Leakage circuit breaking device of electrical equipment

A leakage circuit breaker and electrical equipment technology, which is applied in the field of leakage circuit breakers, can solve problems such as easy loss of working ability, and achieve the effects of improving installation convenience, ensuring stability, and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

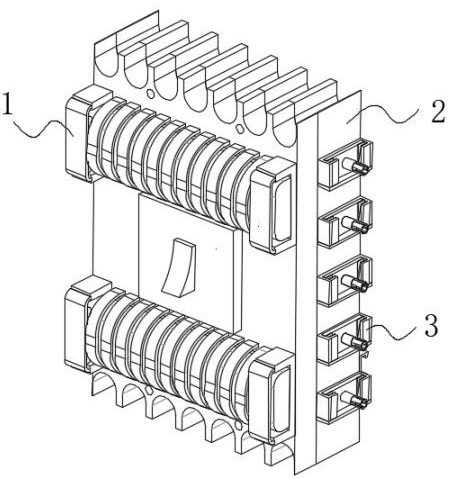

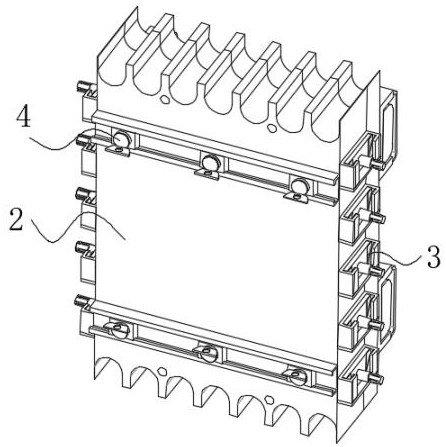

[0030] like Figure 1-Figure 8 As shown in the figure, a leakage circuit breaker for electrical equipment according to the present invention includes a circuit breaker main body 2, and a constant temperature device 1 is symmetrically arranged on the front of the circuit breaker main body 2. By setting the constant temperature device 1, the leakage current of the electrical equipment can be improved. The working performance of the circuit breaker, and the front surface of the circuit breaker main body 2 is fixedly connected to the back of the thermostat device 1, and the two ends of the circuit breaker main body 2 are evenly provided with plug-in devices 3. By arranging the plug-in devices 3, this kind of electrical equipment can be improved. The heat dissipation effect of the leakage circuit breaker is improved, and the inner wall of the plug-in device 3 is fixedly connected with both ends of the circuit breaker main body 2;

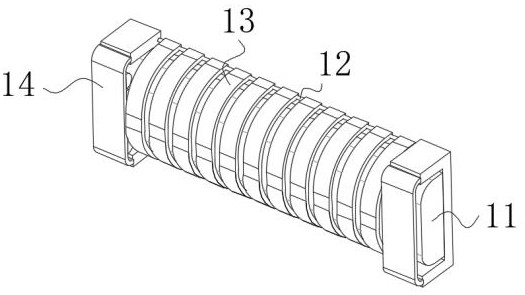

[0031] The thermostatic device 1 includes a fasten...

Embodiment 2

[0038] like Figure 1-Figure 8 As shown in the present invention, a leakage circuit breaker for electrical equipment according to the present invention, on the basis of the first embodiment, the plug device 3 includes a receiving frame 36. The circuit breaker is movably connected, so that there is no tight connection between the leakage circuit breakers of this kind of electrical equipment, which is conducive to its heat dissipation. The interior of the storage frame 36 is provided with a movable plate 33, and the inner wall of the storage frame 36 is connected to the movable plate. The bottom of 33 is in contact with each other, and the plug-in cylinder 31 and the limit cylinder 35 provided outside the plug-in device 3 are used in conjunction, so that the leakage circuit breaker of the electrical equipment can be movably connected, which improves the installation of the leakage circuit breaker of the electrical equipment. For convenience, two ends of the movable plate 33 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com