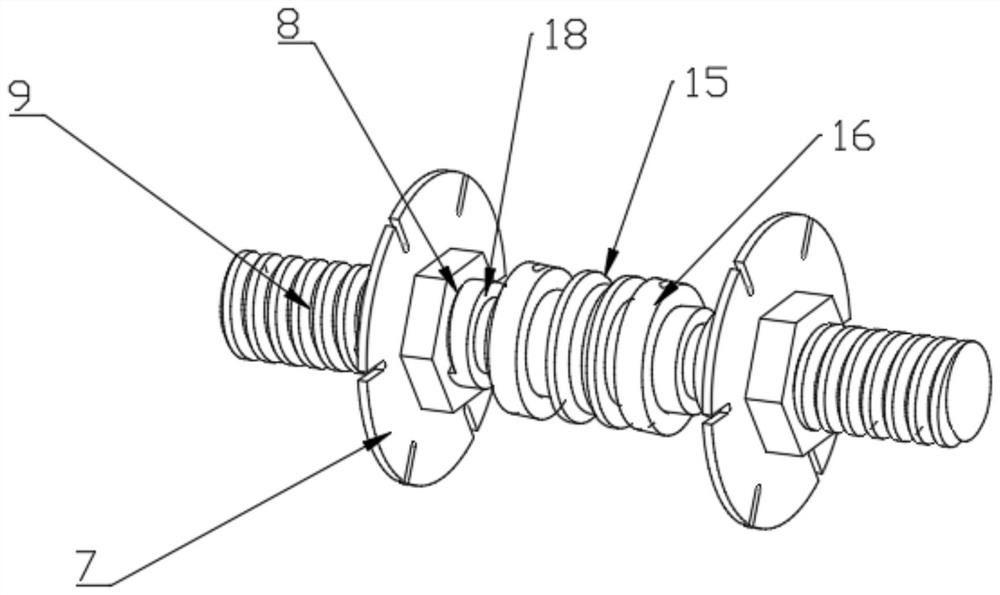

Multifunctional road pavement groover

ActiveCN106065560ASolve the problem of stagnant waterSolve the problem that cannot be constructedRoads maintainenceDrive shaftAgricultural engineering

The invention discloses a multifunctional road pavement groover. The groover comprises a frame, the frame is provided with a knife drum installation housing, a grooving knife drum is installed in the knife drum installation housing, the upper part of the frame is provided with a motor, the motor is provided with a first output shaft and a second output shaft, the second output shaft is provided with a first belt pulley, the front end of the frame is provided with a fan installation rack, the upper end of the fan installation rack is provided with a fan, an air outlet of the fan is connected to a three-way joint, one end of the three-way joint is connected to a quick joint, the other end of the three-way joint is connected to an air pressurization valve, the air pressurization valve is respectively connected to a flame gun and a high pressure gas-based gap-cleaning gun through the quick joint, two wheels are arranged below the frame, a wheel transmission shaft is arranged between the wheels and the wheel transmission shaft is connected to an electric transmission assistant mechanism. The multifunctional road pavement groover has four functions of grooving, pavement drying, strong dedusting and groove gap cleaning.

Owner:济南弗格森道路养护技术有限公司

Grooving device for hydroelectric decoration

ActiveCN112757504AImprove parallelismAvoid irregularitiesWorking accessoriesStone-like material working toolsGear wheelCivil engineering

The invention is suitable for the technical field of buildings, and provides a grooving device for water and electricity decoration. The grooving device for water and electricity decoration comprises a mounting frame, a rotating shaft, cutting blades and a driving part, wherein the rotating shaft is rotationally arranged on the mounting frame; the two cutting blades are fixedly mounted at the two ends of the rotating shaft and used for cutting a grooving position; the driving part is mounted on the mounting frame, is connected with the rotating shaft through a transmission part, and is used for driving the cutting blades to rotate for cutting; an output shaft of the driving part is coaxially connected with at least one incomplete gear; a lifting rod is arranged on the mounting frame in a liftable mode; insections are arranged on the lifting rod; a breaking head is fixedly connected to the bottom of the lifting rod; the driving part drives the cutting blades to rotate through the transmission part so as to cut the grooving position; the driving part drives the incomplete gear to rotate so as to drive the lifting rod to ascend; and the lifting rod descends to crush the grooving position. The grooving device for water and electricity decoration provided by the invention has the advantages of being simple in structure, convenient to operate, capable of saving energy, good in grooving quality, high in working efficiency and high in adaptability.

Owner:湖南弘佑集成科技有限公司

Plate slotting device

InactiveCN106994723AImprove slotting effectGuaranteed slotting effectWood mortising machinesGlue vesselsAdhesiveEngineering

The invention relates to equipment in the field of wood processing, and the name is a plate slotting device, which includes a frame, on which is a conveying platform, and a first cantilever on the frame, under which is a slotting device driven by power Knife, the conveying platform conveys the plate, the operation of the slotting knife can slot the plate, and the conveying platform moves forward; it is characterized in that: the frame also has a second cantilever and a third cantilever, the second cantilever and the third cantilever are respectively on the left and right sides of the first cantilever, the second cantilever and the third cantilever are under the cylinder, under the cylinder is the pressure plate, and the pressure plate is pressed on the left and right sides of the slotted surface. The glue device, the glue supply device has an output pipeline, and there is an outlet under the pressure plate, and the output pipeline is connected to the outlet of the pressure plate. There is also a heating device in the pressure plate in front of the outlet. Such a plate grooving device has a The advantages of more complete plate and better groove effect.

Owner:CHANGGE SHUANGFENG WOOD IND CO LTD

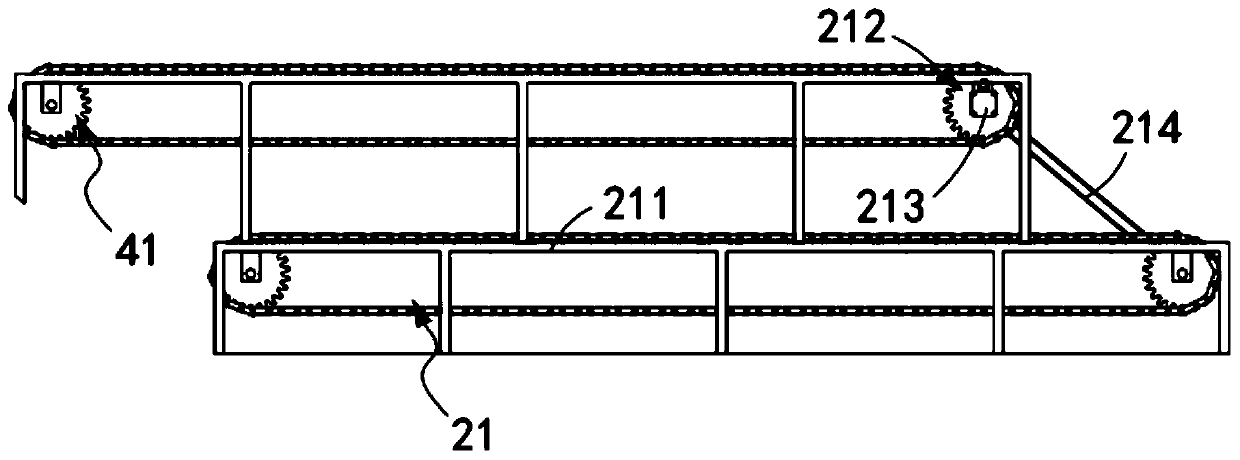

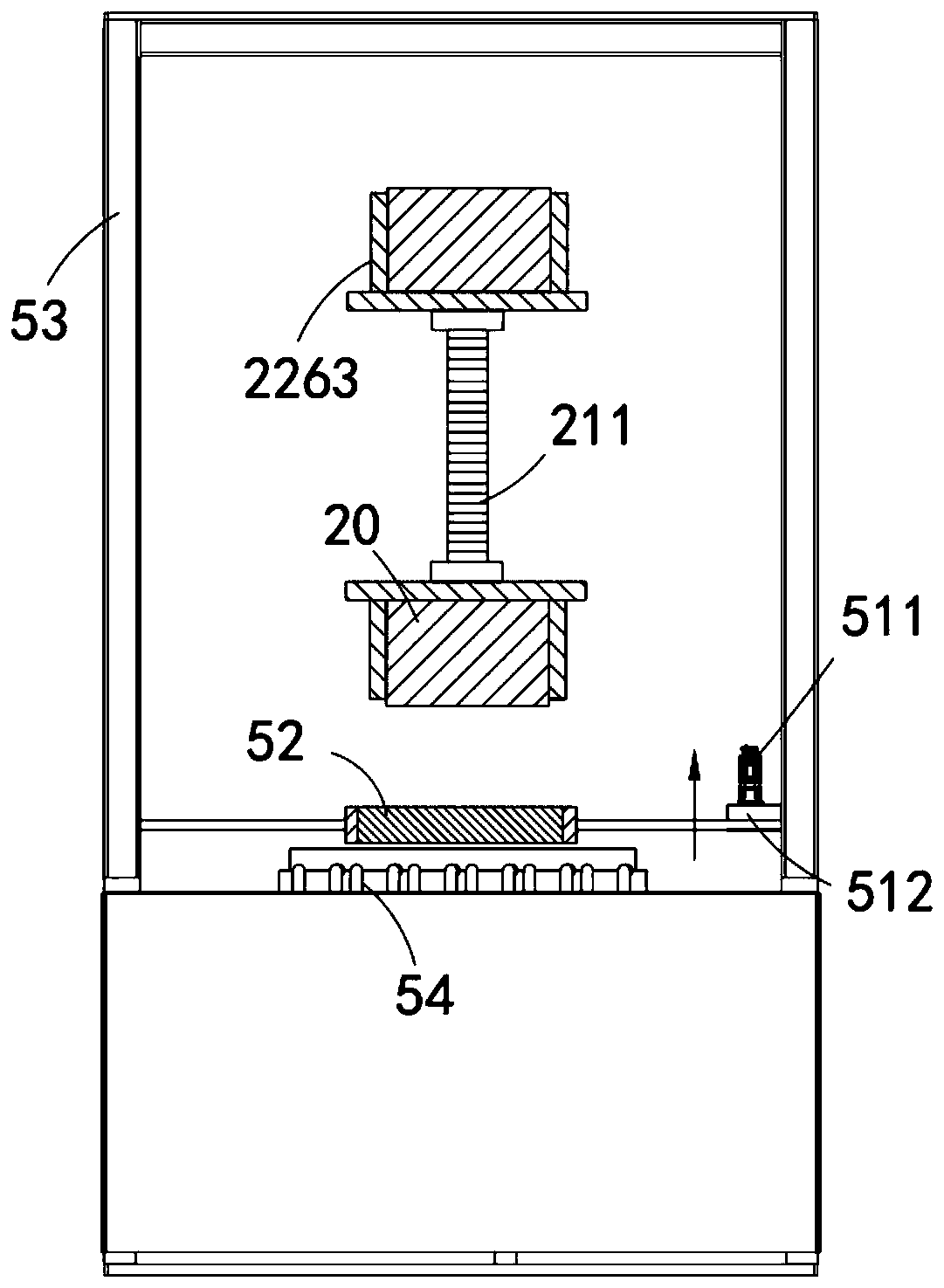

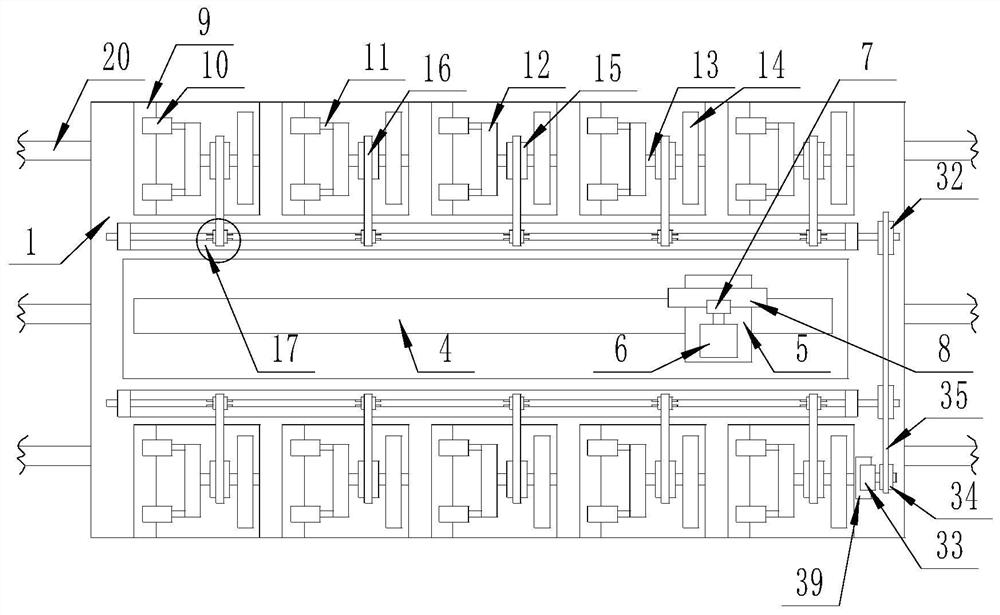

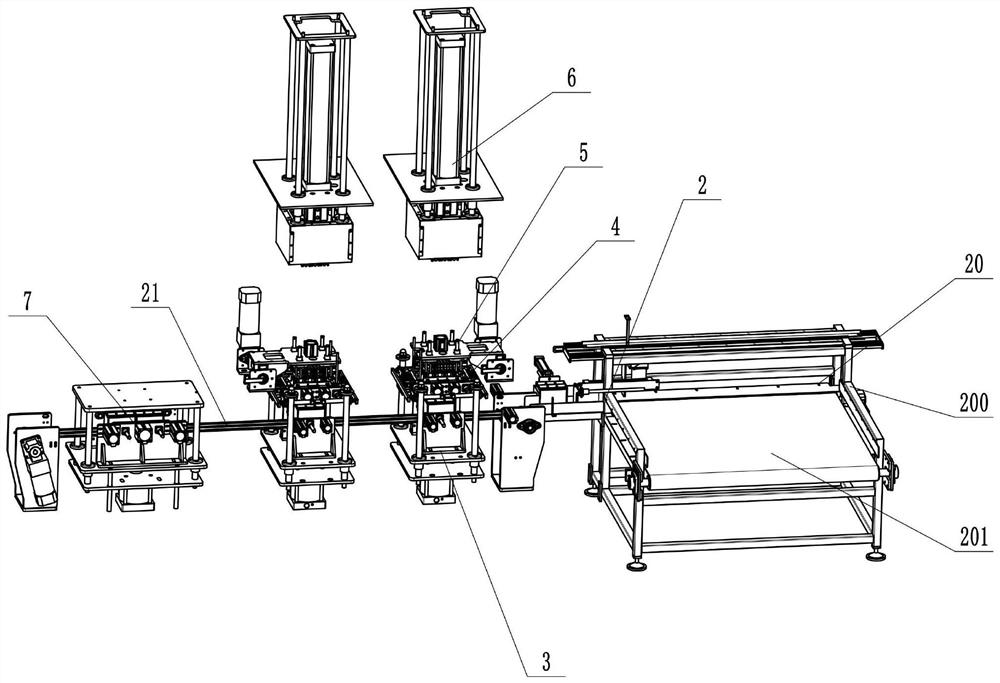

Post-processing equipment for storage battery pole group

InactiveCN111342006AEasy to pack for workWon't wear outAssembling battery machinesFinal product manufactureControl engineeringMechanical engineering

The invention relates to post-processing equipment for a storage battery pole group. The post-processing equipment comprises a pole group conveying mechanism, a pole group clamping mechanism, a shellconveying mechanism, a shell clamping mechanism, and a battery output mechanism. A first guide assembly controls a first hooping assembly to clamp a pole group in a conveying state and convey the polegroup backwards. A second guide assembly controls a second hooping assembly to clamp a storage battery shell in the conveying state and convey the storage battery shell backwards. A third guide assembly lifts the first hooping assembly and inserts the first hooping assembly into the storage battery shell clamped by the correspondingly arranged second hooping assembly. A fourth guide assembly is used for jacking the second hooping assembly to the output end of a pushing assembly, and the pushing assembly is used for pushing the jacked storage battery to a discharging assembly. The technical problem that during groove entering for work, grouped pressing and batched output are needed, and batched interval output is conducted at the same time, which do not facilitate later one-to-one separated machining and packaging is solved.

