Gantry type automatic chip burner

A burner, gantry-type technology, applied in conveyor objects, software deployment, transportation and packaging, etc., can solve the problems of many processes, low work efficiency, complex structure, etc., to ensure accuracy, improve accuracy, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

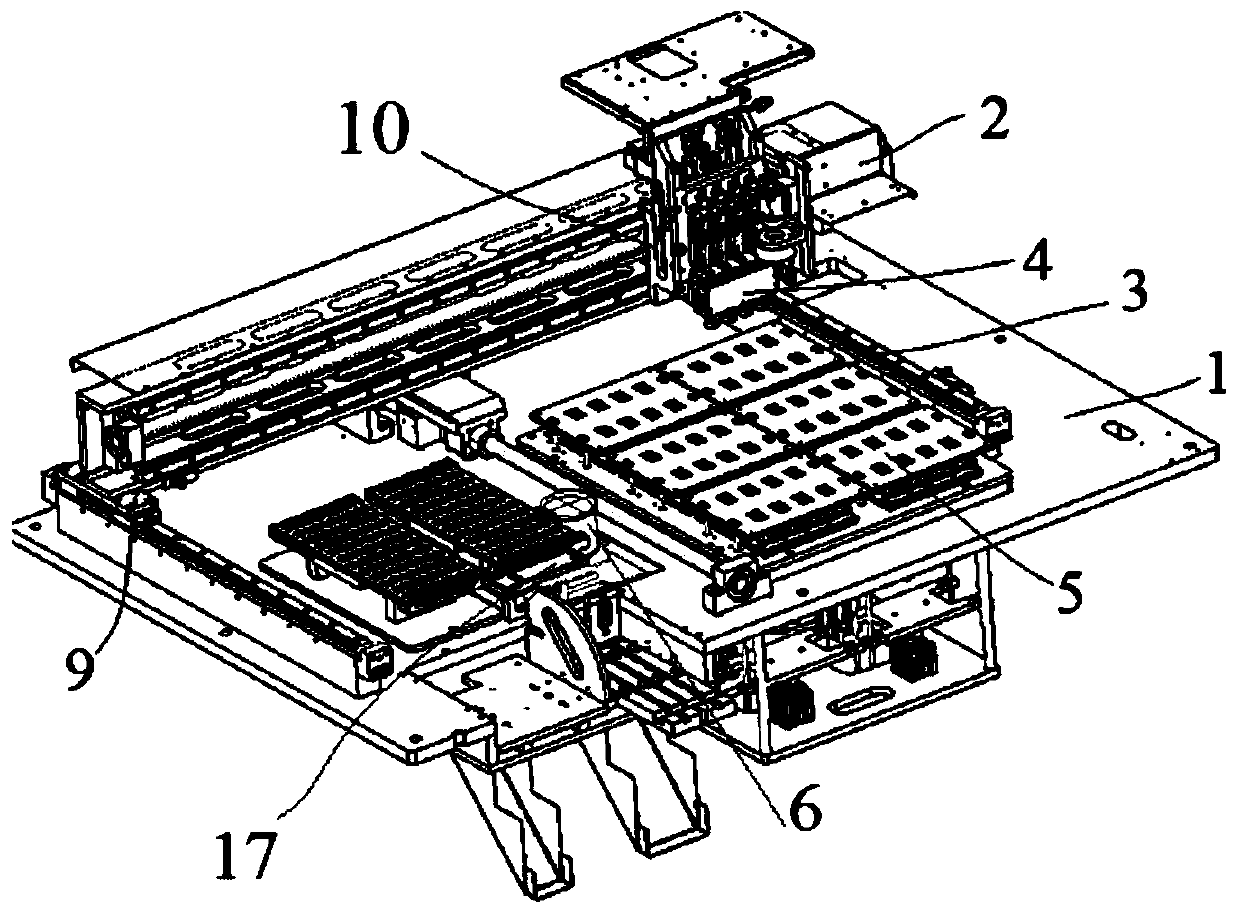

[0039] Embodiment 1: A gantry type automatic chip programming machine, including a substrate 1, an X-axis drive mechanism 2, a Y-axis drive mechanism 3, a suction mechanism 4 and a programming mechanism 5, and the Y-axis drive mechanism 3 is arranged on the substrate 1 on the upper surface, the X-axis driving mechanism 2 is installed and connected with the Y-axis driving mechanism 3 through several XY connecting blocks 9 and can reciprocate in the Y-axis direction, and the suction mechanism 4 is movably installed on the X-axis through XZ connecting blocks 10 The shaft driving mechanism 2 can reciprocate along the X-axis direction, and the burning mechanism 5 is installed on the substrate 1 and located below the suction mechanism 4;

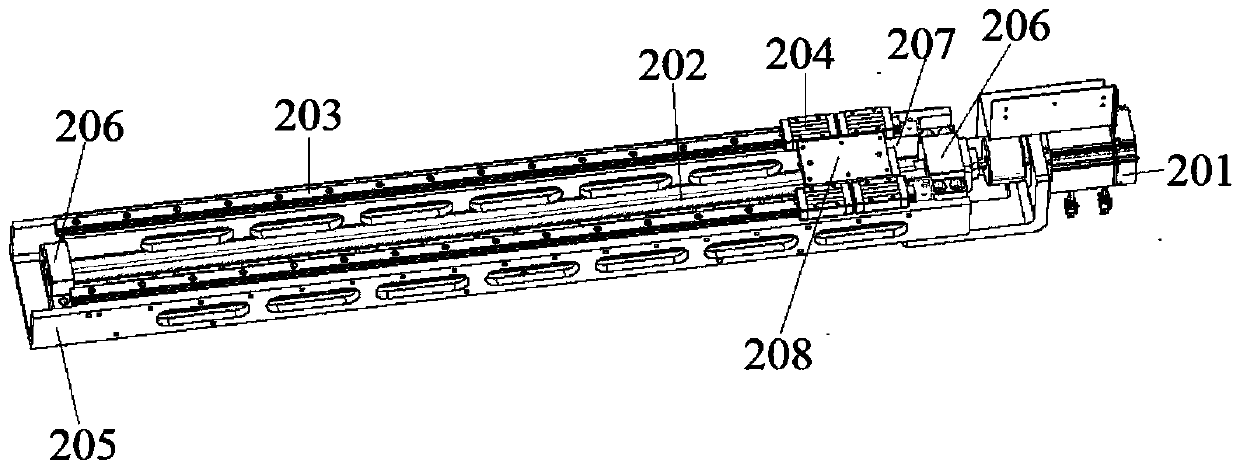

[0040] The Y-axis drive mechanism 3 further includes a Y-axis motor 301, a Y-axis screw 302 connected to the Y-axis motor 301, at least one Y-axis slide rail 303, and several Y-axis sliders movably mounted on the Y-axis slide rail 303 304, the X-a...

Embodiment 2

[0051] Embodiment 2: A gantry type automatic chip programming machine, including a substrate 1, an X-axis drive mechanism 2, a Y-axis drive mechanism 3, a material suction mechanism 4 and a programming mechanism 5, and the Y-axis drive mechanism 3 is arranged on the substrate 1 on the upper surface, the X-axis driving mechanism 2 is installed and connected with the Y-axis driving mechanism 3 through several XY connecting blocks 9 and can reciprocate in the Y-axis direction, and the suction mechanism 4 is movably installed on the X-axis through XZ connecting blocks 10 The shaft driving mechanism 2 can reciprocate along the X-axis direction, and the burning mechanism 5 is installed on the substrate 1 and located below the suction mechanism 4;

[0052]The Y-axis drive mechanism 3 further includes a Y-axis motor 301, a Y-axis screw 302 connected to the Y-axis motor 301, at least one Y-axis slide rail 303, and several Y-axis sliders movably mounted on the Y-axis slide rail 303 304,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com