Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Improve dust removal ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

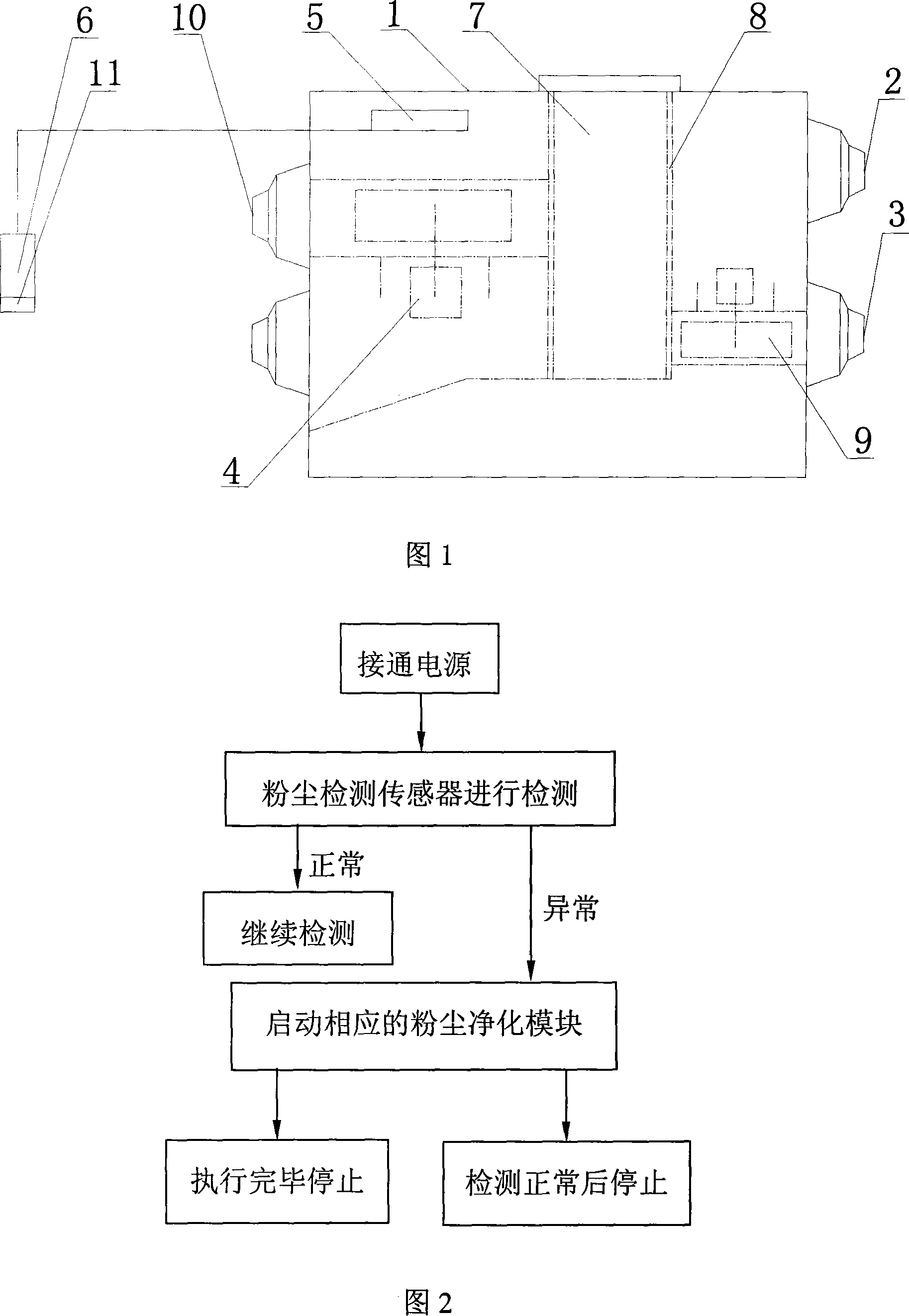

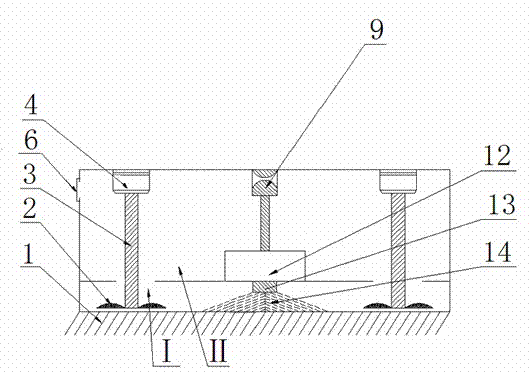

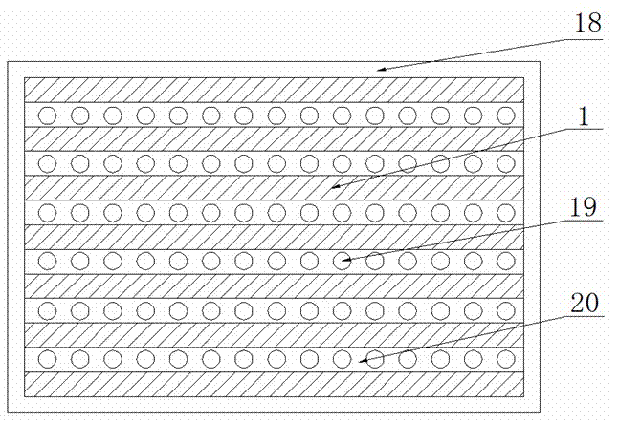

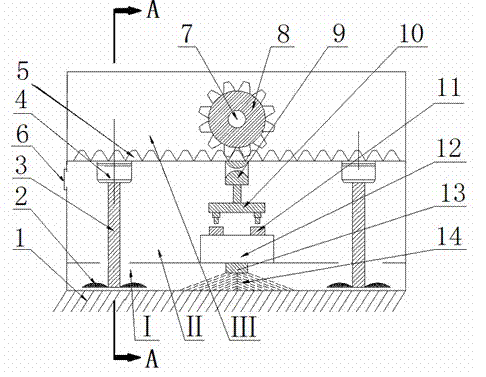

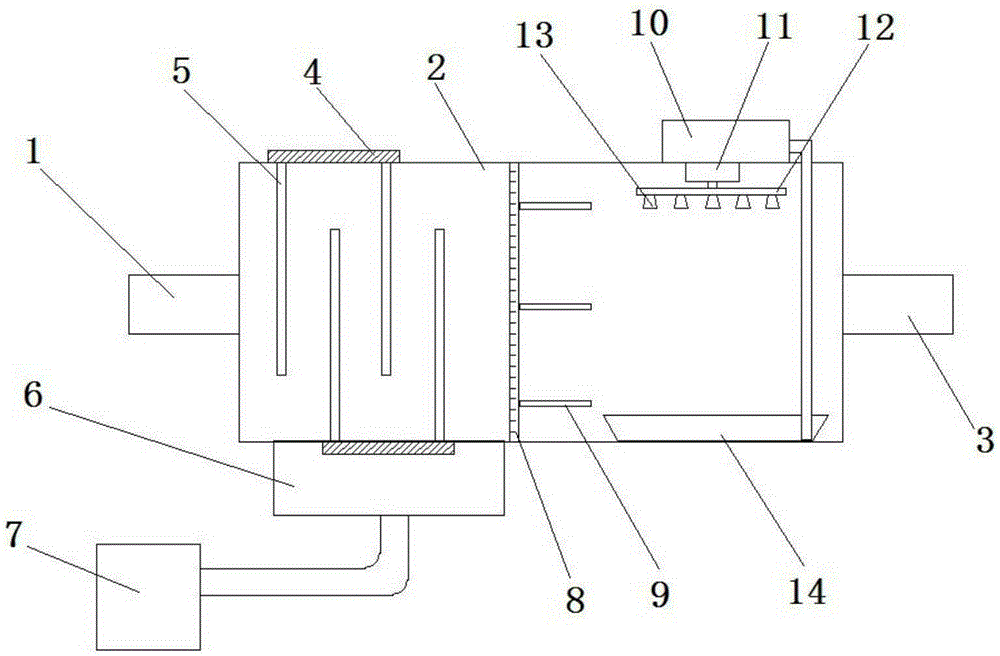

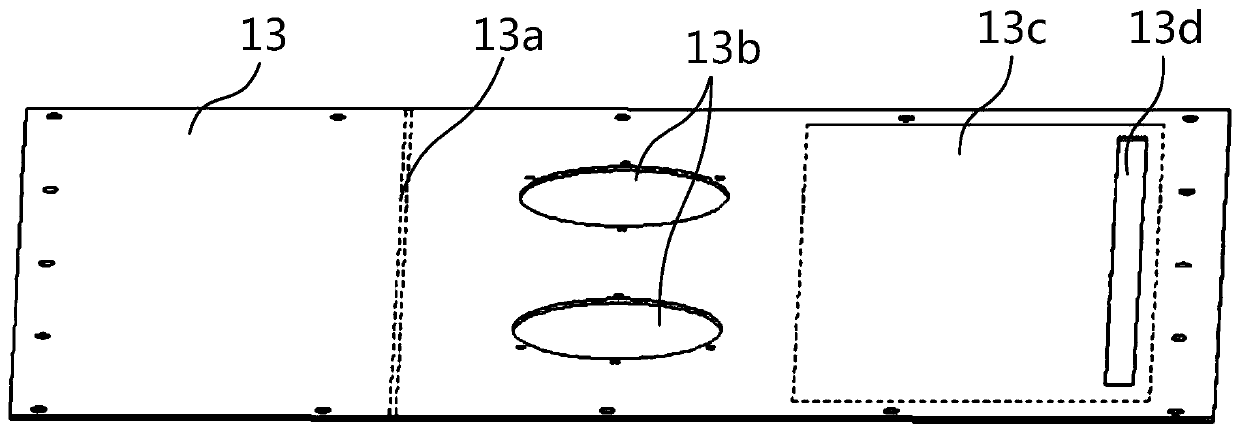

Total heat exchanger with dust detecting and dust eliminating modules

InactiveCN101021347AGood effectStrong dust removal abilitySpace heating and ventilation safety systemsLighting and heating apparatusFresh airEngineering

The present invention relates to a heat exchanger with dust detection and dust-removing module. It also includes mixing chamber, fresh air inlet and fresh air outlet communicated with mixing chamber, motor and at least two fans connected with motor, controller and air quality detection sensor. It is characterized by that said heat exchanger possesses an independent dust detection sensor and a dust cleaning module.

Owner:HAIER GRP CORP +1

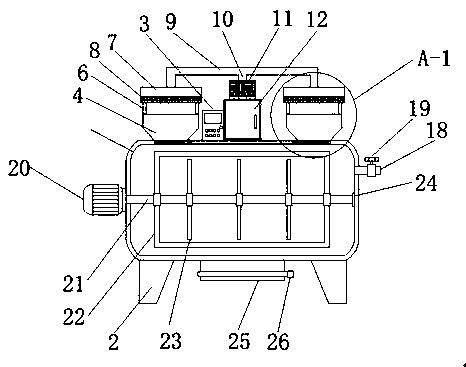

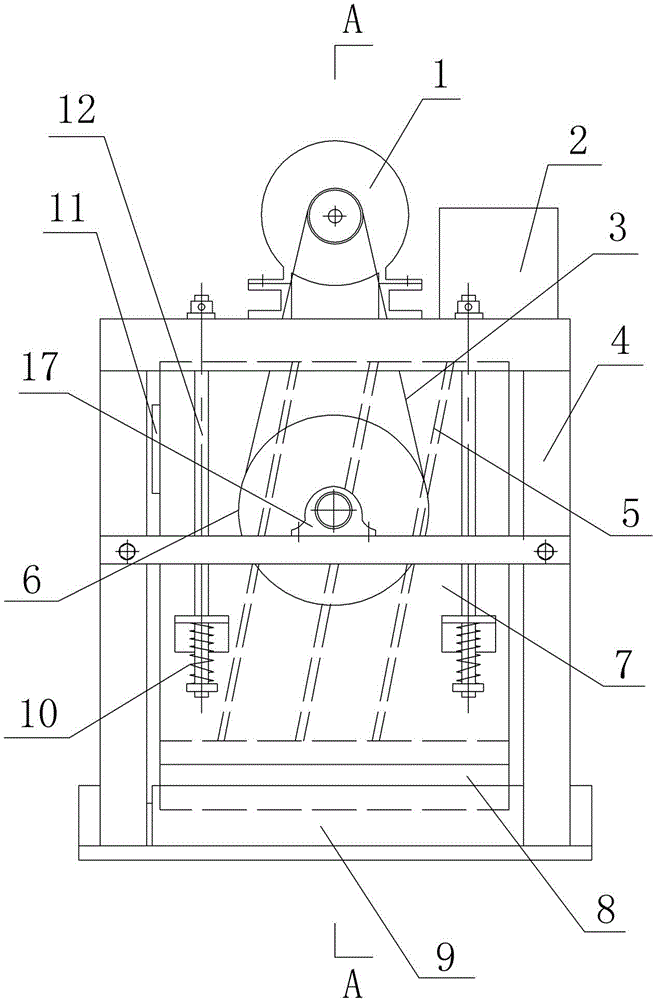

Vibration dust removing machine of traditional Chinese medicines

InactiveCN107138477AImprove cleanlinessQuality improvementCleaning using gasesEngineeringChinese herbology

The invention discloses a vibrating dust remover for traditional Chinese medicinal materials, which comprises a frame, a shell, a bracket, an upper cover and legs; Mechanism; the housing is fixed on the movable plate, and a vibrating seat is arranged in the housing, and a downwardly recessed trough is provided at the upper end of the vibrating seat, and an upwardly recessed arc surface is provided at the lower end of the vibrating seat. A cam is provided below the upper cover, and a wind collecting hood is communicated on the upper cover; a collection device is also provided on the movable plate, and the collection device includes a support plate, a second rotating shaft, a collection bucket and a counterweight; The top of the top is rotatably connected with a material guide plate through the first rotating shaft. The present invention drives the vibrating base to move up and down through the set cam, shakes off the soil on the surface of the medicinal material, makes the soil finer, facilitates dust raising, has good dust removal effect, greatly reduces the carrying amount of soil in the medicinal material, and ensures that the medicinal material is clean.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

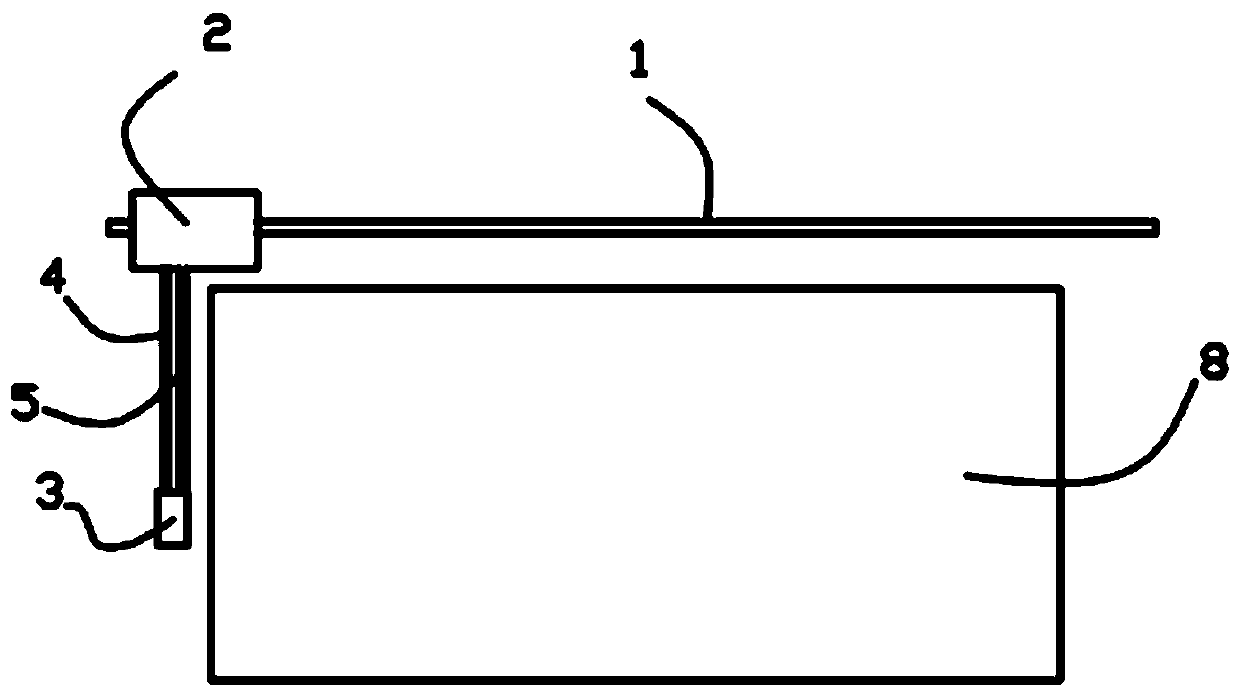

Dust absorption spray type blackboard eraser

InactiveCN103204023AImprove dust removal effectImprove dust removal abilityBoard cleaning devicesWater storage tankSprayer

The invention discloses a dust absorption spray type blackboard eraser. The dust absorption spray type blackboard eraser is characterized in that one inner side surface of a shell of an erasing surface of the blackboard eraser is provided with a spraying chamber and a dust storage chamber which are fixedly connected, wherein the spraying chamber is next to the shell of the erasing surface of the blackboard eraser, dust absorption ports in the outer surface of the shell of the erasing surface of the blackboard eraser and hair brushes are crosswise distributed, a dust absorption fan and a dust absorption motor are arranged in the dust storage chamber, and when the hair brushes are used for erasing a blackboard, the dust absorption motor receives signals and begins to rotate to drive the dust absorption fan to rotate, so that dust erased off from the blackboard is absorbed into the dust storage chamber through the dust absorption ports; at least a nozzle is arranged in the spraying chamber, the nozzle, a water storage tank and a pressure-sensitive sensor form a sprayer, when the blackboard is not erased cleanly, a user applies an external force to the blackboard eraser, so that the pressure-sensitive sensor receives signals and further controls the nozzle to spray out water mist from the water storage tank for wetting the blackboard, and then the wetted blackboard is erased. The dust absorption spray type blackboard eraser has the advantages of good dust removal effect, reducing the chalk dust suction volume of teachers and students, cleanly erasing the blackboard and improving the learning efficiency of the students in a classroom.

