Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Guaranteed electrical connection performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

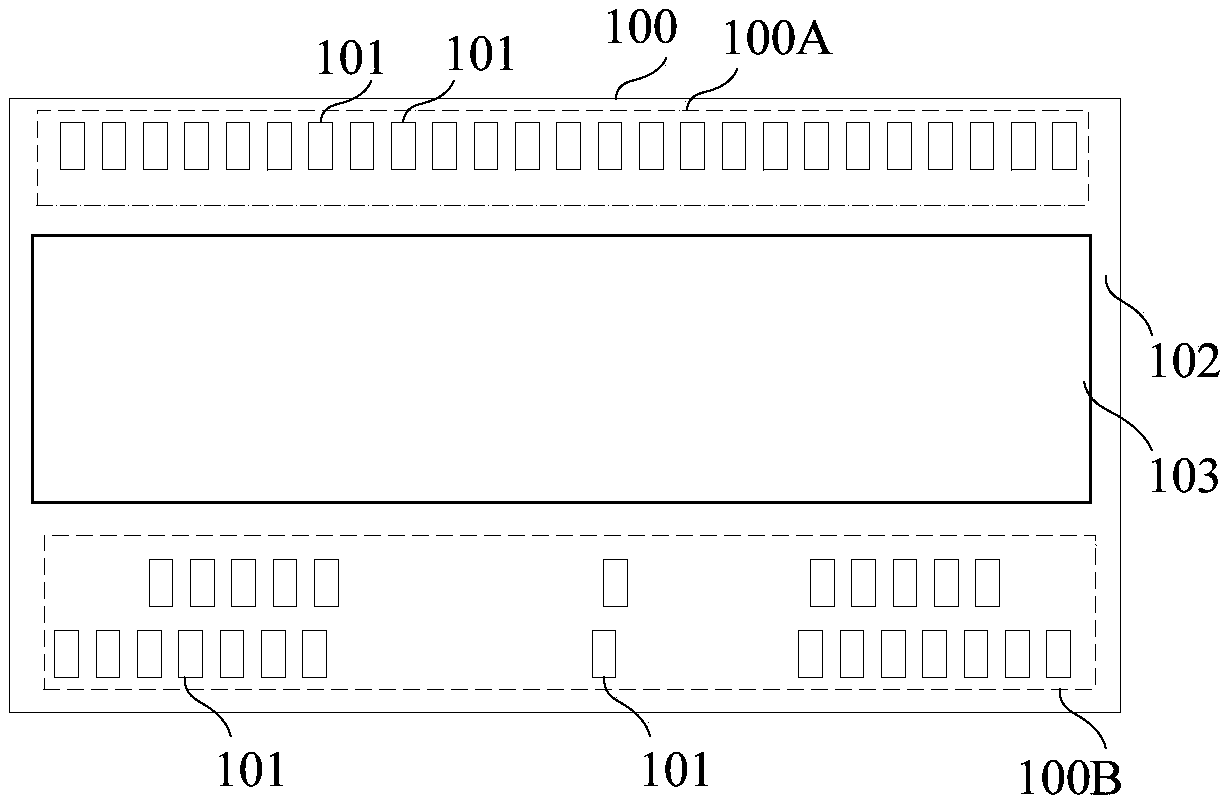

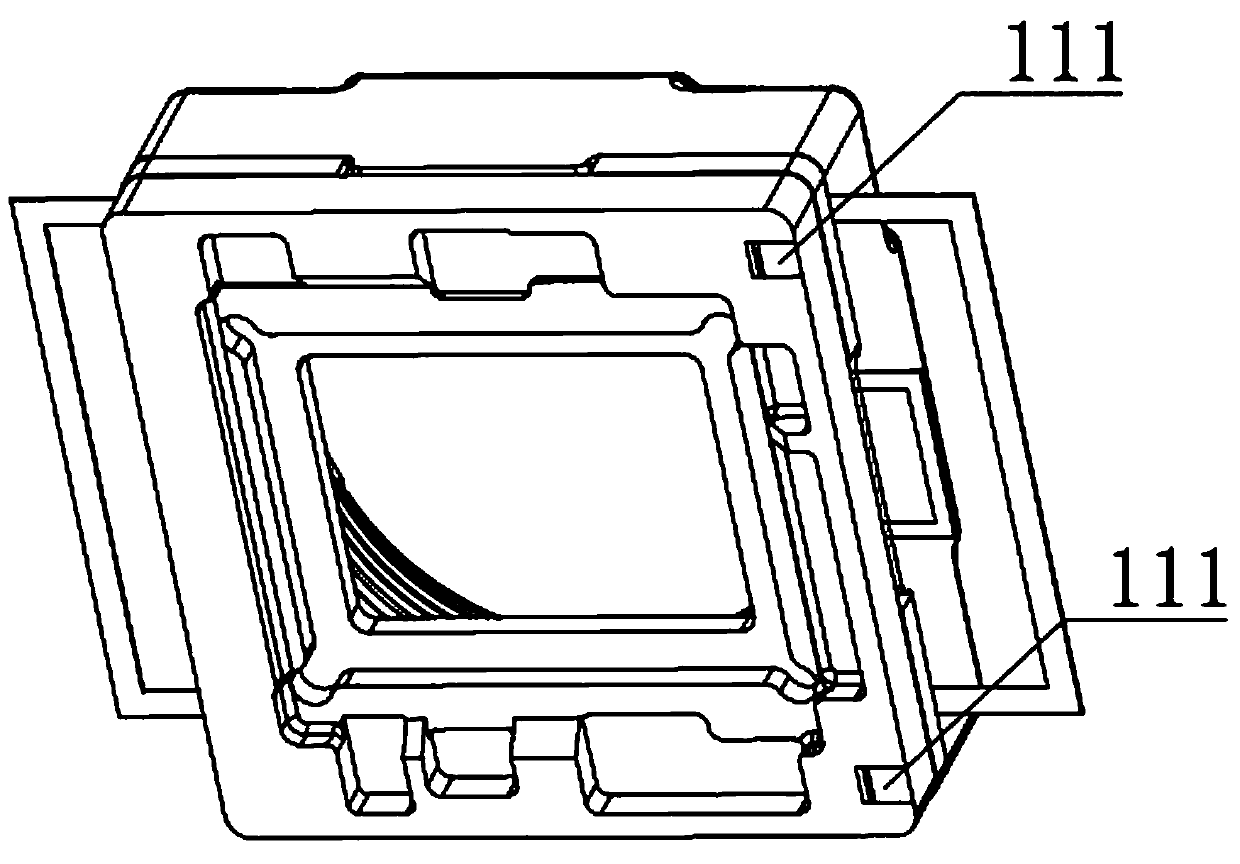

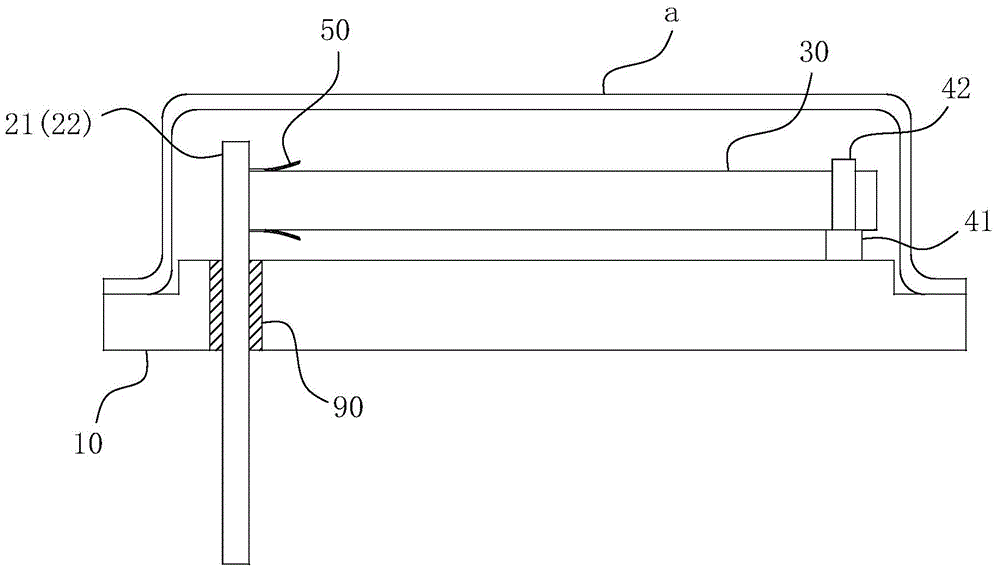

Circuit board module

InactiveCN102238806ADoes not affect reliabilityGuaranteed electrical connection performanceCoupling device connectionsStacked spaced PCBsRestoring forceElectrical and Electronics engineering

