Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Guaranteed placement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

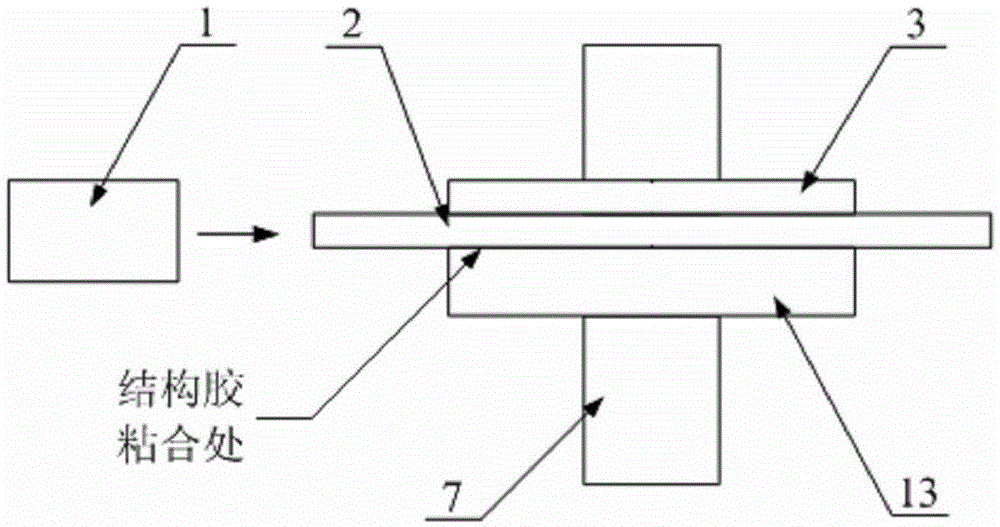

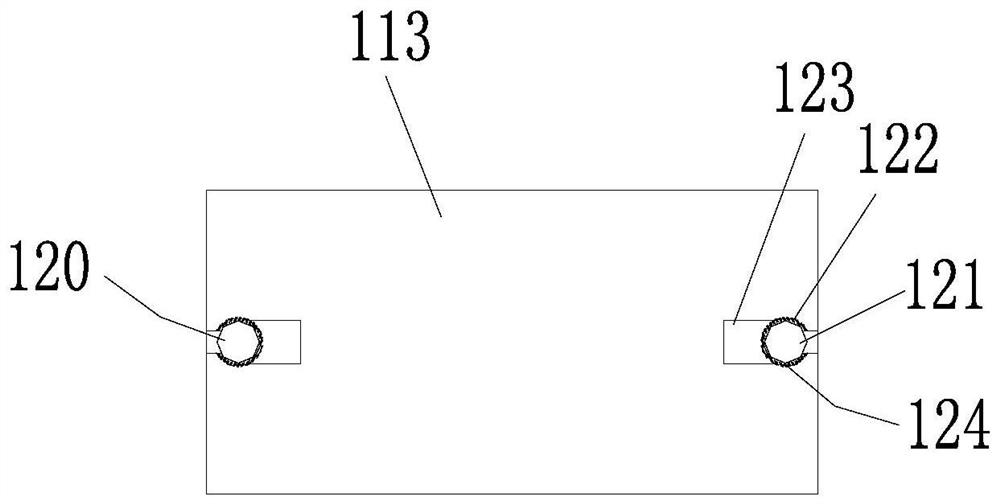

Laser and grating coupler packaging structure and method

ActiveCN105259623AGuaranteed placement accuracyEfficient couplingLaser detailsSemiconductor laser optical deviceGratingEngineering

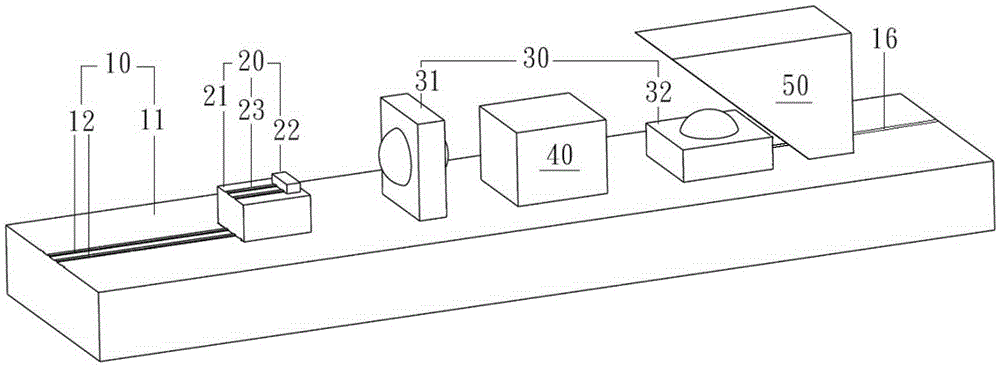

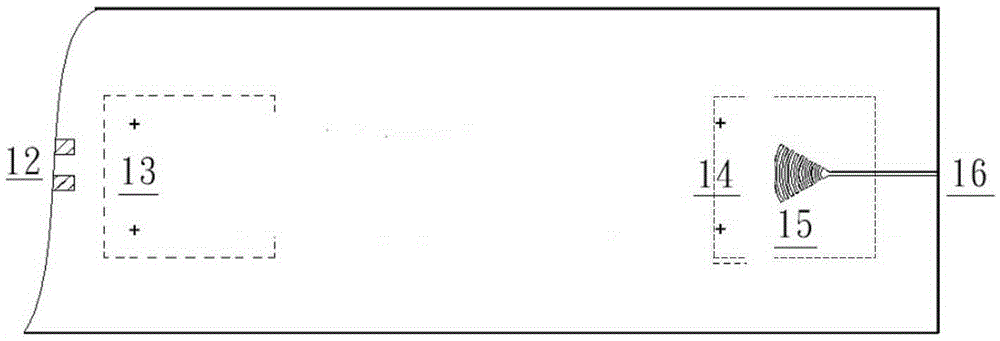

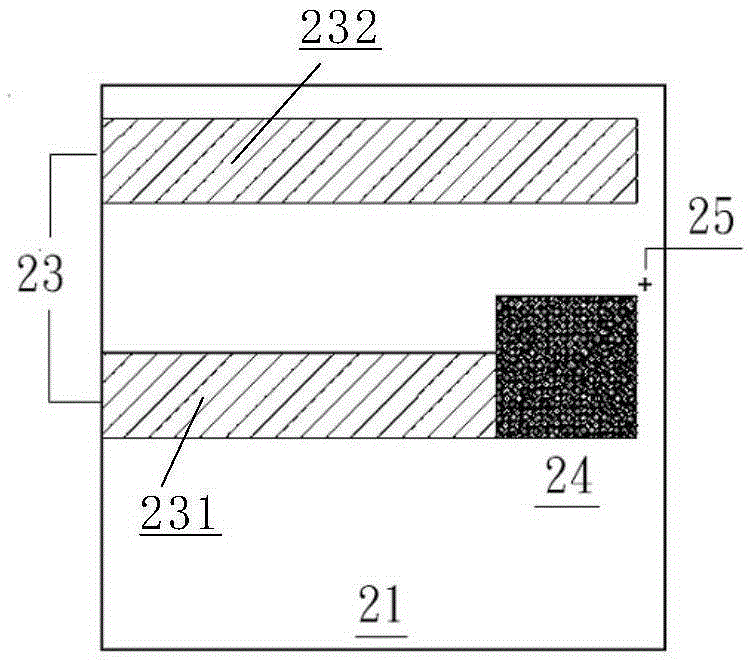

The invention provides a laser and grating coupler packaging structure and method. The packaging structure comprises a laser unit, a collimating lens, an isolator and a reflection prism, wherein the laser unit, the collimating lens, the isolator and the reflection prism are mounted on a silicon-based photoelectric chip. The silicon-based photoelectric chip comprises a first electrode, first and second marks, a grating coupler and a waveguide layer which are all arranged at the surface; the laser unit comprises a transitional substrate and a laser; the collimating lens comprises a first lens and a second lens, the first lens is vertical to the surface, the second lens is arranged at the surface at the position of the second mark, and thus, the grating coupler is placed in the central area of the main axis of the optical path of the second lens; and the isolator is mounted at the surface between the first lens and the second lens, so that diverging light output by the laser is collimated by the first lens, then reflected to the reflection prism through the isolator, deflected by the reflection prism for certain angle, and gathered by the second lens, and the gathering point is placed at the surface of the grating coupler. Thus, technical problems in accurate in-place packaging are solved, convenience is provided for preparation, and the yield rate is improved.

