PCB surface mounting equipment

A surface mount and PCB board technology, which is applied to the assembly of printed circuits with electrical components, electrical components, and printed circuit manufacturing. It can solve problems such as low work efficiency and large product quality defects, and achieve the effect of ensuring mounting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

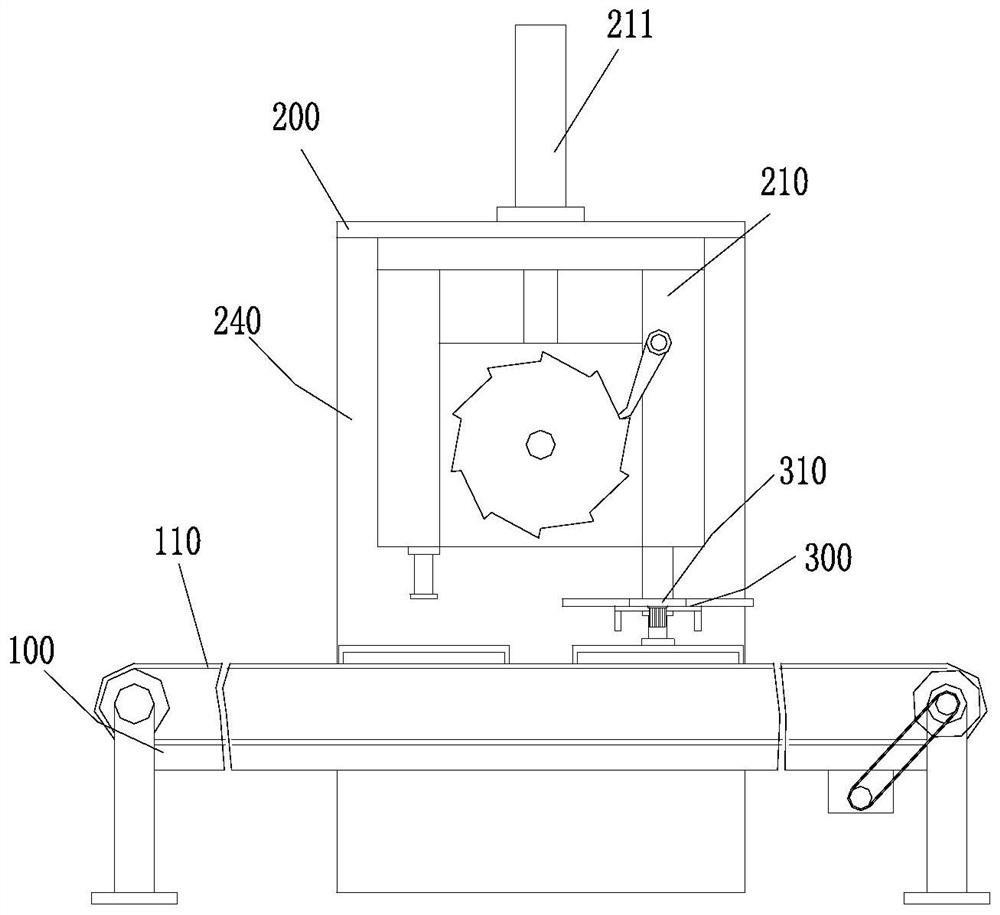

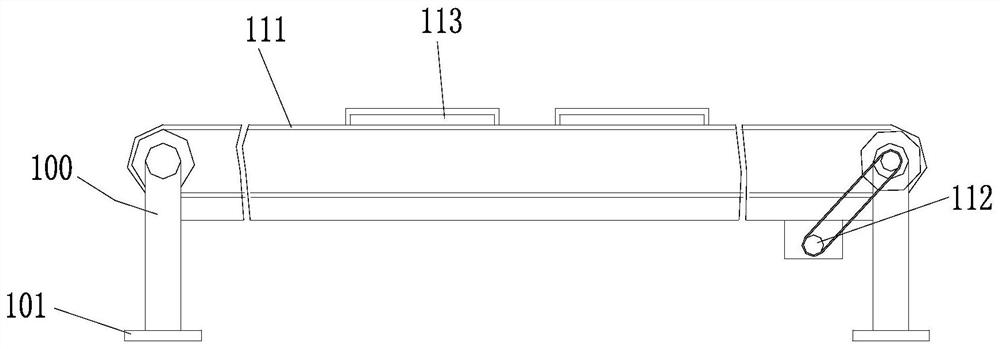

[0039] The present invention provides a technical solution: a PCB surface mount equipment, including a workbench 100, a conveying mechanism 110 is arranged on the workbench 100, and the conveying mechanism 110 is used to convey the PCB board. The conveyor belt 111 and the first servo motor 112 arranged at the lower end of the workbench 100, the first servo motor 112 is used to drive the conveyor belt 111 to move at intervals, the conveyor belt 111 is provided with several groups of placement grooves 113 at intervals, and the placement grooves 113 For positioning and placing PCB boards;

[0040] Fixed frame 200, fixed frame 200 is arranged on the middle part of the upper end of workbench 100, and mounting mechanism 210 is installed on the fixed frame 200, and mounting mechanism 210 comprises first movable arm 216, second movable arm 215 and driving assembly, and driving assembly is used for Drive the first movable arm 216 and the second movable arm 215 to lift respectively. The...