Owner:长兴水木机电有限公司

Adjustable edge cutting device for corrugated paperboard

PendingCN109177310ASmooth edgesEfficiency and precisionPaper-makingBox making operationsPaperboardWaste recycling

The invention discloses an adjustable edge cutting device for a corrugated paperboard. The adjustable edge cutting device comprises a base, wherein two groups of moving tables are movably connected with the top of the base; a first bearing table and a second bearing table are fixedly connected with the top of the moving table; the first bearing table and the second bearing table are distributed ina staggered manner and movably connected in a clamping manner through first inserting gear rack and a second inserting gear rack; cutting wires are fixedly mounted on the right sides of waste ports;lifting mechanisms are fixedly mounted on both sides of the middles of clamping edges; supporting beams are fixedly connected with the inner side walls of the lifting mechanisms; connecting frames andcutter holders are movably connected onto guiding rails; two groups of cutting blades are fixedly mounted at the bottoms of the cutter holders; pressing-down strips are movably connected into the cutter holders and positioned between the cutter blades; and cutter heads are fixedly connected with the bottoms of the pressing-down strips. The adjustable edge cutting device is applicable to the edgecutting and the positioning of corrugated paperboards of different sizes; the grooving length can be adjusted; and the automatic grooving and waste recycling can be achieved.

Owner:安徽金田彩印包装有限公司

Grooving equipment for dining table top processing

InactiveCN108748464AImprove practicalityImprove slotting effectWood mortising machinesWood slotting machinesArchitectural engineeringMachine tool

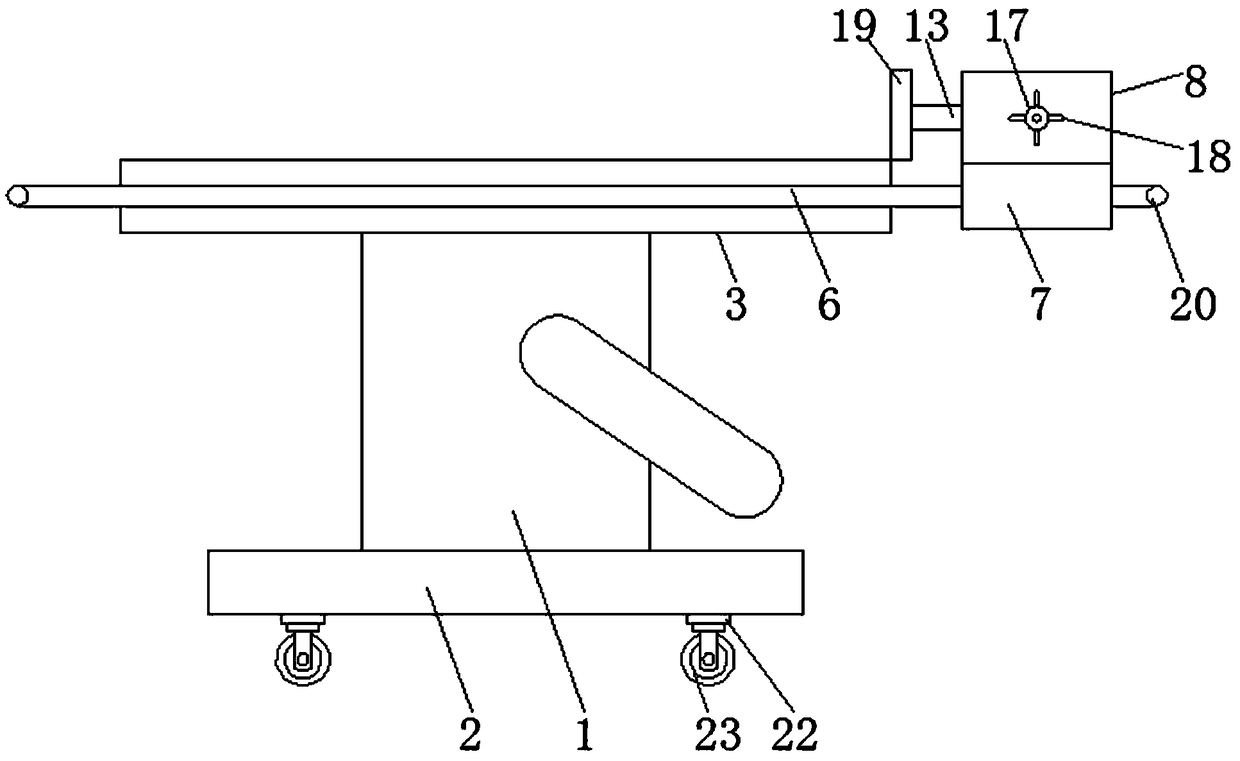

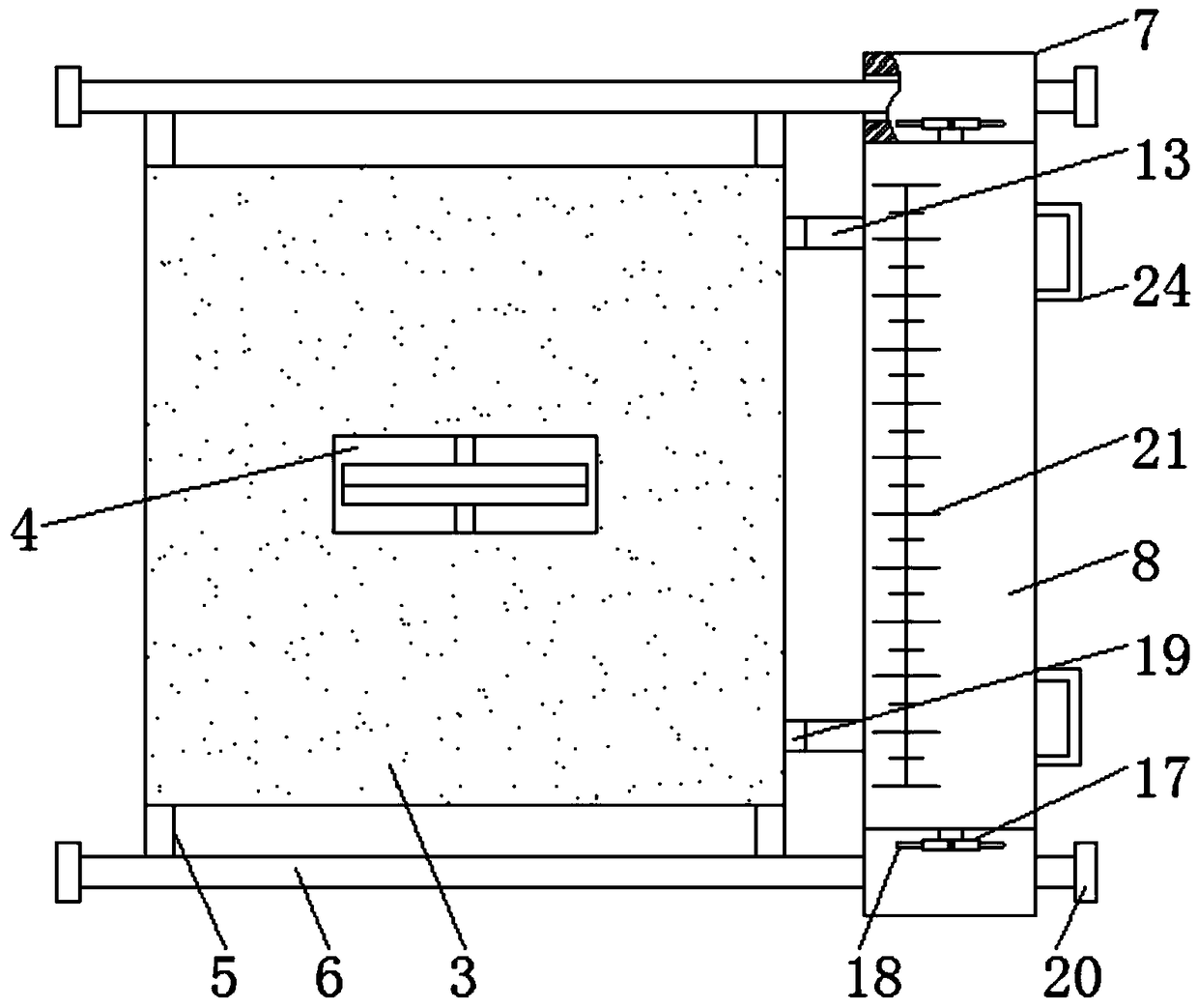

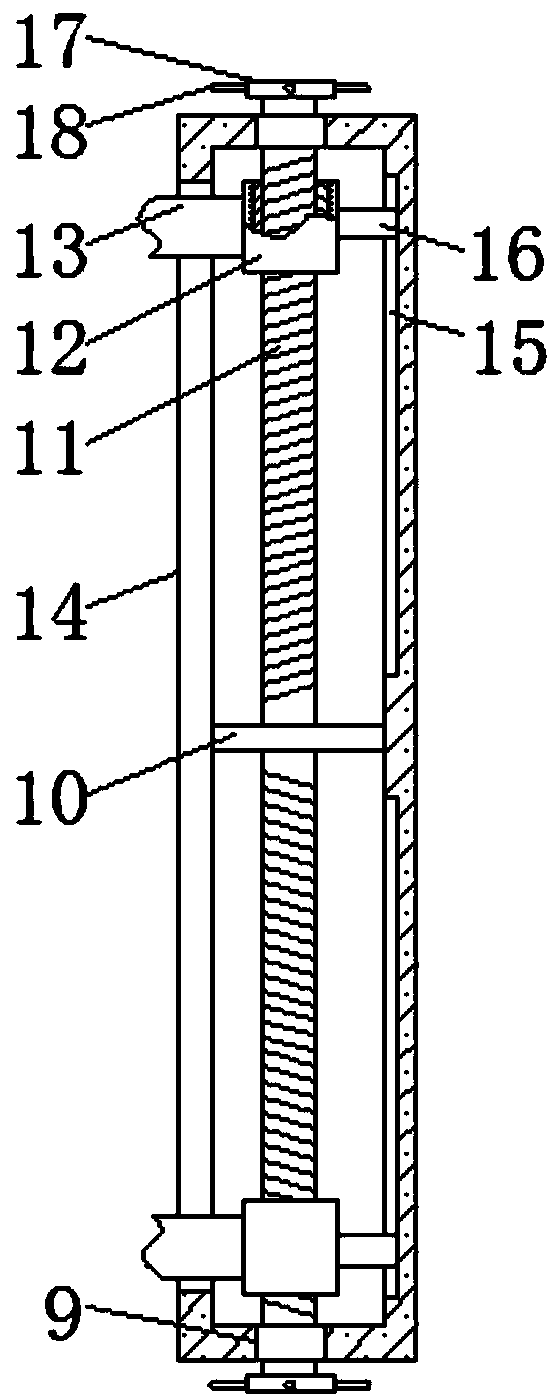

The invention discloses grooving equipment for dining table top processing. The grooving equipment comprises a grooving equipment body. A base is fixedly connected with the bottom of the grooving equipment body. A machine tool body is fixedly connected with the top of the grooving equipment body. An equipment groove is formed in the center of the top of the machine tool body. Connecting rods are fixedly connected with the front side and the rear side of the machine tool body. Through coordinate application of a sliding rod, a sliding block, a shell, a bearing, a partition plate, a threaded rod, a threaded pipe, a fixing rod and a scale plate, the problems that when existing grooving equipment is used, dining table tops are often pushed manually to move on the surface of a machine tool andare liable to be deviated in the pushing process, consequently, the grooving effect is poor, and the grooving precision is low are solved, the grooving equipment for dining table top processing has the advantages of being good in table top fixing effect and high in grooving precision, and is convenient to operate, the effect of saving time and effort is achieved, and the practicability of the grooving equipment for dining table top processing is improved.

