Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "High sizing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ASA paper-making sizing agent emulsion

InactiveCN101333789AReduce dosageEmulsification is cheapWater-repelling agents additionPolyelectrolyteHigh concentration

The invention relates to a process for preparing an emulsion of ASA paper sizing agent, comprising the following steps of: (1) mixing and then dispersing inorganic nano-particles with positive charges and inorganic nano-particles with negative charges to form a water phase; (2) mixing oily ASA with the water phase to form an oil-water mixture; and (3) cutting and emulsifying the mixture by a high-speed mixing device to obtain an ASA emulsion. Wherein, the oil-water mixture ratio is 1: 4 to 1:1, particles with negative charges and ASA are in a ratio of 1:30 to 1:5, and particles with positive charges and particles with negative charges are in a ratio of 1:150 to 1:7.5. The preparation process has advantages of simple emulsification process, having no need of surface active agent and complex polyelectrolyte particles for emulsifying the ASA into stable emulsion, low emulsifying agent consumption, low emulsification cost, and high concentration, good stability and high sizing efficiency of the prepared emulsion.

Owner:QILU UNIV OF TECH

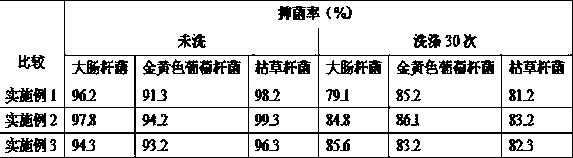

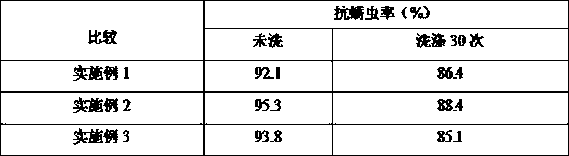

Antibacterial fabric, preparation technology thereof and textile thereof

InactiveCN103255522ANon-irritatingImprove thermal stabilityWeft knittingCarbon fibresBiotechnologyPolyester

The invention relates to the field of functional fabrics, in particular to an antibacterial fabric, a preparation technology of the antibacterial fabric and textile of the antibacterial fabric. The antibacterial fabric comprises, by weight, 10-20 parts of short fiber silk, 20-25 parts of anion polypropylene staple fibers, 15-25 parts of nano bamboo carbon fiber, 2-5 parts of nano-titanium dioxide, 5-10 parts of nano-silver fiber, 2-4 parts of anti-mite finishing agent, 3-8 parts of sweat-absorbent quick-drying processing agent, 12-18 parts of binder, 2-4 parts of dispersing agent, 3-5 parts of fabric softener and 80-85 parts of polyester cotton fiber. Due to the fact that the anion polypropylene staple fibers are added, effects of nerve stability, sleep improvement, inflammation diminishing and pain relief are provided. Due to the fact that the anti-mite finishing agent is added, trouble caused by mites to a human body can be effectively prevented. Due to the fact that the sweat-absorbent quick-drying processing agent is added, sweat generated by the body can be rapidly absorbed, discomfort can be reduced, and breeding of germs under a humid environment can be prevented. The antibacterial fabric can be applied to clothing, home textiles, sports goods, medical care, bacteria resistance and insect prevention textiles.

Owner:广东雄兴内衣实业有限公司

Method for preparing AKD emulsion sizing agent

InactiveCN101942780AReduce dosageImprove stabilityWater-repelling agents additionActive agentSurface-active agents

The invention relates to a method for preparing an AKD emulsion sizing agent. The method comprises the following steps of: dissolving chitosan in diluted acid to form solution of chitosan; moisturizing and dispersing nanometer titanium dioxide particles with deionized water to prepare nanometer titanium dioxide colloid; uniformly mixing the solution of chitosan and the nanometer titanium dioxide colloid to obtain a mixture serving as an aqueous phase, and heating to over melting point of the AKD for later use; and heating the AKD until the AKD is melted, and mixing the AKD and the heated aqueous phase under stirring, increasing the stirring speed after mixing to ensure that the melted AKD is dispersed into small drops in the aqueous phase to obtain the AKD emulsion. The method has simple preparation process, small using amount of emulsion and no need of any surfactant or bactericide; and the prepared AKD emulsion has the advantages of high stability, high sizing efficiency and high sizing curing speed.

Owner:QILU UNIV OF TECH

Method for preparing high-stabliliy ASA papermaking sizing agent emulsion

InactiveCN101574834AReduce dosageImprove stabilityWater-repelling agents additionPaper/cardboardEmulsionMontmorillonite

The invention relates to a method for preparing a high-stabliliy ASA papermaking sizing agent emulsion, which comprises the following steps that: smectite is dispersed in water to form a suspension; the suspension is mixed with oleosus ASA under the action of mechanical agitation to prepare a stable smectite ASA emulsion; and then a chitosan solution dissolved in dilute acid is added in the emulsion; and then a weak alkali is added to form the stable O / W type ASA emulsion under the action of the mechanical agitation. The method has the advantages that: the preparation process is simple; emulsifier dosage is less; surfactant addition is adovided; and the made ASA latices has high stability, short bubble diameter and high gluing efficiency.

Owner:QILU UNIV OF TECH

Method for preparing AKD emulsion sizing agent

The invention discloses a method for preparing an AKD emulsion sizing agent, comprising the following steps of: wetting and dispersing hectorite nano particles by using deionized water, and putting for a certain time to prepare a hectorite colloid, and simultaneously, dissolving micromolecule amine in water to compound an aqueous solution; adding a micromolecule amine solution to the hectorite colloid and regulating the pH value of the colloid by using dilute acid; heating the colloid to the melting point of AKD for later use; and heating the AKD to melt down the AKD; and under the action of mechanical stirring, mixing the heated hectorite colloid with the molten AKD, and then emulsifying to obtain a stable AKD emulsion. The method has low use level of the emulsion and simple emulsifying process, and completely does not use the traditional surface active agents; and the sizing efficiency of the obtained emulsion can be greatly increased.

Owner:QILU UNIV OF TECH

Alkenyl succinic anhydride emulsion sizing agent and its preparation method

InactiveCN102493273AImprove stabilityHigh sizing efficiencyWater-repelling agents additionAluminium sulfatePolymer science

The invention relates to an alkenyl succinic anhydride emulsion sizing agent which belongs to the papermaking industrial sizing agent technical field, and the sizing agent comprises alkenyl succinic anhydride, hydrophilic nanometer titanium dioxide or hectorite, Al2(OH)2x(SO4)3-x and deionized water. The preparation method comprises the following steps: dispersing the hydrophilic nanometer titanium dioxide or hectorite in deionized water, mixing with polyaluminium sulfate sol, taking the mixture as a water phase, alkenyl succinic anhydride is taking as an oil phase, uniformly mixing the water phase and the oil phase. The present invention has the beneficial effects that no any surfactant are required to add, the prepared alkenyl succinic anhydride emulsion sizing agent has the advantages of good stability and high sizing efficiency.

