Method for preparing grapheme nano belts by etching carbon nano tubes through water vapor

A technology of graphene nanobelts and carbon nanotubes, which is applied in the direction of graphene, nanocarbon, nanotechnology, etc., can solve the problems of many graphene wrinkles, serious pollution, cumbersome process, etc., and achieve good quality and high yield of nanobelts , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put 0.01g of multi-walled carbon nanotubes with a diameter of 8-15nm into the bottom of a polytetrafluoroethylene inner substrate with a volume of 20mL, add 100μL of distilled water into it, oscillate to spread the nanotubes evenly, and then seal the inner liner into the Stainless steel reactor. Put the reaction kettle into a blast drying oven, set the temperature to 200°C, and react at a constant temperature for 5 hours. After the reaction, the sample is taken out, dried under an infrared lamp, and the graphene nanobelt can be obtained after the water evaporates completely.

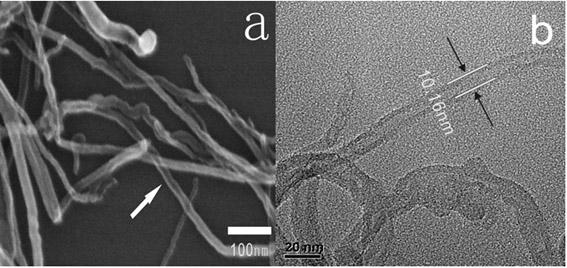

[0023] The samples were analyzed by scanning electron microscopy, and the results were as follows: figure 1 as shown in a. from figure 1 a It can be seen that a small part of the multi-walled carbon nanotubes is cracked to form graphene nanoribbons. The dark part is the graphene nanoribbon formed by the carbon nanotubes being etched by water vapor, and the bright part is the original carbon nan...

Embodiment 2

[0025] Put 0.02g of multi-walled carbon nanotubes with a diameter of 8-15nm into the bottom of a polytetrafluoroethylene inner substrate with a volume of 20mL, add 200μL of distilled water into it, oscillate to spread the nanotubes evenly, and then seal the inner liner into the Stainless steel reactor. Put the reaction kettle into a blast drying oven, set the temperature to 225° C., and react at a constant temperature for 10 hours. After the reaction, the sample is taken out, dried under an infrared lamp, and the graphene nanobelt can be obtained after the water evaporates completely.

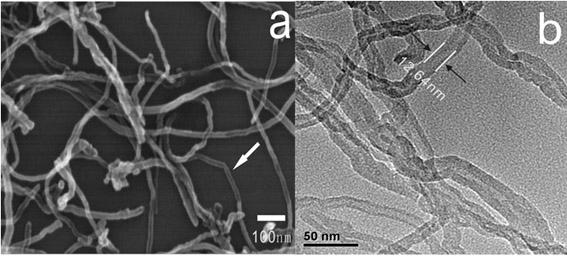

[0026] The samples were analyzed by scanning electron microscopy, and the results were as follows: figure 2 as shown in a. from figure 2 a It can be seen that the multi-walled carbon nanotubes are partially cracked to form graphene nanoribbons. The dark part is the graphene nanoribbon formed by the carbon nanotubes being etched by water vapor, and the bright part is the original carbon nan...

Embodiment 3

[0028] Put 0.005g of multi-walled carbon nanotubes with a diameter of 8-15nm into the bottom of a polytetrafluoroethylene inner substrate with a volume of 20mL, add 200μL of distilled water into it, oscillate to spread the nanotubes evenly, and then seal the inner liner into the Stainless steel reactor. Put the reaction kettle into a blast drying oven, set the temperature to 150° C., and react at a constant temperature for 10 hours. After the reaction, the sample is taken out, dried under an infrared lamp, and the graphene nanobelt can be obtained after the water evaporates completely.

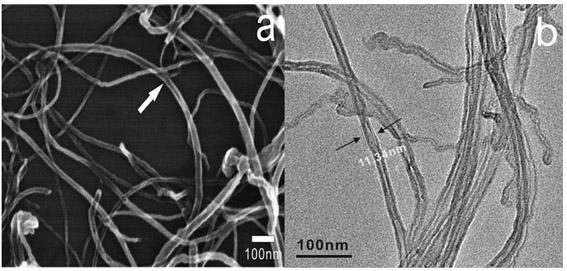

[0029] The samples were analyzed by scanning electron microscopy, and the results were as follows: image 3 as shown in a. from image 3 a It can be seen that the multi-walled carbon nanotubes are partially cracked to form graphene nanoribbons. The dark part is the graphene nanoribbon formed by the carbon nanotubes being etched by water vapor, and the bright part is the original carbon nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com