Owner:安吉木亦家具有限公司

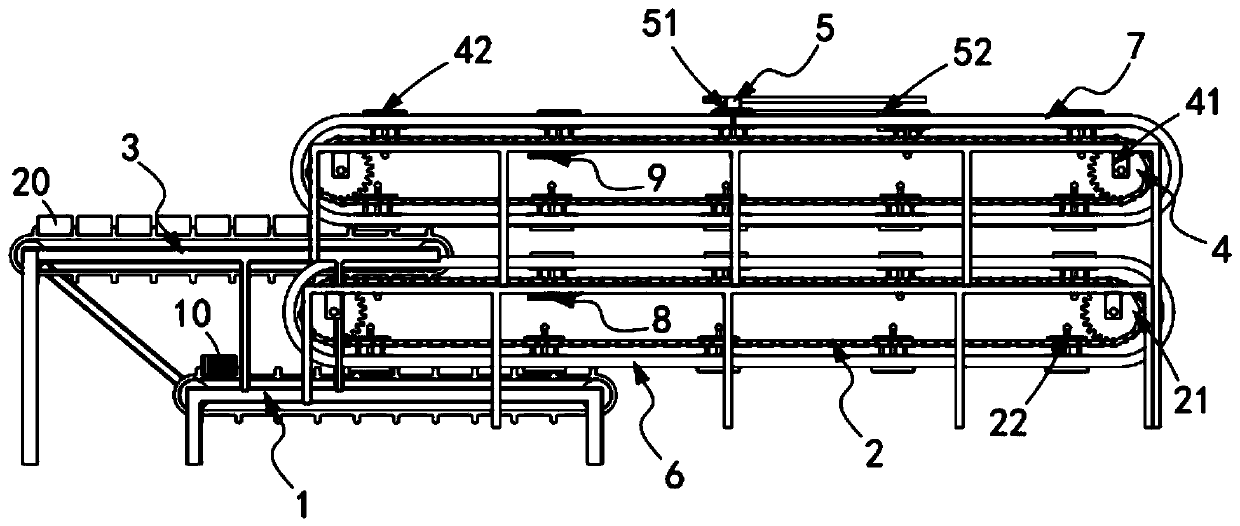

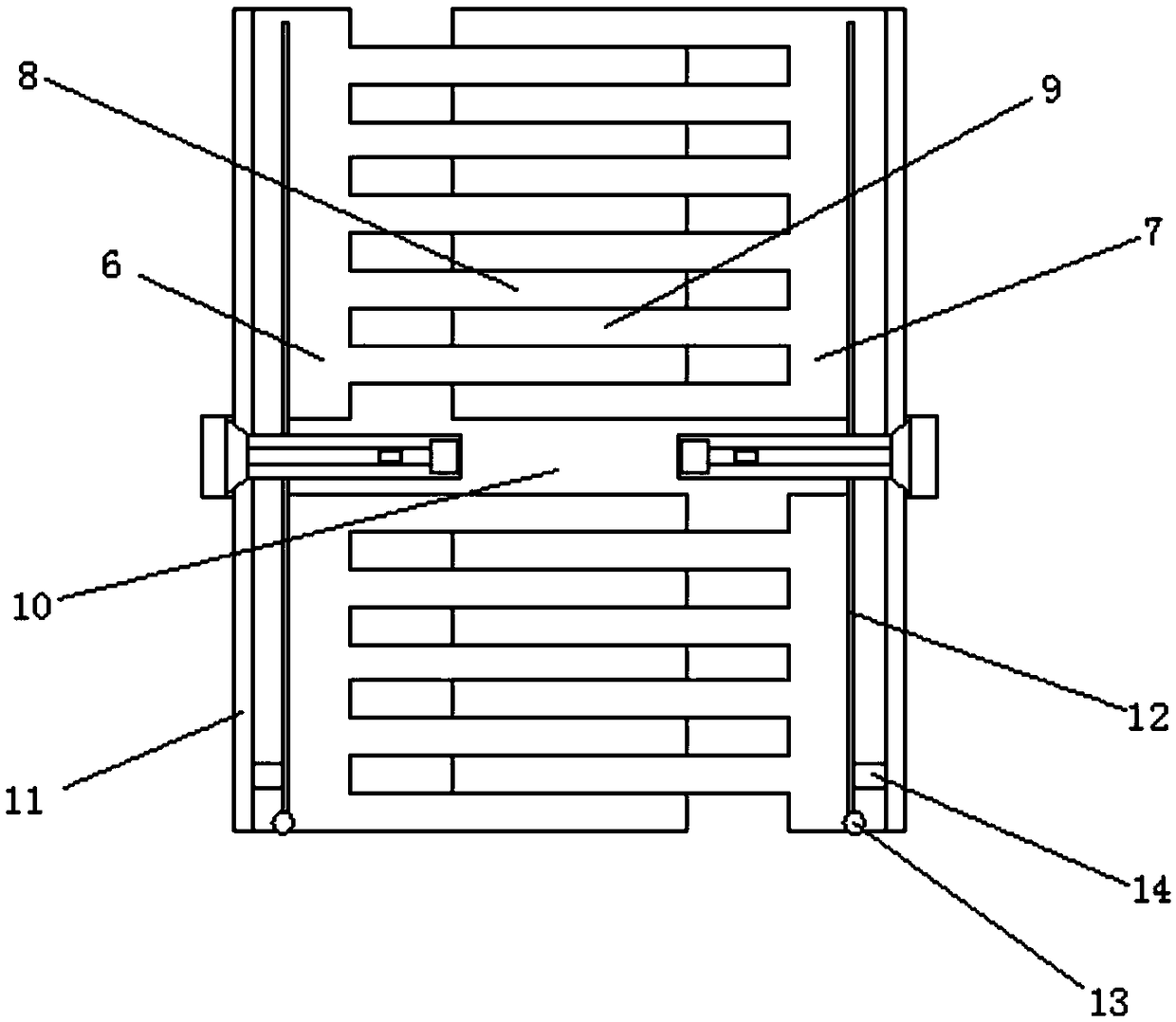

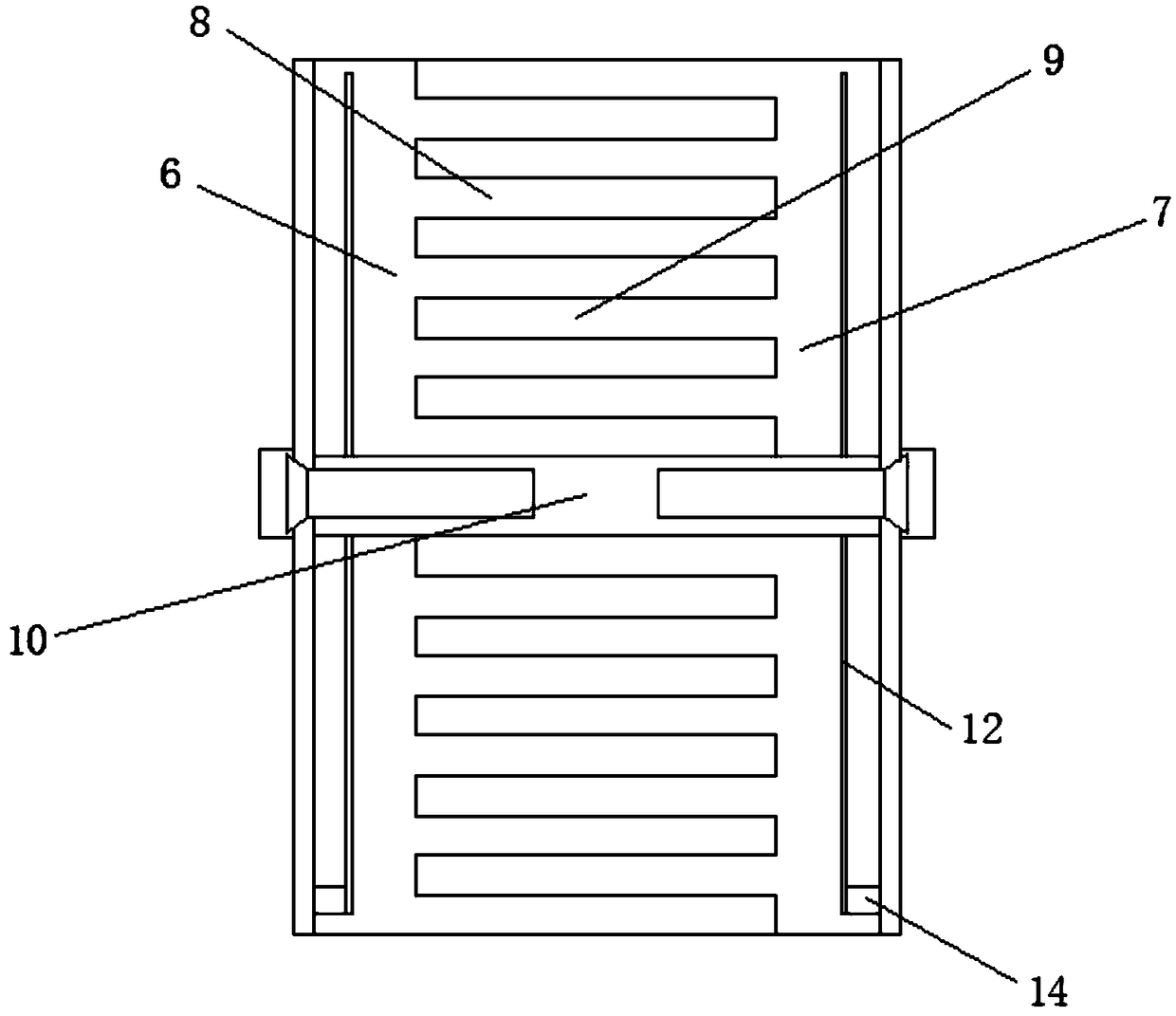

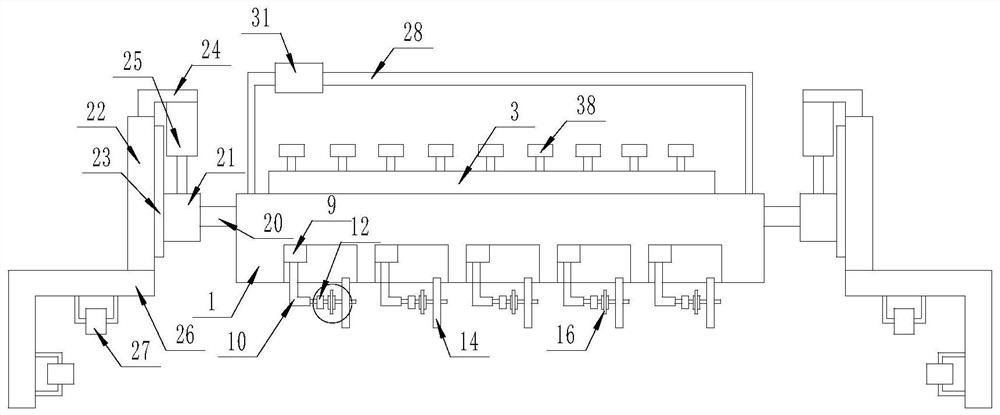

Pole plate group continuous slot entering device for lead-acid storage battery

InactiveCN111403828AWon't wear outPrecise groove entryConveyorsFinal product manufactureControl theoryMechanical engineering

The invention relates to a pole plate group continuous slot entering device for a lead-acid storage battery. The device comprises a pole plate group conveying mechanism; a pole group clamping mechanism which comprises a first conveying assembly and a first hooping assembly; a housing transmission mechanism; and a housing clamping mechanism which comprises a second conveying assembly and a second hooping assembly. A first guide assembly mounted on a rack controls the first hooping assembly to clamp the pole plate group in a conveying state and convey the pole plate group backwards; a second guide assembly installed on the rack controls the second hooping assembly to clamp the pole plate group in the conveying state and convey the pole plate group backwards; and a third guide assembly mounted on the rack lifts the first hooping assembly and inserts the first hooping assembly into the storage battery housing clamped by the correspondingly arranged second hooping assembly. According to theinvention, the technical problem of low working efficiency caused by incapability of realizing continuous slot entering work due to waiting of the next group of pole groups to be subjected to slot entering work when the previous group of pole groups are subjected to slot entering work through slot entering work of the pressing plate is solved.

Owner:长兴水木机电有限公司

Wood slotting and cutting device

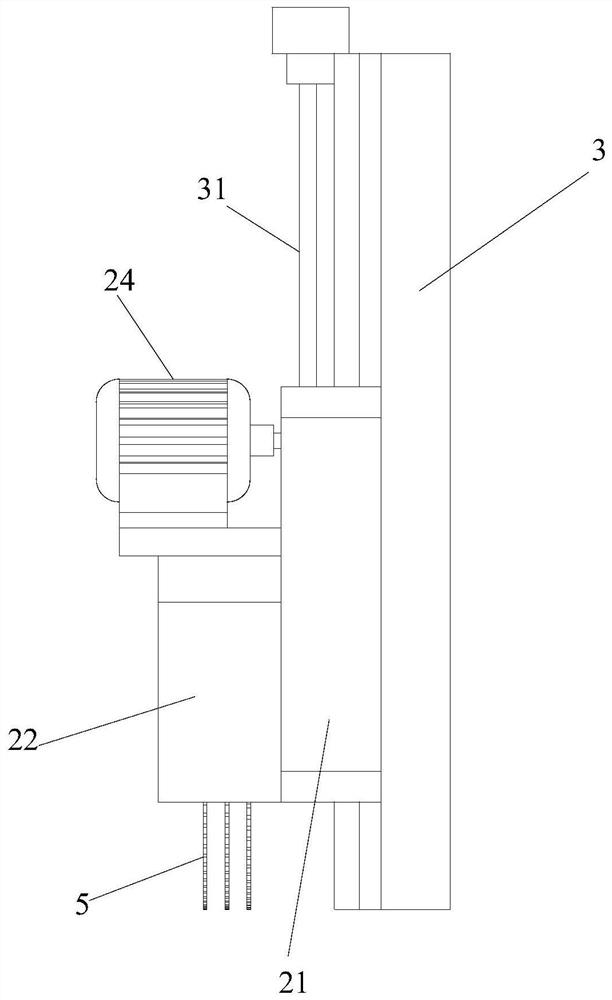

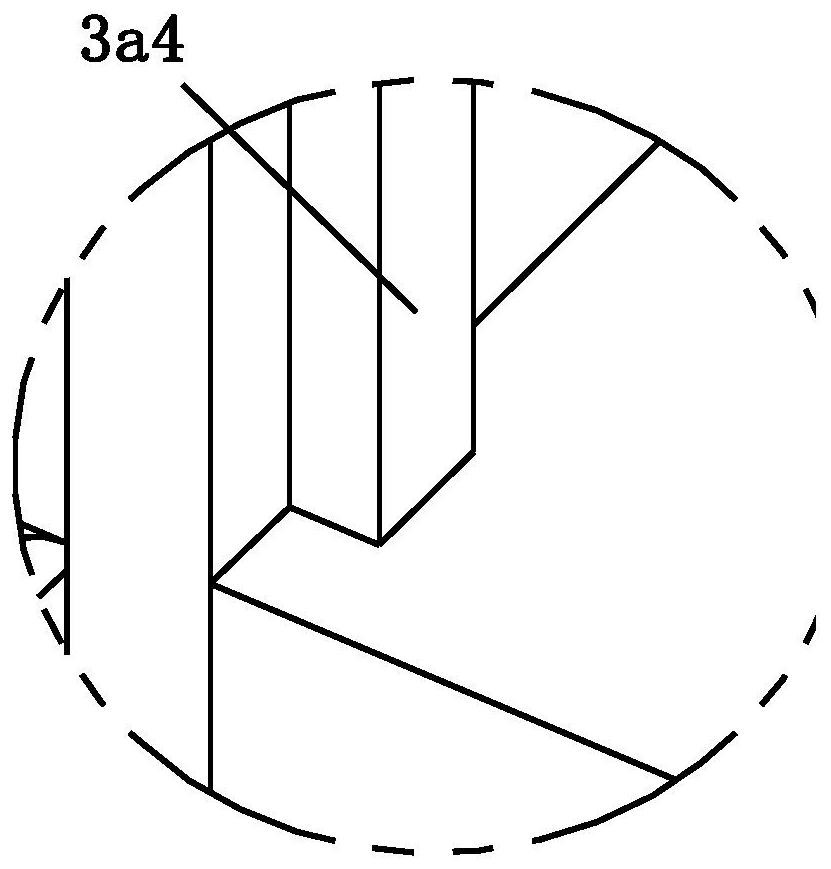

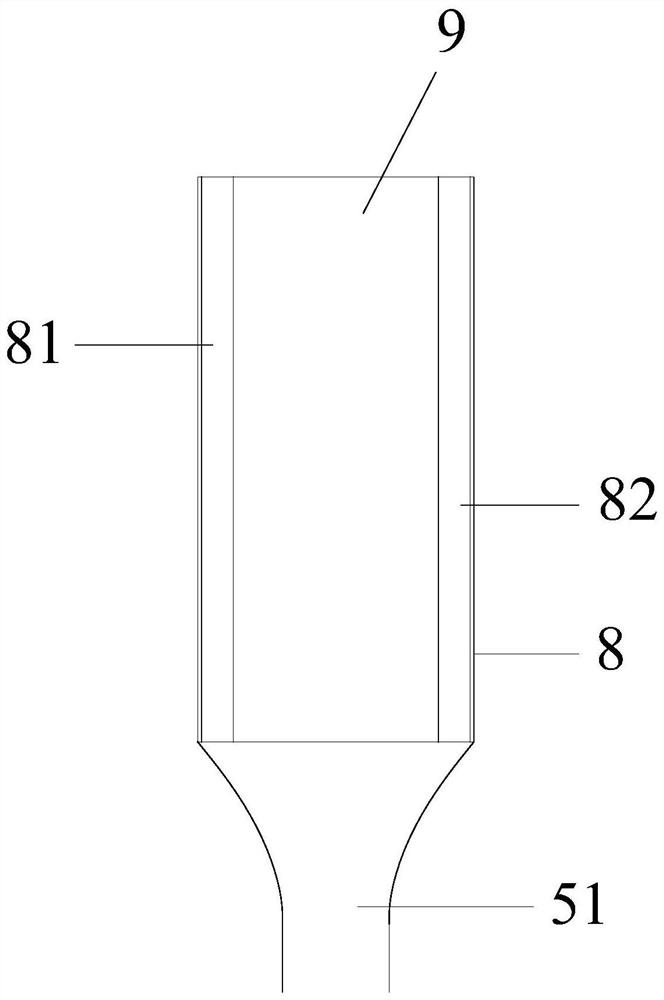

ActiveCN110900729BImprove slotting effectIncrease widthProfiling/shaping machinesBark-zones/chip/dust/waste removalWood splinterKnife blades

The invention discloses a wood slotting and cutting device, which comprises a support frame and a cutting unit arranged on the support frame capable of moving up and down. A lifting seat is fixed on the frame, and the cutting unit is slidingly connected with the lifting seat; the cutting unit includes a sliding seat that is slidingly connected with the lifting seat, and the sliding seat is provided with a rotatable output shaft. Three cutting knives are installed on the output shaft, and two adjacent cutting knives are coaxial and can rotate relatively. The present invention uses a plurality of blades to cut, and solves the problem that wood chips are easily accumulated between two adjacent blades, and can effectively remove chips while realizing cutting to ensure the cutting effect.

