Post-processing equipment for storage battery pole group

A battery and pole group technology, applied in the field of battery pole group post-processing equipment, can solve problems such as unfavorable separate processing and packaging, and achieve the effects of high degree of automation, good slotting effect, and power output saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

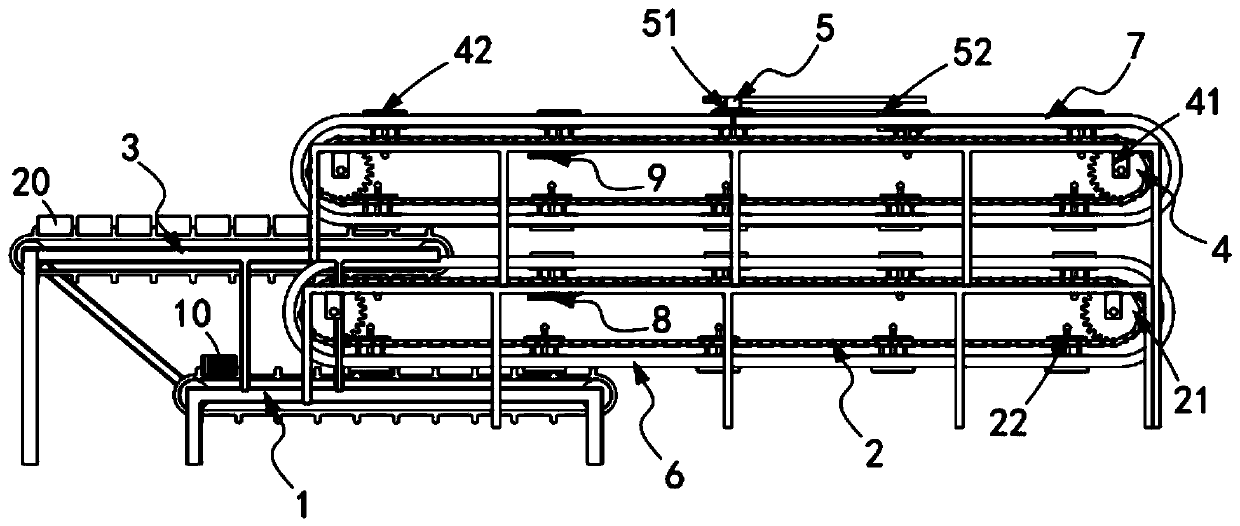

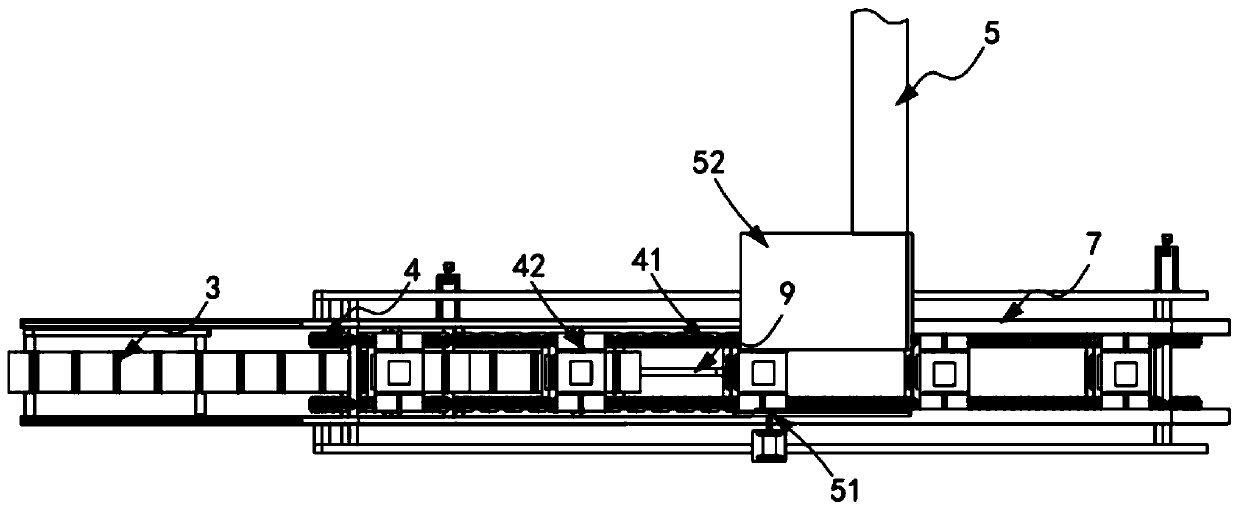

[0056] Such as figure 1 , figure 2 As shown, a battery pole group post-processing equipment includes:

[0057] The pole group transmission mechanism 1, the pole group transmission mechanism 1 is used to sequentially transport several groups of pole groups 10 backward;

[0058] The pole group clamping mechanism 2, the pole group clamping mechanism 2 is located above the pole group transmission mechanism 1, and it includes a first transmission assembly 21 and a number of equidistant along the transmission direction of the first transmission assembly 21. A first tightening component 22 assembled and installed on the first conveying component 21;

[0059] A shell transmission mechanism 3, which is located above the pole group clamping mechanism 2, and is used to sequentially transport several groups of battery shells 20 backwards;

[0060] The shell clamping mechanism 4, the shell clamping mechanism 4 is located above the shell transmission mechanism 3, it includes a second tr...