Owner:SHANGHAI UNIV

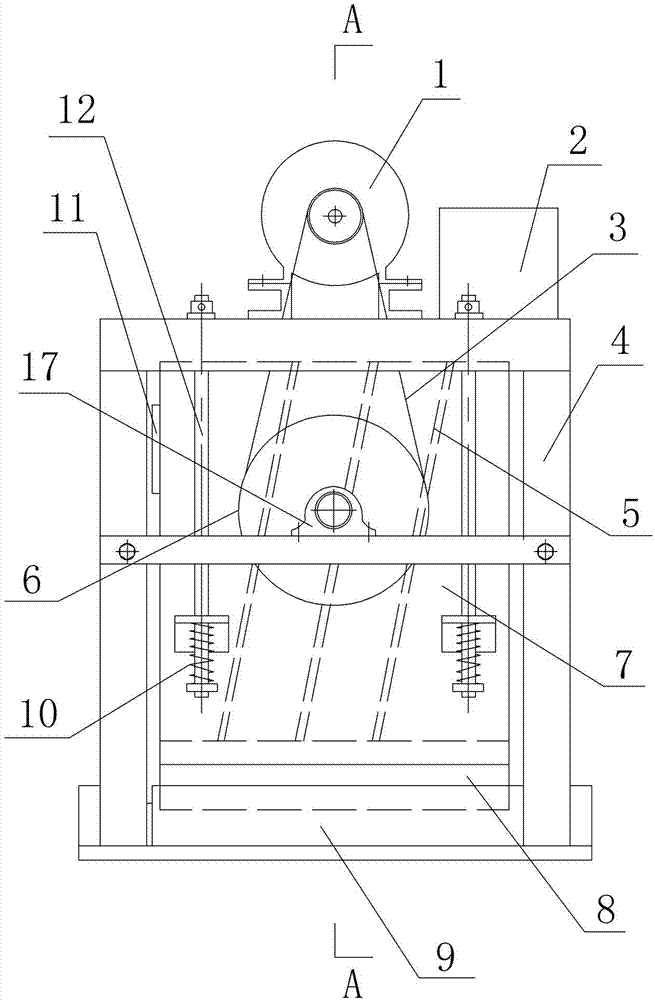

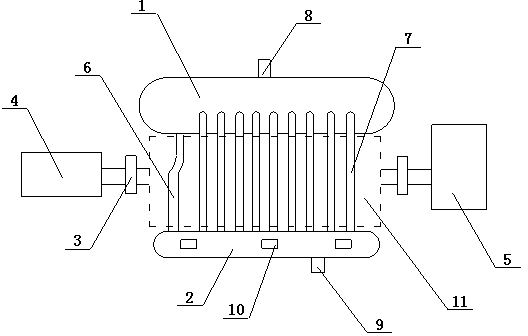

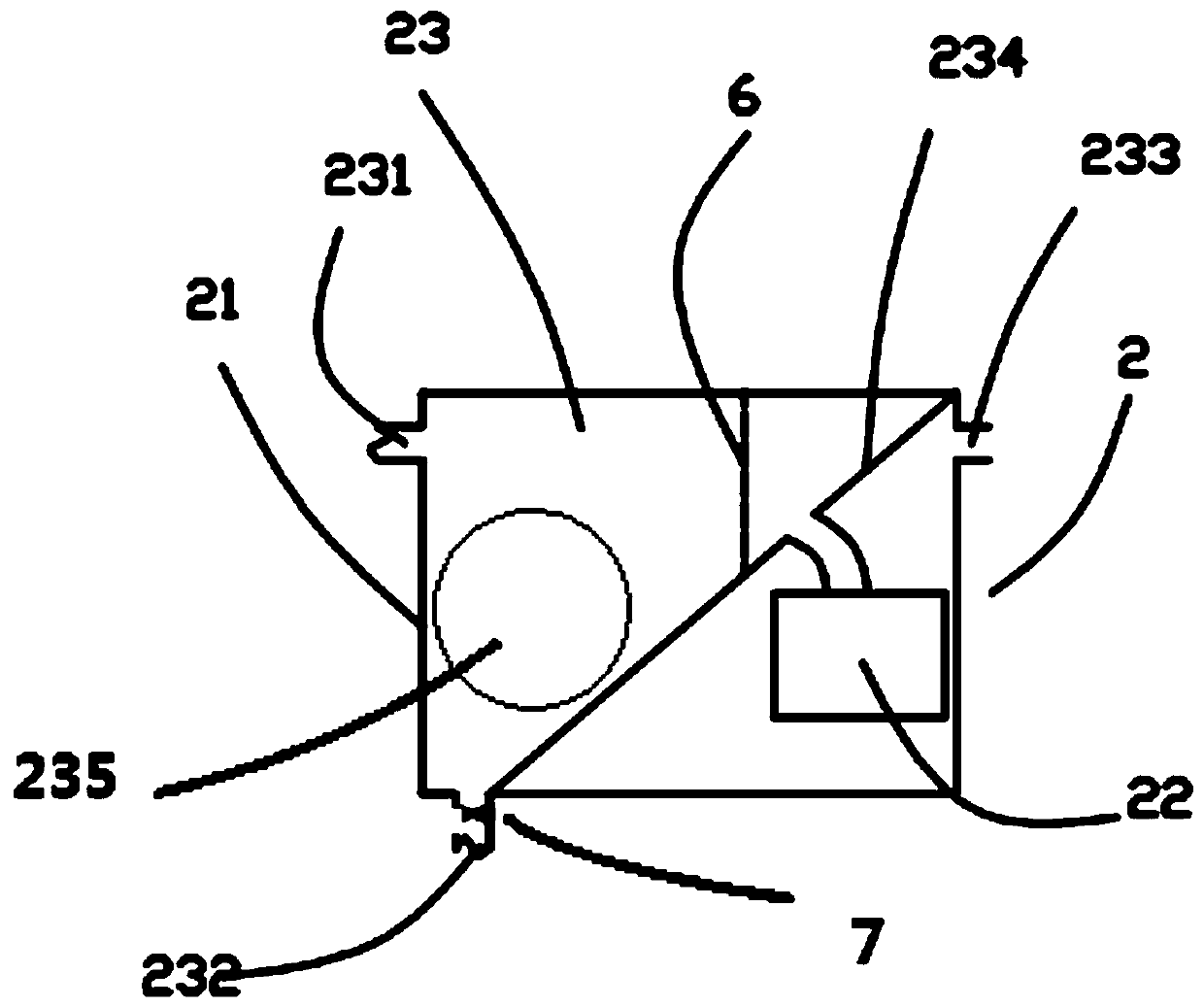

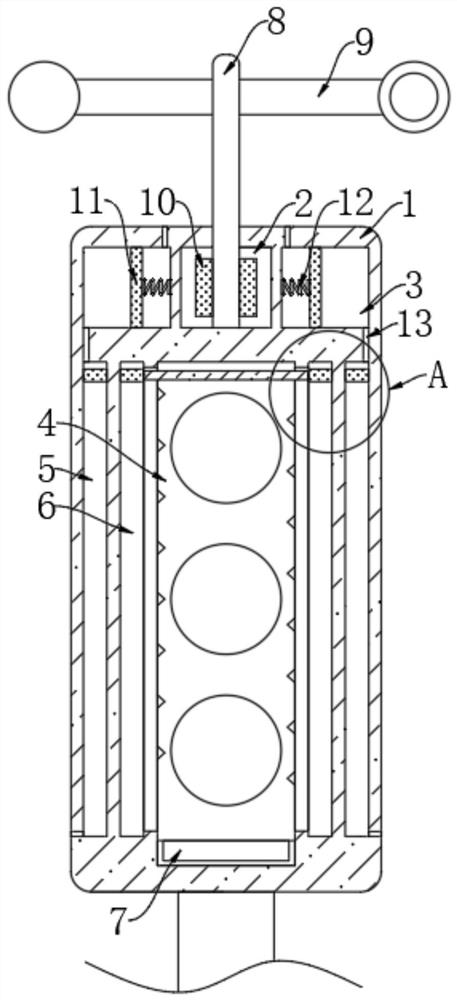

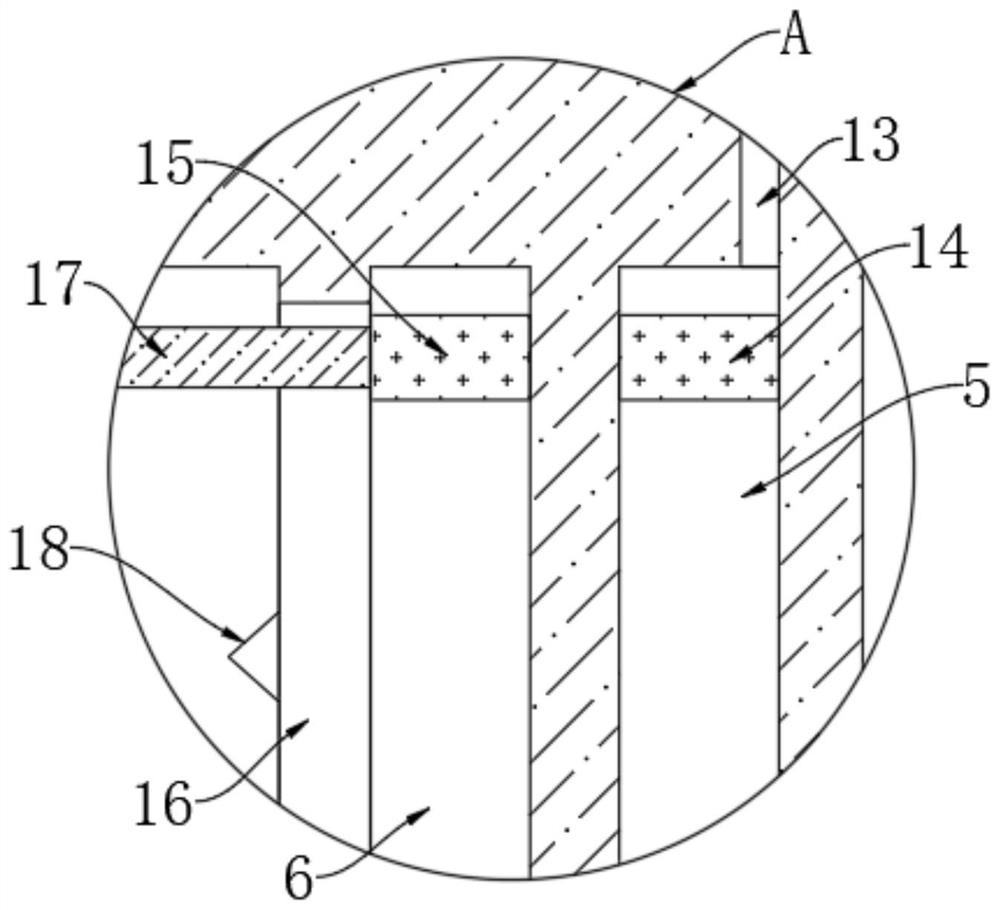

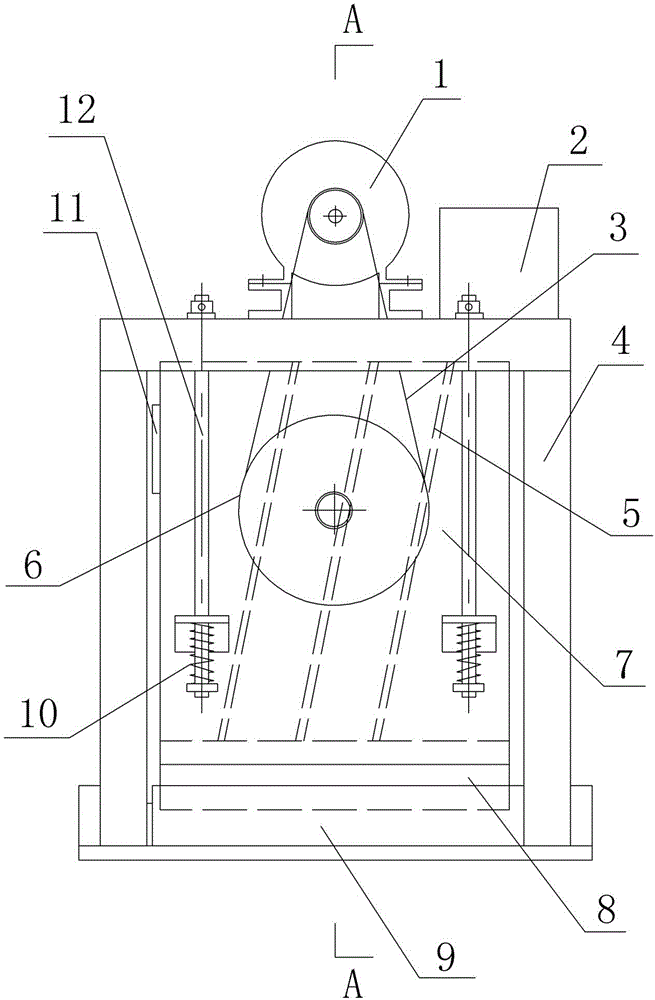

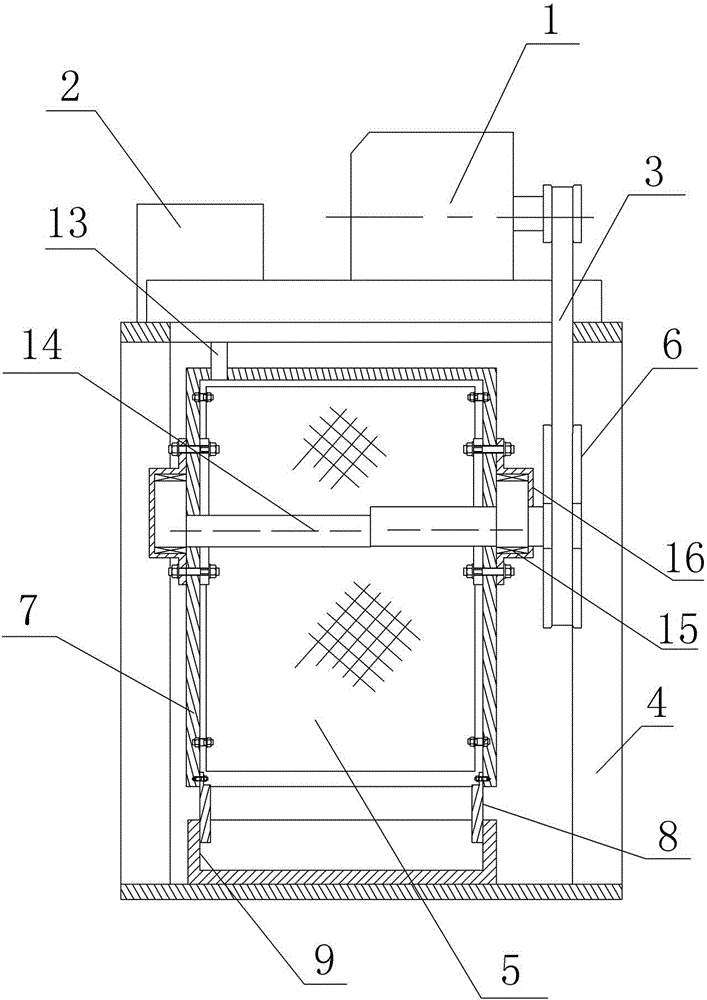

Negative oxygen ion air exchanger with screen dust removal

ActiveCN103111151AReduce volumeImprove dust removal efficiencyCombination devicesPhysicsElectric machinery

The invention discloses a negative oxygen ion air exchanger with screen dust removal. The air exchanger comprises a stand, a machine box and a circuit control system, wherein the machine box is hung in the stand through a hanging rod; two or three inclined screens are fixed in the machine box; an eccentric shaft which transversely penetrates the machine box is arranged in the waist middle of the machine box; through rotation of the eccentric shaft, the machine box is synchronously vibrated; a belt wheel is arranged at one end of the eccentric shaft; a motor is fixed above the stand; and the eccentric shaft is synchronously rotated through operation of the motor. The negative oxygen ion air exchanger disclosed by the invention is wide in application range and high in dust removal efficiency; and after dust is removed through the two or three screens, fog-like water vapor is sprayed on the space of the last screen, and negative ions generated from friction and vibration are combined with the water vapor to form negative oxygen ions which are air vitamins and can make users feel comfortable to breathe, thereby achieving the purposes of preserving health and prolonging life.

Owner:ZHENGZHOU UNIV +2

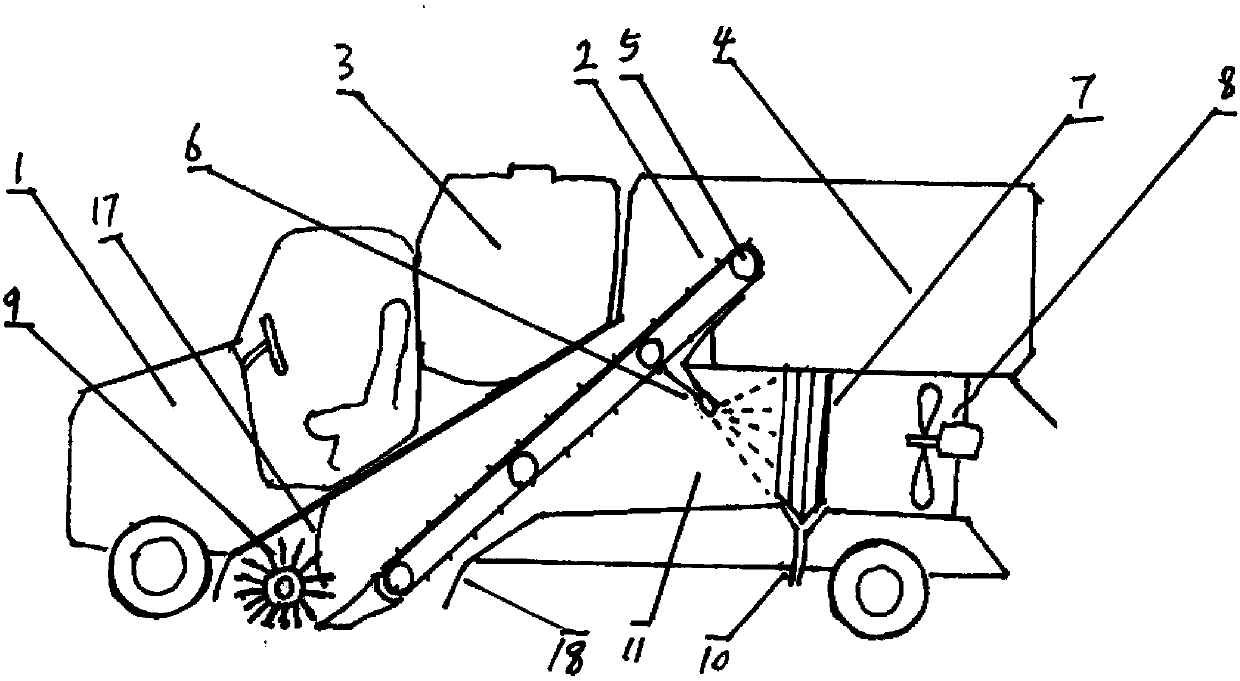

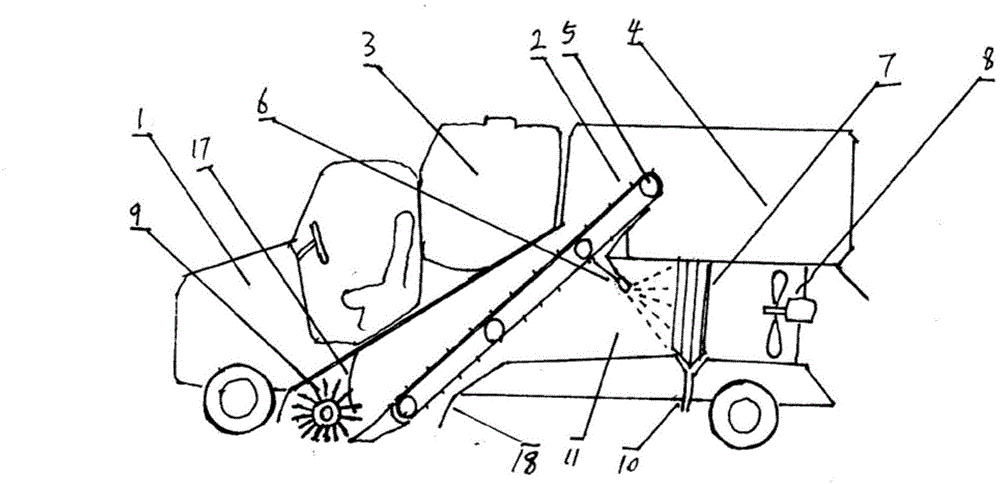

Dust-free pavement sweeper

The invention discloses a dust-free pavement sweeper. The dust-free pavement sweeper comprises a travelling system, a ground sweeping system, a garbage conveying system and a dust removal system, wherein the travelling system is suitable for being installed on fuel vehicle of various garbage sweeping devices; the ground sweeping system comprises a liftable ground sweeping rotary roll; the garbage conveying system comprises a garbage conveying wheel shaft, a garbage conveying belt and a garbage storage tank; and the dust removal system comprises an exhaust pipeline, an exhaust fan, a water tank, a water sprayer and a multi-layer dust filter gauze. The dust-free pavement sweeper adopts the sweeping rotary roll parallel to the ground to rotationally sweep the ground, and does not produce lateral elastic force when rotating, and the dust removal system adopts the water sprayer to spray water mist onto the multi-layer dust filter gauze, so that dust adhered onto the multi-layer dust filter gauze downwards flows away along with water drop, and the dust processing capacity of the dust-free pavement sweeper is very powerful.

Owner:山东恒阳重工科技有限公司

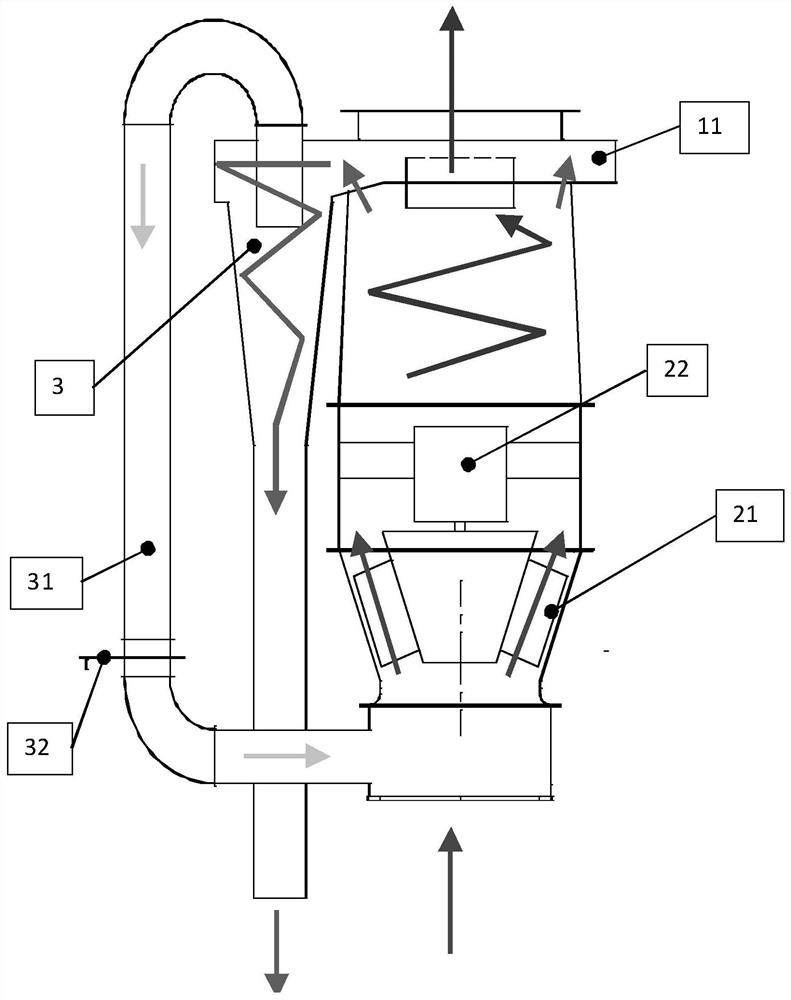

Waste gas treatment device for power station

InactiveCN106731368AEasy to handleImprove the blocking effectCombination devicesPower stationTreatment effect

The invention discloses a waste gas treatment device for a power station. One end of a box body is connected with a gas inlet pipe; the other end of the box body is connected with a gas exhaust pipe; a fixed plate is arranged on the external side, close to one end of the gas inlet pipe, of the box body; a baffle is perpendicular to the fixed plate; the baffle extends into the box body; the baffle can be pulled out by the fixed plate; a collecting box is arranged at the lower end of the fixed plate; the collecting box is connected with a dust cleaning box through a pipeline; a filter screen is arranged on the right side of the baffle; a plurality of air guide plates are uniformly arranged on the right side of the filter screen; a circulating pump is arranged on the external side of the top end of the box body on the right sides of the air guide plates; a motor is arranged at the top end of the internal side of the box body; the lower end of an output shaft of the motor is connected with a dispersion pipe; a plurality of atomizing nozzles are arranged at the lower end of the dispersion pipe; the circulating pump is connected with the dispersion pipe; a collecting pond is arranged right under the dispersion pipe; and one end of a pipeline extends to the bottom of the collecting pond, and and the other end of the pipeline is connected with the circulating pump. The waste gas treatment device for the power station, disclosed by the invention, has the advantages of simple structure, convenient use, strong dust cleaning capacity, low operation cost and good waste gas treatment effect.

