Automatic taking device for stand column parts

A technology for automatic reclaiming of materials and parts, applied in auxiliary devices, transportation and packaging, conveyor objects, etc., can solve problems such as low efficiency, and achieve the effect of improving efficiency, ensuring placement accuracy, and improving welding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

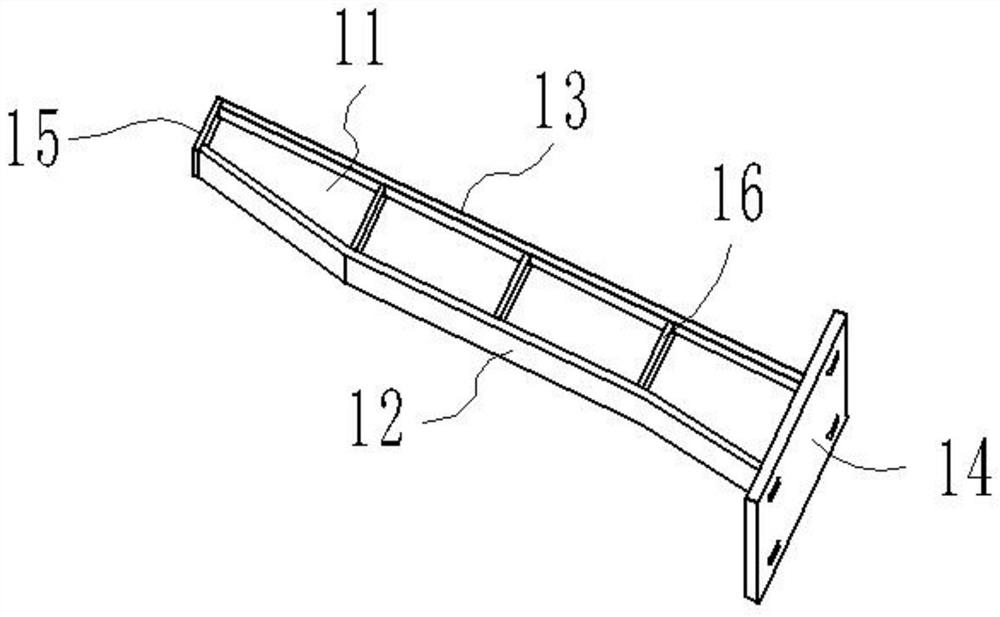

[0029] The structure of the column formed after welding the column components in this embodiment is as follows: figure 1 As shown, the first vertical plate 12 and the second vertical plate 13 are spaced apart, and one end of the first vertical plate 12 and one end of the second vertical plate 13 are welded to the bottom plate 14, and the other end of the first vertical plate 12 is connected to the second vertical plate 14. The other end of the plate 13 is welded with the top plate 15, and the partition plate 11 is welded and fixed in the frame-shaped structure formed by the welding of the first vertical plate 12, the bottom plate 14, the second vertical plate 13 and the top plate 15 in turn, and the partition plate 11 is welded. Rib plates 16 are welded symmetrically on both sides, and two ends of the rib plate 16 are connected with the first vertical plate 12 and the second vertical plate 13 .

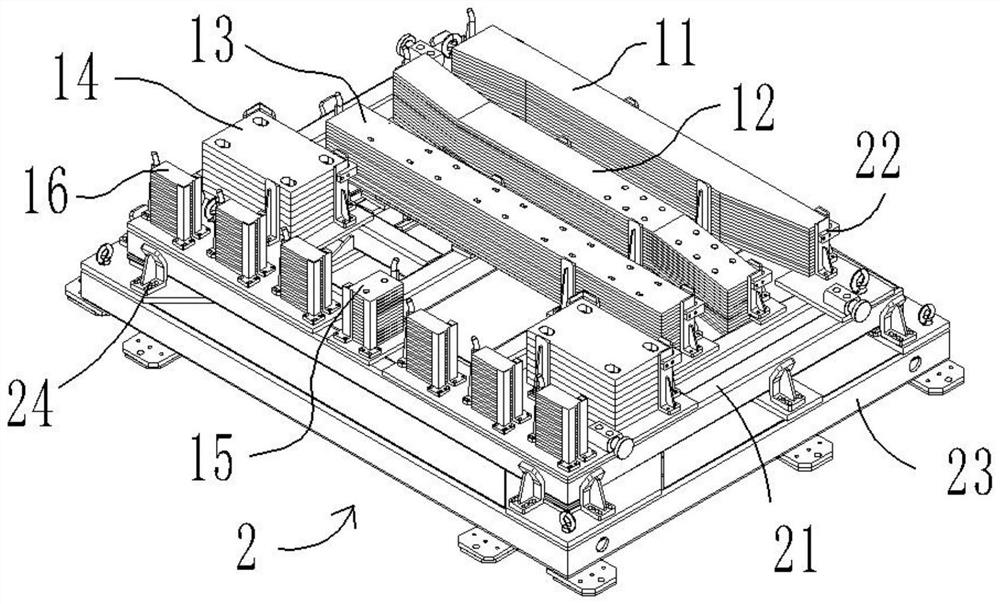

[0030] like figure 2 As mentioned above, an automatic identification device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com