Embodiment 2

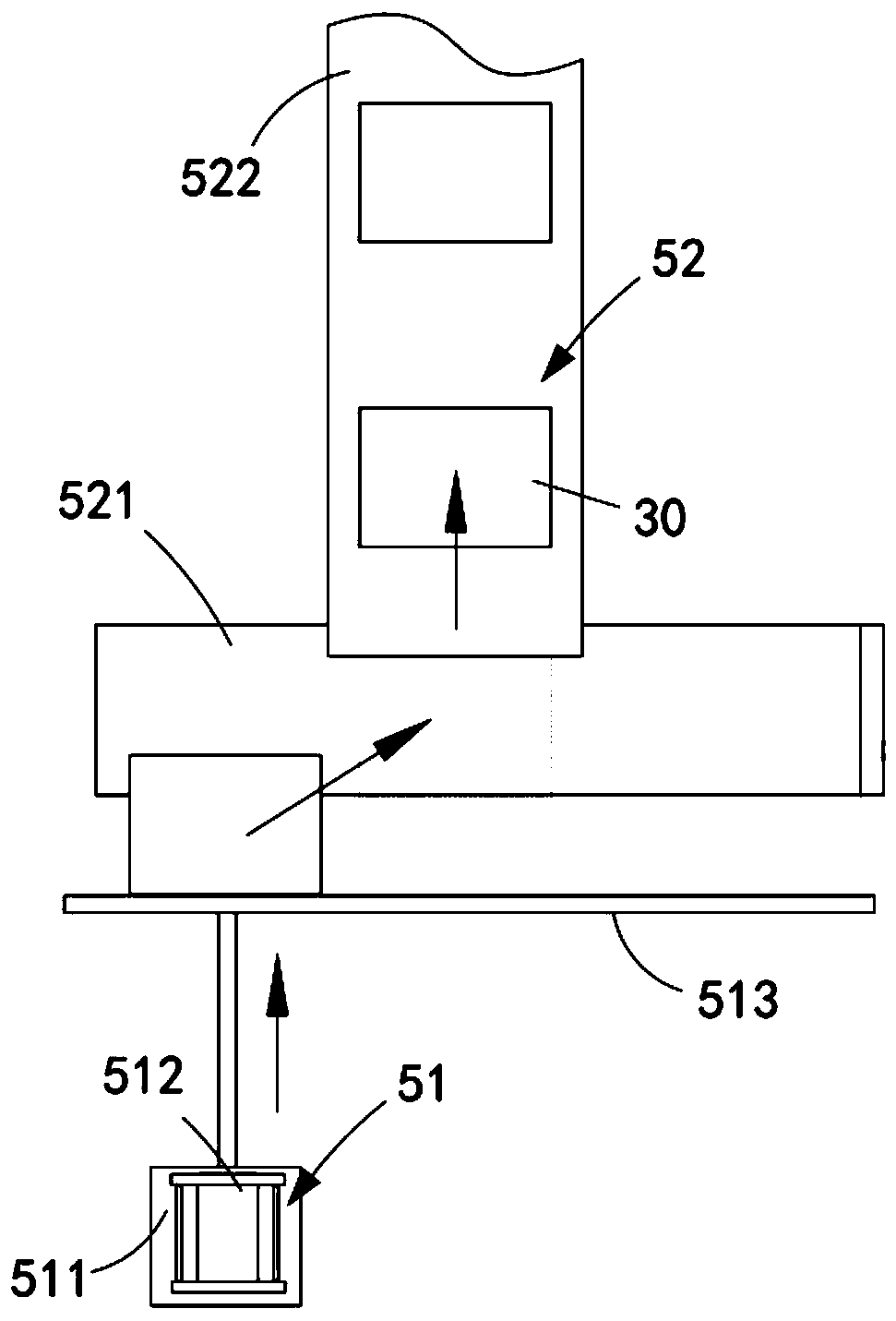

[0087] Such as Figure 4 , Figure 5 and Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0088] further, such as Figure 4 , Figure 5 and Figure 6 As shown, the first tightening assembly 22 and the second tightening assembly 42 both include:

[0089] Base 221, the base 221 is installed on the sprocket chain unit 212 and the sliding seat 81 is vertically slidably arranged on the base 221, the lower end of the base 221 is provided with a support rod 222, the two sides of the base 221 A support rod 222 is arranged on the side, and the end of the support rod 222 is slidably arranged in the limit groove on the machine tool 211. The installation plate 83 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com