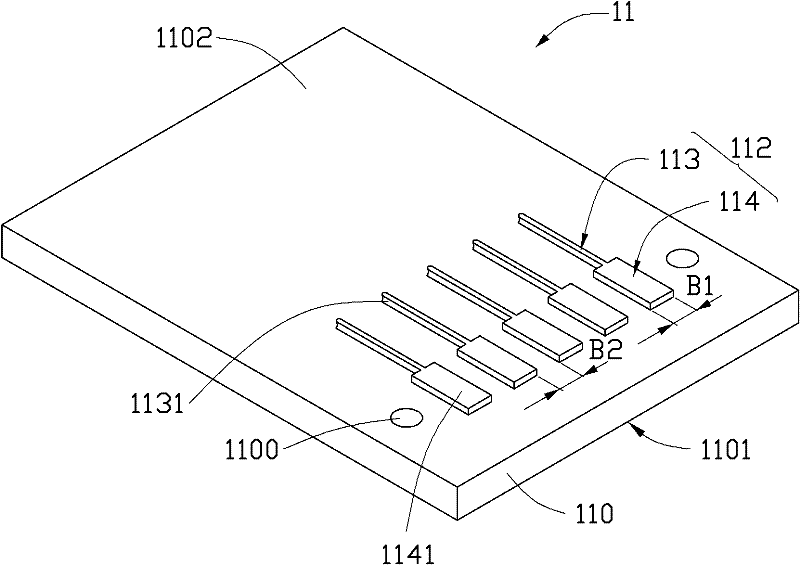

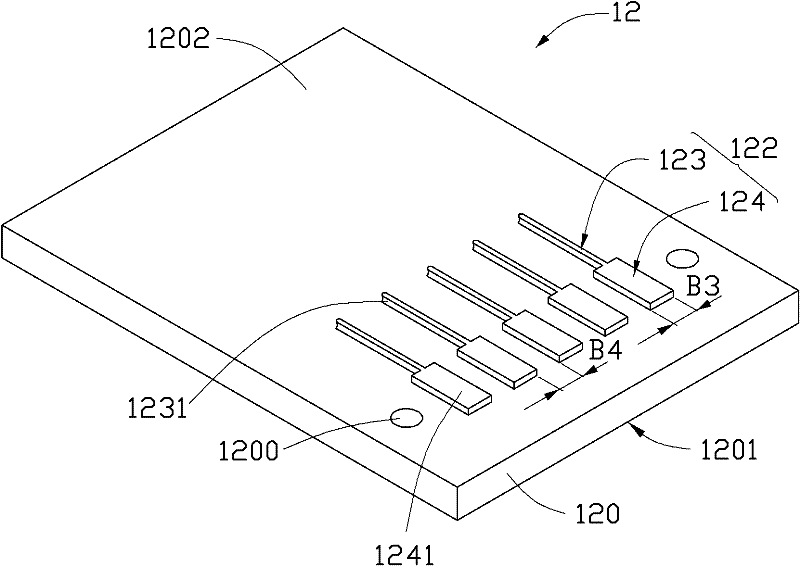

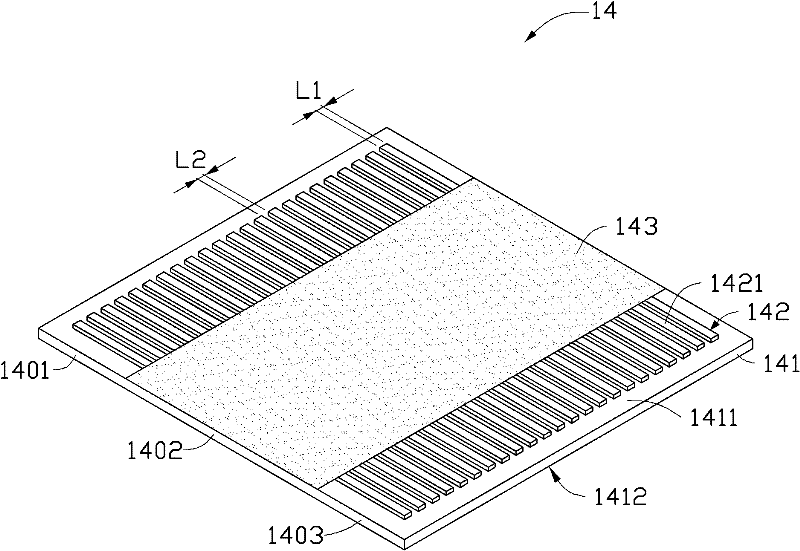

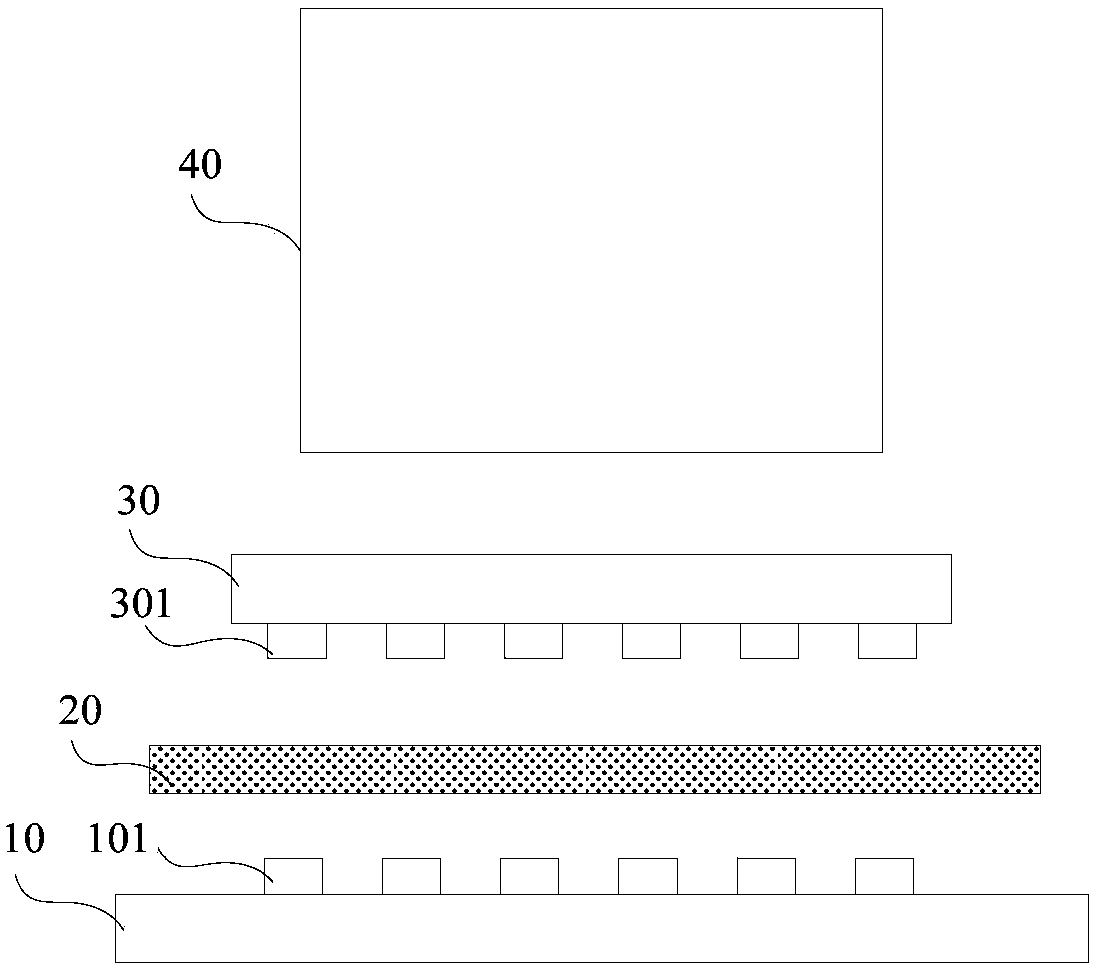

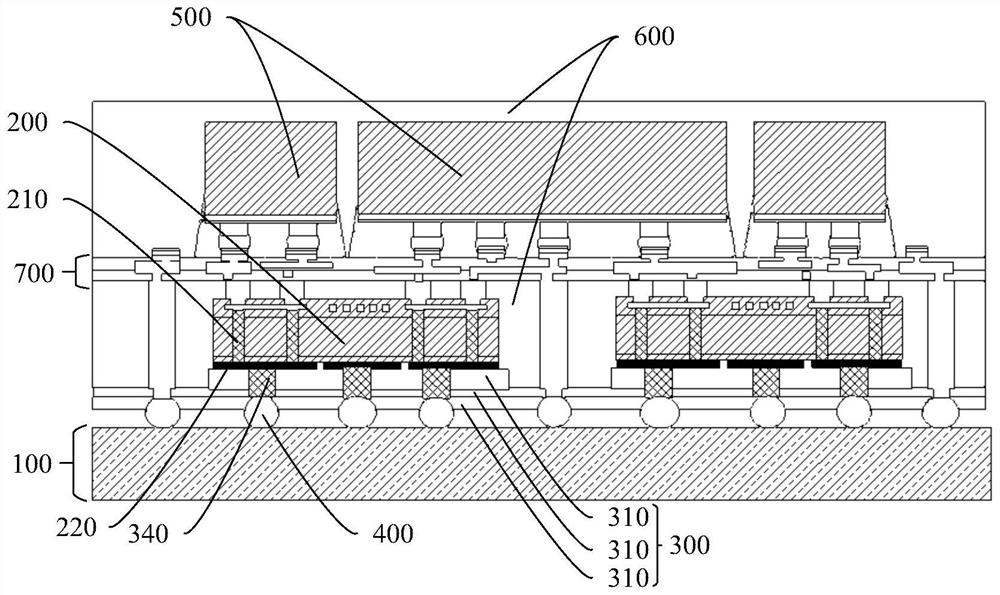

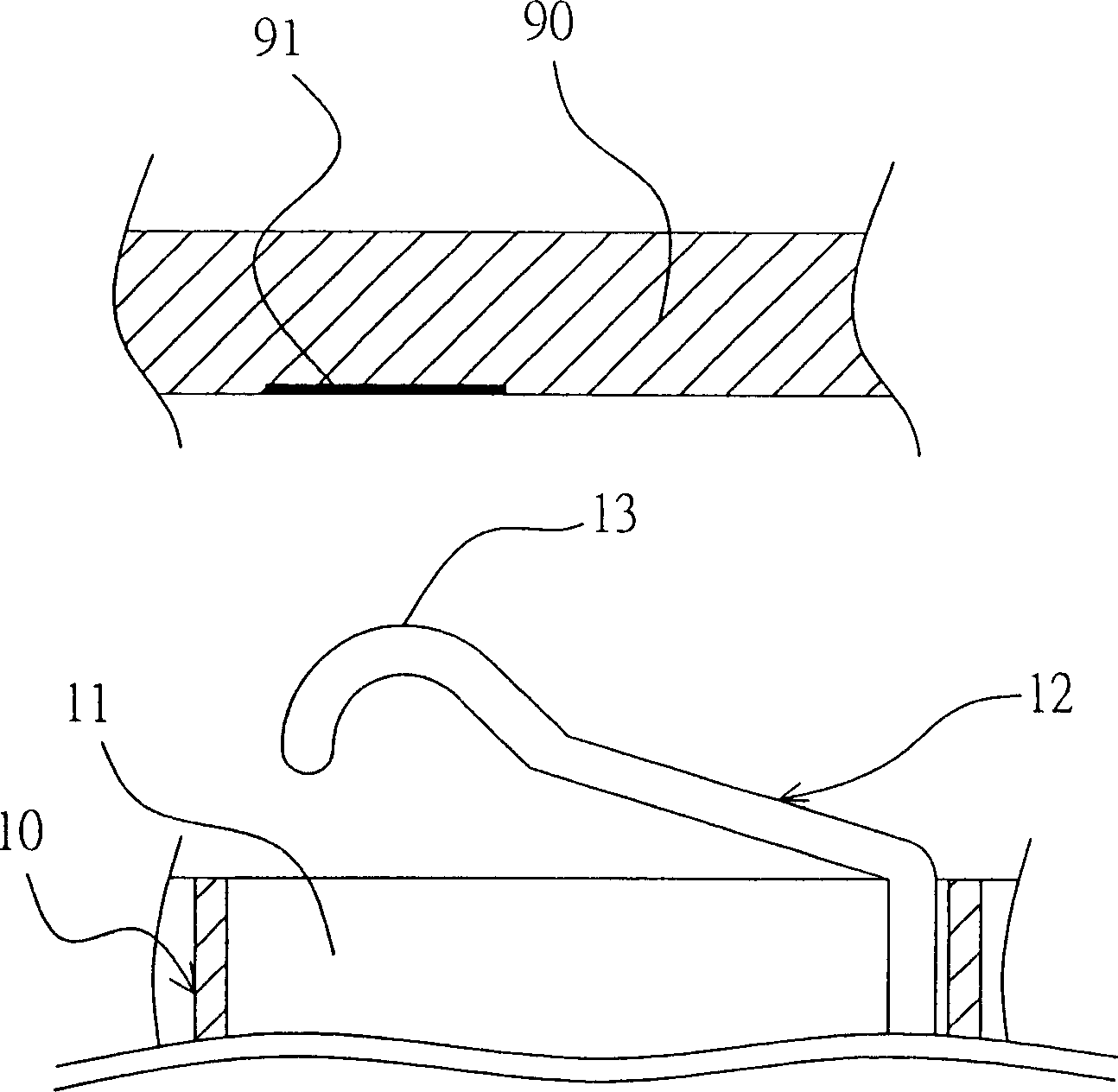

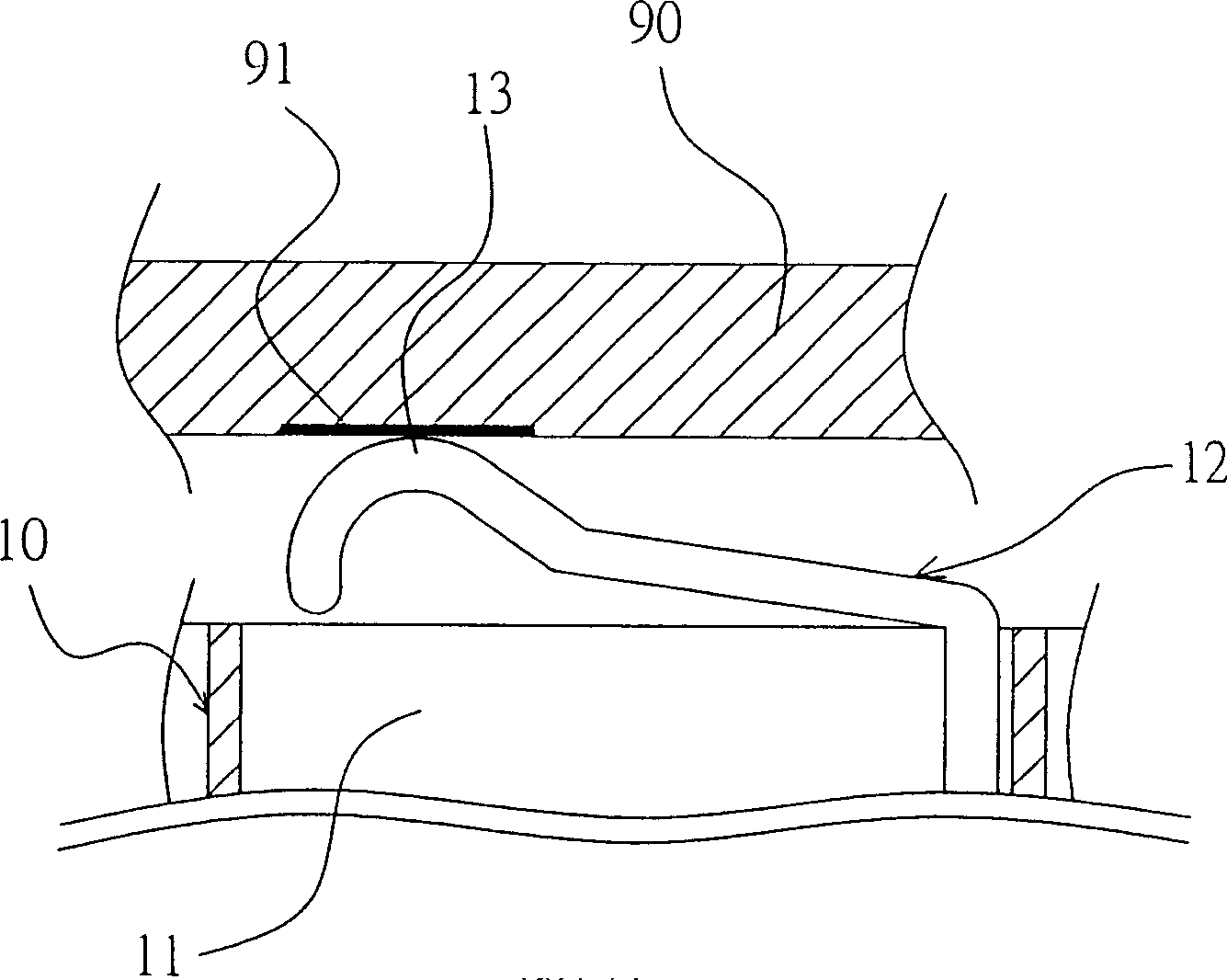

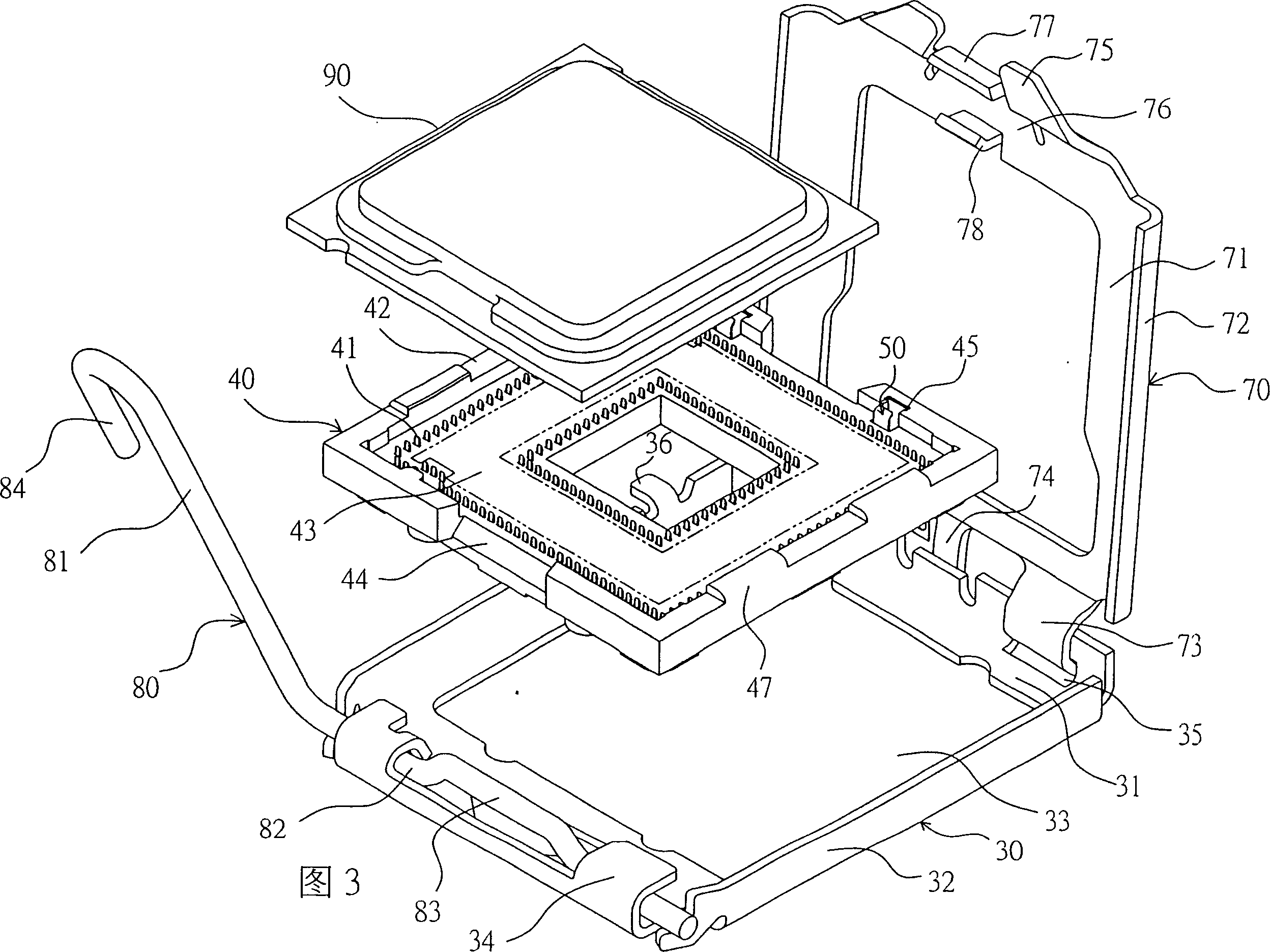

The invention provides a circuit board module. The circuit board module comprises a first circuit board, a second circuit board and a connecting assembly, wherein the first circuit board is provided with a plurality of first connecting terminals; the second circuit board is provided with a plurality of second connecting terminals; the connecting assembly comprises a flexible connecting plate, an elastic element and a fixing element; the flexible connecting plate is positioned between the first circuit board and the second circuit board and comprises a first connecting part, a bending part and a second connecting part which are sequentially connected with one another, and a plurality of connecting lines which are extended from the first connecting part to the second connecting part and are insulated from one another; and the flexible connecting plate is bent to enable the first connecting part to contact the plurality of first connecting terminals and the second connecting part to contact the plurality of second connecting terminals. The elastic element is positioned between the first connecting part and the second connecting part, the fixing element is used for fixing the first circuit board and the second circuit board, and the elastic element is enabled to generate a compressed deformation, so that the electrical connecting performance of the first circuit board and the second circuit board is ensured according to an elastic restoring force of the elastic element.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

