Full-automatic mounting system of tape-type flaky electronic components

A technology for electronic components and placement systems, applied in the field of automatic placement systems, which can solve problems such as low efficiency and unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

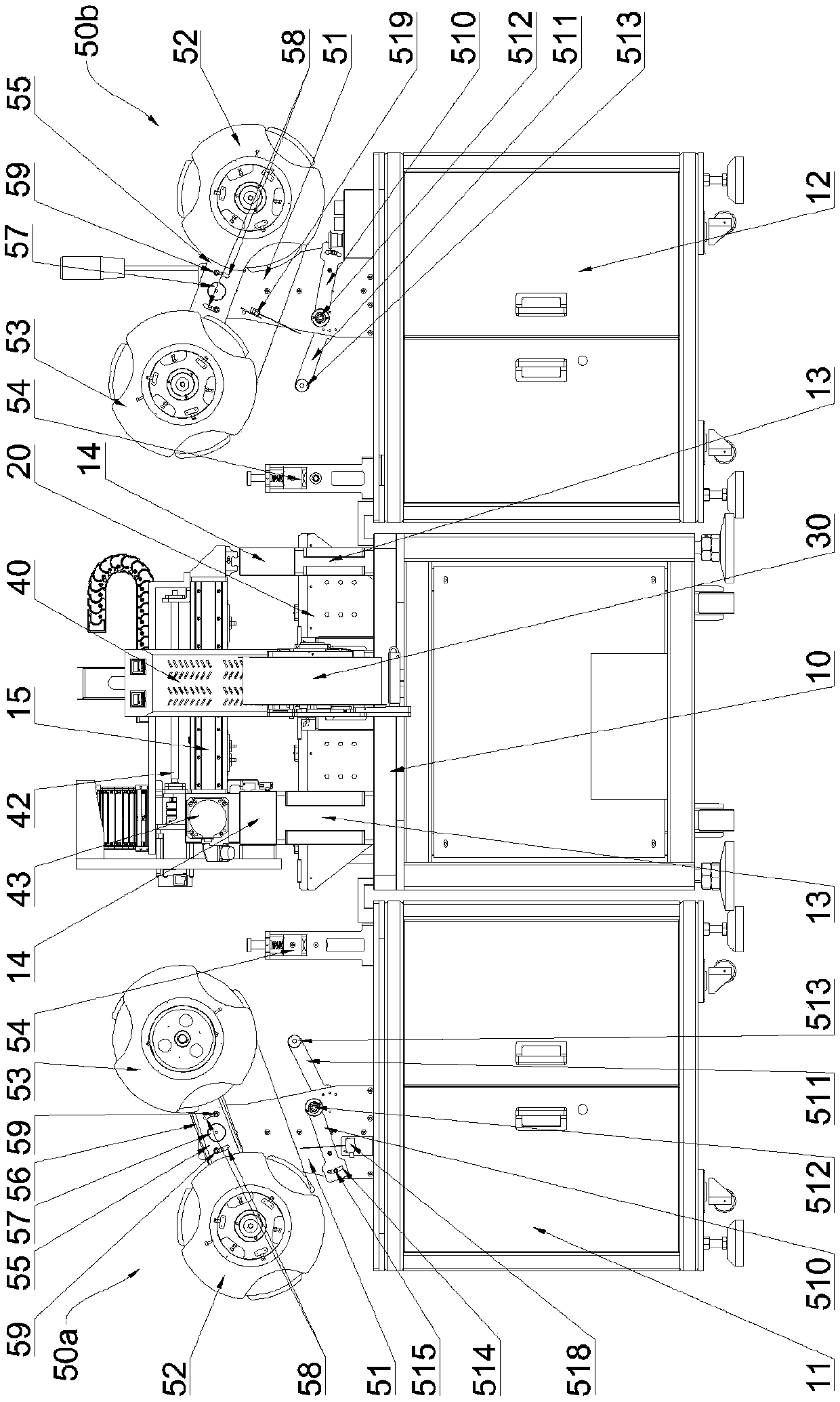

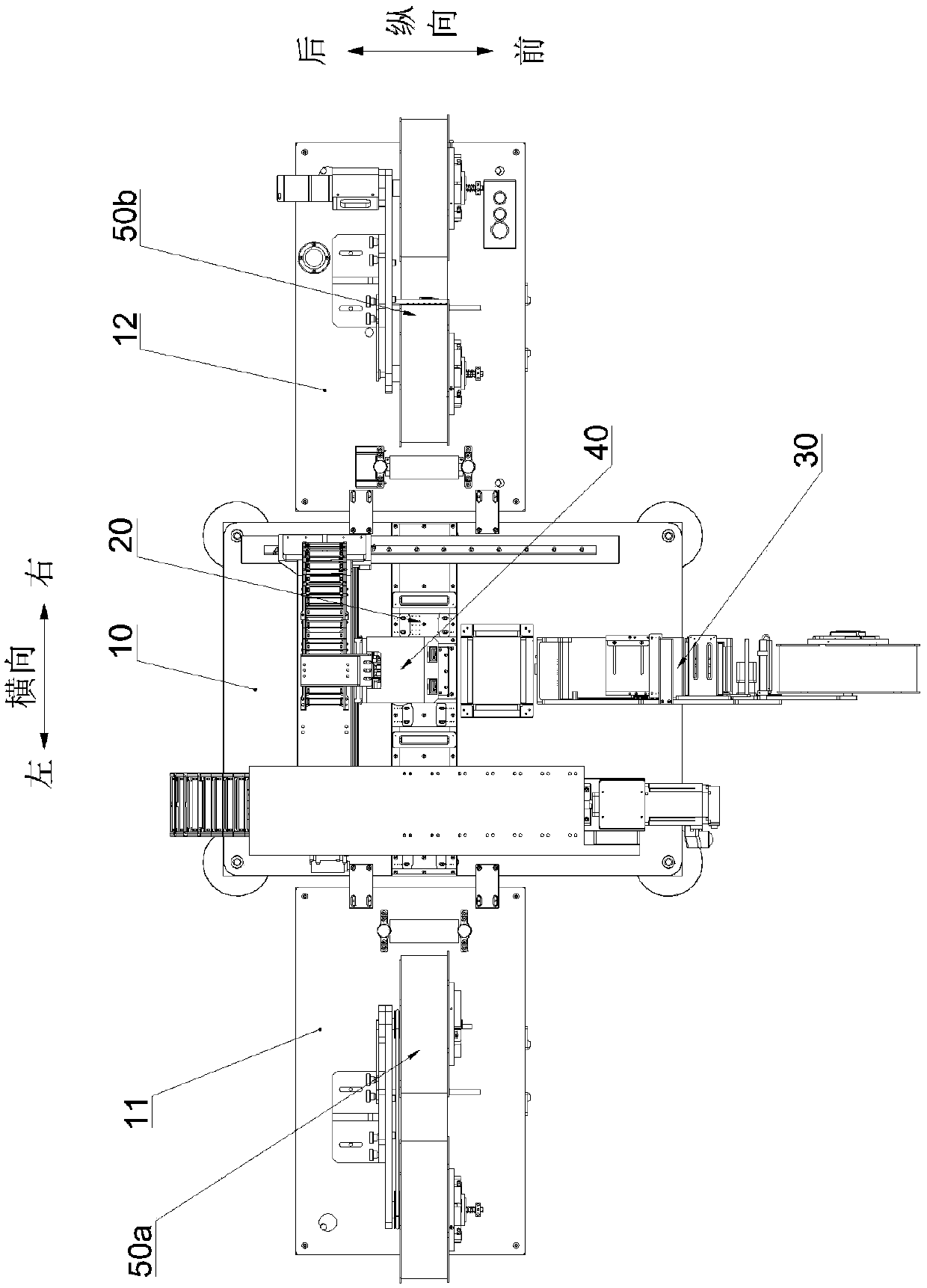

[0059] See Figure 1 ~ Figure 3 , the fully automatic placement system for braided chip electronic components of the present invention includes a rack platform 10, and it also includes a feeding and receiving device 50 for braided components and a component positioning device that is installed on the rack platform 10. Device 20, auxiliary material feeding device 30 and auxiliary material suction and placement device 40, component positioning device 20 is horizontally installed on the frame platform 10 along the horizontal direction, and the horizontal left and right ends of component positioning device 20 are respectively the feeding end of braided type components, At the discharge end, the feeding and receiving device of the braided component includes a discharging mechanism 50a and a receiving mechanism 50b. One side of the feed end and one side of the discharge end of the positioning device 20, and the discharging mechanism 50a, the component positioning device 20, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com