Automatic egg loading machine for poultry egg production and processing

An automatic and egg-packing technology, applied in the application, poultry industry, poultry cages or houses, etc., can solve the problems of low egg packaging operation efficiency, high labor cost, slow speed, etc., to improve packaging quality and packaging efficiency, The effect of ensuring placement accuracy and improving packaging efficiency

Inactive Publication Date: 2021-05-14

XIAN XINGUIXI INFORMATION TECH CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the common automatic egg picking machines on the market generally only have the function of automatically picking up the eggs on the chicken cage and collecting them together. The eggs collected like this still need to be manually put into the egg tray one by one. The egg machine improves the efficiency of picking eggs, but due to the slow speed of manual egg loading, the operation efficiency of the entire egg packaging is still low, and manual egg loading requires a lot of labor costs

[0004] Therefore, although the existing technology can successfully realize the effect of automatic egg loading, solve the problem of consuming a lot of manpower and material resources, and improve efficiency, it is still not easy to promote and use because it cannot accurately locate the position of poultry eggs and then realize automatic picking and placing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

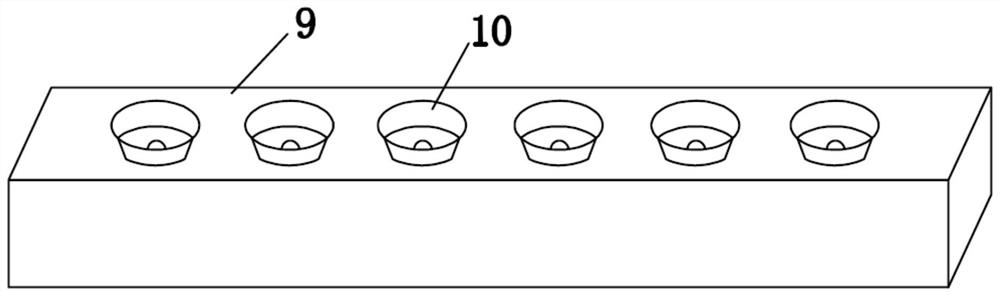

[0031] The difference from Embodiment 1 is that the trachea rod 9 is set in a plate-like structure, thereby increasing the number of absorbed eggs.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