Embodiment 2

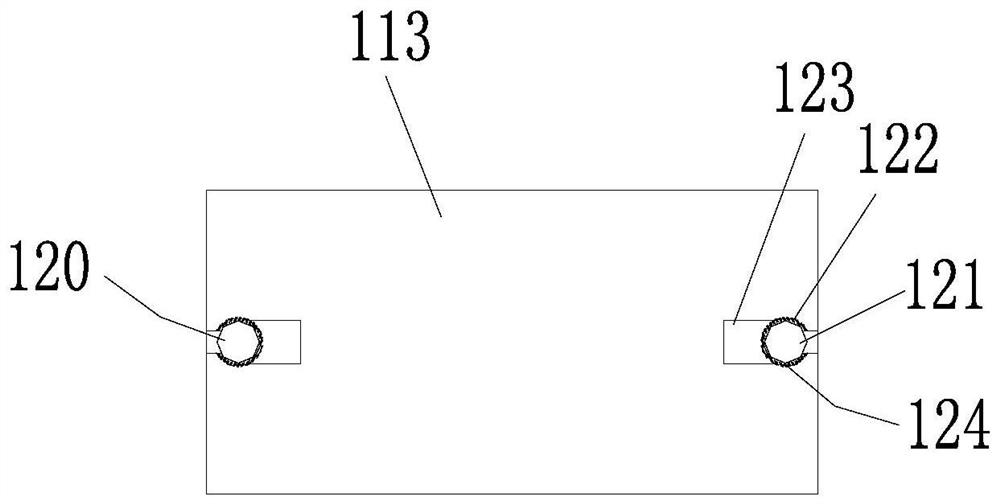

[0044] On the basis of Embodiment 1, the lower end of the workbench 100 is provided with supporting legs, and the supporting legs are affixed to the ground through the connecting plate 101; Clamping mechanism 120. The clamping mechanism 120 includes support rods 121 arranged on both sides of the placement groove 113. A movable sleeve 122 is sleeved on the support rod 121. One side of the movable sleeve 122 is connected with an abutment plate 123. The support rod 121 is wound with Compression spring 124, compression spring 124 is connected with movable sleeve 122; Adsorption mechanism 230 comprises the suction nozzle 232 that is arranged on the lower end of first movable arm 216, and suction nozzle 232 is equipped with driving source 231, can control suction nozzle 232 to carry out suction action and drop actions.

[0045] Specifically, the workbench 100 is fixedly connected to the ground, and when working, the overall state is kept stable, and the PCB board in the placement gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com