Owner:QILU UNIV OF TECH

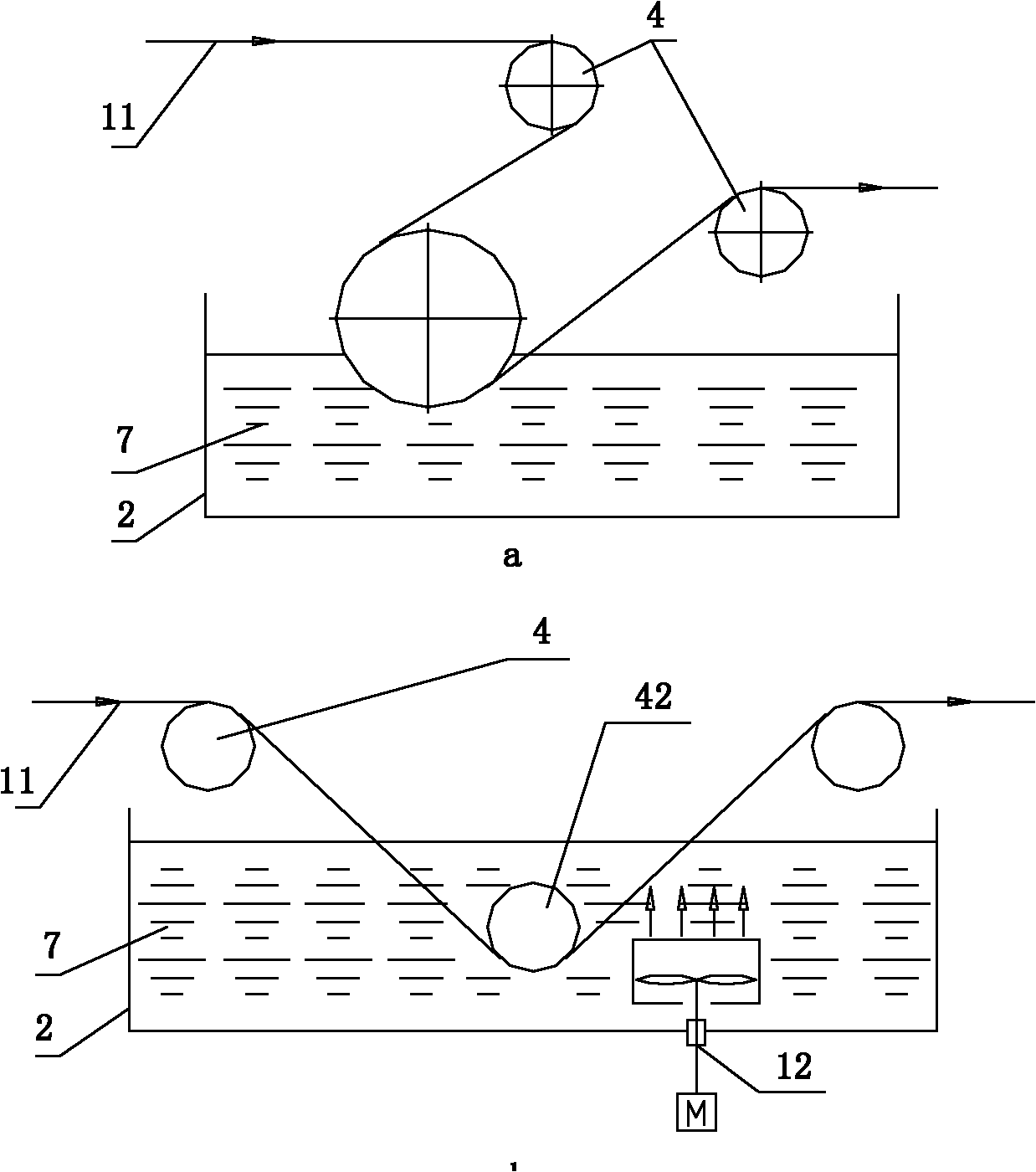

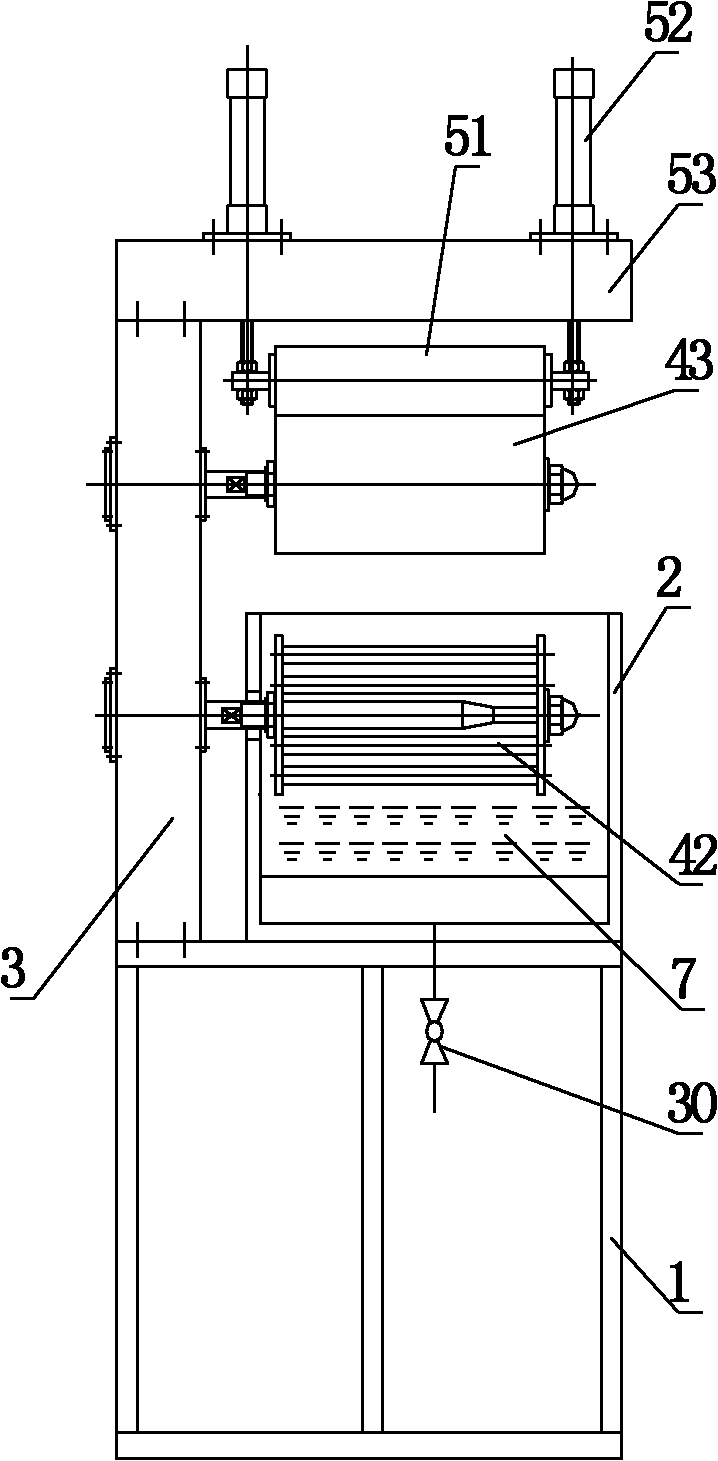

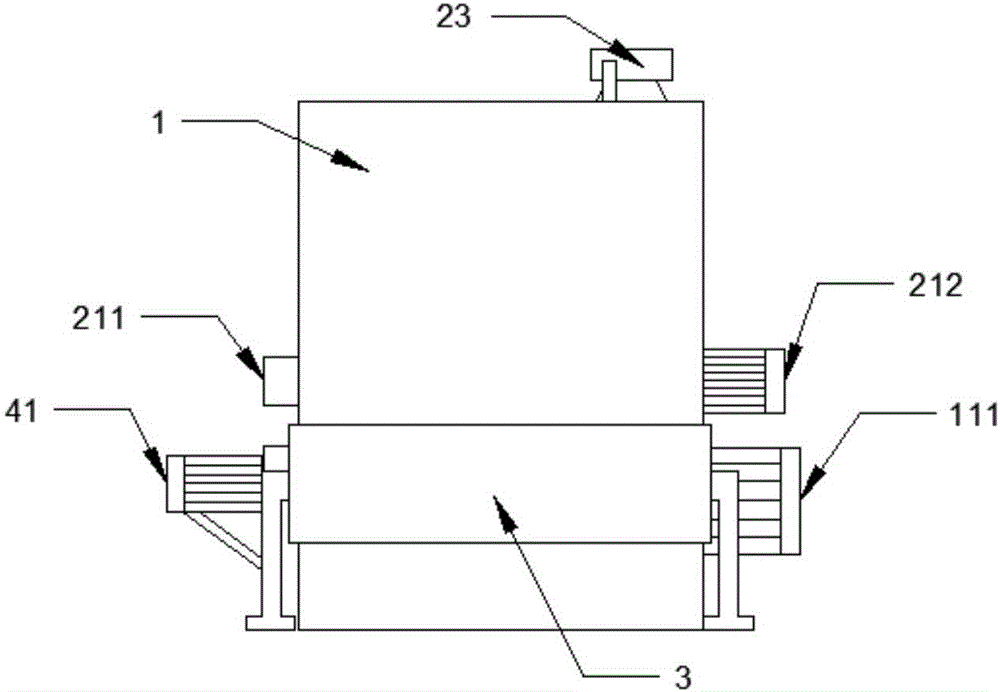

Sizing machine for producing continuous carbon fibers

InactiveCN102031654AAvoid Shaft Sealing ProblemsFlexible rotationTextile treatment rollersLiquid/gas/vapor yarns/filaments treatmentFiberCarbon fibers

The invention belongs to a sizing machine for producing continuous carbon fibers, comprising a box body, a sizing groove arranged in the box body and a driving device fixed on the box body, wherein the sizing groove comprises a groove body and a partition board, a liquid distribution plate and an overflow plate which are arranged in the groove body from left to right and are vertical to the bottom of the groove body; the driving device comprises an inlet driving roller arranged at the upper-left part of the sizing groove, two sizing driving rollers positioned in a sizing area and an outlet driving roller arranged at the upper-right part of the sizing groove; the two sizing driving rollers are horizontally arranged and positioned between the inlet driving roller and the outlet driving roller; and driving shafts of the two sizing driving rollers are higher than the liquid level of a sizing agent of the sizing area. The invention solves the problems of long stay time of the carbon fibers in the sizing agent, poor sizing effect, complex structure, high manufacturing cost and inconvenience for daily cleaning and maintenance caused by the traditional sizing machine. By using the invention, the processing and manufacturing cost of the equipment can be reduced, the time of the carbon fibers in the sizing agent can be prolonged and the favorable sizing effect can be obtained.

Owner:西安航科等离子体科技有限公司

Environment-friendly type textile sizing agent

Owner:SUZHOU RUNHONG TRADING

Stable ASA (Alkenyl Succinic Anhydride) papermaking sizing emulsion and preparation method thereof

InactiveCN102493275AReduce dosageIncrease concentrationWater-repelling agents additionActive agentSurface-active agents

The invention relates to the technical field of papermaking sizing agents, in particular to stable ASA (Alkenyl Succinic Anhydride) papermaking sizing emulsion. The stable ASA papermaking sizing emulsion comprises deionized water, ASA, hectorite and urea, wherein the mass ratio of the ASA to the deionized water is 1:(0.8-4); the mass ratio of the hectorite to the ASA is 1:(20-200); and the mass ratio of the urea to the hectorite is 1:(2-100). The preparation method comprises the following steps of: dispersing the hectorite with the deionized water to obtain a hectorite colloid; dissolving the urea in residual deionized water to prepare an aqueous solution of the urea; mixing the hectorite colloid with the aqueous solution of the urea; adjusting the pH value to be 5-8; and then uniformly mixing the mixture with the ASA to obtain the ASA papermaking sizing emulsion. According to the invention, the consumption of an emulsifying agent is little; no traditional surfactant is used; the emulsion has high concentration, favorable stability and high sizing efficiency; the preparation method is simple in process; the emulsification cost is low; and the sizing efficiency of the obtained emulsion can be greatly increased.