Owner:TIANJIN FANGYUAN ELECTRIC EQUIP

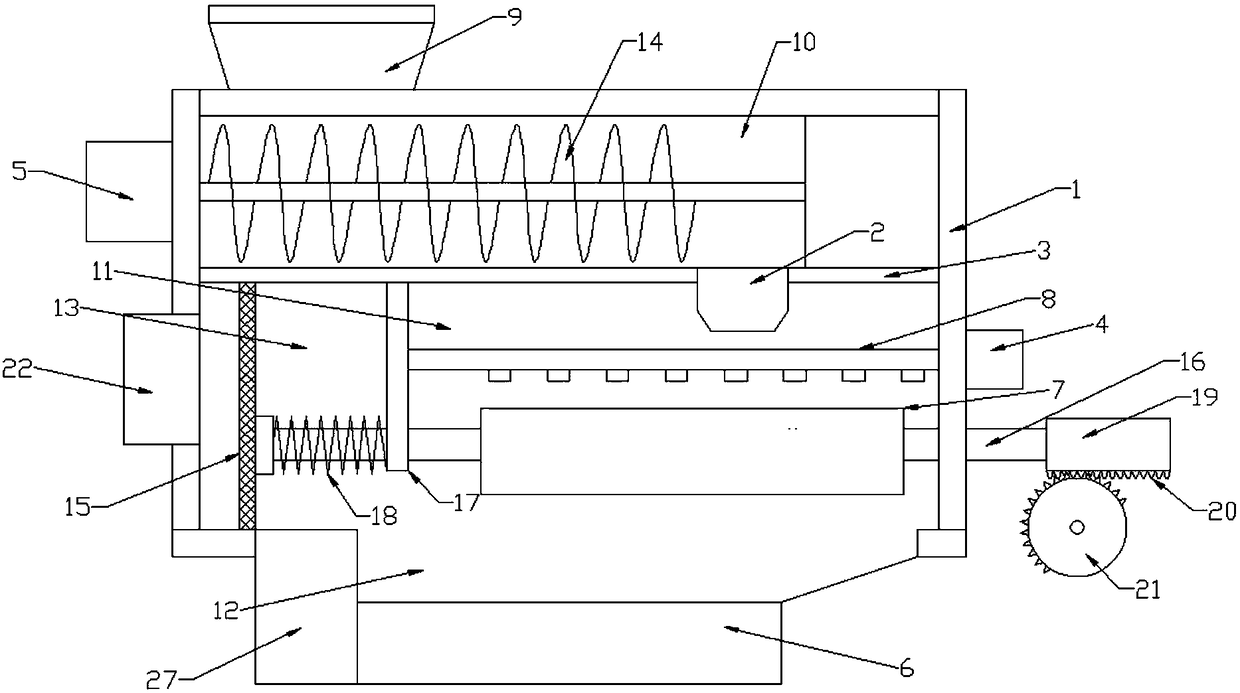

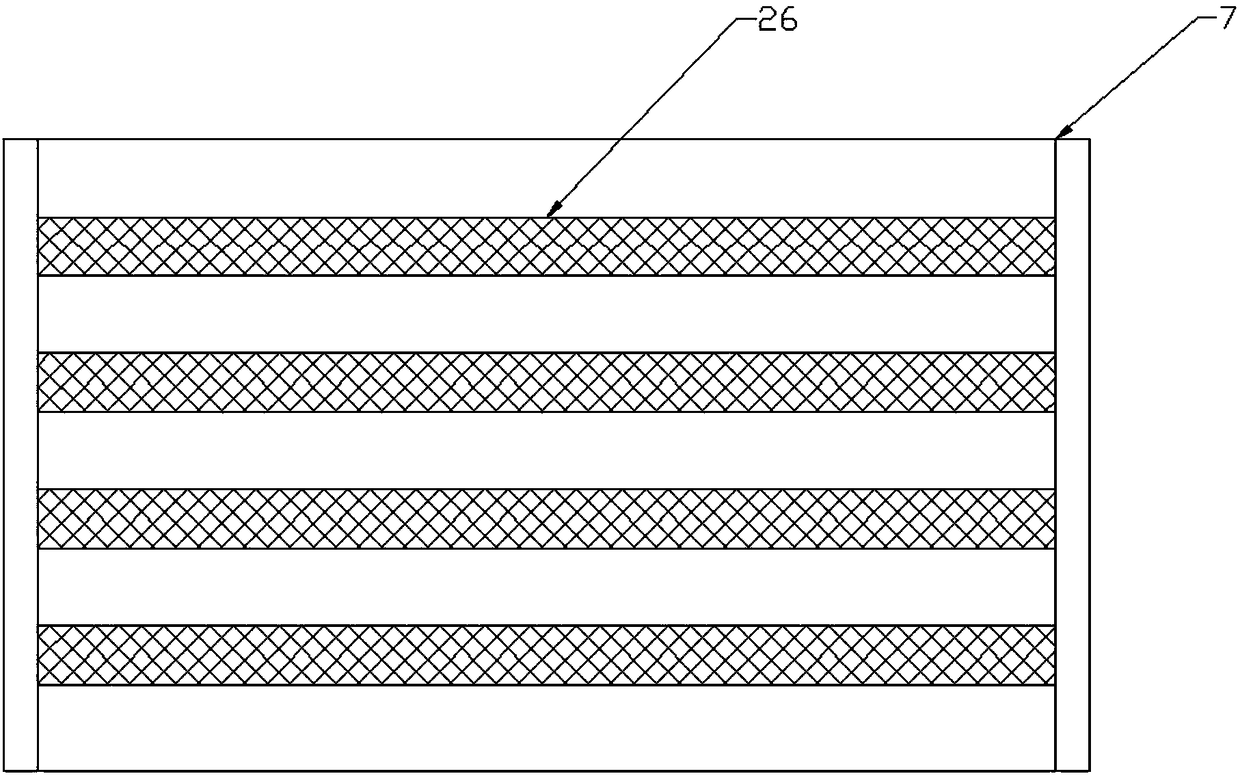

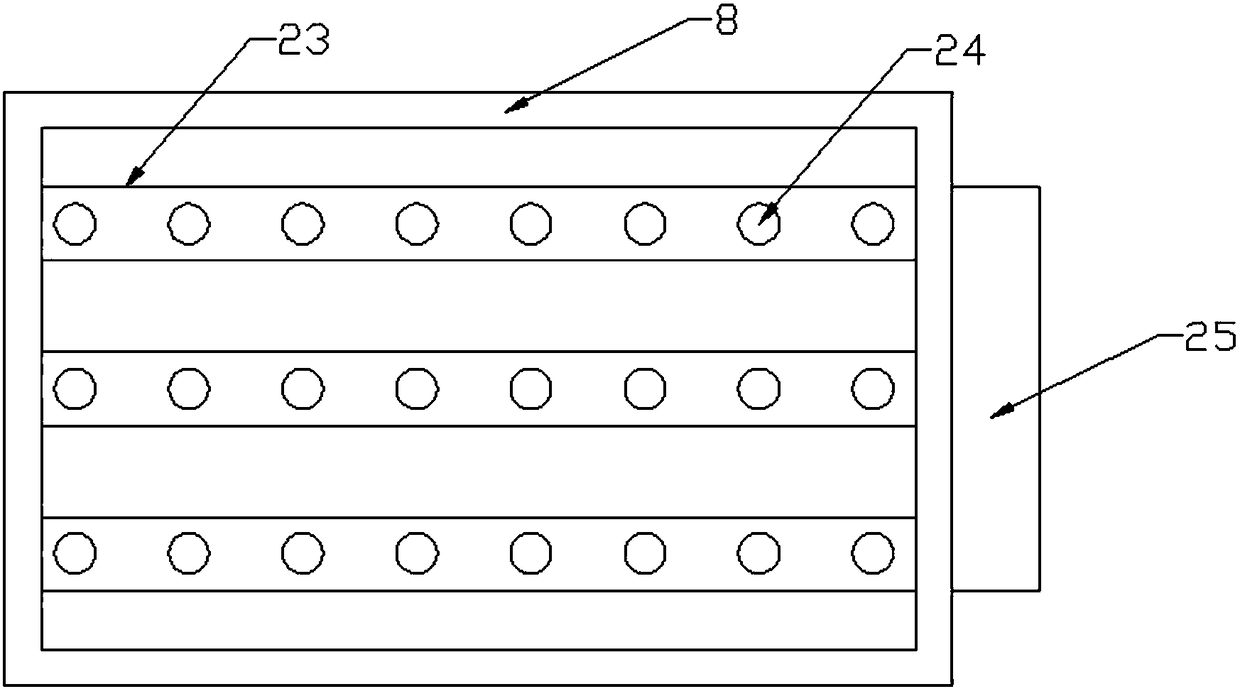

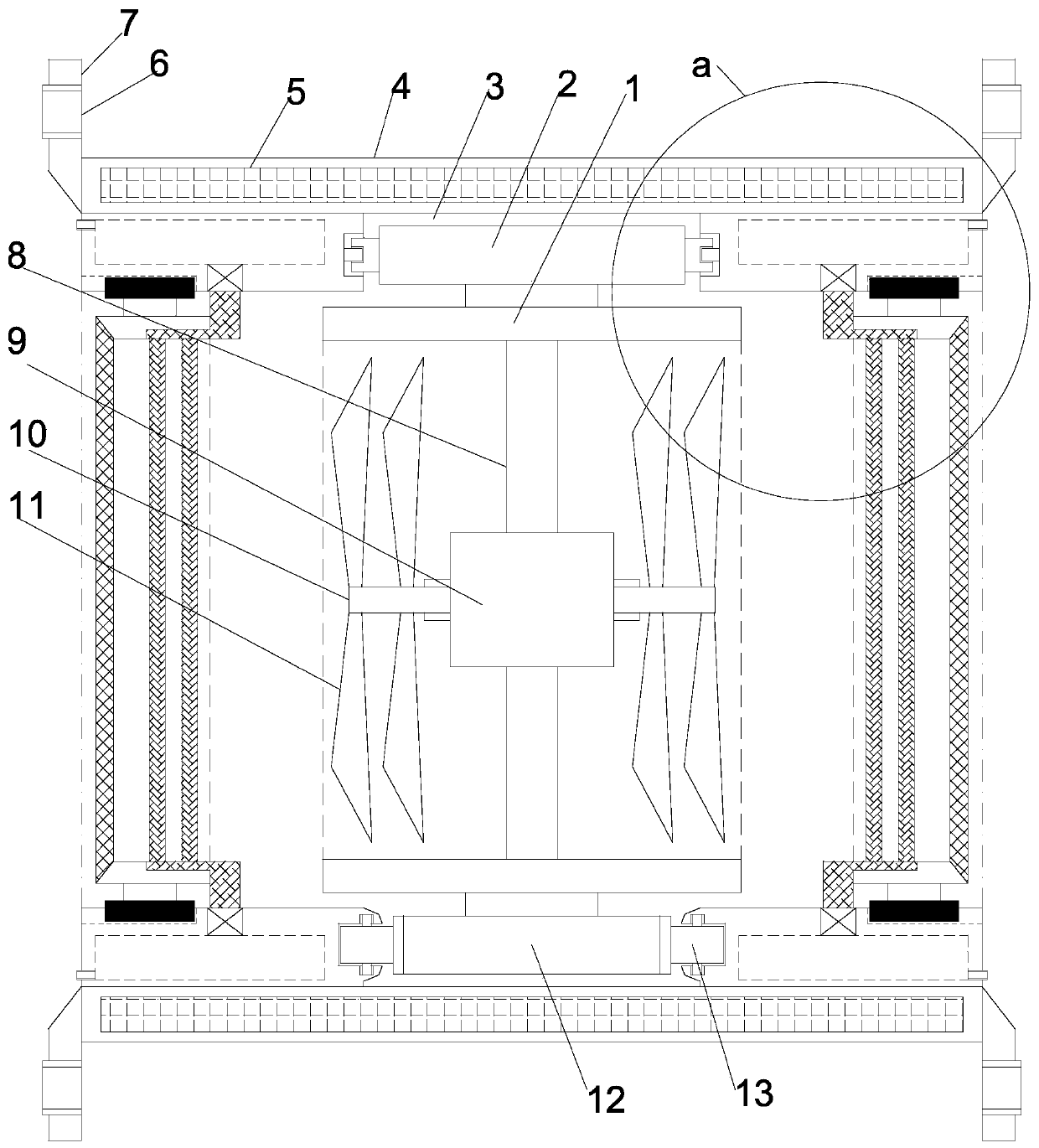

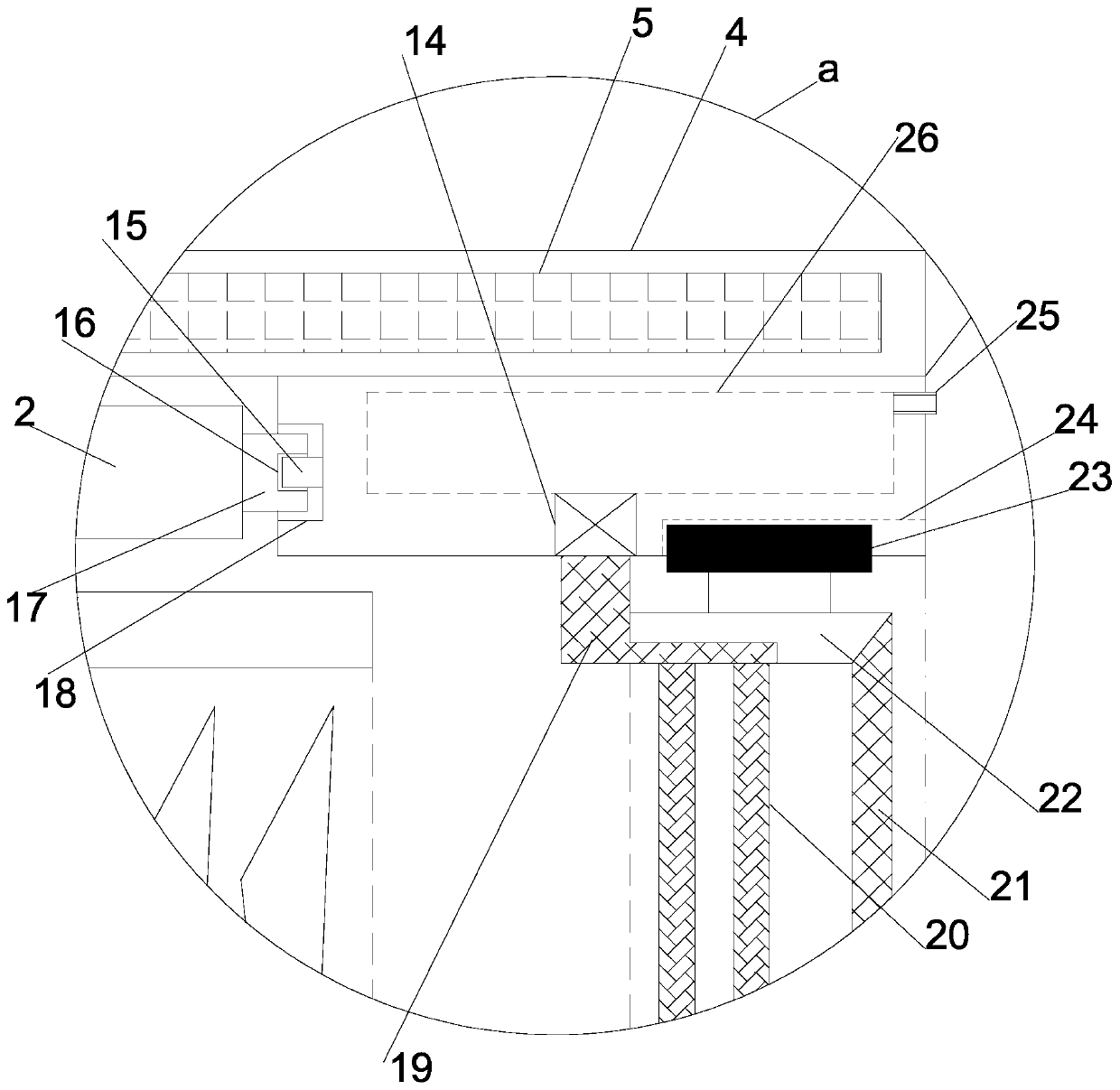

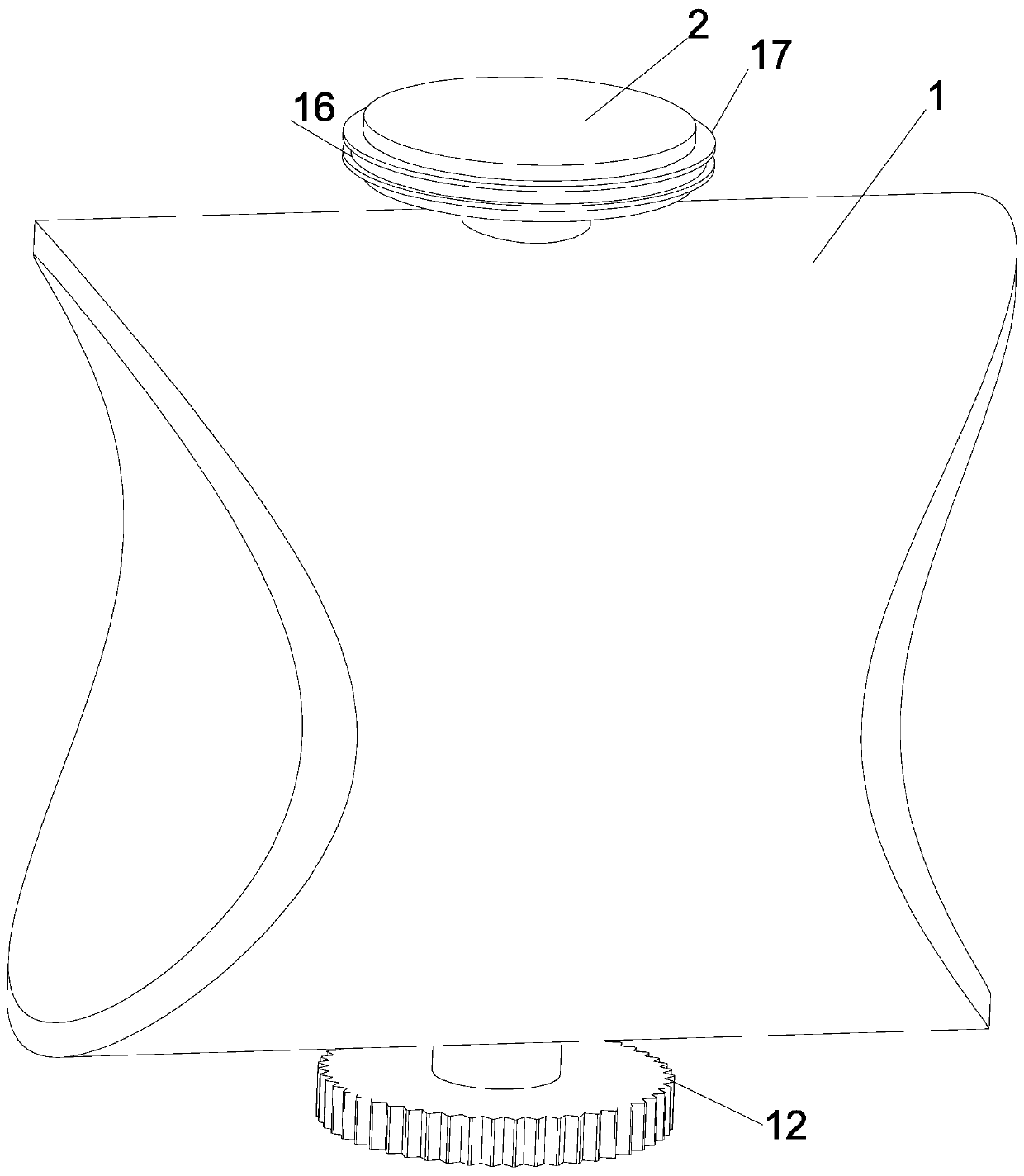

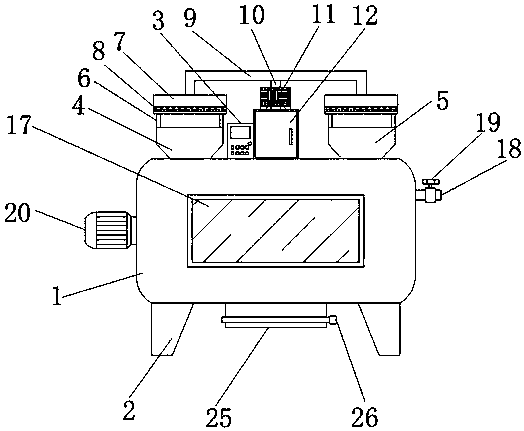

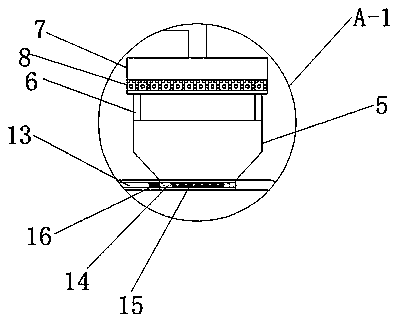

Dedusting apparatus for rice milling

InactiveCN108284062AEvenly dispersedQuality improvementGas current separationGear wheelHelical blade

The invention discloses a dedusting apparatus for rice milling. The dedusting apparatus for rice milling comprises a box body, a feeding hopper, a clapboard, a fan, a motor and a collecting box. An output shaft of the motor is fixedly connected with a level helical blade. A spoiler separates the lower part of the clapboard into a filter chamber on the left and a blower chamber on the right. The left end of a supporting pole is sleeved with a spring, and a toothed plate is fixed to the right end of the supporting pole. A half gear is connected to the lower side of the toothed plate in a meshingmode. A horizontal reduction gearbox is fixed to the supporting pole by use of a bolt. A plurality of level blowpipes is fixed in a fixing frame. A collecting bucket is connected to the lower side ofthe blower chamber. A dust collecting groove is arranged at the bottom of the inner wall of a filter screen. The dedusting apparatus for rice milling makes falling rice evenly dispersed by the installed reduction gearbox which can move left and right. Air blown into the reduction gearbox takes away dust shaken off. Therefore, dust and rice are separated. The dedusting effect is improved by filtering and collecting procedures. Thus, rice quality is improved and rice taste is ensured.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

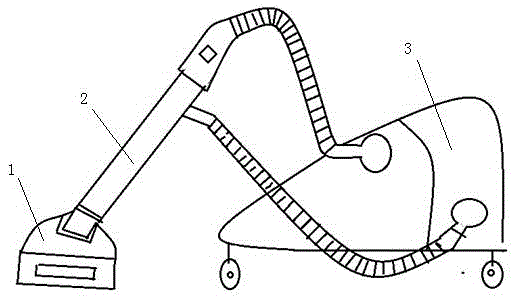

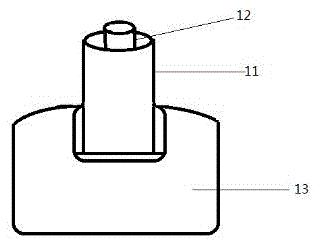

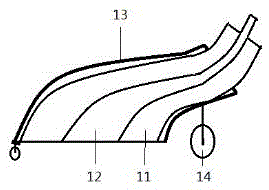

Dust collector sucking head and dust collector containing same

The invention discloses a dust collector which comprises an air suction pipe and a shell arranged on the outer side of the air suction pipe and is further provided with an air outlet pipe which is isolated from and parallel to the air suction pipe, the air outlet pipe is located in the center of the interior of the air suction pipe, and the cross section area of the air outlet pipe is smaller than or equal to half the cross section area of the air suction pipe. The invention further discloses a dust collector which comprises the sucking head, a sucking rod and a main machine. The sucking rod comprises an air suction channel and an air outlet channel which are connected with the air suction pipe and the air outlet pipe of the sucking head respectively; the main machine comprises an air suction mechanism and an air outlet mechanism, the air suction mechanism is connected with the air suction channel, and the air outlet mechanism is connected with the air outlet channel. According to the dust collector, an air outlet is added, dust or dirt which is located in a carpet, at the root of a hairy fabric and an uneven ground and is difficult to remove is fully dispersed through air flow impact of the air outlet, then a high dedusitng effect is achieved through sucking force of an air suction opening, and cleaning of the environment is achieved more easily.

Owner:HENAN INST OF SCI & TECH

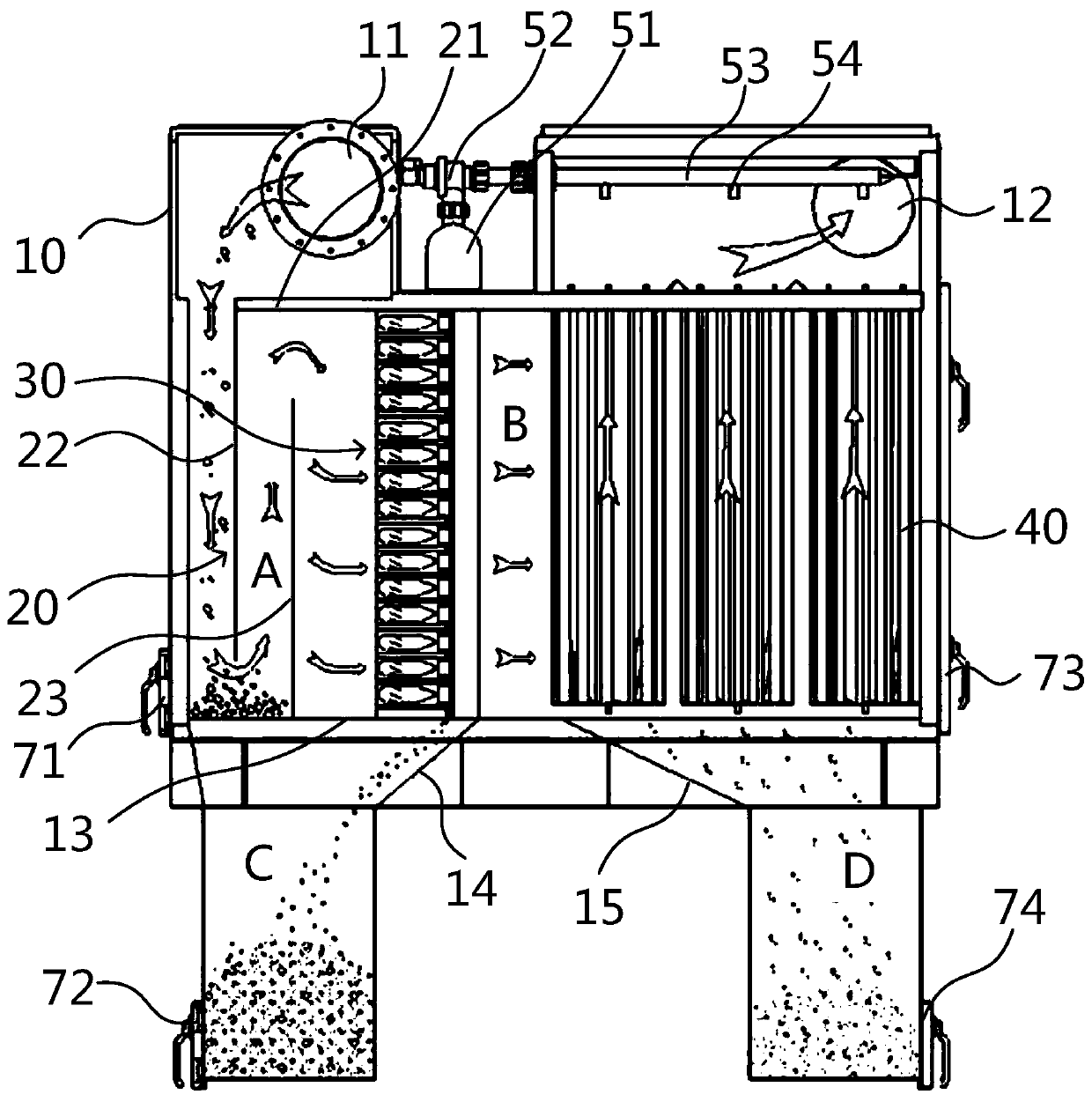

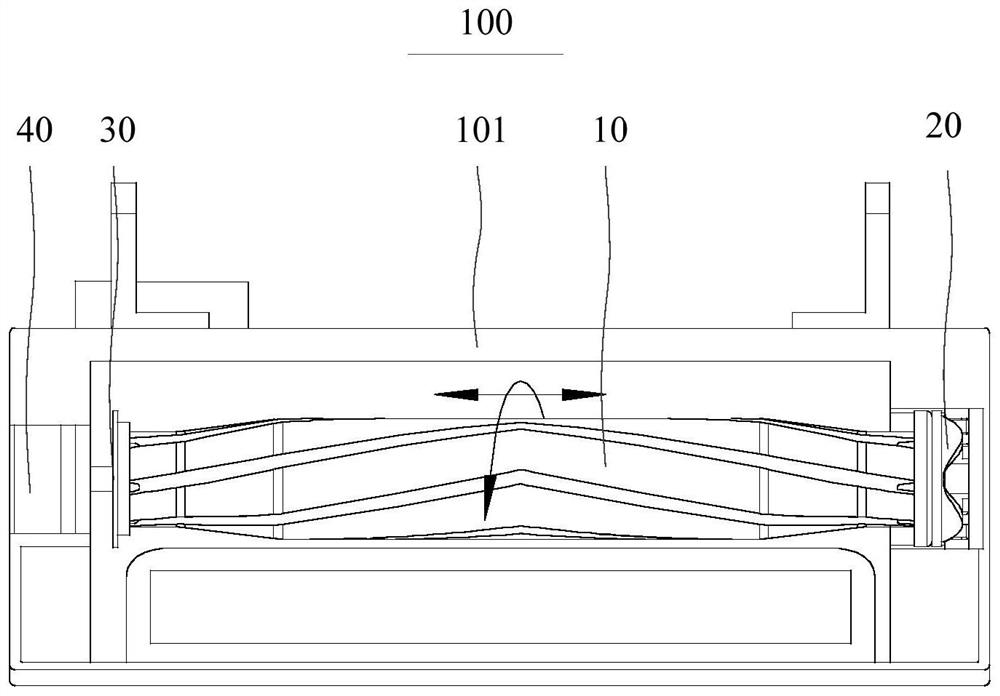

Dust removal device and vacuum operation vehicle

PendingCN110711455AStrong dust removal abilityReduce cleanup burdenCombination devicesTank vehiclesEngineeringDust control

The invention relates to a dust removal device and a vacuum operation vehicle, wherein the dust removal device comprises: a box body (10) which comprises a first filtering chamber (A) and a second filtering chamber (B) communicated with the first filtering chamber (A); a settling structure (20) that is arranged in the first filtering chamber (A); a filter cylinder body (40) which is arranged in the second filter chamber (B); a combined cyclone dust removal structure (30) that is arranged in a communication channel between the first filter chamber (A) and the second filter chamber (B). The boxbody (10) is provided with an air inlet (11) and an air outlet (12), wherein the air inlet (11) is formed in the first filtering chamber (A), and the air outlet (12) is formed in the second filteringchamber (B). According to the embodiments of the invention, the requirement of filtering precision is met through integrated arrangement of multi-stage filtering, and the cleaning burden of the dust removal device is reduced.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

