carbon fiber hot air balloon

A carbon fiber and hot-air balloon technology, applied in the direction of airbag arrangement, etc., can solve the problems of low utilization rate of heat energy, lower requirements for hot-air balloon meteorological conditions, and low safety, so as to improve control safety, reduce self-weight, and stabilize working conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

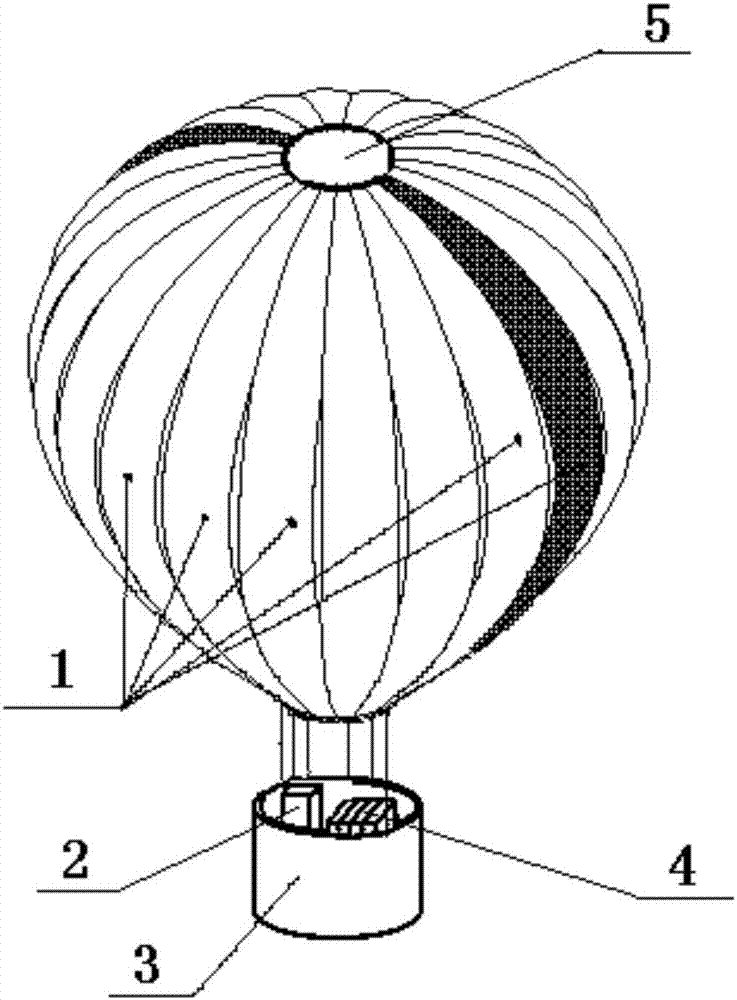

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the novel carbon fiber electric heating energy-saving hot air balloon in the present invention includes a carbon fiber electric heating balloon 1 , an electric control device 2 , a hanging basket 3 , a storage battery pack 4 , and a pod 5 .