Owner:WUHAN TELECOMM DEVICES

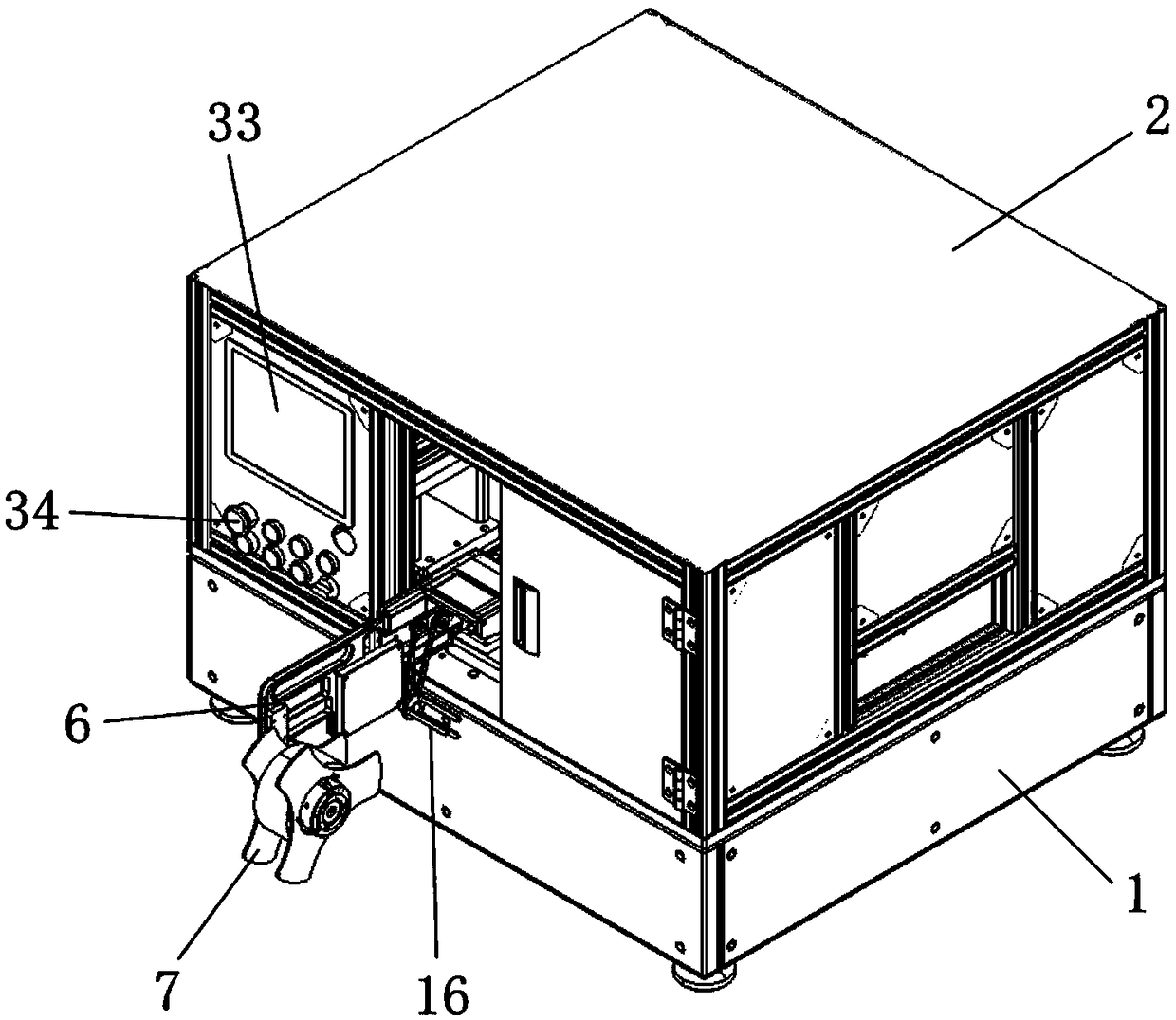

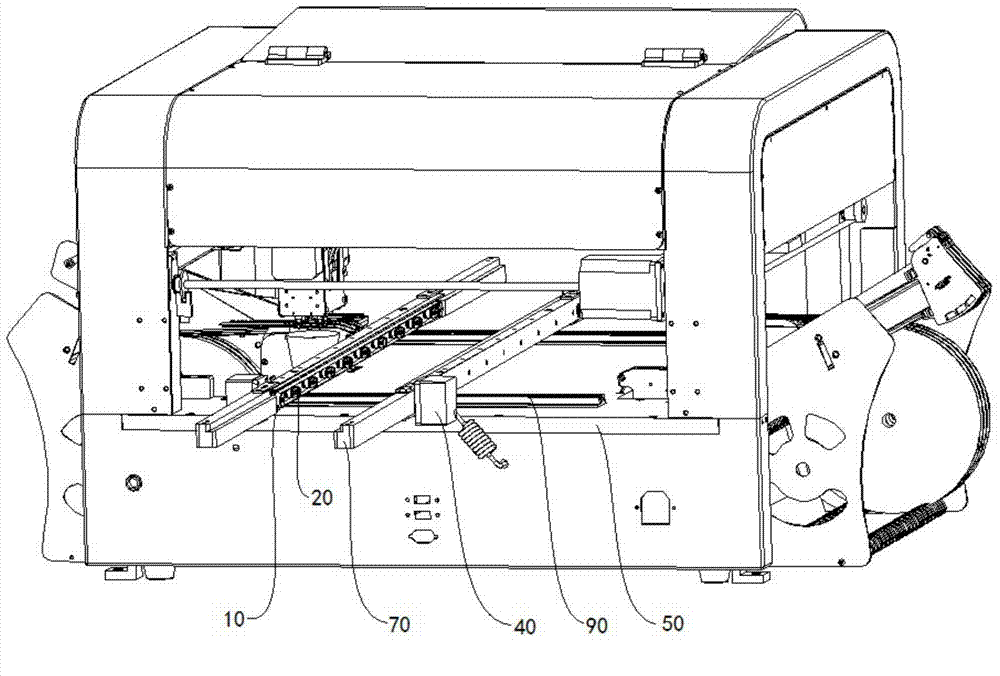

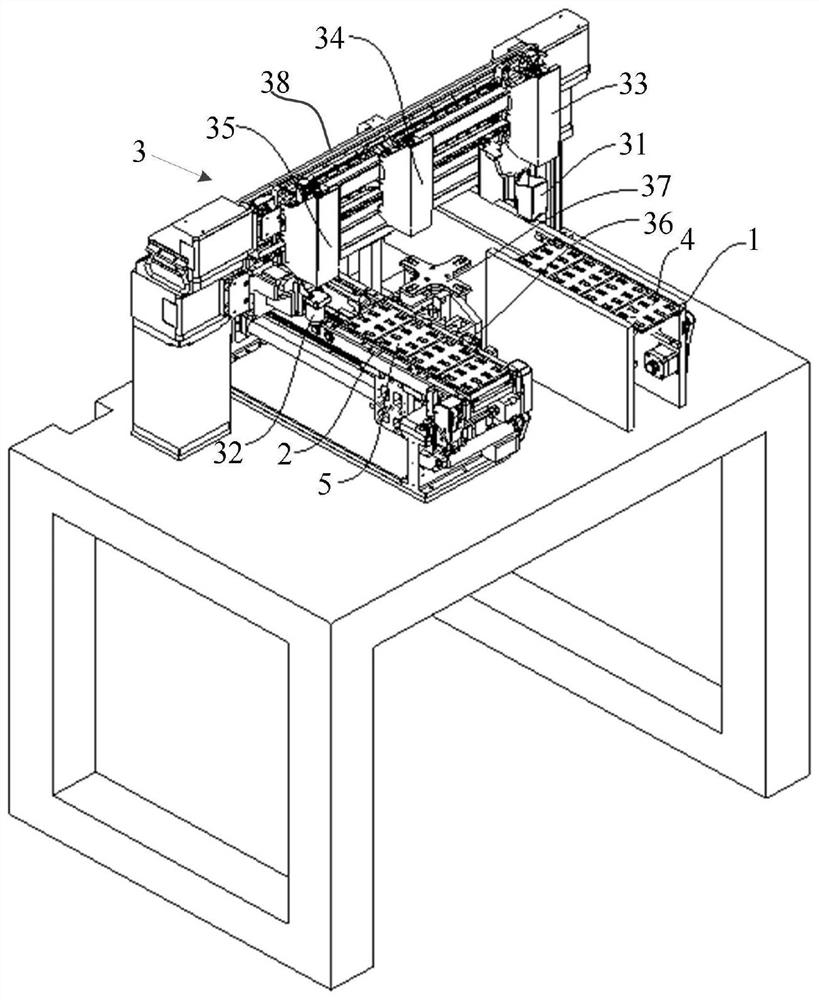

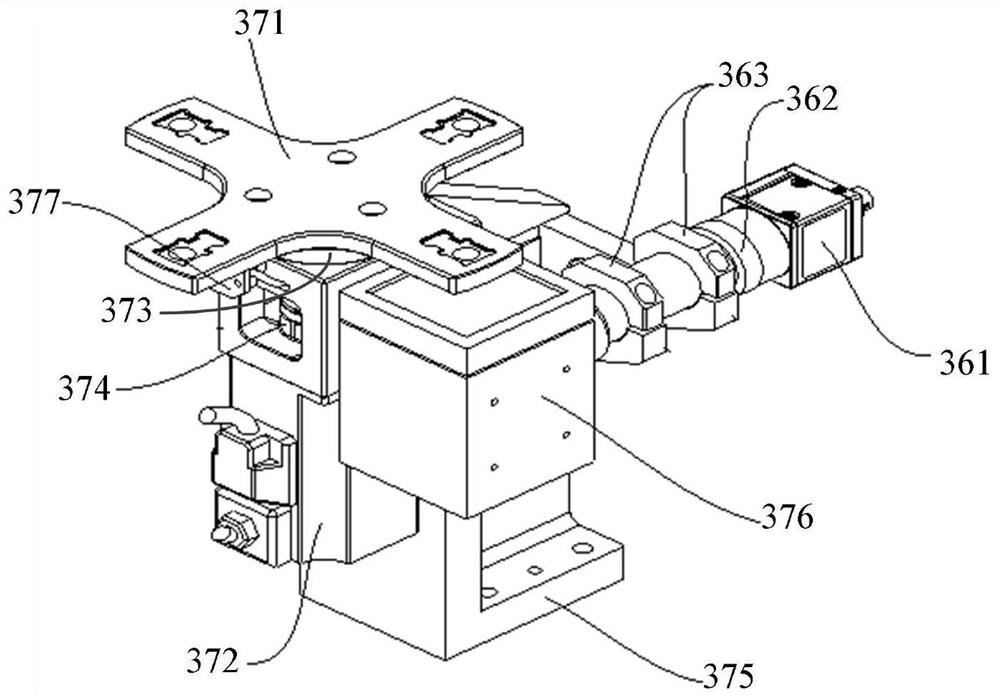

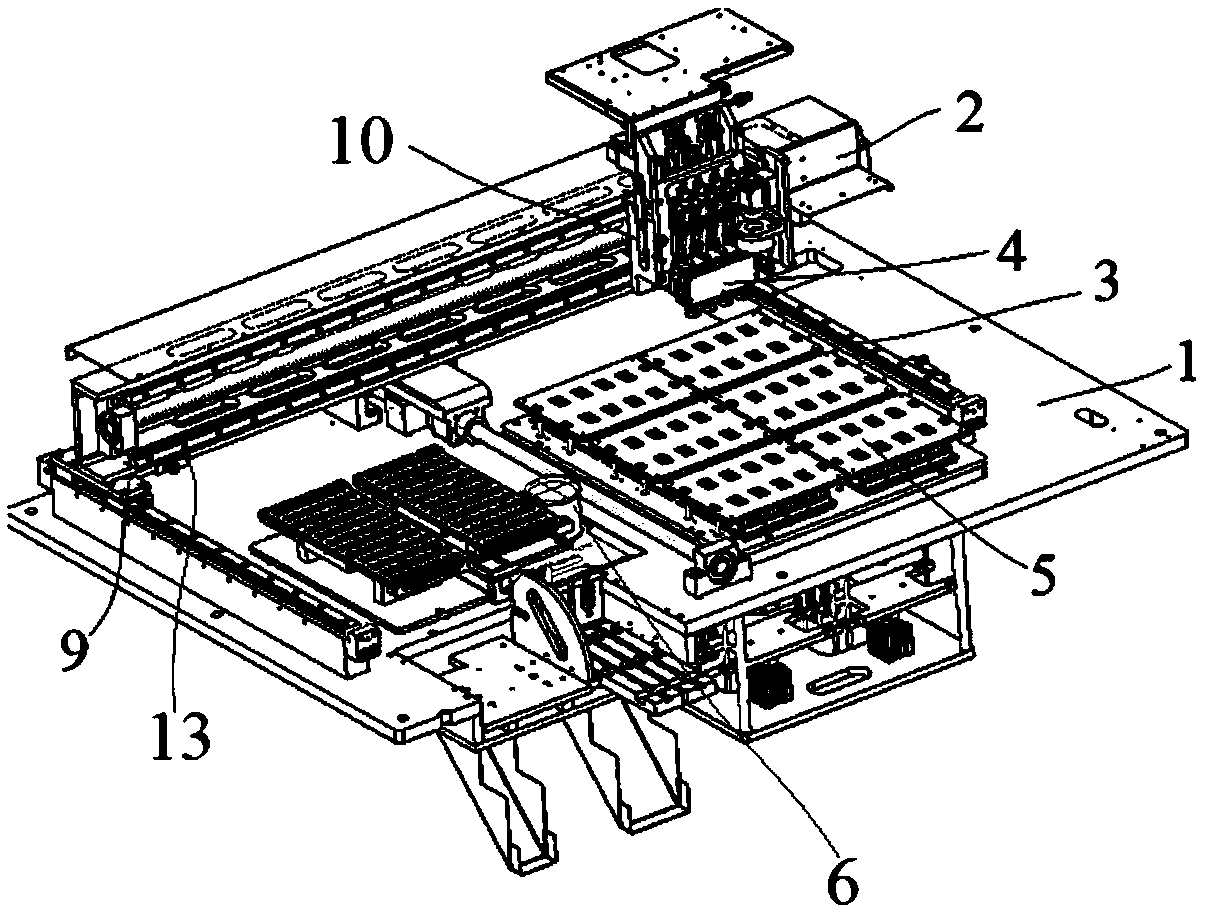

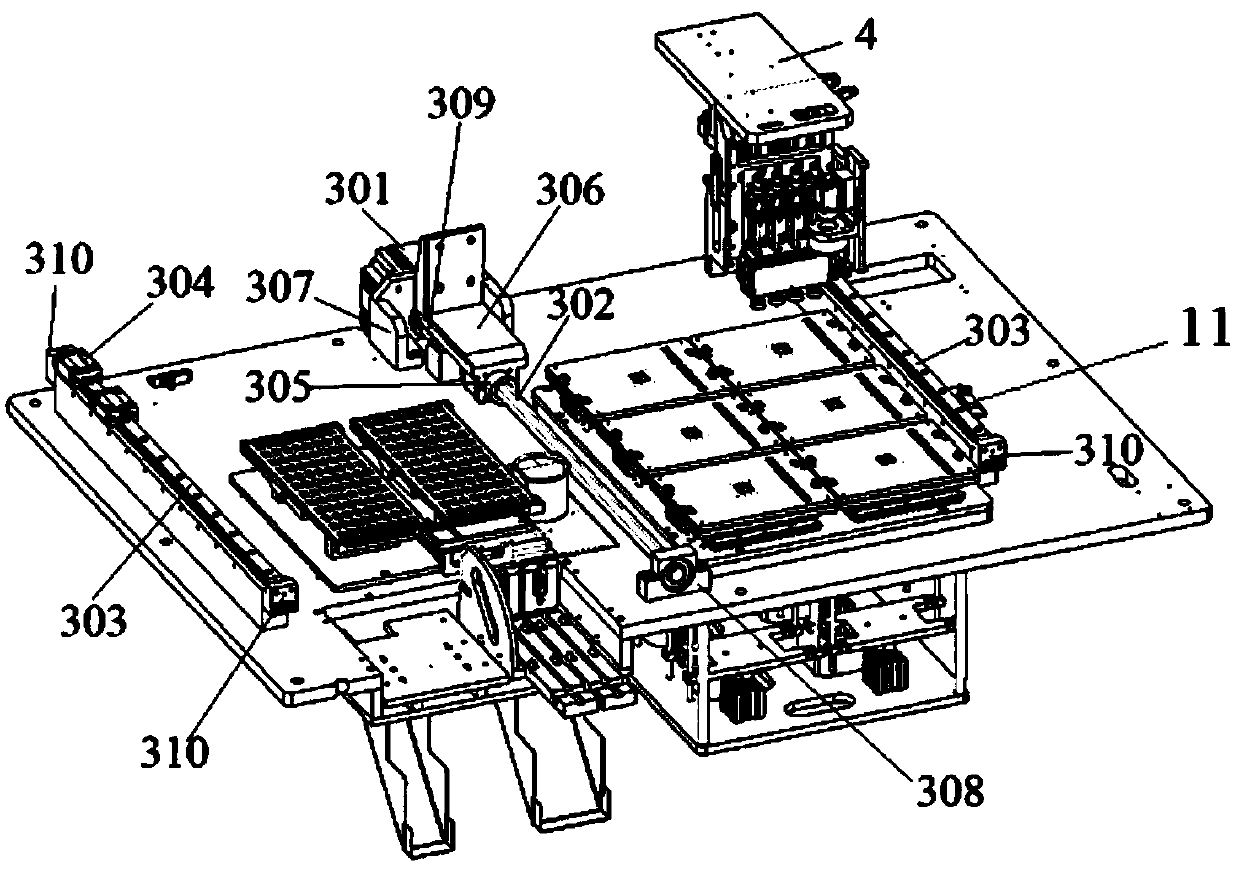

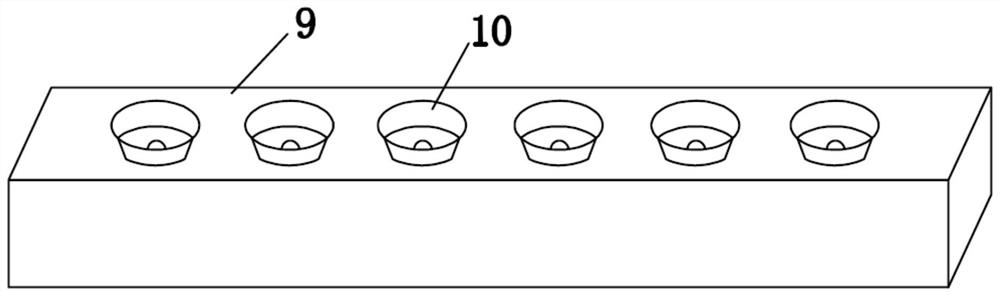

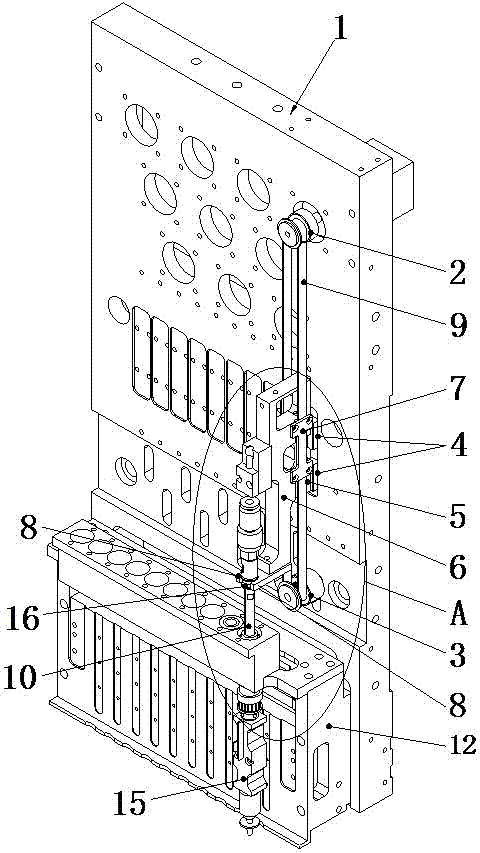

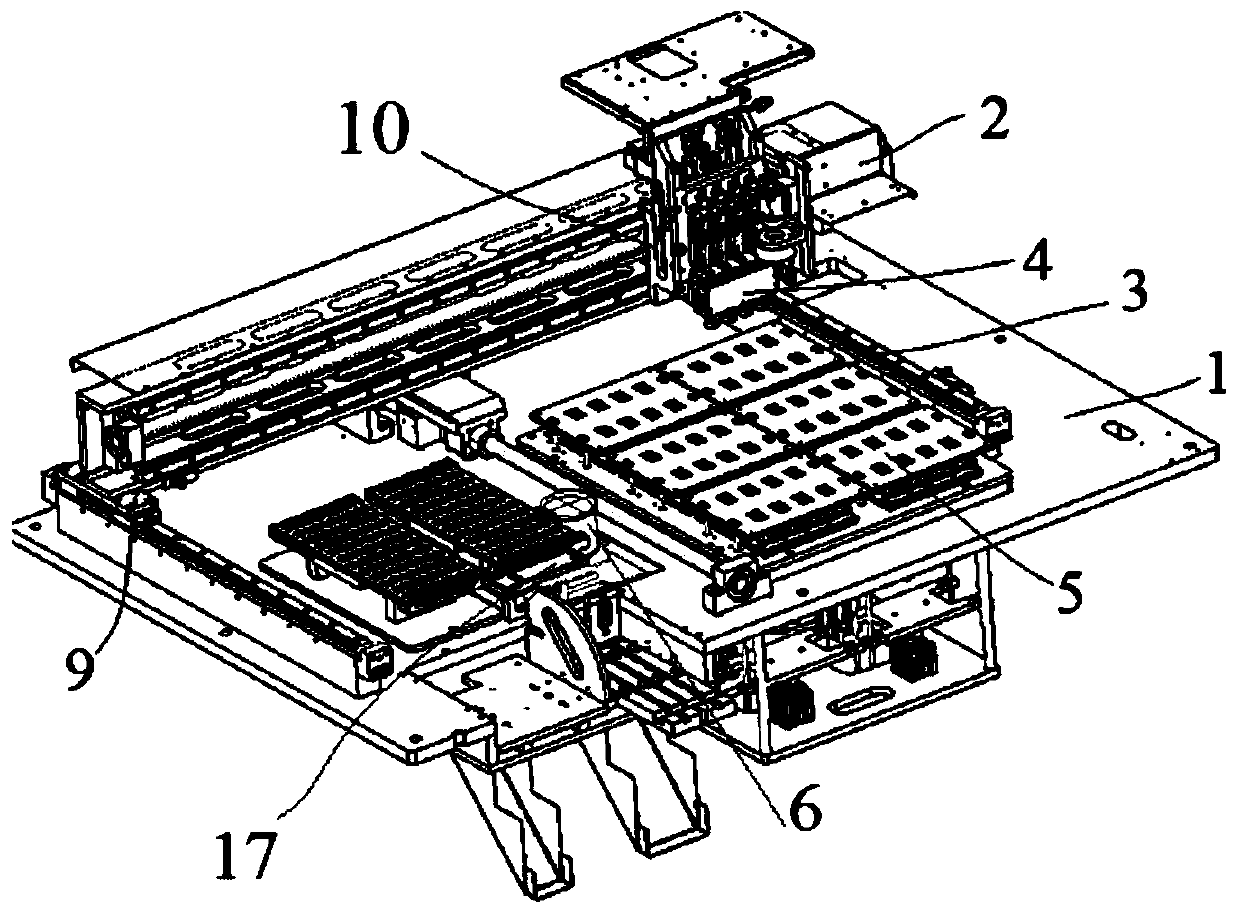

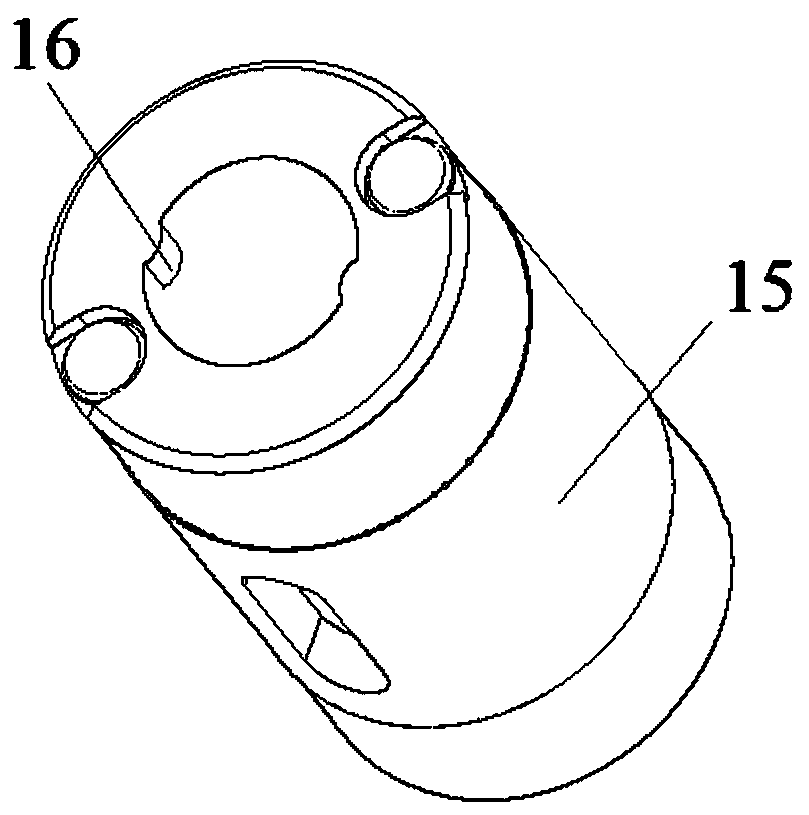

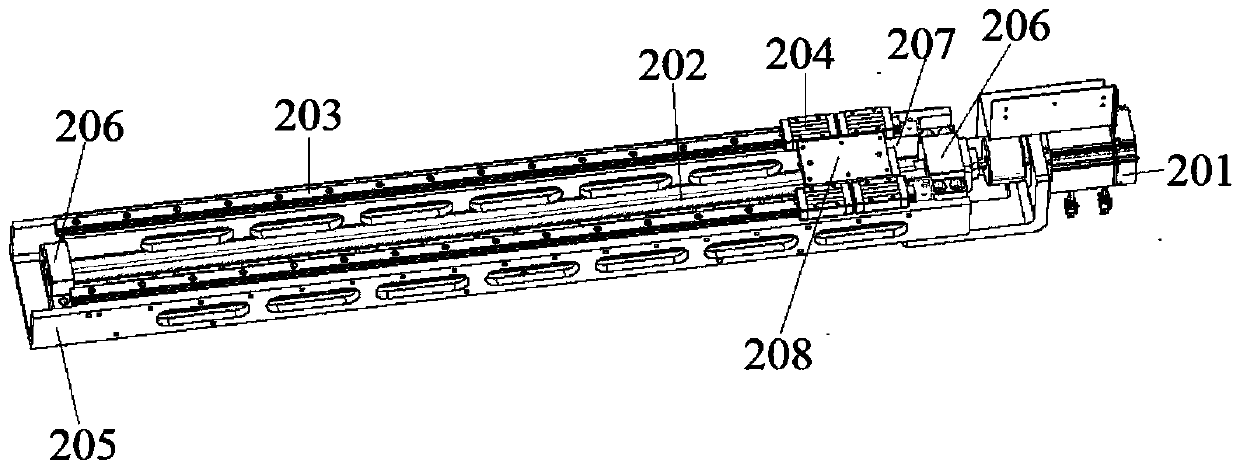

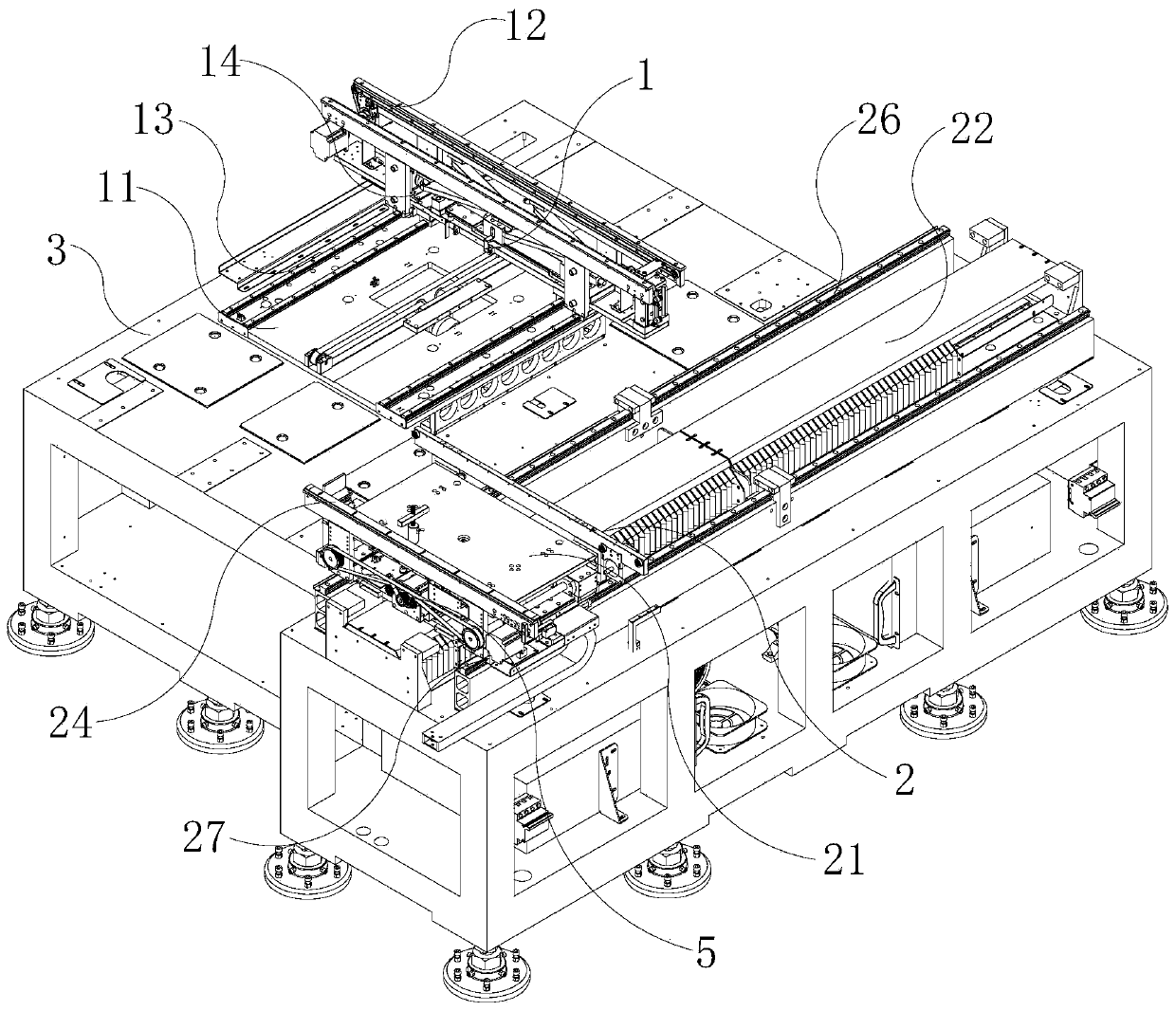

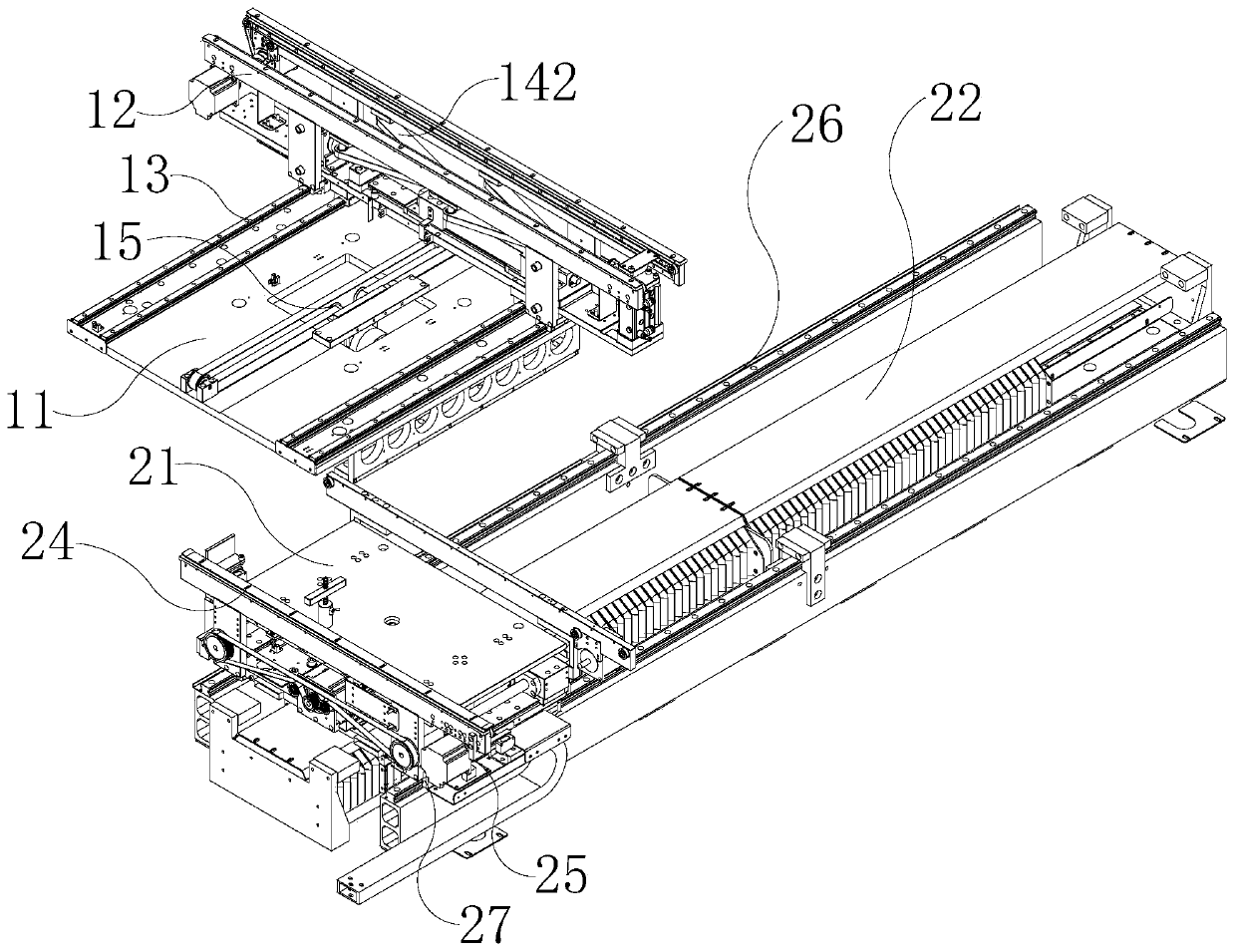

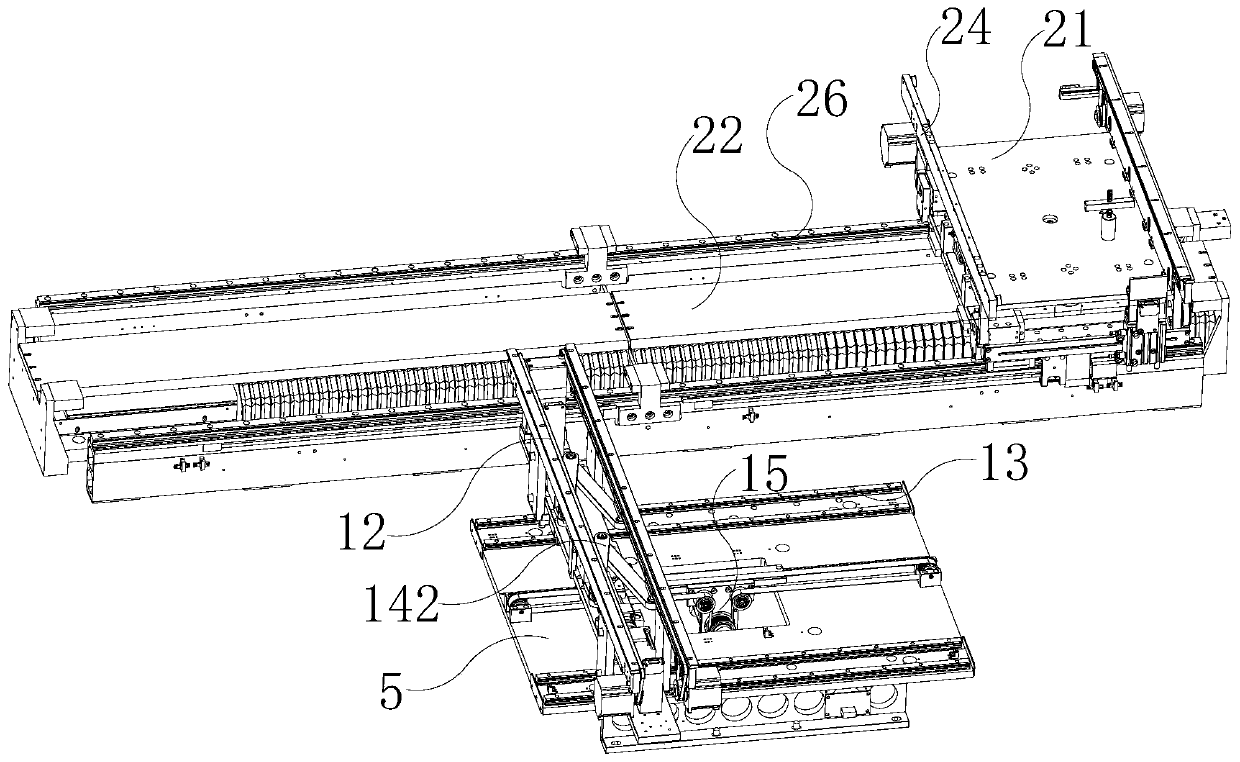

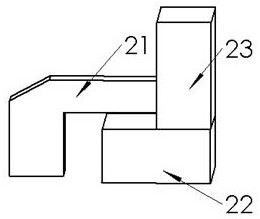

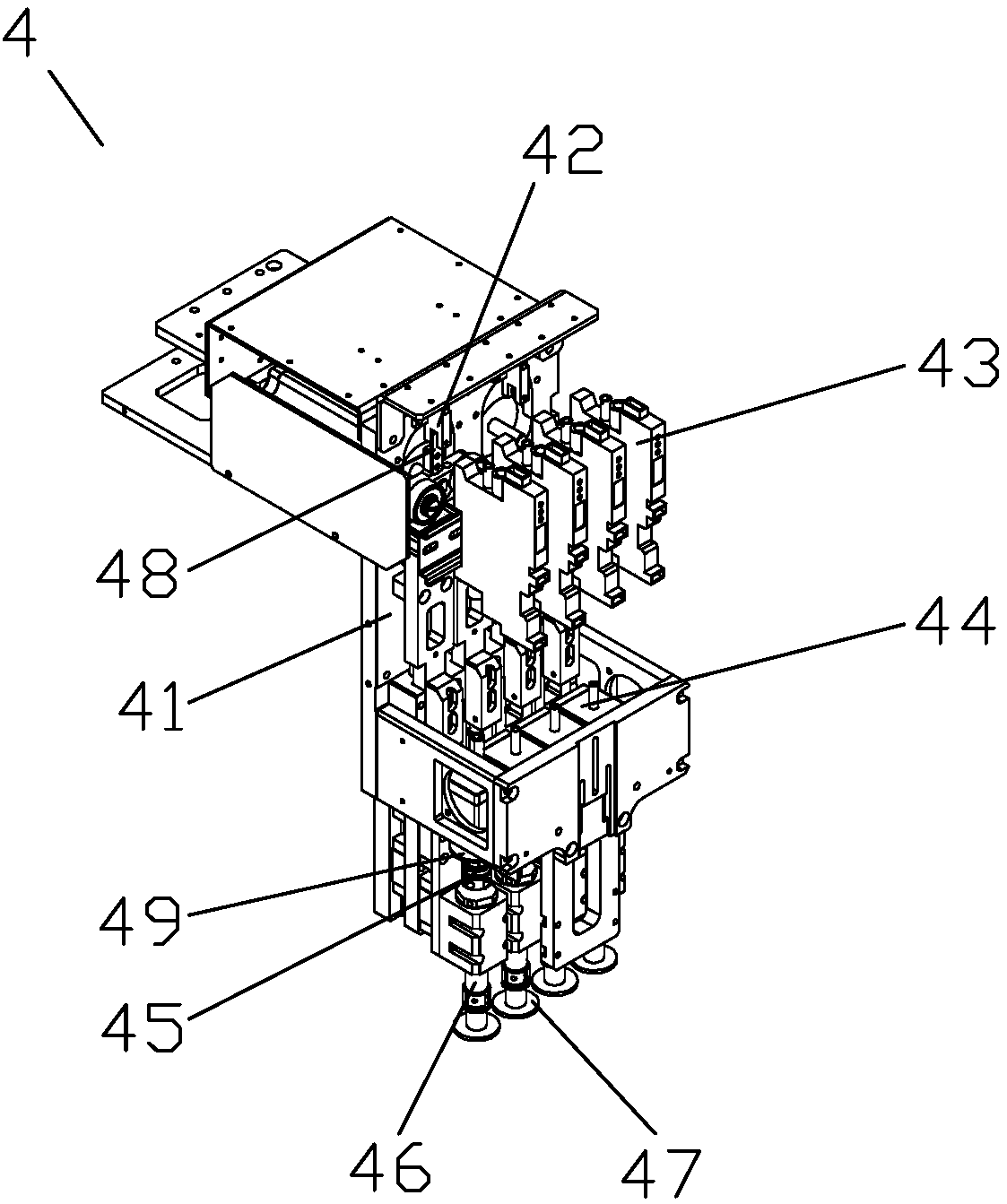

Special mounter for shielding cap

PendingCN108243580AFull match sizeSynchronous workabilityPrinted circuit assemblingCouplingEngineering

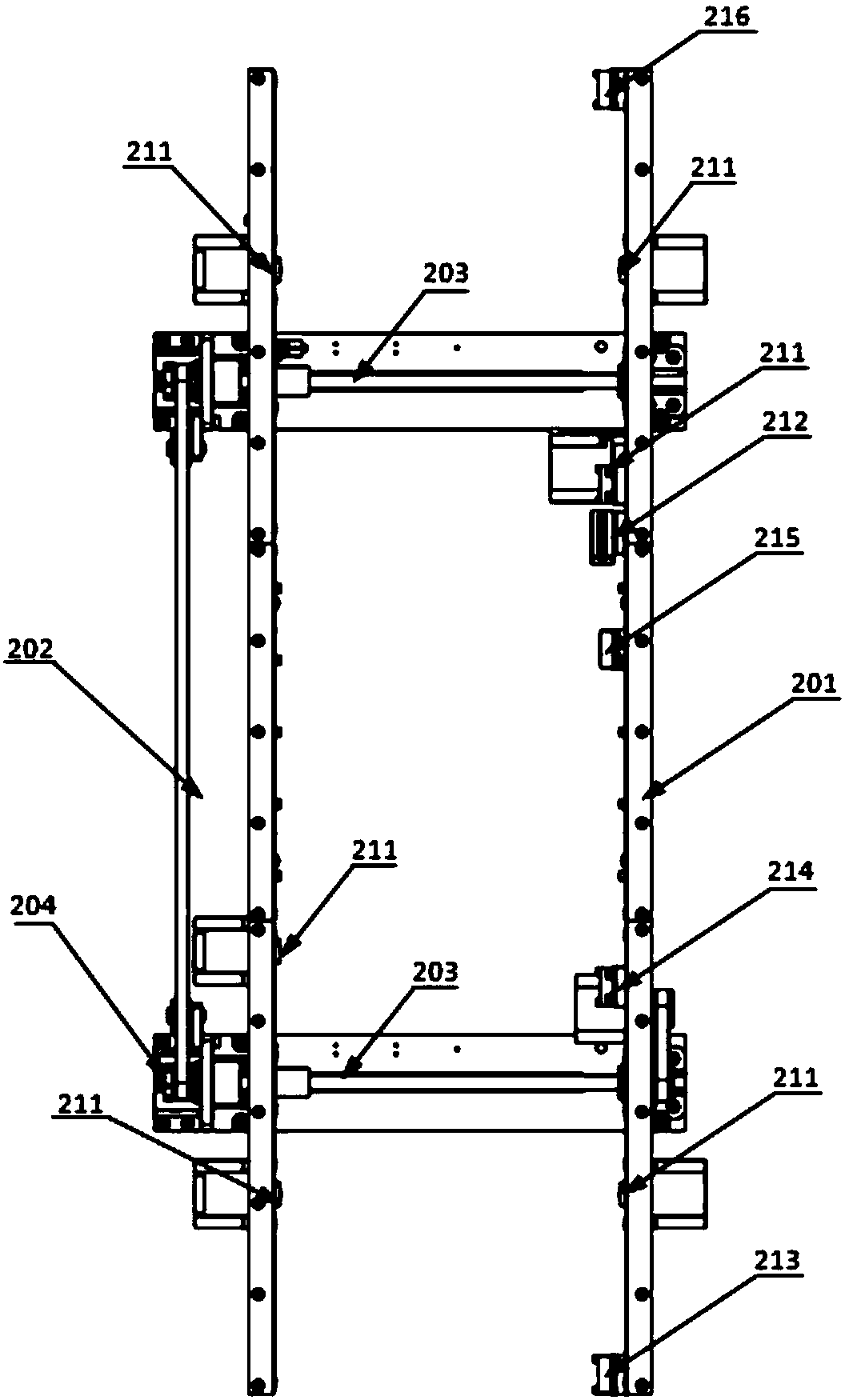

The invention discloses a special mounter for a shielding cap, which comprises a main frame, a board conveying device, a Y-axis arch frame assembly, an X-axis arch frame assembly, a mounting head assembly and a feeding platform, wherein the moving side edge of the board conveying device is provided with a width regulation motor; and the Y-axis arch frame assembly and the X-axis arch frame assemblyform an XY moving platform of the mounting head assembly. Through arranging the width regulation motor, a stop block, a board entering sensor, a mounting sensor, a board exiting sensor and the like,the size of the shielding cap can be matched, the width of the board conveying device is adjusted, and the board conveying working position is high in accuracy and safety; through arranging the special mounting head assembly, the size of the shielding cap can be matched thoroughly, nozzle synchronous working can be kept, and the mounting efficiency is effectively enhanced; through arranging a coupling to be connected with a motor shaft and a shaft, elastic movement in the moving process is avoided, and the mounting accuracy and the stability are ensured; and through arranging the special feeding platform, the feeding accuracy is ensured, and the feeding efficiency is improved.