Owner:QILU UNIV OF TECH

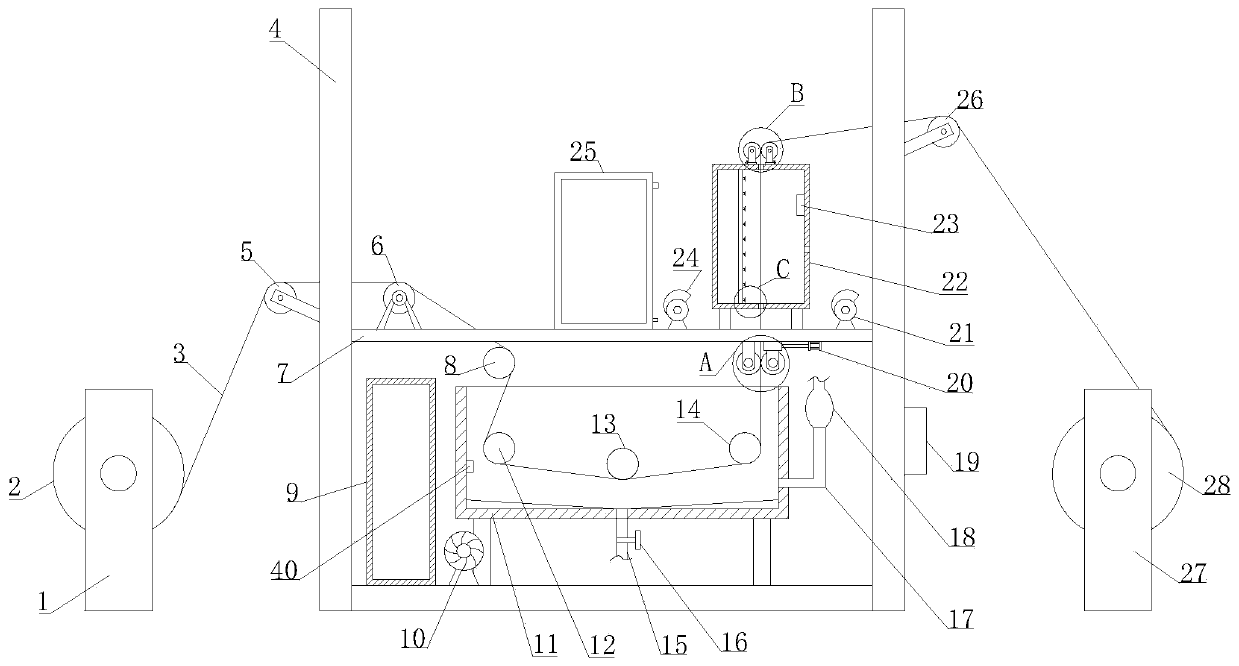

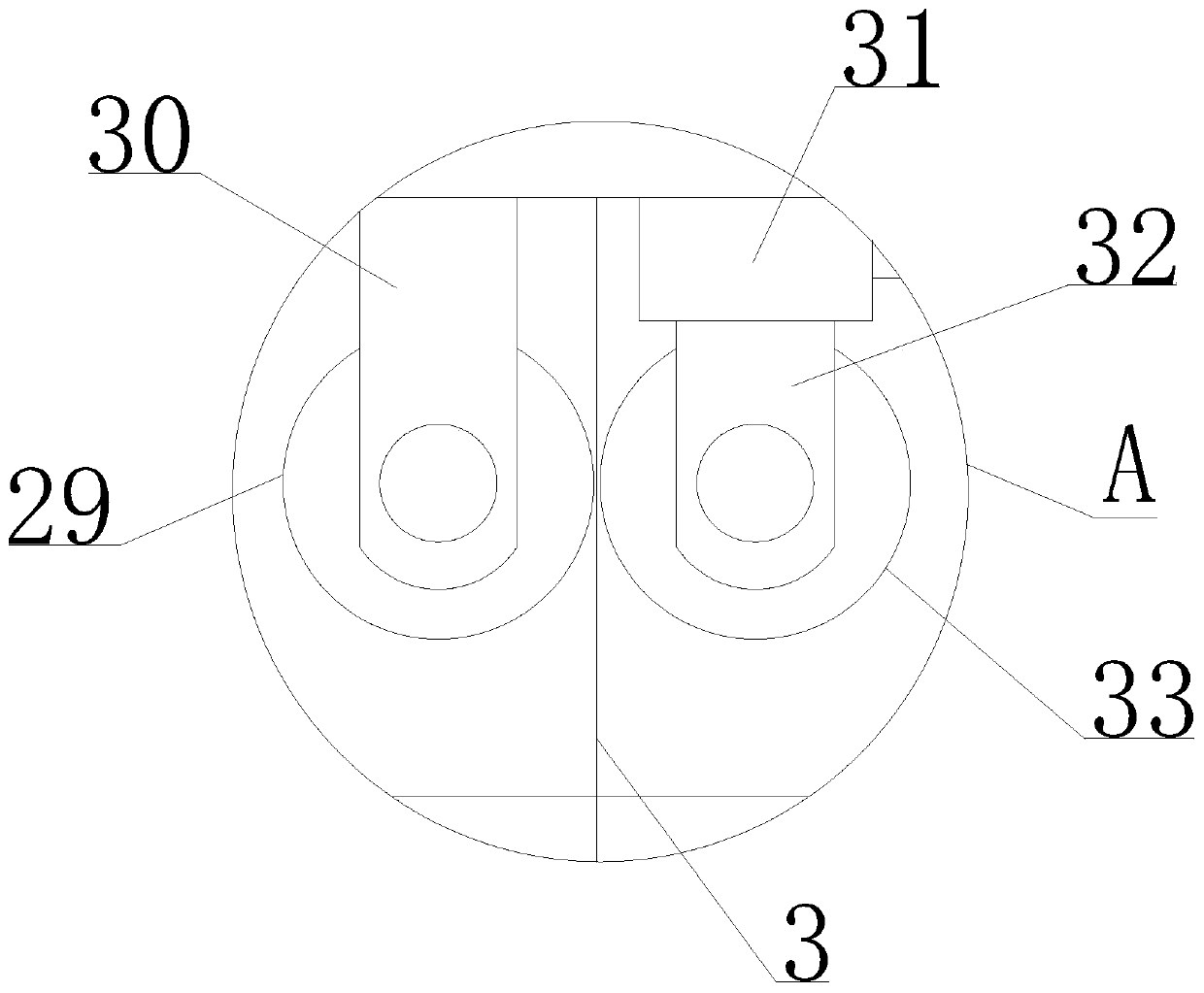

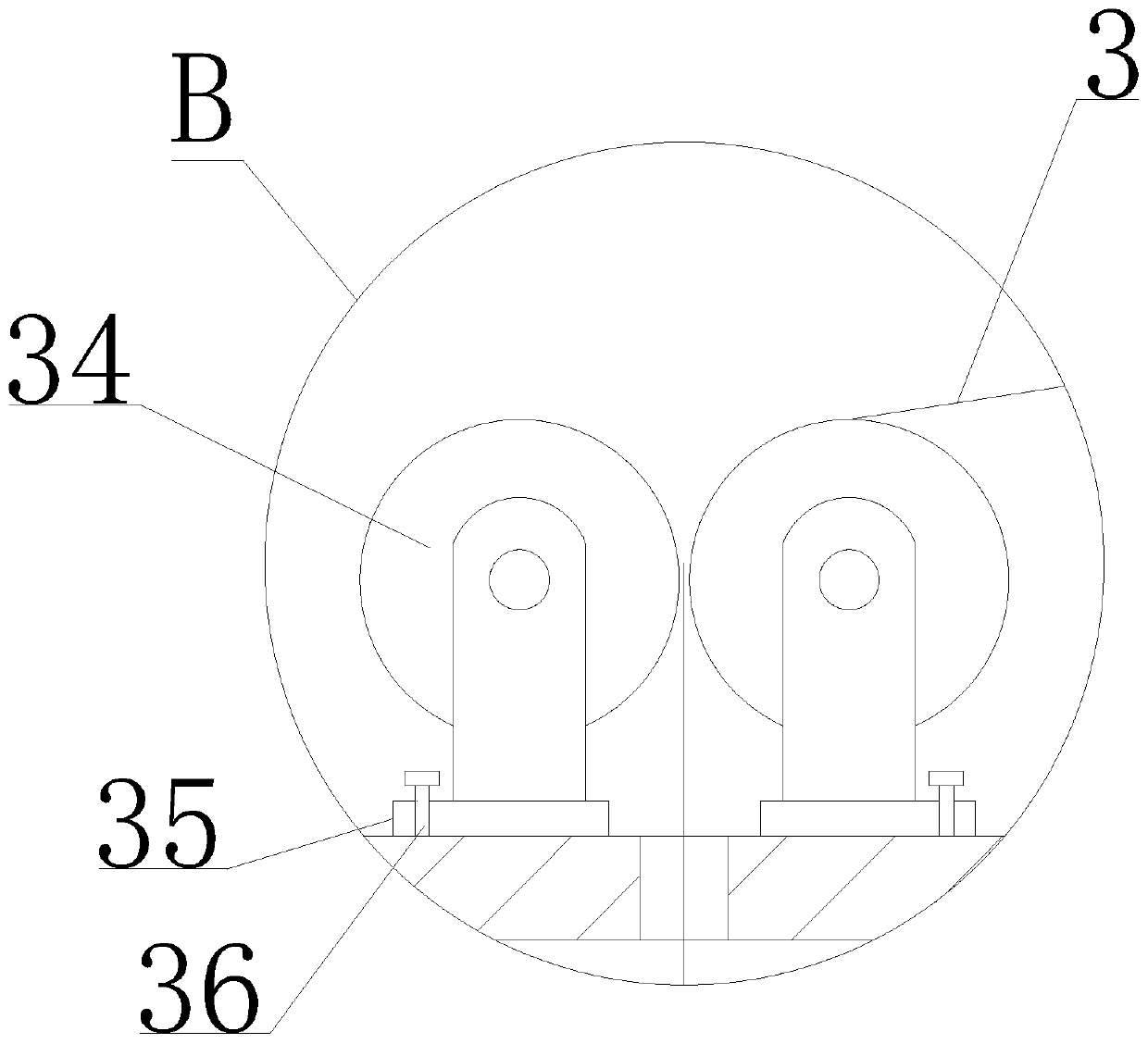

Cotton yarn processing slasher

InactiveCN110344192AConveying orderlyQuick and orderly sizingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsYarnPulp and paper industry