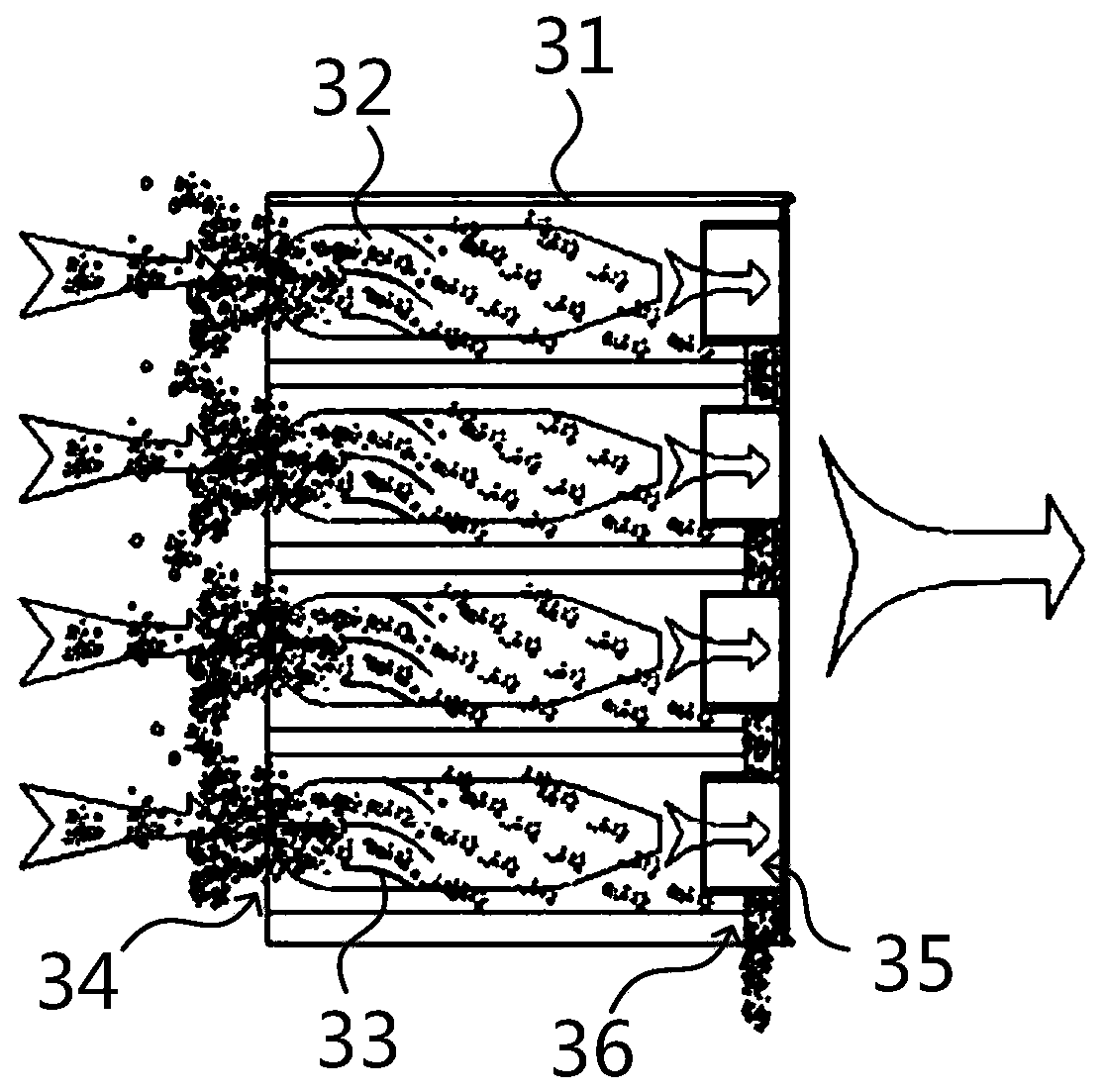

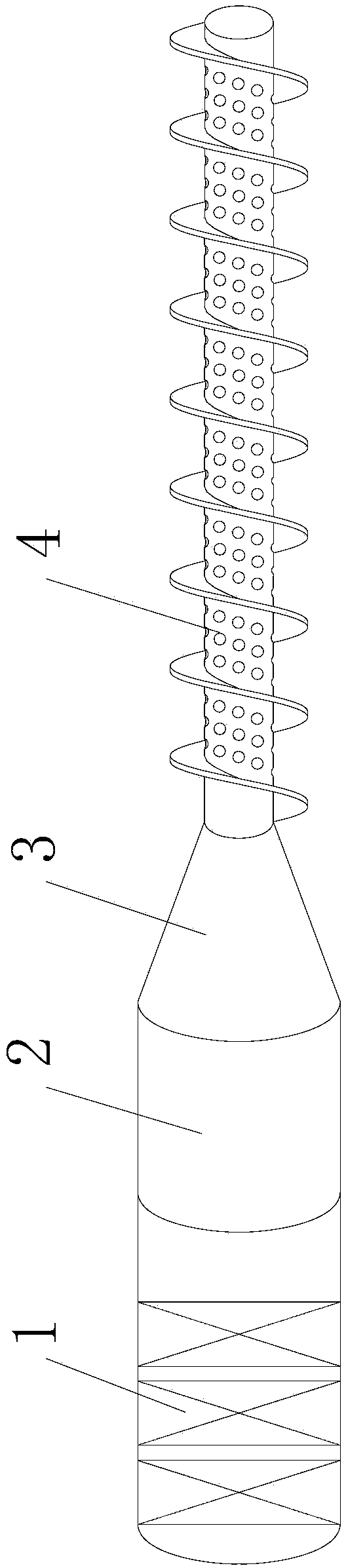

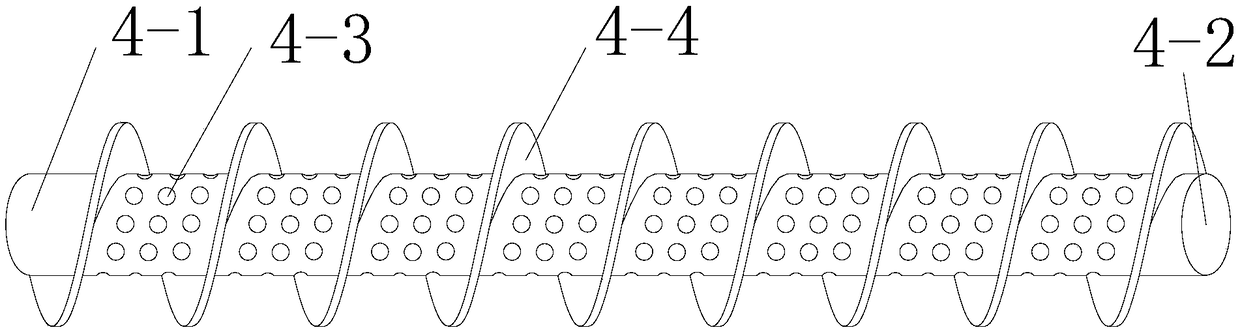

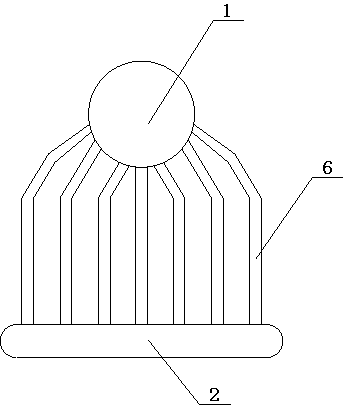

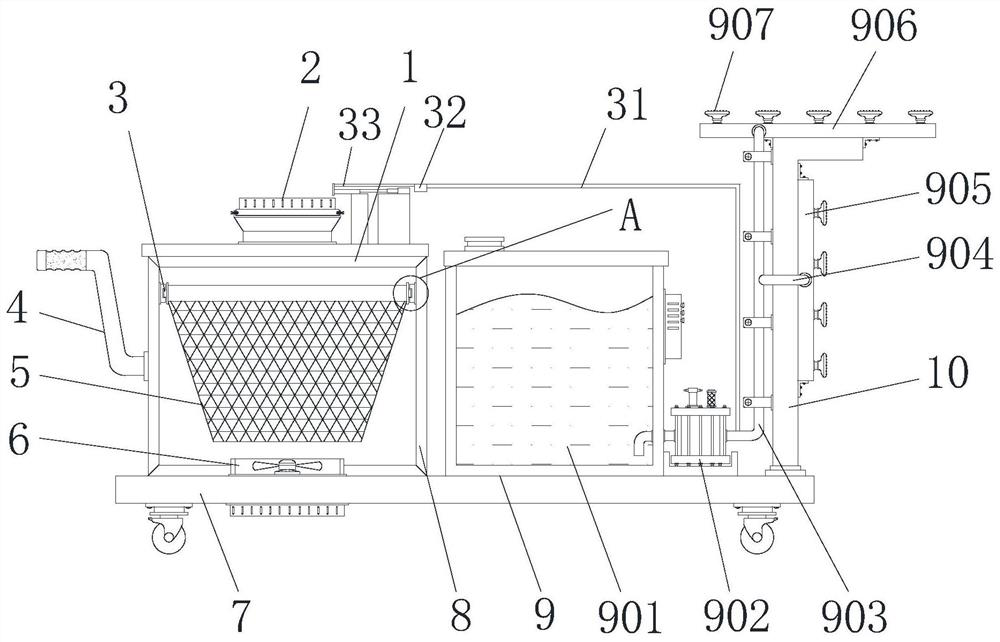

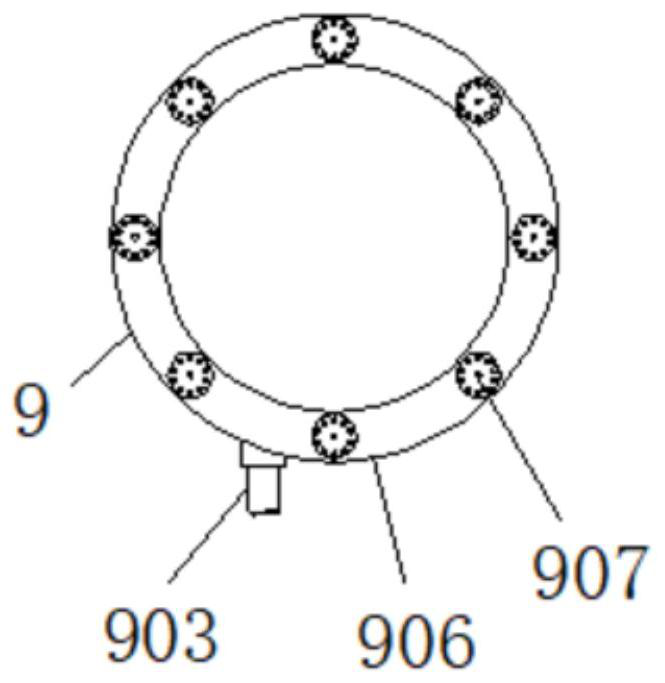

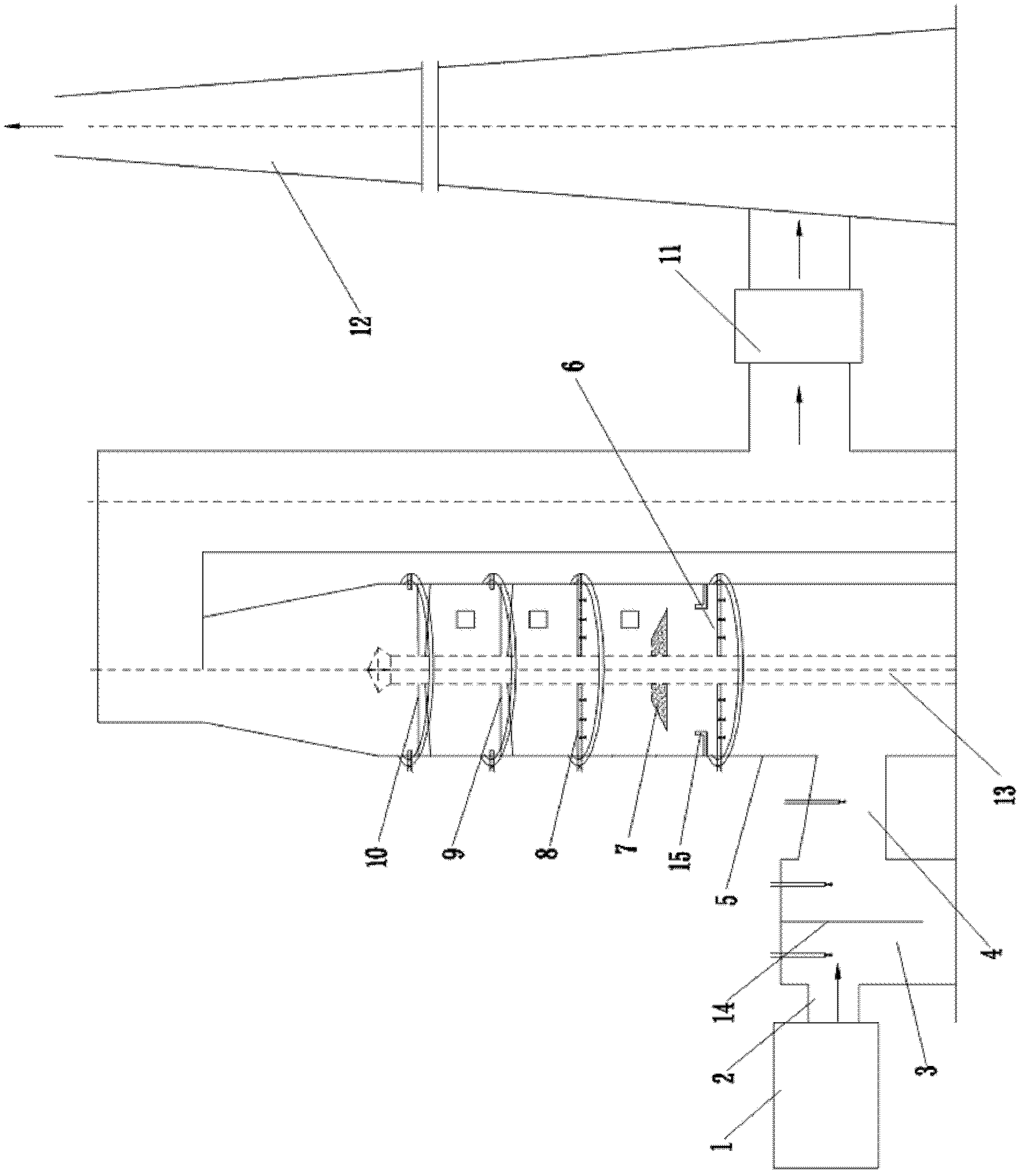

Negative pressure ventilating and dust removing device for mine

PendingCN109026115AImprove dust removal abilityImprove dust removal effectDust removalFire preventionAirflowEngineering

The invention discloses a negative pressure ventilating and dust removing device for a mine, which comprises an air cylinder, a multi-stage fan communicated with one end of the air cylinder and a horn-shaped connecting pipe communicated with the other end of the air cylinder. One end of the horn-shaped connecting pipe, away from the air cylinder, is connected with an air collecting pipe, and the horn mouth of the horn-shaped connecting pipe connected with the air cylinder is larger than the horn mouth of the horn-shaped connecting pipe connected with the air collecting pipe. The air collectingpipe comprises a pipe body and air guide fins which are spirally arranged on the pipe body, a plurality of meshes are arranged on the air collecting pipe sections between two adjacent spiral rings inthe air guide fin, one end of the pipe body is communicated with the horn-shaped connecting pipe, and the other end of the pipe body is an air collecting port of the air collecting pipe. Accoriding to the invention, the device is novel in design, by using the multi-stage fan, the pressure difference between the air in the dust removing device and the external air is increased, the flow velocity of the air is accelerated, the dust removing capacity is increased, the dust is guided by the air guide fins to enter the pipe body in a spiral shape, and the air flow obtains the rotary motion, the dust entering the pipe body forms vortex, thereby increasing the dust collecting range and the dust absorption speed and improving the dust removing effect.

Owner:XIAN UNIV OF SCI & TECH +1

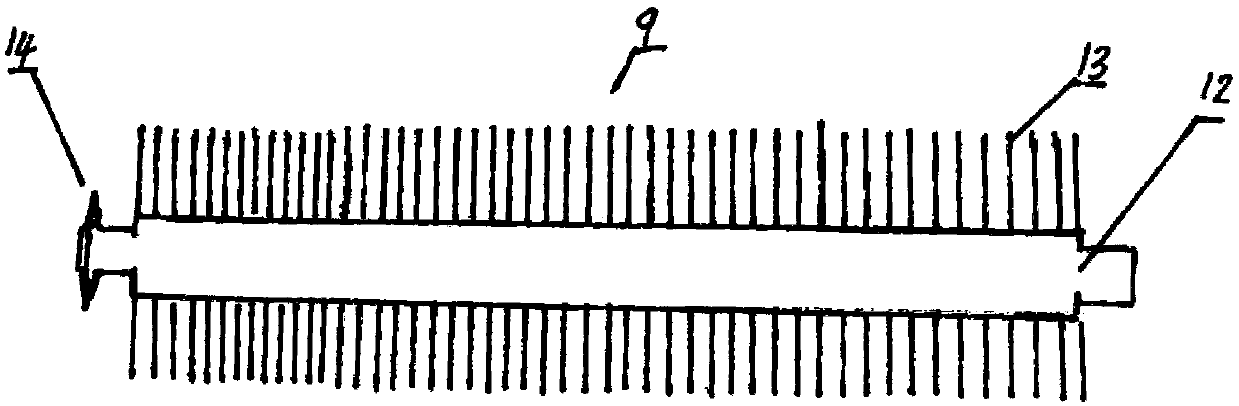

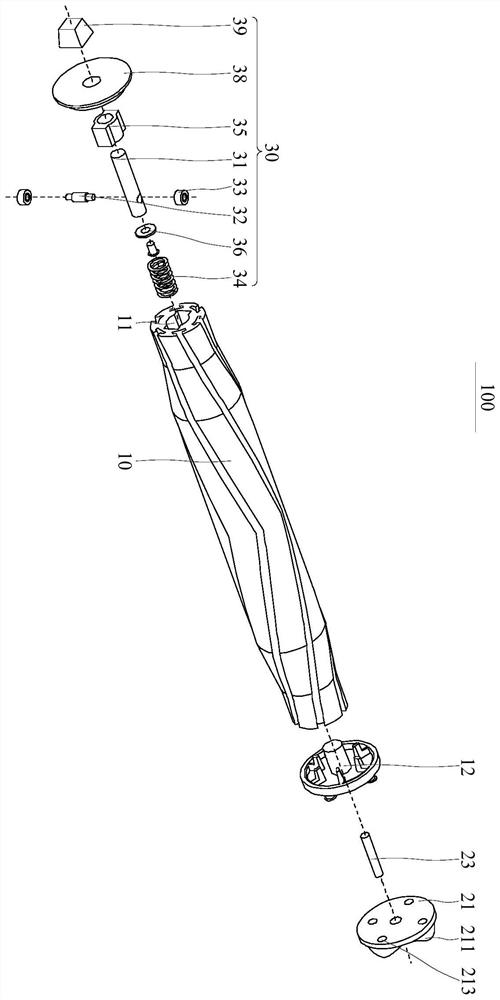

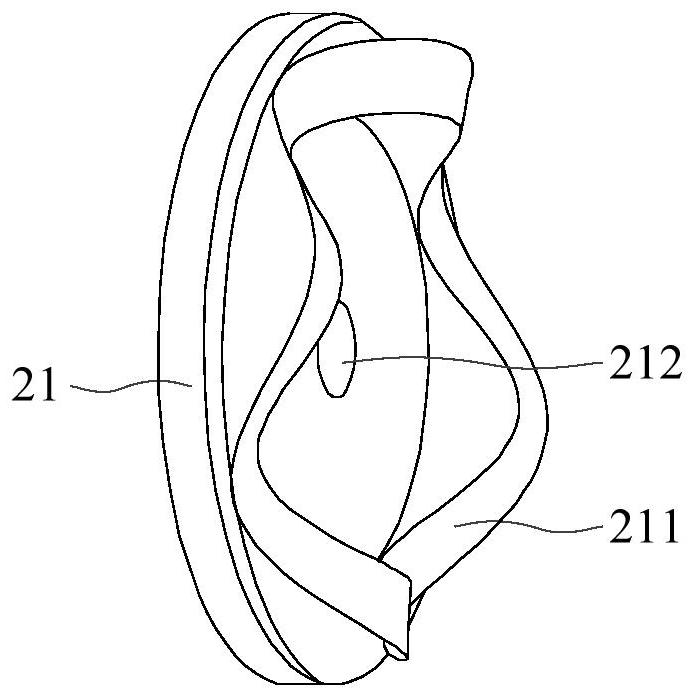

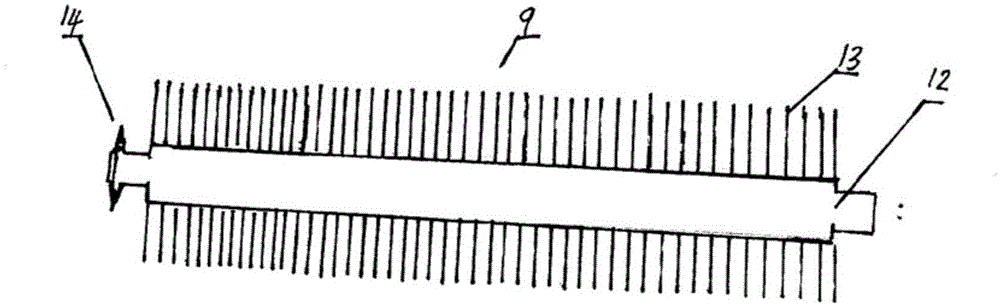

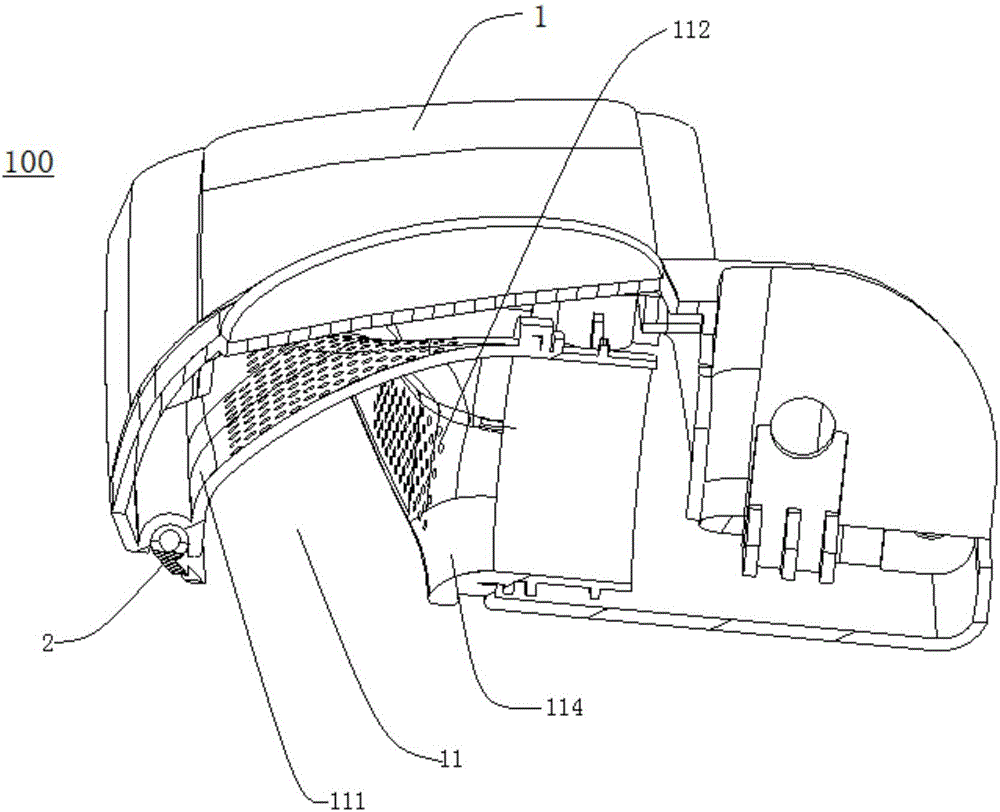

Rolling brush assembly and cleaning device with same

ActiveCN111904345AImprove dust removal abilityImprove dust removal efficiencyCarpet cleanersFloor cleanersReciprocating motionBrush

The invention relates to the technical field of cleaning equipment, in particular to a rolling brush assembly and a cleaning device with the same. The invention provides a rolling brush assembly whichcomprises a rolling brush shell, wherein a rolling brush cavity is formed in the rolling brush shell; a rolling brush shaft located in the rolling brush cavity and connected with a driving device ofthe rolling brush assembly; an axial reciprocating motion mechanism, wherein the first end of the rolling brush shaft is installed on the first side of the rolling brush shell through the axial reciprocating motion mechanism, and when the driving device drives the rolling brush shaft to rotate, the axial reciprocating motion mechanism drives the rolling brush shaft to do axial reciprocating motion. The rolling brush assembly can drive the rolling brush shaft to do axial reciprocating motion through the axial reciprocating motion mechanism in the process that the driving device drives the rolling brush shaft to do circumferential rotating motion, and therefore the rolling brush shaft can achieve combined motion of circumferential rotating motion and axial reciprocating motion, and the dusting effect and the dedusting efficiency of the rolling brush assembly are improved.