Owner:广东木几智能装备有限公司

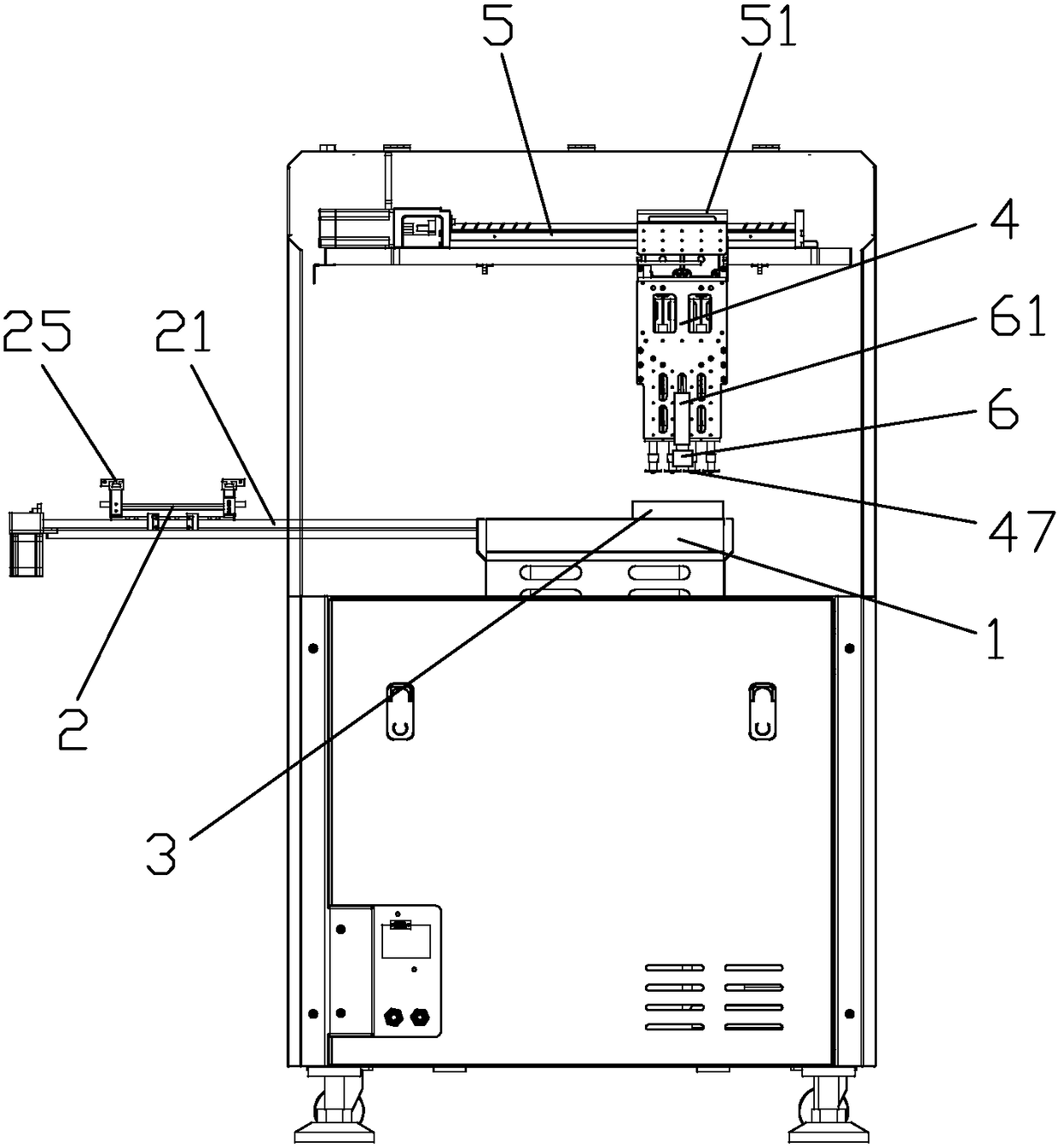

Vision-guided automatic mounting machine and using method thereof

PendingCN108882674AChange positionImprove placement accuracyElectrical componentsControl systemCcd camera

The invention discloses a vision-guided automatic mounting machine and a using method thereof. The vision-guided automatic mounting machine comprises a displacement mechanism, a feeding mechanism, a fixture conveying mechanism, a mounting mechanism, a first CCD camera mechanism, a second CCD camera mechanism and a control system. The displacement mechanism can change the position of the mounting mechanism more quickly, so the mounting accuracy is improved. The feeding mechanism can continuously scrape materials on a material belt, so the material fetching efficiency is improved. The fixture conveying mechanism can quickly convey mounted products to corresponding positions, so the processing efficiency is improved. The mounting mechanism can quickly obtain the materials and then carries outmounting operations, so the mounting efficiency is improved. The first CCD camera mechanism and the second CCD camera mechanism can take photos and record the positions of the materials and the mounted products, thereby ensuring the mounting accuracy. The control system can stably control the whole machine. The vision-guided automatic mounting machine can carry out mounting operations on a plurality of products, is improved in universality, and improves the mounting efficiency and accuracy at the same time.