Owner:江苏刘一刀精密机械有限公司

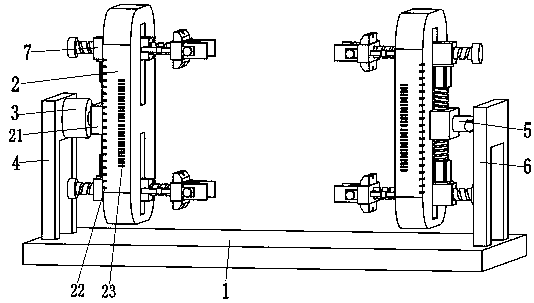

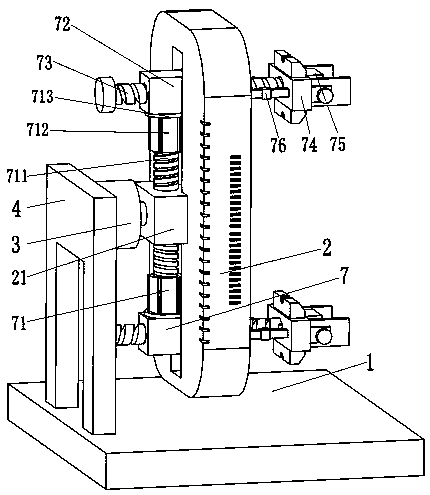

A kind of cement prefabricated board slot processing equipment for house construction

InactiveCN111070452BNo shakingImprove slotting effectWorking accessoriesConstruction engineeringElectric machinery

The invention relates to cement prefabricated slab clamping groove machining equipment for house building. The cement prefabricated slab clamping groove machining equipment comprises a bottom plate, clamping support plates, a rotating motor, a side vertical frame, a following rotating shaft, a rotating shaft plate and clamping mechanisms, the clamping support plates are distributed at the left endand the right end of the upper part of the bottom plate correspondingly, each clamping support plate is provided with two square grooves with sliding grooves formed in the side walls, and each squaregroove in the corresponding clamping support plate is internally connected with the corresponding clamping mechanism; and the clamping mechanisms comprise adjusting assemblies, clamping blocks, rotating bolts, clamping press plates, abutting blocks and limiting rods. The problems existing during existing clamping groove forming treatment of a cement prefabricated slab that the cement prefabricated slab cannot be locked in all directions, thus a clamping groove skews during grooving treatment of the cement prefabricated slab, and the position of forming the clamping groove in the cement prefabricated slab deviates to a certain extent can be solved.

Owner:宜昌市洋坤建筑有限公司

A graphite carbon tube processing equipment

ActiveCN111890581BImprove slotting efficiencyImprove slotting effectWorking accessoriesStone-like material working toolsGraphite carbonWorking environment

The invention relates to a graphite carbon tube processing equipment, comprising a bottom plate, a clamping device, a slotting device and a dust suction device, the clamping device is installed on the bottom plate, and a slotting device and a dust suction device are installed on the clamping device , the present invention can solve the following problems that exist when the existing graphite carbon tubes are slotted. One, when the traditional graphite carbon tubes are slotted, they are generally polished by manual hand-held grinding equipment, and the efficiency of manual slotting of graphite carbon tubes is low , it is also difficult to ensure safety, and the operators work in an environment with powder and dust for a long time, which is harmful to health; 2. When the existing graphite carbon tube slotting equipment is slotting the graphite carbon tube, the slotting operation cost It is relatively high and has low efficiency. It cannot perform stable clamping operations on graphite carbon tubes, and cannot promptly absorb dust generated when graphite carbon tubes are slotted. It can also reduce the hazards of dust in the working environment to workers.

Owner:内蒙古京航特碳科技有限公司

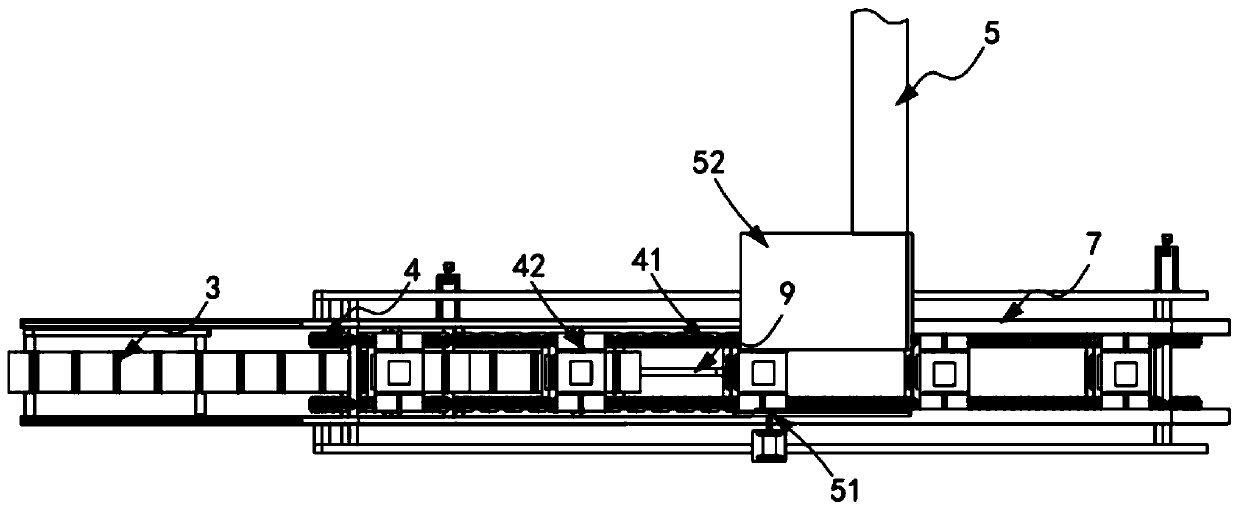

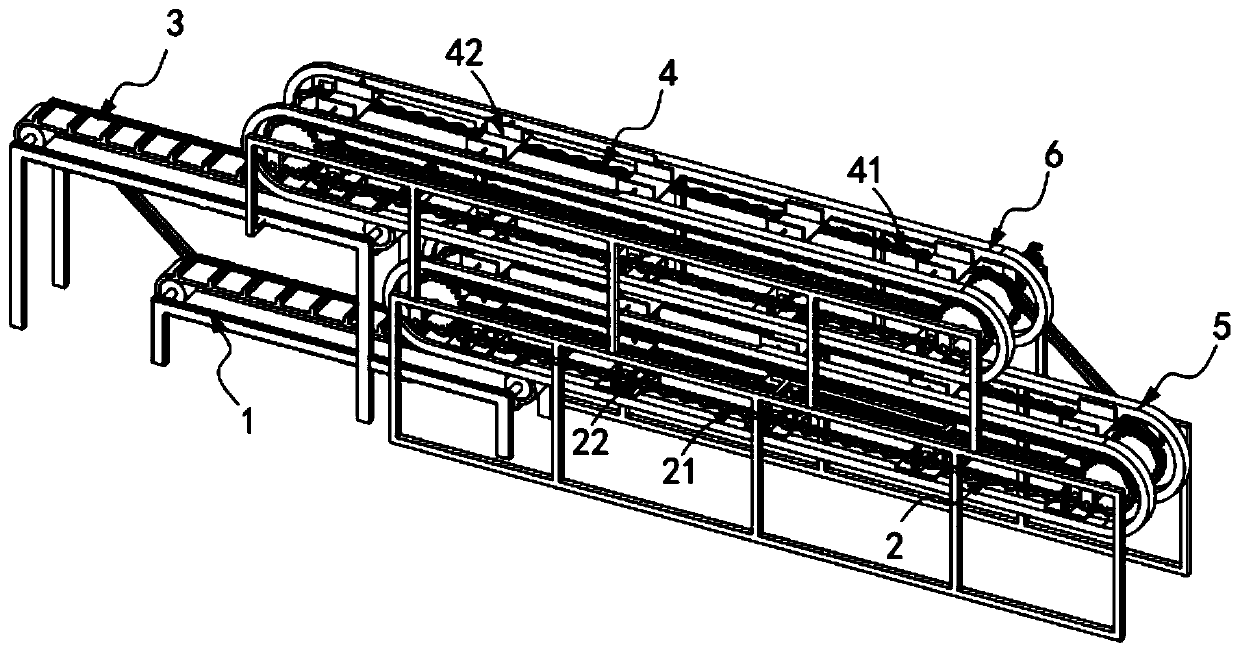

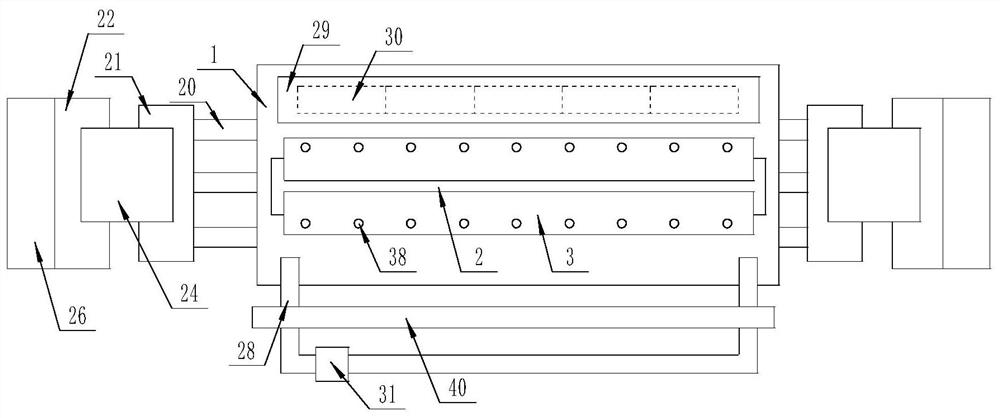

Storage battery plate group processing production line

InactiveCN111370778ARealize automatic outputImplement inputConveyorsFinal product manufactureProduction lineEngineering

The invention relates to a storage battery pole group processing production line, which comprises a pole group transmission mechanism, a pole group clamping mechanism; a housing transmission mechanism; a housing clamping mechanism; and a cast-weld machine; the first guiding assembly controls the first hooping assembly to clamp the pole group in a conveying state and convey the pole group backwards; the second guiding assembly controls the second hooping assembly to clamp the storage battery shell in the conveying state and convey the storage battery shell backwards. The third guiding assemblypushes down the plate group clamped on the first hooping assembly and inserts the plate group into the storage battery shell clamped by the correspondingly arranged second hooping assembly; accordingto the invention, the technical problems are solved that the device cannot realize automatic input and output of the storage battery, is poor in automation degree, cannot be integrally connected withcast-weld work for work, and is low in working efficiency.

Owner:长兴水木机电有限公司

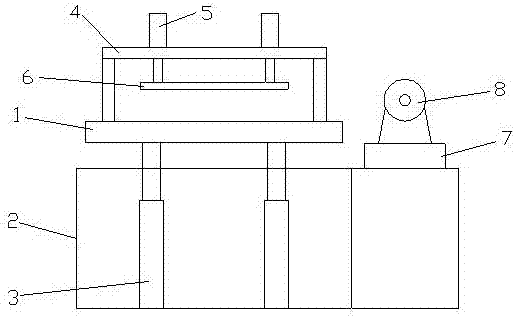

Grooving machine

InactiveCN107150384AFixedSimple structureWood mortising machinesWood slotting machinesEngineeringMachining

The invention discloses a slotting machine, comprising a workbench and a base, a lifting cylinder is fixedly arranged under the workbench, a gantry support beam is fixedly installed above the workbench, and the lift cylinder is fixedly arranged on the base Inside, an air cylinder is fixedly installed on the gantry support beam, a pressure beam is fixedly installed at the lower end of the air cylinder, a pneumatic slide table is fixedly installed at the upper end of the base on the side of the workbench, and a processing motor is fixedly installed above the air slide table. Its advantages are: the structure of the present invention is simple, the design is reasonable, and the height of the workbench can be adjusted through the lifting cylinder, that is, the height of the slotting position of the wooden board can be adjusted. At the same time, the processing motor is installed on the pneumatic slide table, and the slotting depth can be adjusted at will. And position, to achieve a good slotting effect, the pressure beam is driven by the cylinder, which can well fix the wooden board that needs to be slotted, and is easy to operate.

Owner:不二新材料科技有限公司

A kind of multifunctional highway pavement slotting machine

ActiveCN106065560BSolve the problem of stagnant waterReduce labor intensityRoads maintainenceDrive shaftAgricultural engineering

The invention discloses a multifunctional road pavement groover. The groover comprises a frame, the frame is provided with a knife drum installation housing, a grooving knife drum is installed in the knife drum installation housing, the upper part of the frame is provided with a motor, the motor is provided with a first output shaft and a second output shaft, the second output shaft is provided with a first belt pulley, the front end of the frame is provided with a fan installation rack, the upper end of the fan installation rack is provided with a fan, an air outlet of the fan is connected to a three-way joint, one end of the three-way joint is connected to a quick joint, the other end of the three-way joint is connected to an air pressurization valve, the air pressurization valve is respectively connected to a flame gun and a high pressure gas-based gap-cleaning gun through the quick joint, two wheels are arranged below the frame, a wheel transmission shaft is arranged between the wheels and the wheel transmission shaft is connected to an electric transmission assistant mechanism. The multifunctional road pavement groover has four functions of grooving, pavement drying, strong dedusting and groove gap cleaning.

