Low foamability drilling fluid and its preparation method

A drilling fluid, low-foaming technology, applied in the field of drilling fluids, can solve the problems of foaming, weighting, foam stabilization and difficult to remove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

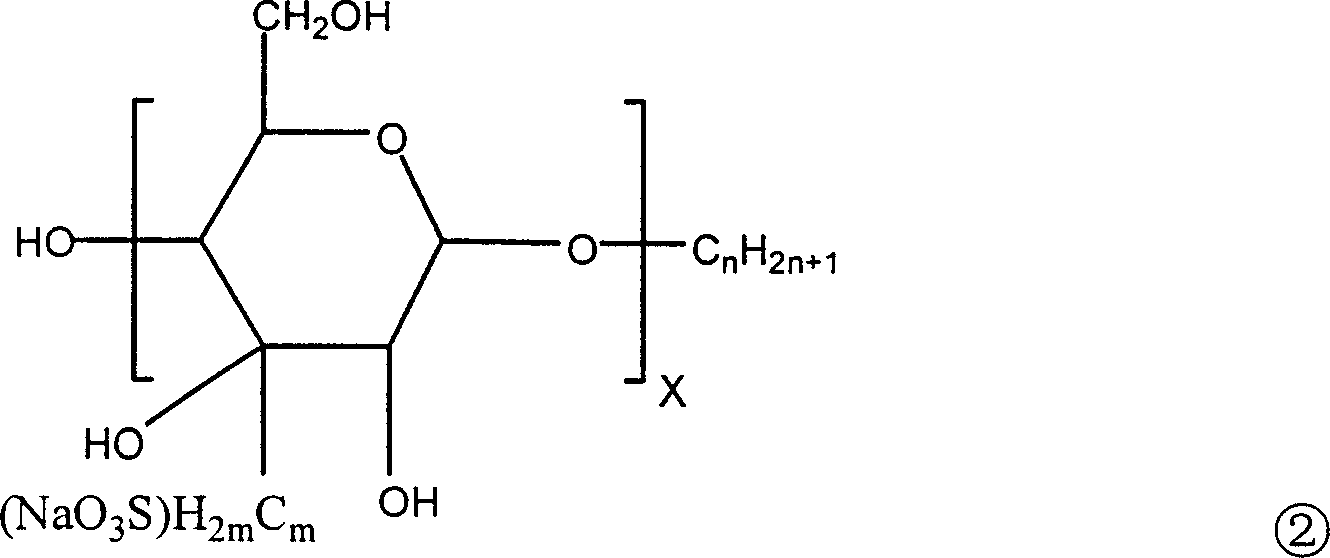

[0067] Take by weighing 100 grams of dry cornstarch with an electronic balance, add 60 grams of anhydrous methanol (chemically pure), 9 grams of sulfuric acid with a concentration of 50% wt, mix uniformly with a stirrer, pour into a reaction kettle equipped with a stirring device, and set the temperature at 85 ± After reacting at 5°C for about 2 hours, take out the reaction product, add 100 grams of dry cornstarch to the reaction product, stir evenly, pour it into the reaction kettle, and react for 1.6 hours to obtain a syrupy viscous liquid; add a concentration of 40% wt The sodium hydroxide solution adjusts the pH value to 9 to obtain a reaction product containing methyl glycoside B1 . Cool down to 55±5°C, then add 110 grams of sodium bisulfite and 100 grams of formaldehyde solution with a concentration of 37% wt, turn on the stirring and continue the reaction for 2 hours to obtain the final reaction product containing sulfomethylated methyl glycoside A1 .

Embodiment 2

[0069] Take by weighing 100 grams of dry cornstarch with a balance, add 100 grams of absolute ethanol (chemically pure), add 15 grams of phosphoric acid (chemically pure) with a concentration of 50% wt, stir and mix evenly with a mixer, and pour into a reaction kettle equipped with a stirring device After reacting at 120°C±5°C for about 4 hours, take out the reaction product, add 100 grams of dry corn starch to the reaction product, stir evenly, pour it into the reaction kettle, and react for 4 hours to obtain a syrupy viscous liquid Add 40% wt of sodium hydroxide solution to adjust the pH value to 11 to obtain a reaction product containing ethyl glycoside B2 . Then cool down to 90±5°C, add 130 grams of sodium bisulfite and 126 grams of acetaldehyde solution with a concentration of 37% wt, turn on the stirring and continue the reaction for 1 hour to obtain the final reaction product containing sulfoethylated ethyl glucoside A2 .

Embodiment 3

[0071] Take by weighing 100 grams of dried cornstarch with an electronic balance, add 100 grams of dehydrated alcohol (chemically pure), 13.5 grams of concentration 37% wt hydrochloric acid, mix uniformly with a stirrer, pour into a reaction kettle equipped with a stirring device, at 130 ± After reacting at 5°C for about 1 hour, take out the reaction product, add 100 grams of dry cornstarch to the reaction product, stir evenly, pour it into the reaction kettle, and react for 0.6 hours to obtain a syrupy viscous liquid; add a concentration of 40% wt sodium hydroxide solution to adjust the pH value to 9 to obtain a reaction product containing ethyl glycoside B3 , lower the temperature to 60±5°C, then add 120 grams of sodium sulfite and 86 grams of formaldehyde solution with a concentration of 37% wt, turn on the stirring and continue the reaction for 2 hours to obtain the final reaction product containing sulfomethylethylglucoside A3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com