Owner:昆山晨鼎嘉电子科技有限公司

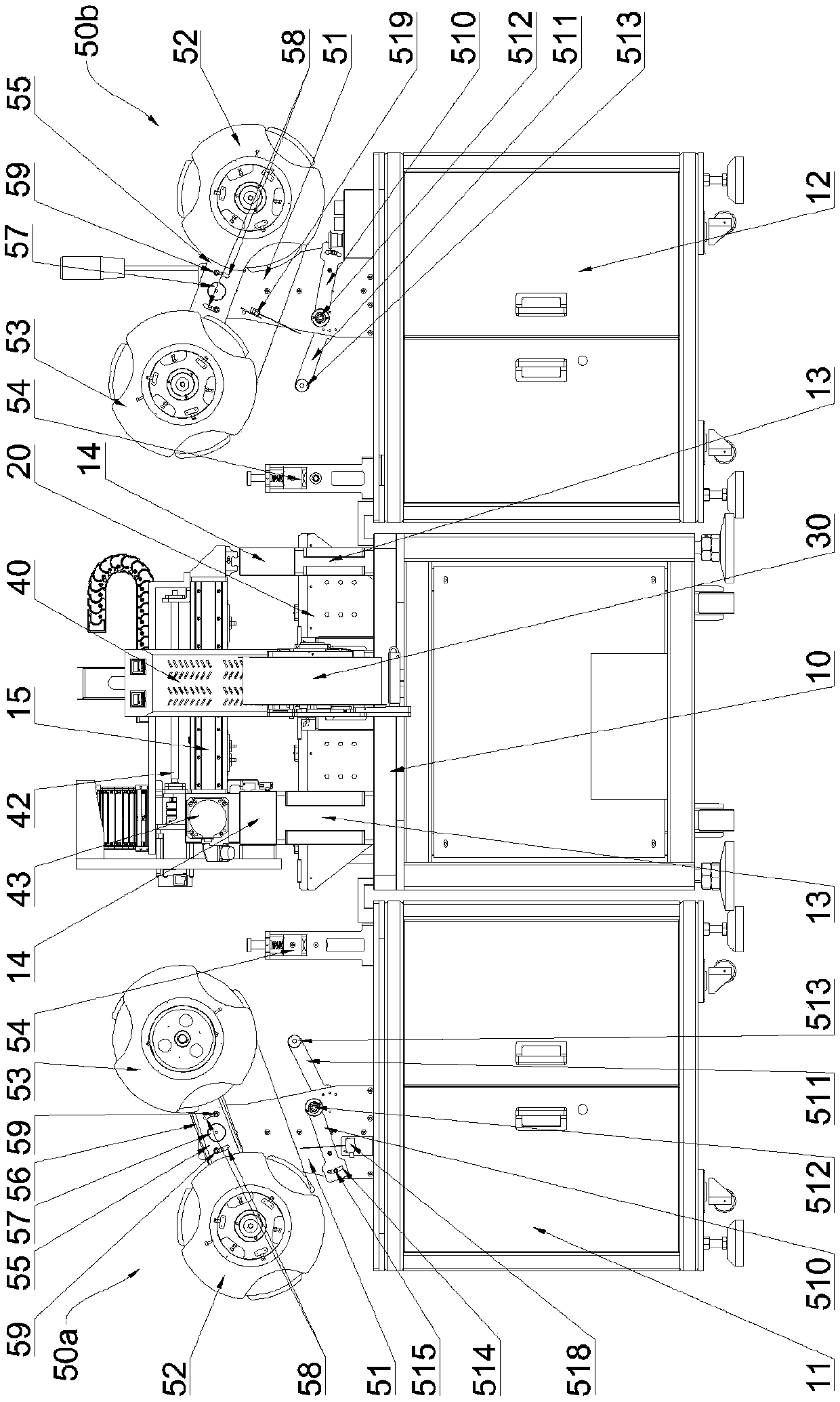

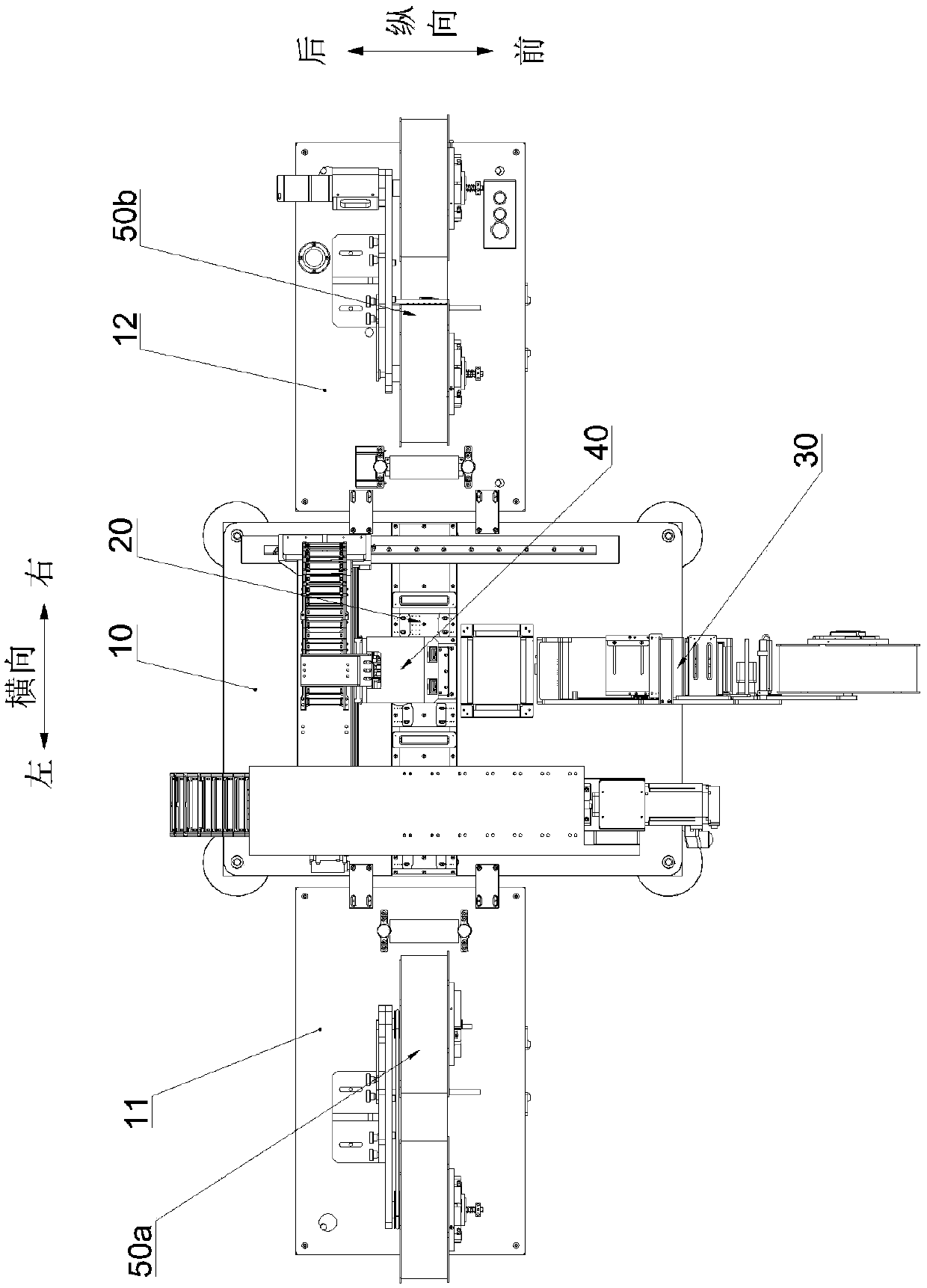

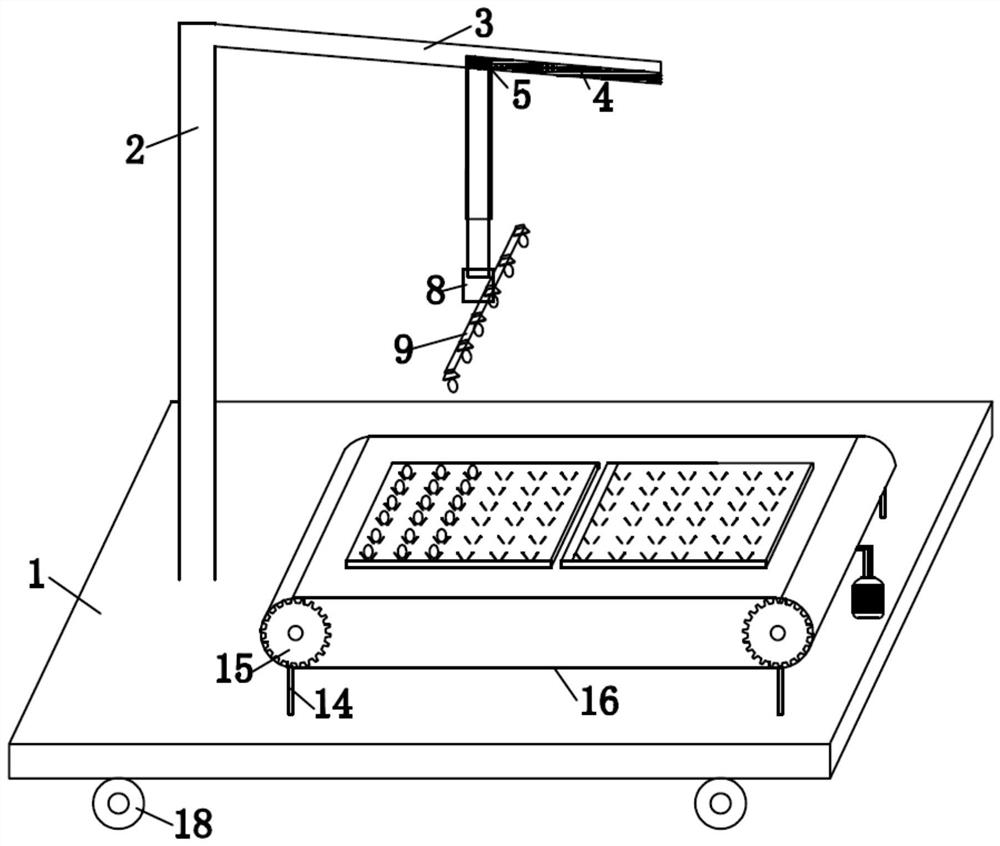

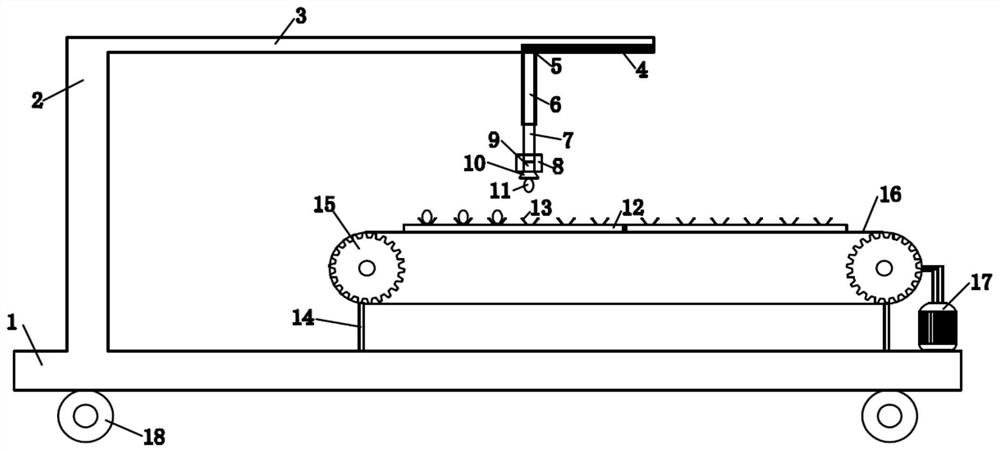

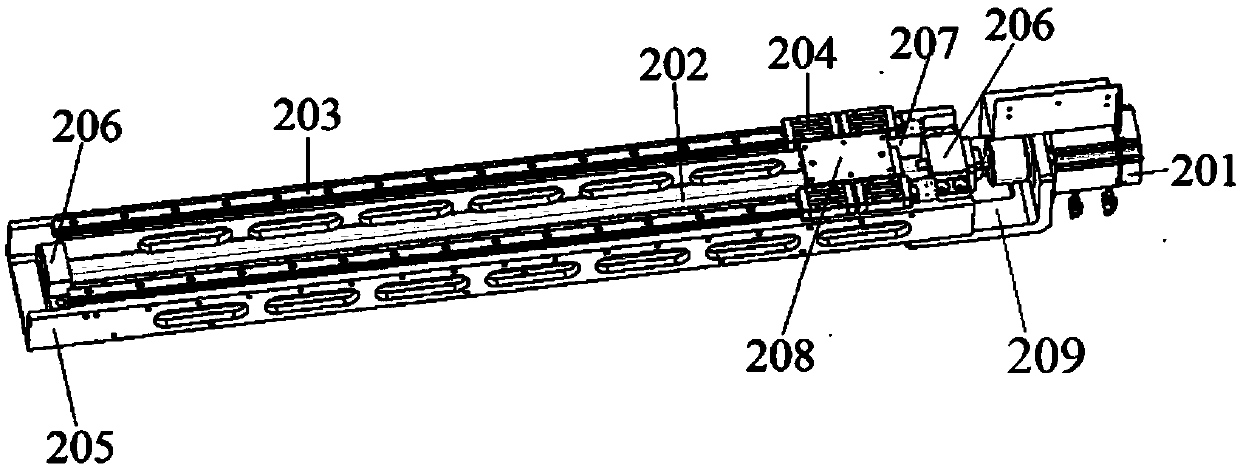

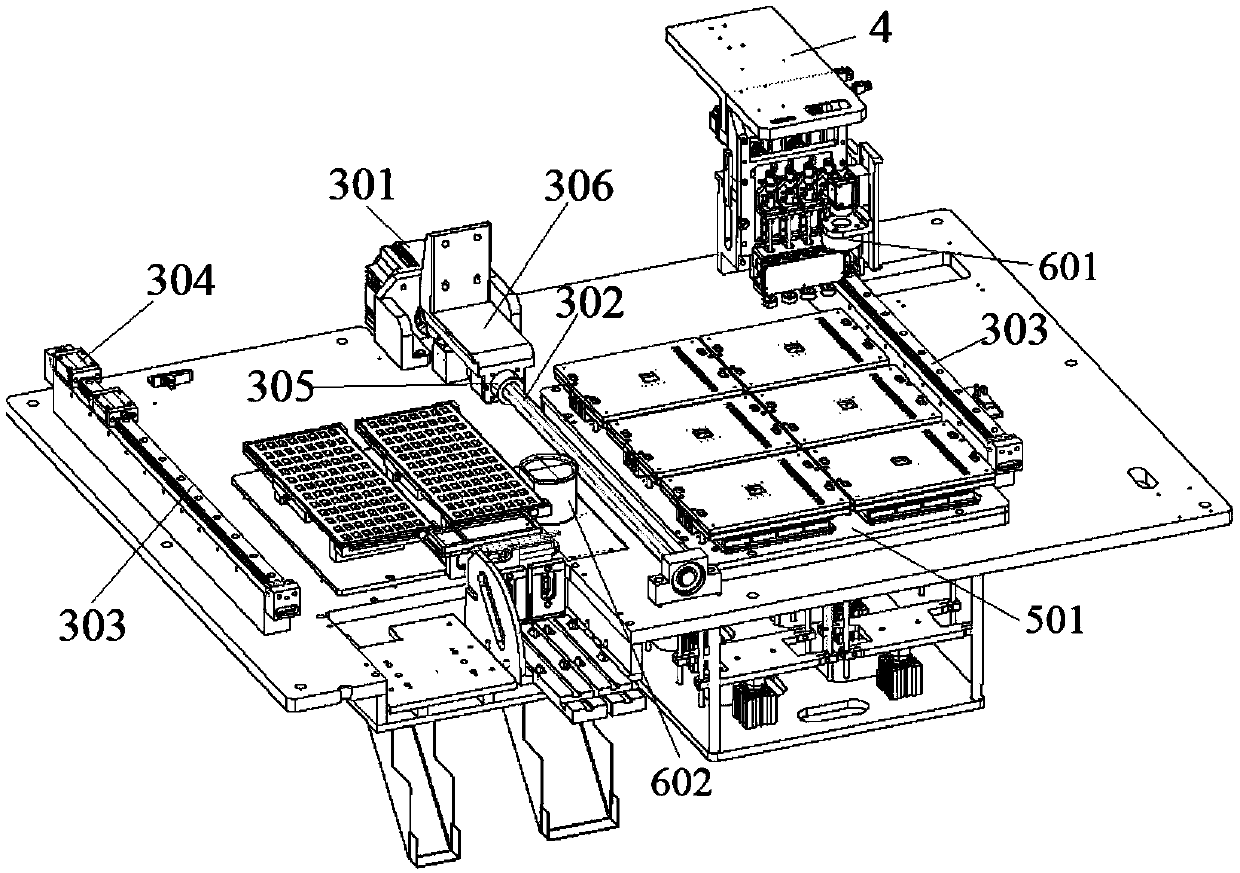

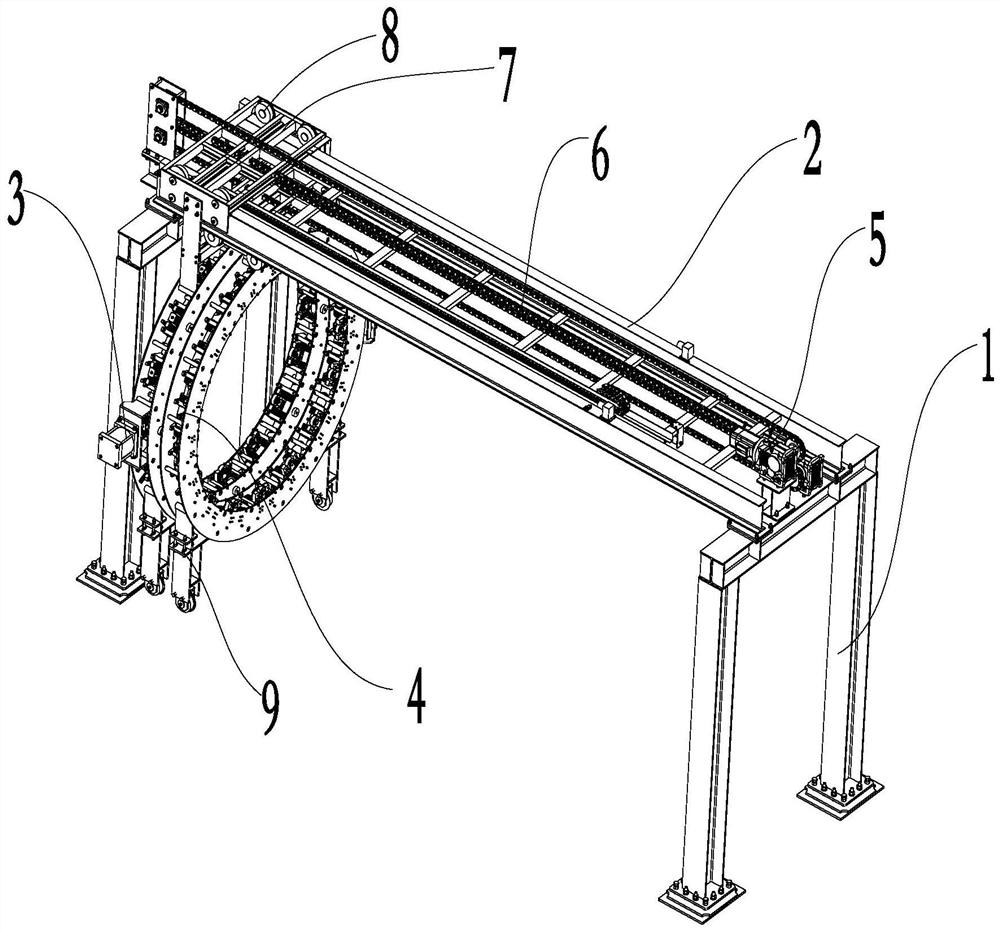

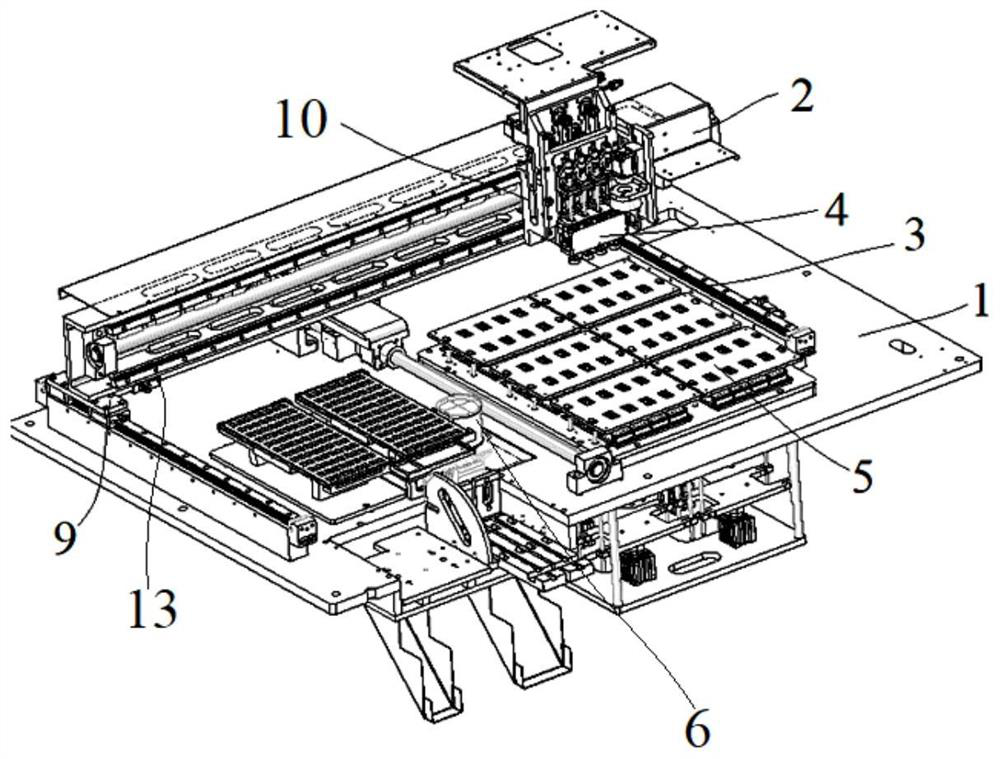

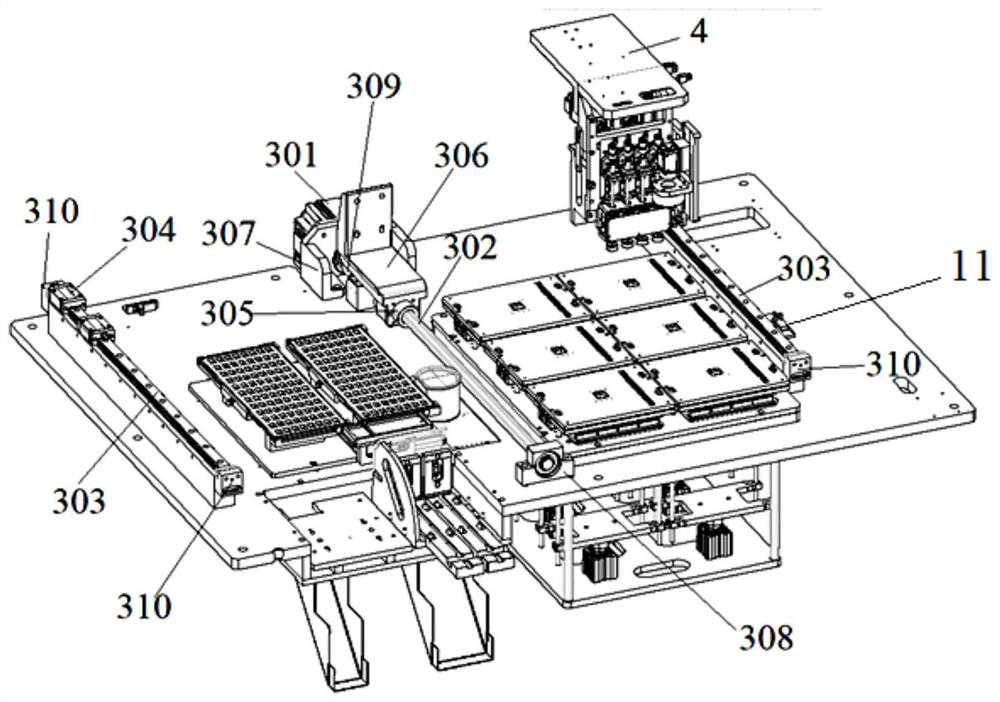

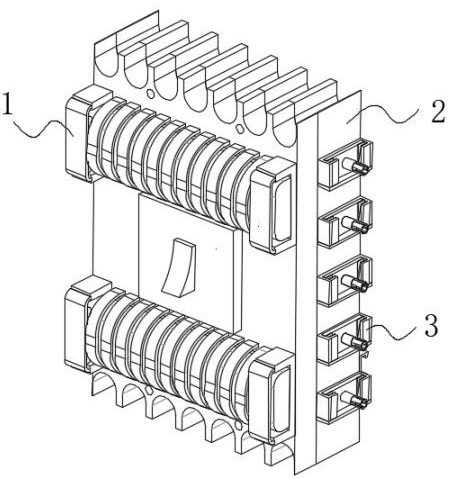

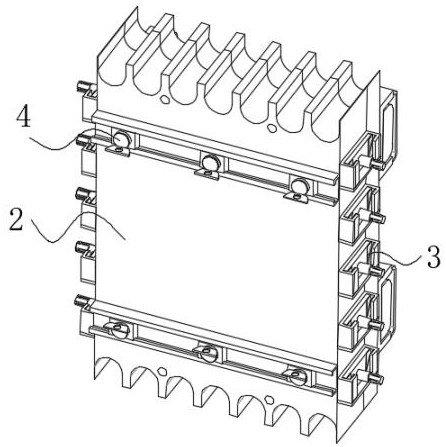

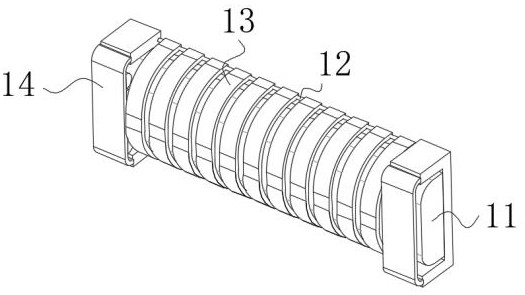

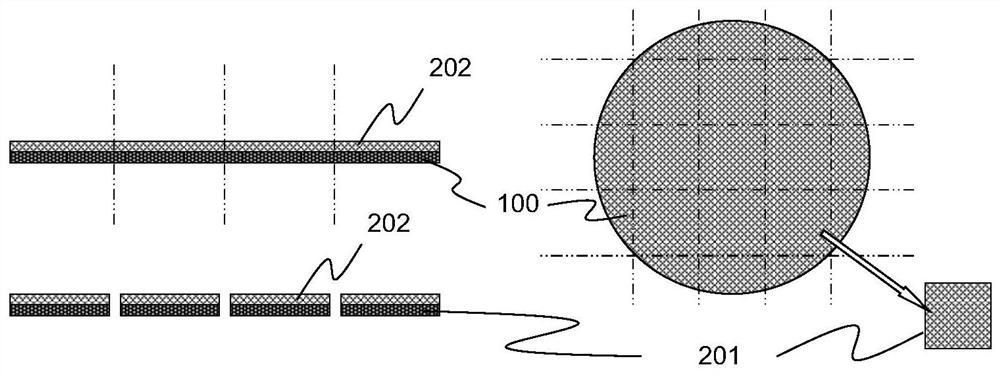

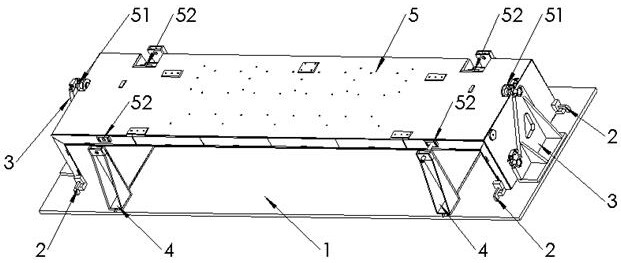

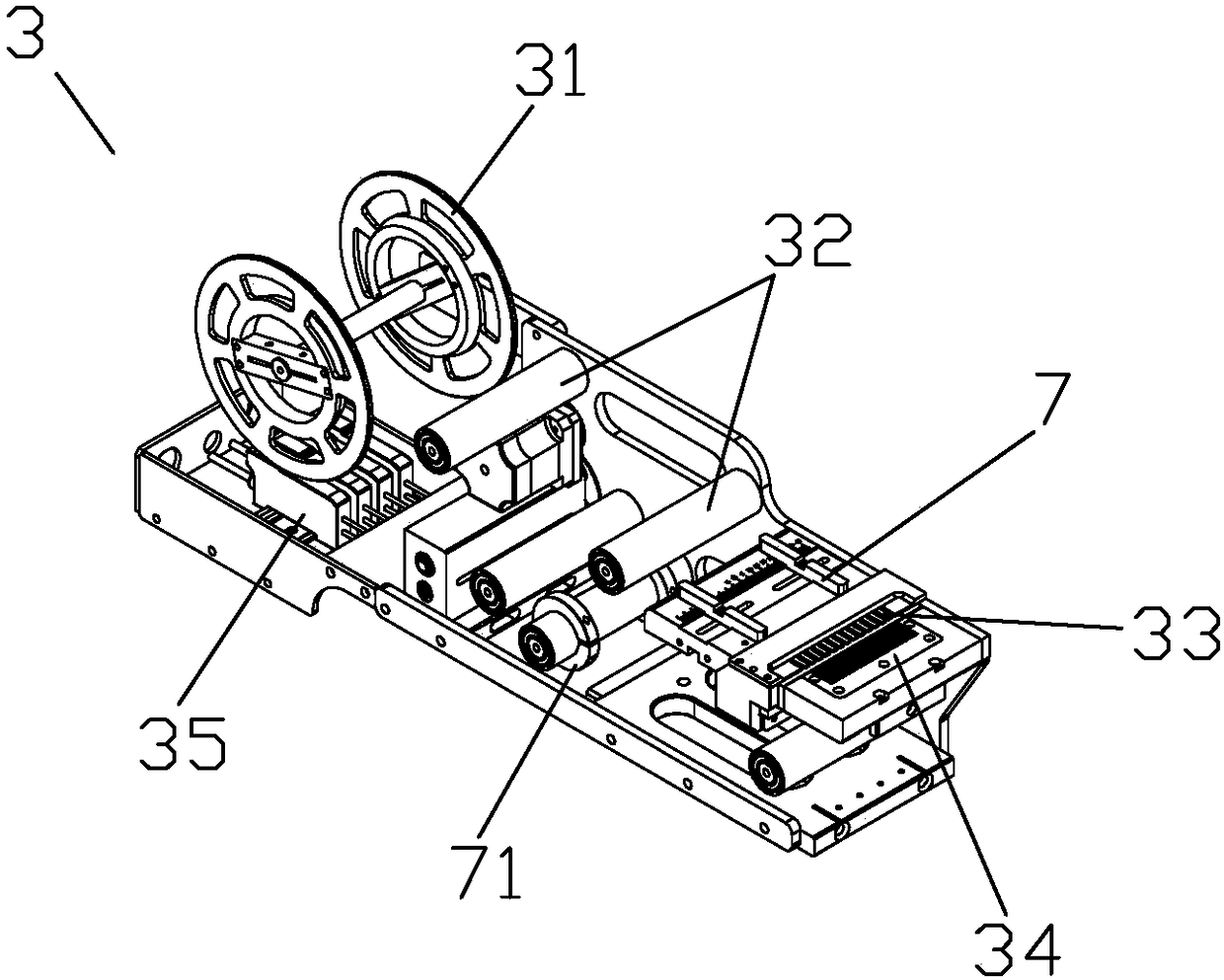

Full-automatic mounting system of tape-type flaky electronic components

PendingCN109625388ARealize automatic feedingEffective automatic positioningPackagingEngineeringElectronic component

The invention provides a full-automatic mounting system of tape-type flaky electronic components. The system can solve the problems that the manual mounting mode is low in efficiency and unstable in quality. The system comprises a tape-type component collecting and placing device, a component positioning device, an auxiliary material feeding device and an auxiliary material sucking and mounting device, wherein the component positioning device, the auxiliary material feeding device and the auxiliary material sucking and mounting device are all installed on a frame platform, the component positioning device is horizontally installed on the machine frame platform in a horizontal mode, the transverse two ends of the component positioning device are a feeding end and a discharging end of the tape-type components, the tape-type component collecting and placing device comprises a discharging mechanism and a collecting mechanism which are installed on one side of the feeding end and one side of the discharging end of the component positioning device, the discharging mechanism, the component positioning device and the collecting mechanism are arranged on the same transversal straight line,the component positioning device is provided with a component mounting position, the auxiliary material feeding device is arranged on the longitudinal front side of the component mounting position ofthe component positioning device, and the auxiliary material sucking and mounting device is arranged above the component positioning device and the auxiliary material feeding device.

Owner:SUZHOU WISETECH AUTOMATION TECH CO LTD

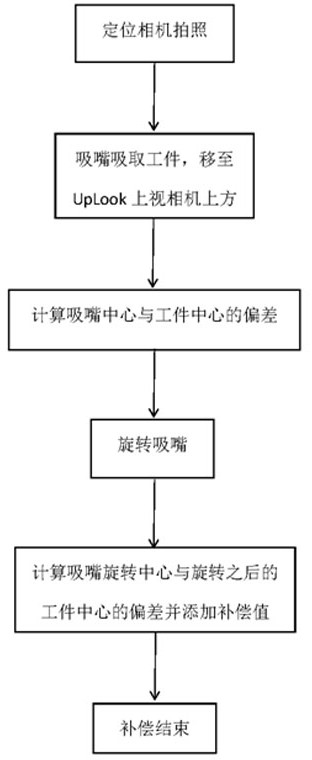

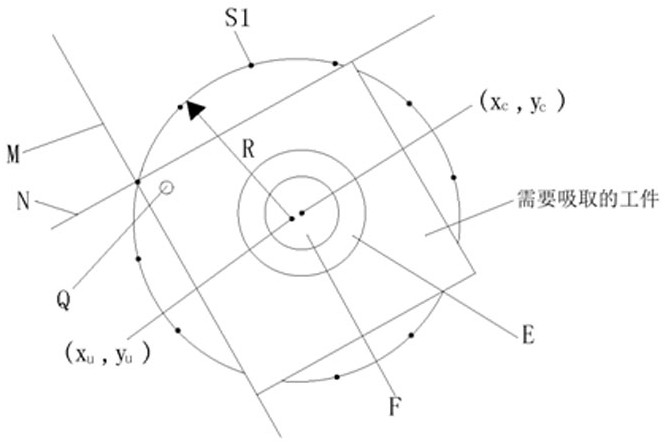

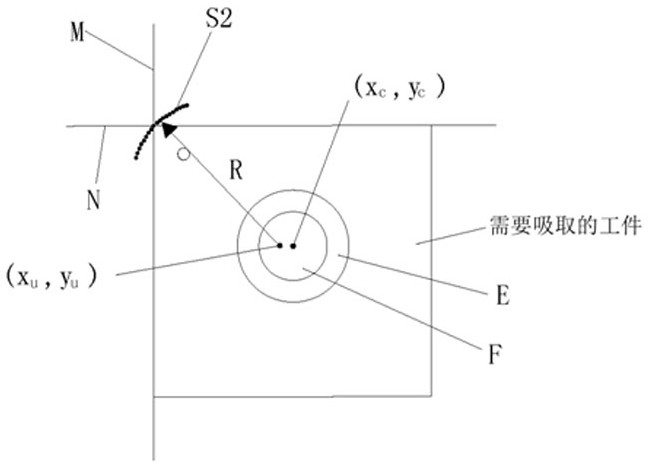

Chip mounter suction nozzle coaxiality error automatic calibration method based on machine vision

ActiveCN113382555AGuaranteed placement accuracyPrinted circuit assemblingElectrical componentsMachine visionEngineering

The invention discloses a chip mounter suction nozzle coaxiality error automatic calibration method based on machine vision. The method comprises the steps of obtaining the Mark information of a product through a CCD positioning camera, and enabling a suction nozzle to be positioned at the position of the product, sucking a product, then moving the product to the position above an UpLook up-looking camera to shoot once every other angle, acquiring image information, conducting fitting on the obtained position information of each Mark of the material according to the image information, and calculating the rotation center of a mechanical shaft, calculating the distances from the Mark points to the rotation center of the product in the rotation process, solving the average value of all the distances, subtracting the calculated average value from the distances from all the Mark points to the rotation center to obtain a value, namely the concentricity deviation caused by rotation of the suction nozzle in the mounting process, and compensating and correcting the concentricity deviation. According to the chip mounter suction nozzle coaxiality error automatic calibration method, it is guaranteed that the concentricity of each time of machining is within an allowable range, and the mounting precision is guaranteed.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

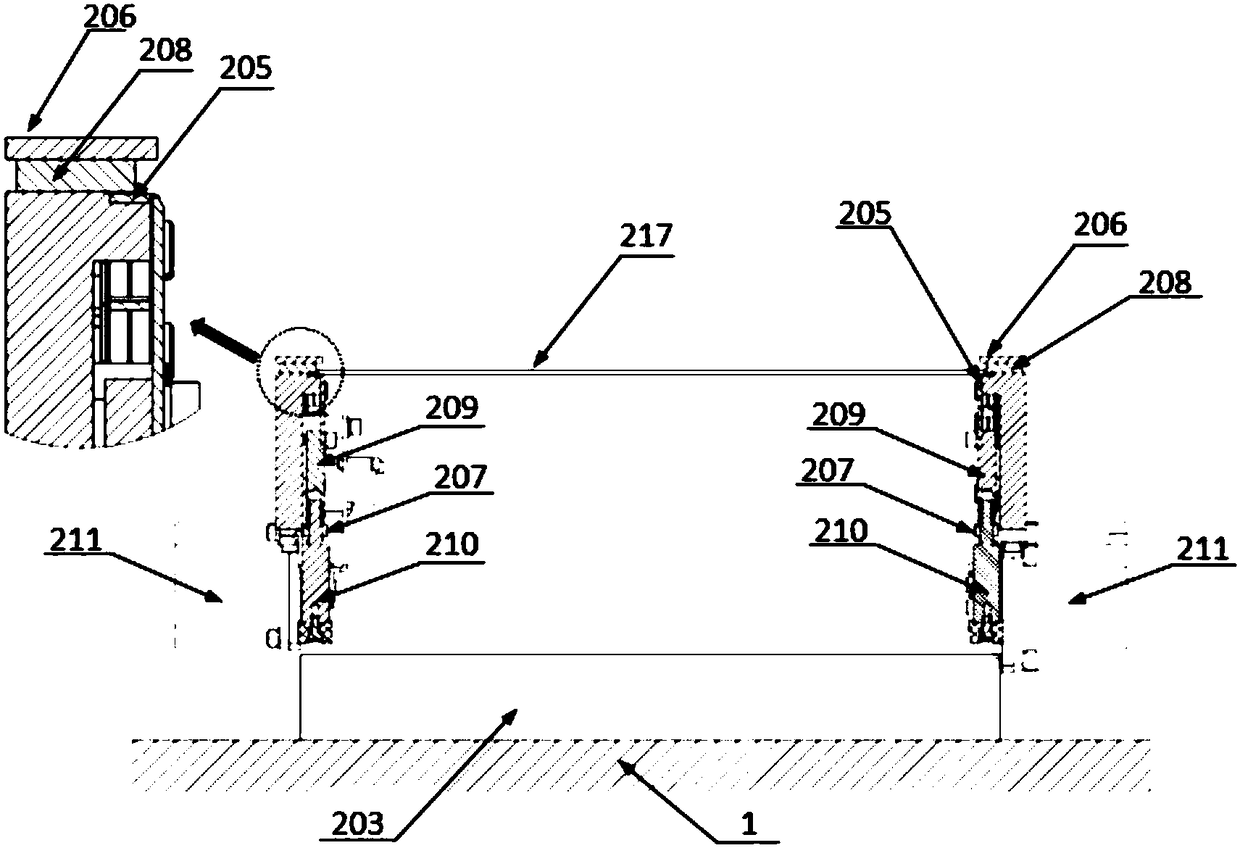

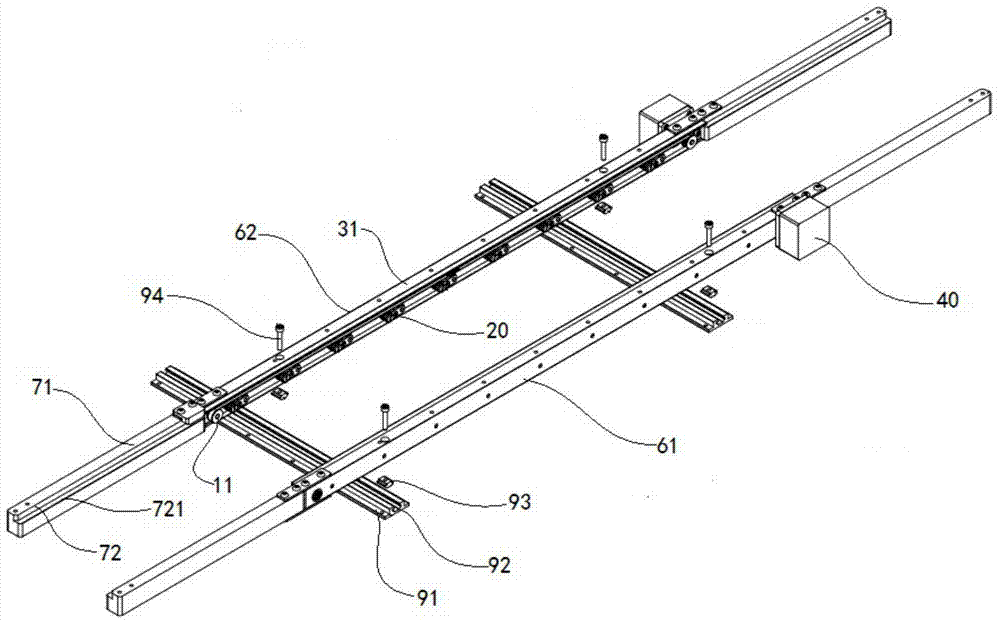

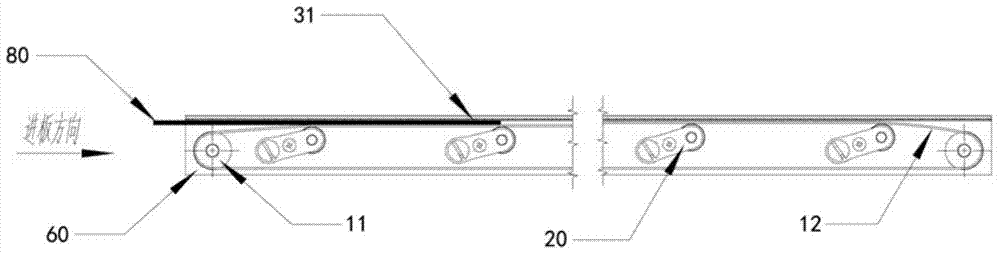

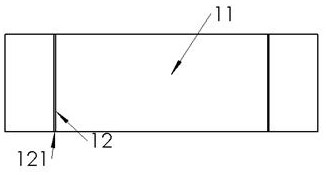

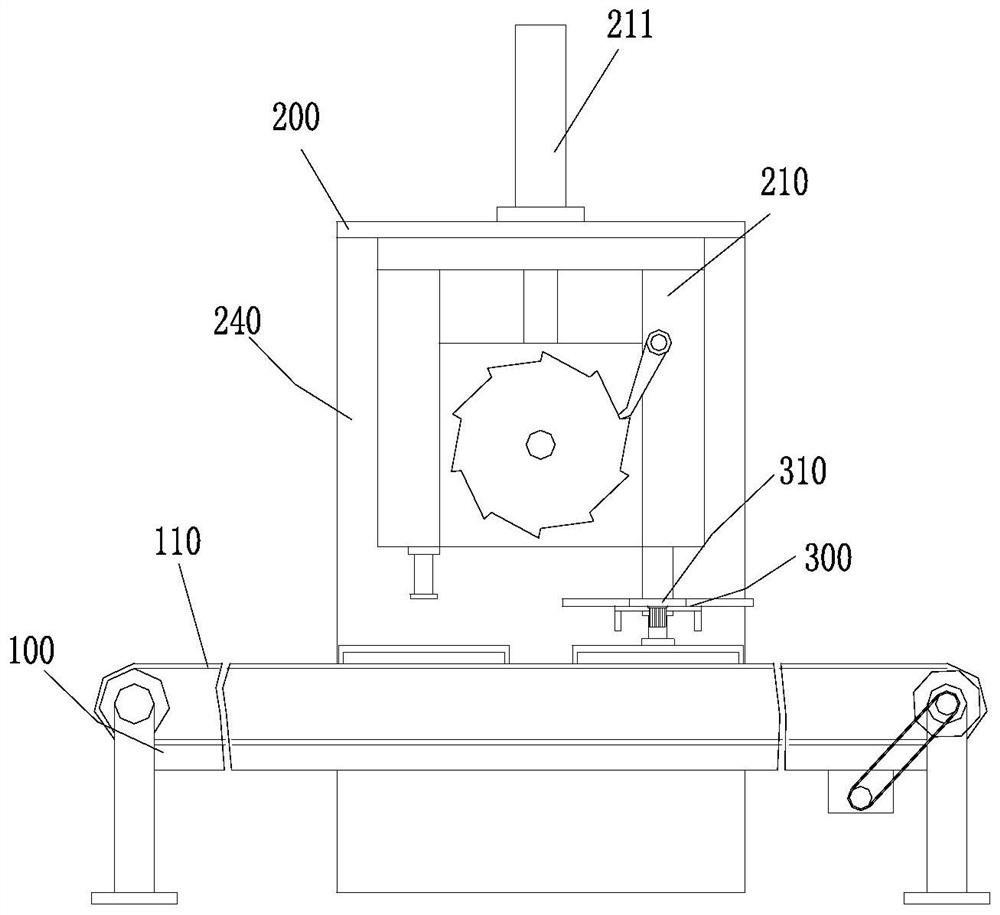

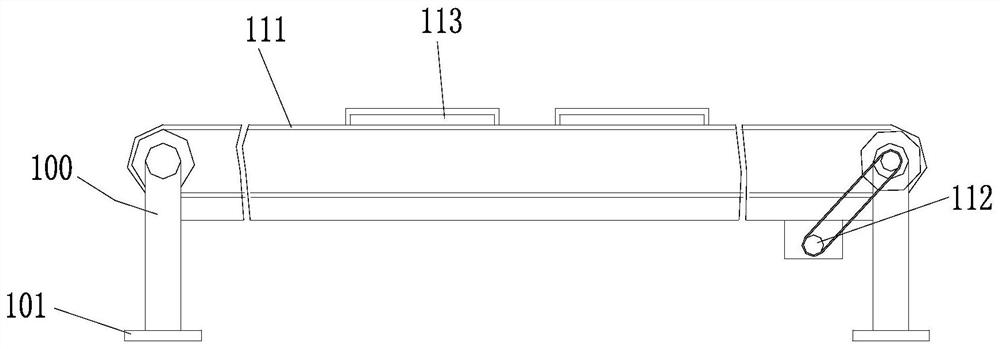

PCB transmission device

InactiveCN104843514AHigh strengthAvoid deformationRegistering devicesArticle feedersEngineeringElectrical and Electronics engineering

The invention relates to a PCB transmission device, in particular to a PCB transmission device which is used for a small SMT automatic assembly printing process. The device comprises a transmission mechanism, an elastic bearing mechanism, a restraining mechanism, a driving mechanism and a machine base, wherein the transmission mechanism bears a PCB to move; the elastic bearing mechanism is used for enhancing the bearing strength of the transmission mechanism; the restraining mechanism is arranged above the transmission mechanism, and the lower contact surface of the transmission mechanism is smoother than the upper contact surface of the transmission mechanism; the driving mechanism is used for driving the transmission mechanism; all the mechanisms are mounted on the machine base; when the transmission mechanism loads, the elastic bearing mechanism jacks the PCB between the lower contact surface of the transmission mechanism and the upper contact surface of the transmission mechanism. The PCB transmission device has the advantages that the structure design is reasonable, the longitudinal height is small, the service life is long, and the device can bear the mounting intensity of a mounting head and cannot deform.