Owner:济南弗格森道路养护技术有限公司

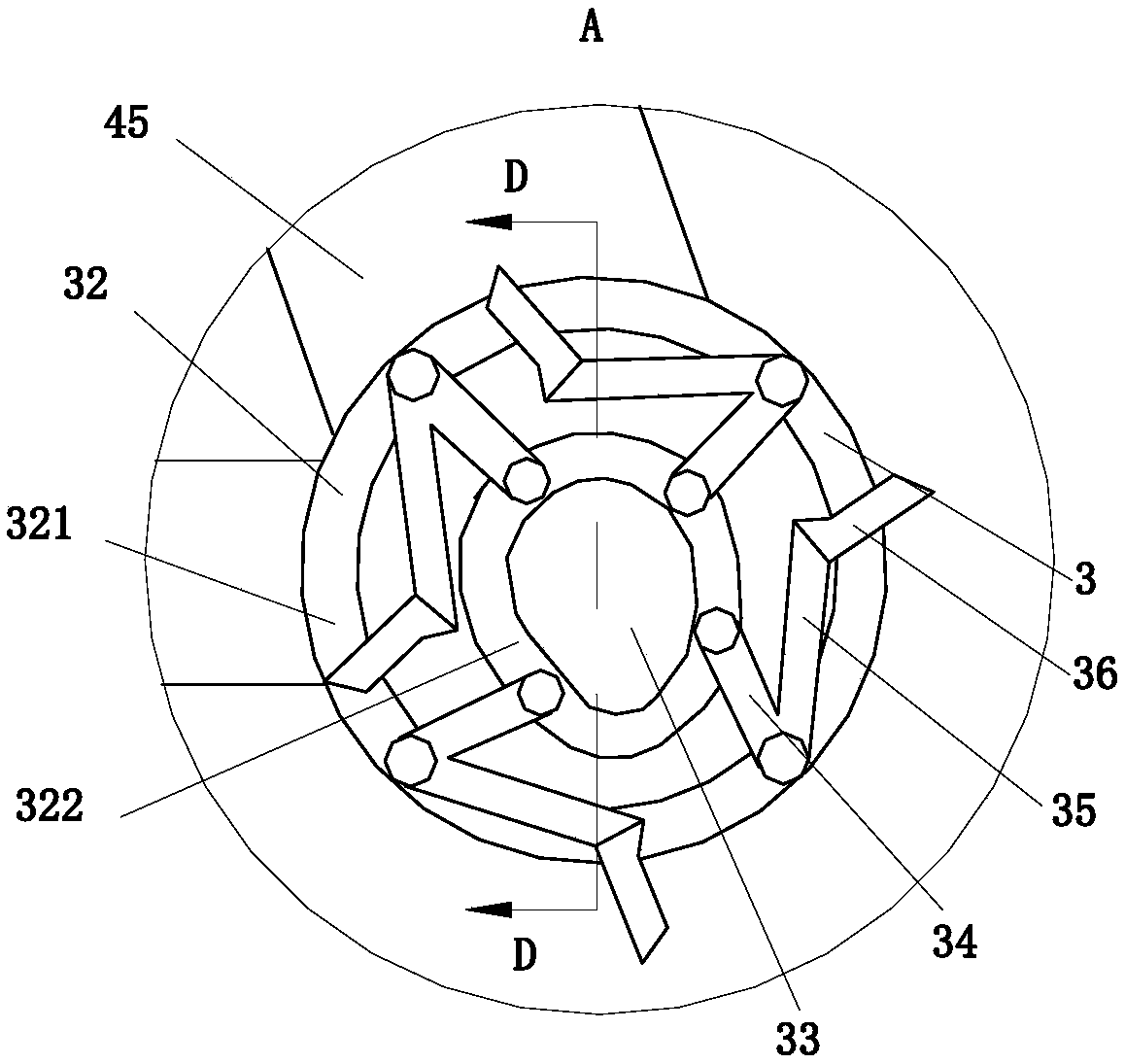

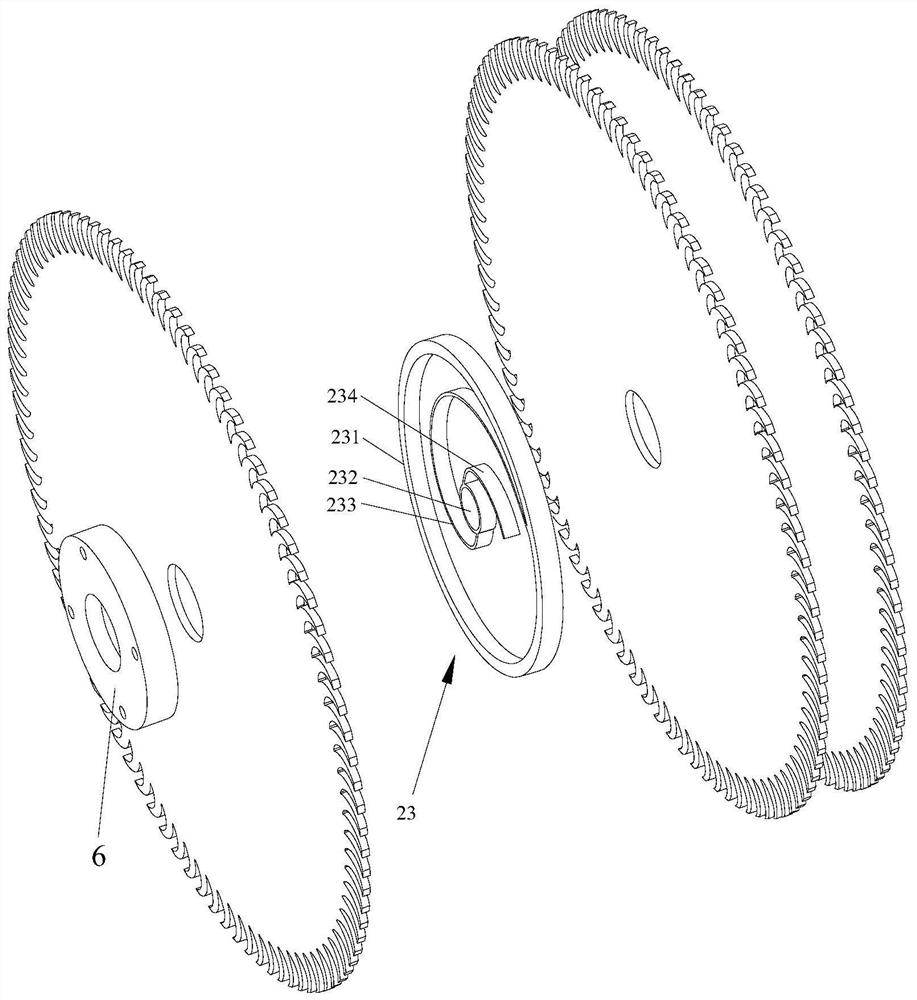

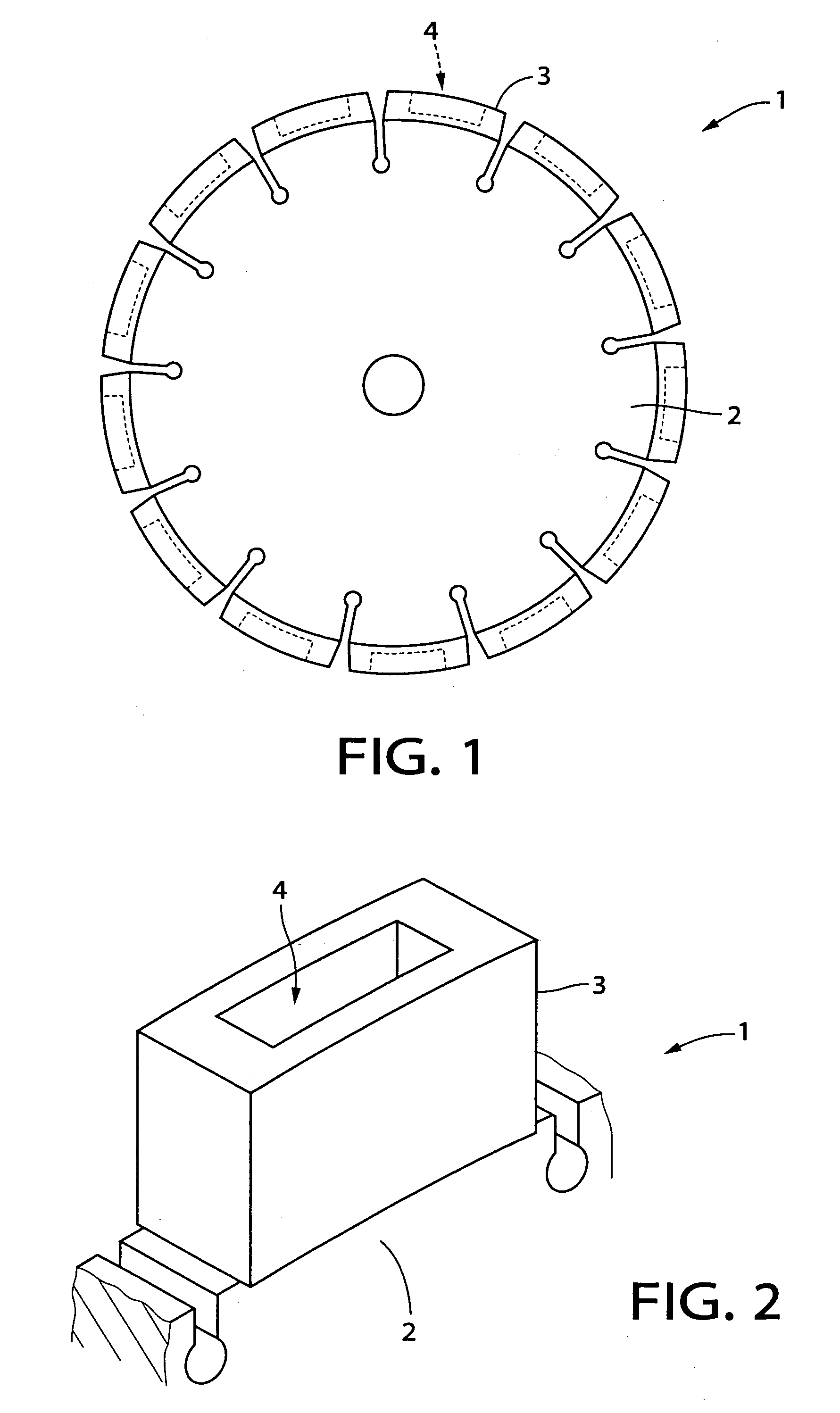

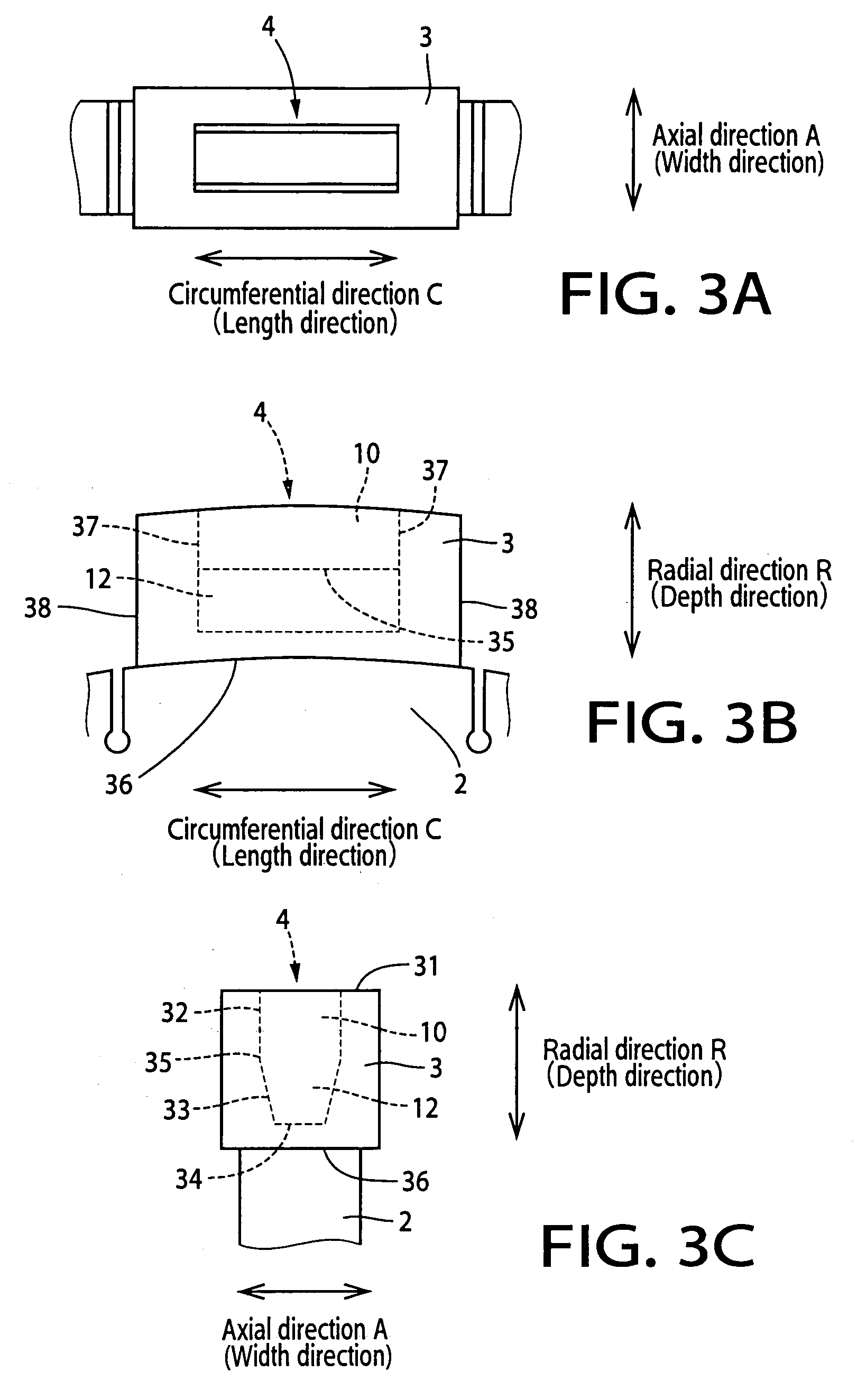

Rotary cutting saw

InactiveUS7021307B1Improve slotting effectLarge widthRevolution surface grinding machinesBonded abrasive wheelsEngineeringMechanical engineering

A rotary cutting saw includes a base disk; and a plurality of abrasive segments which are fixed to an outer circumferential surface of the base disk, and which have respective outer surfaces cooperating with each other to constitute an outer circumferential surface of the rotary cutting saw; wherein each of the abrasive segments has at least one recess opening in the outer surface thereof; wherein each of the at least one recess has a radially outer portion and a radially inner portion which is located inwardly of the radially outer portion as viewed in a radial direction of the base disk; and wherein the radially outer portion has a width that is constant in the radial direction, and the radially inner portion has a width that varies in the radial direction.