Owner:MIDEA ROBOZONE TECH CO LTD

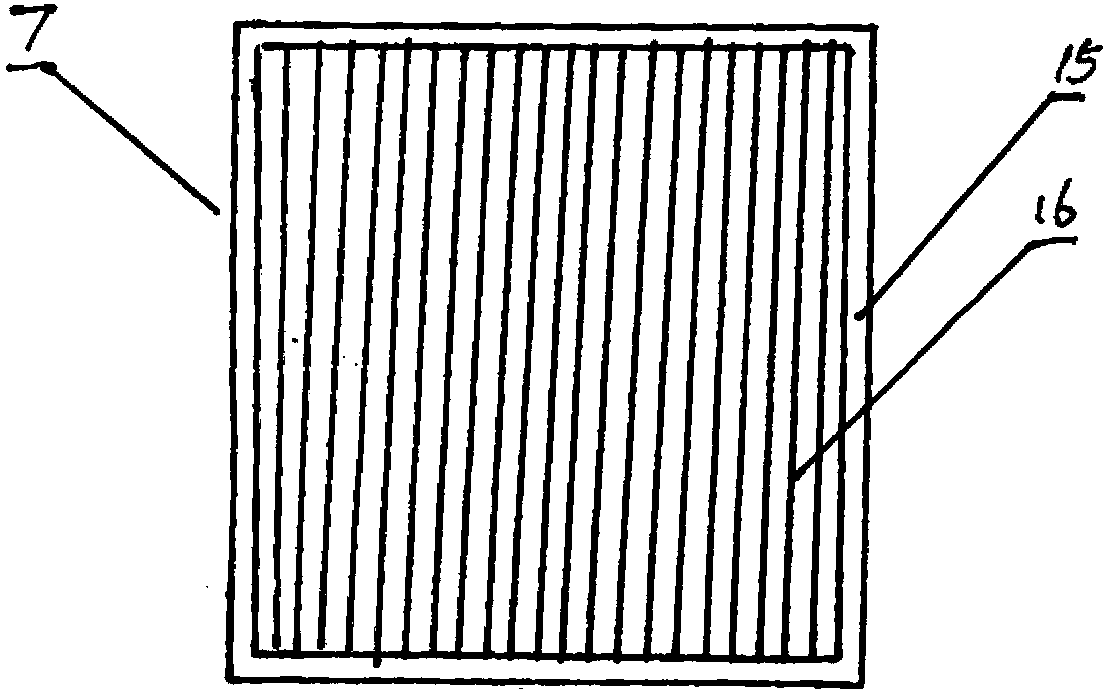

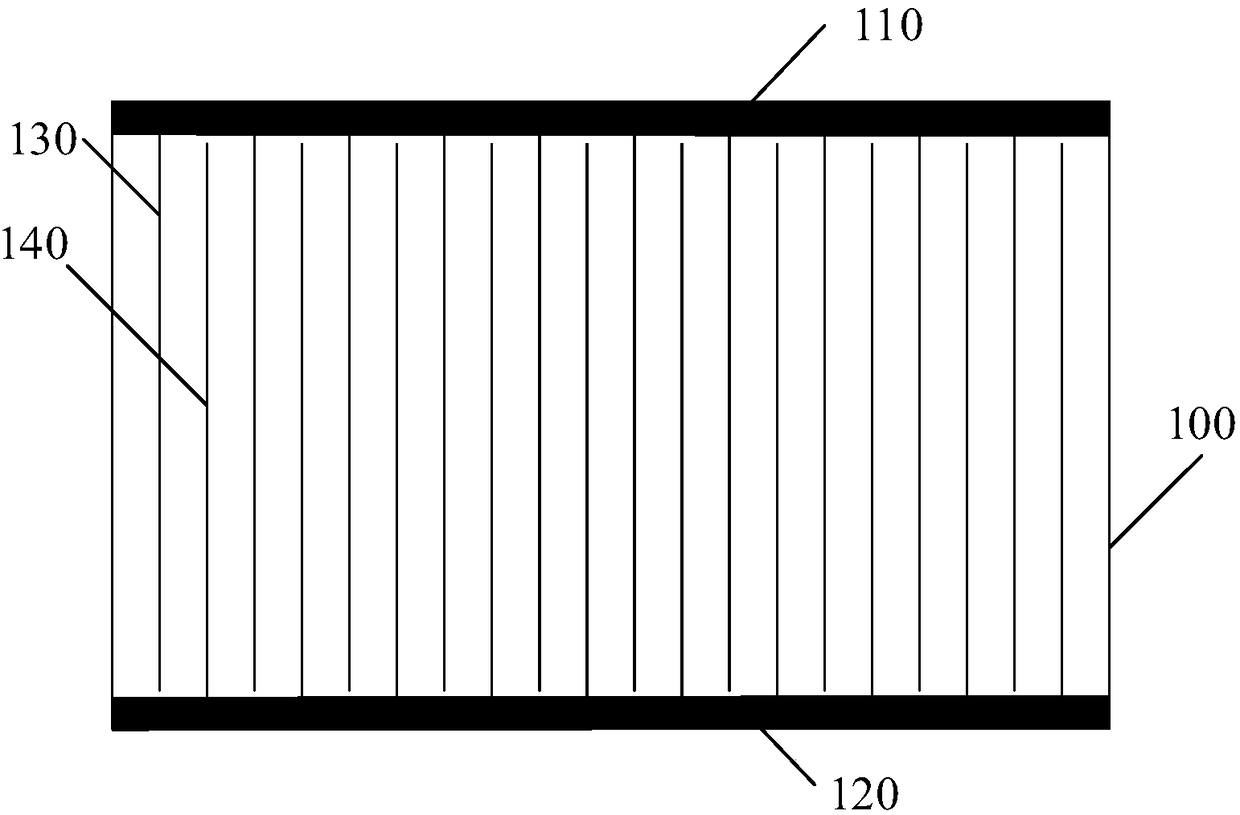

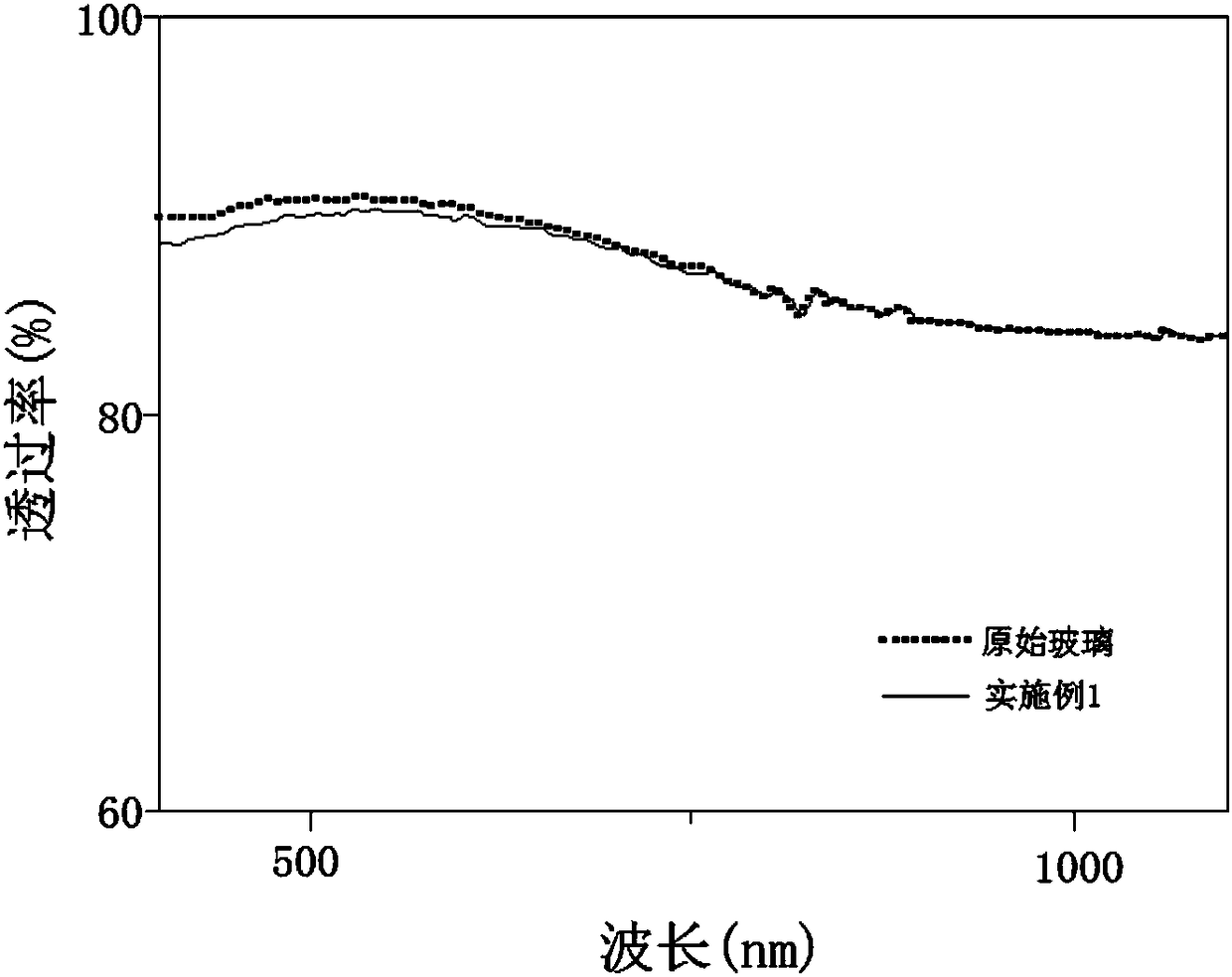

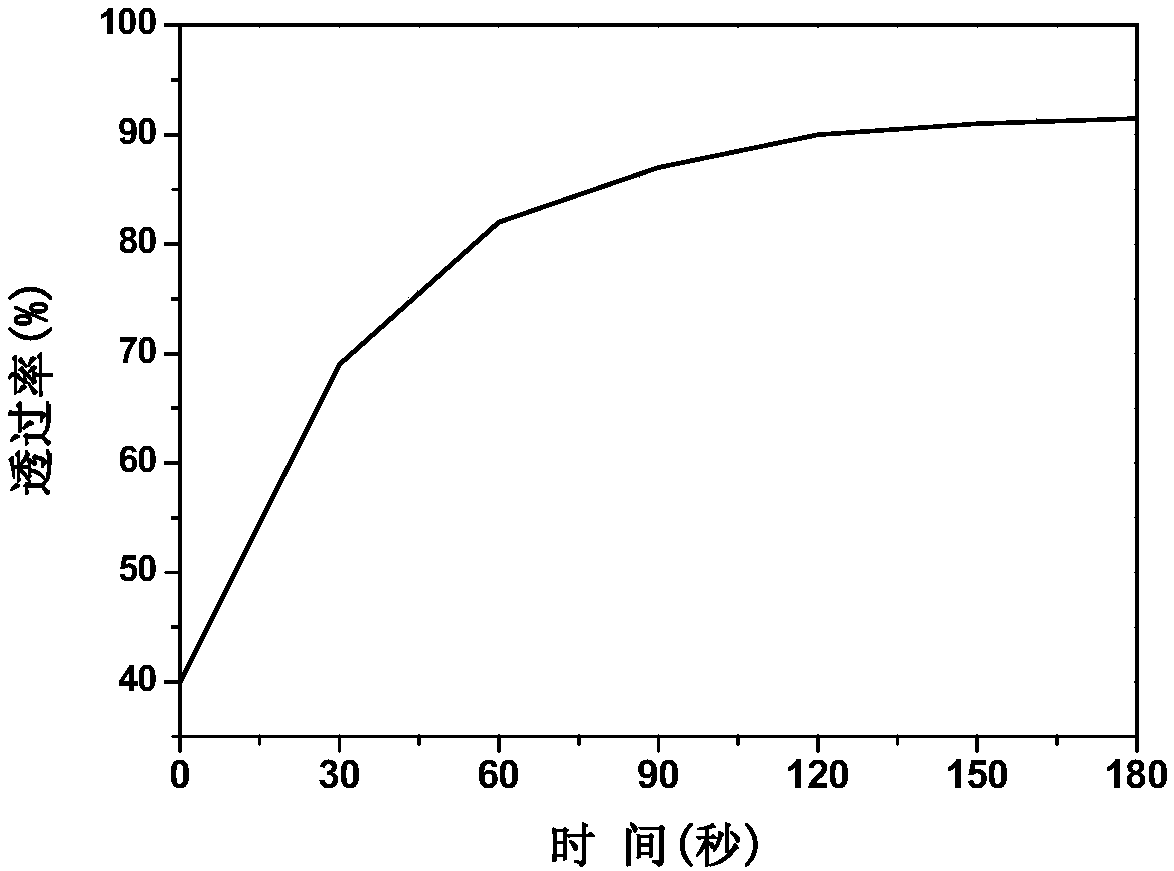

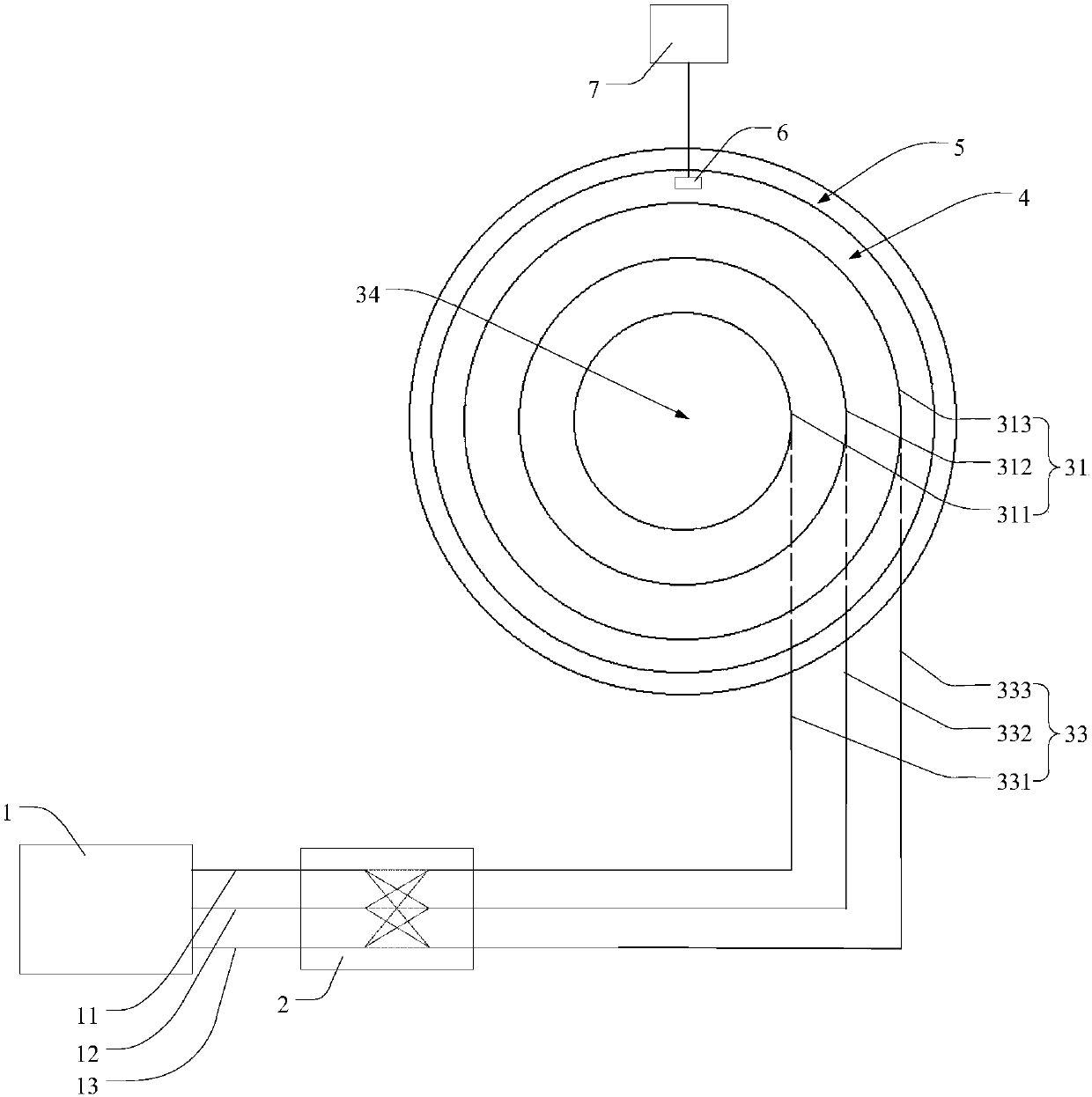

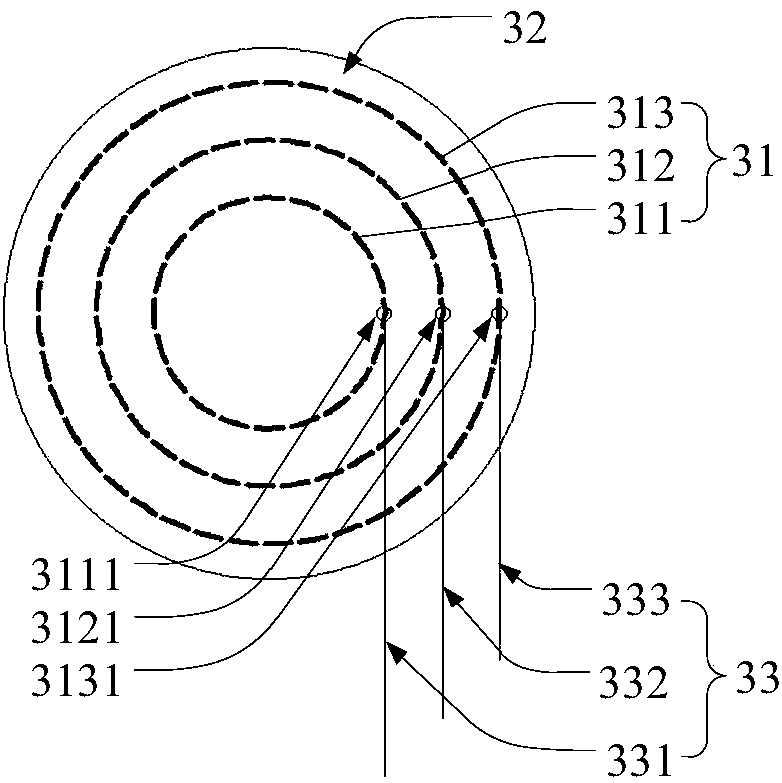

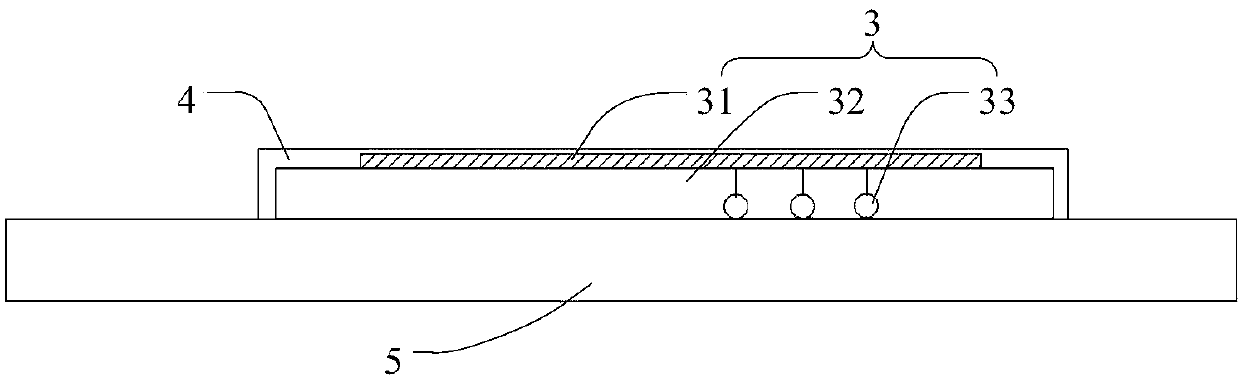

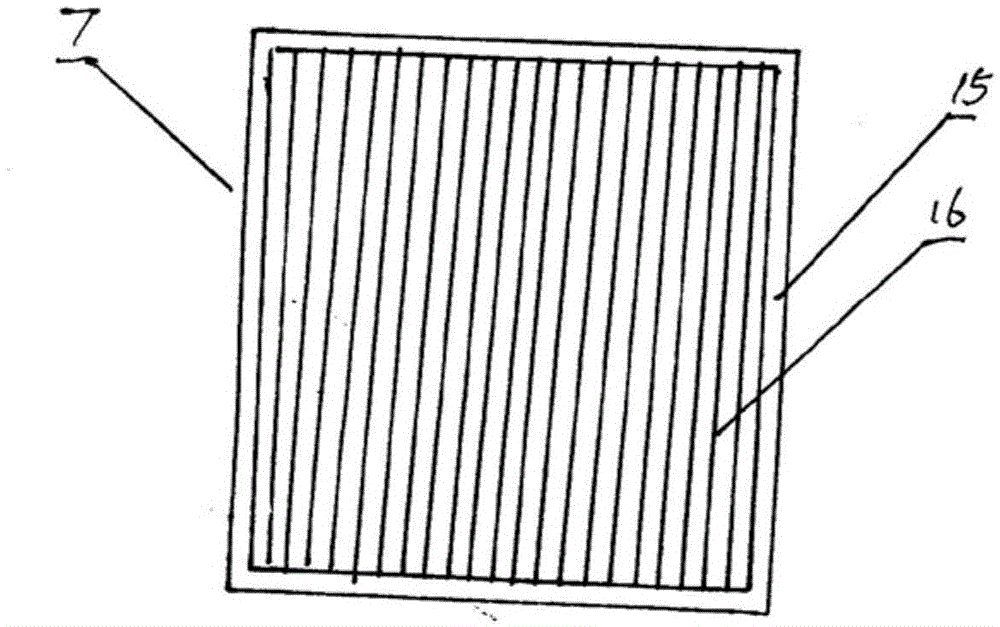

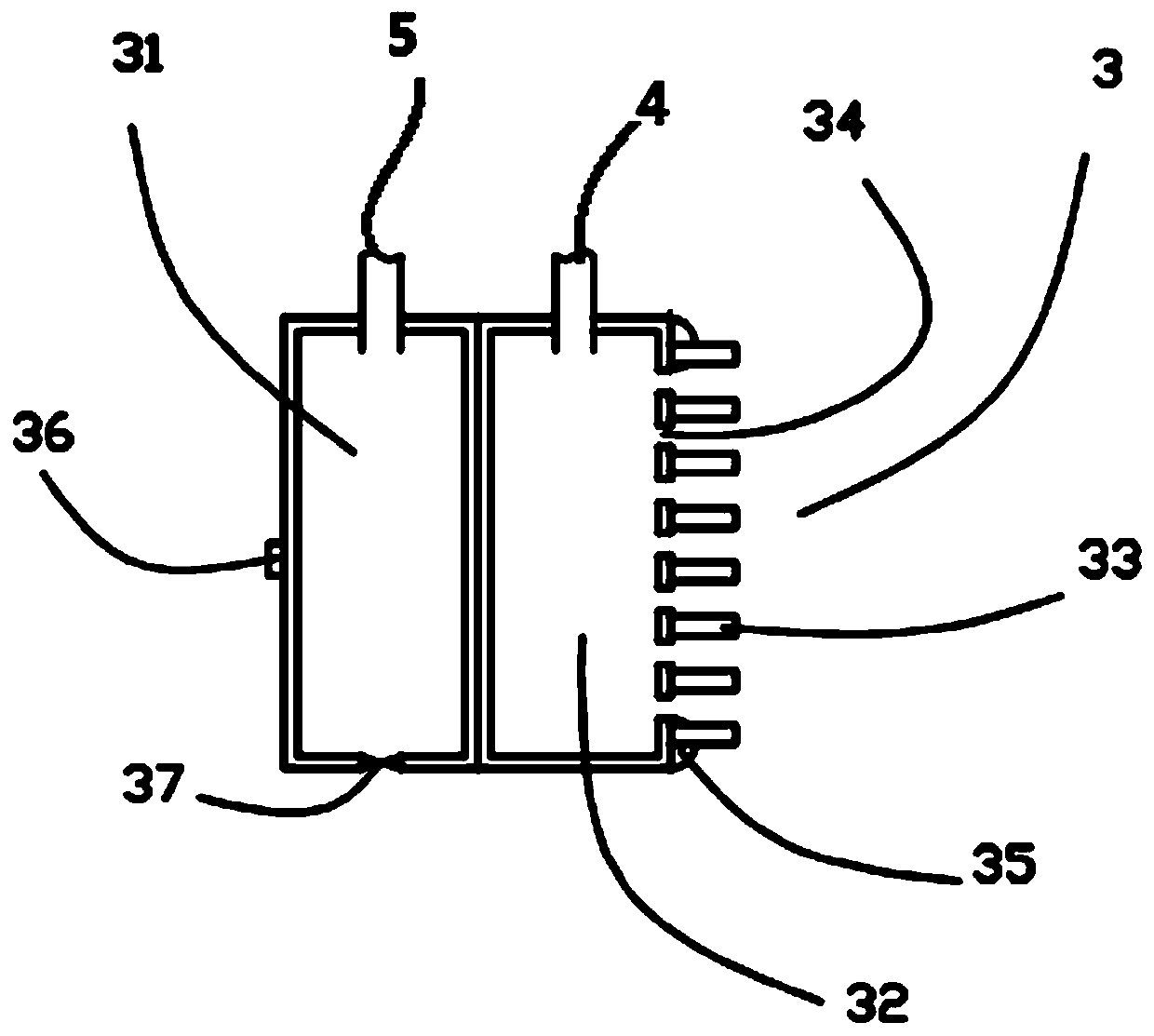

Electrostatic dust-removing glass, manufacturing method thereof, electrostatic dust-removing lens and camera equipment

PendingCN108160331AStrong dust removal abilityImprove practicality and application rangeTelevision system detailsColor television detailsElectrostatic precipitatorEngineering

The invention discloses electrostatic dust-removing glass, a manufacturing method thereof, an electrostatic dust-removing lens and camera equipment. The electrostatic dust-removing glass comprises a positive electrode, a negative electrode, a plurality of positive electrode wires and a plurality of negative electrode wires. The positive electrode and the negative electrode are parallelly arrangedon the two sides of the glass; the multiple positive electrode wires are arranged on the surface of the glass and connected to the positive electrode, and are perpendicular to the positive electrode;the multiple negative electrode wires and the positive electrode wires are alternately arranged on the surface of the glass, and the negative electrode wires are connected to the negative electrode, and are perpendicular to the negative electrode; and the spaces between the positive electrode wires and the negative electrode wires are 500-1000 [mu]m. The electrostatic dust-removing glass can achieve the very high dust-removing ability only through the relative small voltage, the practicability of the electrostatic dust-removing glass can be greatly improved, and the application range of the electrostatic dust-removing glass can be greatly enlarged.

