High-voltage brushless motor grooving machine

A technology of brushless motor and slotting machine, which is applied in the direction of stone processing tools, working accessories, manufacturing tools, etc., which can solve difficult problems, poor control of straightness, and different cutting depths of straight grooves and arc grooves. problems, to achieve the effect of improving slotting efficiency and precision, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

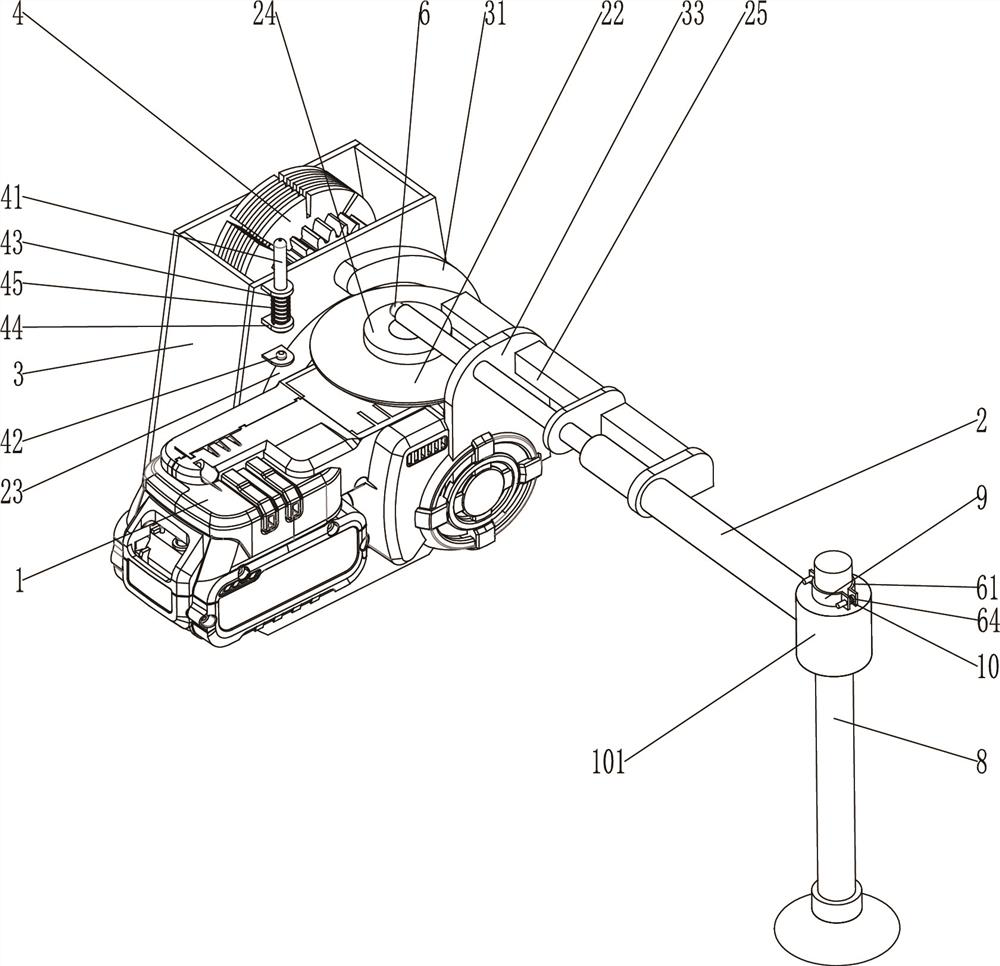

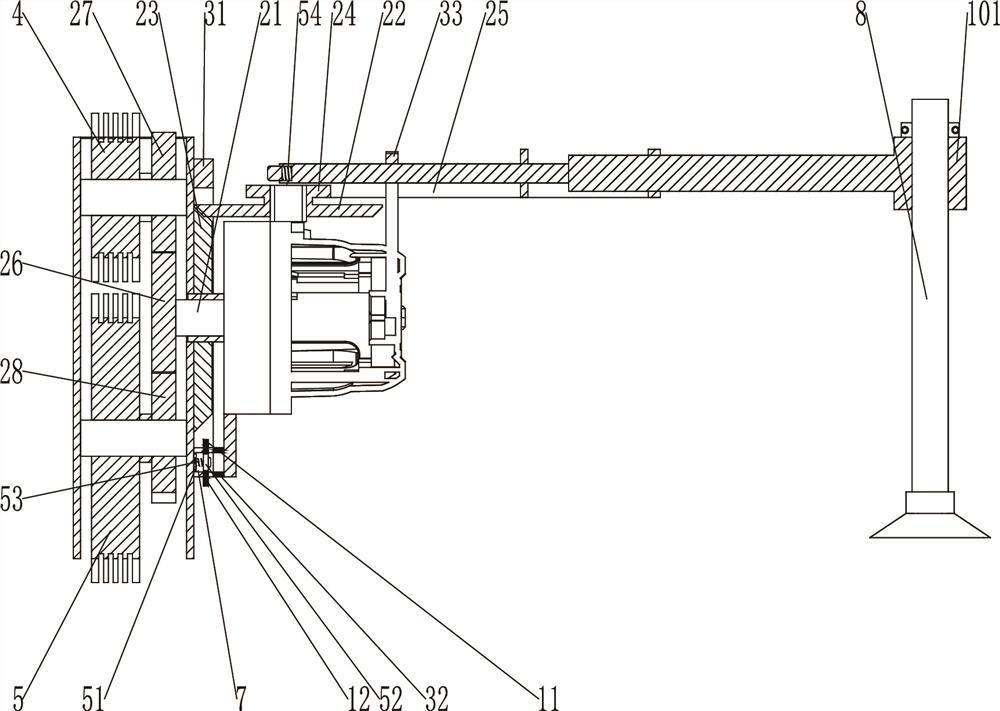

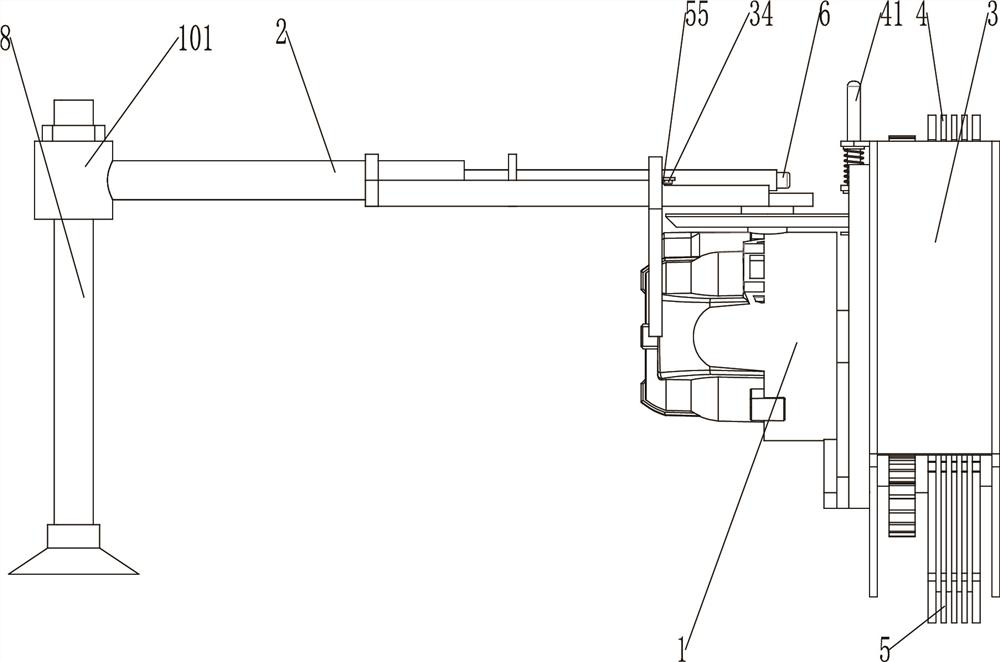

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 8 , a high-voltage brushless motor slotting machine, including a slotting machine 1 and an auxiliary rod 2, the auxiliary rod 2 is an auxiliary device when the slotting machine 1 needs to open an arc-shaped slot, and the slotting machine 1 A support plate 33 is fixedly provided.

[0024] The auxiliary rod 2 includes a main body of the auxiliary rod 2 and a rack 25 arranged on one side of the auxiliary rod 2, and the support plate 33 is provided with a hole for the auxiliary rod 2 and the rack 25 to pass through, that is, the auxiliary rod 2 The rod 2 and the rack 25 can slide through the support plate 33 when they cooperate with the slotting machine 1 .

[0025] The slotting machine 1 is provided with an output shaft 21 and a housing 3, the housing 3 is rotatably installed on the slotting machine 1, and the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com