Environmental protection type starch textile sizing gent and preparing method thereof

A textile sizing and environment-friendly technology, which is applied to the field of environment-friendly starch textile sizing and its preparation, can solve the problems of insufficient sizing strength of starch sizing, insufficient affinity of polyester fibers, pushing up printing and dyeing enterprises, etc., so as to improve sizing. Efficiency, enhanced sizing effect, reduced hydrogen bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

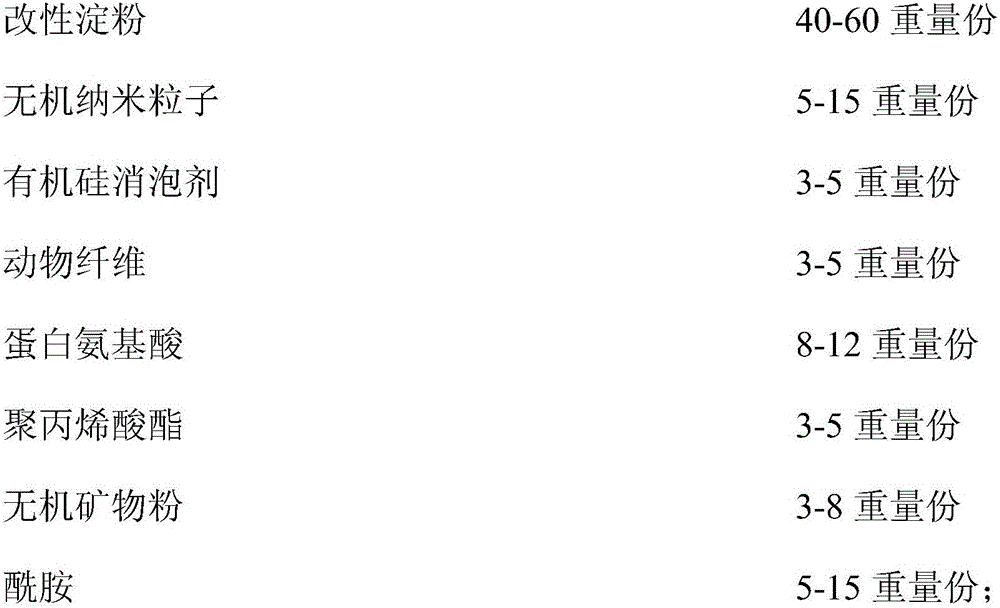

[0040] In this embodiment, the textile slurry is mainly prepared from the following raw materials in parts by weight:

[0041]

[0042] Wherein, the nano-silica modified starch: the mass ratio of glucoamylase modified starch is 27:1, the starch: the mass ratio of nano-silica is 78:1, the starch: the mass ratio of glucoamylase 86:1, the particle size of the nano-titanium dioxide is 20nm, and the particle size of the bentonite is 53nm.

[0043] The preparation method is as follows:

[0044] (1) Add the modified starch and the inorganic nano-particles of formula quantity to reactor, stir 20nm;

[0045] (2) Add organosilicon defoamer, animal fiber, protein amino acid, polyacrylate, inorganic minerals and amides to the reaction mass of step (1), after mixing evenly, heat up and cook, and burn the slurry under normal pressure for 30 minutes. The starch textile size can be obtained.