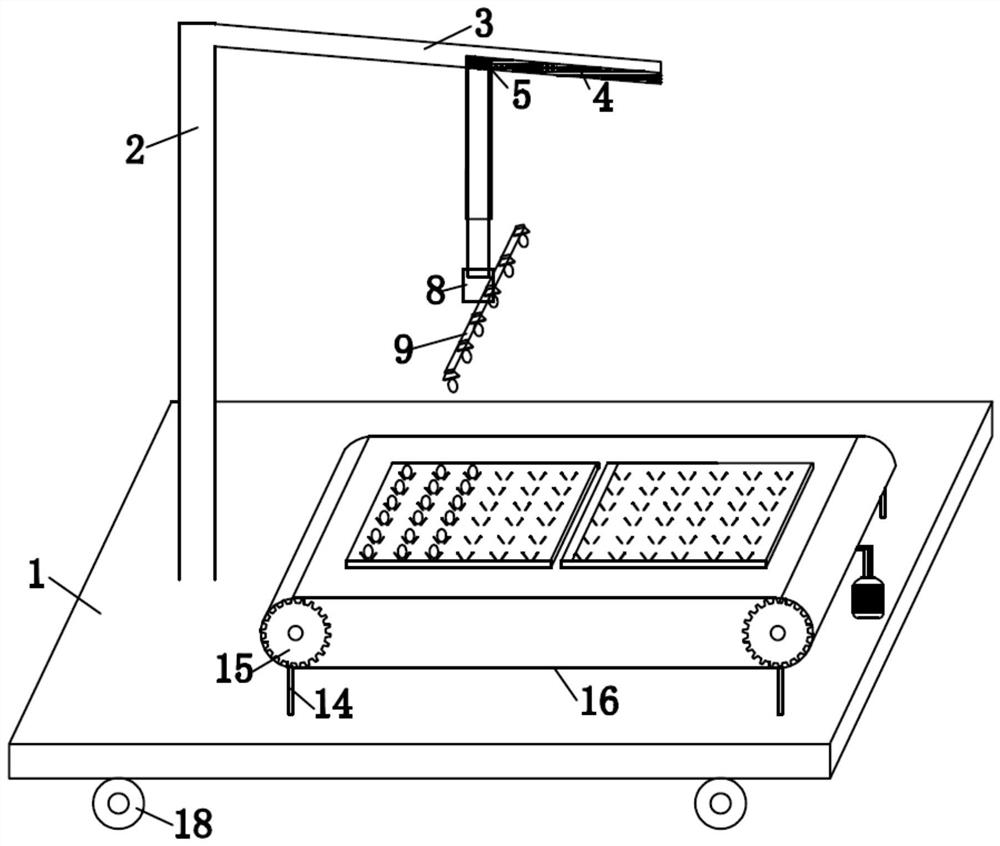

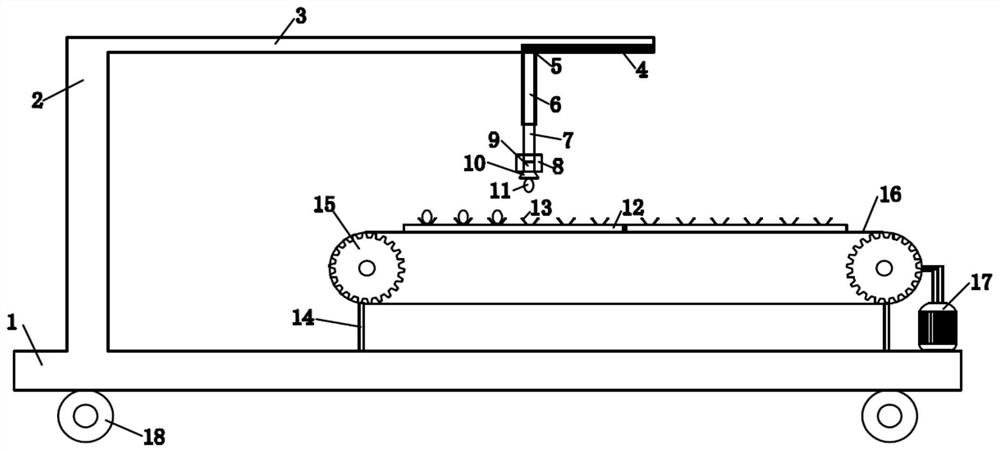

Login to View More Abstract

The invention discloses an automatic egg loading machine for poultry egg production and processing. The automatic egg loading machine comprises a bottom plate and a vertical rod, wherein the vertical rod is installed on the bottom plate, the top end of the vertical rod is connected with a transverse rod, an egg conveying device is arranged at the end, away from the vertical rod, of the transverse rod and comprises a sliding groove in the bottom of the right end of the transverse rod, the sliding groove is slidably connected with a sliding block, the sliding block is electrically connected with the output end of a motor, the bottom of the sliding block is fixedly connected with a pushing assembly, the pushing assembly comprises an electric push rod groove and an electric push rod, and the upper end of the electric push rod groove is fixedly connected with the sliding block. An existing device is improved, picking of eggs and later packaging of the eggs are completed through negative pressure adsorption, the packaging efficiency is greatly improved, the grabbing precision and the later placement precision are guaranteed when the eggs are picked, and therefore the packaging quality is improved.

Description

technical field [0001] The invention relates to the technical field of packaging equipment, in particular to an automatic egg loading machine for poultry egg production and processing. Background technique [0002] In the process of poultry and egg breeding in chicken farms, due to the large number of laying hens, a large number of eggs will be produced every day. These eggs generally need to be picked up on the same day, otherwise the eggs will be squeezed on the chicken cage and easily cracked and damaged. For eggs The picking generally adopts an automatic egg picking machine to pick up eggs. The automatic egg picking machine can automatically pick up the eggs on the chicken cage and collect them together without manual picking up one by one, which greatly improves the efficiency of picking eggs. Egg farms are widely used. [0003] However, the common automatic egg picking machines on the market generally only have the function of automatically picking up the eggs on the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A01K31/16

CPCA01K31/165

Inventor 吴华夏

Owner XIAN XINGUIXI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com