Wood slotting and cutting device

A cutting device and wood technology, applied in wood processing equipment, molding/shaping machines, special molding/shaping machines, etc., can solve the problems of easy accumulation of wood chips, etc., and achieve the effect of promoting chip removal, improving the effect, and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

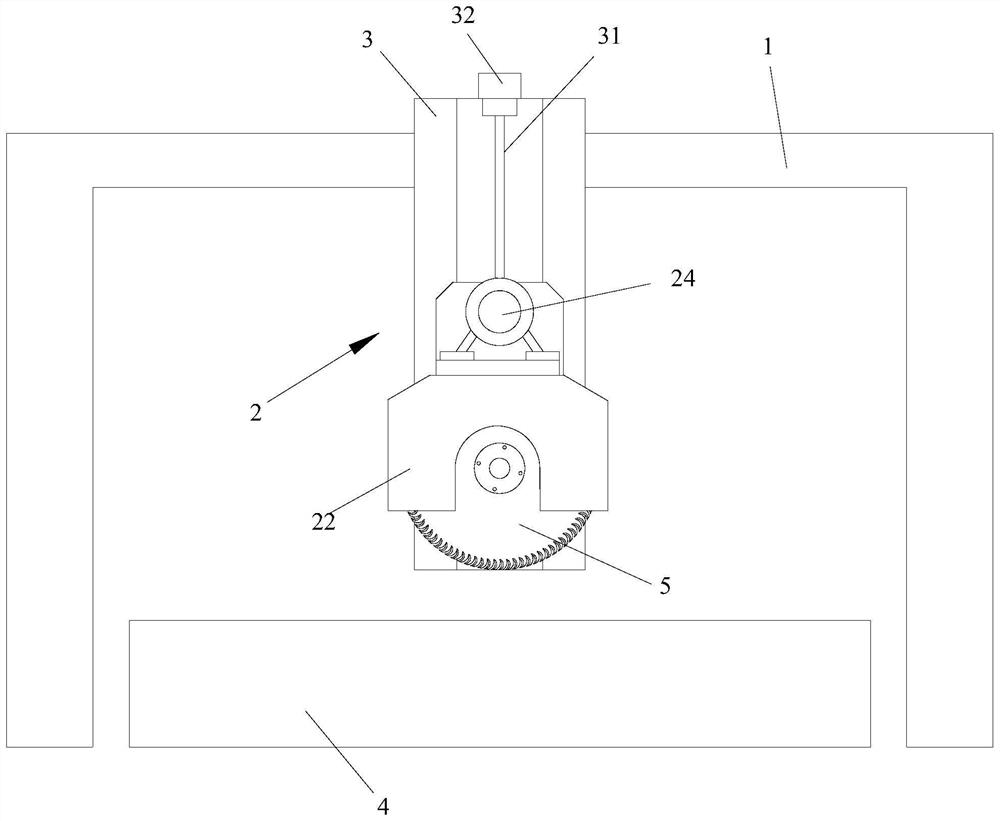

[0024] Such as figure 1 and figure 2 As shown, the present invention provides a wood grooving and cutting device, which includes a support frame 1 and a cutting unit 2 that can move up and down on the support frame 1, and an operating platform 4 is arranged directly below the cutting unit 2 , the lifting base 3 is fixed on the support frame 1, and the cutting unit 2 is slidingly connected with the lifting base 3;

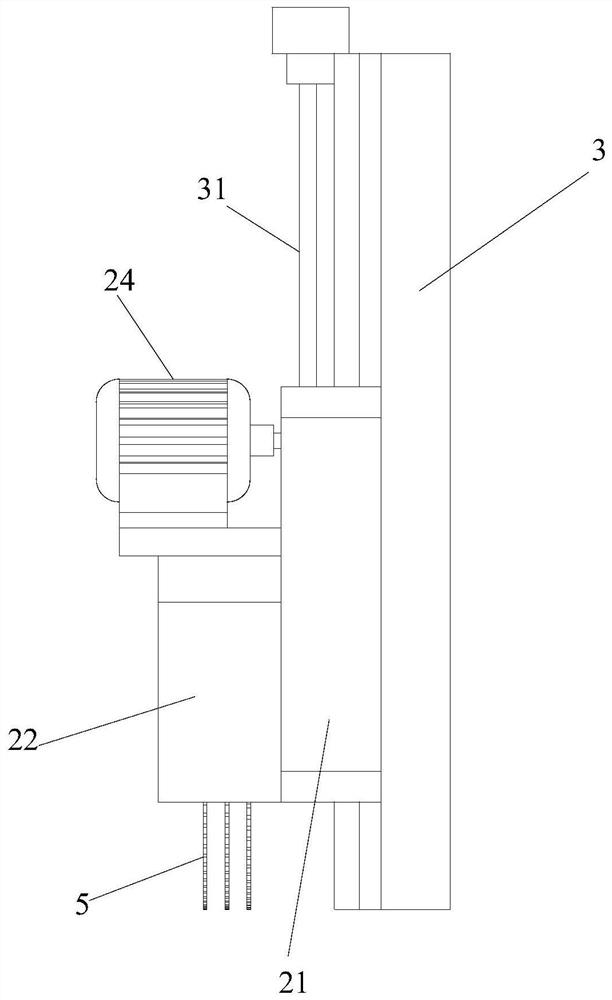

[0025] Wherein the cutting unit 2 comprises a sliding seat 21 that is slidably connected with the lifting seat 3, the lifting seat 3 is provided with a rotatable lead screw 31, the sliding seat 21 is threadedly connected with the leading screw 31, and the lifting seat 3 The top of the top is provided with a first motor 32 for driving the screw 31 to rotate, that is, the lifting of the sliding seat 21 is realized by the driving of the screw 31. In order to ensure the stability of the sliding seat 21, the sliding seat 21 and the lifting seat 3 pass through a T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com