New energy automobile cable cutting and packaging device

A new energy vehicle and cable technology, applied in packaging and other directions, can solve problems such as reducing the efficiency of cable packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

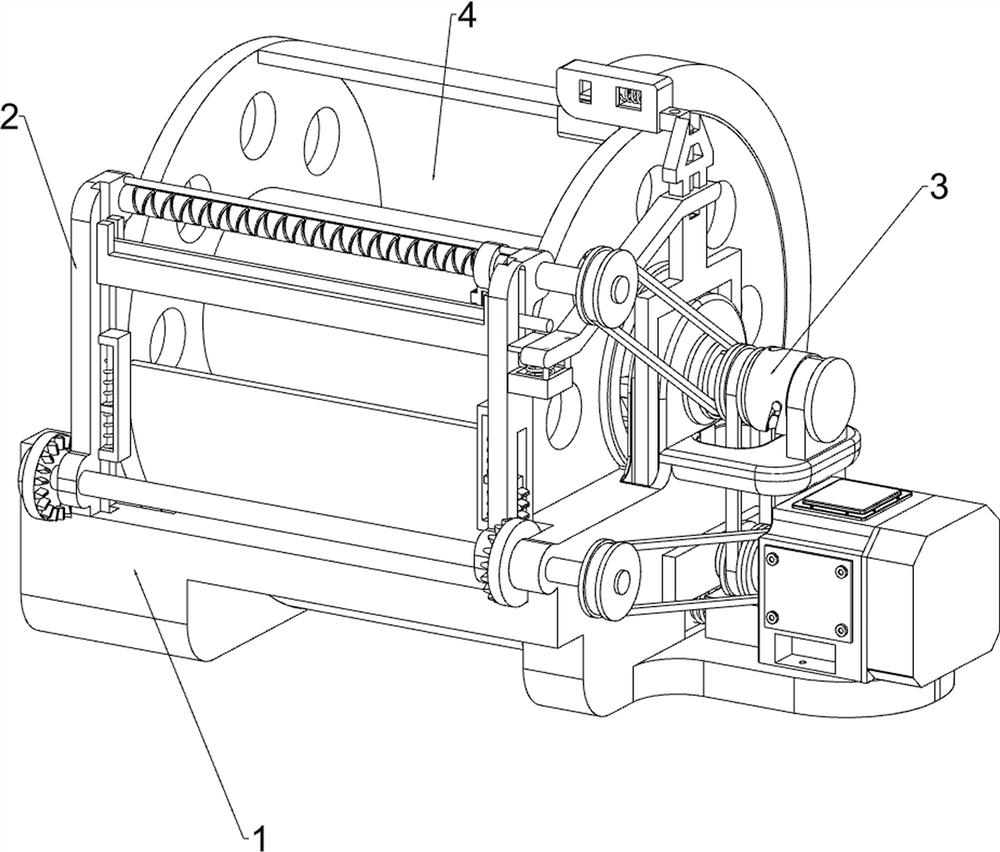

[0028] A new energy vehicle cable cutting and packaging device, such as Figure 1 to Figure 4 As shown, it includes a base 1, a support frame 2, a rotating and fixing mechanism 3 and a packaging mechanism 4. The front side of the base 1 is connected with a supporting frame 2, and the base 1 is provided with a rotating and fixing mechanism 3. A packing mechanism 4 is provided.

[0029] When it is necessary to cut and pack the new energy vehicle cables, the packing mechanism 4 can be placed on the rotating fixing mechanism 3, and then one end of the cable is fixed in the packing mechanism 4, and then the rotating fixing mechanism 3 is controlled to drive the packing mechanism 4 to carry out Rotate so that the cables are rolled up, and when enough cables are rewound in the packing mechanism 4, the cables can be cut off, and then the packing mechanism 4 can be taken off to complete the packing work of the cables.