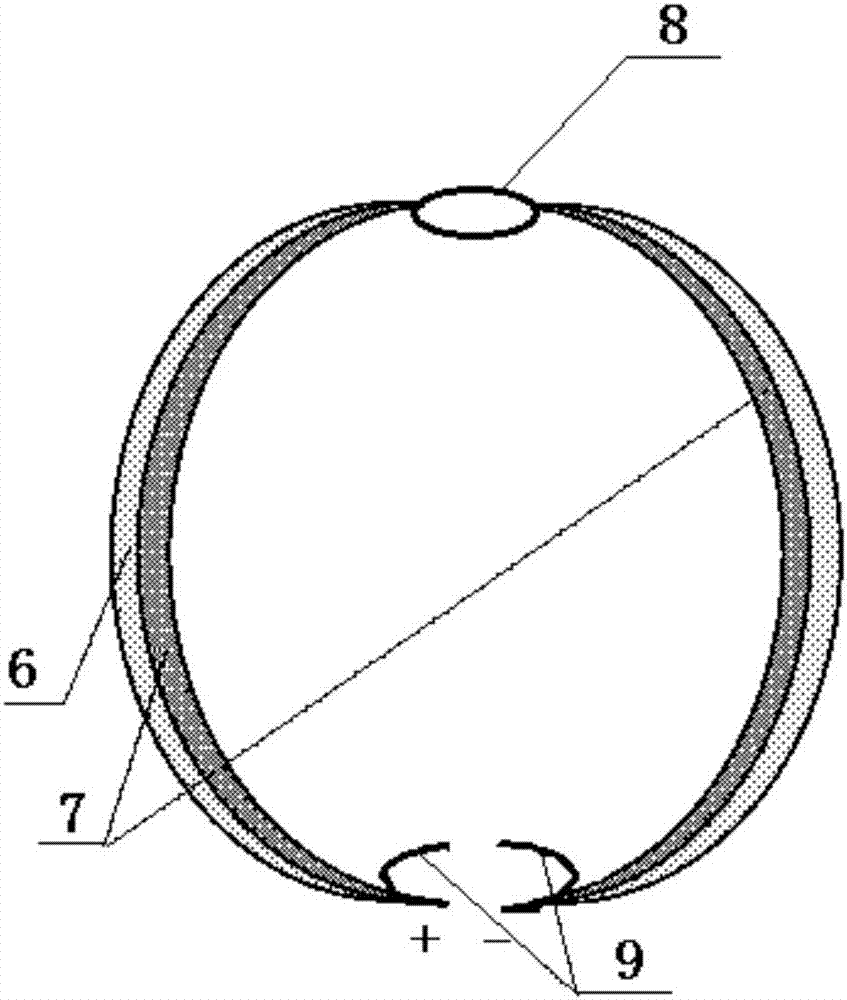

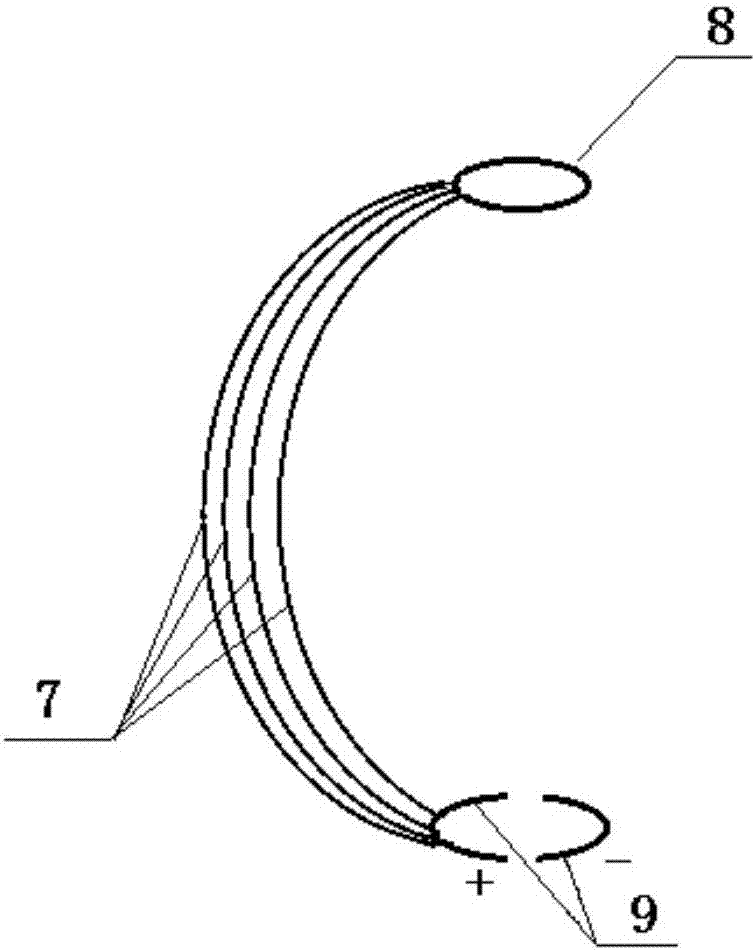

[0042] control figure 2 image 3 3,000 equal-length electric heating carbon fiber bundles 7 (ie, carbon fiber tows) and heat-gathering functional cloth 6 are made into a carbon fiber electric heating balloon 1 through mechanical adhesive hot pressing equipment or sewing equipment. The 3000 electric heating carbon fiber bundles are all distributed along the top of the balloon 1 to the bottom of the balloon 1 , and the 3000 electric heating carbon fiber bundles are evenly distributed around the central symmetrical axis of the balloon 1 . According to needs, the number of electric heating carbon fiber bundles 7 can be flexibly adjusted, and can be 10 to 100,000. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com