Grooving process of grooved rods for quartz long boats

A quartz and long boat technology, applied in the field of grooving of quartz grooved rods, can solve the problems of uneven grooved position, difficult to remove square rods, fracture of square rods, etc., achieving good fixing effect, not easy to vibrate, and accurate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the slotted rod slotting process of quartz long boats, comprising the following steps:

[0035] A. Grind the round quartz rod on all sides to make a square rod of 22mm*22mm;

[0036] B. Cut the two ends of the square rod to check the flatness, length and verticality of the square rod;

[0037] The length of the rear bar after cutting is 1550mm, ensuring that any adjacent two sides of the square bar are kept vertical, and the flatness of each face is kept within 0.2.

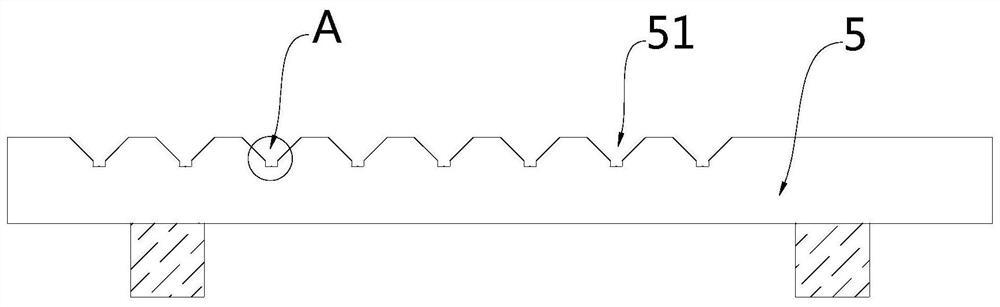

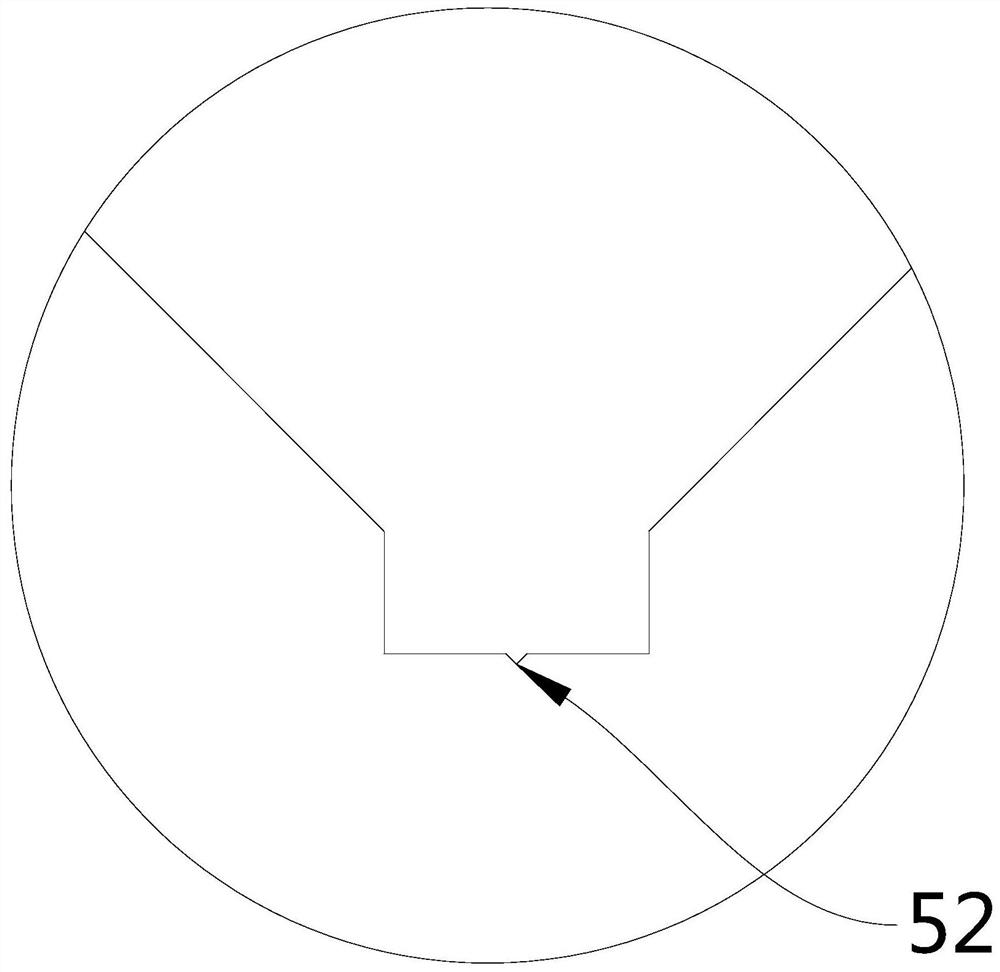

[0038] C. Embed several square rods on the surface of the graphite plate with an equal number of parallel "V" grooves, pour liquid wax into the connection between the square rods and the "V" grooves, and cool the liquid wax to solidify, complete Fixing of square rods;

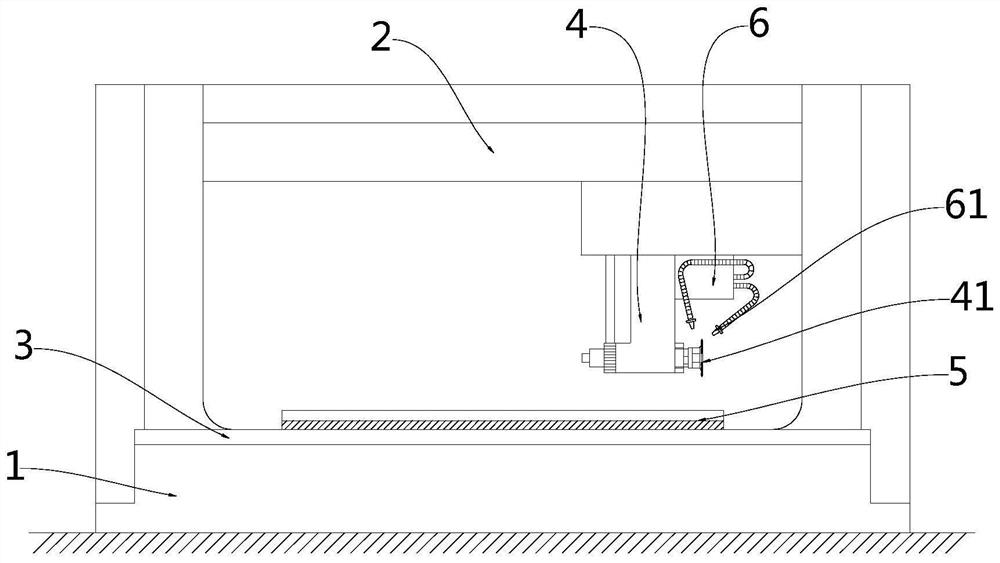

[0039] D. Put the graphite plate with the wax-fixed square rod on the table of the CNC machine tool;

[0040] E. Adjust the angle of the blade shaft of the CNC machine tool and install the blade;

[0041] F. Call the progr...

Embodiment 2

[0050] Embodiment 2: the slotted rod slotting process of quartz long boats, comprising the following steps:

[0051] A. Grind the round quartz rod on all sides to make a square rod of 22mm*22mm;

[0052] B. Cut the two ends of the square rod to check the flatness, length and verticality of the square rod;

[0053] The length of the rear bar after cutting is 1550mm, ensuring that any adjacent two sides of the square bar are kept vertical, and the flatness of each face is kept within 0.2.

[0054] C. Embed several square rods on the surface of the graphite plate with an equal number of parallel "V" grooves, pour liquid wax into the connection between the square rods and the "V" grooves, and cool the liquid wax to solidify, complete Fixing of square rods;

[0055] D. Put the graphite plate with the wax-fixed square rod on the table of the CNC machine tool;

[0056] E. Adjust the angle of the blade shaft of the CNC machine tool and install the blade;

[0057] F. Call the progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com