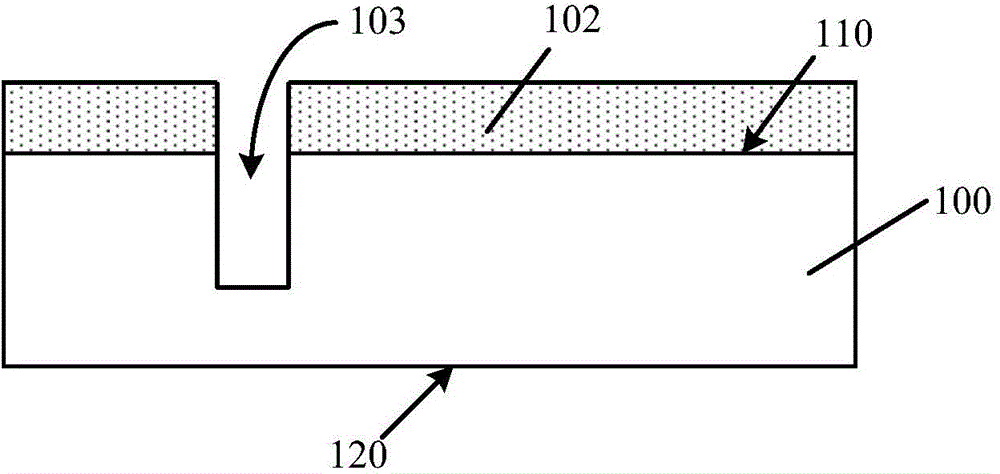

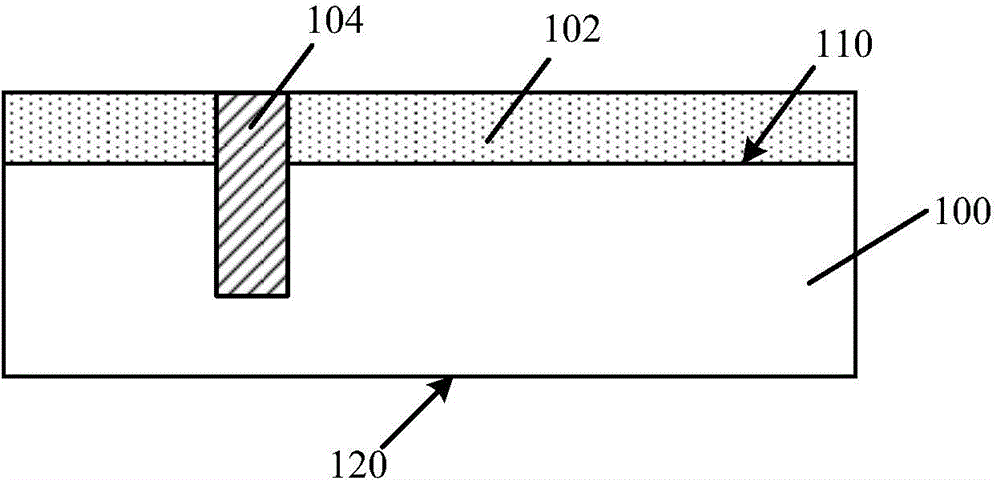

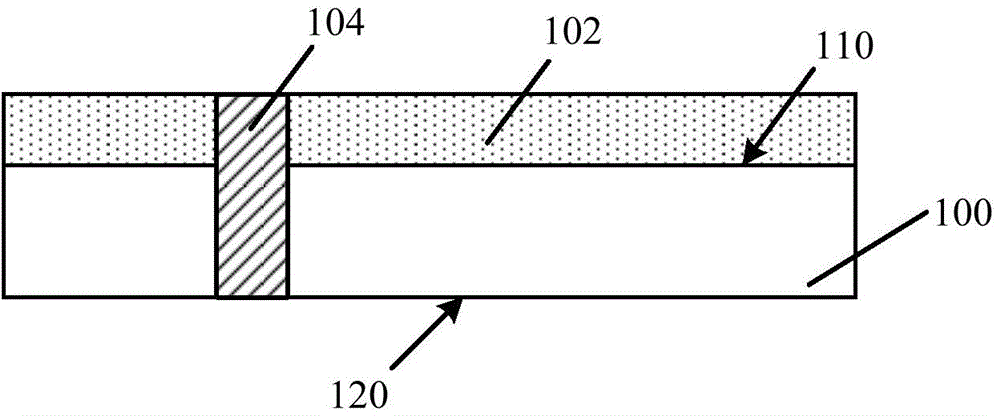

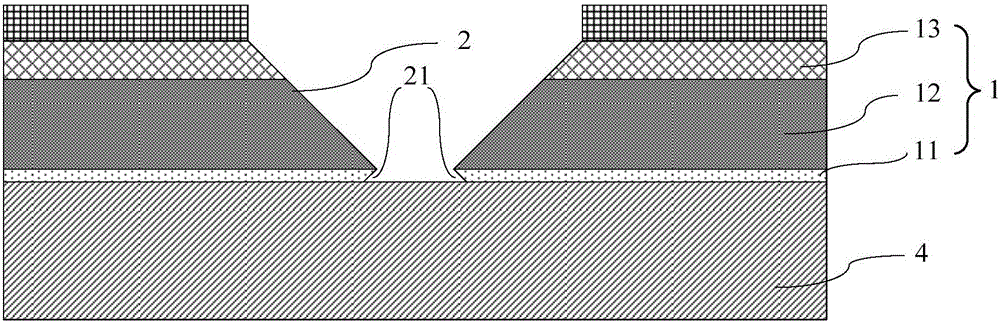

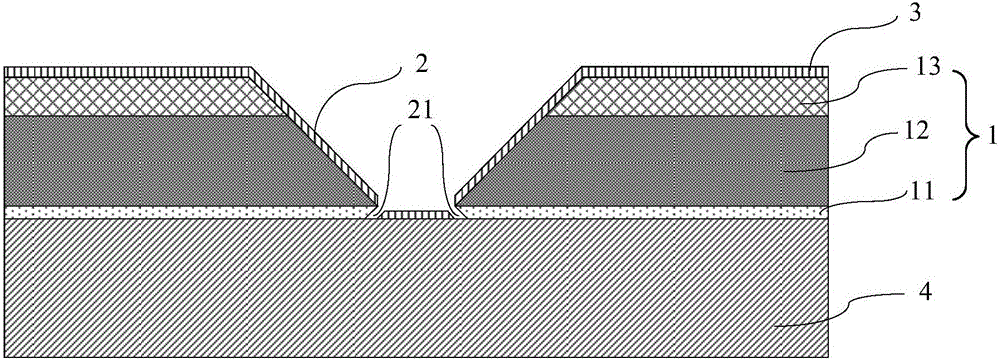

Display substrate and manufacturing method thereof, display panel and display device

ActiveCN109860224AAvoid air bubblesGuaranteed electrical connection performanceSolid-state devicesSemiconductor devicesAnisotropic conductive filmInsulation layer

The invention discloses a display substrate and a manufacturing method thereof, a display panel and a display device, and belongs to the field of displays. The display substrate includes a bonding area, a plurality of bonding pads arranged at intervals are arranged at the bonding area, the bonding pads are separated from one another through an insulation layer, and the insulation layer between atleast two adjacent bonding pads is provided with a groove. The insulation layer between at least two adjacent bonding pads is provided with the groove to allow an ACF (Anisotropic Conductive Film) toflow to the grooves when pressing-down of the ACF is performed to ensure the uniform distribution of the ACFs between the at least two adjacent Pads so as to solve the unfairness caused by difficult ACF glue discharge between the display substrate and a drive IC (Integrated Circuit), avoid a condition that bubbles are generated due to unfairness of the ACFs and ensure the electrical connection performance between the display substrate and the drive IC.