Embodiment 2

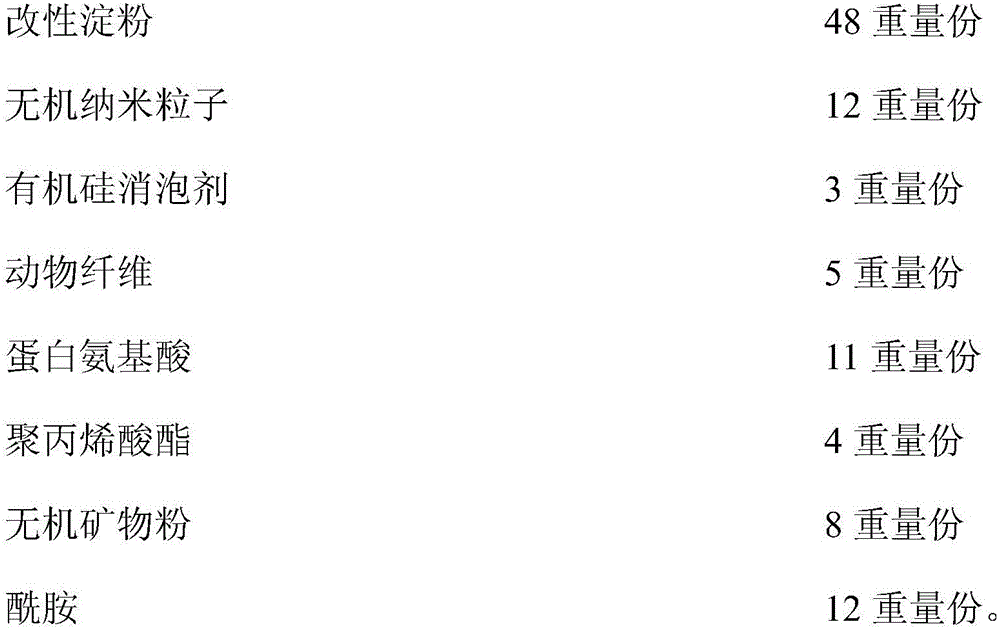

[0047] In this embodiment, the textile slurry is mainly prepared from the following raw materials in parts by weight:

[0048]

[0049] Wherein, the nano-silica modified starch: the mass ratio of glucoamylase modified starch is 20:1, the starch: the mass ratio of nano-silica is 70:1, the starch: the mass ratio of glucoamylase 80:1, the particle size of the nano-titanium dioxide is 10nm, and the particle size of the bentonite is 30nm.

[0050] The preparation method is as follows:

[0051] (1) Add the modified starch and the inorganic nano-particles of formula quantity to reactor, stir 10nm;

[0052] (2) Add organosilicon defoamer, animal fiber, protein amino acid, polyacrylate, inorganic minerals and amide in the reaction mass of step (1), after mixing evenly, heat up and cook, and burn the slurry under normal pressure for 40 minutes and get ready The starch textile size can be obtained.

Embodiment 3

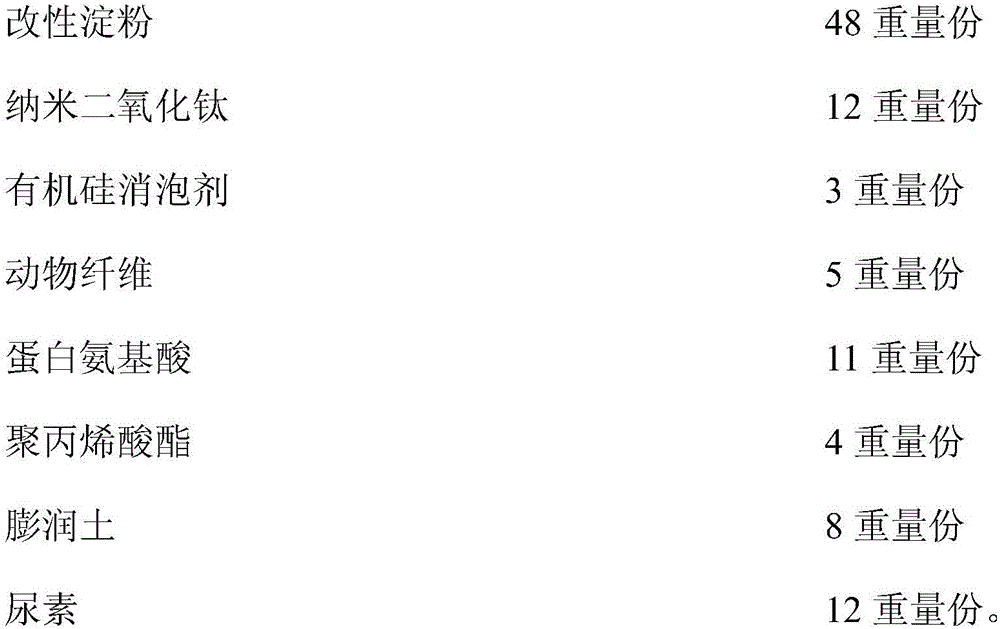

[0054] In this embodiment, the textile slurry is mainly prepared from the following raw materials in parts by weight:

[0055]

[0056] Wherein, the nano-silica modified starch: the mass ratio of glucoamylase modified starch is 30:1, the starch: the mass ratio of nano-silica is 85:1, the starch: the mass ratio of glucoamylase 90:1, the particle size of the nano-titanium dioxide is 30nm, and the particle size of the attapulgite is 70nm.

[0057] The preparation method is as follows:

[0058] (1) Add the modified starch and the inorganic nano-particles of formula quantity to reactor, stir 30nm;

[0059] (2) Add organosilicon defoamer, animal fiber, protein amino acid, polyacrylate, inorganic minerals and amides to the reaction mass of step (1), after mixing evenly, heat up and boil, and burn pulp under normal pressure and suffocate for 20min. The starch textile size can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com