Efficient thick-oil emulsified adhesive-reducing agent

A technology for emulsification and viscosity reduction, heavy oil, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as salt resistance or temperature resistance or unsatisfactory viscosity reduction efficiency, and achieve the reduction of viscosity of heavy oil, The effect of improving oil recovery and improving viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

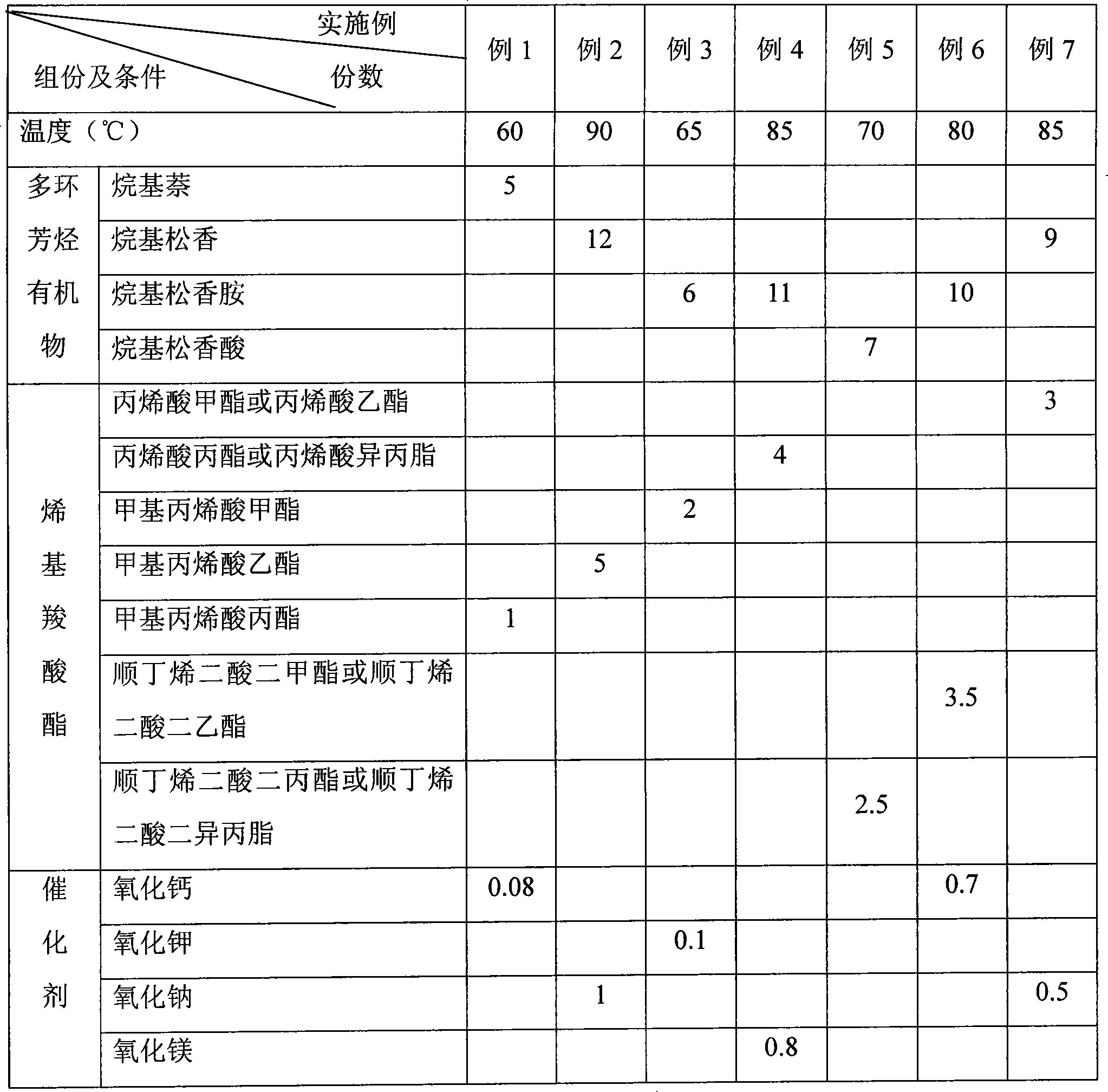

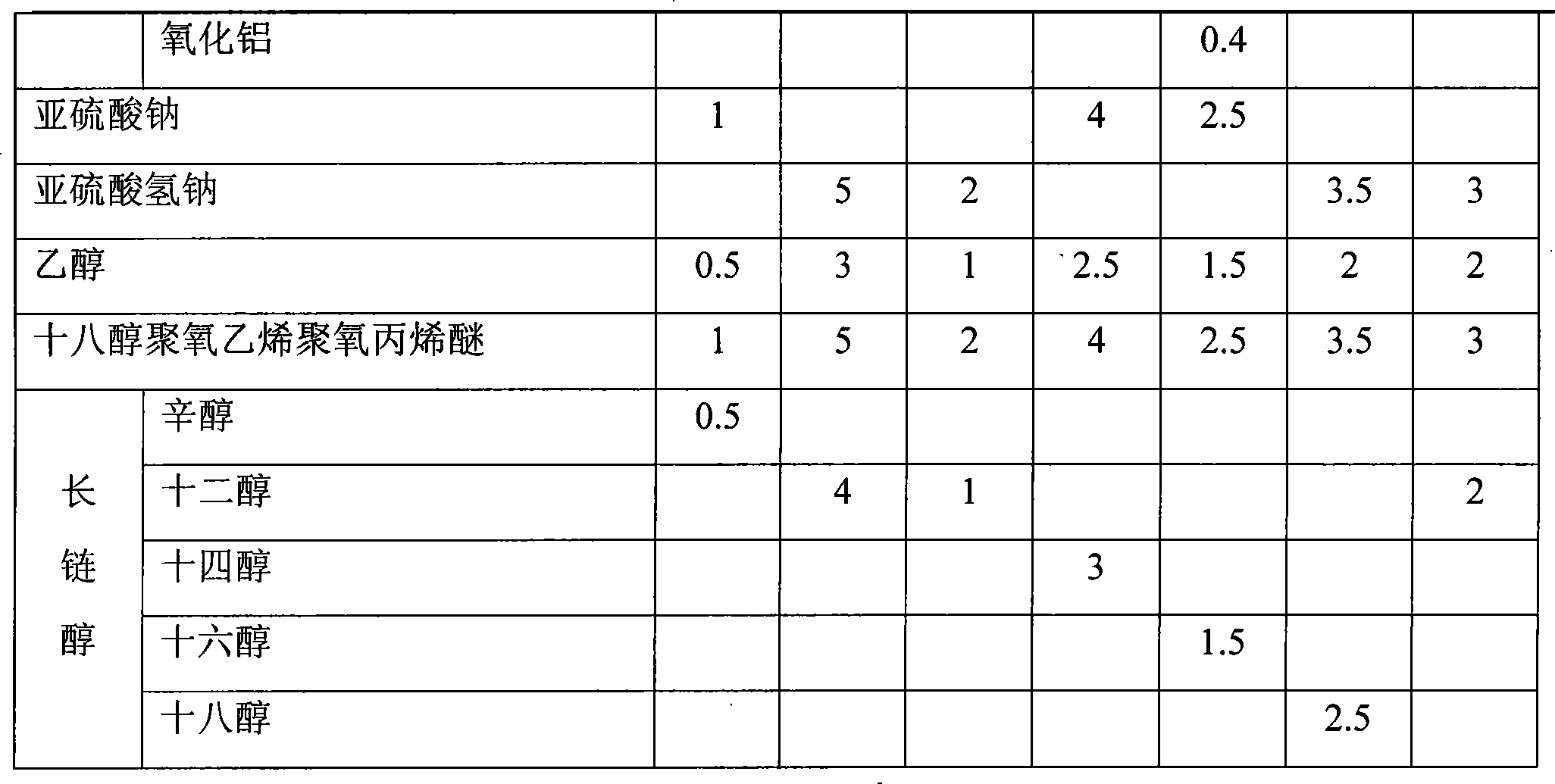

[0017] A high-efficiency thick oil emulsifying viscosity reducer of the present invention is composed of polycyclic aromatic hydrocarbon organic matter, alkenyl carboxylate, catalyst, sodium sulfite or sodium bisulfite, ethanol, polyoxyethylene polyoxypropylene ether of stearyl alcohol and long-chain Alcohol is prepared by the following steps in parts by weight:

[0018] a. Mix 5 to 12 parts of polycyclic aromatic hydrocarbons, 1 to 5 parts of alkenyl carboxylate, and 0.08 to 1 part of catalyst, and react at 60°C to 90°C for 1 to 3 hours;

[0019] b. Add 1 to 5 parts of sodium sulfite or sodium bisulfite and 0.5 to 3 parts of ethanol to the reaction solution in step a, and react under reflux for 1 to 4 hours;

[0020] c. Add 1 to 5 parts of stearyl alcohol polyoxyethylene polyoxypropylene ether and 0.5 to 4 parts of long-chain alcohol to the substance in step b, and reflux for 0.5 to 2 hours, that is, the synthetic effective content is 20% to 60%. Efficient heavy oil emulsify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com