Owner:BOE TECH GRP CO LTD +1

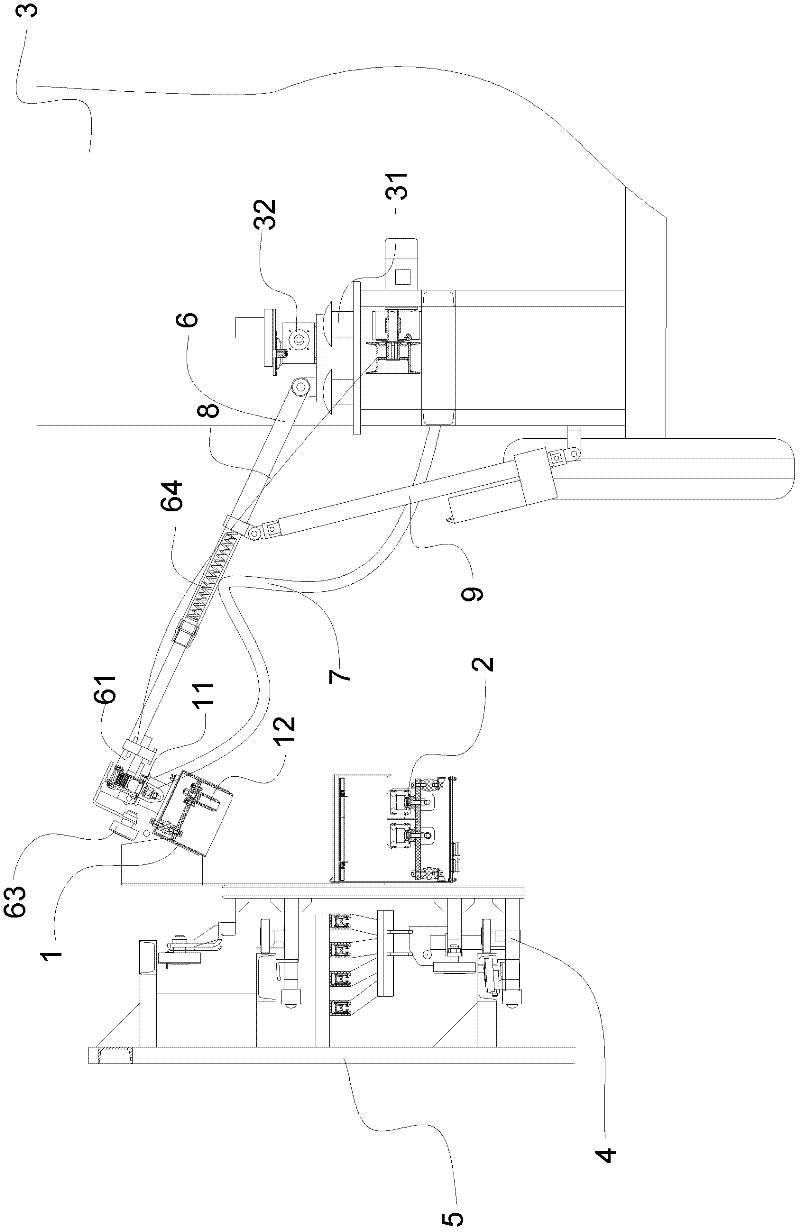

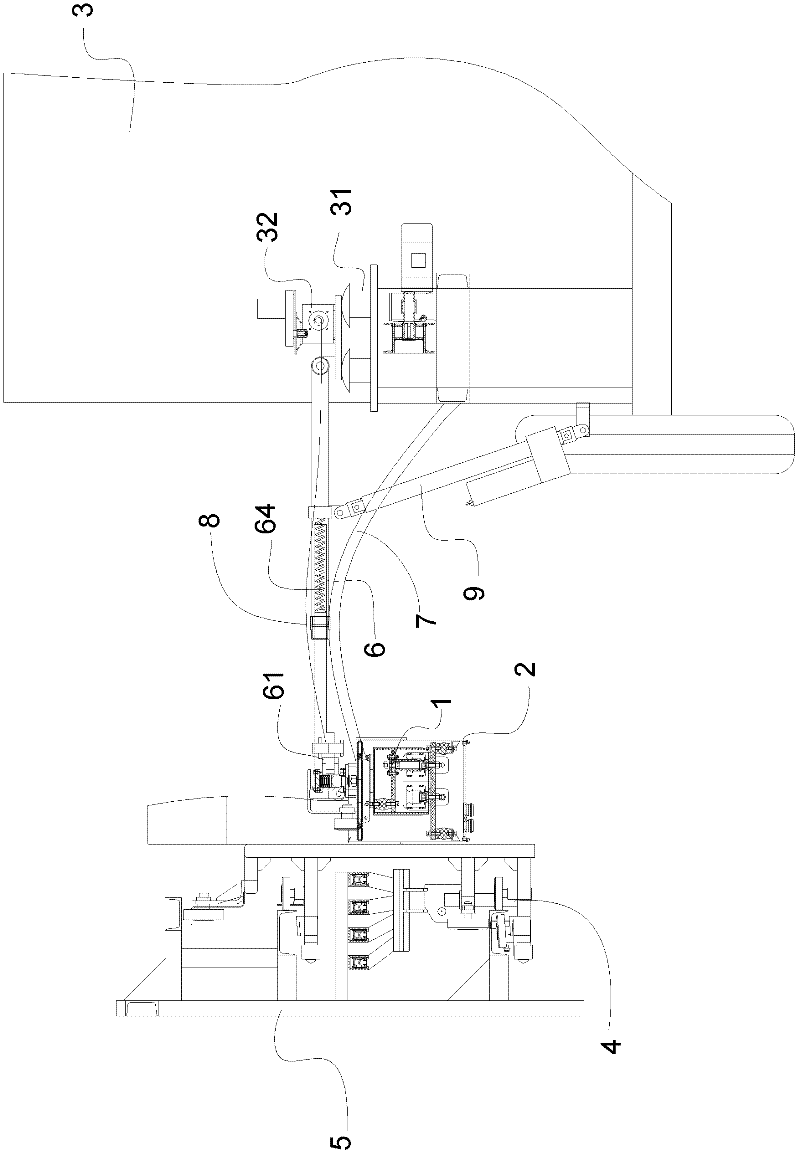

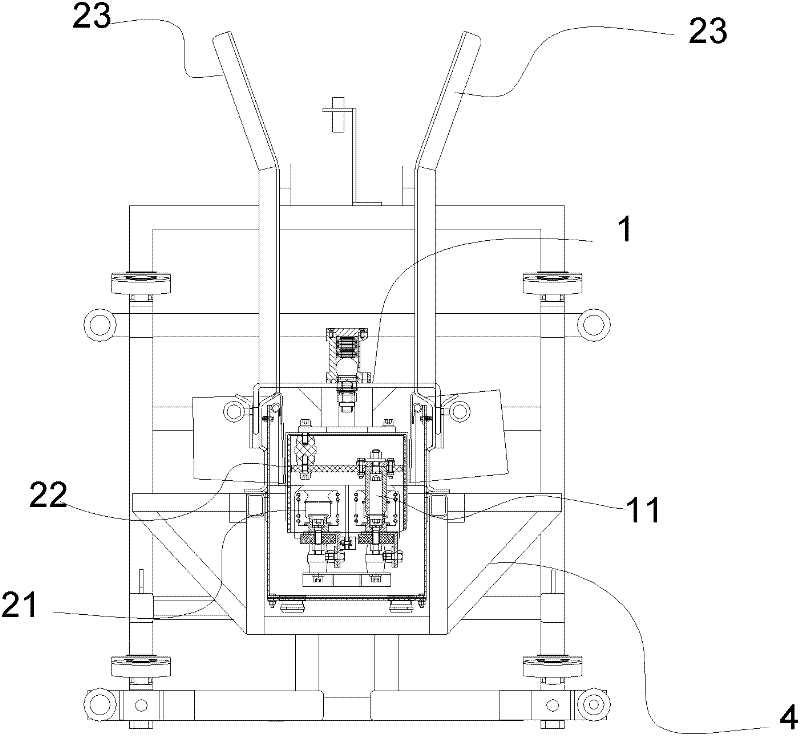

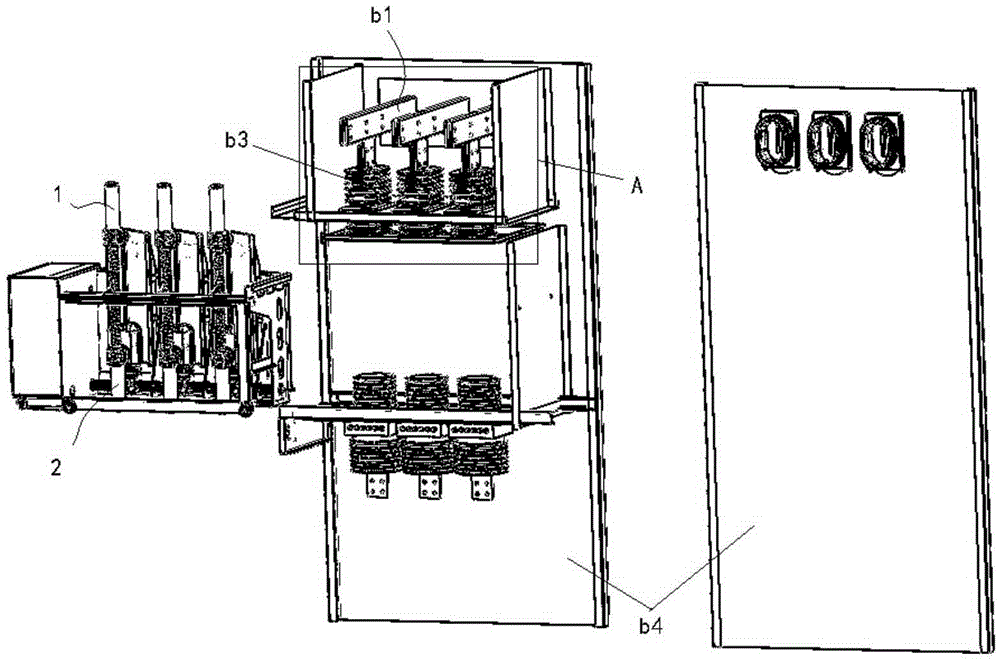

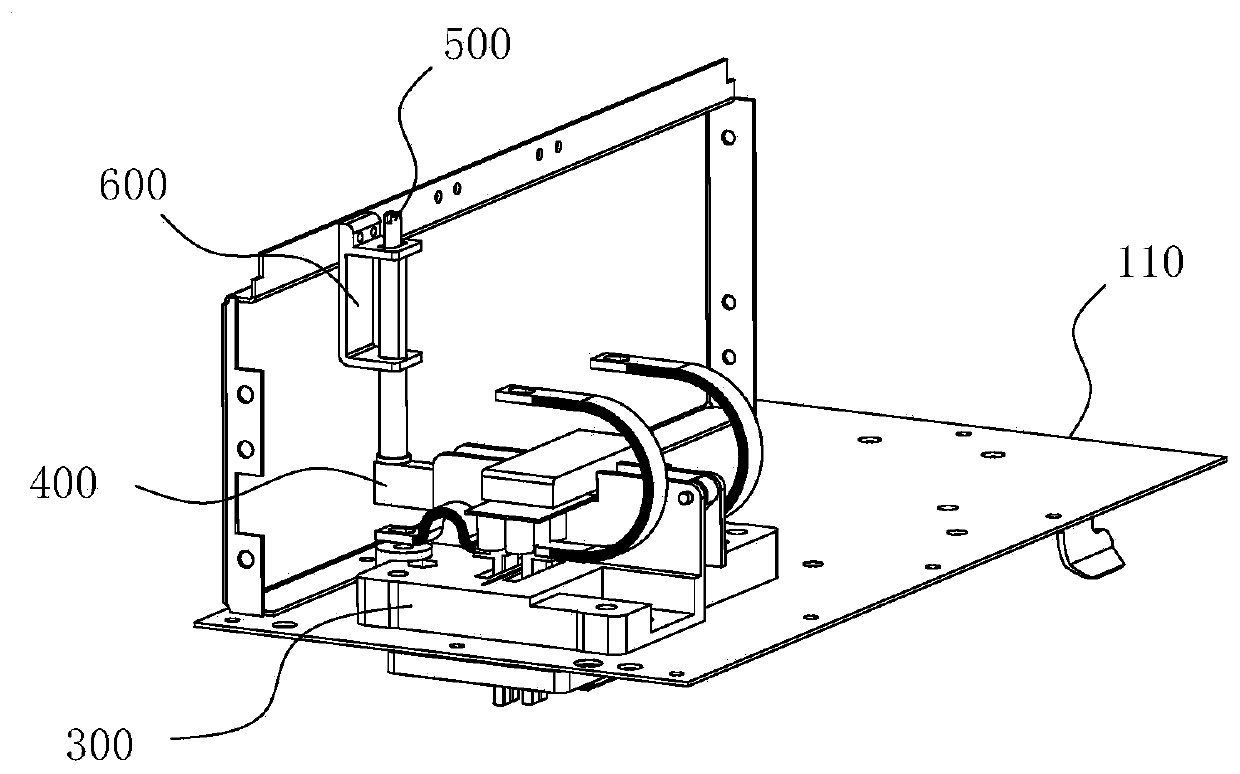

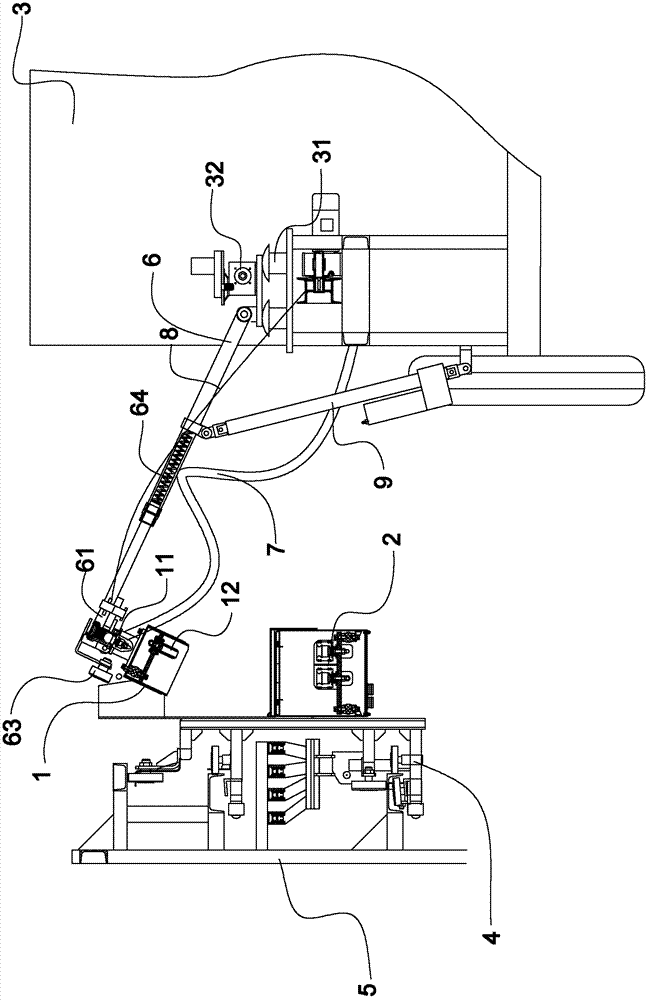

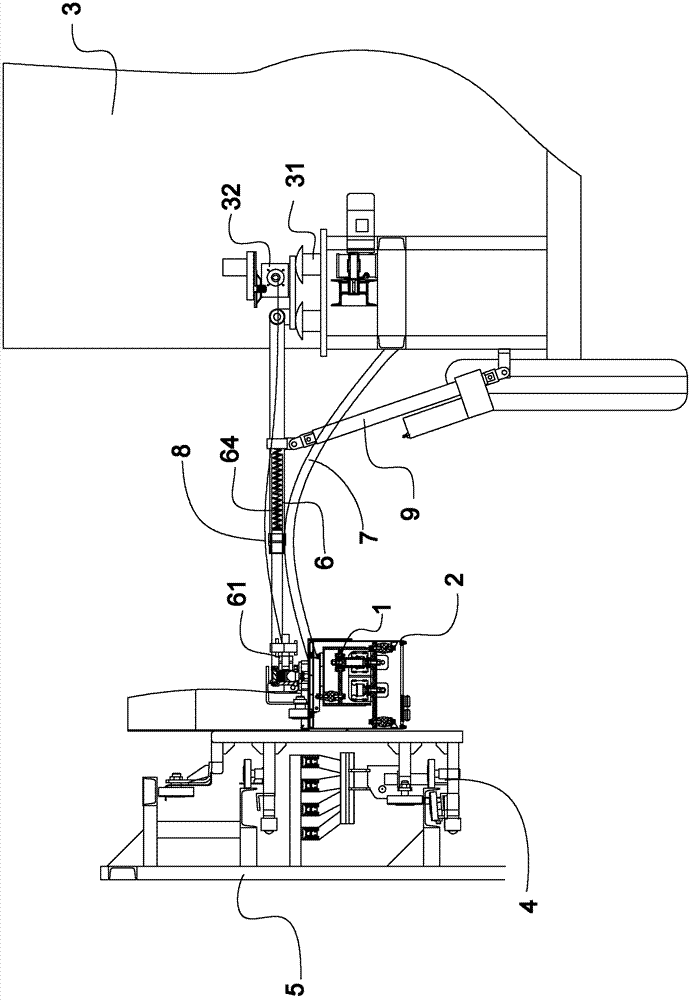

Automatic electricity conversion apparatus for rubber-tyred crane transmission

ActiveCN102363504AHigh protection levelReduce quality problemsLoad-engaging elementsElectricityEngineering

The invention relates to an automatic electricity conversion apparatus for the rubber-tyred crane transmission. The apparatus which comprises an electricity getting dolly which is fixed on a sliding contact wire and can move on the sliding contact wire is characterized in that: the electricity getting dolly has a socket; a rubber-tyred crane has a movable plug; the plug is inserted into the socket to make the rubber-tyred crane get electricity from the sliding contact wire; and the rubber-tyred crane has a plugging mechanism for inserting the plug into the socket or pulling the plug out of the socket. The electricity getting dolly is directly arranged on the sliding contact wire in the invention, so the reduced mass of conveying rods allows the service life and performances of the conveying rods to be guaranteed, the protection level of the sliding contact wire to be improved and connecting performances between the electricity getting dolly and the sliding contact wire to be improved.

Owner:NINGBO WEILONG PORT MASCH CO LTD

Semiconductor structure and formation method therefor

InactiveCN105336672AReduce volumeImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The invention discloses a semiconductor structure and a formation method therefor. The formation method comprises the steps that a substrate is provided, wherein the substrate is provided with a first surface and a second surface that are opposite; a first plug is formed in the substrate, wherein the first plug is provided with a first end and a second end; the first end of the first plug is flush with the first surface of the substrate; the second end of the first plug is positioned in the substrate; the length of the first plug is a first size; the second surface of the substrate is thinned after the first plug is formed until the thickness of the substrate is a second size, wherein the second size is larger than the first size; a second