Owner:NEODEN TECH CO LTD

Surface mounting equipment and surface mounting method

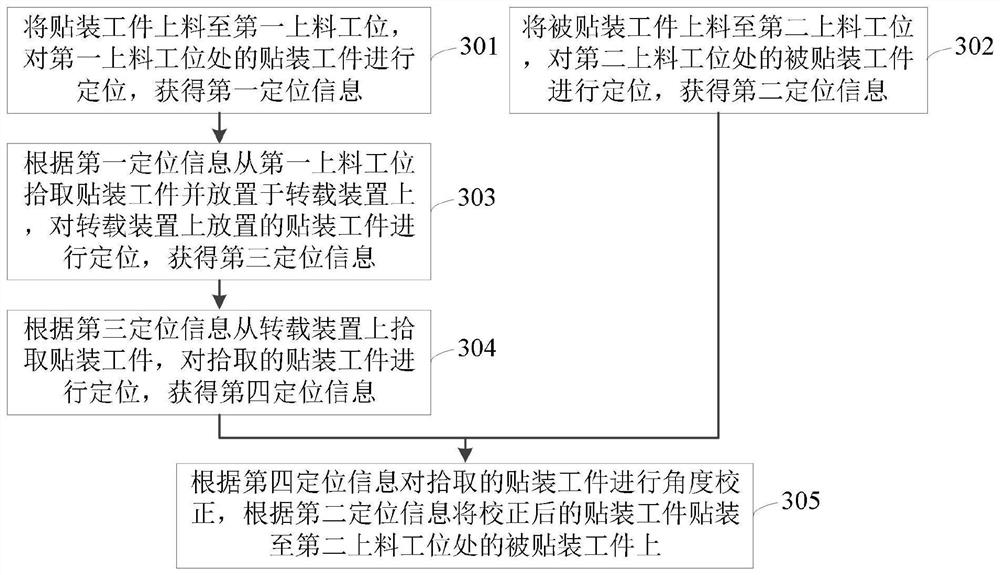

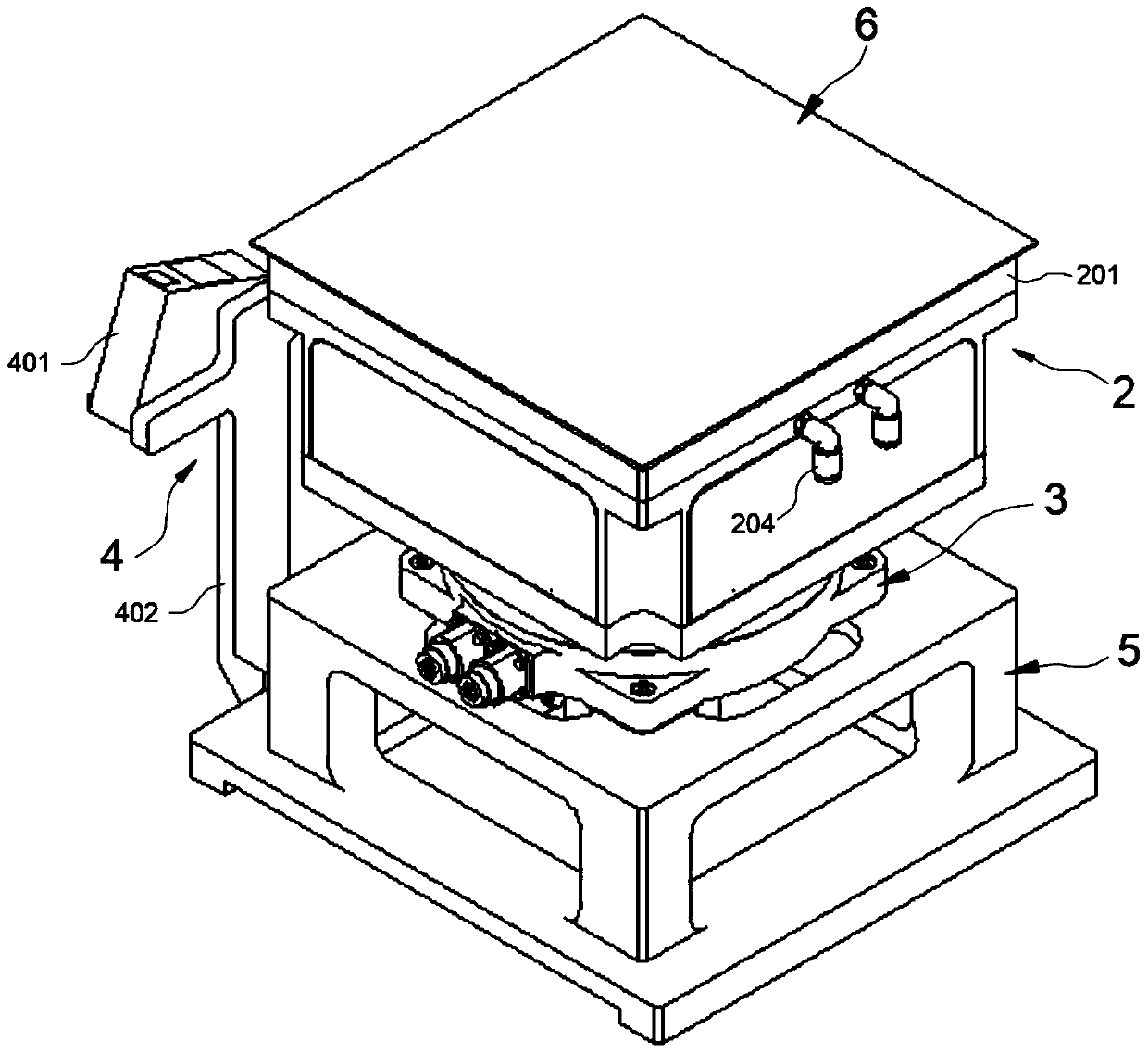

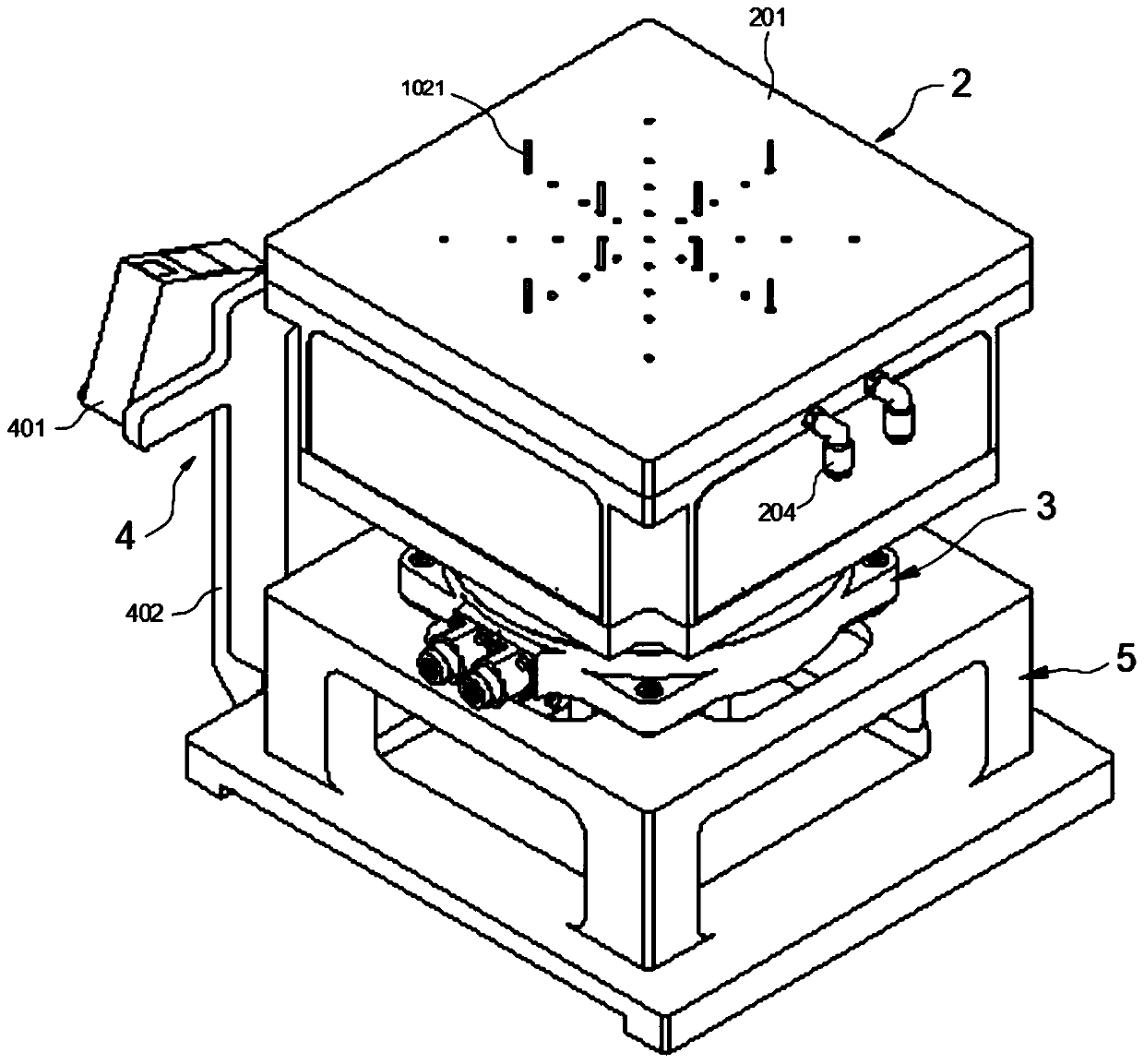

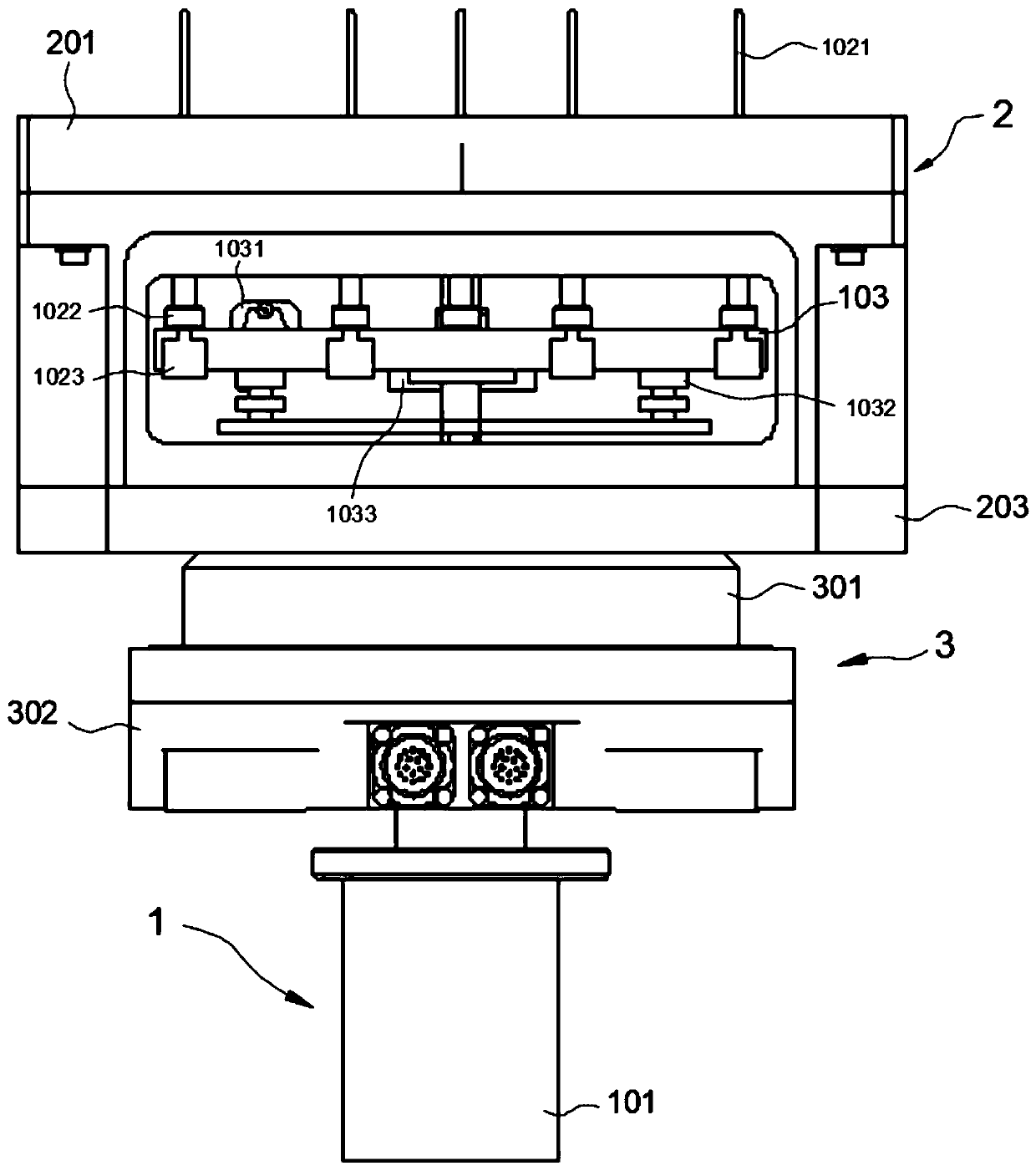

ActiveCN112261865AGuaranteed placement accuracyAchieve positioningFinal product manufactureElectrical componentsSurface mountingPhysics

The invention discloses surface mounting equipment and a surface mounting method. The surface mounting equipment comprises a first workpiece conveying device, a second workpiece conveying device and mounting equipment, wherein a mounting workpiece is positioned through a first positioning device so as to make a first mounting head pick up the mounting workpiece and place the mounting workpiece ona transfer device, the mounting workpiece on the transfer device is positioned through a third positioning device so as to make a second mounting head pick up the mounting workpiece from the transferdevice, the mounting workpiece picked up by the second mounting head is positioned through a fourth positioning device, and the mounted workpiece is positioned through the second positioning device soas to accurately attach the mounting workpiece picked up by the second mounting head to the positioned mounted workpiece, so that positioning of key position information such as mounting workpiece feeding, mounting workpiece transferring, mounted workpiece feeding and the like in the mounting process is achieved, and the mounting precision is guaranteed.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Transfer device for jet printing of film substrate, electronic printing system and electronic printing method

ActiveCN110572940AGuaranteed placement accuracyImprove finished product qualityConveyorsCircuit board tools positioningEnvironmental resistanceEngineering

The invention discloses a transfer device for jet printing of a film substrate, an electronic printing system and an electronic printing method, which belong to the technical field of printing. A lifting assembly, an adsorption assembly and a rotating assembly are correspondingly arranged on the base. The transfer device comprises a lifting motor, a support plate, a thimble mechanism, a rotating motor and the like, and by using mutual matching work of the components, stable feeding, adsorption and angle adjustment of the film substrate on the top surface of the adsorption plate can be accurately realized, and the placement accuracy of the film substrate in the electronic printing process is ensured. The transfer device for jet printing of the film substrate has the advantages that the structure is simple, the control is simple and convenient, the accuracy and the automatic degree are high, the positioning accuracy of the film substrate before printing can be greatly enhanced, the rejection rate in the preparation process of the printed circuit board is reduced, the cost is saved and the device is economical and environment-friendly. Besides, according to the electronic printing system arranged based on the transfer device, the printing method has simple steps, the control is simple and convenient, the substrate electronic printing efficiency can be further enhanced, and the substrate preparation cost is reduced.

Owner:武汉国创科光电装备有限公司

Chip recording machine capable of automatically feeding and blanking

ActiveCN110718490AHigh precisionGuaranteed accuracySoftware engineeringConveyor partsStructural engineeringMechanical engineering

The invention discloses a chip recording machine capable of automatically feeding and blanking. The device comprises a substrate, an X-axis driving mechanism, a Y-axis driving mechanism, a material suction mechanism and a recording mechanism. The Y-axis driving mechanism is arranged on an upper surface of the substrate. The X-axis driving mechanism is installed and connected with the Y-axis driving mechanism through a plurality of XY connecting blocks and can reciprocate in a Y-axis direction. A limiting support is also arranged. The limiting support is fixedly installed at a lower portion ofa front side surface of an installation plate. Several suction rods penetrate through the limiting support. The suction rods are connected with an upper plate of the limiting support through a drivingspline, the suction rods are connected with an installation portion of a corner installation plate through a driven spline, and the driving spline and the driven spline comprise cylindrical shells and at least two rows of balls vertically arranged on inner walls of the cylindrical shells. In the invention, automatic operation of a whole process of chip feeding, recording and blanking in a chip recording process is realized, precision is high, cyclic operation can be realized, and the precision, efficiency and an automation degree of chip recording are improved.

Owner:苏州永测电子有限公司

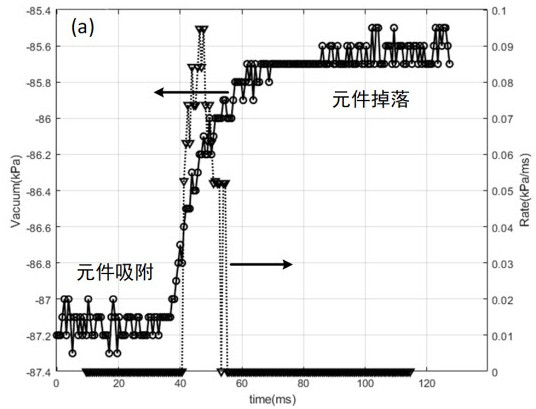

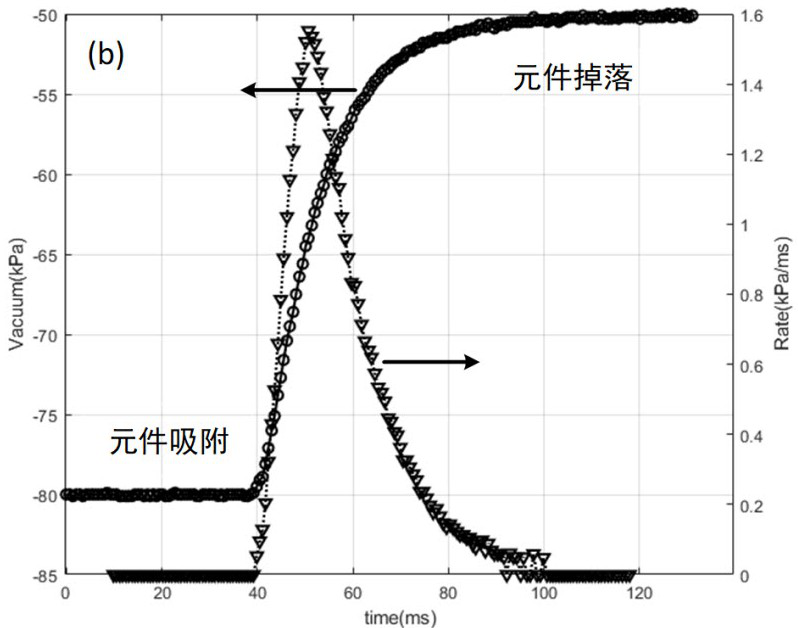

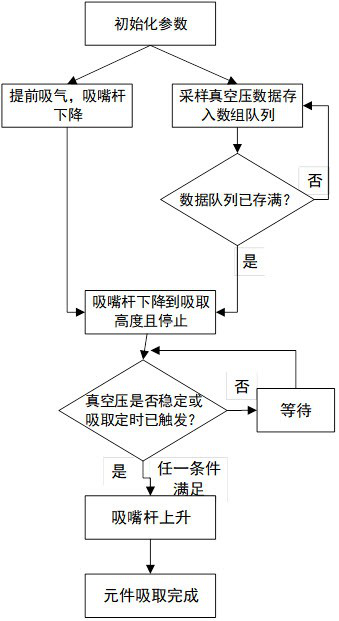

Real-time monitoring method and system for falling, sucking and mounting of elements in chip mounter

PendingCN114599169AImprove the success rate of absorptionGuaranteed placement accuracyPrinted circuit assemblingElectrical componentsComputer hardwareVacuum pressure

The invention relates to the technical field of chip mounter control, and particularly discloses a real-time monitoring method and system for falling, sucking and mounting of components in a chip mounter, and the real-time monitoring method comprises the following steps: initializing a vacuum sampling rate, and storing an array queue length and a threshold value of vacuum pressure; according to the vacuum sampling rate and the group queue length, vacuum pressure is collected in real time and stored in an array queue; monitoring whether the element falls or not in real time according to the vacuum pressure and the threshold value in the array queue; and / or, monitoring whether the element is sucked in real time according to the vacuum pressure and the threshold value in the array queue; and / or, monitoring whether the element is mounted in real time according to the vacuum pressure and the threshold value in the array queue. According to the scheme, element falling, element sucking and element mounting states can be efficiently and accurately monitored, and then the element mounting quality is influenced.

Owner:合肥安迅精密技术有限公司

Automatic egg loading machine for poultry egg production and processing

InactiveCN112790123AImprove packaging efficiencyGuaranteed placement accuracyBird housingsElectric machineryEgg load

The invention discloses an automatic egg loading machine for poultry egg production and processing. The automatic egg loading machine comprises a bottom plate and a vertical rod, wherein the vertical rod is installed on the bottom plate, the top end of the vertical rod is connected with a transverse rod, an egg conveying device is arranged at the end, away from the vertical rod, of the transverse rod and comprises a sliding groove in the bottom of the right end of the transverse rod, the sliding groove is slidably connected with a sliding block, the sliding block is electrically connected with the output end of a motor, the bottom of the sliding block is fixedly connected with a pushing assembly, the pushing assembly comprises an electric push rod groove and an electric push rod, and the upper end of the electric push rod groove is fixedly connected with the sliding block. An existing device is improved, picking of eggs and later packaging of the eggs are completed through negative pressure adsorption, the packaging efficiency is greatly improved, the grabbing precision and the later placement precision are guaranteed when the eggs are picked, and therefore the packaging quality is improved.

