Adjustable edge cutting device for corrugated paperboard

A corrugated cardboard and adjustable technology, applied in the field of machinery, can solve the problems of not having corrugated cardboard, etc., and achieve the effect of better slotting effect, simple structure and precise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

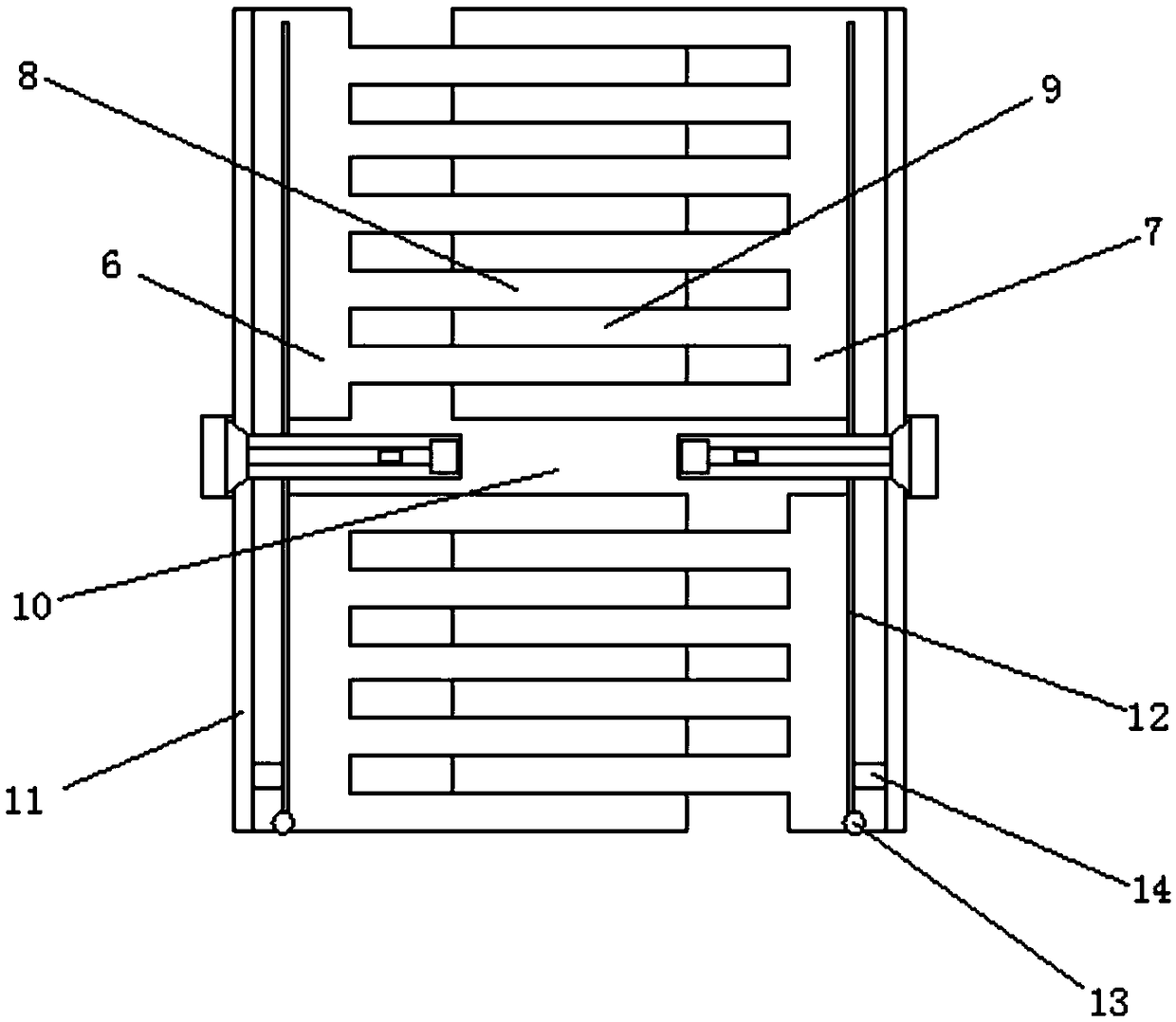

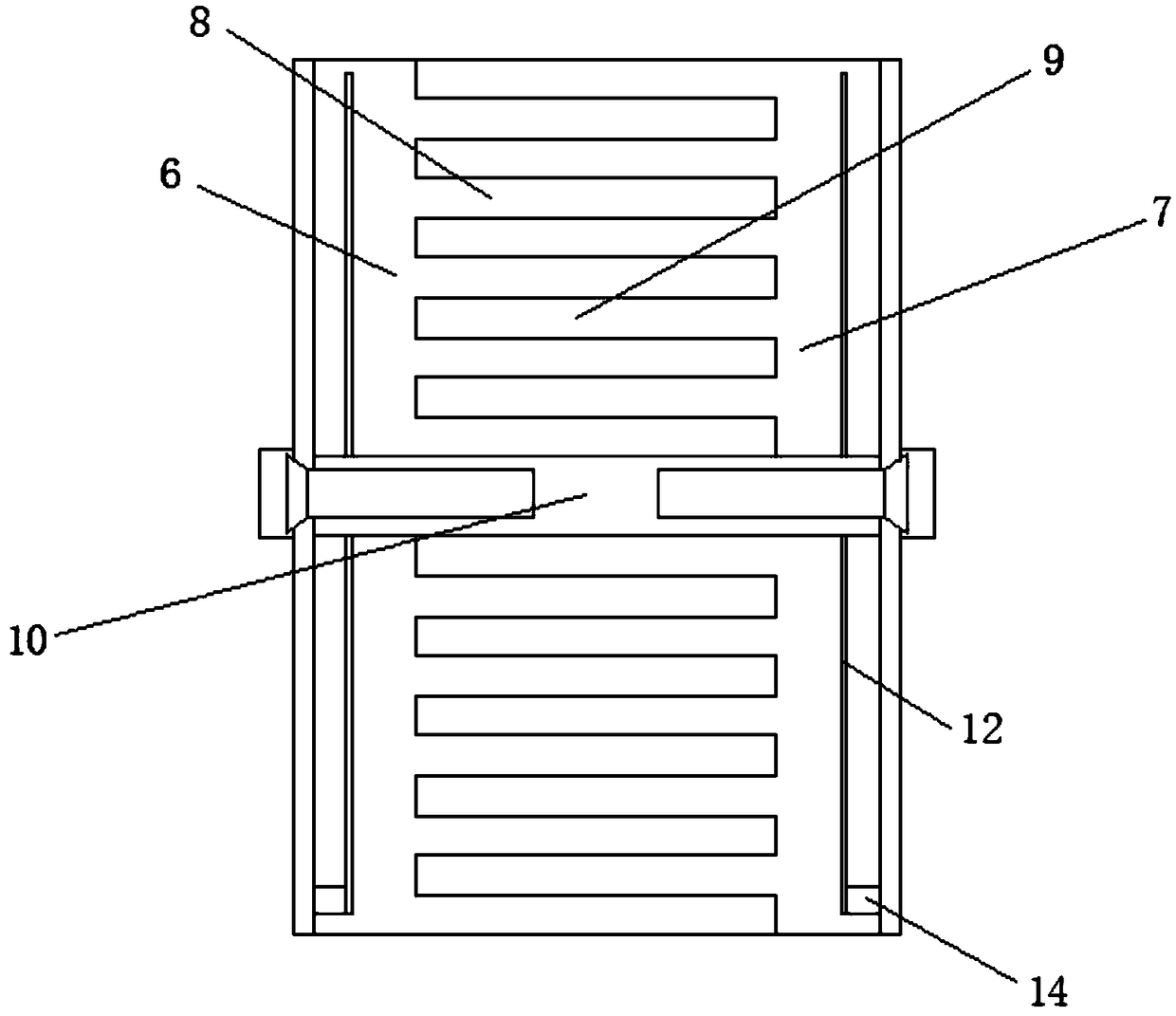

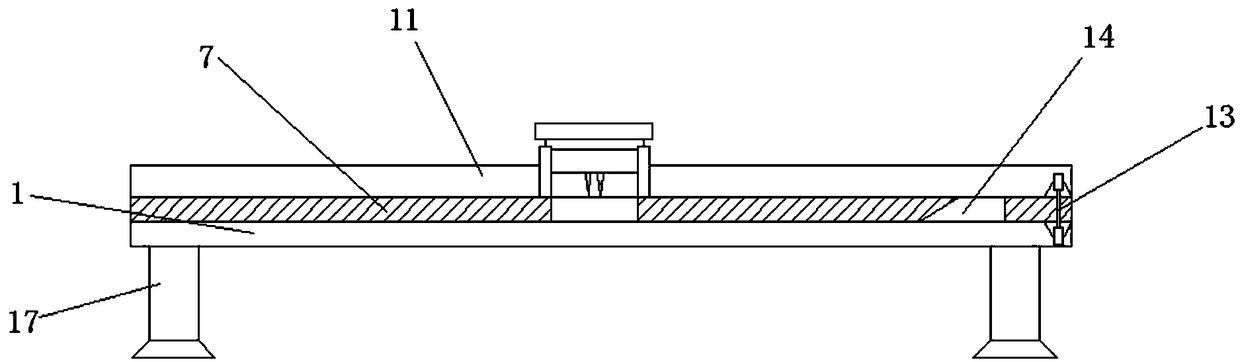

[0028] Example 1: Such as Figure 1-9 As shown, an adjustable edge trimming device for corrugated cardboard includes a base 1, four sets of feet 17 are fixedly installed on the bottom of the platform 1, and a rotating rod 2 is rotatably connected to the top of the base 1, and A rotating handle 18 is fixedly connected to one end of the rod 2, and the left and right parts of the rotating rod 2 are respectively provided with a first thread 3 and a second thread 4, and the first thread 3 and the second thread 4 face oppositely, The first thread 3 and the second thread 4 are respectively movably connected to two groups of mobile platforms 5, and the top of the mobile platforms 5 are respectively fixedly connected to a first stage 6 and a second stage 7, the first Both the middle part of a stage 6 and the middle part of the second stage 7 are provided with a break 10, the right side of the first stage 6 is fixedly connected with a first inserting rack 8, and the second stage A second...

Embodiment 2

[0030] Example 2: Such as Figure 1-11 As shown, an adjustable edge trimming device for corrugated cardboard includes a base 1, four sets of feet 17 are fixedly installed at the bottom of the platform 1, and a rotating rod 2 is rotatably connected to the top of the base 1, and One end of the rod 2 is fixedly connected with a rotating handle 18, the left and right parts of the rotating rod 2 are respectively provided with a first thread 3 and a second thread 4, and the first thread 3 and the second thread 4 are respectively movably connected There are two groups of mobile stations 5, the top of the mobile station 5 is fixedly connected with a first stage 6 and a second stage 7, respectively, the middle of the first stage 6 and the second stage 7 The middle part is provided with a break 10, the right side of the first stage 6 is fixedly connected with a first plug-in rack 8, and the left side of the second stage 7 is fixedly connected with a second plug-in rack 9 , The first plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com