Owner:SHENZHEN ZHONGTIAN GALAXY TECH

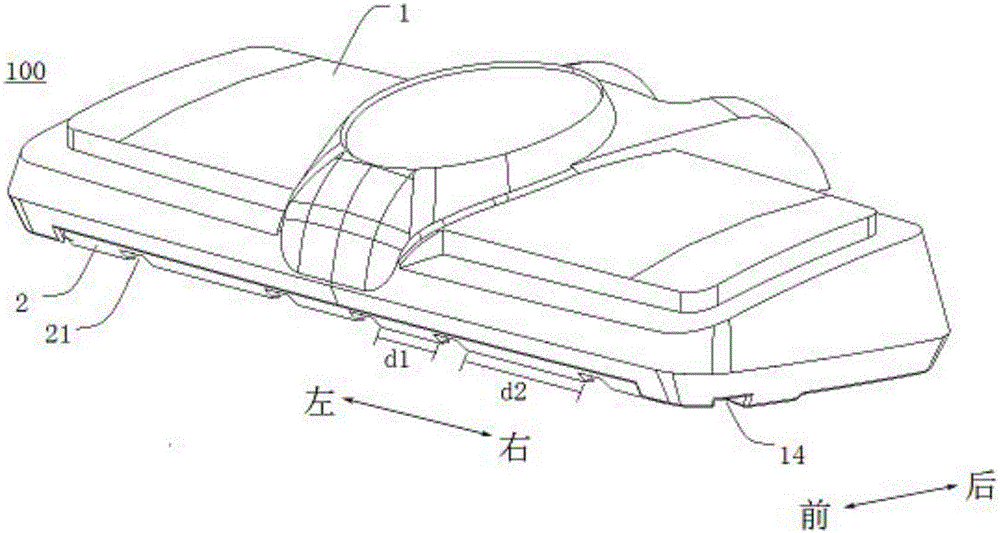

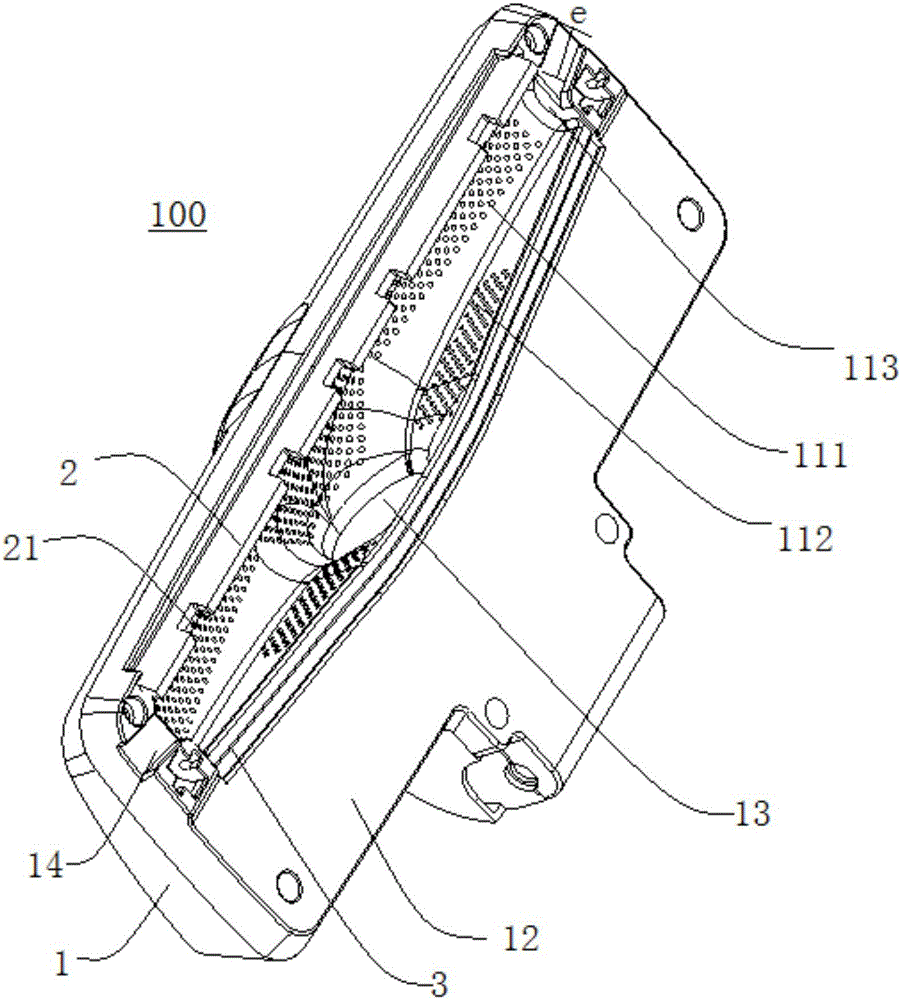

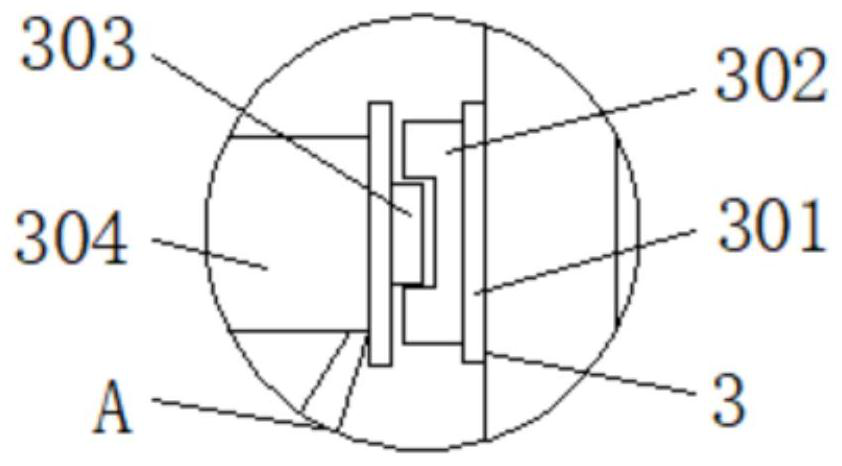

Dust removal cover and dust removal device

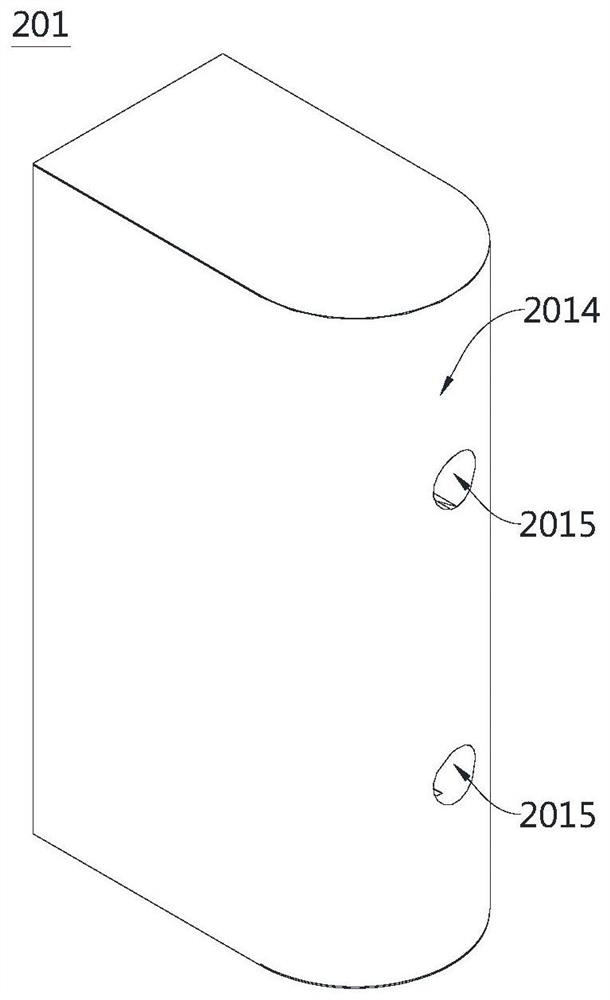

ActiveCN111774377AReduce the impactImprove dust removal abilityCleaning using gasesElectrical batteryDust control

The invention discloses a dust removal cover and a dust removal device, and belongs to the field of battery packaging. The dust removal cover comprises a cover body, and the cover body is provided with a cavity, an air inlet channel and an air outlet channel, and the air inlet channel and the air outlet channel are communicated with the cavity. The cover body is provided with a cavity having an opening defined by an inner surface. The air inlet channel penetrates through the outer surface and the inner surface of the cover body and forms an air inlet at the first position of the curved surfacepart; the air outlet channel penetrates through the outer surface and the inner surface of the cover body and forms an air outlet at a second position, different from the first position, of the curved surface portion. The dust removal cover can be used for efficiently removing dust on the surface of a pole piece in the roller passing process.

Owner:XIAMEN HAICHEN NEW ENERGY TECH CO LTD

Internal steering type dust removal and ventilation device

PendingCN111467922AAvoids problems requiring power-off commutation drivesAvoid the problem of reduced drainage capacityCombination devicesUsing liquid separation agentImpellerDust control

The invention relates to the field of ventilation equipment, and specifically relates to an internal steering type dust removal and ventilation device which comprises a horizontally arranged support mounting cylinder, a plurality of fixed mounting plates are outwards arranged at the two ends of the support mounting cylinder at equal angles; fixed mounting holes are formed in the fixed mounting plates in a penetrating manner; a rotary mounting cylinder is horizontally arranged in the middle of the interior of the support mounting cylinder; rotary mounting grooves are formed in the inner sides,right opposite to the upper side and the lower side of the rotary mounting cylinder, of the support mounting cylinder; a steering turntable is horizontally arranged in the middle of the upper end of the rotary mounting cylinder through a connecting column; an internal steering rotating structure is adopted, the interior of the device can be directly steered without power off; the problem that a traditional device needs to be powered off for reversing driving is avoided, the problem that the flow guiding capacity of impeller rotation is reduced after reversing driving is avoided, through a guiding installation structure, the device has good maintainability, the service life of the device is remarkably prolonged, a seepage adsorption structure is adopted, and the device can always keep gooddust removing capacity.

Owner:HUNAN VOCATIONAL INST OF TECH

Camera self-cleaning system and method

InactiveCN109967454AReduce energy consumptionImprove dust removal abilityCleaning processes and apparatusElectric fieldEngineering

The invention provides a camera self-cleaning system and method. The camera self-cleaning system comprises an N-phase power source, a changeover switch and N-phase electrodes; the N-phase electrodes comprise N polygonal electrodes, polygonal centers of all electrodes are the same in position, and the distances between every two adjacent electrodes are equal; under the condition that the N-phase power source is connected to the N-phase electrodes through the changeover switch, electric field waves extending outwards from the polygonal centers are generated by the N-phase electrodes, so that dust or particles attached to a camera can generate directional movement under the action of the electric field waves, and dust removal of the camera is completed; and under the condition that the N-phase electrodes are powered on, the electrodes can generate heat to evaporate moisture on the camera, and surface dehumidification of the camera is completed. The camera self-cleaning system and method have the advantages of low energy consumption, the long electrode service life and the strong dust removal effect.

Owner:重庆国太科技有限公司

Efficient garbage cleaning vehicle

An efficient garbage cleaning vehicle is characterized by being composed of an advancing system, a ground sweeping system, a garbage transmission system and a dust removal system. The advancing system is suitable for various fuel vehicles provided with a garbage cleaning device; the ground sweeping system comprises a lifting ground sweeping roller; the garbage transmission system comprises a garbage conveying axle, a conveyor belt conveyor belt and a garbage storage tank; the dust removal system comprises a draft pipeline, a draft fan, a water tank, a water sprayer and a multi-layer strainer. The ground is cleaned by rotating the sweeping roller parallel to the ground, and lateral elastic force in the transverse direction is not generated in rotation; and mist is sprayed onto the multi-layer strainer through the water sprayer of the water sprayer, so dust adhered to the multi-layer strainer flows downwards along with the water drops and thus the dust handling capacity is high.

Owner:李先强

Ground brush of dust collector and dust collector

ActiveCN106108778AOptimize the air ductImprove dust removal effectSuction nozzlesExhaust-air diffusionAirflowEngineering

The invention discloses a ground brush of a dust collector and the dust collector. The ground brush of the dust collector comprises a body and front dust collecting strip. An air channel is defined in the body. The bottom plate is provided with a suction port connected with the air channel. The back side of the body is provided with an air exhaust opening. When the body covers a to-be-cleaned surface, an air-tight space is formed between the air channel and the to-be-cleaned surface. The front dust collecting strip is arranged at the front end of the body for supporting the ground brush of the dust collector on the to-be-cleaned surface. The front dust collecting strip is provided with multiple forwarding air inlets communicating with the air channel and oblique relative to the normal direction of the to-be-cleaned surface. According to the ground brush of the dust collector, the air channel of the ground brush of the dust collector is optimized and a air-flow state of the ground brush of the dust collector is improved. Therefore, de-dusting capability of the ground brush of the dust collector is effectively enhanced and noise of the ground brush of the dust collector is reduced. The ground brush of the dust collector is simple in structure and low in cost.

Owner:GUANGDONG MIDEA WHITE GOODS TECH INNOVATION CENT CO LTD +1

Waste heat boiler for small waste incineration plant

InactiveCN103900091AStrong dust removal effectGuaranteed cleanlinessIncinerator apparatusSteam generation using hot heat carriersExpansion jointSafety valve

The invention discloses a waste heat boiler for a small waste incineration plant. The waste heat boiler comprises a waste heat boiler body, a steam pocket and a lower header. One end of the waste heat boiler body is connected with an incinerator through an expansion joint, and the other end thereof is connected with a dust remover through an expansion joint. One end, close to the incinerator, of the lower header is connected with the steam pocket through an anti-coking pipe. One end, close to the dust remover, of the lower header is connected with the steam pocket through a convection heat absorption tube bundle. The convection heat absorption tube bundle comprises a light tube bundle and a fin tube bundle which are sequentially arranged along a smoke coming direction. A safety valve is connected to the upper surface of the steam pocket. A blow-down valve is disposed on the lower surface of the lower header. Dust cleaning openings are symmetrically formed on the sides of the lower header. The waste heat boiler is capable of fully utilizing waste heat.

Owner:海诺尔环保产业股份有限公司

Raw material mixing device for chemical fertilizer production

InactiveCN109224921AImprove mixing efficiencyPrecise proportioning and mixingRotary stirring mixersTransportation and packagingEngineeringMixing tank

The invention relates to the technical field of chemical fertilizer production equipment, in particular to a raw material mixing device for chemical fertilizer production. The raw material mixing device comprises a mixing tank body and a controller; supporting legs are fixedly arranged at the bottom of the mixing tank body; a dust collecting box is fixedly arranged at the center of the top of themixing tank body; the controller is arranged on the left side, close to the dust collecting box, of the top of the mixing tank body; a first feeding hopper is fixedly arranged on the left side of thetop of the mixing tank body; a second feeding hopper is fixedly arranged on the right side of the top of the mixing tank body; supporting rods are fixedly arranged at four corners of the upper edges of the tops of the first feeding hopper and the second feeding hopper; dust covers are fixedly arranged at the tops of the supporting rods; dust suction plates are fixedly arranged in the dust covers;and a branch pipe is connected to the tops of the dust covers. The whole device has the advantages that precise weighing, proportioning and mixing are realized, the working efficiency is high, the structure is simple, the use is convenient, the stability and the practicability are high, and a certain popularization value is achieved.

Owner:潍坊晟源新能源机械设备有限公司

Environment-friendly dust removal device for building construction

ActiveCN111643995AReduce noiseEasy to disassemble and replaceCombination devicesDispersed particle filtrationArchitectural engineeringMechanical engineering

The invention discloses an environment-friendly dust removal device for building construction. The device comprises a dust suction box, a dust suction port, a push handle and a bottom plate, wherein adust suction port is fixedly connected to the top end of the dust suction box, a dust suction fan is fixedly connected to the bottom end of the interior of the dust suction box, a bottom plate is fixedly connected to the bottom end of the dust suction box, a noise reduction structure is fixedly connected to the inner side wall of the dust suction box, and a first dust falling mechanism is fixedlyconnected to one side of the top end of the noise reduction structure. Dust is removed through the arrangement of the dust suction fan and the first dust falling mechanism, so that the dual dust removal function is achieved, and the dust removal efficiency is improved.

Owner:深圳市卓越装饰工程有限公司

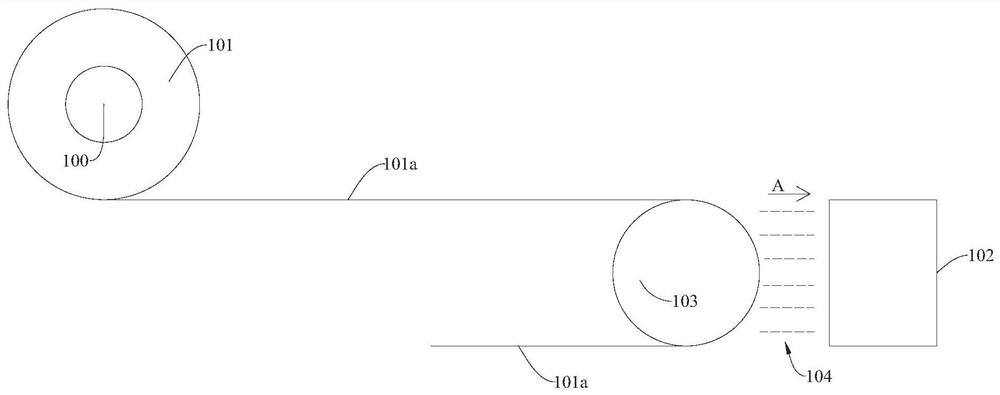

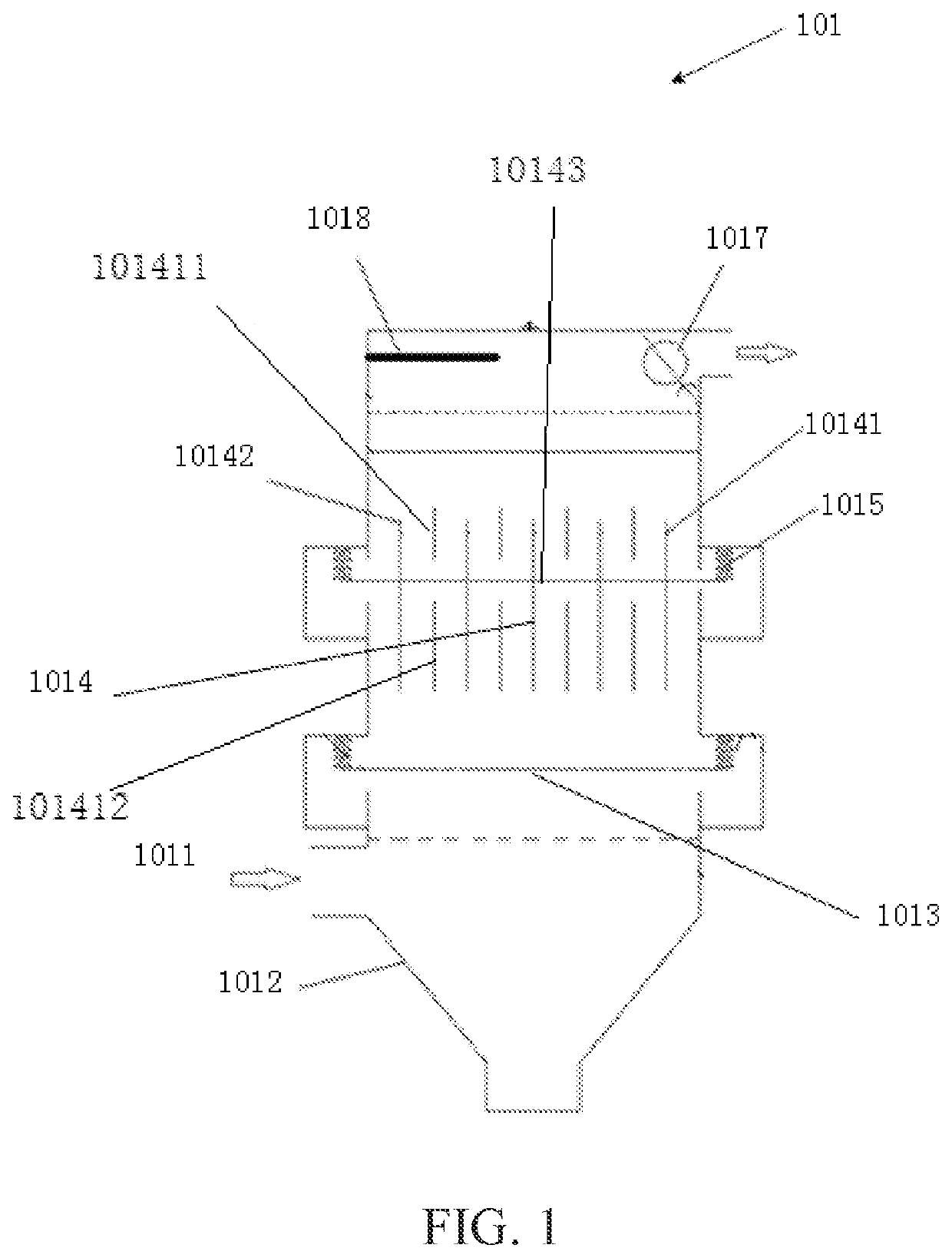

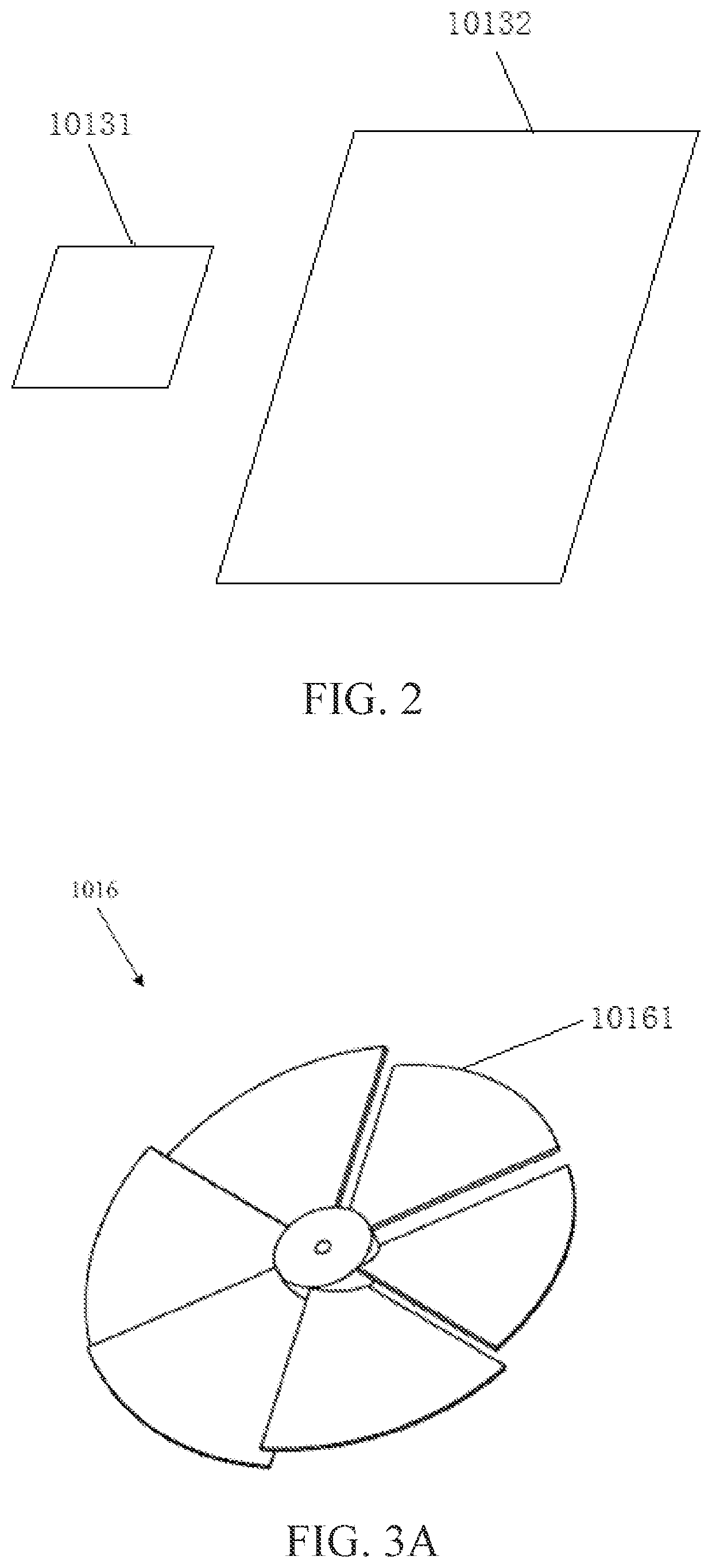

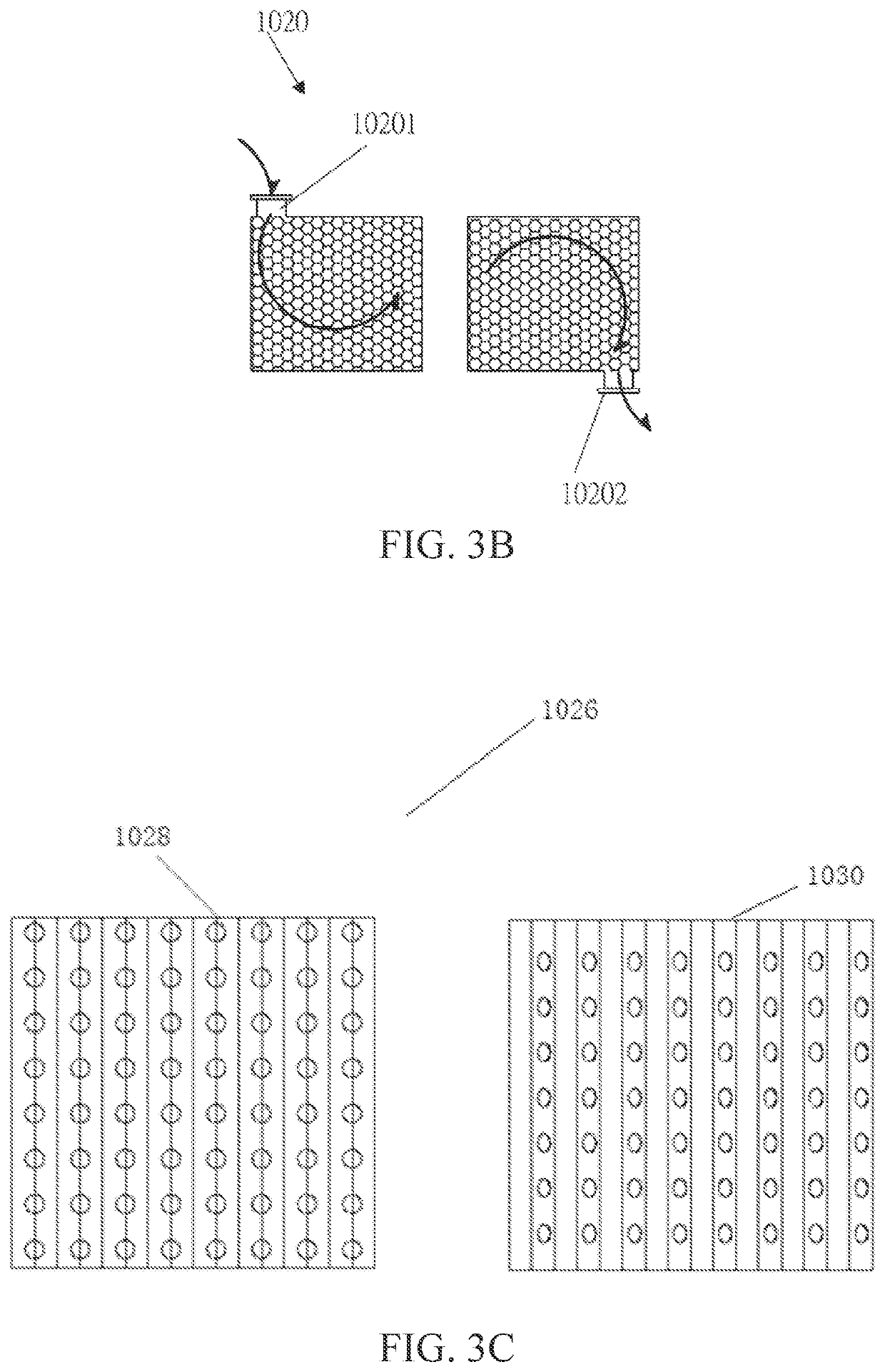

Air dust removal system and method

InactiveUS20210308692A1Not implemented efficientlyImprove dust removal abilityInternal combustion piston enginesLighting and heating apparatusParticulatesAtmospheric sciences

An air dust removal system (101) and method, comprising a dust removal system inlet, a dust removal system outlet, and an electric field device. The electric field device comprises an electric field device inlet (1011), an electric field device outlet (1012), a dust removal electric field cathode (10142), and a dust removal electric field anode (10141). The dust removal electric field cathode (10142) and the dust removal electric field anode (10141) are used to generate an ionizing dust removal electric field. The present air dust removal system (101) and method may effectively remove particulate matter from the air.

