Flatness detection packaging device

A technology of flatness detection and roll packaging, which is applied in the field of machinery, can solve the problems of low work efficiency and low accuracy of manual detection of flatness, and achieve the effect of improving accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

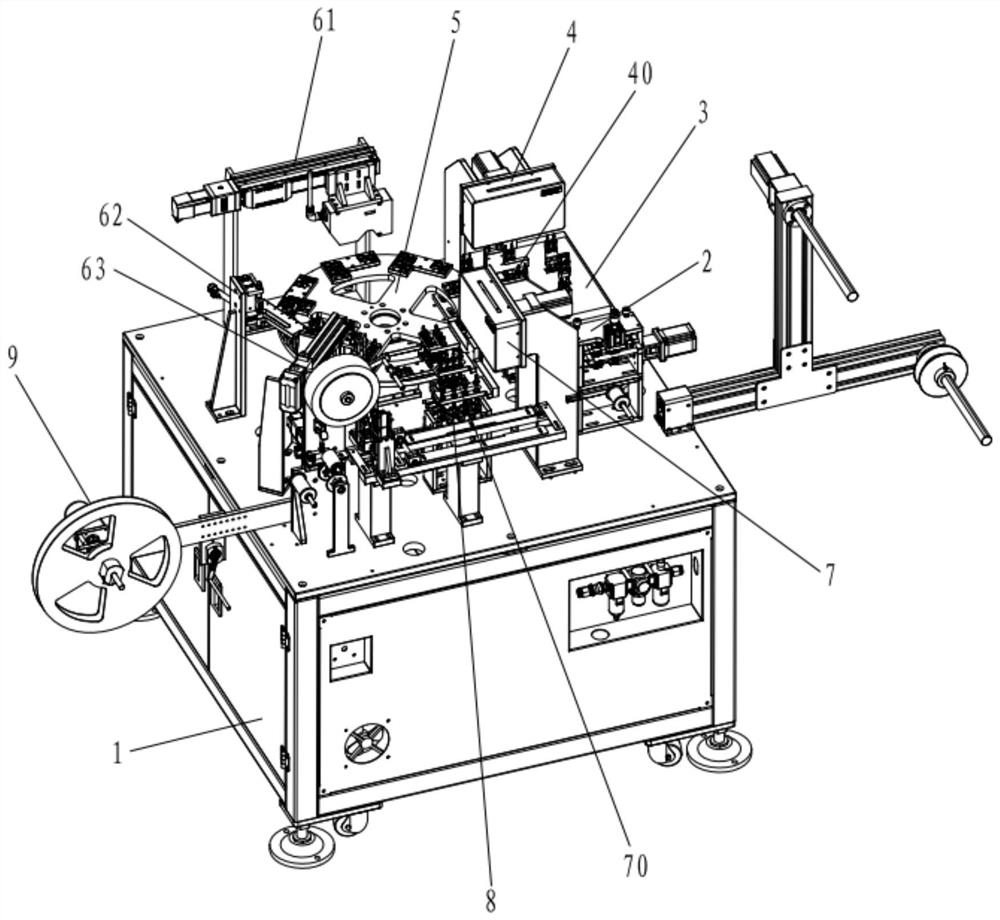

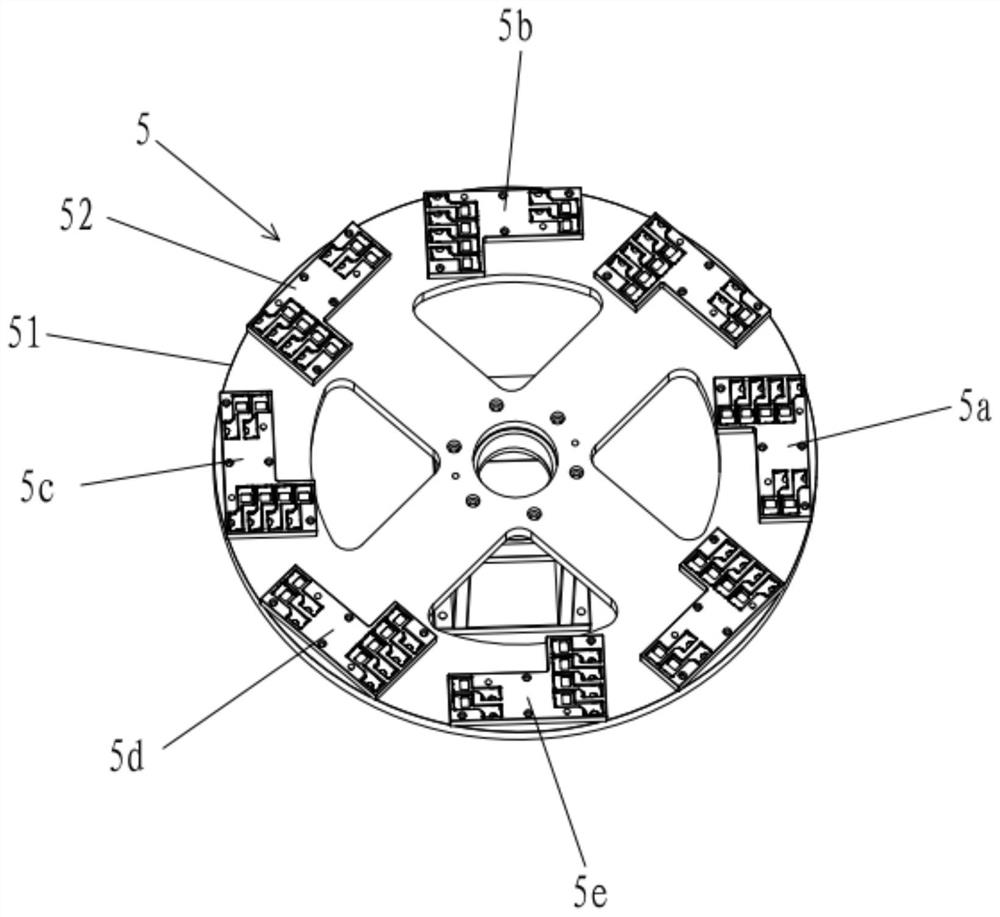

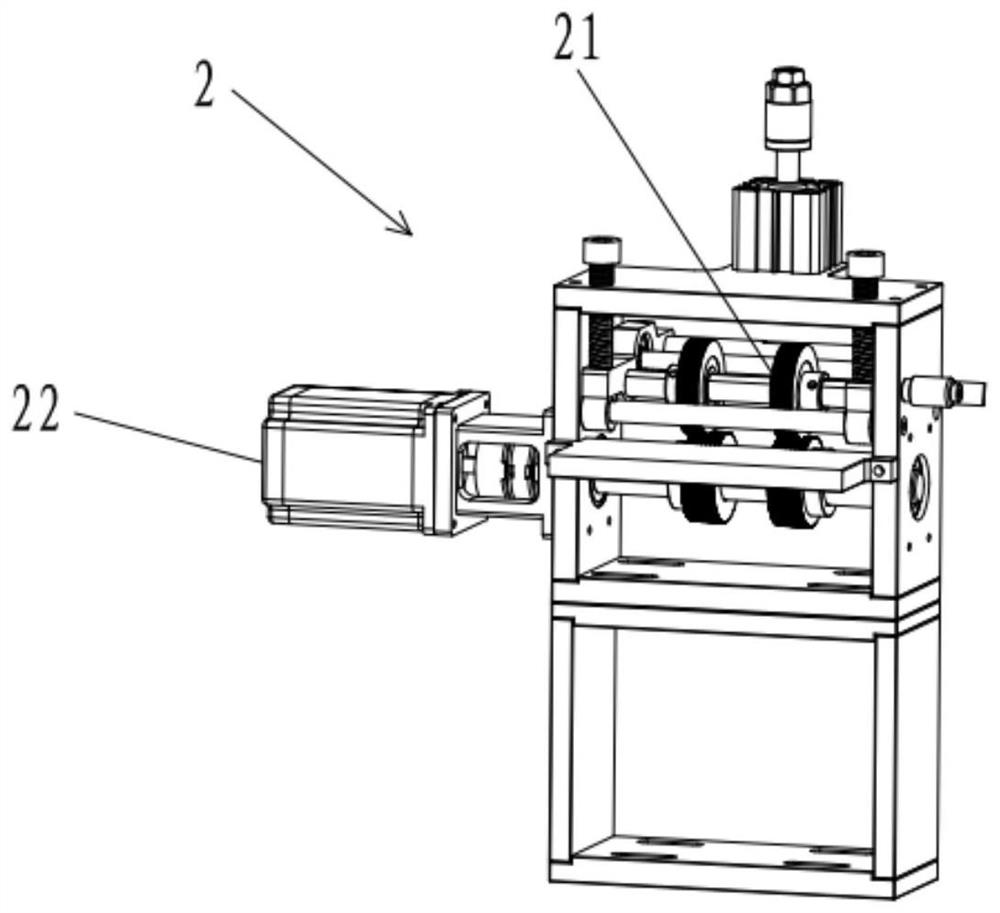

[0051] refer to Figure 1 to Figure 16 , a flatness detection and packaging device, including a feed mechanism 5, the feed mechanism 5 includes a turntable 51, and the turntable 51 is sequentially provided with a loading station 5a, a detection station 5b, a waste discharge station 5d and a blanking station 5e, the above-mentioned Corresponding placement jigs 52 are provided at each station;

[0052] The detection station 5b is provided with a 3D line scanning detection mechanism 61;

[0053] A waste discharge mechanism 63 is provided at the waste discharge station 5d.

[0054] To further illustrate, the placement jig 52 includes a first placement area 52a, a second placement area 52b and a third placement area 52c;

[0055] There is also a transposition station 5c between the detection station 5b and the waste discharge station 5d;

[0056] A transpositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com