The invention belongs to the technical field of cotton yarn processing, particularly relates to a cotton yarn processing slasher, and aims to solve the problem of low sizing efficiency of an existingyarn. The technical scheme includes that the slasher comprises a frame, a first guide roller, a second guide roller, a third guide roller, a squeezing roller component and a fourth guide roller, a yarn unwinding device and a yarn winding device are arranged on two sides of the frame, a squeezing device, a drying box and a heating box are arranged on a mounting plate on the frame, the drying box iscommunicated with the heating box through an air supply device, a sizing box storing slurry is arranged on the frame, yarns are outputted by the yarn unwinding device, sequentially pass the first guide roller, the second guide roller, third guide roller and the squeezing roller component and are soaked into the slurry, the yarns are squeezed by the squeezing device, and the squeezed yarns penetrate the drying box, pass the fourth guide roller and are wound on the yarn winding device. According to the slasher, the yarns can be rapidly conveyed, sized, dried and wound, so that the sizing efficiency of the yarns is improved.

Owner:徐州嘉搏纺织股份有限公司

Bismuth-containing free-cutting steel

ActiveCN103255539ANon-irritatingImprove thermal stabilitySucessive textile treatmentsWeft knittingPolyketoneUltimate tensile strength

The invention discloses bismuth-containing free-cutting steel. The bismuth-containing free-cutting steel comprises the following components in percentage by weight: 0.04%-0.15% of C, 0-0.15% of Si, 0.9%-1.6% of Mn, 0.02%-0.11%of P, 0.25%-0.45% of S, 0-0.2% of Cr, 0-0.2% of Ni, 0-0.2% of Cu, 0.05%-0.2% of Bi, 0.005%-0.05% of Ti, 0.005%-0.05% of N, 0-0.2% of impurities and the balance of Fe. According to the bismuth-containing free-cutting steel disclosed by the invention, lead is substituted by the bismuth, so that a lead pollution problem is solved; meanwhile, the thermal plasticity and the after-breakage elongation are better, so that the bismuth-containing free-cutting steel is unlikely to fracture during a rolling process. The bismuth-containing free-cutting steel disclosed by the invention has excellent comprehensive mechanical performances, cutting performances superior to those of the common free-cutting steel, and cutting performances equivalent to those of the lead-containing free-cutting steel. Meanwhile, the bismuth-containing free-cutting steel is free of lead, good in environment friendliness, and beneficial to popularization and utilization.

Owner:ZHEJIANG WANQIAN CLOTHING CO LTD

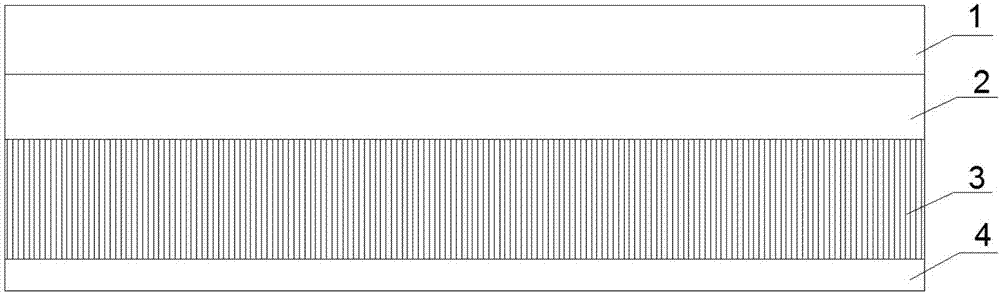

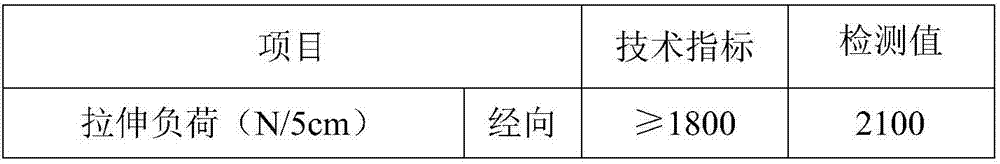

Efficient sunshade double-color tent material

InactiveCN107325444AImprove practicalityImprove shadingSynthetic resin layered productsLight resistant fibresPolyvinyl chlorideEngineering

The invention relates to an efficient sunshade double-color tent material. The tent material sequentially comprises a white polyvinyl chloride (PVC) film, a black PVC lightproof film, base cloth and a PVC bottom film from top to bottom; the tent material is prepared by the following steps: starching the double sides of the base cloth, drying and heating; then, synchronously sticking the base cloth together with the preheated white PVC film, the black PVC lightproof film and the PVC bottom film; embossing, trimming and reeling. The efficient sunshade double-color tent material provided by the invention has the characteristic of being used at the both sides; the white PVC film has good ink absorption, thus being used for jet drawing; the black PVC lightproof film has excellent lightproof property, thus being capable of preventing the transmission of sunlight and ultraviolet rays and further effectively achieving the effects of sun-shading and heat insulation; the red PVC film is obtained by adding pigment and calendaring molding, thus having good color fastness to water and color fastness to sunlight. After the technology of synchronously sticking the three films and the one piece of cloth is adopted, the processing flow is simplified, the production efficiency is improved, and the stripping fastness is more reliable.

Owner:浙江明士达股份有限公司

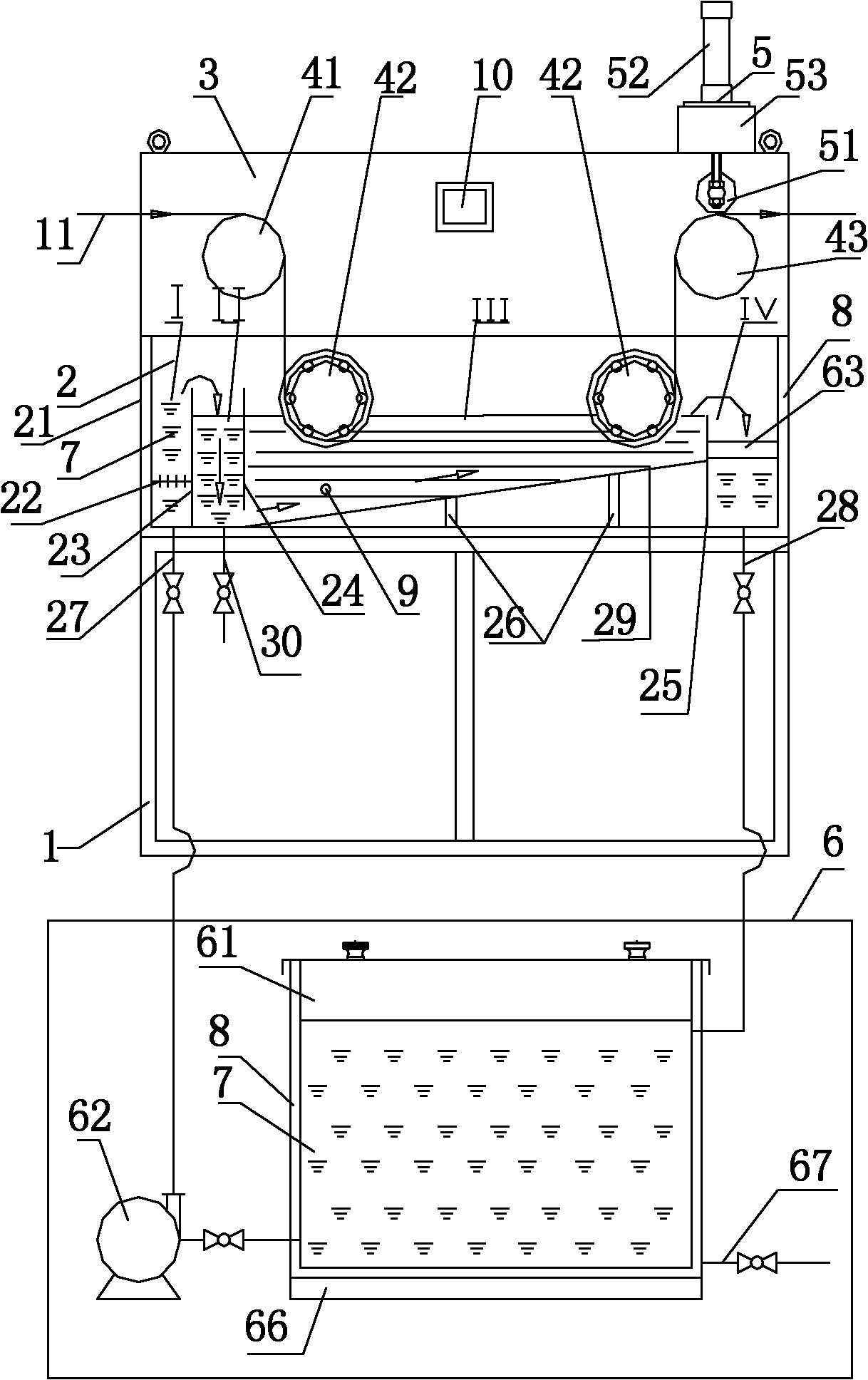

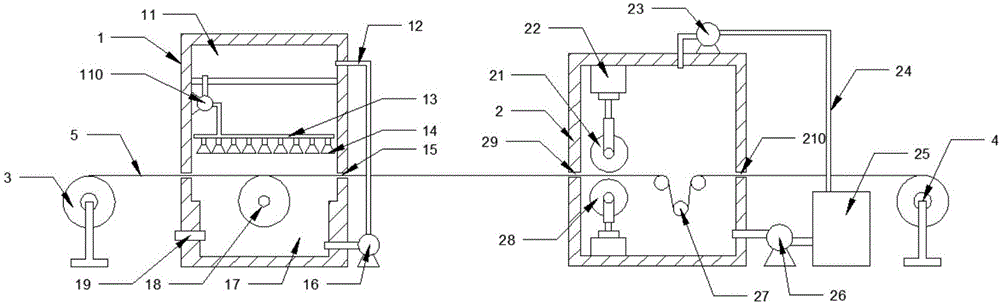

Textile sizing machine

InactiveCN106283447ASimple structureReasonable designLiquid/gas/vapor removalTextile treatment machine arrangementsSizingHigh pressure