Owner:SHANGHAI BIXIUFU ENTERPRISE MANAGEMENT CO LTD

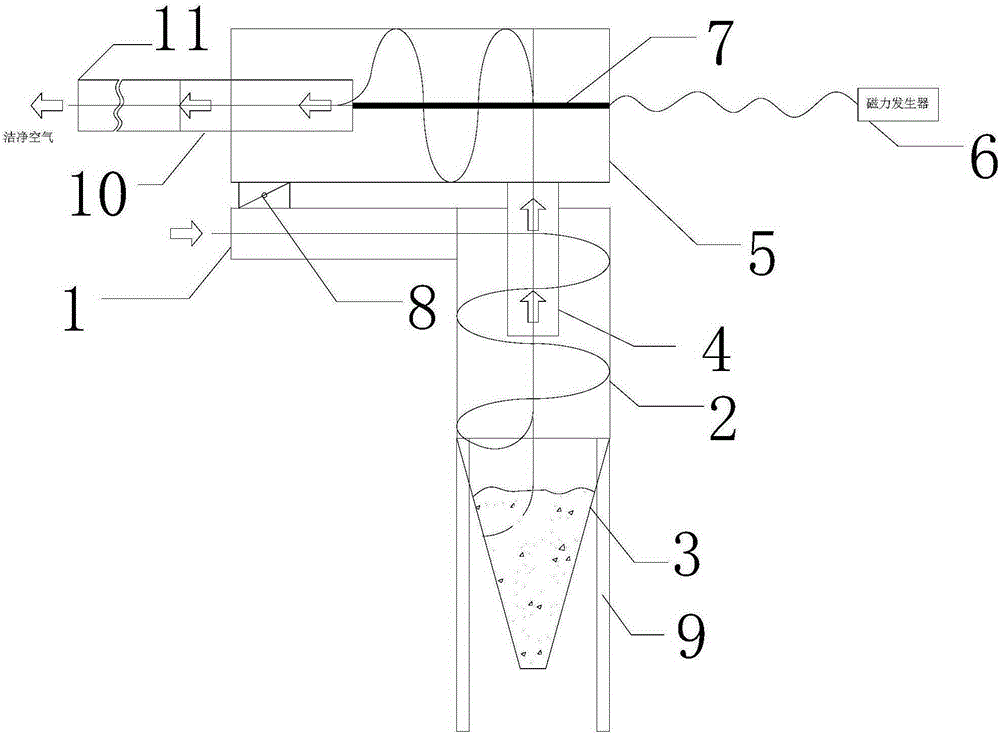

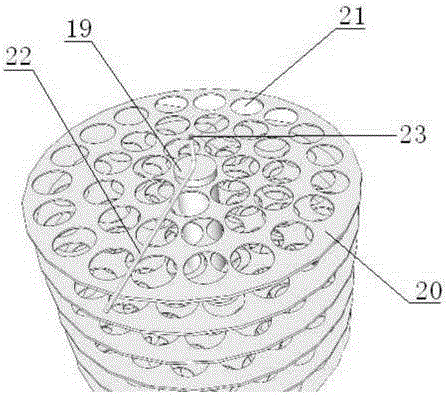

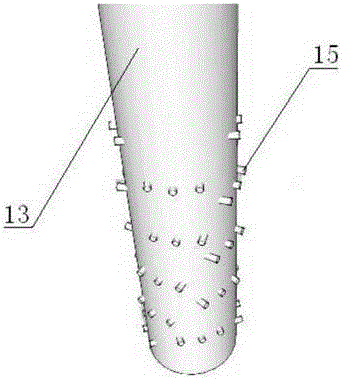

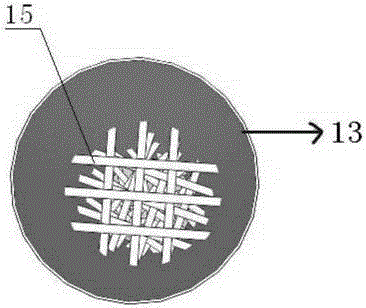

Two-stage cyclone magnetic dust remover

The invention discloses a two-stage cyclone magnetic dust remover. The two-stage cyclone magnetic dust remover comprises an air inlet pipe, a vertical cyclone barrel, a dust hopper, an air raising pipe, a cyclone body, a magnetic field generator, a magnetic line, a one-way dust falling valve, supporting legs, an exhaust pipe and an air receiving draught fan. The air inlet pipe is a cylindrical hollow pipe. The vertical cyclone barrel is cylindrical. The supporting legs are arranged on the edge of the bottom of the vertical cyclone barrel for supporting. The dust hopper is connected to the bottom of the vertical cyclone barrel. The air raising pipe is installed on the top of the vertical cyclone barrel. The cyclone body is cylindrical. The leftmost end of the bottom of the cyclone body is connected with the top of the air inlet pipe through the one-way dust falling valve. The exhaust pipe is installed on the left side face of the cyclone body. The air receiving draught fan is installed at the left end of the exhaust pipe. The magnetic generator is connected with the magnetic line. The floor space of the dust remover is smaller, filtering precision and dust removing efficiency are substantially improved, the dust removing effect is high, the service life of the dust remover is longer, and the application range is wide.

Owner:ZHEJIANG JUHONG MECHANICAL TECH

No-smoke environment-friendly and energy-saving funnel

ActiveCN106765255AGuaranteed tightnessEnsure thoroughnessChimneysCombustion technology mitigationDust controlSewage

The invention discloses a no-smoke environment-friendly and energy-saving funnel. The no-smoke environment-friendly and energy-saving funnel is characterized in that an air-removed sewage pool and an air-removed pure water pool are two closed cuboid spaces clinging to each other, and a smoke exhaust pipeline connected with a boiler communicates with the air-removed sewage pool through a smoke prevention and dust control device; the smoke exhaust pipeline comprises a plurality of insulated pipes which communicate in sequence, and a plurality of layers of transversely staggered and sequentially communicating heat absorbing water pipes are arranged in each insulated pipe in the length direction to absorb heat in exhaust gas of the boiler; and the smoke prevention and dust control device comprises a plurality of smoke prevention sheets arranged on a central upright in a sleeving manner, a plurality of round holes distributed in the circumferential direction are formed in each smoke prevention sheet, and the round holes in every two adjacent smoke prevention sheets are mutually staggered, so that smoke sedimentation and exhaust gas separation are guaranteed. According to the no-smoke environment-friendly and energy-saving funnel, energy of exhaust gas of the boiler is re-utilized through the heat absorbing water pipes, meanwhile, the leakproofness and the thoroughness of smoke prevention and dust control are guaranteed, and therefore, the no-smoke environment-friendly and energy-saving funnel is energy-saving and environment-friendly, long in service life and convenient to use and maintain.

Owner:董立丰 +1

Dust removing blackboard eraser

The invention provides a dust removing blackboard eraser. The blackboard eraser comprises a sliding rod, a dust collecting device, a blackboard erasing device, a dust suction pipe and a dust outlet pipe, the dust collecting device is slidably connected with the sliding rod, the dust collecting device comprises a housing and a negative pressure device, the housing is internally provided with the negative pressure device, the negative pressure device is provided with a dust suction hole, a dust outlet and a gas discharging hole, and the blackboard eraser is provided a dust suction cavity, a duststorage cavity and bristles; the dust suction cavity is connected with a negative pressure chamber through the dust suction pipe to form a dust suction loop, and the dust storage cavity is connectedwith the dust outlet through the dust outlet pipe to form a dust outlet loop. The blackboard eraser has the advantages that the use is convenient and flexible, the dust removing capacity is high, timeand strength are saved when large-area erasing is conducted, and the targeting performance is high when the blackboard eraser is used for performing targeted revising on mistakes or small-area erasing.

Owner:刘维

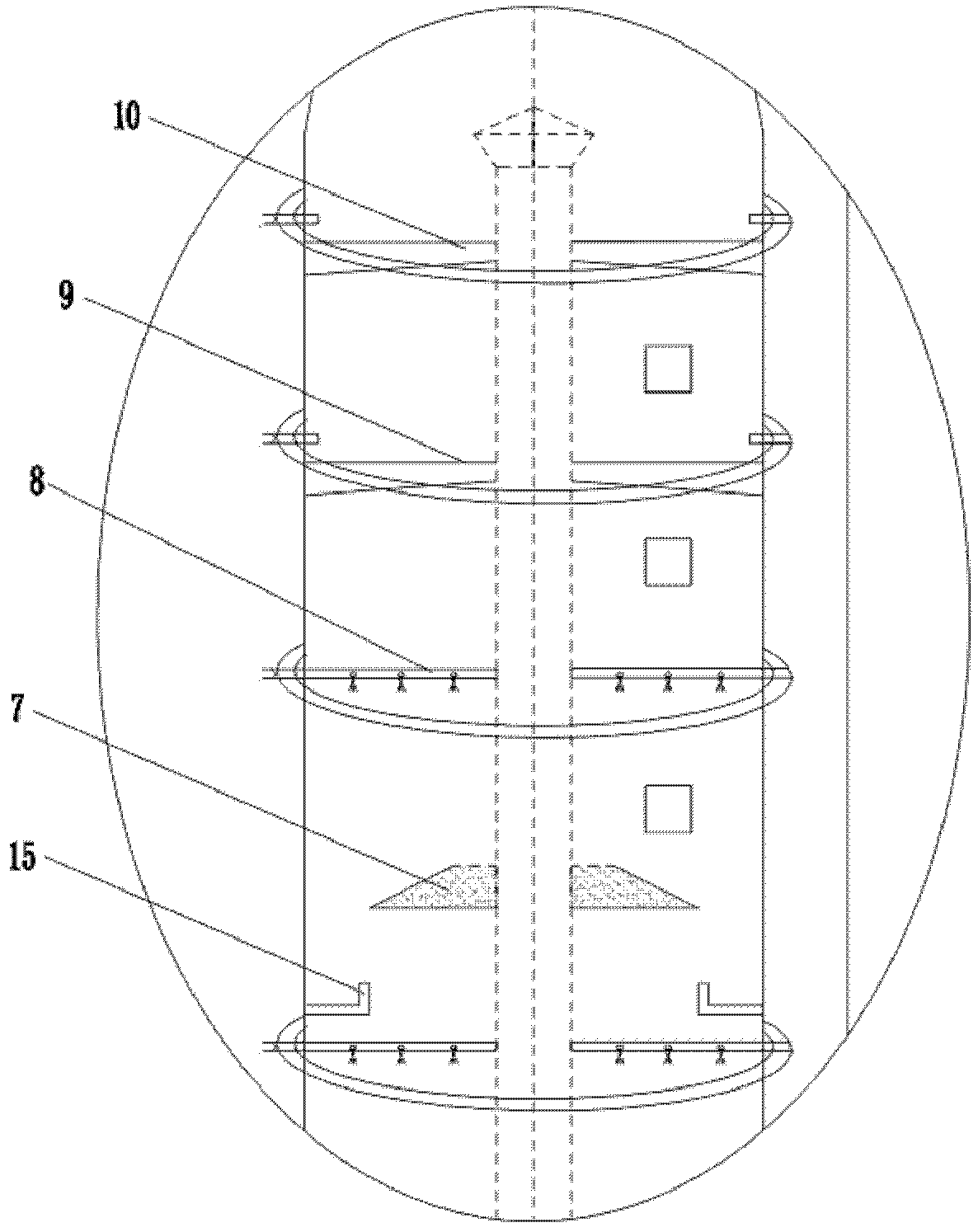

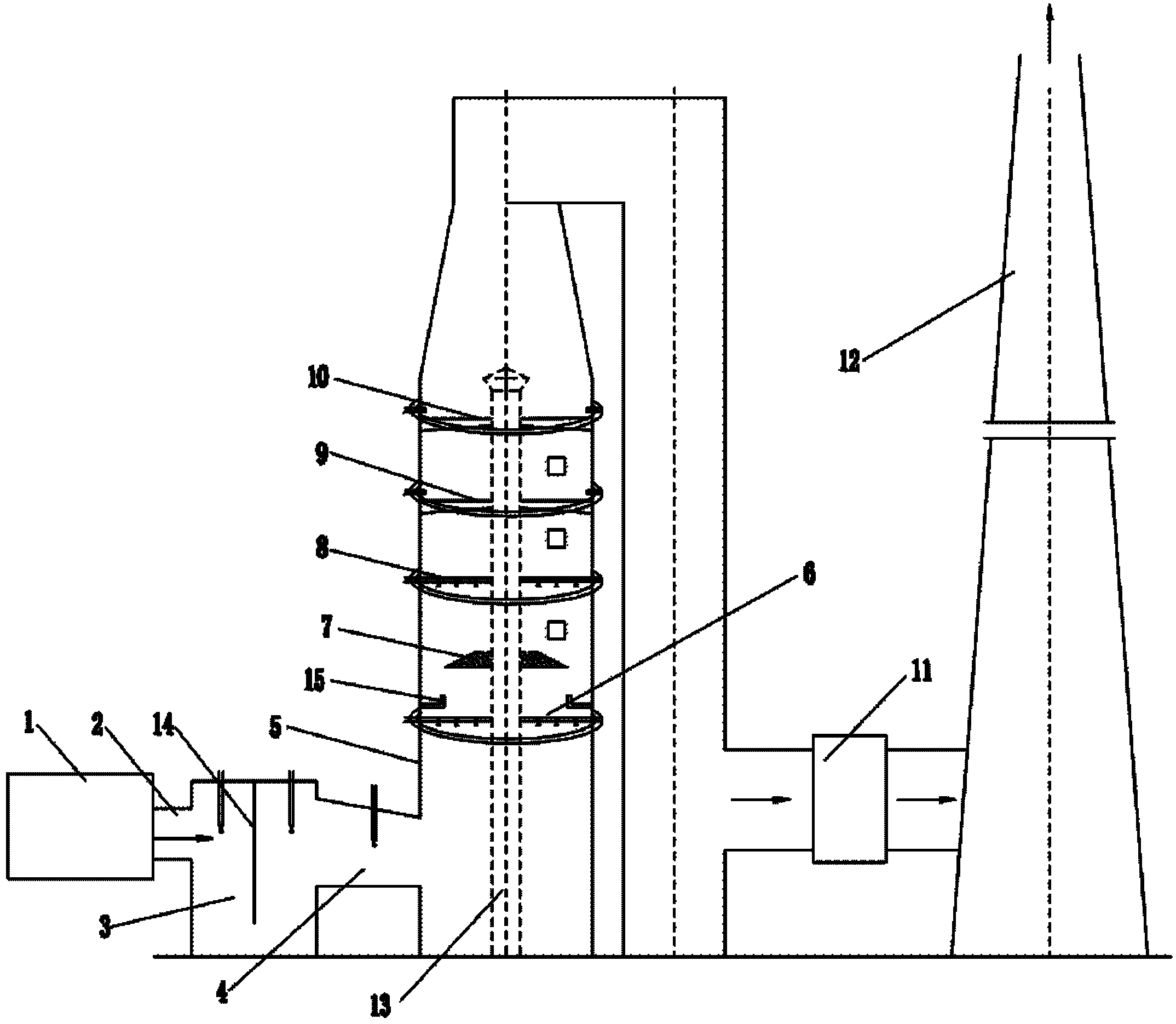

Wet dedusting-desulfurization compound purification device

InactiveCN102553386ASimple internal structureEfficient combinationCombination devicesUsing liquid separation agentPulp and paper industryTower

The invention discloses a wet dedusting-desulfurization compound purification device. The wet dedusting-desulfurization compound purification device is characterized in that the outlet of an industrial boiler or an industrial stove is sequentially connected with a gas flue, an impacted type pre-dedusting desulfurizer and a venturi tube in series, wherein the outlet of the venturi tube is connected with the lower part of a dedusting-desulfurization compound tower main cylinder; the main cylinder is internally and sequentially provided with a wet spray atomization layer, a water-keepoff separating cap, a spray atomization layer, a spray atomization rotational flow plate and a gas-water separating plate from bottom to top, and the top end of the main cylinder is sequentially communicated with a draught fan and a chimney. According to the wet dedusting-desulfurization compound purification device disclosed by the invention, the impacted type pre-dedusting desulfurizer, the venturi tube and the dedusting-desulfurization compound tower main cylinder are effectively combined together, thus the inner structure of a dedusting-desulfurization main tower is optimized, and the dedusting-desulfurization effect is increased.

Owner:安徽金森源环保工程有限公司

Self-triggered traffic light for traffic with dedusting module

ActiveCN112317370AAvoid dangerImprove dust removal effectRoad vehicles traffic controlCleaning using toolsDust controlEngineering

The invention discloses a self-triggered traffic light for traffic with a dedusting module. The traffic light comprises a shell, wherein two extrusion cavities are symmetrically formed in the shell, arotating cavity is formed in the shell, the rotating cavity is located between the two extrusion cavities, two compression cavities and two moving cavities are symmetrically formed in the shell, thetwo moving cavities are located between the two compression cavities, and the two compression cavities and the two moving cavities are located below corresponding extrusion cavities. According to thetraffic light, an air cup is driven to rotate by means of natural wind, the air cup drives a sponge block to dedust, and a dedusting effect is enhanced as the sponge block moves left and right. The sponge block shrinks to shake off dust and collect the dust. Moreover, the sponge block has a very high dedusting effect. The device removes dust by means of natural wind without using electric energy,so that the traffic light meets the demand on energy conservation and emission reduction in modern society. Furthermore, the traffic light is not scrubbed manually, so that the probability of danger of staff scrubbing the traffic light is prevented.

Owner:ANHUI ZHAOLI OPTO ELECTRONICS TECH

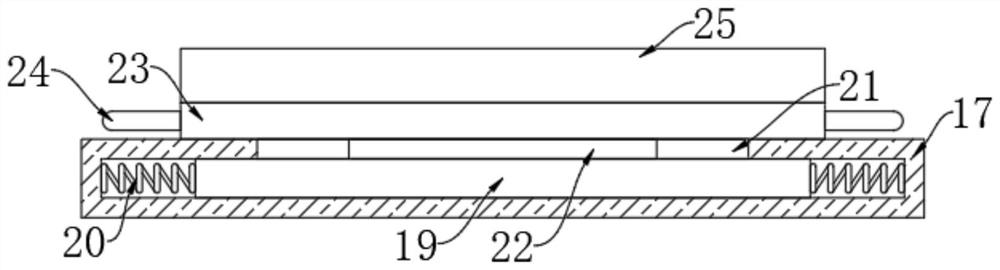

Negative oxygen ion air exchanger with screen dust removal

ActiveCN103111151BImprove dust removal abilityWon't clogCombination devicesMotor driveControl system

A screen dust removal negative oxygen ion ventilator, including a frame, a machine box and a circuit control system, the machine box is suspended in the frame through a suspender, and two or three oblique screens are fixed in the machine box , There is an eccentric shaft crossing the machine box in the middle of the machine box waist, the machine box realizes synchronous vibration through the rotation of the eccentric shaft, one end of the eccentric shaft is provided with a pulley, and a motor is fixed above the frame, and the operation of the motor drives the eccentric shaft Synchronized rotation. The screen dust removal negative oxygen ion ventilator of the present invention has a wide range of applications and high dust removal efficiency. After the dust passes through two or three layers of screens for dust removal, mist-like water vapor is sprayed on the space of the last layer of screens, and the friction Negative ions produced by vibration combine with water vapor to form negative oxygen ions, which are air vitamins, and people will feel very comfortable breathing them to achieve the purpose of health and longevity.