Owner:NORITAKE CO LTD +1

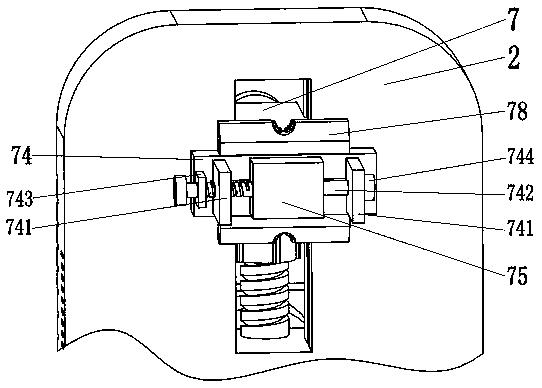

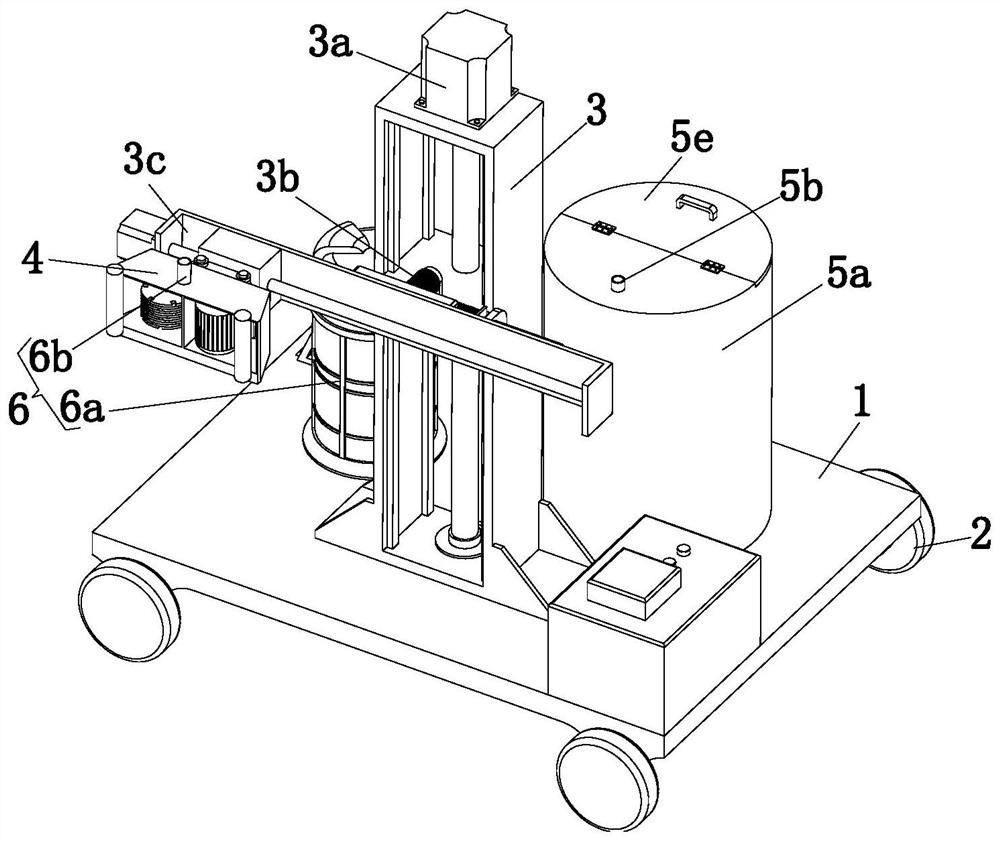

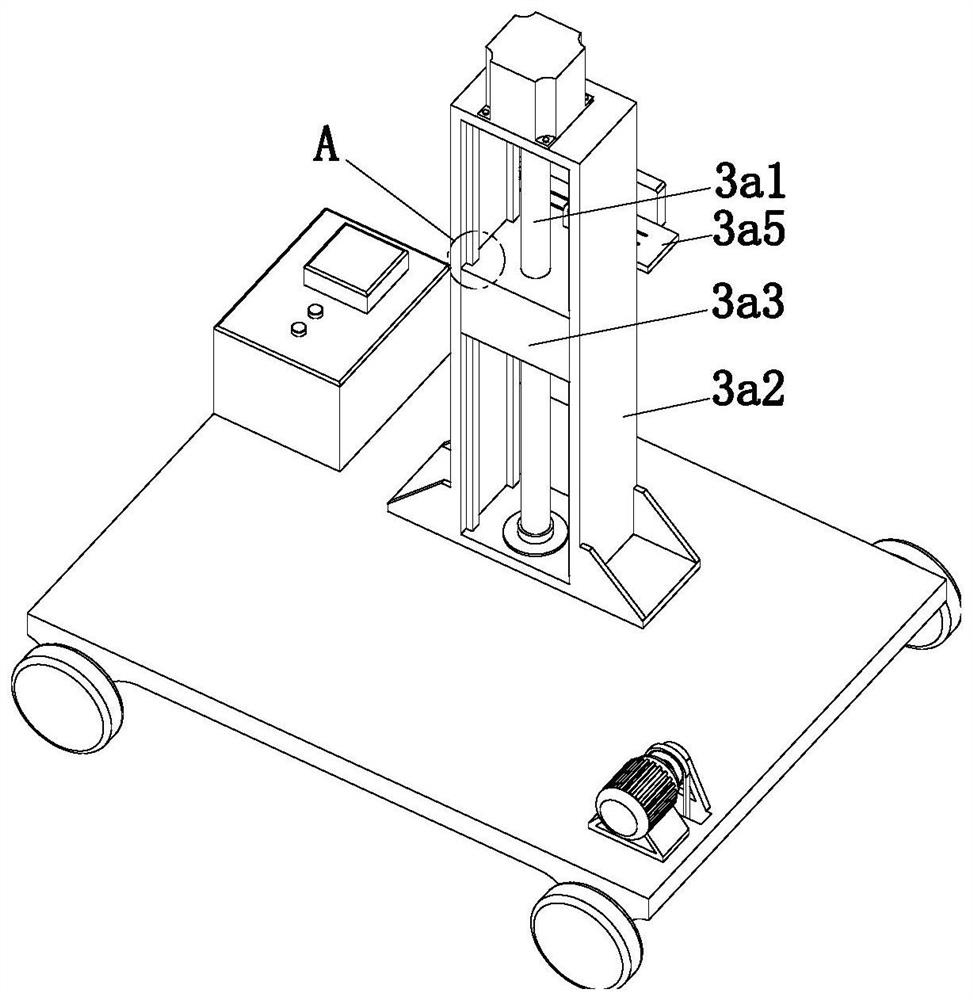

A device for slotting a building wall

ActiveCN109129943BReduce wearImprove slotting effectWorking accessoriesStone-like material working toolsArchitectural engineeringDust control

The invention relates to the technical field of building equipment, in particular to a wall grooving device. The wall grooving device comprises a base, travelling mechanisms, a regulating mechanism, agrooving mechanism, a spraying mechanism and a dust removal mechanism. The travelling mechanisms are installed at the lower end of the base, the regulating mechanism, the spraying mechanism and the dust removal mechanism are all installed on the upper end of the base, and the grooving mechanism is fixedly connected with the regulating mechanism. The regulating mechanism comprises a lifting assembly, a rotating assembly and a moving assembly. The lifting assembly is installed at the upper end of the base, the rotating assembly is installed at the upper end of the lifting assembly, and the moving assembly is fixedly connected with the rotating assembly. The grooving mechanism comprises an installation frame, a driving assembly and a grooving assembly. The installation frame is fixedly connected with the moving assembly, the driving assembly and the grooving assembly are both installed in the installation frame, and the driving assembly is connected with the grooving assembly in a transmission mode. The building wall grooving device has the beneficial effects that flying dust can be effectively reduced, grooving can be carried out at multiple angles, disassembly is convenient, and maintenance is convenient.

Owner:福建辰曦建筑装饰工程有限公司

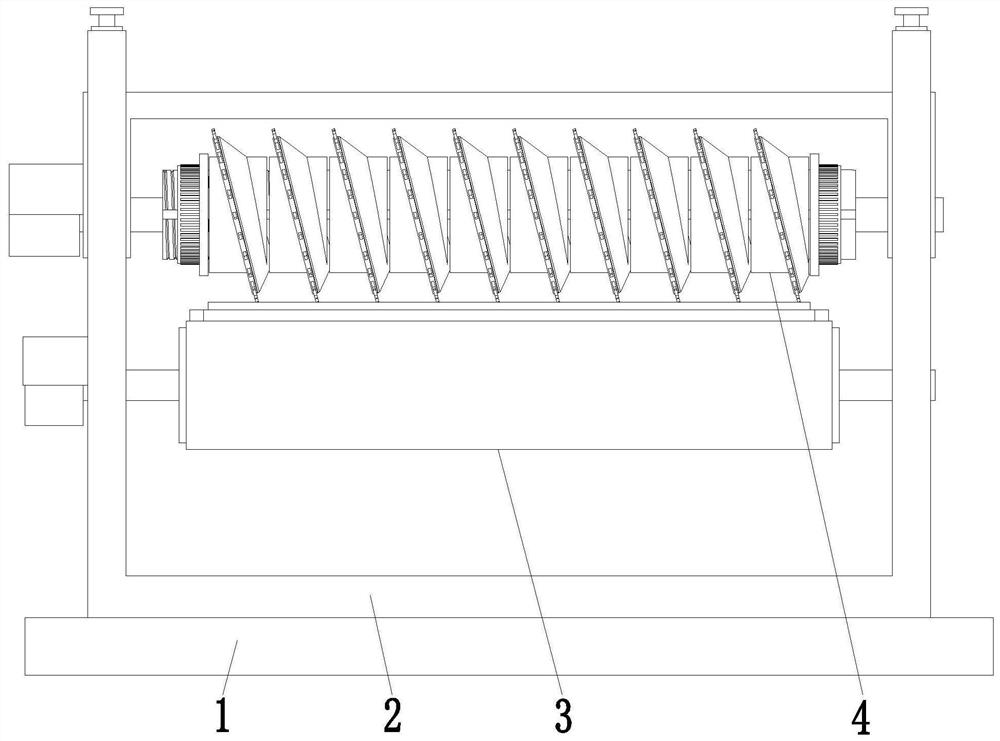

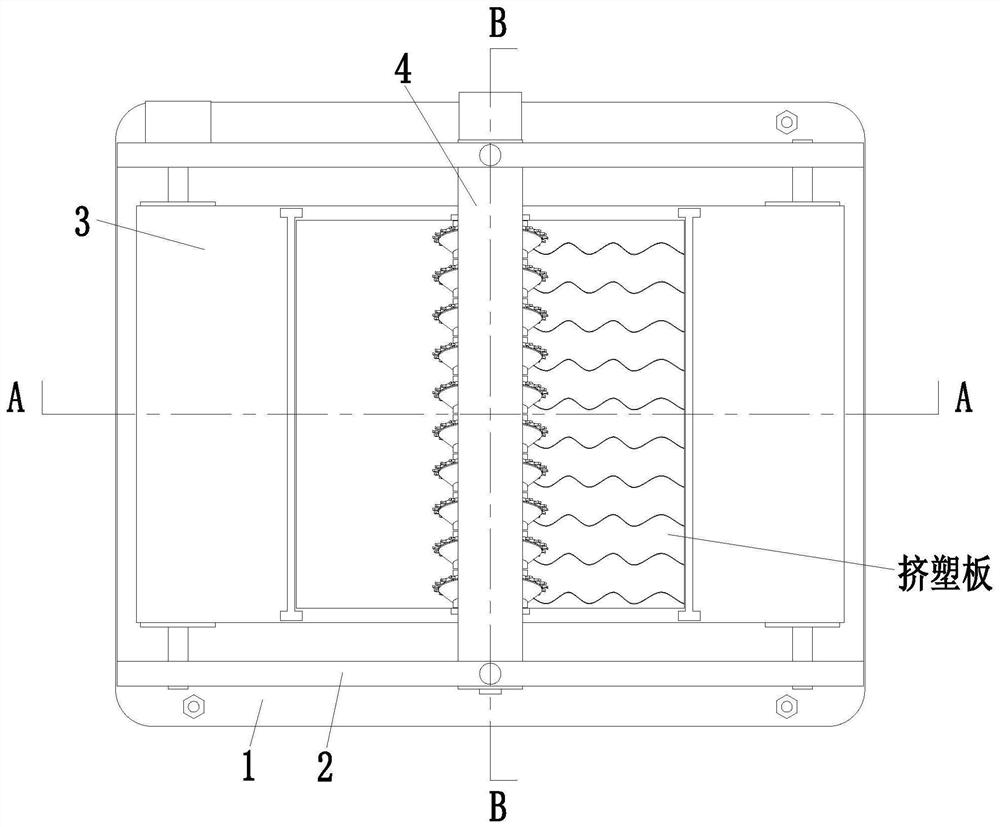

Extruded sheet surface treatment equipment

ActiveCN113172688AAvoid warpingEasy to useMetal working apparatusStructural engineeringMechanical engineering

The invention relates to extruded sheet surface treatment equipment which comprises a bottom plate, a fixing frame, a conveying unit and a treatment unit. The fixing frame is installed at the upper end of the bottom plate, the section of the fixing frame is of a U-shaped structure, the conveying unit is installed at the inner lower end of the fixing frame, the treatment unit is arranged above the conveying unit, and the treatment unit is installed on the fixing frame. The the problems that when surface treatment is conducted on an extruded sheet through existing equipment, the machining treatment effect is poor, generally, only grooving is conducted on the surface of the extruded sheet, an inclined groove cannot be formed, the contact effect of the extruded sheet and mortar is poor, and the phenomenon that the extruded sheet is warped after being used for a long time is still caused; and meanwhile, when existing equipment is used for carrying out surface treatment on the extruded sheet, adjustment cannot be carried out according to the size and thickness of the extruded sheet, the adjustment effect is poor, adjustment is inconvenient, and the subsequent use effect is affected are solved.

Owner:淮北科创节能科技有限公司

Ground grooving equipment for road engineering and construction method thereof

InactiveCN112538809AImprove slotting effectConducive to pipeline constructionUsing liquid separation agentRoad cleaningElectric machineryStructural engineering

The invention discloses a ground grooving equipment for road engineering and a construction method thereof. The ground grooving equipment for road engineering comprises a first plate body, a second plate body is welded to the upper surface of the first plate body, a first limiting sliding groove is formed in one side of the second plate body, and a first limiting sliding block is slidably connected to the inner side wall of the first limiting sliding groove; and a first fixing plate is welded to one side of the first limiting sliding block, a second fixing plate is fixedly connected to the upper surface of the first fixing plate, and a motor is mounted on the upper surface of the second fixing plate.In the process of using the ground grooving equipment, by meshing a first bevel gear with asecond bevel gear, the motor is started to drive the second bevel gear to move, and the first fixing plate and a first L-shaped plate are driven to move to adjust the position of a hob, so that the grooving depth of the ground is adjusted, the grooving depth can be conveniently and accurately adjusted even for workers with weak construction experience, the grooving effect is improved, and subsequent pipeline construction is facilitated.