The invention provides a textile sizing machine. The textile sizing machine comprises a sizing device. A box body of the sizing device is internally provided with an upper liquid storage trough and a lower liquid storage trough. A liquid conveying pipe is communicated between the upper liquid storage trough and the lower liquid storage trough. The liquid conveying pipe is provided with an infusion pump capable of pumping liquid in the lower liquid storage trough into the upper liquid storage trough. The sizing and drying device is simple in structure and reasonable in design, double-face sizing is achieved, roller sizing is adopted on one side of textile cloth, spraying sizing of a plurality of high-pressure nozzles is adopted on the other side of the textile cloth, sizing uniformity is good, and the sizing efficiency is high; during drying, the distance between heating rollers can be adjusted, adjustment can be carried out according to different cloth materials, and a good drying effect is guaranteed.

Owner:TIANJIN JIAXUAN TEXTILE

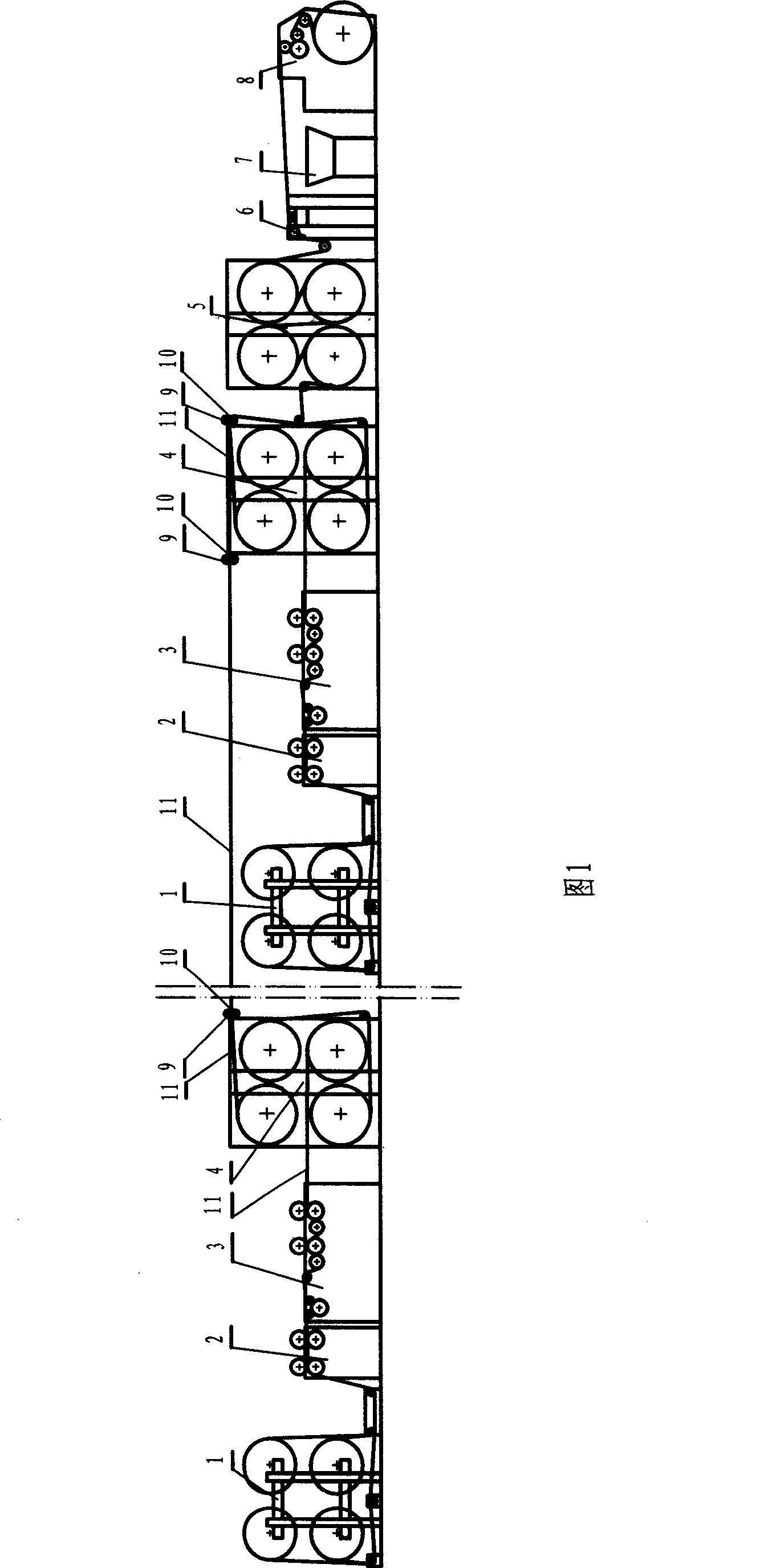

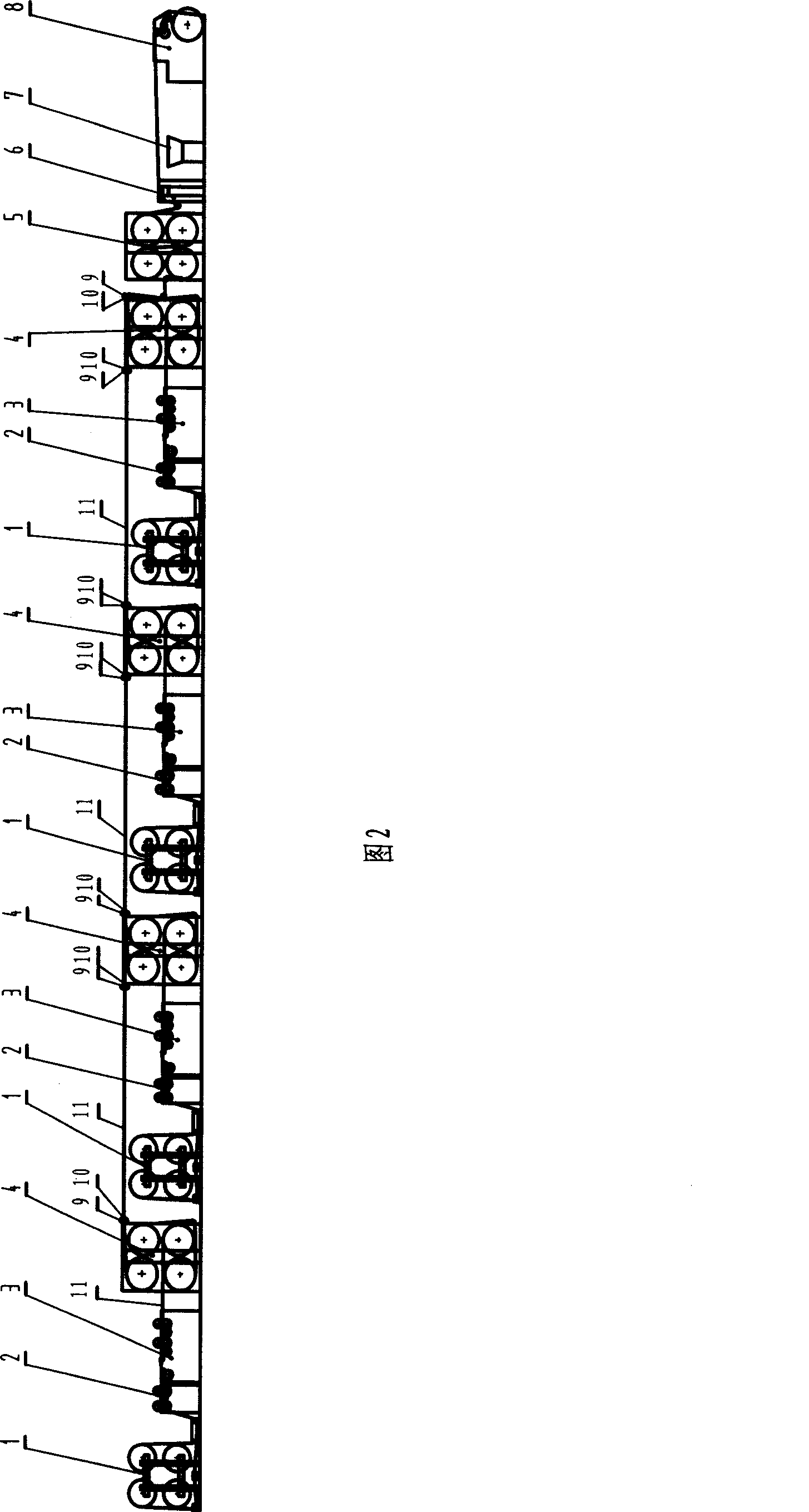

Multi-color chromaticity multi-stock trough composite slasher and technological process thereof

InactiveCN101413192AAvoid Blurred Color BoundariesReduced sizing costsSucessive textile treatmentsTextile treatment machine partsState of artYarn

The invention relates to a sizing machine, in particular to a multicolor chromatic multi-size box composite sizing machine, which is characterized in that more than three sizing areas are arranged on the rear of a common area. The process method is as follows: yarns with different colors are subjected to sizing and pre-drying in different sizing areas respectively, and combined, dried and winded into a warp beam. Compared with the prior art, the machine can divide various yarns with large color difference into several groups, and the yarns are cooked in different size boxes, subjected to pre-drying respectively and composite drying, and combined into the warp beam. The sizing machine avoids cooking and sizing of the yarns with various colors in the same size box, and avoids causing vague color division due to mutual staining of the yarns with the various colors to directly influence the product quality. Firstly, the machine is a breakthrough in sizing of the yarn dyed fabric industry; and secondly, compared with a technology for performing sizing on the yarns with different colors and weaving the yarns after warp rebeaming, the machine greatly reduces the sizing cost and improves the sizing efficiency.

