Preparation method of composite thick oil viscosity reducer

A technology for viscosity reducer and conditions for heavy oil, applied in the field of preparation of compound heavy oil viscosity reducer, can solve the problems of increased viscosity reduction cost, reduced performance of heavy oil viscosity reducer, low viscosity reduction rate of heavy oil, etc. The effect of viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

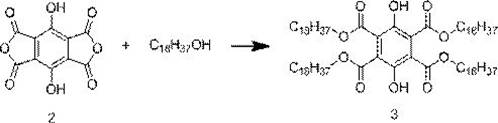

Image

Examples

Embodiment 1

[0046] A preparation method of a composite heavy oil viscosity reducer, specifically comprising the steps of:

[0047] Step S1: Add acrylamide, sodium p-styrenesulfonate, 2-acrylamido-2-methylpropanesulfonic acid, and deionized water into the reaction kettle, and stir until the propylene Amide, sodium p-styrenesulfonate, and 2-acrylamido-2-methylpropanesulfonic acid are completely dissolved to obtain a mixed solution;

[0048] Step S2: Disperse the viscosity-reducing additive in ethanol, stir at a rotational speed of 200r / min, add the mixed solution and azobisisobutyronitrile, and react for 8 hours at a temperature of 70°C , under the condition that the temperature is 110°C, carry out distillation to remove the distillate, and obtain the compound heavy oil viscosity reducer.

[0049] Described viscosity-reducing additive is made by following steps:

[0050] Step A1: Add concentrated sulfuric acid and deionized water into the reaction kettle, stir for 10 minutes at a speed of...

Embodiment 2

[0056] A preparation method of a composite heavy oil viscosity reducer, specifically comprising the steps of:

[0057] Step S1: Add acrylamide, sodium p-styrenesulfonate, 2-acrylamido-2-methylpropanesulfonic acid, and deionized water into the reaction kettle, and stir until the propylene Amide, sodium p-styrenesulfonate, and 2-acrylamido-2-methylpropanesulfonic acid are completely dissolved to obtain a mixed solution;

[0058] Step S2: Disperse the viscosity-reducing additive in ethanol, stir at a speed of 300r / min, add the mixed solution and azobisisobutyronitrile, and react for 10 hours at a temperature of 70°C , under the condition that the temperature is 110°C, carry out distillation to remove the distillate, and obtain the compound heavy oil viscosity reducer.

[0059] Described viscosity-reducing additive is made by following steps:

[0060] Step A1: Add concentrated sulfuric acid and deionized water into the reaction kettle, stir for 10 minutes at a speed of 800 r / min...

Embodiment 3

[0066] A preparation method of a composite heavy oil viscosity reducer, specifically comprising the steps of:

[0067] Step S1: Add acrylamide, sodium p-styrenesulfonate, 2-acrylamido-2-methylpropanesulfonic acid, and deionized water into the reaction kettle, and stir until the propylene Amide, sodium p-styrenesulfonate, and 2-acrylamido-2-methylpropanesulfonic acid are completely dissolved to obtain a mixed solution;

[0068] Step S2: Disperse the viscosity-reducing additive in ethanol, stir at a speed of 300r / min, add the mixed solution and azobisisobutyronitrile, and react for 10 hours at a temperature of 80°C , under the condition that the temperature is 120°C, carry out distillation to remove the distillate, and obtain the compound heavy oil viscosity reducer.

[0069] Described viscosity-reducing additive is made by following steps:

[0070] Step A1: Add concentrated sulfuric acid and deionized water into the reaction kettle, stir for 15 minutes at a speed of 800 r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com