plug is formed in the substrate after the second surface of the substrate is thinned, wherein the second plug is positioned in the surface of the second end of the first plug; the top of the second plug is flush with the second surface of the substrate; a conductive plug is formed by the first plug and the second plug; and the conductive plug penetrates through the substrate. The reliability and the stability of the semiconductor structure are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

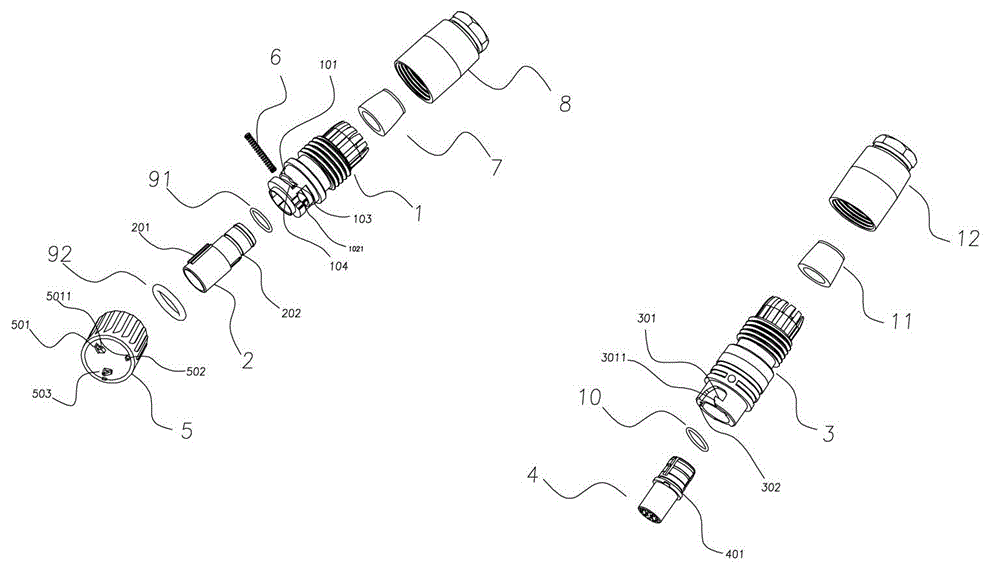

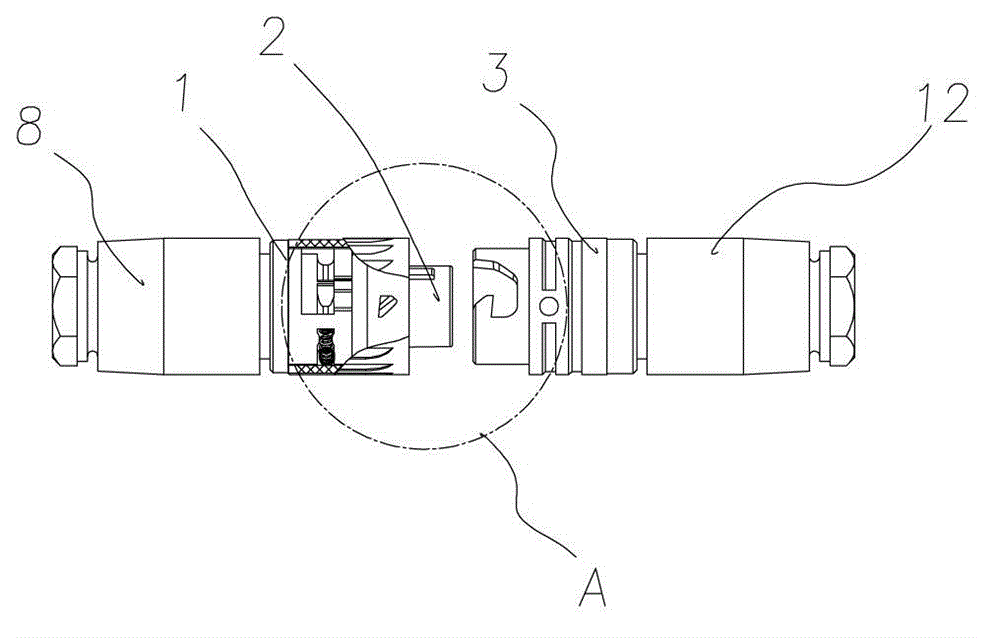

Low-intermodulation compatible type connection radio frequency socket and plug and operation method thereof

ActiveCN104577400AOvercome Contact NonlinearityLow intermodulation characteristicsEngagement/disengagement of coupling partsCoupling device engaging/disengagingElectrical conductorEngineering

The invention provides a low-intermodulation compatible type connection radio frequency socket and plug. The socket comprises an outer socket conductor, an inner jack conductor, a socket insulating support, an end face reed and a radial reed. The outer socket conductor is internally provided with an annular groove matched with and coupled to an outer plug conductor. The inner side of the annular groove is the front-segment tongue diameter, and the end face of the annular groove is a mechanical benchmark face. The front-segment tongue diameter and the mechanical benchmark face are designed to be of an integrated structure. The inner plug conductor in the plug is internally provided with an annular groove matched with and coupled to the outer socket conductor and an unlocking sleeve. The inner side of the annular groove is matched with the outer side of a socket-shaped groove in the radial direction, the satisfactory axial matching length is set, and the bottom of the annular groove is the mechanical benchmark face. According to the low-intermodulation compatible type connection radio frequency socket and plug, improvement is conducted on the mechanical benchmark face and electrical benchmark face separating design and contact outer conductor slotting design in the prior art, continuity of full-spectrum characteristic impedance and electric connectivity of a contact port are guaranteed, intermodulation interference and reflection coefficients are further lowered, and wider working bands and excellent return losses are achieved.