Owner:王学东 +4

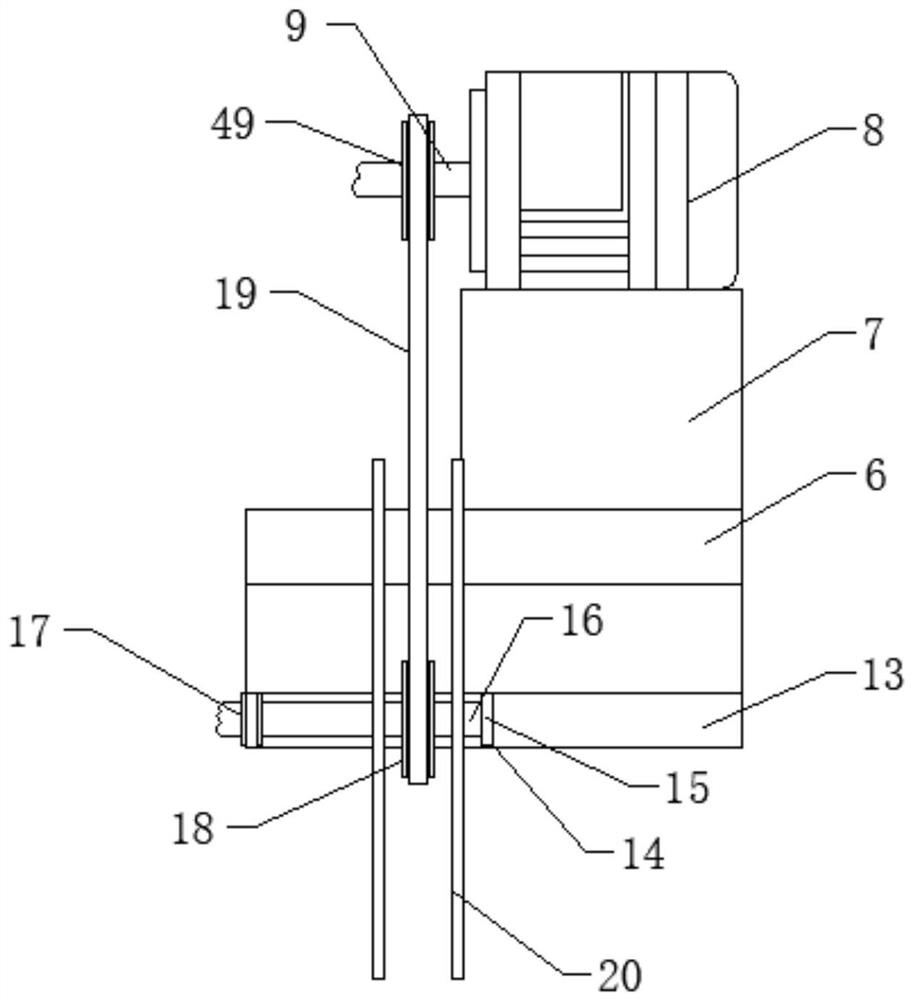

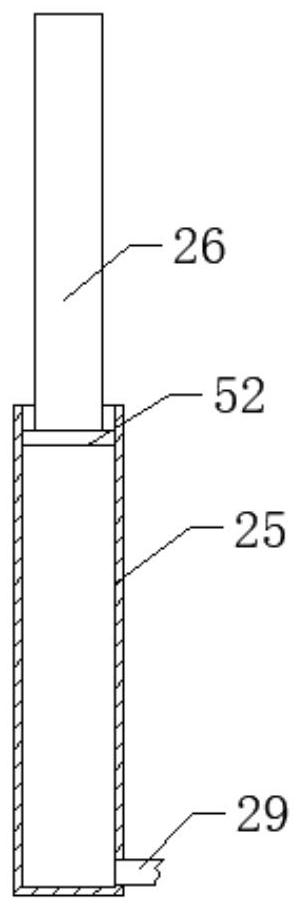

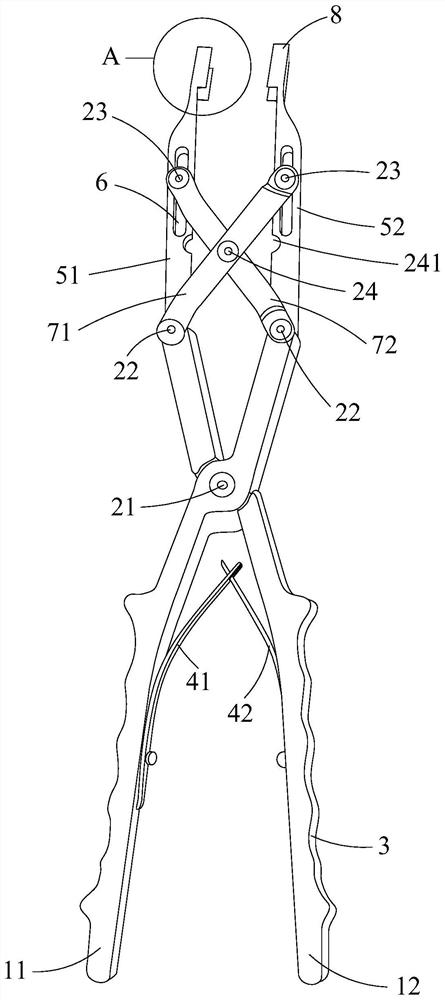

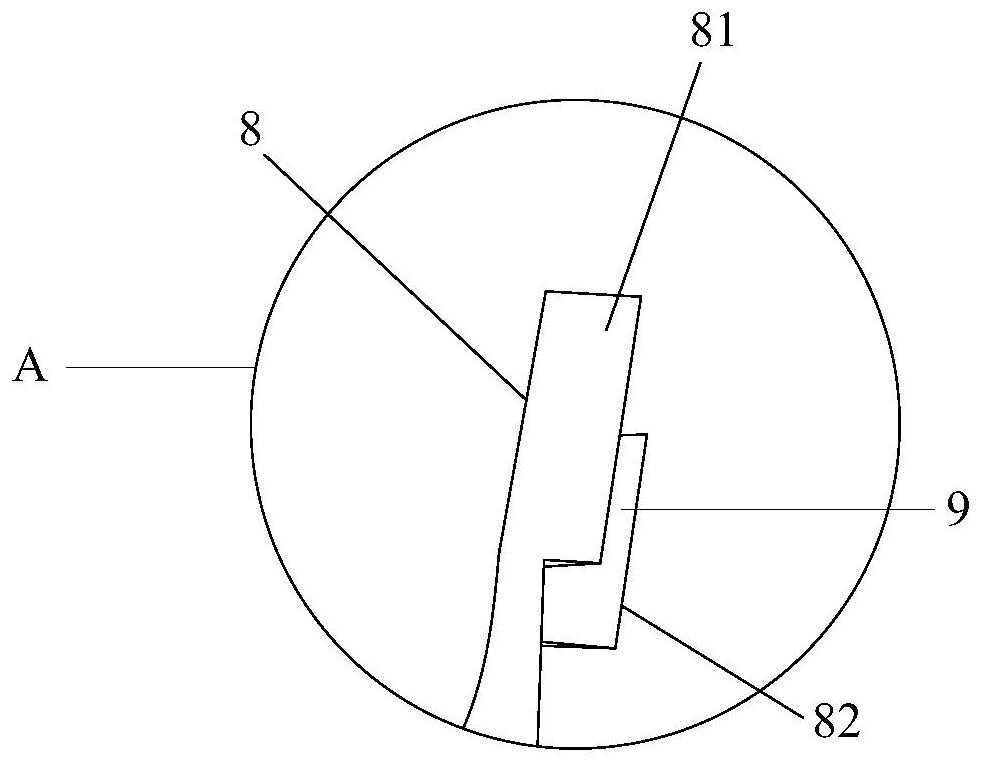

Vertebral advancement slotting tool

The invention relates to a slotting tool for vertebral body advancement, which is provided with a first handle and a second handle hinged in a cross shape by a first hinge shaft, and the distal ends of the first handle and the second handle pass through A second hinge shaft is respectively hinged with the second knife arm and the first knife arm, and each of the first knife arm and the second knife arm is provided with a chute, and a third hinge shaft is arranged in the chute ; The first limiting piece and the second limiting piece are hinged into a cross shape by the fourth hinge shaft, and the two ends of the first limiting piece and the second limiting piece are respectively connected with the corresponding second hinge shaft and the second The three hinged shafts are hinged; the distal ends of the first knife arm and the second knife arm are each provided with a slotting knife, and the slotting knife is provided with a first cutting edge and a second cutting edge protruding inward , the first cutting edge and the second cutting edge are parallel to each other, and the space between them constitutes an accommodating cavity; the distal end surface of the slotting knife is open. The invention has the advantages of quickness, safety and high efficiency when used for notching the vertebral body.

Owner:SECOND AFFILIATED HOSPITAL SECOND MILITARY MEDICAL UNIV

Concrete beam construction operation equipment

ActiveCN110466074BEasy for slotting constructionEasy to adjustWorking accessoriesBridge erection/assemblyConcrete beamsArchitectural engineering

Owner:福建省泷澄建设集团有限公司

A method of repairing damaged asphalt pavement

ActiveCN109082990BImprove securityExtended service lifeDispersed particle separationRoads maintainenceArchitectural engineeringControl cell

The invention belongs to the technical field of road construction, in particular to a method for repairing damaged asphalt pavement. The method adopts a repairing device which comprises a locomotive and a rolling wheel. The utility model also comprises a No. 1 plate, a driving unit, a cutting unit, a control unit and a No. 1 cleaning unit. The rolling roller is used for tamping the asphalt concrete mixture; The cutting unit is used for slotting the damaged part of the pavement; The No. 1 cleaning unit cleans the slotted road surface. On the one hand, the asphalt concrete mixture is completelypoured into the repairing notch, and the pavement is leveled by the rolling roller, so that the driving safety of the vehicle is improved; on the other hand, the asphalt concrete mixture is completelypoured into the repairing notch by the mutual cooperation of the cutting unit, the cleaning unit No. On the other hand, the dust in the pavement cutting is cleaned out of the notch to increase the bonding force between the asphalt concrete mixture and the notch, thus prolonging the service life of the highway pavement.