Owner:XIAN XINGUIXI INFORMATION TECH CO LTD

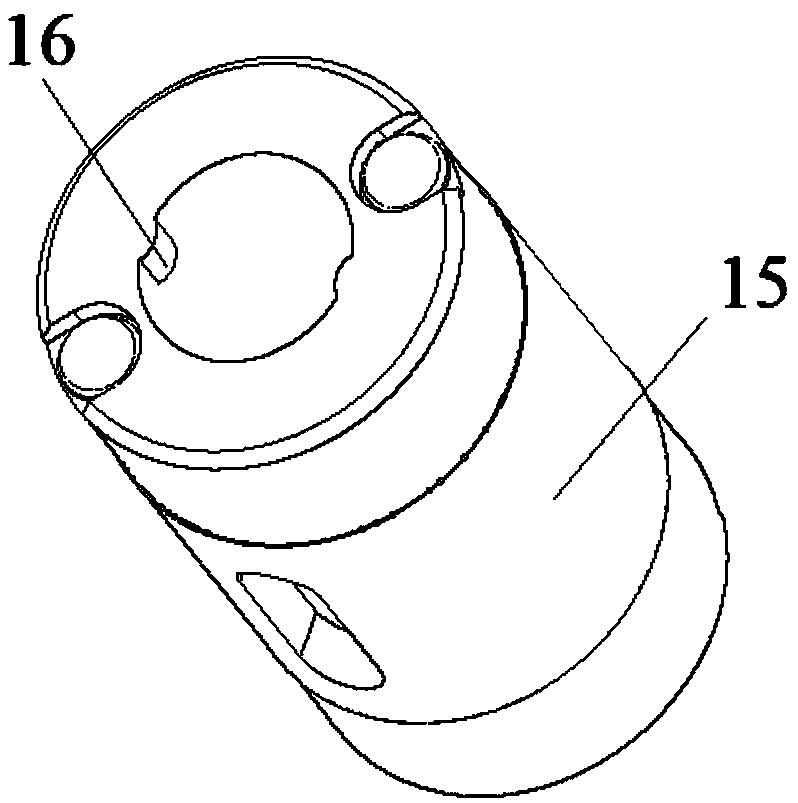

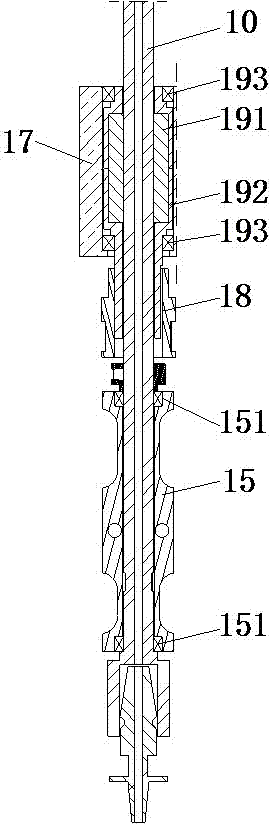

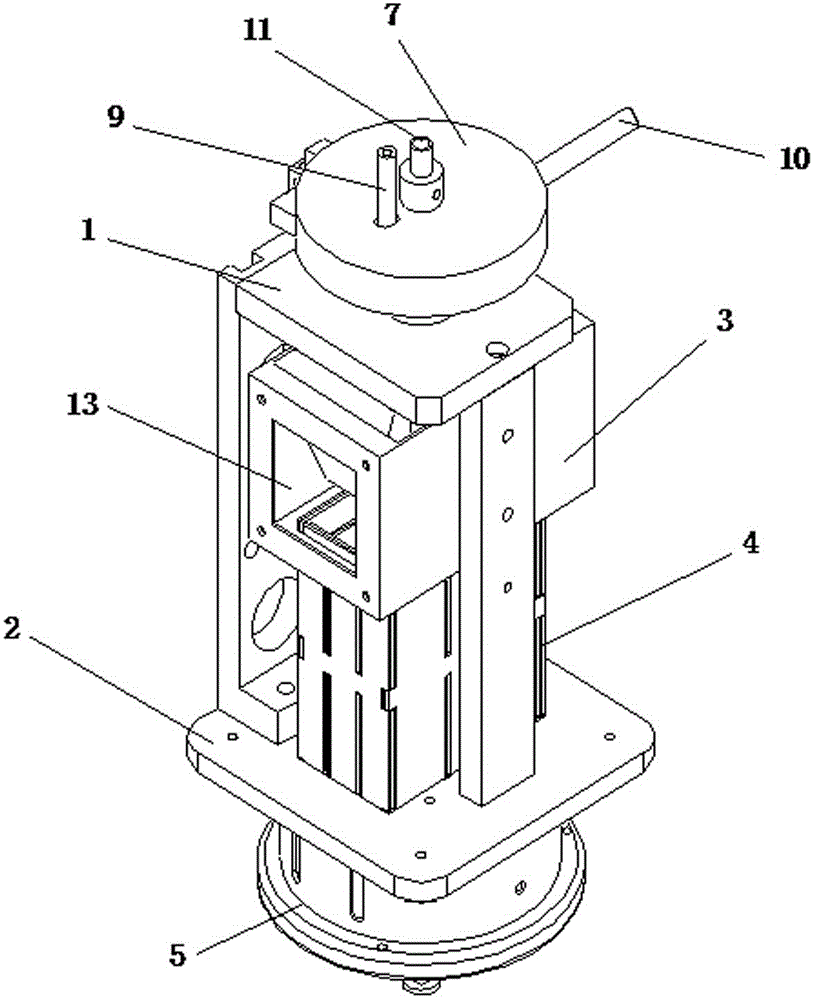

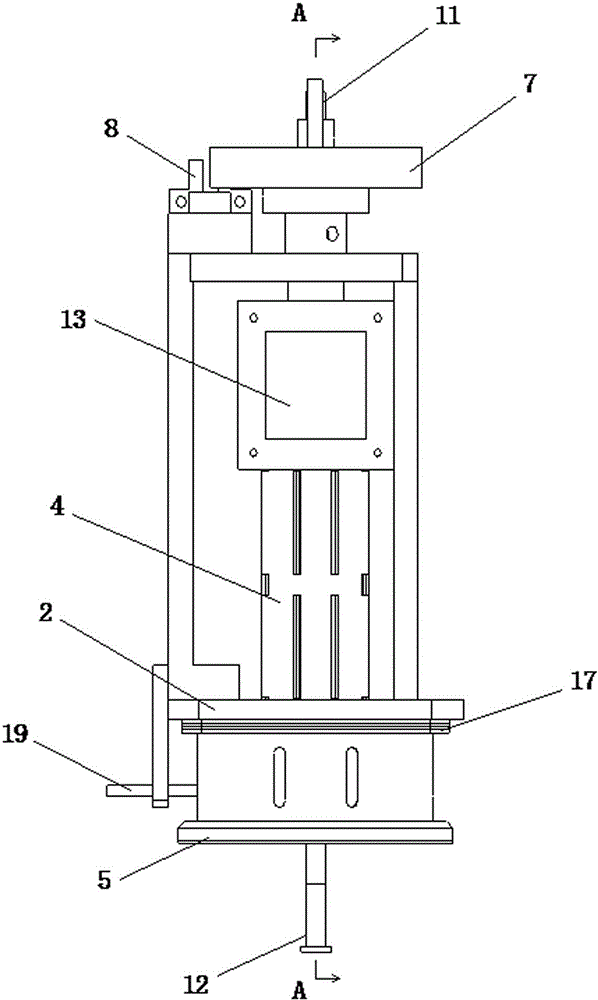

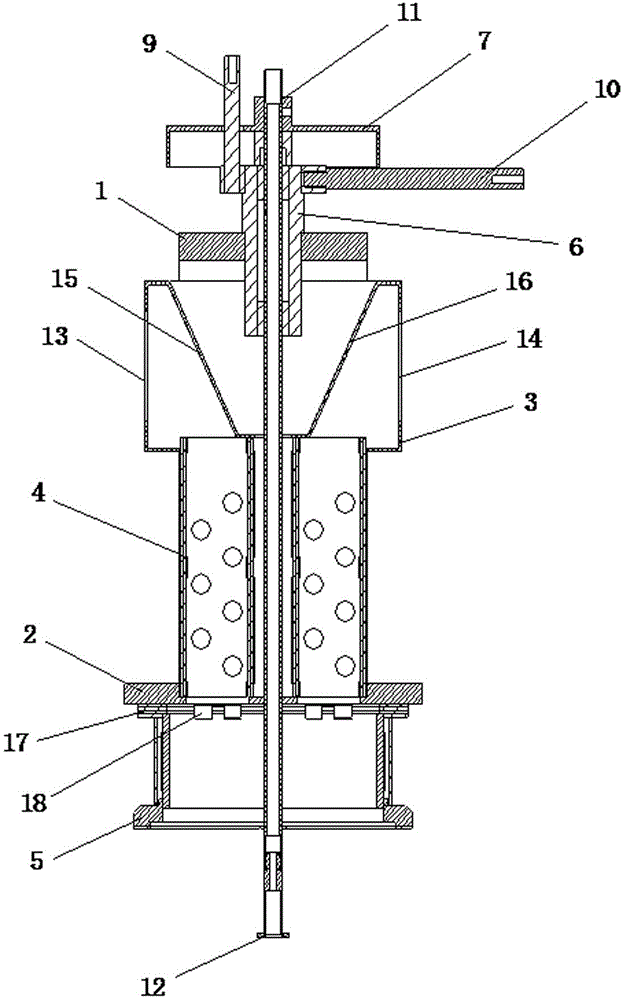

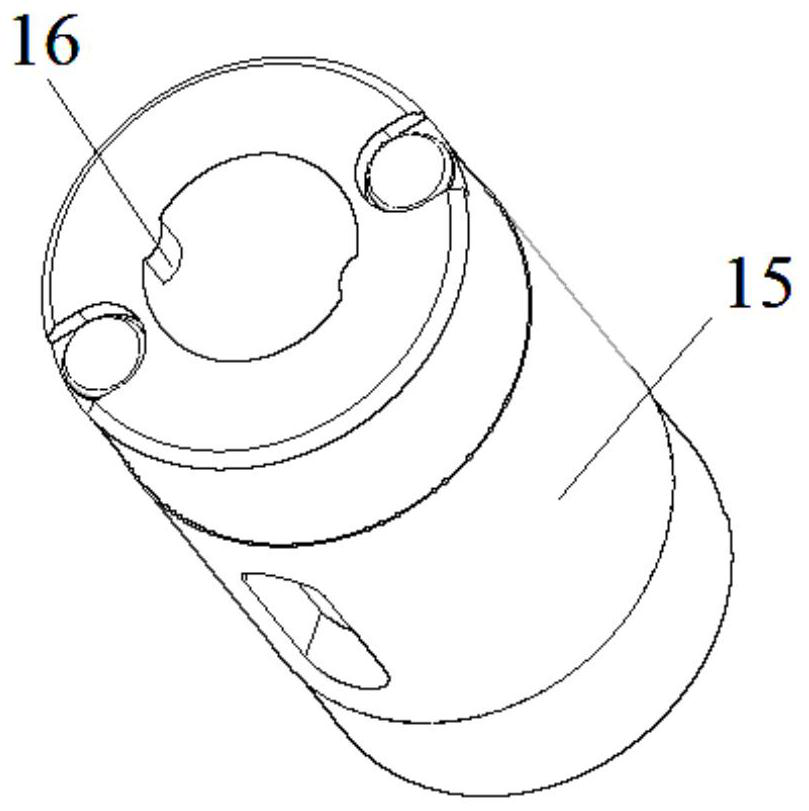

Z-axis driving connection mechanism of nozzle rod of SMT system

ActiveCN107517584AGuaranteed accuracyGuaranteed stabilityElectrical componentsSurface mountingFixed frame

The invention relates to the technical field of SMT (surface mount technology) systems, in particular to a Z-axis driving connection mechanism of a nozzle rod of an SMT system. The Z-axis driving connection mechanism comprises a press-down linkage plate, the surface of a surface mount head fixing base plate is fixedly connected with the press-down linkage plate through a guide mechanism, one end of a nozzle rod press plate is fixedly arranged at the bottom end of the press-down linkage plate, the nozzle rod press plate is connected with the nozzle rod through a bearing component consisting of flange bearings, and a nozzle rod sleeve is connected to the outer circumferential wall of the nozzle rod through a rod sleeve bearing. One end of a slidable fixed frame is fixedly arranged on the surface of the surface mount head fixing base plate while the other end thereof is connected with the nozzle rod through a slide mechanism body, and the nozzle rod sleeve is capable of sliding on the slide mechanism body along the length direction of the nozzle rod. The Z-axis driving connection mechanism has the advantages that miniaturization of the SMT system is facilitated, mounting is facilitated to reduce production cost of a surface mount head, and surface mount precision is guaranteed enduringly.

Owner:浙江华企正邦自动化科技有限公司

A gantry type intelligent burner for a chip

InactiveCN109597629AHigh precisionGuaranteed accuracySoftware deploymentReciprocating motionElectrical and Electronics engineering

The invention discloses a gantry type intelligent burner for a chip, which includes a substrate, an X-axis driving mechanism, a Y-axis driving mechanism, a suction mechanism and a burning mechanism; the Y-axis driving mechanism is arranged on the upper surface of the base plate; the X-axis driving mechanism is mounted and connected with the Y-axis driving mechanism through a plurality of XY connecting blocks and can reciprocate in the Y-axis direction; The burning mechanism is installed on the substrate and located below the material suction mechanism. a limiting bracket is also arranged; Thelimiting support is fixedly installed on the lower portion of the front side face of the installation plate, the suction rod is connected with an upper plate of the limiting support through a drivingspline, the calibration mechanism further comprises an upper camera and a lower camera, the upper camera is installed on the material suction mechanism, and the lower camera is installed on the base plate and arranged opposite to the upper camera. The position of the chip in the X / Y axis and the circumferential direction can be calibrated and corrected, the accuracy of the position of the chip placed in the burning base is guaranteed, and therefore high-precision burning of the precise chip is achieved.

Owner:苏州永创智能科技有限公司

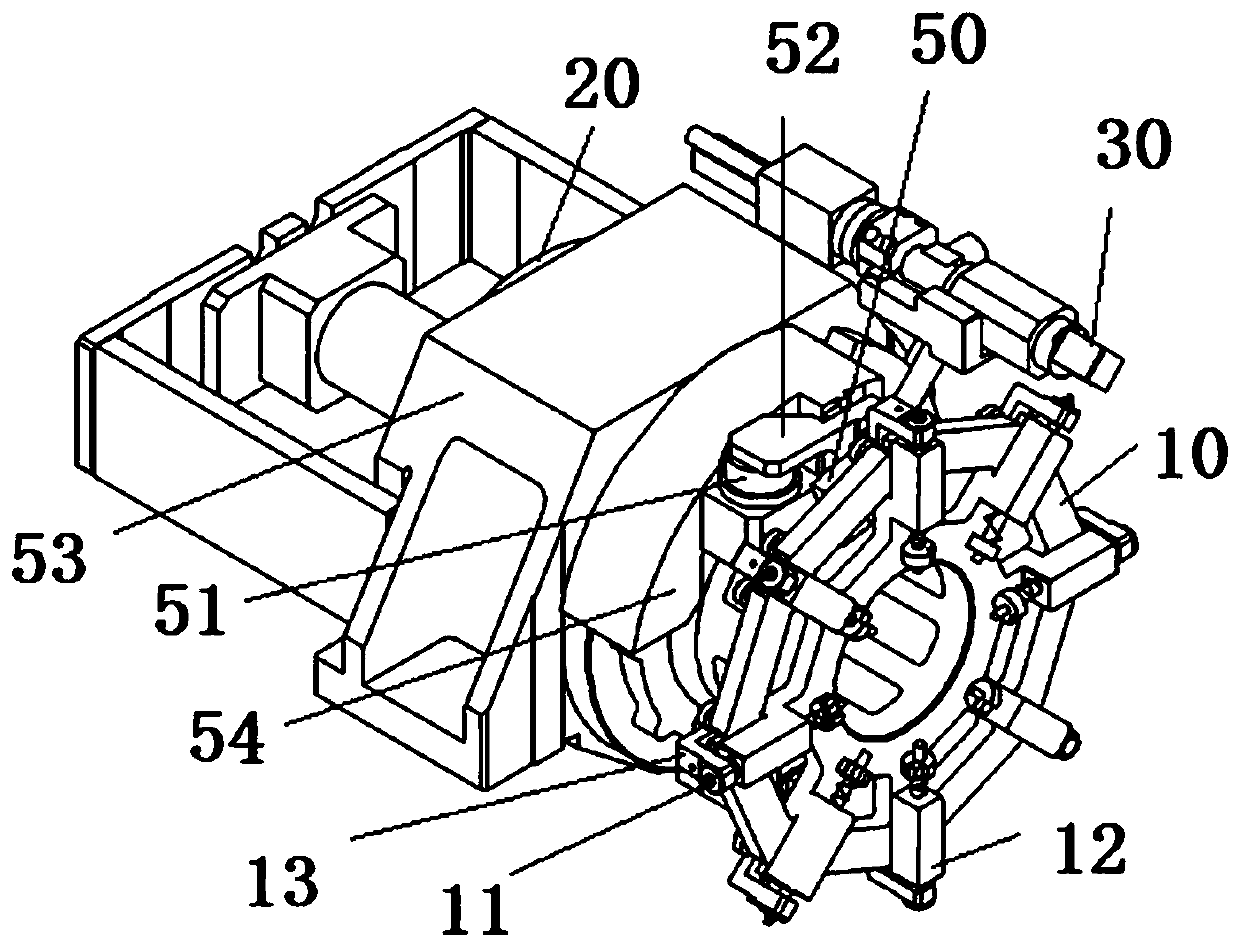

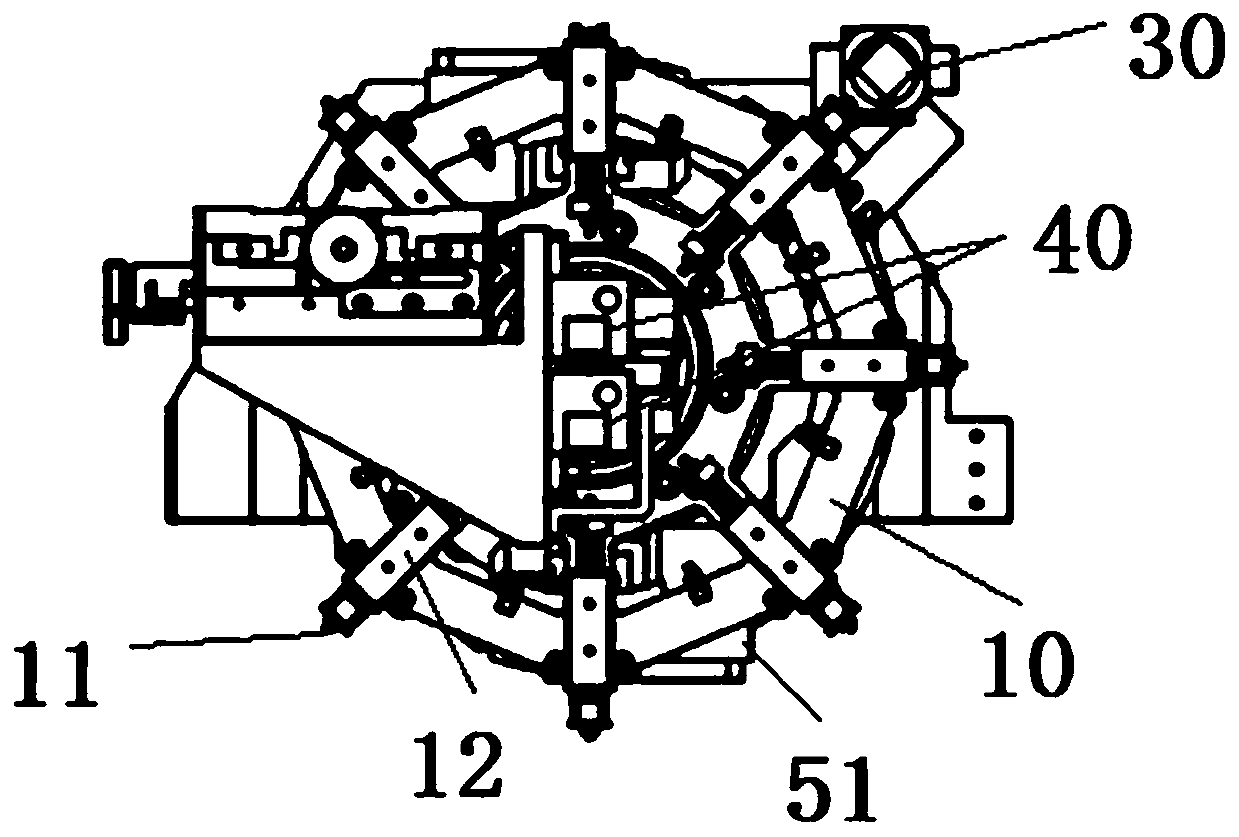

Rotating mounter head mechanism

InactiveCN109588039AHas a buffering effectAvoid instabilityElectrical componentsElectric machineInstability

The invention provides a rotating mounter head mechanism. The mechanism comprises a rotating head, a drive motor, a first identification camera, a second identification camera, a jacking structure anda buffer plate, wherein the rotating head is provided with a plurality of telescopic movable suction nozzles; the drive motor is connected to the rotary head and is capable of driving the rotating head to rotate; the first identification camera is used for acquiring a first image of a wafer chip of each of the suction nozzles; the first image is used for acquiring first position information of the wafer chip; the second identification camera is used for acquiring a second image of a to-be-mounted position of the wafer chip on a work platform; the second image is used for acquiring the secondposition information of the to-be-mounted position; the jacking structure is disposed adjacent to the rotating head and is capable of driving the nozzles to telescopically move; the buffer plate and the jacking structure are connected; the buffer plate can stop against the nozzles when the nozzles are rotated to the corresponding position of the jacking structure; and the jacking structure can drive the buffer plate to drive the nozzles to telescopically move. With the rotating mounter head mechanism provided by the invention, the instability of the jacking structure can be avoided when the nozzles are lifted by the jacking structure so that the picking and mounting movement is smooth, and the picking or mounting precision is guaranteed.

Owner:CETC BEIJING ELECTRONICS EQUIP

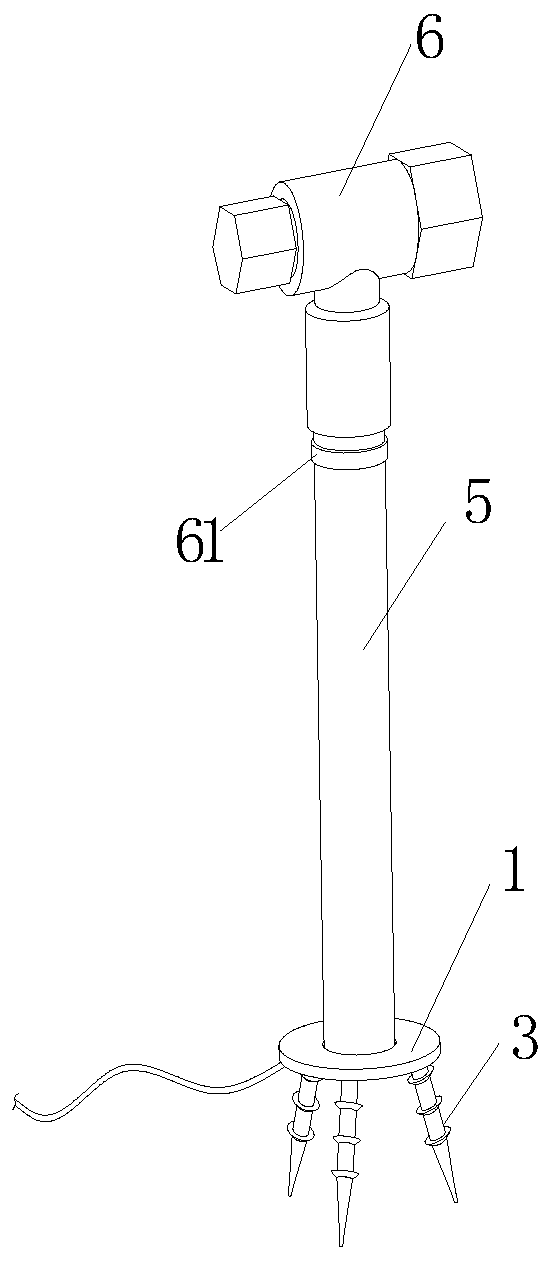

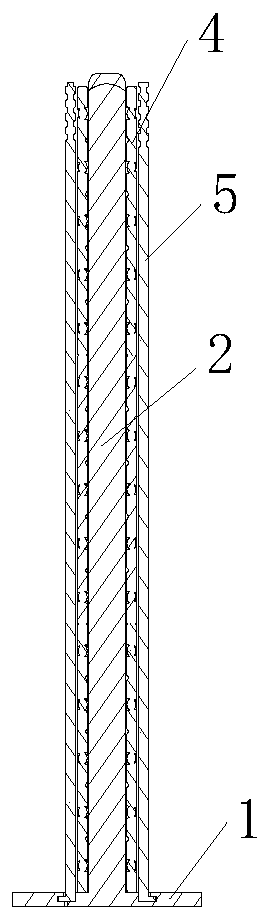

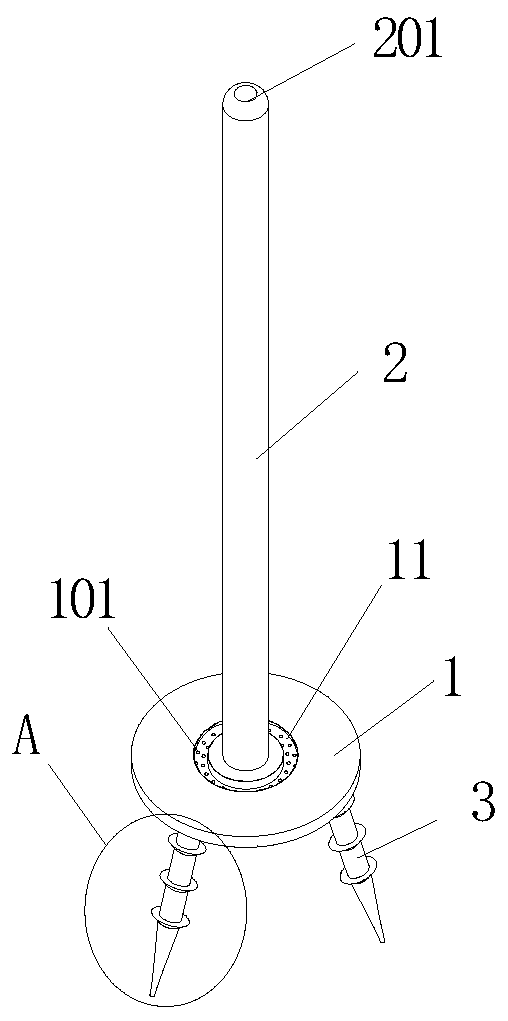

Mobile electronic projection device for measuring paying off

PendingCN110657791ANot easy to shakeEasy to adjust directionReference line/planes/sectorsLaser transmitterEngineering

The invention discloses a mobile electronic projection device for measuring paying off. The device comprises a base body, a supporting rod, an inner sleeve and an outer sleeve. Supporting legs are arranged at the bottom of the circular-truncated-cone-shaped base body; a vertical supporting rod is arranged in the center of the upper surface of the base body; the inner sleeve sleeves the periphery of the supporting rod; through holes are evenly distributed in the pipe wall where the inner sleeve is located; and the through holes are filled with balls. The outer sleeve is connected to the outer wall of the inner sleeve in a sleeving mode and rotates on the outer wall of the inner sleeve; and a protruding edge protruding outwards is arranged at the bottom of the outer sleeve and is sleeved inan annular groove of the base body. A laser receiver is arranged at the top where the outer sleeve is located; and an annular laser transmitter is connected to the outer wall of the outer sleeve in asleeving mode. An accurate pay-off point position is accurately and rapidly located according to the mutual synergistic effect of the annular laser transmitter and the laser receiver. Moreover, the device is used conveniently; the labor cost is lowered; the pay-off time is saved; the pay-off speed is increased; the high pay-off point precision is ensured; and the engineering quality is guaranteedindirectly.

