Paper tube shaping machine

A technology of shaping machine and paper tube, which is applied in the direction of grinding workpiece supports, grinding machines, metal processing equipment, etc., can solve the problems of low production efficiency, waste, and multiple processing, and achieve high production efficiency, reduce production costs, and slot Accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be described in detail below in conjunction with accompanying drawing, the advantage of the present invention and outstanding contribution relative to prior art are further set forth, it can be understood that the following examples are only detailed descriptions of preferred embodiments of the present invention , should not be construed as any limitation on the technical solution of the present invention.

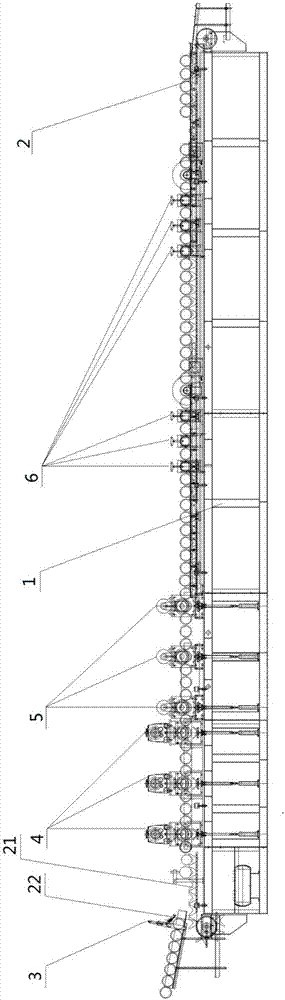

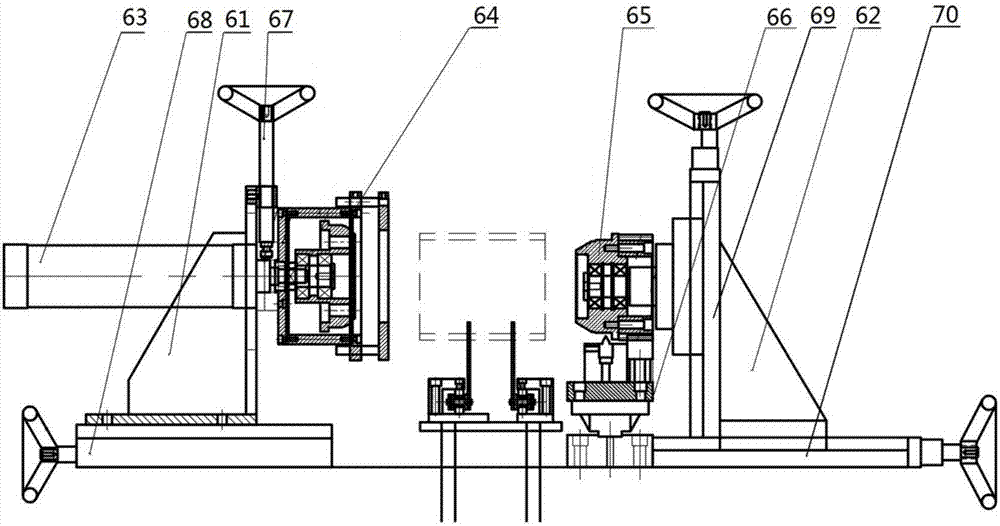

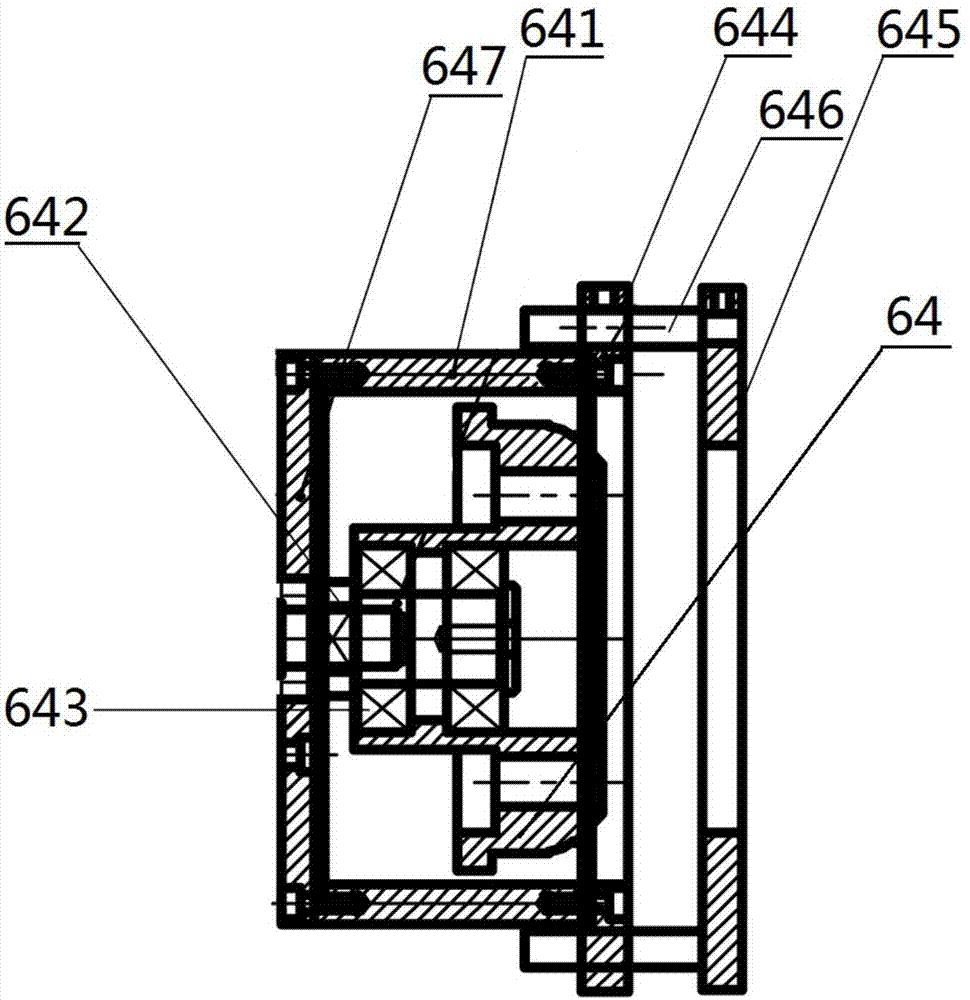

[0017] Such as Figure 1-4 As shown, a paper tube shaping machine includes a frame 1, and the middle part of the upper end of the frame 1 is provided with a conveying device 2. The belt 21 and the drive motor 22 that drives the conveyor belt 21 to rotate, the upper end of the frame 1 is provided with a feeding device 3, a grinding head device 4, a polishing device 5 and an opening device in sequence from left to right along the two sides of the conveyor belt 22. Groove device 6, three sets of grinding head devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com