Owner:江苏雨梦建设有限公司

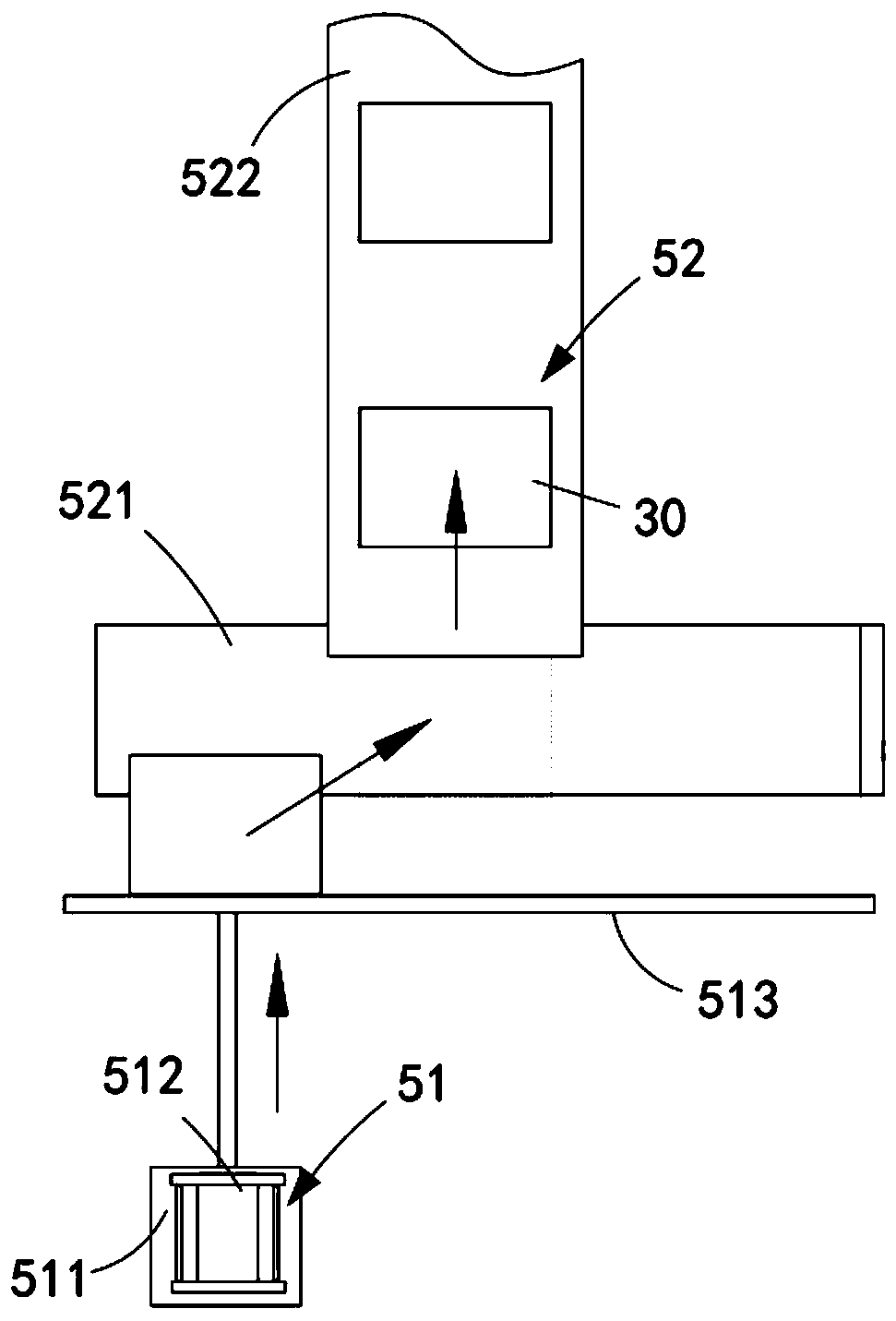

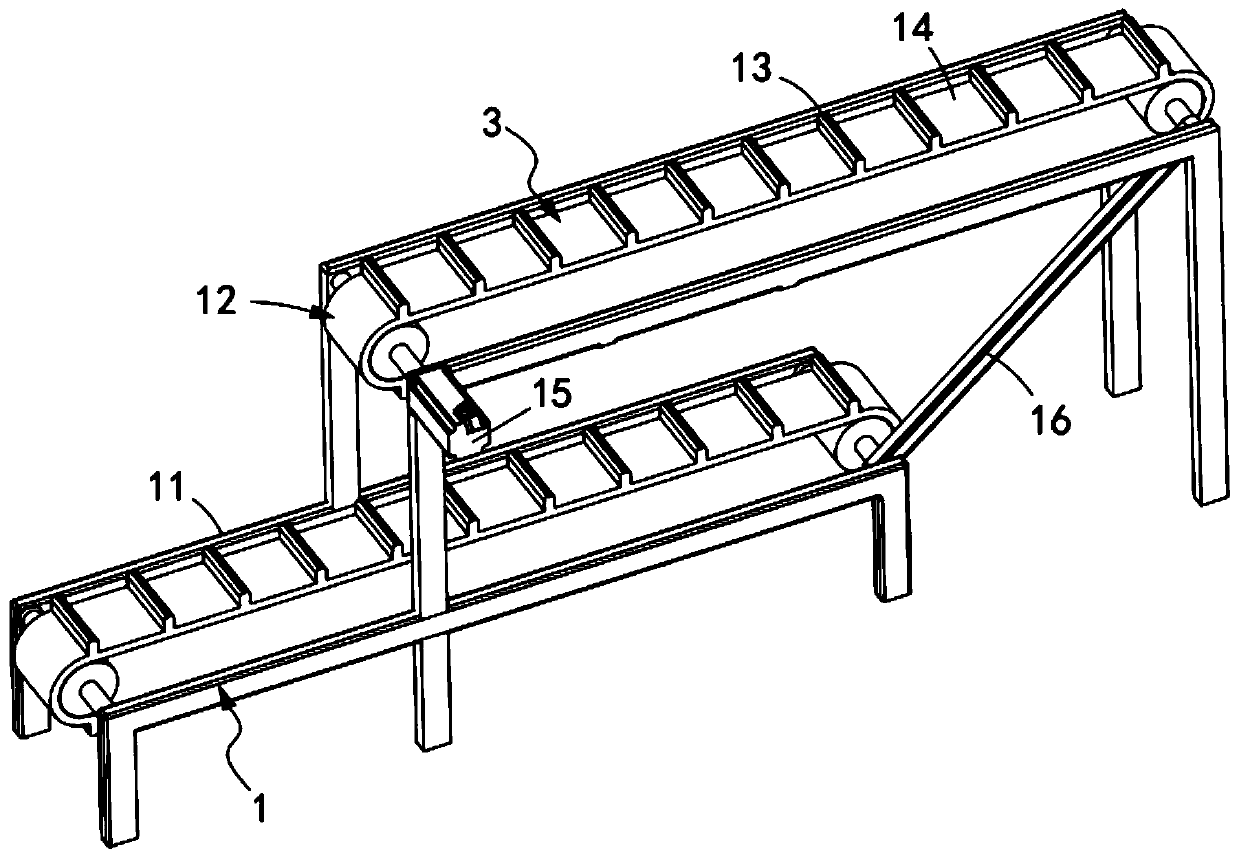

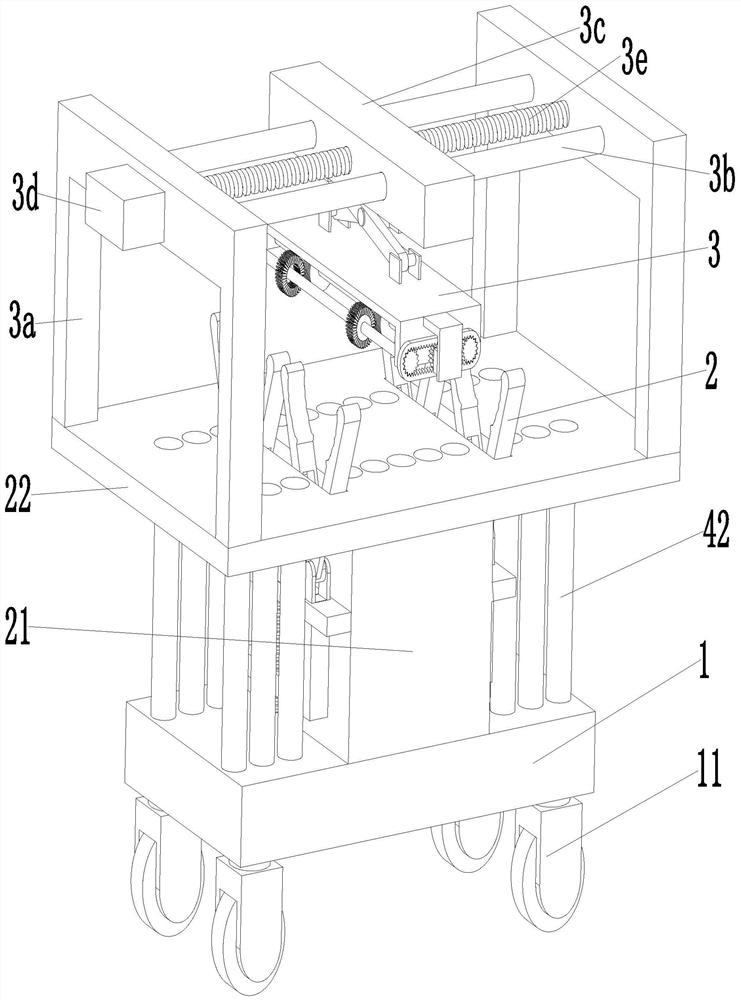

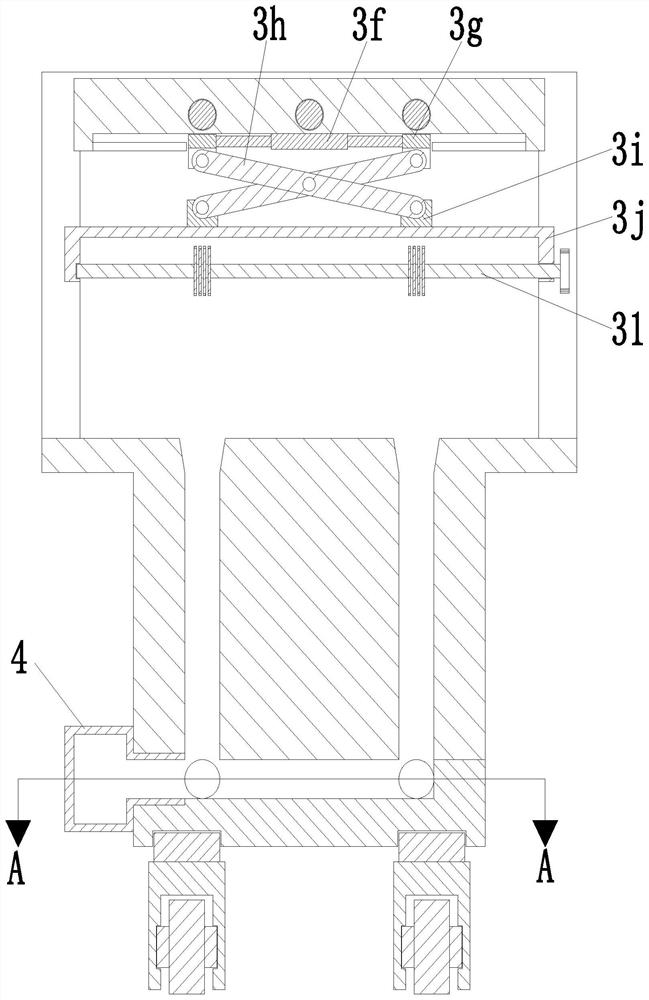

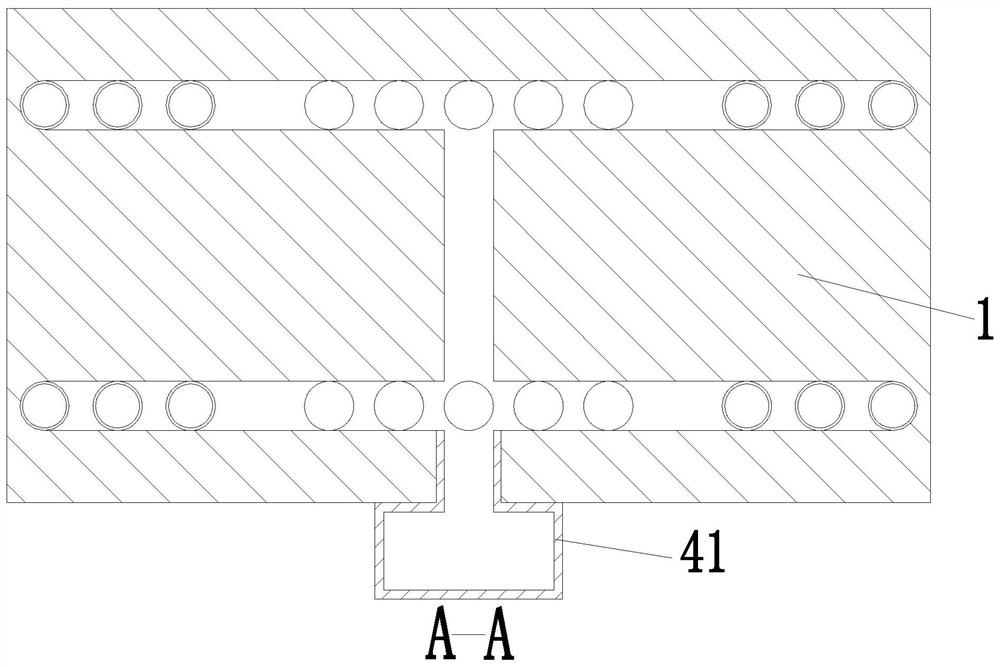

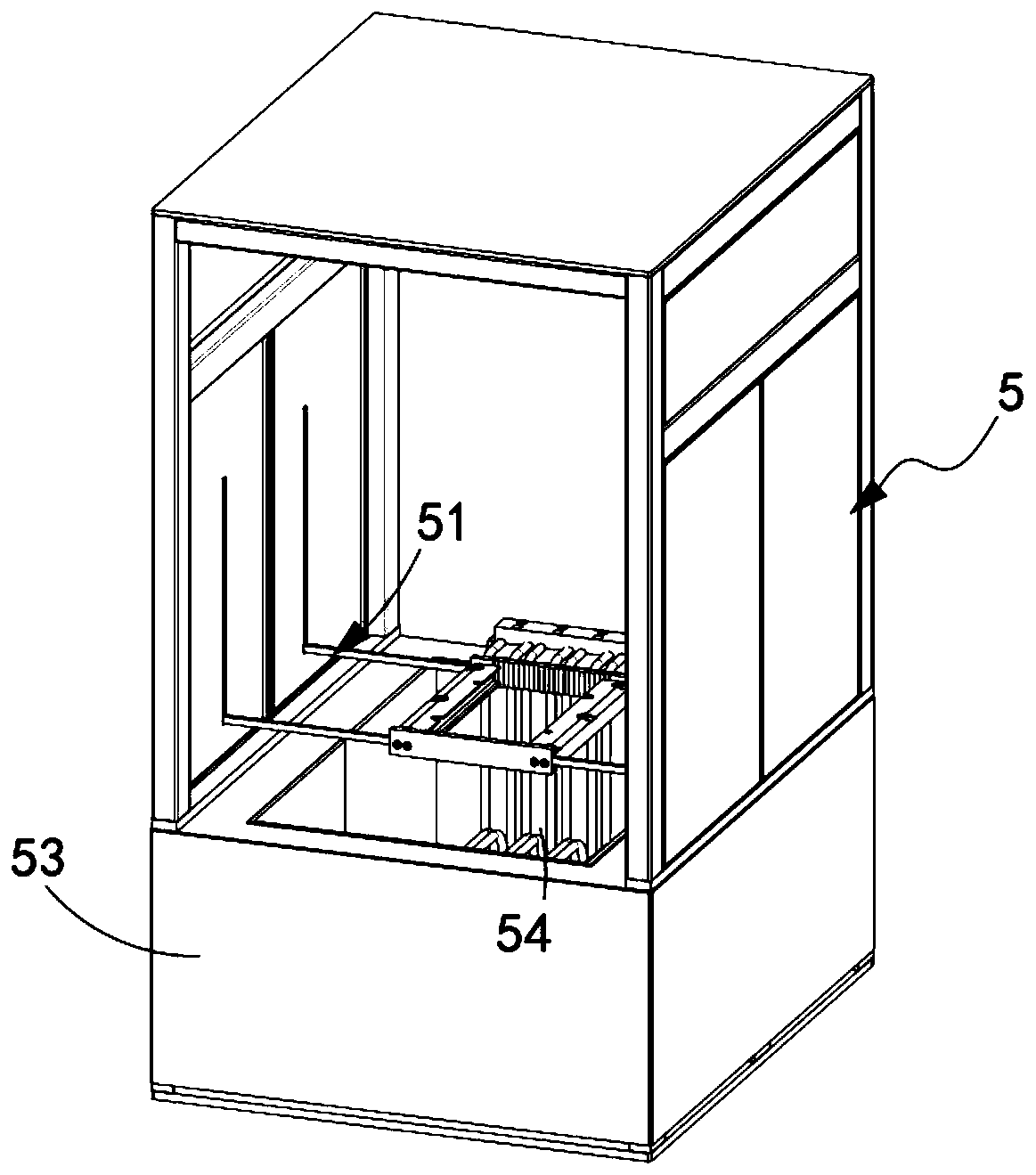

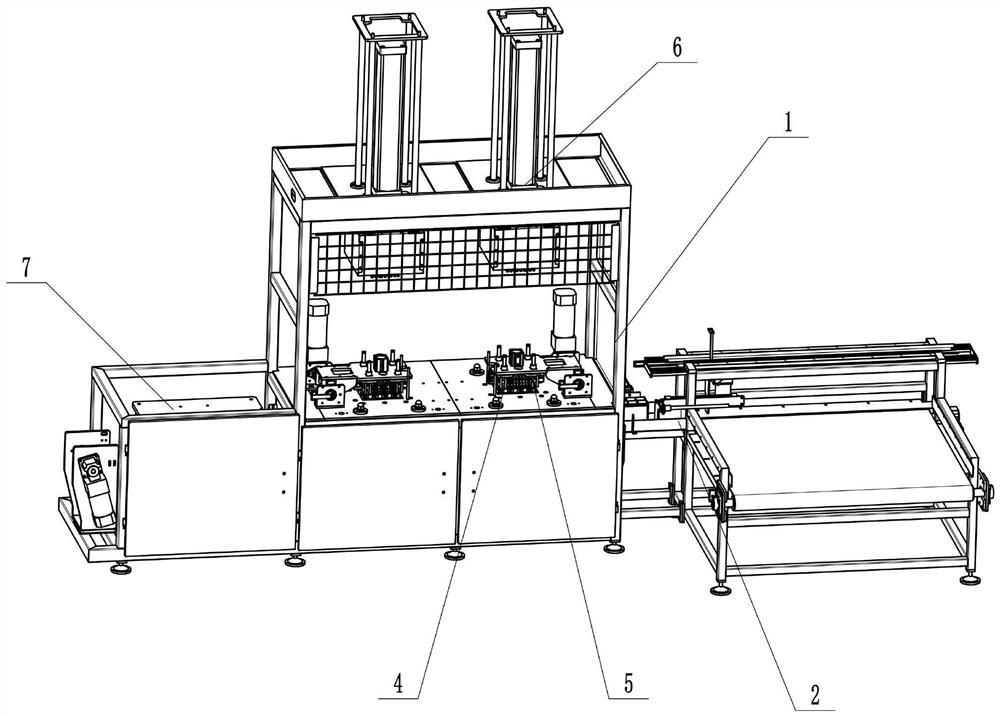

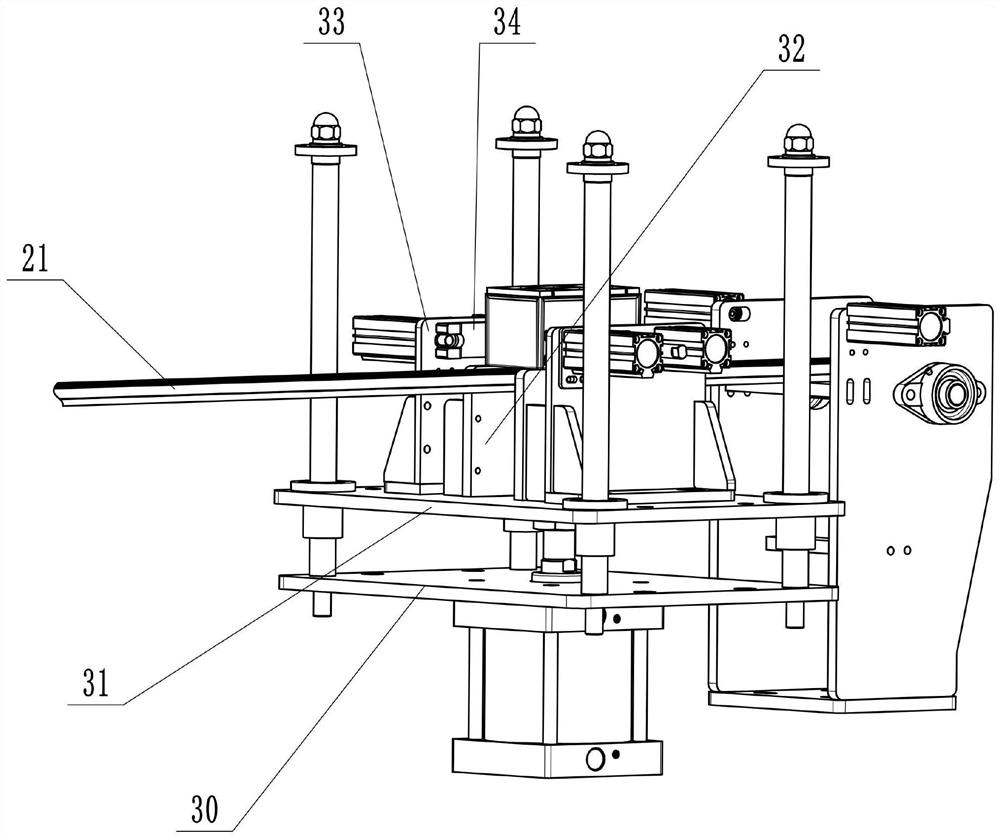

Horizontal groove entering machine capable of achieving secondary groove entering

PendingCN113363596AImprove automation performanceImprove slotting effectFinal product manufactureCleaning using gasesStructural engineeringMachine

The invention discloses a horizontal groove entering machine capable of realizing secondary groove entering, and aims to provide the horizontal groove entering machine capable of realizing secondary groove entering, which can realize secondary groove entering, ensures a good groove entering effect of a pole group and is high in assembling property. The horizontal groove entering machine comprises a channel type support, wherein the support is connected with a plastic shell conveying device, two plastic shell ejecting devices are arranged on the left side of the plastic shell conveying device, a clamp device is arranged above the plastic shell ejecting devices, the plastic shell ejecting devices and the clamp device are arranged in the support, a turnover lug trimming mechanism is arranged above the clamp device, a punching needle mechanism sliding up and down is arranged above the lug trimming mechanism, the lug trimming mechanism and the pin punching mechanism are connected with the support, a secondary groove entering mechanism capable of achieving secondary groove entering is arranged on the left side of the plastic shell ejecting device, and the plastic shell conveying device penetrates through the plastic shell ejecting device and the secondary groove entering mechanism. The horizontal groove entering machine has the beneficial effects that the automation effect is high; the groove entering effect is good due to two groove entering operations, and the pole group is compacted in place in the plastic shell; and it is ensured that there is no sundries or dust during preliminary groove entering, and the sundries and dust are prevented from influencing the functions of the storage battery.

Owner:长兴佳灵机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com