Owner:盐城华特纺织机械有限公司

Textile size applicable to polyester fabrics

The invention relates to a textile size applicable to polyester fabrics. The textile size comprises the following components in mass ratio: 50 parts of nano silicon dioxide modified starch, 26 parts of protein size, 20 parts of water-based copolyether ester, 2 parts of glycerol, 2 parts of modified silicone oil defoaming agent, 3 parts of argine monohydrochloride, 1 part of sodium sulfamate and 1 part of polyacrylate. The size has favorable film forming property and permeability, is particularly applicable to the sizing of the polyester fabrics and is more environment-friendly as the formula does not contain polyvinyl alcohol.

Owner:SUZHOU RUNHONG TRADING

ASA emulsion sizing agent and preparation method thereof

InactiveCN102493272AHigh sizing efficiencyImprove stabilityWater-repelling agents additionInorganic compound additionActive agentOil phase

The present invention relates to the technical field of a sizing agent in the paper industry, and specifically to an ASA emulsion sizing agent. The ASA emulsion sizing agent comprises alkenyl succinic anhydride, hectorite, nano-titanium dioxide and deionized water, wherein a mass ratio of the alkenyl succinic anhydride to the deionized water is 1:0.5-4, a mass ratio of the hectorite to the alkenyl succinic anhydride is 1:20-200, and a mass ratio of the nano-titanium dioxide to the hectorite is 1:6-50. The preparation method for the ASA emulsion sizing agent comprises: dispersing the hectorite in the deionized water, and adjusting the pH value to 6-7 to obtain the aqueous phase; dispersing the nano-titanium dioxide in the alkenyl succinic anhydride to obtain the oil phase, and uniformly mixing the aqueous phase and the oil phase to prepare the ASA emulsion sizing agent. According to the present invention, the additions of any surfactants are not required, and the prepared ASA emulsion sizing agent has characteristics of good stability and high sizing efficiency.

Owner:QILU UNIV OF TECH

Low-pollution textile sizing agent

The invention relates to a low-pollution textile sizing agent. The low-pollution textile sizing agent comprises following components in parts by mass: 64 parts of nano silicon dioxide modified starch, 18 parts of a protein sizing agent, 5 parts of polyvinyl alcohol, 11 parts of polyacrylate emulsion, 2 parts of a modified silicone oil de-foaming agent, 3 parts of protein amino acid, 4 parts of kaolin, 3 parts of sodium sulfamate and 1 part of polyacrylate. The sizing agent with the formula has good film-forming property and permeability; the formula contains less polyvinyl alcohol so that the pollution to the environment is low.

Owner:SUZHOU RUNHONG TRADING

Quaternary ammonium salt modified hectorite emulsifier and method for emulsifying ASA (acetylsalicylic acid) by using same

ActiveCN103451994AImprove modification efficiencyImprove stabilityWater-repelling agents additionPaper/cardboardQuaternary ammonium cationEmulsion

The invention relates to a quaternary ammonium salt modified hectorite emulsifier and a method for emulsifying ASA (acetylsalicylic acid) by using the quaternary ammonium salt modified hectorite emulsifier and belongs to the technical field of emulsification of papermaking sizing agents. The emulsifier is composed of independently existing quaternary ammonium salt and hectorite; and the mass ratio of the quaternary ammonium salt to the hectorite is 1: (50-500). According to the quaternary ammonium salt modified hectorite emulsifier, the quaternary ammonium salt has high modification efficiency to hectorite, is small in dosage when stabilizing ASA sizing emulsion and has good emulsion effect on the stable ASA sizing emulsion; the ASA sizing emulsion stabilized by the quaternary ammonium salt modified hectorite emulsifier is good in stability, free of granular aggregation or precipitation or water phase separation after being stood still for 24 hours, is hardly hydrolyzed and is small in sizing performance change after being placed for 3 hours and high in sizing efficiency; and compared with ASA emulsion singly stabilized by hectorite, the ASA emulsion stabilized by the emulsifier has greatly improved sizing efficiency.

Owner:山东熙来淀粉有限公司

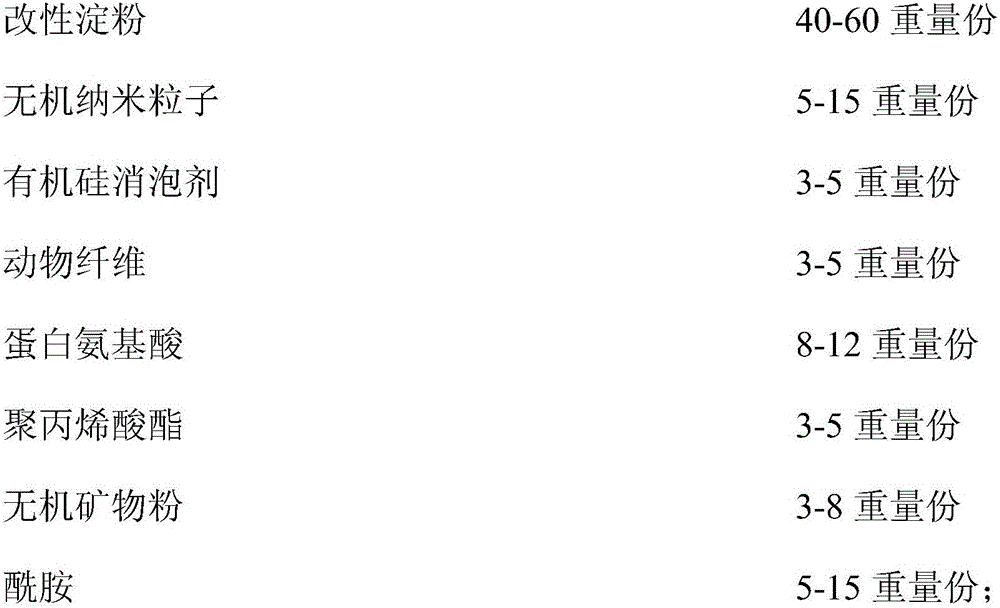

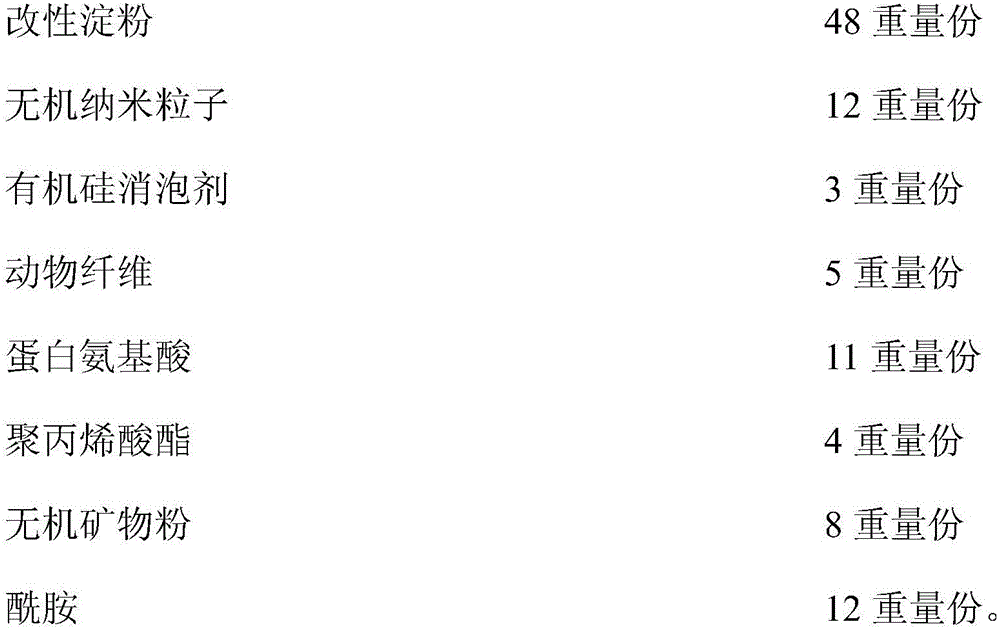

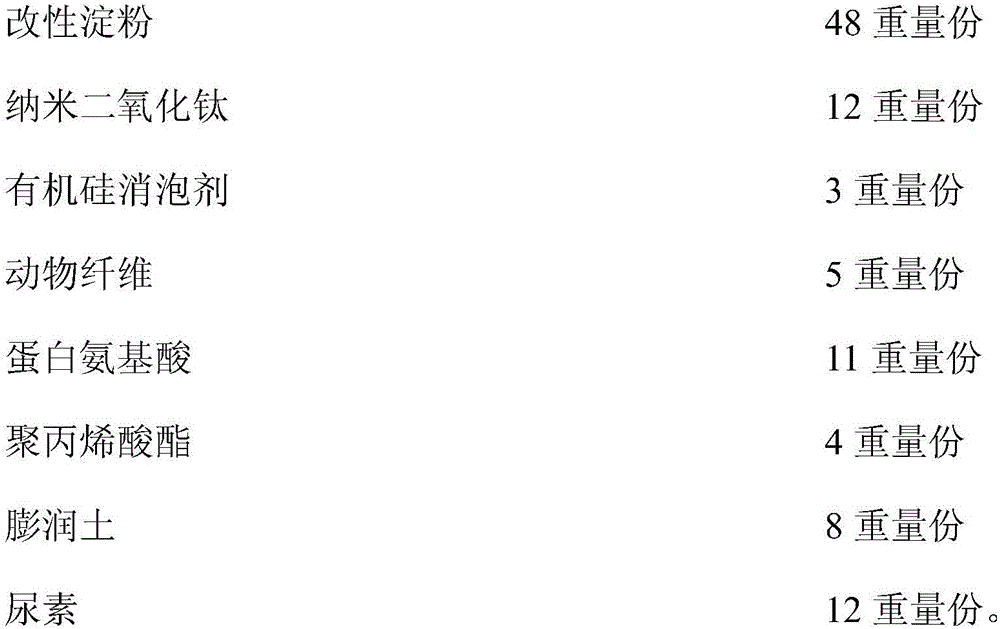

Environmental protection type starch textile sizing gent and preparing method thereof