Owner:THE FOURTH ENG CO LTD OF CCCC FIRST HIGHWAY ENG

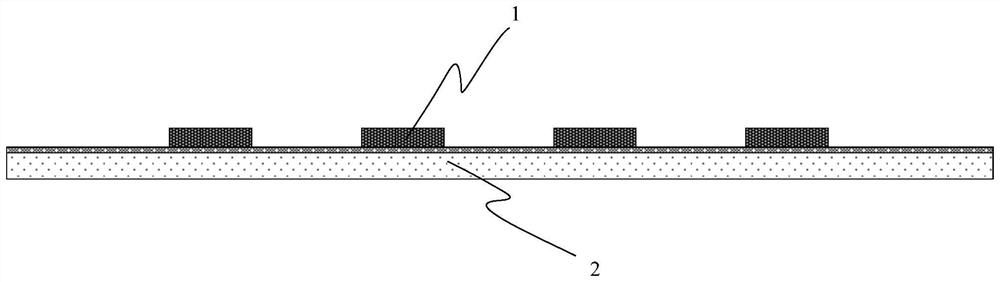

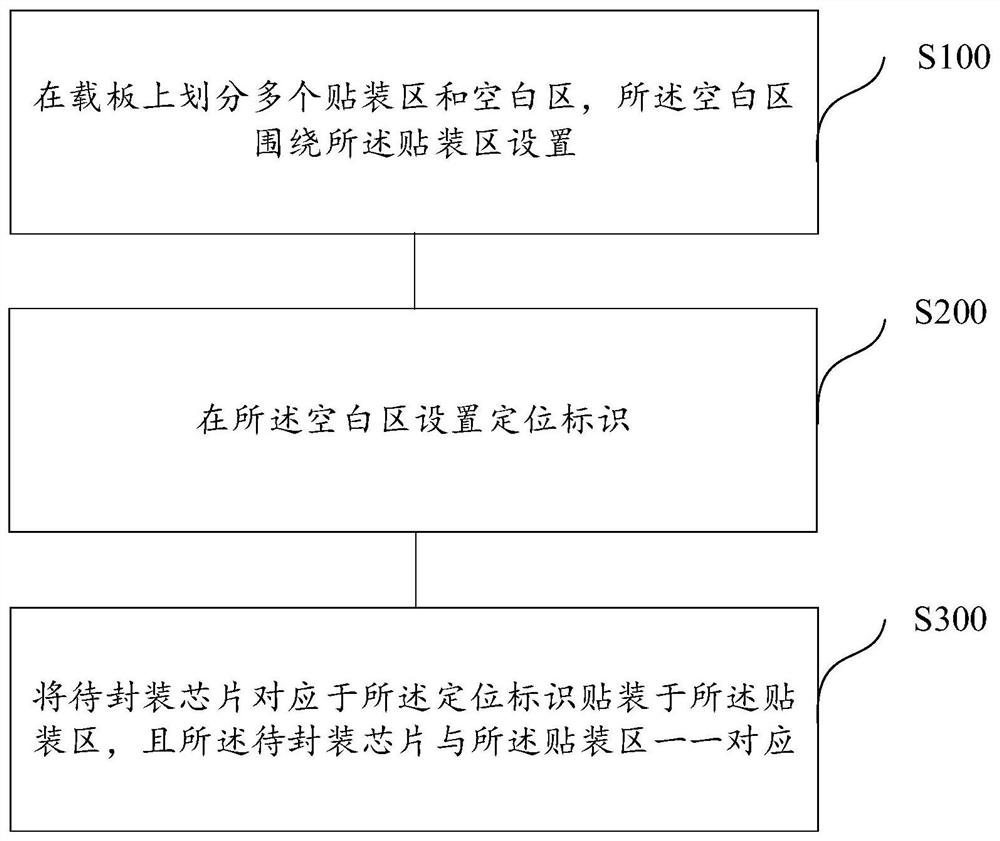

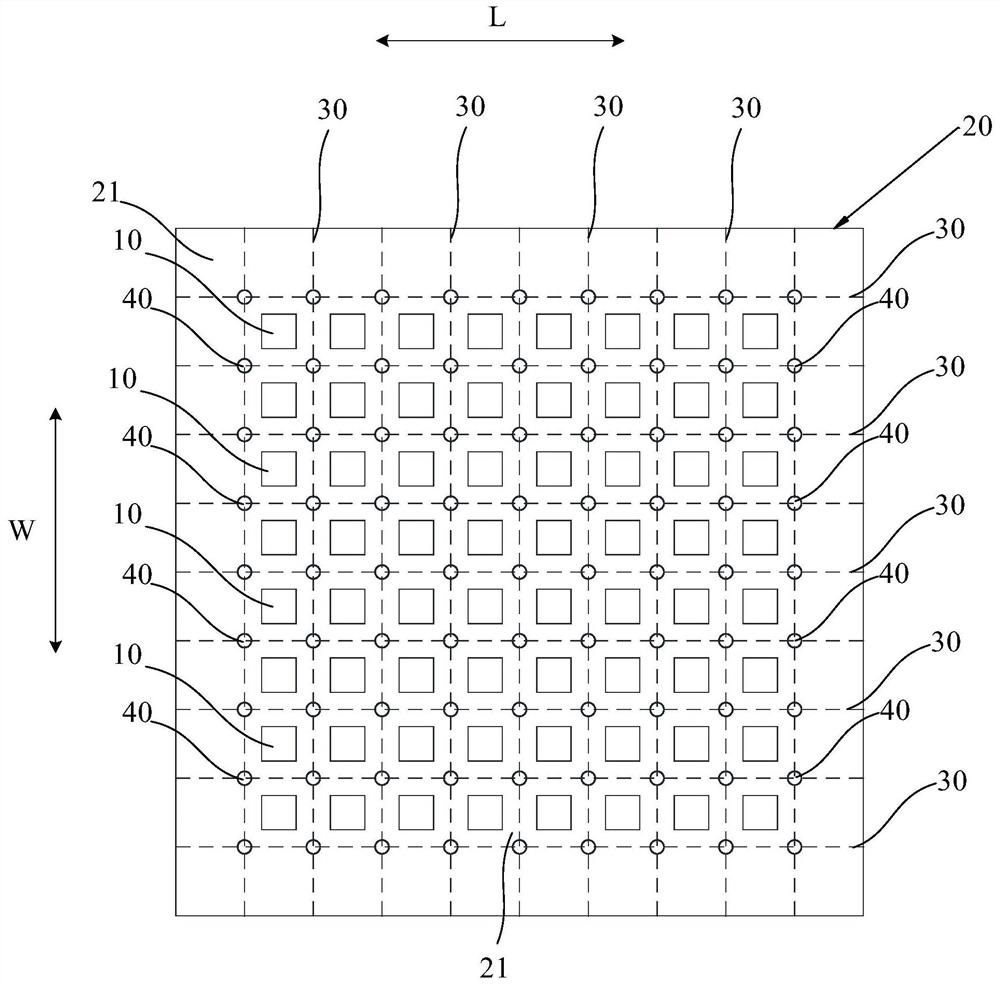

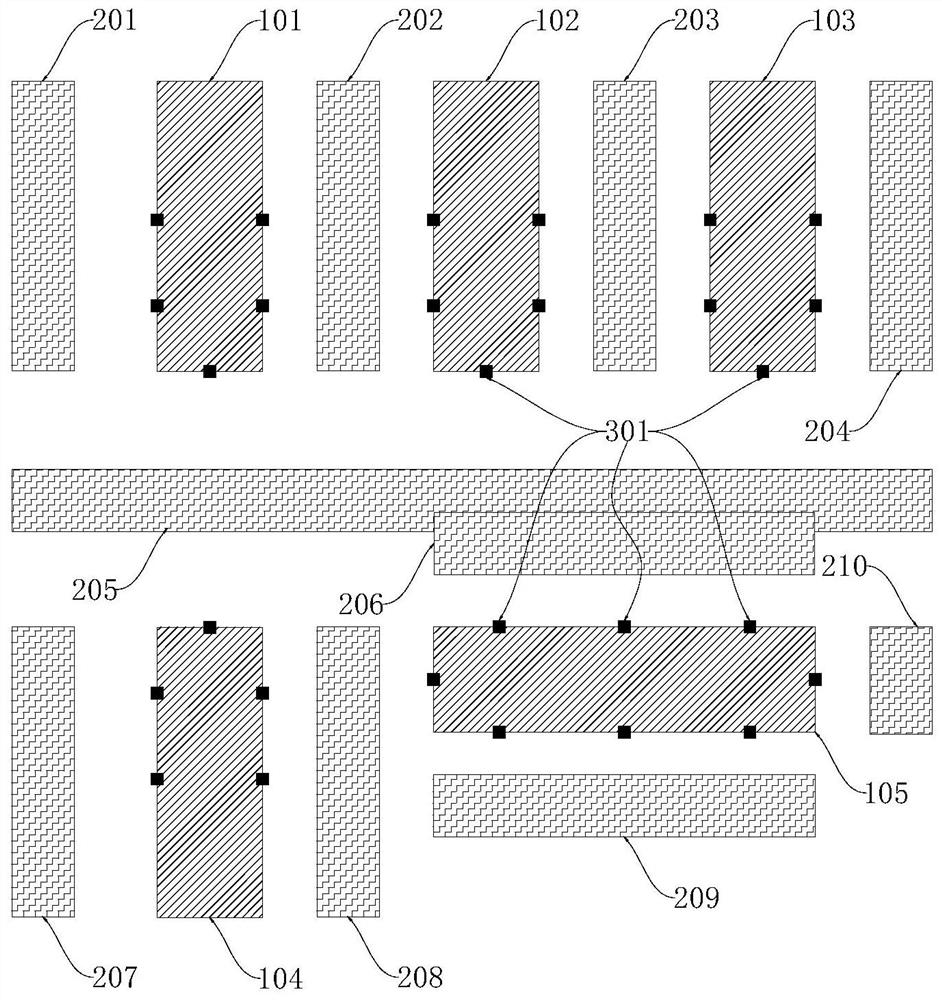

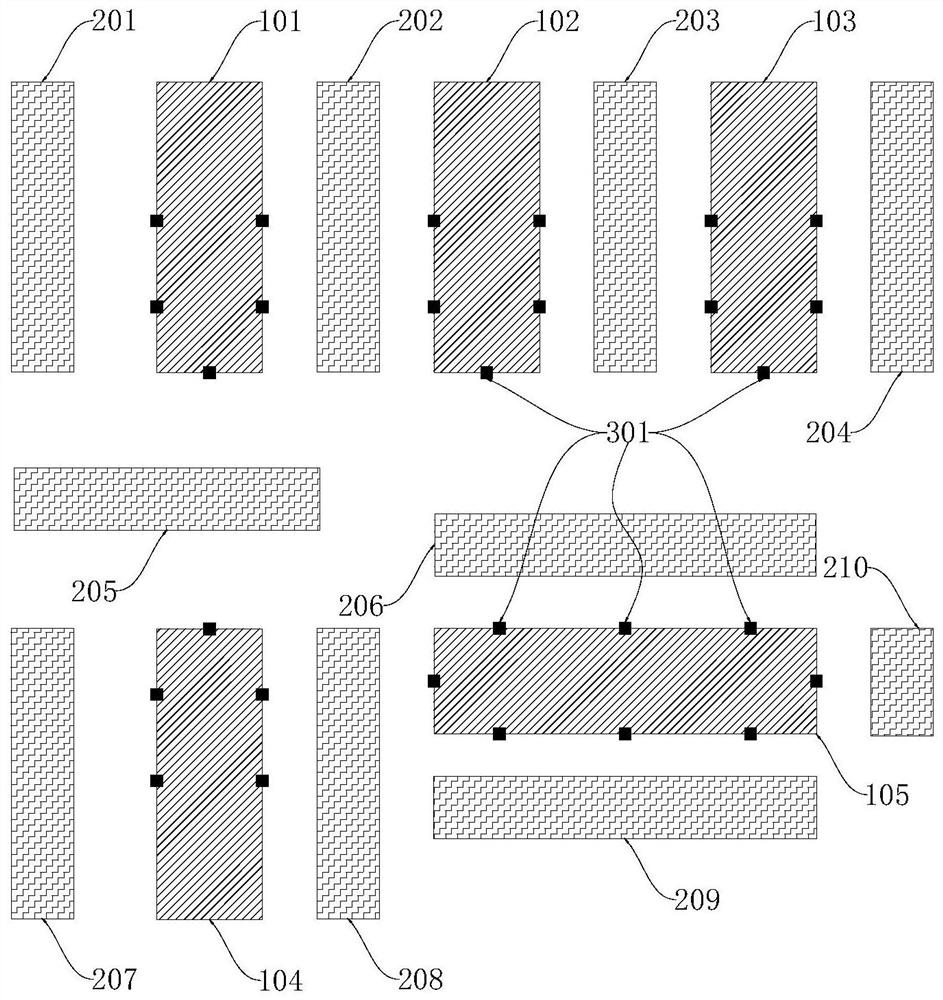

Packaging patch positioning method

PendingCN111769051AGuaranteed placement accuracyGuaranteed success rateSemiconductor/solid-state device manufacturingMechanical engineeringEmbedded system

The invention provides a packaging paster positioning method, and the method comprises the steps: dividing a carrier plate into a plurality of mounting regions and blank regions, and the blank regionsbeing arranged around the mounting regions; setting a positioning identifier in the blank area; and mounting chips to be packaged on the mounting areas in a manner of corresponding to the positioningidentifiers, wherein the chips to be packaged are in one-to-one correspondence with the mounting areas. According to the invention, the positioning identifier is arranged in the blank area of the carrier plate, the accurate position of the to-be-packaged patch on the carrier plate is positioned through the positioning identifier, the chip mounting precision in the chip mounting process can be ensured, and the chip mounting precision can be detected according to the position of the positioning identifier, so that the mounting position of the to-be-packaged chip can be adjusted in real time, and meanwhile, the precision production requirements of subsequent processes can be met, thereby ensuring the success rate of later packaging and the yield of products.

Owner:SIPLP MICROELECTRONICS CHONGQING CO LTD

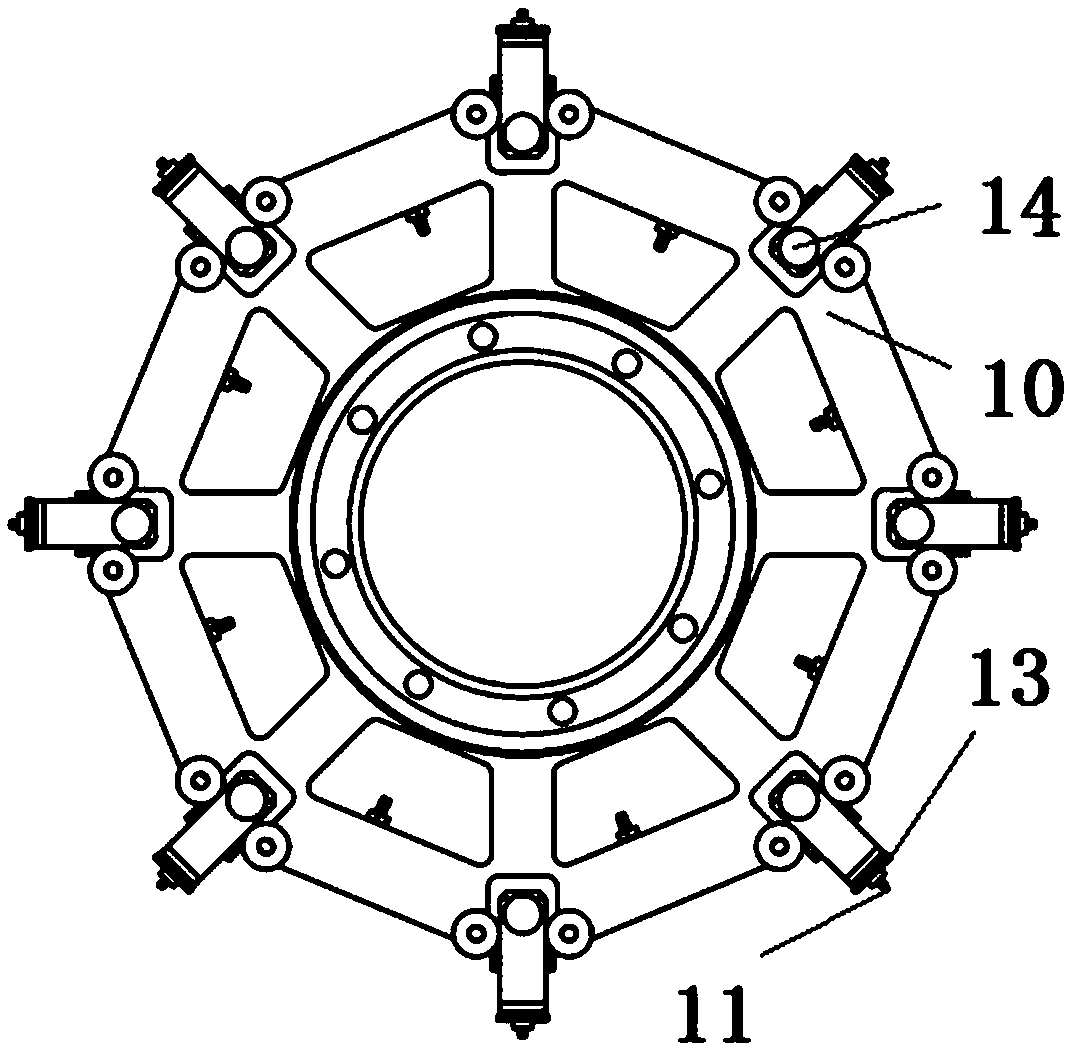

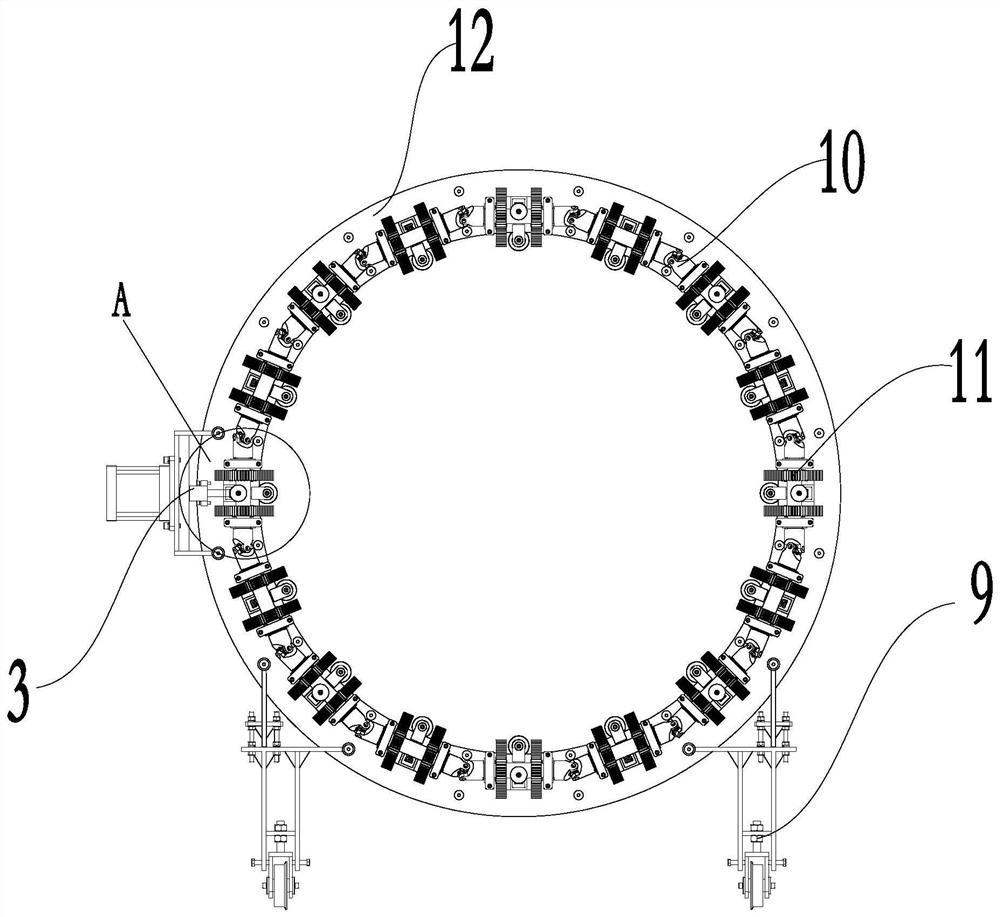

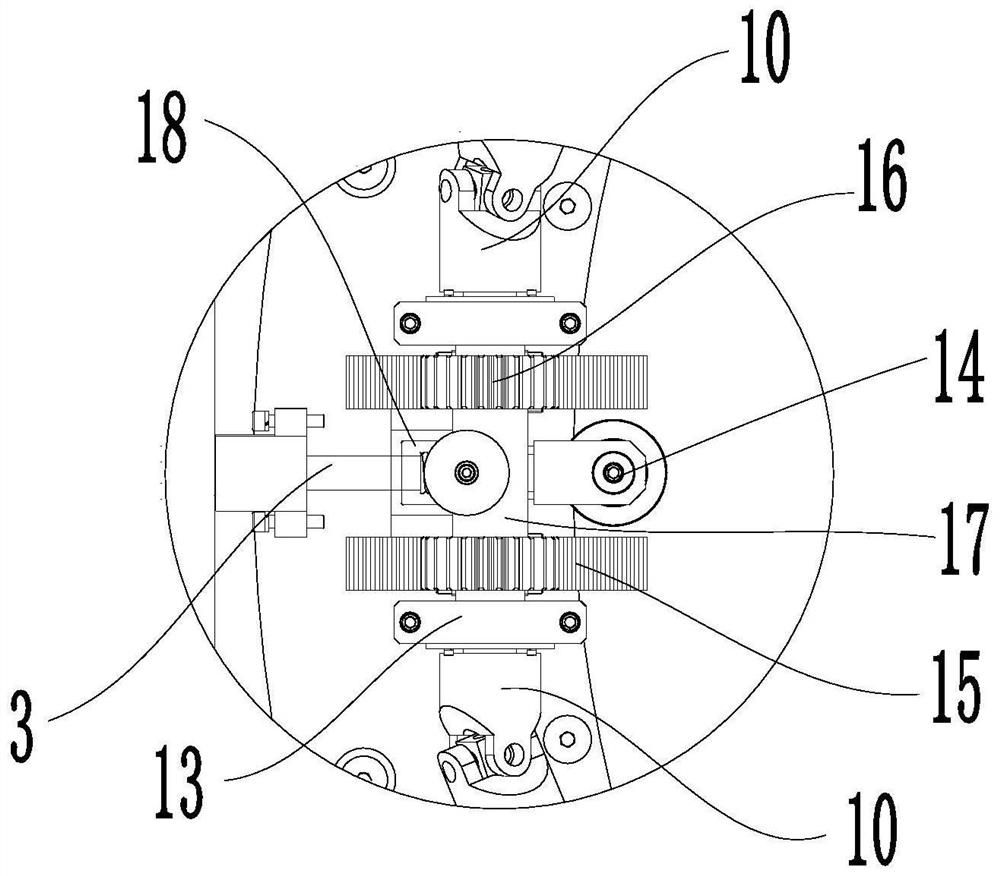

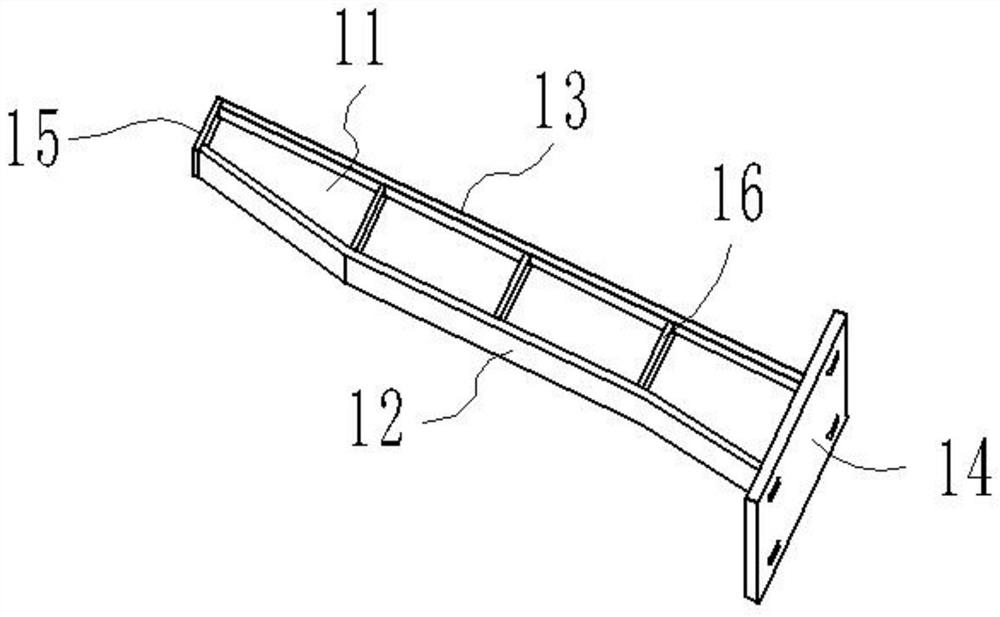

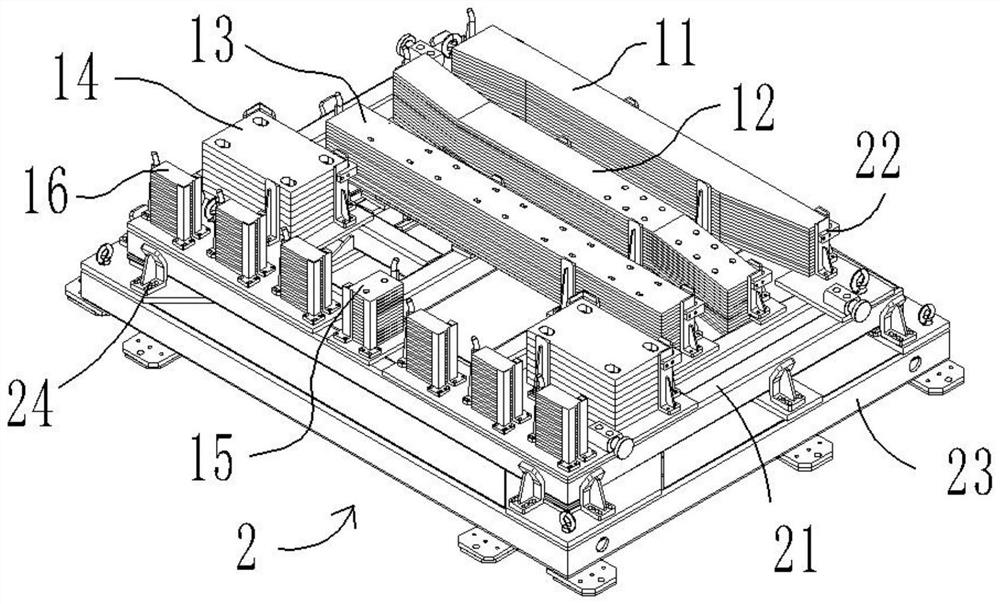

Clamping and rounding device

PendingCN111774790AGuaranteed roundness and accuracy of placement of artificial bladesImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPhysicsEngineering

The invention relates to a clamping and rounding device. The clamping and rounding device comprises a rack, a travelling frame, a travelling driving piece, a telescopic piece and lower clamping mechanisms, wherein the travelling frame is arranged on the rack; the lower clamping mechanisms comprise a plurality of sliding mechanisms and universal couplings, the adjacent sliding mechanisms are connected through the universal couplings, and the sliding mechanisms and the universal couplings form an annular structure; the sliding mechanisms comprise connecting bases, jacking pieces, racks and gears, rotating shafts are arranged on the connecting bases, the gears are fixed to the racks, the jacking pieces are connected with the racks, and the jacking pieces and the racks are movably connected tothe connecting bases; the movable end of the telescopic piece is connected with the racks, the telescopic piece can drive the jacking pieces and the racks to move in the radial directions of the lower clamping mechanisms, and the gears are meshed with the racks; and the two ends of the rotating shafts are connected with connecting shafts of the universal couplings on the two sides of the slidingmechanisms correspondingly. The invention provides the clamping and rounding device capable of guaranteeing the roundness of a stirring barrel and the manual blade placement precision, and capable ofeffectively improving the placement welding efficiency of blades inside the stirring barrel.