Owner:WUTONG HLDG GRP CO LTD +1

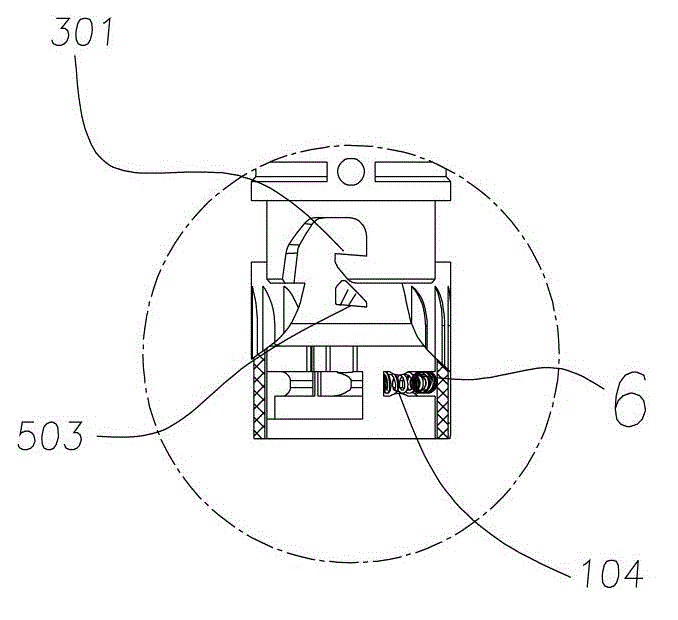

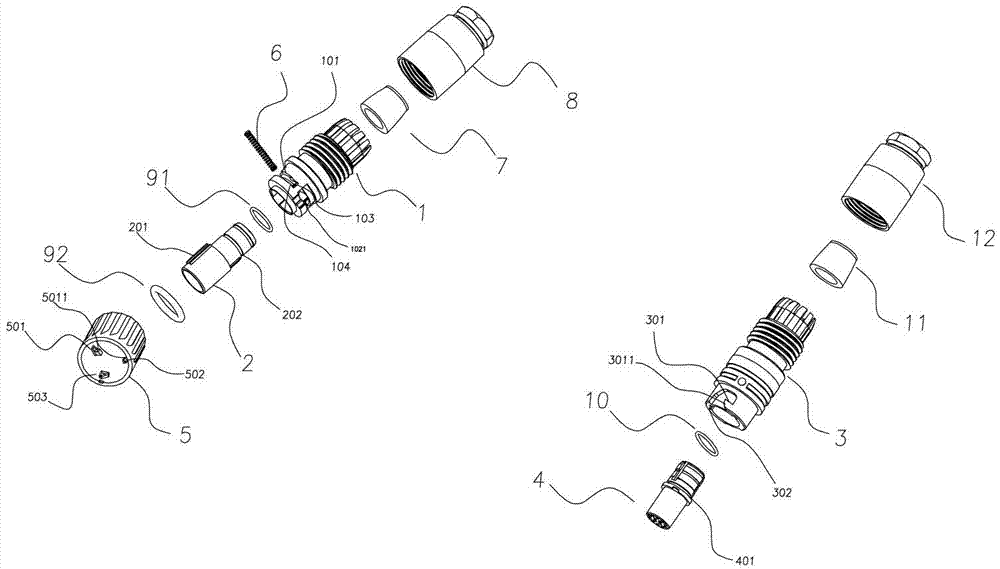

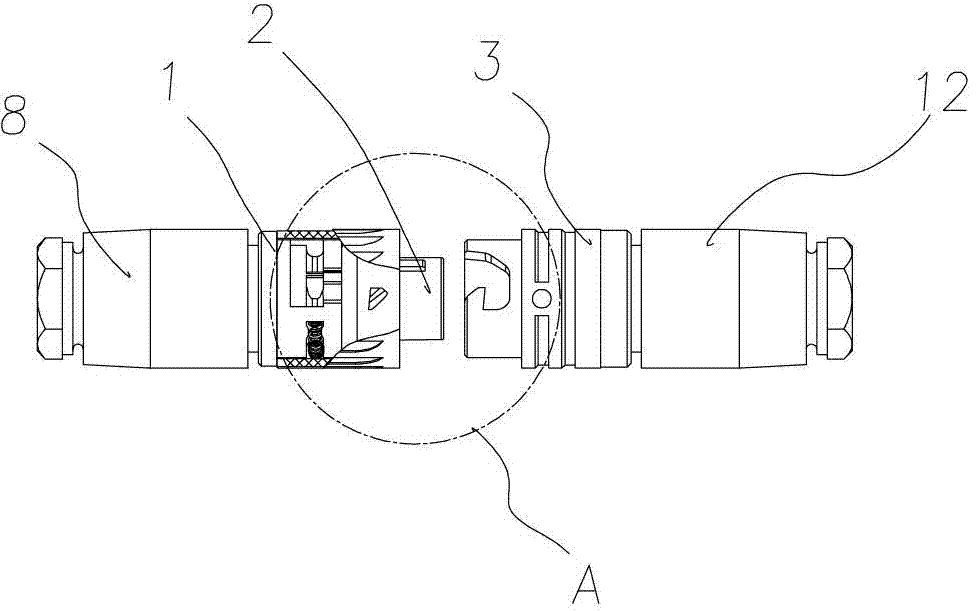

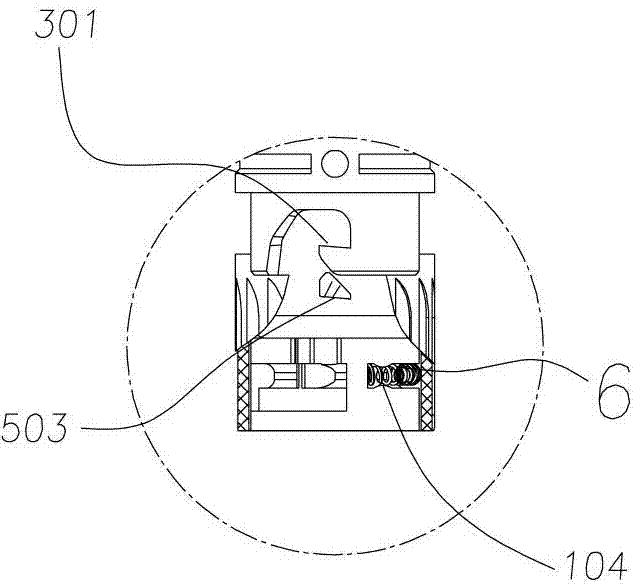

Self-locking type electric connector

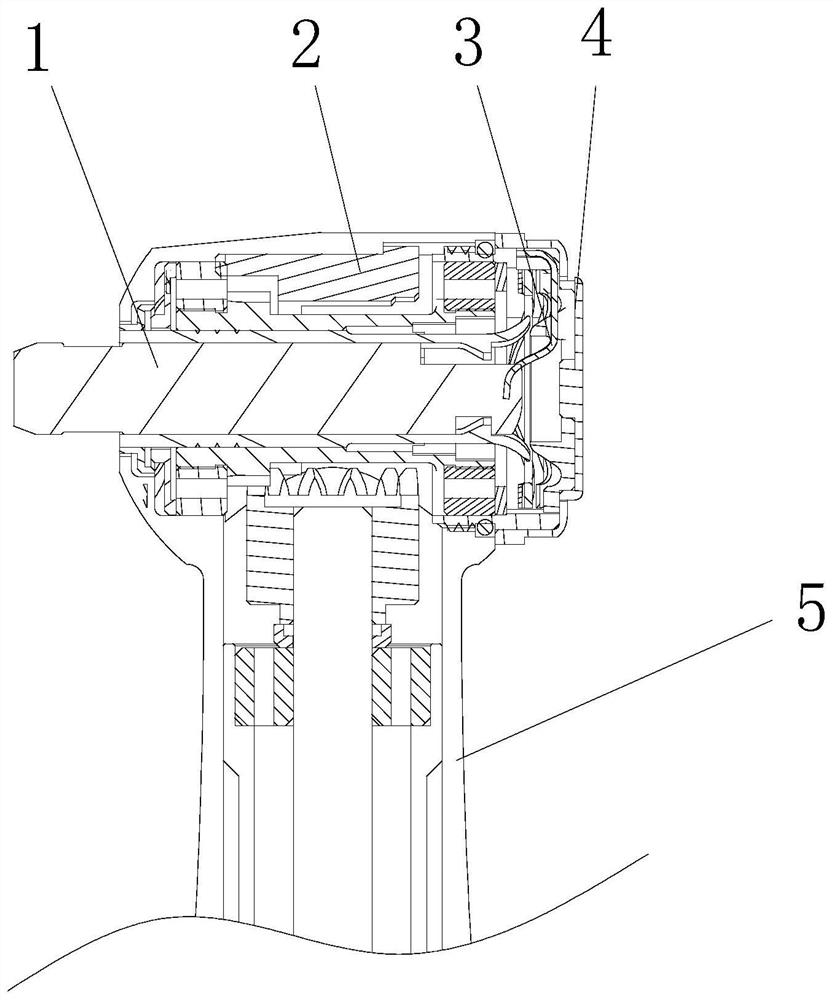

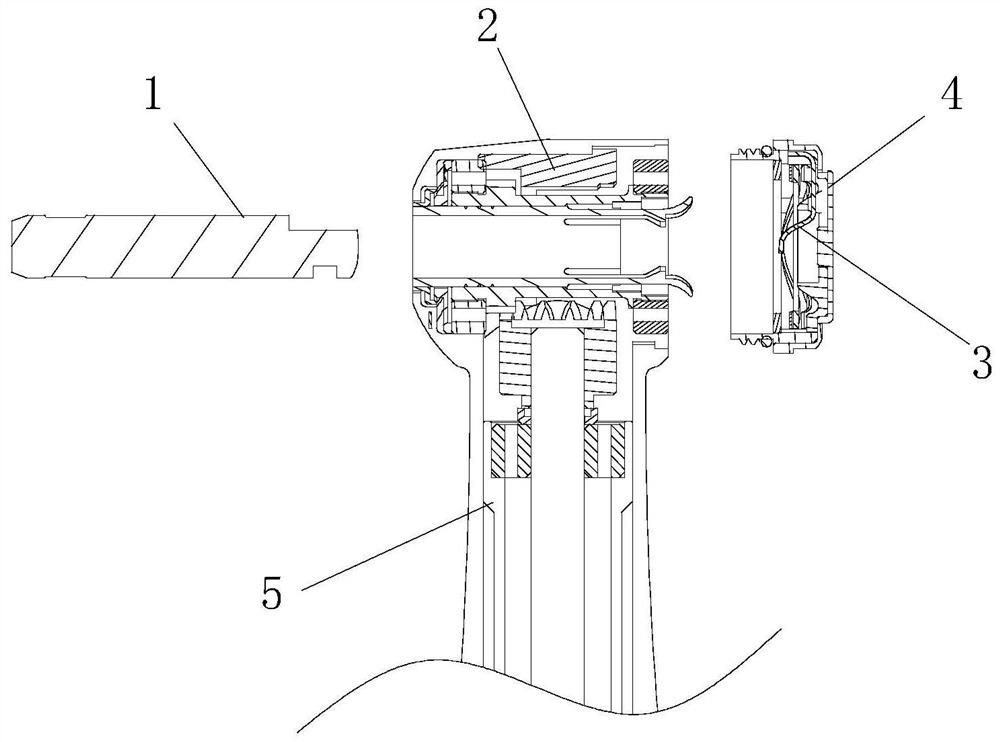

InactiveCN102882064AGuaranteed electrical connection performanceFirmly connectedElectric discharge tubesCoupling device detailsSelf lockingEngineering

The invention relates to a self-locking type electric connector, comprising a first middle sleeve sleeved on a first rubber head, a second middle sleeve sleeved on a second rubber head, a first outer sleeve sleeved on the first middle sleeve and a second outer sleeve sleeved on the second middle sleeve; and the first middle sleeve and the second middle sleeve are in self-locking type connection through a locking ring. According to the electric connector disclosed by the invention, the locking ring is driven to rotate and reset by inserting locking springs after two connecting ends are abutted and inserted in place and pass over critical points so as to realize automatic locking; the connecting ends are inserted in place and the automatic locking is realized so that the connection electric performance of the two connecting ends is good, the connection is stable and firm, the two connecting ends do not automatically cut off and are connected on a straight line, and the self-locking type electric connector is rapid and convenient; furthermore, the sealing and waterproof performances are good; and the structure is simple and the weight is light.