InactiveCN106400494AWeaken the strength of hydrogen bondsParticle shape is smoothFibre typesProteinogenic amino acidInorganic nanoparticles

The invention belongs to the technical field of textile sizing agent, and relates to an environmental protection type starch textile sizing agent and a preparing method thereof. The textile sizing agent is prepared from, by weight, 40-60 parts of modified starch, 5-15 parts of inorganic nanoparticles, 3-5 parts of organic silicon defoamer, 3-5 parts of animal fiber, 8-12 parts of proteinogenic amino acids, 3-5 parts of polyacrylic ester, 3-8 parts of inorganic mineral powder or 5-15 parts of acid amides, wherein the modified starch is the mixture of nano-silica modified starch and saccharifying enzyme modified starch, wherein the mass ratio of the nano-silica modified starch to the saccharifying enzyme modified starch is (20-30) : 1. Choosing the nano-silica modified starch and the saccharifying enzyme modified starch as raw materials to prepare the textile sizing agent makes the textile sizing agent easy to be degraded, thus the starch textile sizing agent is environment-friendly and pollution-free and has wide application prospects.

Owner:西达(无锡)生物科技有限公司

Sizing method of low-pollution textile slurry

The invention relates to a sizing method of low-pollution textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 52 DEG C; immersing the fabric into the slurry in the slurry trough for 6 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 12KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 3 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 14KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

Sizing method of environment-friendly textile slurry

ActiveCN103882709ASizing fitImprove sizing effectSucessive textile treatmentsFibre treatmentEngineeringSlurry

The invention relates to a sizing method of environment-friendly textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 55 DEG C; immersing the fabric into the slurry in the slurry trough for 5 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 13KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 2 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 15KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

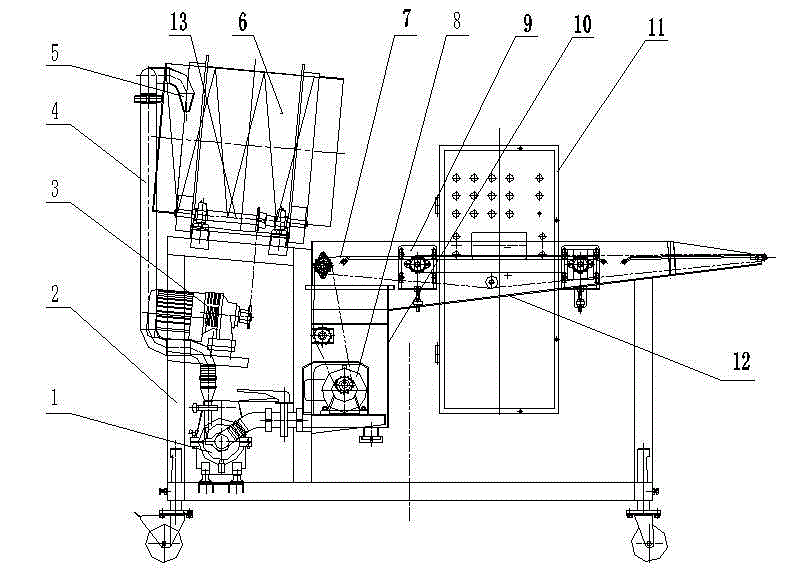

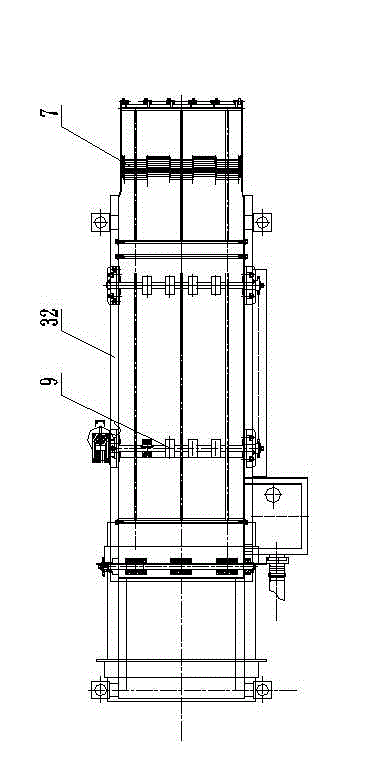

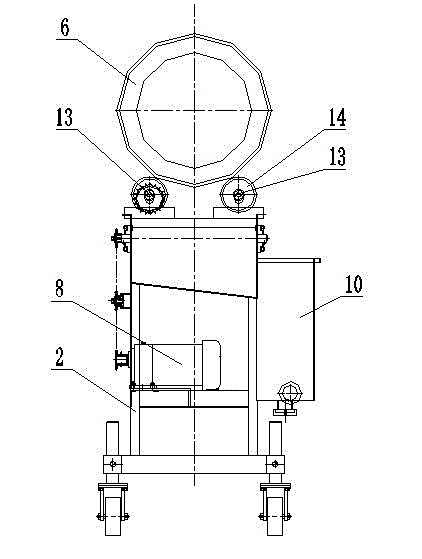

Food starching machine

InactiveCN102715631ASimple ingredientsImprove sizing efficiencyFood coatingFood shapingEngineeringScallop

The invention discloses a food starching machine, belonging to the technical field of food processing machinery. The food starching machine comprises a frame (2) and is characterized in that a rotatable roller (6) and a size loading device are arranged on the frame (2), and a size spraying port (5) of the size loading device corresponds to a feed port of the roller (6); and a mesh belt conveyor is arranged corresponding to the discharge end of the roller (6). The food starching machine disclosed by the invention can enable the food material in the roller to rotate along with the roller and simultaneously starch the food material through the rotation of the roller, the starching of the food material is simple, and the starching efficiency is high. The food starching machine disclosed by the invention is particularly suitable for starching the food materials with smaller volume and difficulty in single placement, such as broken and small meat pieces, dried shrimps, scallops and the like, and can be widely applied to the food processing industry.

Owner:JINAN HIWELL MACHINERY

Emulsifier making AKD glue fast cured

InactiveCN105088861AGood gelGood film formingWater-repelling agents additionAluminium chlorohydrateEmulsion

The invention discloses an emulsifier making AKD glue fast cured. The emulsifier is composed of 2-8% of modified starch, 15-25% of aluminium polychlorid, 20-35% of modified polyamide epichlorhydrin resin, 30-45% of acrylamide, 1-2% of PH modifier and 2-4% of anti-sticking cross-linking agent. Compared with the prior art, the emulsifier has the advantages that safety is achieved, toxins do not exist, the environment cannot be polluted, intermediate-alkaline glue can be fast emulsified, the curing speed is higher, the water resistance is enhanced, and the stability and the gluing efficiency of a prepared AKD emulsion are obviously improved.