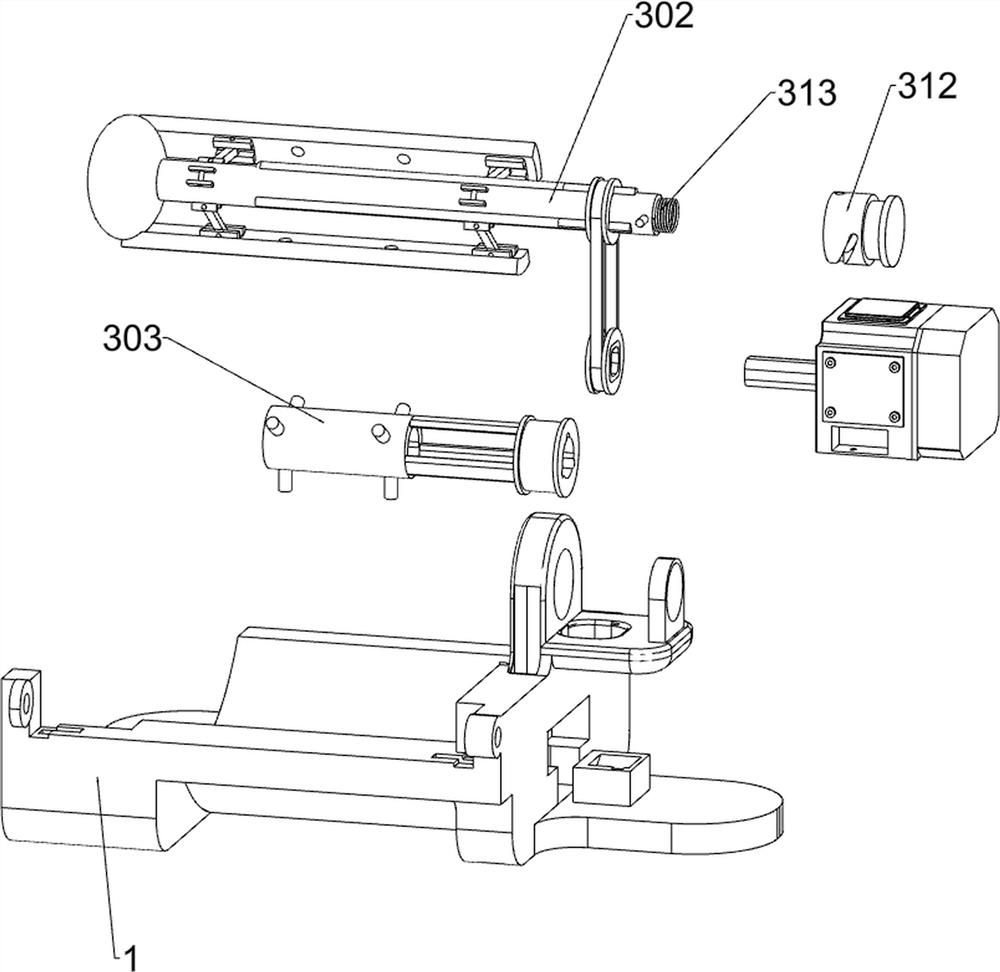

[0030] The rotation fixing mechanism 3 includes a shaft seat 301,...

Embodiment 2

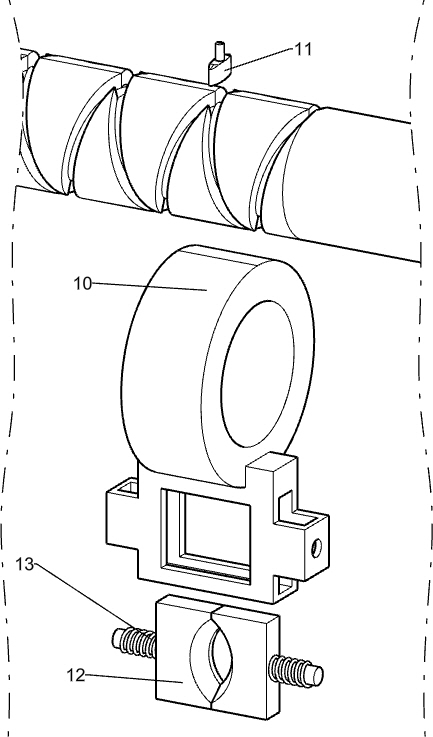

[0035] On the basis of Example 1, such as Figure 5 to Figure 8 As shown, it also includes a wedge block 5, a guide post 6 and a second elastic member 7, the upper right side of the winding barrel 401 is slidingly provided with a guide post 6, the right side of the guide post 6 is connected with a wedge block 5, and the guide post 6 is connected to the right side of the guide post 6. A second elastic member 7 is connected between the winding barrels 401 .

[0036] When one end of the cable needs to be fixed on the winding barrel 401, the wedge block 5 and the guide post 6 can be moved to the left, the second elastic member 7 is compressed, and then one end of the cable can be placed on the winding barrel 401 On the right side of the upper part, the wedge block 5 and the guide post 6 can then be released, and the second elastic member 7 will rebound to drive the wedge block 5 and the guide post 6 to reset, and the wedge block 5 will fix one end of the cable.

[0037] Also incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com