Owner:ZHENGZHOU UNIV +2

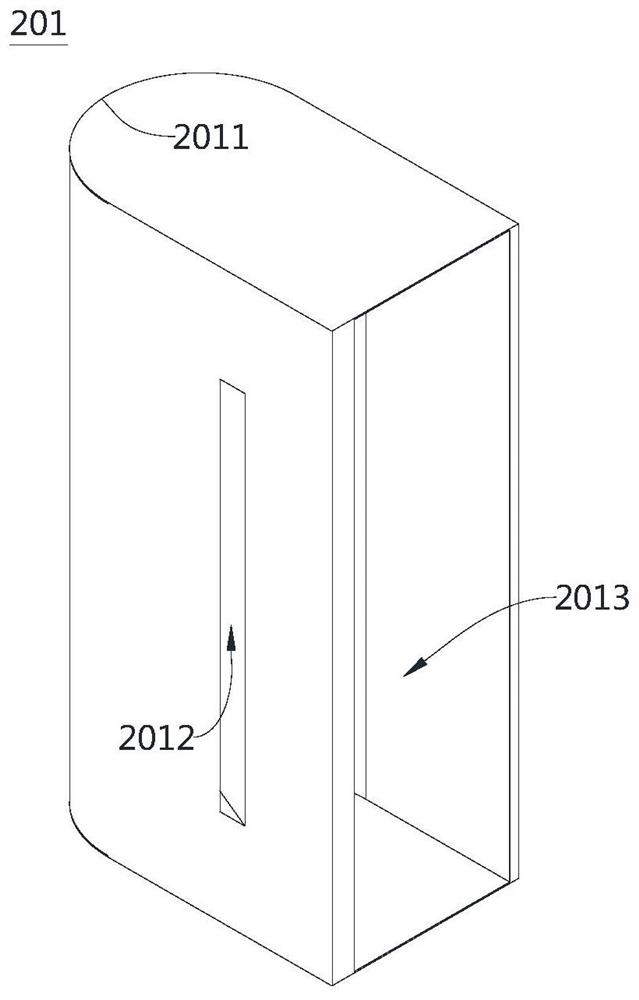

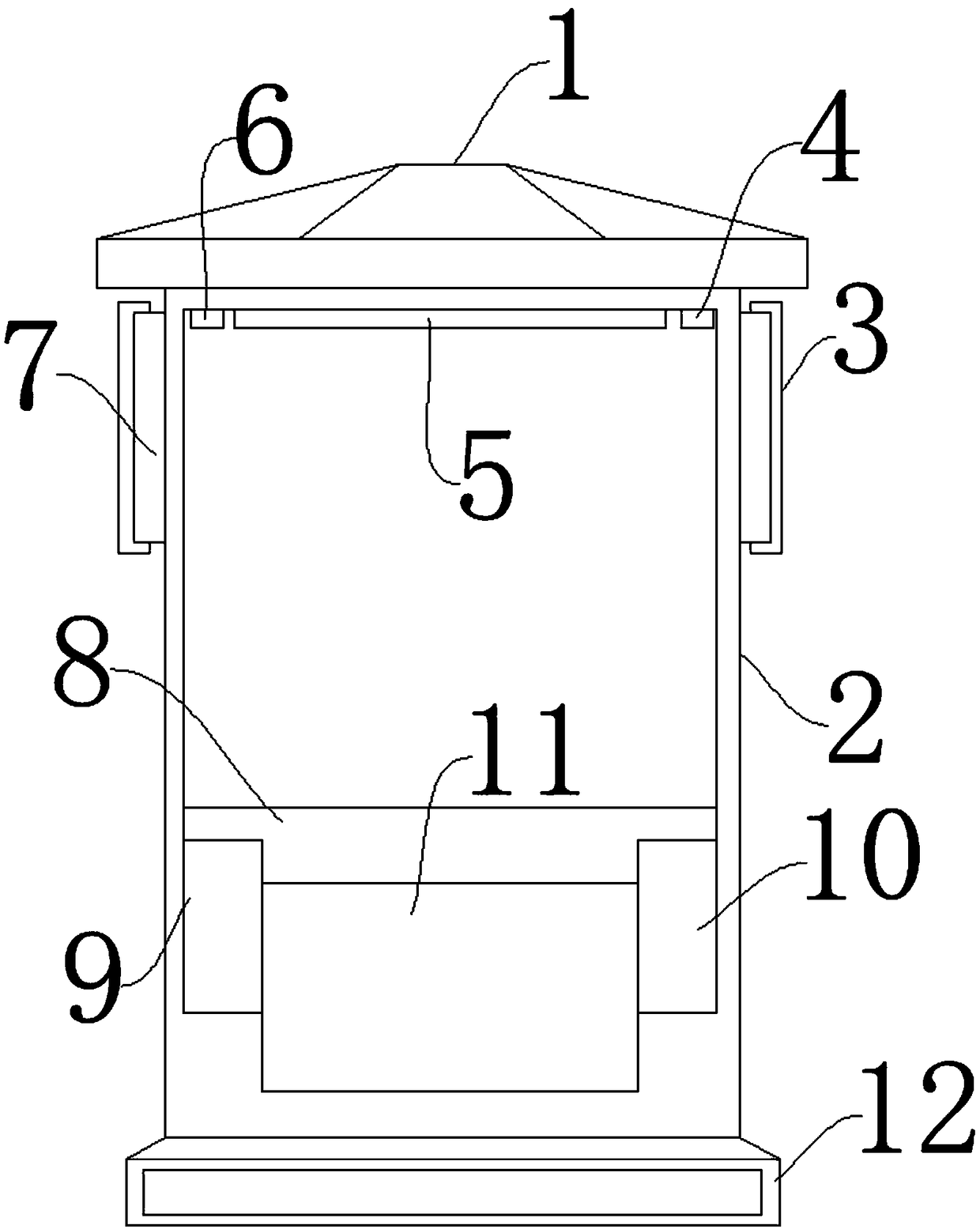

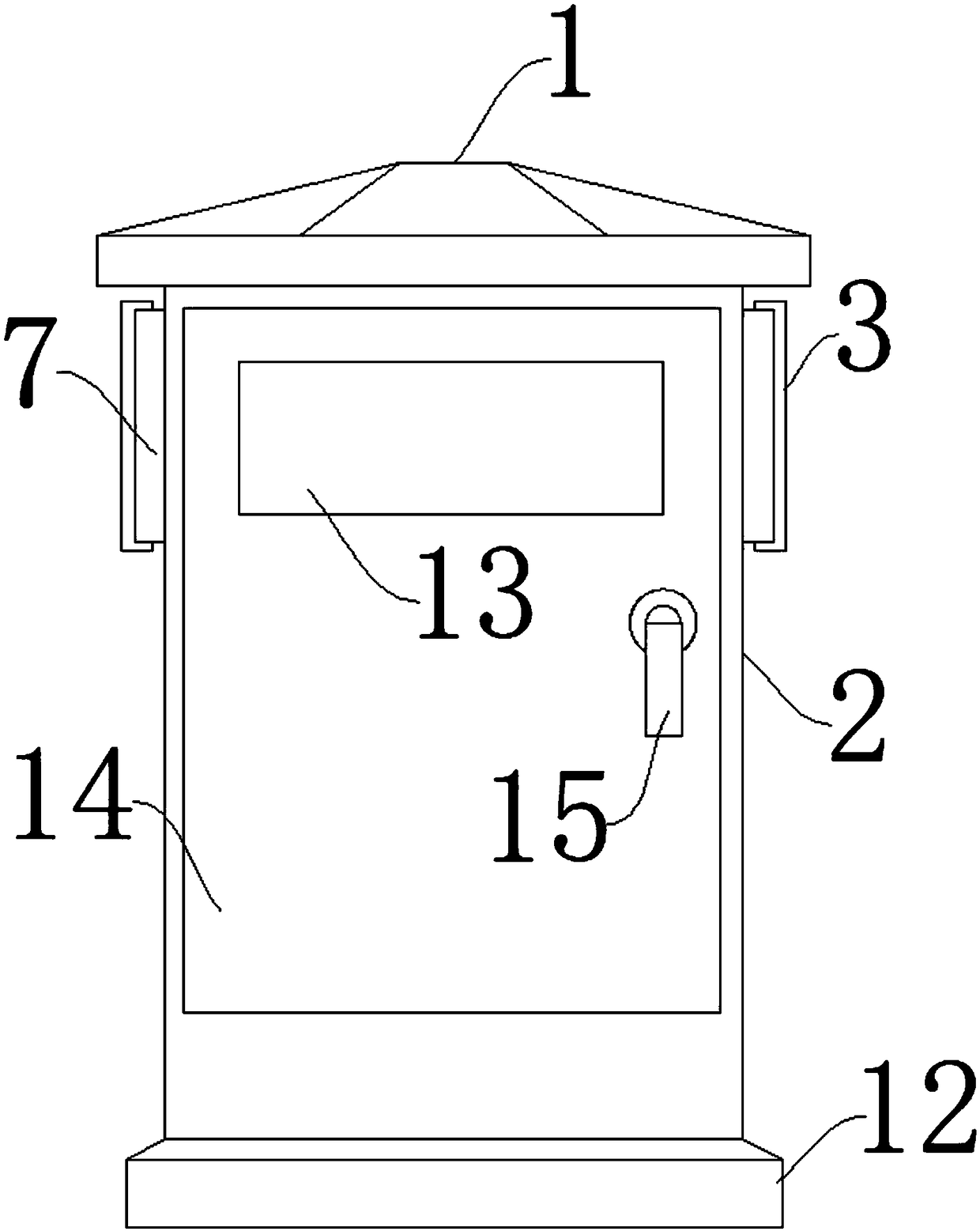

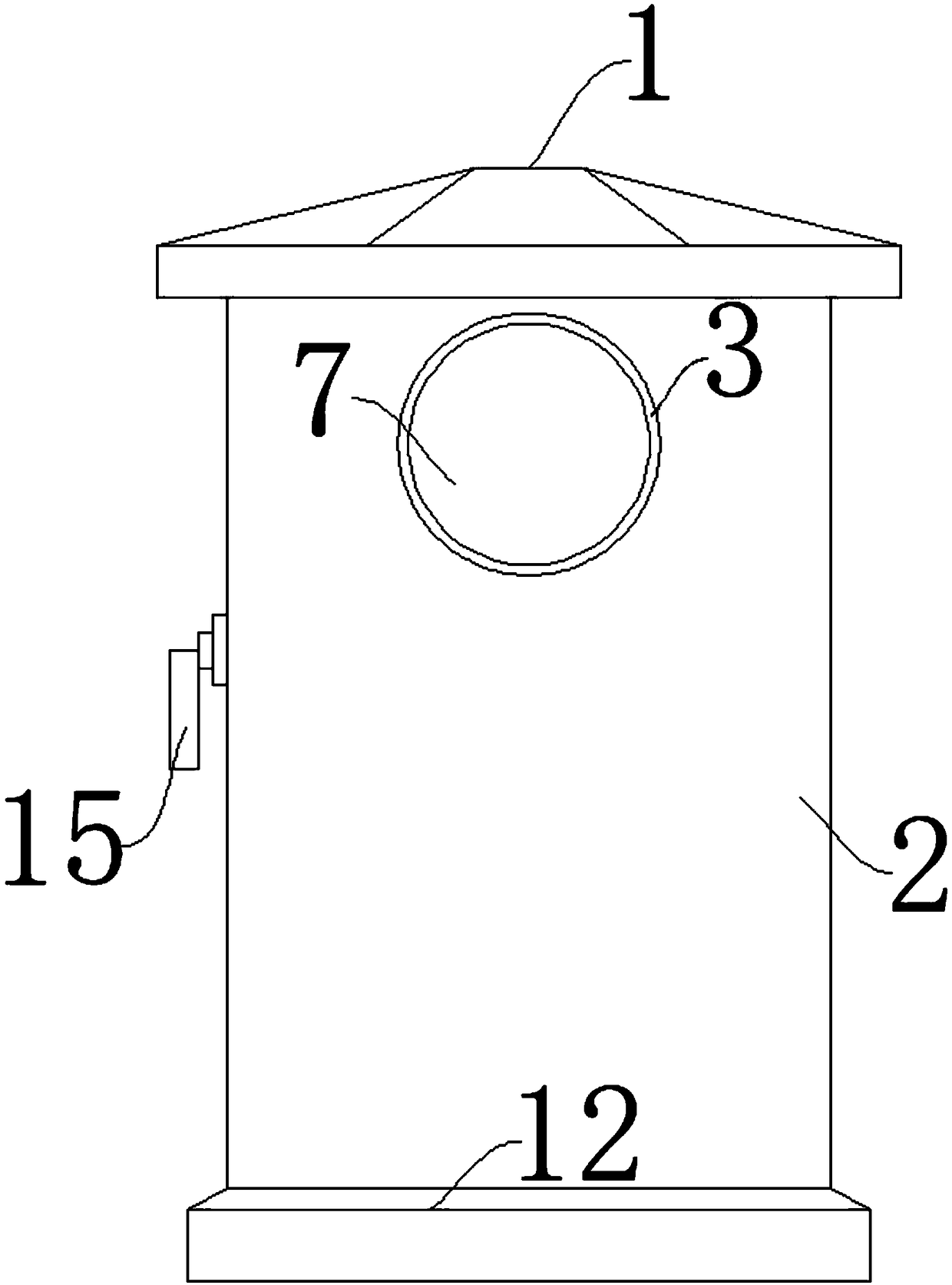

Multifunctional outdoor cabinet

InactiveCN108282975AScientific and reasonable designExtended service lifeCasings/cabinets/drawers detailsModifications using gaseous coolantsEngineeringFault rate

The invention discloses a multifunctional outdoor cabinet which comprises a rain sheltering top cover, a box body, a box door, an article placement plate and a cavity base. The box body is arranged above the cavity base, the rain sheltering top cover is arranged above the box body, the box door is arranged on the box body, visible glass is arranged on the box door, a handle is arranged below the visible glass, an exhaust fan is arranged on one side of the box body, a dustproof cover is arranged on the exhaust fan, a lighting lamp is arranged inside the box body, a temperature sensor is arranged on one side of the lighting lamp, a photosensitive sensor is arranged on the other side of the lighting lamp, the article placement plate is arranged below the lighting lamp, and a standby battery is arranged below the article placement plate. The multifunctional outdoor cabinet has the advantages that compared with existing outdoor cabinets, the multifunctional outdoor cabinet is complete in function, scientific and reasonable in design, long in service life, low in fault rate, high in dustproof ability, good in cooling and dehumidifying effect and high in safety and quality.

Owner:詹佳妮

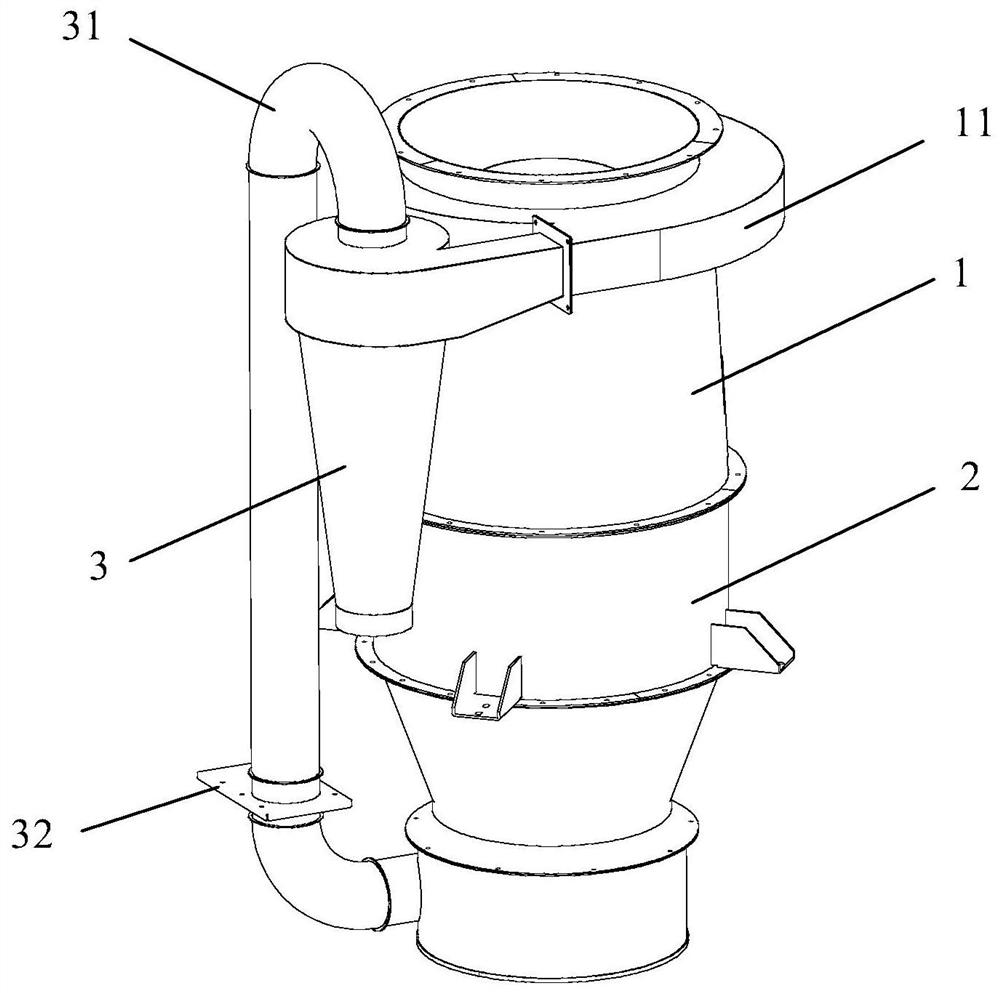

Dedusting air feeder

PendingCN113154864AReduce lossReduce wind lossDispersed particle separationDrying gas arrangementsThermodynamicsEngineering

The invention provides a dedusting air feeder. The dedusting air feeder comprises a first-stage cyclone separator, a diagonal fan and a second-stage cyclone separator. The first-stage cyclone separator is an axial entering type cyclone separator; the diagonal fan is arranged at the inlet end of the first-stage cyclone separator and blows air with dust into the first-stage cyclone separator; the second-stage cyclone separator is a tangential entering type cyclone separator, and an inlet of the second-stage cyclone separator is communicated with a dust outlet of the first-stage cyclone separator; and gas with dust is subjected to first-stage purification through combination of the diagonal fan and the first-stage cyclone separator, clean air is output, a dust removal opening of the first-stage cyclone separator is formed at the top of the inner wall of a shell, that is, dust is concentrated in the top area after being separated, an outlet is formed at the top of a shell of the first-stage cyclone separator, the outlet is connected with the second-stage cyclone separator, and the second-stage cyclone separator is used for second-stage purification, and finally the dust is discharged.

Owner:大连静冈制机有限公司

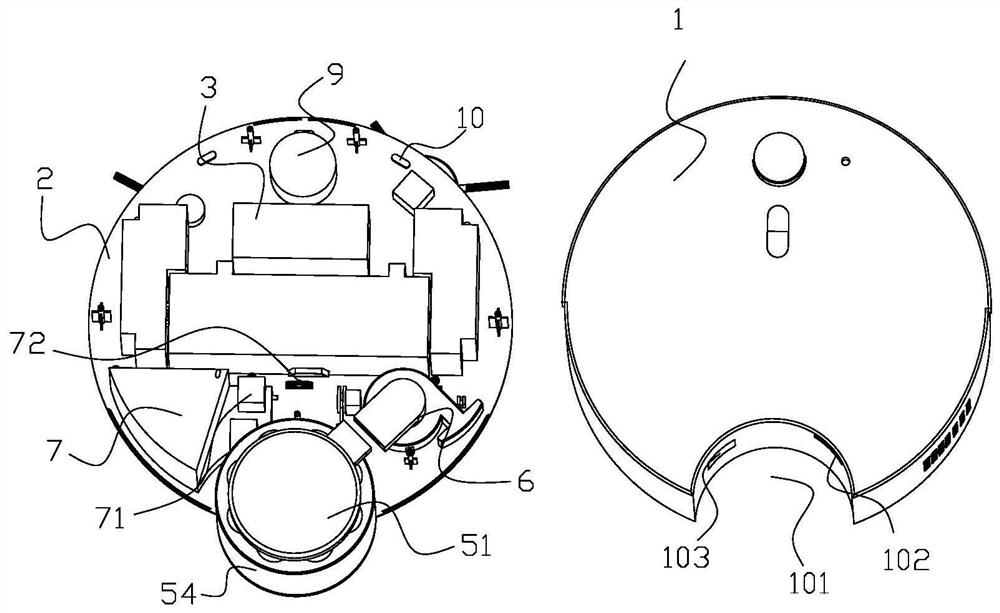

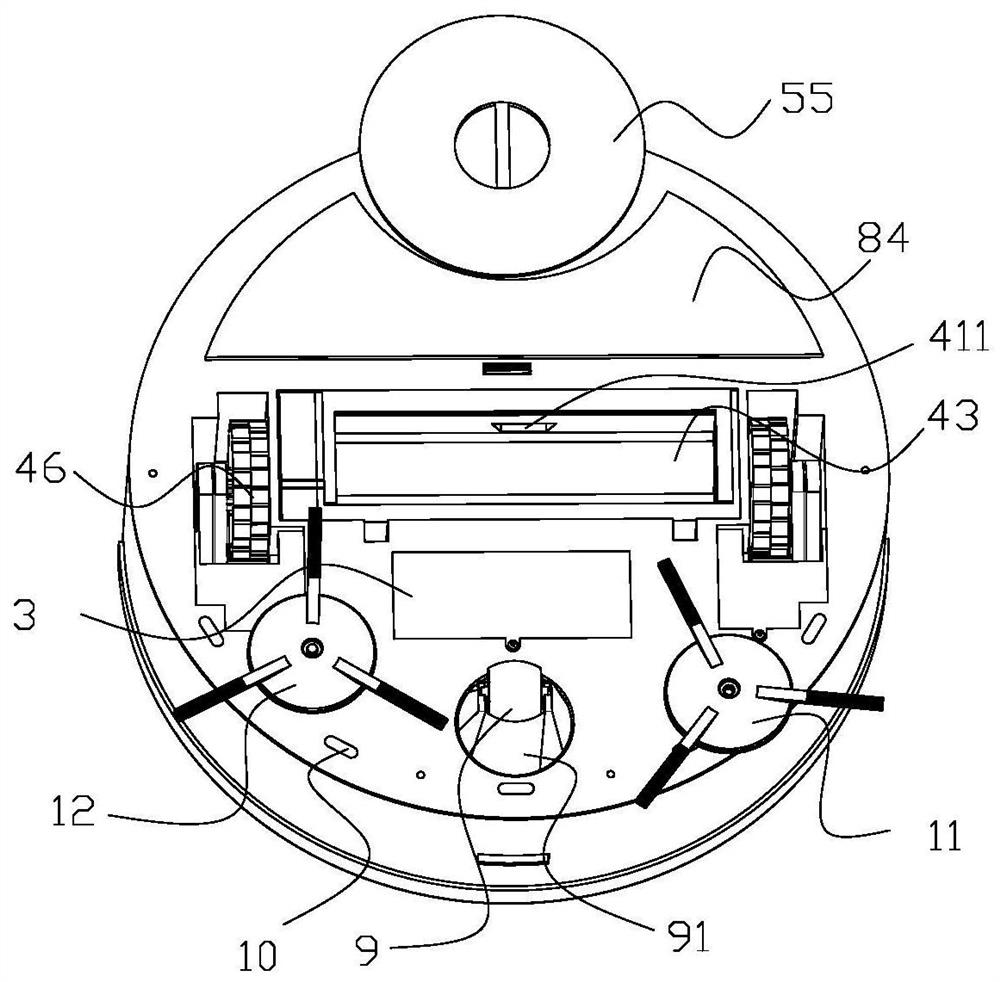

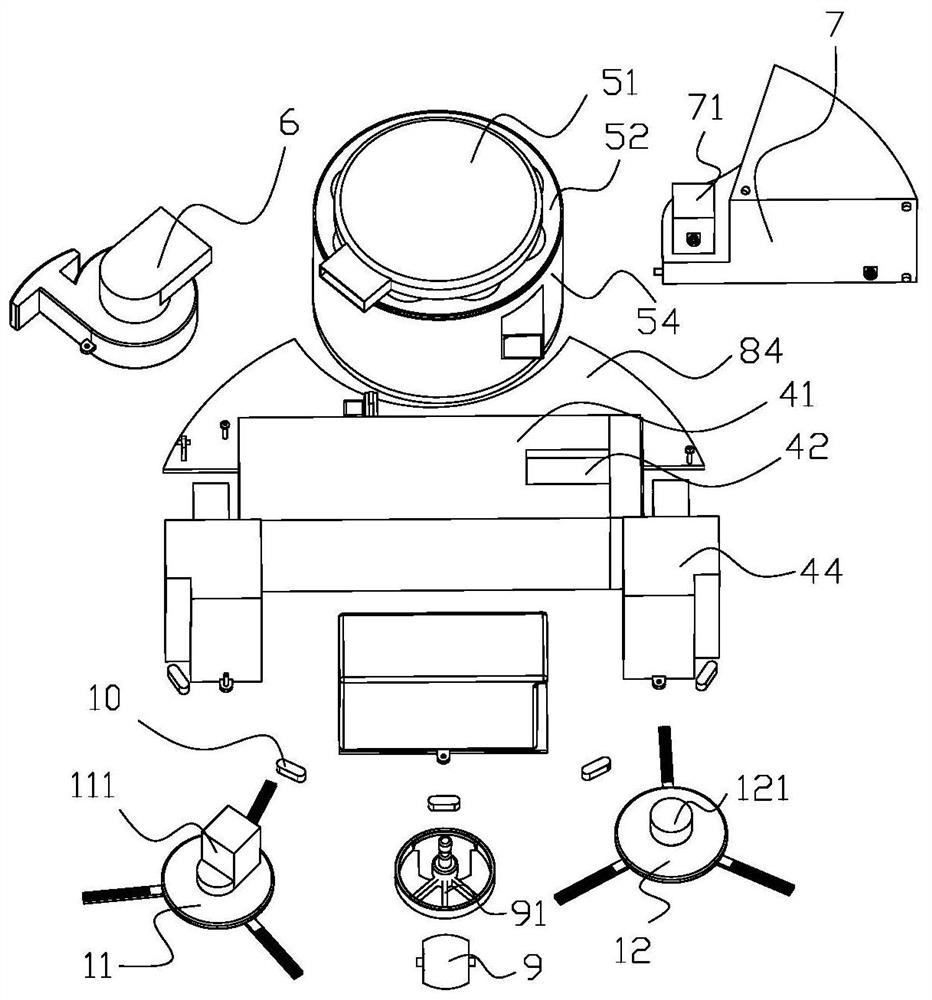

A sweeping robot

The invention relates to the technical field of dust removal, in particular to a cyclone dust removal robot. A sweeping robot, the sweeping robot includes a cyclone module and a fan; the cyclone module includes a cyclone cover, a cyclone bracket, a plurality of cyclones, a dust box and a bottom cover of the dust box; the cyclone cover is provided with a connection port that matches the groove of the cyclone cover The cyclone cover is arranged on the cyclone bracket, and the cyclone bracket is provided with a plurality of conical inner cavities in the circumferential direction; the side wall of the cyclone bracket is provided with an arc-shaped opening; the arc-shaped opening communicates with the conical inner cavity; the upper part of the cyclone bracket has an inlet Air port; the center of the bottom of the cyclone bracket is provided with a general air inlet; the dust box is set on the cyclone bracket; the bottom cover of the dust box is set on the bottom of the dust box; each cyclone is set on each cone cavity; the fan is set On the left rear side of the main brush driver module. Good dust removal effect, prevent secondary pollution of dust. The beneficial effects of the invention are: good dust removal effect, prevention of dust secondary pollution, ability to clean corners and automatic water spraying and mopping.

Owner:胡陈和

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com