Owner:HEFEI LONGFA PACKING CO LTD

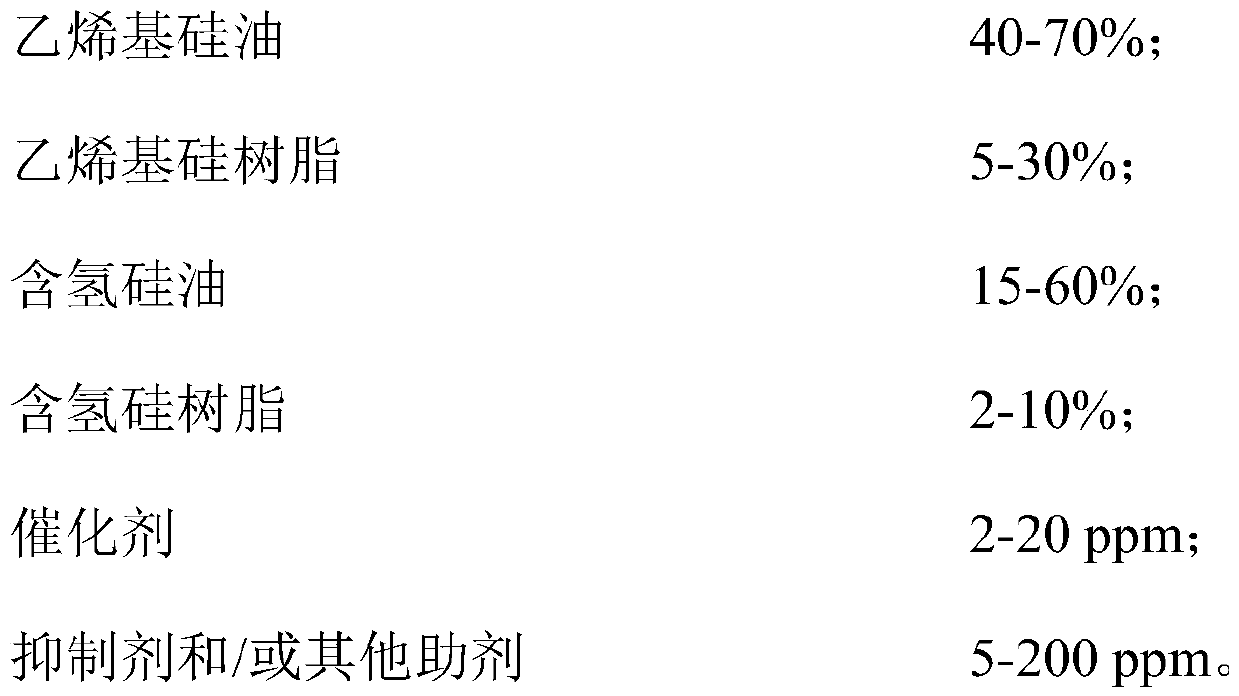

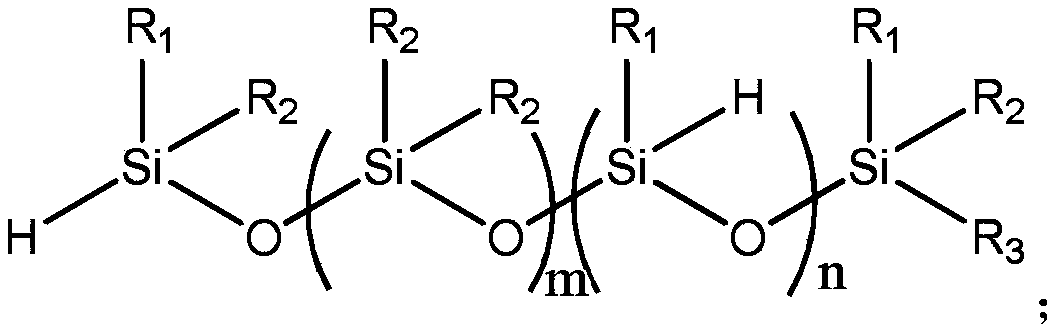

Thermosetting liquid optical adhesive composition and application thereof

ActiveCN111154451AStable PenetrationImprove heat stabilityNon-macromolecular adhesive additivesNeedle penetrationPolymer science

The invention provides a thermosetting liquid optical adhesive composition and an application thereof; the thermosetting liquid optical adhesive composition is tested according to a GB / T 4509-2010 asphalt needle penetration determination method, and the needle penetration of the thermosetting liquid optical adhesive composition is 160-250 mm. The thermosetting liquid optical adhesive provided by the invention has proper needle penetration after being cured, is easy to repair, does not greatly fluctuate along with the influence of temperature, humidity, UV aging irradiation and the like, and has higher cohesion strength, better binding power and excellent binding power for a binding material of a display module.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Synergistic and stable ASA sizing agent emulsion stabilized by cooperation of hectorite and polyvinylpyrrolidone

InactiveCN103790071ANot easy to hydrolyzeHigh sizing efficiencyWater-repelling agents additionPaper/cardboardFlocculationPyrrolidinones

The invention relates to an ASA sizing agent emulsion stabilized by cooperation of hectorite and polyvinylpyrrolidone, belonging to the technical field of emulsification of sizing agents for papermaking. On one hand, polyvinylpyrrolidone can initiate weak flocculation of hectorite, so that the hydrophilcity of hectorite particles is reduced, the affinity of ASA is improved, hectorite is promoted to be adsorbed to an ASA-water interface, and continuous granular membranes are formed at the peripheries of the ASA oil drops; on the other hand, polyvinylpyrrolidone can be directly adsorbed to the ASA-water interface and is arranged on the surfaces of the hectorite particle layer and the ASA oil drops in a coating manner to form a stable mechanical barrier, so that the ASA is effectively prevented from bleeding out of the coating layer, and the hydrolysis of ASA is prevented. Moreover, the mechanical barrier can be tightly combined with water, and aggregation among ASA droplets can be effectively avoided. Therefore, the stability of the ASA sizing agent stabilized by the cooperation of hectorite and polyvinylpyrrolidone is obviously improved.

Owner:QILU UNIV OF TECH

Cable winding and packaging device

The invention discloses a cable winding and packaging device. A shell is included. The front side of the shell is provided with a fixing pulley, a horizontal moving pulley and a winding pipe. A limiting rod is fixedly connected to the front end of the winding pipe. A first baffle and a limiting threaded sleeve are arranged on the surface of the limiting rod. The end, close to the shell, in the winding pipe is provided with a position adjustable second baffle and a sliding sleeve. One side of the sliding sleeve is provided with a locking mechanism in a penetrating manner. Long holes are symmetrically formed in the two sides of the winding pipe. The sliding sleeve is fixedly connected with the winding pipe through the locking mechanism. Through adjustment of the distance between the first baffle and the second baffle, the packaging width can be changed, meanwhile, operation is simple, and the packaging size adjusting efficiency is improved. Cable processing enterprises can produce cablewinding bags different in packaging size according to actual needs of the market, the usage requirements of people for the cable packaging size can be met, more selections are provided for customers so that the sale volume can be increased, and economic benefits are improved.

Owner:ZHEJIANG LIZHOU CABLE

Textile size applicable to high-count cotton fabrics

The invention relates to a textile size applicable to high-count cotton fabrics. The textile size comprises the following components in mass ratio: 80 parts of nano silicon dioxide modified starch, 10 parts of protein size, 8 parts of polyacrylate emulsion, 2 parts of modified silicone oil defoaming agent, 5 parts of argine monohydrochloride, 2 parts of sodium sulfamate and 2 part of polyacrylate. The size has favorable film forming property and permeability, is particularly applicable to the sizing of the high-count cotton fabrics and is more environment-friendly as the formula does not contain polyvinyl alcohol.

Owner:SUZHOU RUNHONG TRADING

Fluorescent alkenyl succinic anhydride (ASA) sizing agent for papermaking and preparation method of fluorescent ASA sizing agent for papermaking

InactiveCN103790072AFluorescentHigh sizing efficiencyWater-repelling agents additionPolyelectrolyteElectrolysis

The invention relates to a fluorescent alkenyl succinic anhydride (ASA) sizing agent for papermaking and a preparation method of the fluorescent ASA sizing agent for papermaking, belonging to the technical field of sizing agent for papermaking. According to the fluorescent ASA sizing agent for papermaking, firstly, a carbon quantum dot is added into the ASA sizing agent, so that ASA sizing emulsion which can be used as the fluorescent sizing agent for papermaking and effectively improves the water resistance of paper is successfully prepared; a new emulsion stabilizer is provided for the ASA sizing agent, and the stable emulsifying agent enables the sizing agent to have fluorescence property and high sizing efficiency; furthermore, the emulsion stabilizer serving as the carbon quantum dot has the advantages of being few in dosage, non-toxic, low in cost, etc. The fluorescent ASA sizing agent for papermaking adopts a simple preparation technology, and a surface active agent, a polymer polyelectrolyte and a dye type fluorescent agent do not need to be added into the fluorescent ASA sizing agent.

Owner:QILU UNIV OF TECH

Fluorescent alkenyl butanedioic anhydride sizing emulsion and preparation method thereof

InactiveCN103774499AGood emulsifying effectImprove stabilityWater-repelling agents additionPolyelectrolytePolymer science

The invention relates to a fluorescent alkenyl butanedioic anhydride sizing emulsion and a preparation method thereof, and belongs to the technical field of emulsification of papermaking sizing agents. According to the invention, the alkenyl butanedioic anhydride sizing emulsion which can serve as a fluorescent papermaking sizing agent and can be used for effectively improving the water resistance of paper is successfully prepared by jointly adding carbon quantum dots and bentonite into an alkenyl butanedioic anhydride sizing agent for the first time. A novel emulsion stabilizer is provided for the alkenyl butanedioic anhydride sizing agent. The emulsion stabilizer ensures that the sizing agent have the fluorescent performance. In addition, carbon quantum dots and bentonite as the emulsifier have the advantages of less use level, no toxicity, low cost and the like. The fluorescent alkenyl butanedioic anhydride sizing emulsion provided by the invention is simple in preparation process, and no surfactants, macromolecular polyelectrolytes and dyeing type fluorescent agents need to be added.

Owner:QILU UNIV OF TECH

Textile auxiliary agent for auxiliary textile sizing and preparation method thereof

InactiveCN105734964AHigh sizing efficiencyStrong penetrating powerFibre treatmentPhosphorous acidPolymer science

The invention discloses a textile auxiliary agent for auxiliary textile sizing. The textile auxiliary agent is prepared from, by weight, 45-55 parts of sodium diethylhexyl sulfosuccinate, 40-50 parts of formamidothiazol-4-acetic acid ethyl ester, 35-45 parts of propyltriethoxysilane, 35-45 parts of 5-aminolevulinic acid, 30-40 parts of zinc phenolsulfonate, 25-35 parts of diphenyl tridecyl phosphite, 20-30 parts of laurate, 15-25 parts of methyl silicone resin, 15-25 parts of azodisisobutyronitrile, 10-20 parts of nonylphenol polyoxyethylene ether, 5-15 parts of hydroxypropyl methyl cellulose, 5-10 parts of nano-graphite powder, 5-10 parts of a cross-linking agent and 5-10 parts of a softening agent. Accordingly, the sizing efficiency can be improved, and the effect that size permeates into a fabric is enhanced. The invention further discloses a corresponding preparation method.

Owner:WUJIANG FUHUIYUAN HOME TEXTILES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com