Owner:SHENZHEN CHOGORI TECH CO LTD

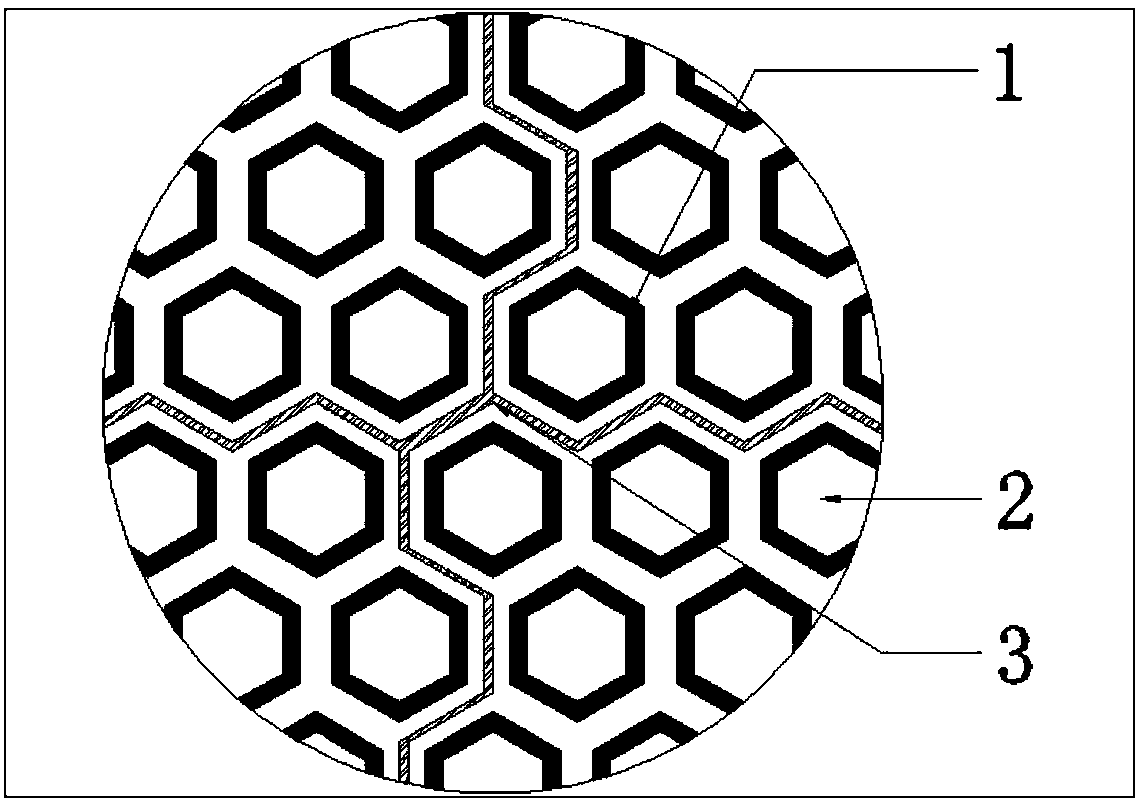

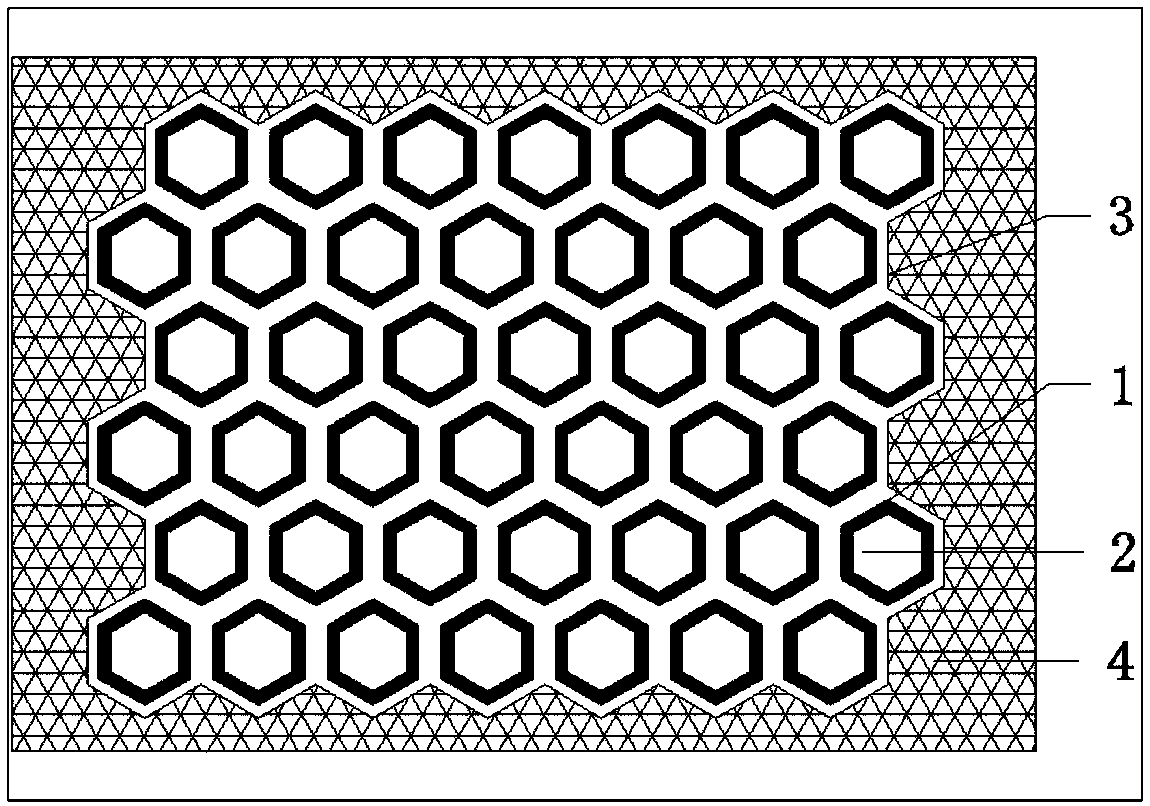

Method for splicing printed board in frequency selective radome processing technology

InactiveCN108123222AWith positioning functionImprove splicing efficiencyRadiating element housingsEngineeringElectrical performance

The invention relates to a method for splicing a printed circuit board in a frequency selective radome processing technology, which is applicable to a condition that an FSS (Frequency Selective Surface) screen required to be spliced is irregular in periodic unit and large in radome size. According to the invention, the boundaries of frequency selective surface submodules required to be spliced arecut into structurally complementary zigzag shapes according to the contour shape and the arrangement pattern of metal units, and the zigzag-shaped contour has a positioning function in splicing. Thezigzag-shaped cutting mode can also ensure that the metal periodic units are not cut off, so that the reflection caused by the discontinuity at the splicing seam is reduced. The splicing method adoptsa non-overlapping mode, the emergence of a splicing seam is allowed, and the processing precision of the printed board can be reduced, so that the processing cost can be reduced. The micro space at the splicing seam is naturally filled by an adhesive film with the dielectric constant being close to that of a printed board substrate in the recombination process of the radome, so that the product is ensured to be highly consistent with a simulation model, and electrical performance guaranteed more easily. The method is simple and good in splicing effect, and has high engineering practicability.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

