Organic silicone modified amphiphilic polymer type heavy oil viscosity reducer easy to demulsify and dewater and preparation method thereof

A thick oil viscosity reducer and amphiphilic polymer technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of demulsification and dehydration of produced fluid, complicated process steps, high price, etc. Strong wet performance, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Synthesis of organosilicon quaternary ammonium salt monomer SQ1

[0057] Add 4.26g of (N,N-dimethylaminopropyl)methacrylamide, 18.62g of 3-chloropropyltris(trimethylsiloxy)silane and 34.32g of isopropanol into a three-necked flask, and stir evenly. After reacting for 60 hours at a temperature of 82° C., it was cooled to room temperature; most of the solvent and some unreacted raw materials were removed by rotary evaporation under reduced pressure. The remaining distillate was washed with ether for 3 to 5 times to obtain 10.17 g of organosilicon quaternary ammonium salt monomer SQ1 with a yield of 75%;

[0058] The synthetic reaction formula is as follows:

[0059]

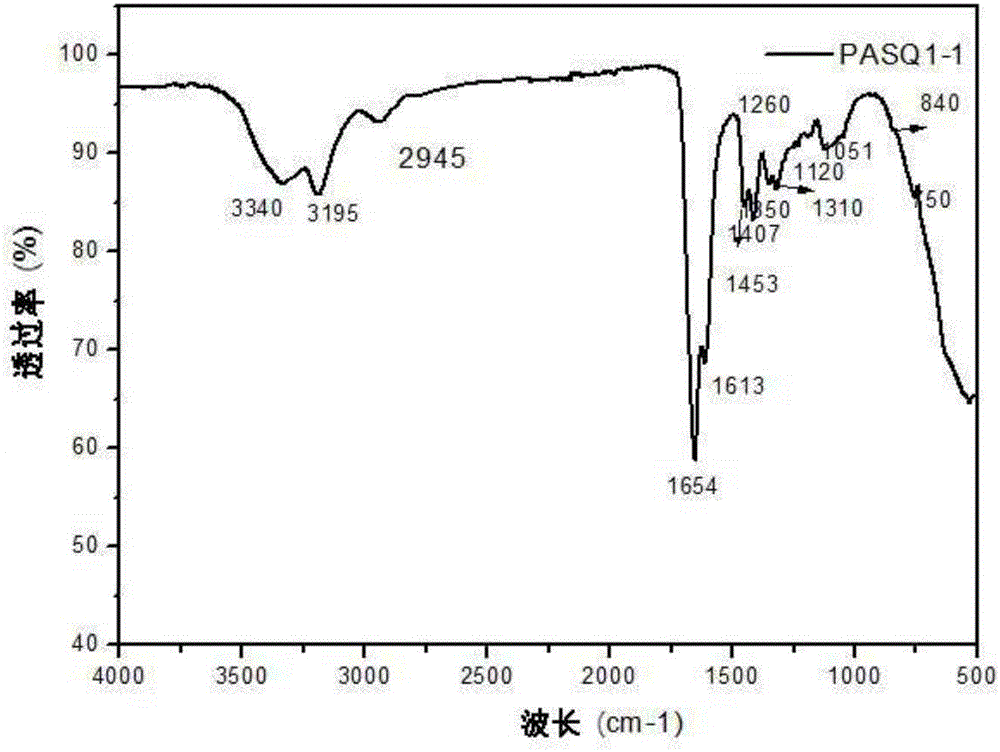

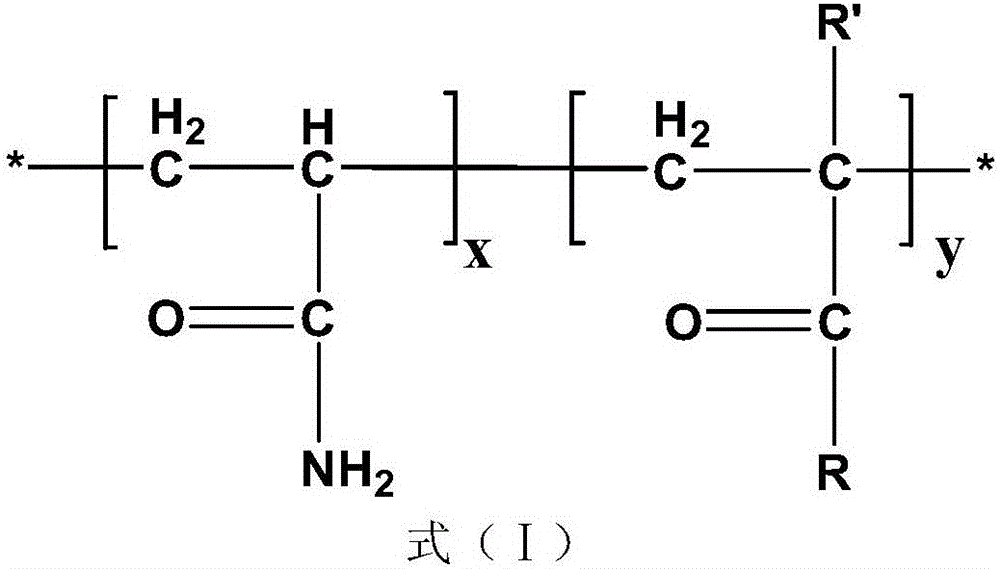

[0060] (2) Synthesis of heavy oil viscosity reducer PASQ1-1

[0061] Weigh 42.6g of acrylamide (AM), 2.13g of organosilicon quaternary ammonium salt monomer SQ1, 298.2g of N,N-dimethylformamide (DMF) 2 In the four-neck flask with air duct, reflux condenser and stirring device, N was passed under st...

Embodiment 2~5

[0070]The synthetic method of thick oil viscosity reducer PASQ1-2, PASQ1-3, PASQ1-4 and PASQ1-5 is as described in Example 1, and difference is: the mass ratio of SQ1 and AM is different (as shown in table 1 below), Other conditions are the same.

[0071] Table 1: Experimental results of heavy oil viscosity reducer PASQ1 in Examples 1-5

[0072] Viscosity reducer SQ1 / AM(%) Yield(%) Molecular weight (×10 6 )

Embodiment 6

[0074] (1) Synthesis of organosilicon quaternary ammonium salt monomer SQ2

[0075] Add 3.93 g of dimethylaminoethyl methacrylate, 12.04 g of 3-chloropropyl (triethoxy) silane and 23.96 g of ethanol into a three-necked flask, and stir evenly. After reacting for 72 hours at a temperature of 78°C, it was cooled to room temperature, and most of the solvent and some unreacted raw materials were removed by rotary evaporation under reduced pressure. The remaining distillate was washed with petroleum ether for 3 to 5 times to obtain 6.96 g of organosilicon quaternary ammonium salt monomer SQ2 with a yield of 70%;

[0076] The synthetic reaction formula is as follows:

[0077]

[0078] (2) Synthesis of heavy oil viscosity reducer PASQ2

[0079] Weigh 42.6g of acrylamide, 4.26g of organosilicon quaternary ammonium salt monomer SQ2, 312.4g of tetrahydrofuran, add 2 In the four-neck flask with air duct, reflux condenser and stirring device, N was passed under stirring. 2 After 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com