Owner:湖南中南智能装备有限公司

Automatic taking device for stand column parts

PendingCN112388209AImprove efficiencyGuaranteed placement accuracyGripping headsWelding/cutting auxillary devicesPhysicsEngineering

The invention relates to an automatic taking device for stand column parts, and belongs to the technical field of stand column welding. An automatic clamping device comprises a material frame and a carrying robot, a bottom plate, a top plate, a first vertical plate, a second vertical plate, a partition plate and a rib plate are placed on the upper area of the material frame, the carrying robot comprises a mechanical arm and a plurality of adsorption devices connected to the mechanical arm, and each adsorption device is used for adsorbing one or more parts. The carrying robot carries the partsinto a welding clamp one by one through the adsorption devices to be fixed. Therefore, existing manual carrying is replaced, the carrying efficiency is improved, meanwhile, the placing precision of all the stand column parts in the welding clamp can be guaranteed, and the welding precision of stand columns can be improved.

Owner:WUCHUAN HEAVY ENG +1

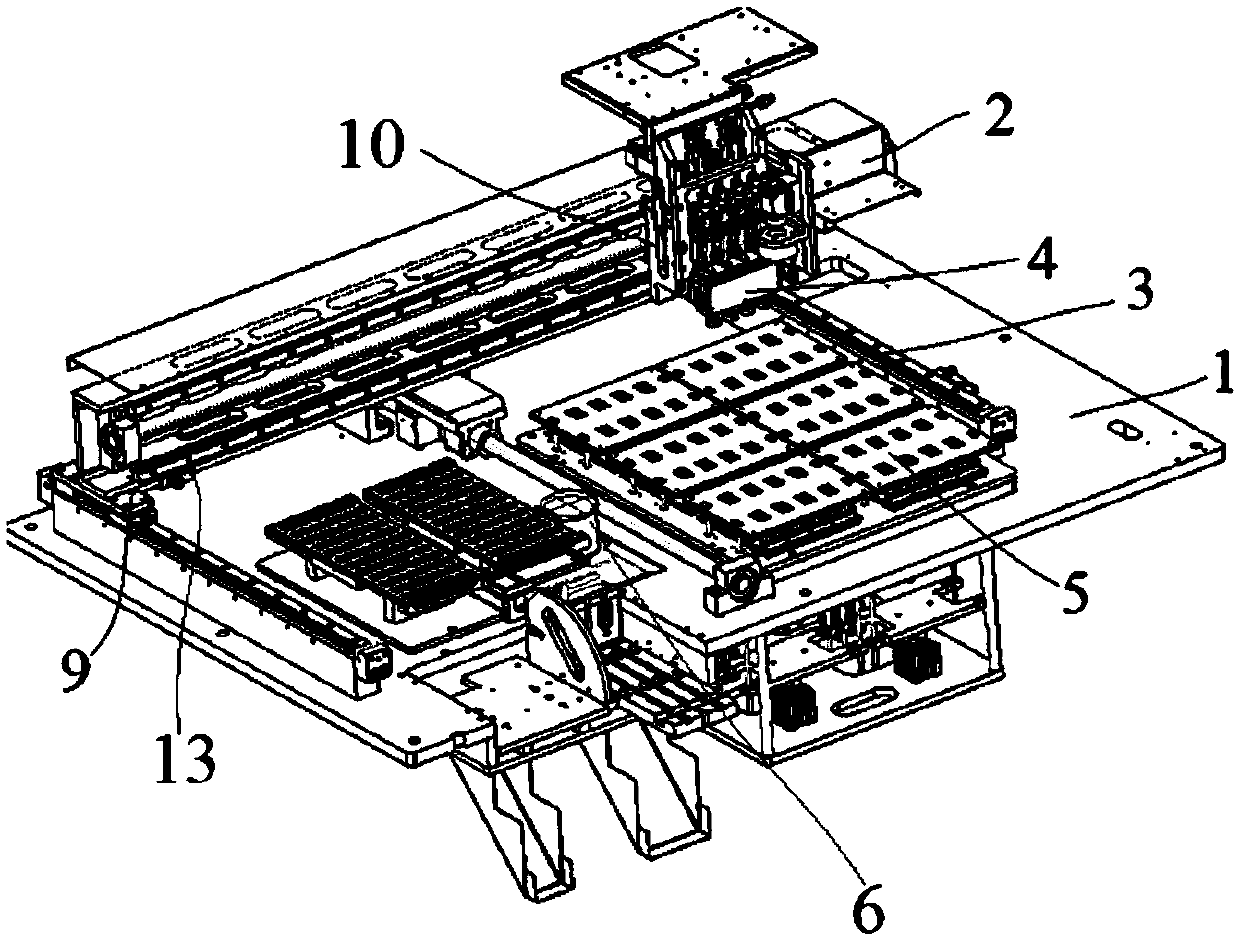

Gantry type automatic chip burner

InactiveCN109753290AHigh precisionImprove efficiencyConveyor partsSoftware deploymentCylindrical enclosureMechanical engineering

The invention discloses a gantry type automatic chip burner, including a substrate, an X-axis driving mechanism, a Y-axis driving mechanism, a suction mechanism and a burning mechanism. The Y-axis driving mechanism is arranged on the upper surface of the base plate. A through hole is formed in the mounting part; a limiting bracket is also arranged. The limiting bracket is fixedly mounted at the lower part of the front side surface of the mounting plate. The suction rod is connected with the upper plate of the limiting bracket through a driving spline. The suction rod is connected with the installation portion of the corner installation plate through a driven spline. The driving spline and the driven spline each comprise a cylindrical shell and at least two rows of balls vertically arrangedon the inner wall of the cylindrical shell, and grooves allowing the balls to be embedded are formed in the suction rod. The suction rod is driven by the motor instead of an air cylinder, so that thesituation that the chip is bounced off or damaged due to overlarge force in the driving process of the air cylinder can be avoided, the speed of the motor can be reduced when the tail end of the suction rod is close to the burning seat, and the stability of taking and placing the chip is ensured.

Owner:苏州永创智能科技有限公司

Integrated heating-placement hot air head

The invention discloses an integrated heating-placement hot air head which is characterized in that a heater fixing seat and a heater support are arranged between an upper fixing plate and a lower fixing plate; a nozzle holder is arranged at the bottom of the lower fixing plate; a hollow sucking rod guiding sleeve is arranged in the upper fixing plate in a penetrating way; the lower end of the sucking rod guiding sleeve extends into the heater fixing seat; a rotating induction coil is arranged at the upper part of the sucking rod guiding sleeve; a sensor is also arranged beside the rotating induction coil; a rotating driving rod is arranged between the rotating induction coil and the sucking rod guiding sleeve; the sucking rod guiding sleeve is connected with a rotating rod; a sucking rodenters from the rotating induction coil, penetrates the sucking rod guiding sleeve and extends out of the nozzle holder; and a suction nozzle is also arranged at one end of the sucking rod outside the nozzle holder. The hot air head disclosed by the invention has the advantages of simple and reasonable structure, small volume, low cost, uniform heating temperature, rapid heating and cooling, longservice life, excellent heat resistance, low heat loss, capability of ensuring placement accuracy and reliability, and convenient installation and maintenance.

Owner:SHENZHEN JT AUTOMATION EQUIP CO LTD

Chip programming machine with automatic loading and unloading

ActiveCN110718490BHigh precisionGuaranteed accuracySoftware engineeringConveyor partsReciprocating motionStructural engineering

The invention discloses a chip burner capable of automatic loading and unloading, comprising a substrate, an X-axis drive mechanism, a Y-axis drive mechanism, a material suction mechanism and a burner mechanism, the Y-axis drive mechanism is arranged on the upper surface of the substrate, and the The X-axis driving mechanism is installed and connected with the Y-axis driving mechanism through several XY connecting blocks and can reciprocate in the Y-axis direction. The rods pass through the limit bracket respectively, the suction rod is connected with the upper plate of the limit bracket by a driving spline, and the suction rod is connected with the mounting part of the corner mounting plate by a driven spline, Both the driving spline and the driven spline include a cylindrical shell and at least 2 rows of balls vertically arranged on the inner wall of the cylindrical shell. The invention realizes the automatic operation of the whole process of chip loading, programming and unloading in the chip programming process, and has high precision and cyclic operation, thereby improving the precision, efficiency and automation degree of chip programming.

Owner:苏州永测电子有限公司

Leakage circuit breaking device of electrical equipment

ActiveCN114823190AImprove work performanceGuaranteed work performanceProtective switch detailsElectric switchesEngineeringElectric equipment

The invention discloses an electric leakage circuit breaker of electrical equipment, which comprises a circuit breaker main body, constant temperature devices are symmetrically arranged on the front surface of the circuit breaker main body, the front surface of the circuit breaker main body is fixedly connected with the back surfaces of the constant temperature devices, and plugging devices are uniformly arranged at two ends of the circuit breaker main body. The inner wall of the plugging device is fixedly connected with the two ends of the circuit breaker main body, the constant temperature device comprises a fastening device, a heat dissipation copper plate is arranged in the fastening device, the inner wall of the fastening device is movably connected with the two ends of the heat dissipation copper plate, and contact devices are uniformly arranged on the outer surface of the heat dissipation copper plate. The outer surface of the heat dissipation copper plate is movably connected with the inner wall of the contact device, and the two ends of the contact device are symmetrically provided with fixing rods. The problem that a traditional small electric leakage circuit breaker easily loses the working capacity after the heat of the device reaches a certain limit is solved.

Owner:南通盛天电气科技有限公司

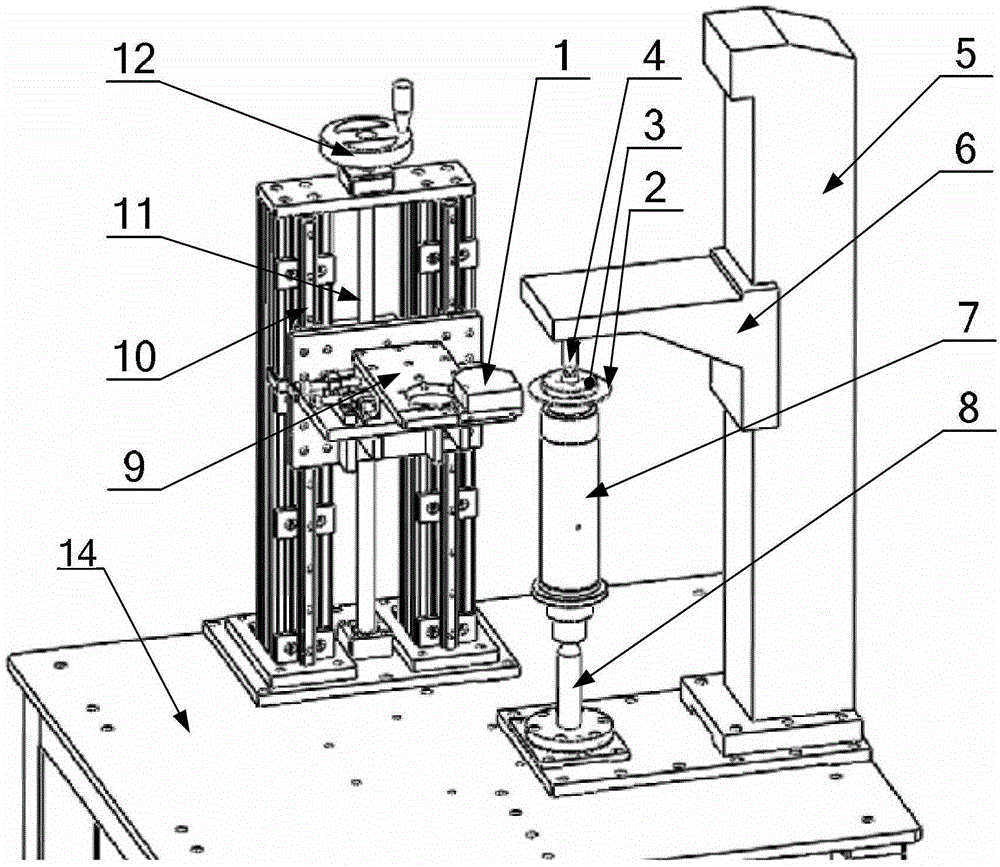

Code disk mounting device and mounting method based on mechanical alignment

ActiveCN103447791BSimple structureHigh precisionMetal working apparatusEngineeringMechanical engineering

The invention provides a device and a method for mounting code discs on the basis of mechanical alignment. The device comprises a sensor regulator and a code disc corrector which are arranged on a workbench. The sensor regulator comprises a displacement sensor, an X-Y direction horizontal micropositioner, linear guide rails, a trapezoidal screw and a rotary handle. The linear guide rails are connected with the workbench and the X-Y direction horizontal micropositioner, the displacement sensor is arranged on the X-Y direction horizontal micropositioner, and the rotary handle is arranged at the top end of the liner guide rails and is connected with the X-Y direction horizontal micropositioner through the trapezoidal screw. The code disc corrector comprises a code disc fastening cap, an upper center, a vertical post, a vertical post slider, a rotary spindle and a lower center, wherein the vertical post is arranged on the workbench and connected with the vertical post slider, the upper center is arranged on the vertical post slider, the lower center is arranged on the workbench, the rotary spindle is connected with the lower center and disposed below the upper center, and the code disc fastening cap is connected with the rotary spindle in a threading manner. The device has the advantages of high mounting precision, simple structure and convenience in operation.

Owner:SHANGHAI JIAOTONG UNIV

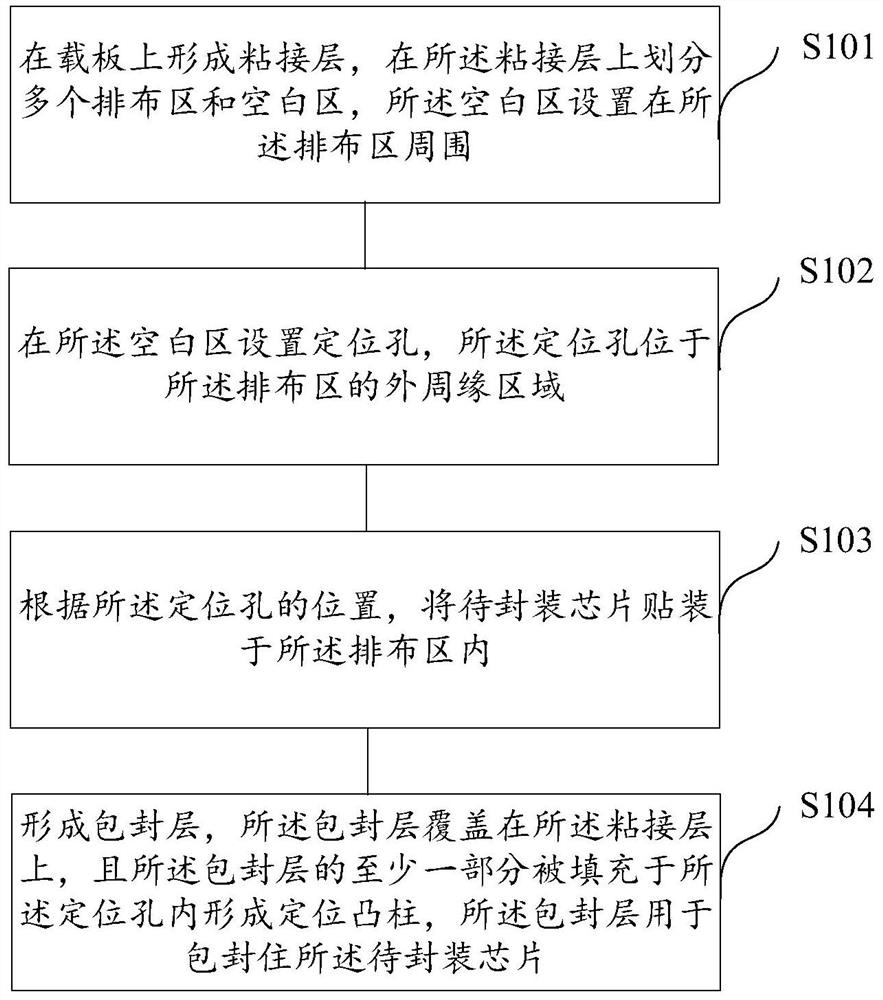

Semiconductor packaging method

ActiveCN112397400BAdjustable positionGuaranteed placement accuracySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

The present application provides a semiconductor packaging method, which includes: forming an adhesive layer on a carrier board, dividing a plurality of arrangement areas and blank areas on the adhesive layer, and setting the blank areas around the arrangement areas; setting positioning on the blank areas The positioning hole is located in the outer peripheral area of the arrangement area; according to the position of the positioning hole, the chip to be packaged is mounted in the arrangement area; an encapsulation layer is formed, the encapsulation layer covers the adhesive layer, and the encapsulation layer At least a part of the positioning holes is filled in the positioning holes to form positioning bumps, and the encapsulation layer is used to encapsulate the chips to be packaged. In the present application, positioning holes are provided to locate the precise position of the patch to be packaged on the carrier board, which can ensure the mounting accuracy in the chip mounting process; the positioning protrusions formed in the positioning holes can be used in the subsequent re-wiring process. The precise positioning identifies the arrangement position of each chip to be packaged, and achieves the function of precise positioning again.

Owner:SIPLP MICROELECTRONICS CHONGQING CO LTD

Bidirectional conveying and board feeding mechanism

PendingCN111038914AImprove flexibility and varietyEase of stabilityConveyorsElectrical and Electronics engineeringMechanical engineering

The invention discloses a bidirectional conveying and board feeding mechanism which comprises a base, an X-axis conveying device and a Y-axis board feeding device. The X-axis conveying device is perpendicular to the Y-axis board feeding device. The X-axis conveying device is used for conveying mounting boards in the X-axis direction onto the Y-axis board feeding device arranged in the Y-axis direction. The board feeding device is slidingly arranged in the Y-axis direction. The movable X-axis conveying device is matched with the Y-axis board feeding device, and the process of conveying the mounting boards to different mounting positions in the two directions is realized. The position of the width-adjustable X-axis conveying device in the Y-axis direction can be adjusted, and the width of the X-axis conveying device can be adjusted, so that the mounting boards of different specifications are moved leftwards and rightwards. The Y-axis board feeding device for performing conveying in cooperation with the X-axis conveying device performs left-right moving and width adjusting on the mounting boards, and meanwhile an ejecting assembly capable of ejecting up the mounting plates is added, so that the mounting plates can be ejected up when two board feeders work alternately, and the mounting efficiency and mounting precision are ensured.

Owner:SHENZHEN ETON AUTOMATION EQUIP

Autoclaved aerated concrete equipment mould box turnover shaft and crank arm shaft seat positioning tool

PendingCN114872181AGuaranteed placement accuracyGuaranteed accuracyPassive housesAuxillary shaping apparatusCrankAutoclaved aerated concrete

The invention relates to an autoclaved aerated concrete equipment mould box turnover shaft and crank arm shaft seat positioning tool, which is used for positioning a mould box turnover shaft and a crank arm shaft seat before welding, and comprises a bottom plate used for placing an autoclaved aerated concrete equipment mould box, a mould box limiting block, a mould box turnover shaft positioning tool and a mould box crank arm shaft seat positioning tool; the mold box limiting block is used for limiting the position of the mold box on the tool; the mold box turnover shaft positioning tool is used for positioning a mold box turnover shaft before welding, and the precision of the mold box turnover shaft is guaranteed; and the mold box crank arm shaft seat positioning tool is used for ensuring the precision of the mold box crank arm shaft seat and positioning the crank arm shaft seat before welding.

Owner:DONGYUE MACHINERY GRP

An automatic calibration method for the coaxiality error of the pick-and-place machine nozzle based on machine vision

ActiveCN113382555BGuaranteed placement accuracyPrinted circuit assemblingElectrical componentsMachine visionEngineering

The invention discloses a method for automatically calibrating the coaxiality error of the suction nozzle of a placement machine based on machine vision. The product Mark information is obtained through a CCD positioning camera, so that the suction nozzle is positioned at the position of the product; the product is sucked and then moved to the UpLook Take pictures at every other angle above the camera to obtain image information, and then fit the position information of each Mark of the material to calculate the rotation center of the mechanical axis; calculate the Mark point to the rotation of the product during the rotation process Center distance, and calculate the average value of all distances, and then subtract the calculated average value from the distance from all Mark points to the center of rotation, which is the concentricity brought by the rotation of the suction nozzle during the placement process deviation, and compensate for it. The automatic calibration method of the coaxiality error of the pick-and-place machine nozzle ensures that the concentricity of each processing is within the allowable range and the mounting accuracy is guaranteed.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Steel sheet automatic laminating machine

ActiveCN105530758BSimple structureGuaranteed placement accuracyPrinted circuit aspectsPrinted circuit manufactureCouplingEngineering

The invention discloses an automatic laminating machine for a steel sheet. The automatic laminating machine comprises a laminating platform, wherein a feeding bracket is arranged at the position, close to an input end, of the laminating platform; a feeding module is arranged at the rear part of the laminating platform; a laminating module is arranged at the upper part of the laminating platform; an X-axis beam and an X-axis guide element are arranged at the upper end of the laminating module; the X-axis guide element is connected with the laminating module; the laminating module comprises a vertical frame, a Z-axis sensor, a vacuum module, an R-axis rotary motor, a coupling, a patch rod and suction nozzles; the Z-axis sensor is arranged at the upper end of the vertical frame; the R-axis rotary motor is located at the lower end of the vacuum module; the coupling is located at the lower end of the R-axis rotary motor; a Z-axis sensor chip is arranged at the lower end of the Z-axis sensor; and an R-axis sensor chip is arranged on the R-axis rotary motor. According to the laminating machine, through reasonable structure improvement, particularly, arrangement of the Z-axis sensor chip and the R-axis sensor chip through the laminating module, the suction nozzles independently rotate 360 degrees to correct deviation; the laminating accuracy is ensured; and the efficiency is greatly improved.

Owner:珠海奇川精密设备有限公司

PCB surface mounting equipment

PendingCN113923887AGuaranteed placement accuracyEasy to mount workPrinted circuit assemblingElectrical componentsSurface mountingEngineering

The invention discloses PCB surface mounting equipment, and the equipment comprises a workbench, a conveying mechanism which is arranged on the workbench and used for conveying a PCB and a fixing frame arranged in the middle of the upper end of the workbench; a mounting mechanism is mounted on the fixing frame, and the mounting mechanism comprises a first movable arm, a second movable arm and a driving assembly. An adsorption mechanism is arranged at the lower end of one movable arm, and a pressing plate is arranged at the lower end of the other movable arm; The equipment also comprises a supporting frame which is arranged below the fixing frame, wherein a feeding mechanism is arranged on the supporting frame, and the feeding mechanism comprises a rotating disc rotationally arranged at the upper end of the supporting frame and a second servo motor arranged below the supporting frame. According to the invention, full-automatic mounting operation is carried out on the PCB, secondary pressing is carried out on the mounted chip, the mounting efficiency is high, the quality is high, and the chip is effectively prevented from loosening on the PCB.

Owner:康正明

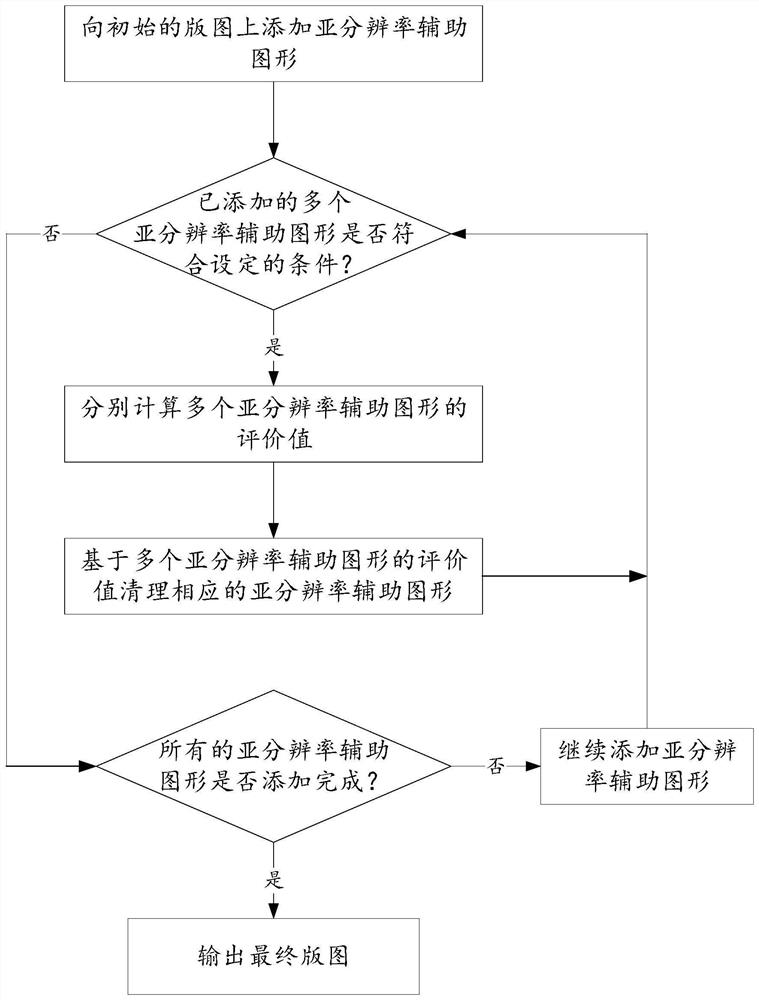

Sub-resolution auxiliary graph adding method and device and computer readable storage medium

ActiveCN112099319AImprove placement accuracyImproving contrast in lithographic imagingPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsAlgorithm

The invention discloses a sub-resolution auxiliary graph adding method and device and a computer readable storage medium. The method comprises the steps that sub-resolution auxiliary graphs are addedto an initial layout, evaluation values of the multiple sub-resolution auxiliary graphs are calculated respectively under the condition that the multiple added sub-resolution auxiliary graphs meet theset condition, and the corresponding sub-resolution auxiliary graphs are cleaned based on the evaluation values of the multiple sub-resolution auxiliary graphs, otherwise, the sub-resolution auxiliary graphes can be added continuously, and finally, the layout is output. The device can comprise an auxiliary graph adding module, an evaluation value calculation module, an auxiliary graph cleaning module and a final layout output module. According to the method, conflict clearing is innovatively carried out in the adding process of the sub-resolution auxiliary patterns, so that the workload and complexity of conflict clearing after all the sub-resolution auxiliary patterns are added can be effectively avoided, and a larger photoetching process window can be obtained; and thus, the photoetching imaging contrast of the target pattern is obviously improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com