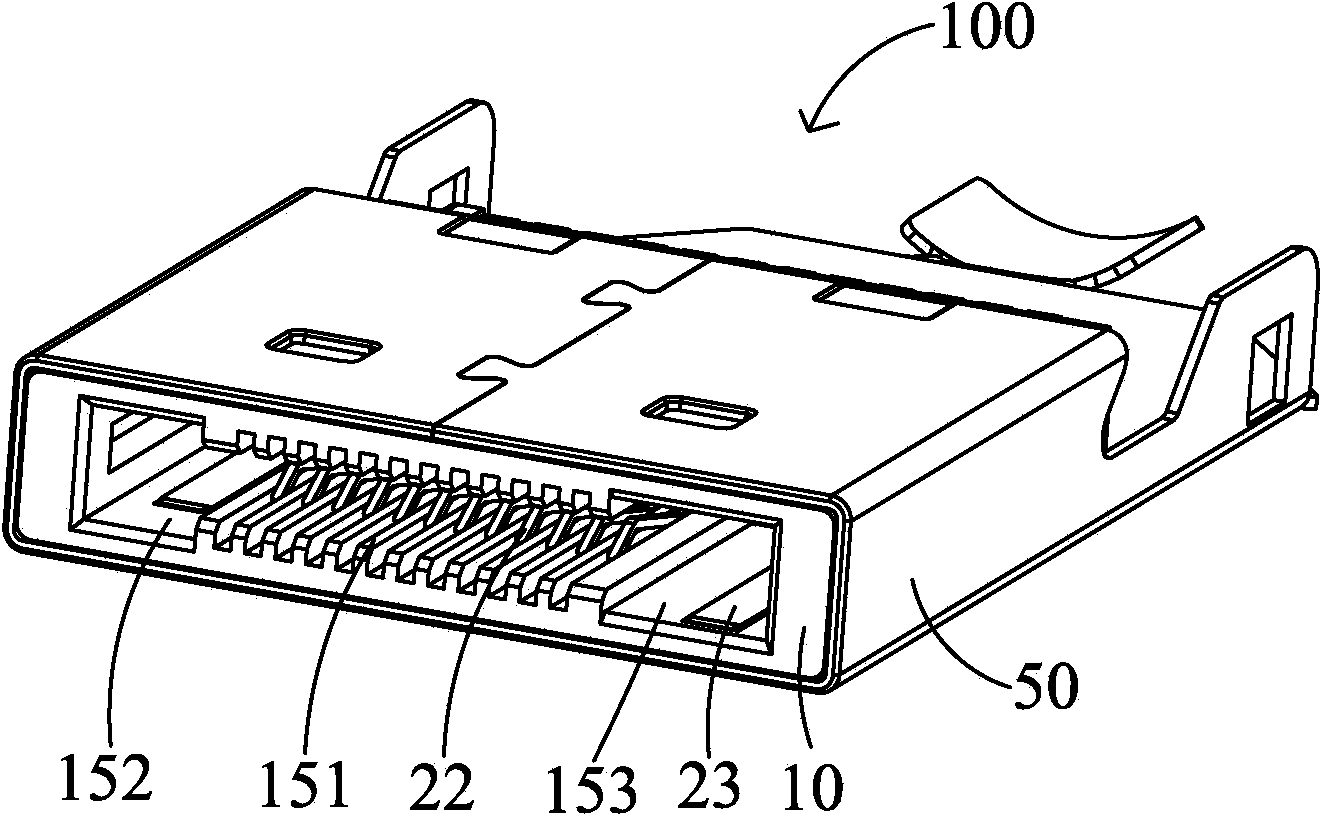

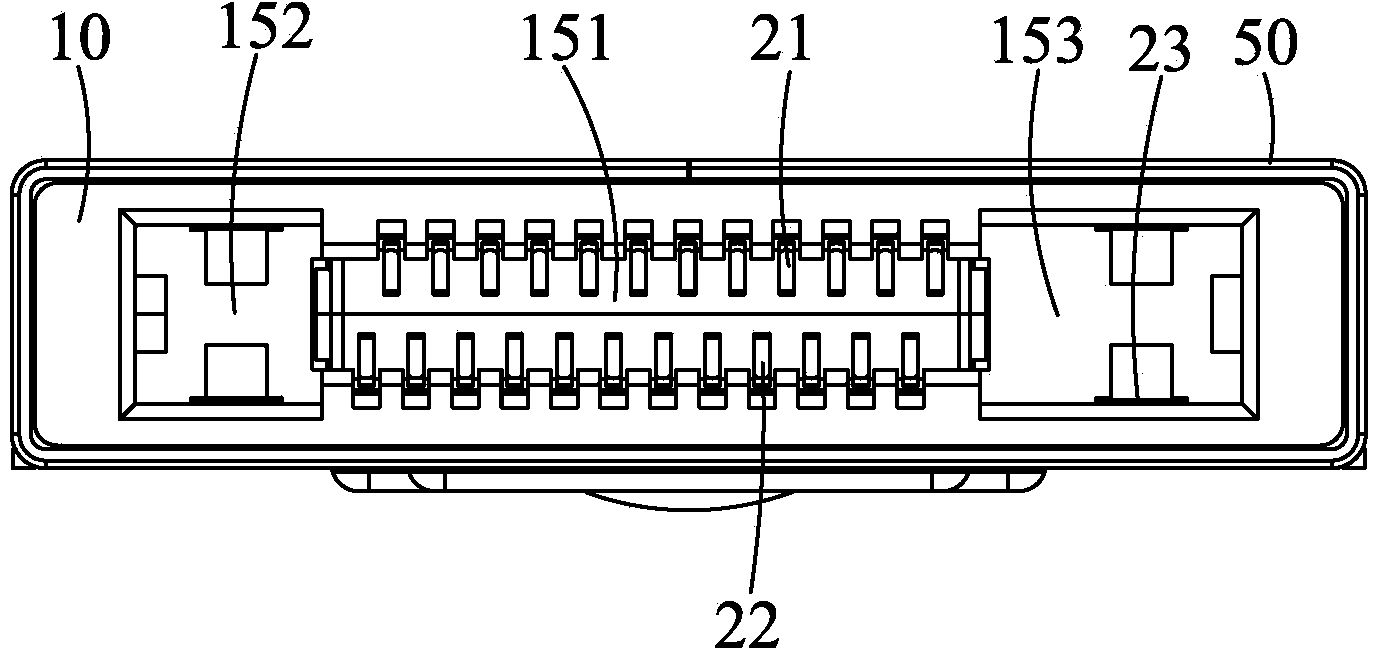

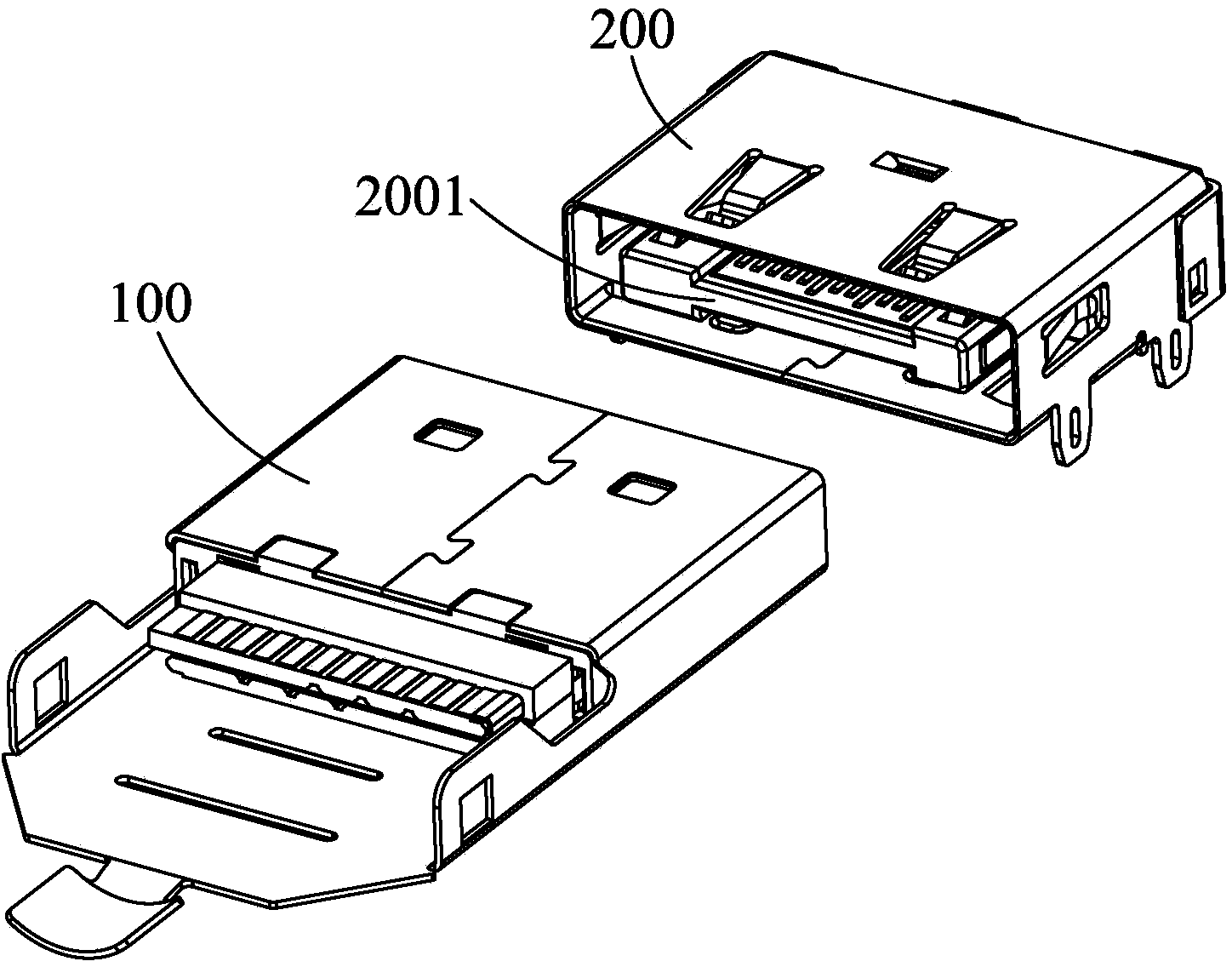

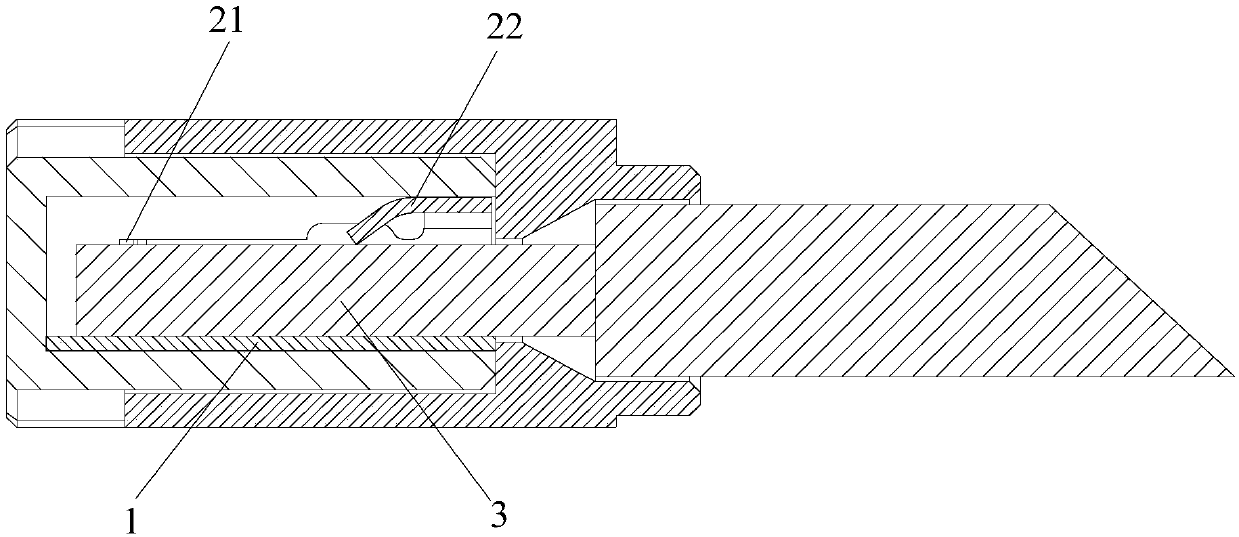

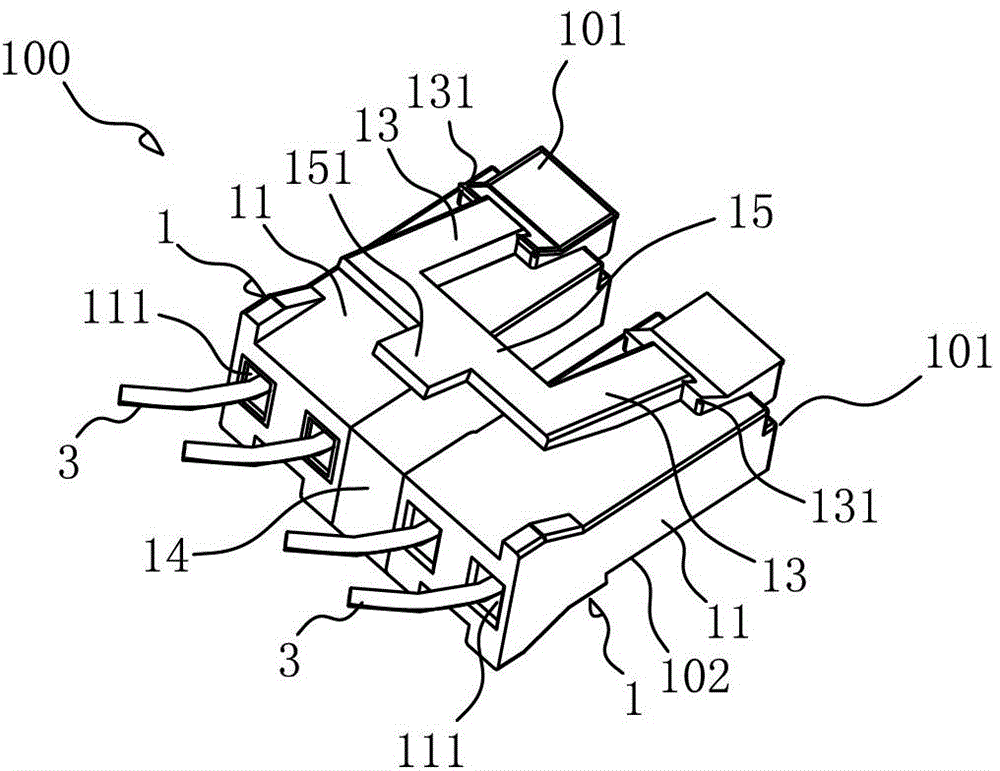

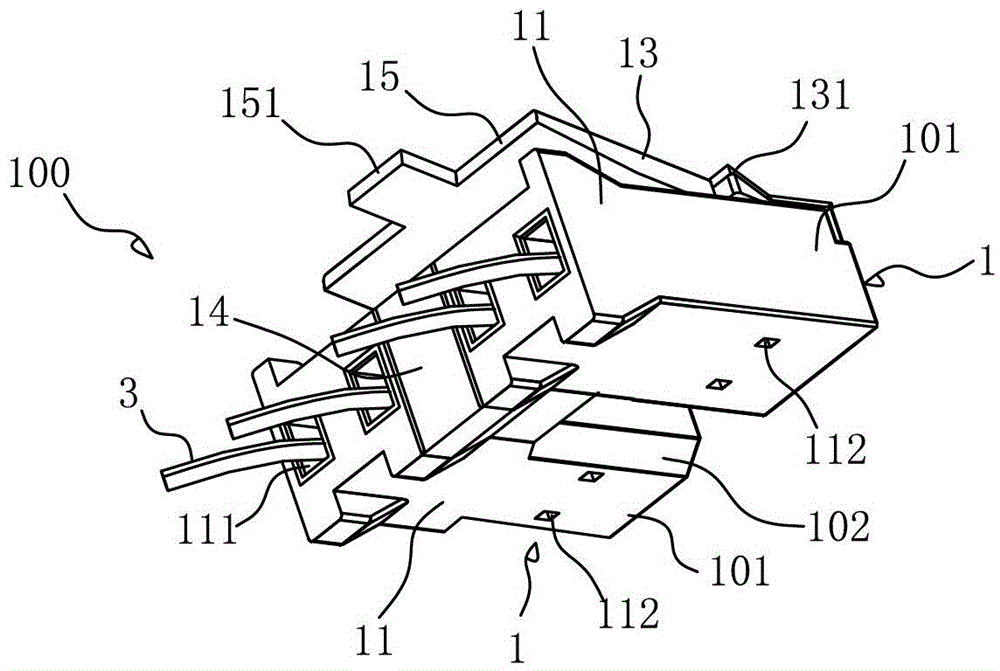

Plug connector

ActiveCN104037549AGuaranteed electrical connection performanceSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

Owner:LUXSHARE PRECISION INDKUNSHAN

Connection terminal

PendingCN109962361AImprove conductivityGood clamping forceSecuring/insulating coupling contact membersMiniaturizationEngineering

The embodiment of the invention provides a connection terminal. The connection terminal comprises a conductive sheet and an elastic sheet. A wire clamping part and an elastic part are arranged on theelastic sheet. The conductive sheet and the elastic part are oppositely arranged, and the wire is pressed between the conductive sheet and the elastic part by elastic deformation of the elastic part.The wire clamping part applies the clamping force to one side of the pressing position of the wire. According to the technical scheme, the purpose that the elastic sheet has better conductive performance and better clamping force can be realized by improving the structure of the elastic sheet without using the high-cost elastic sheet or additionally arranging new components, and the structure is simple and the product is easier to realize miniaturization.

Owner:陈斌斌

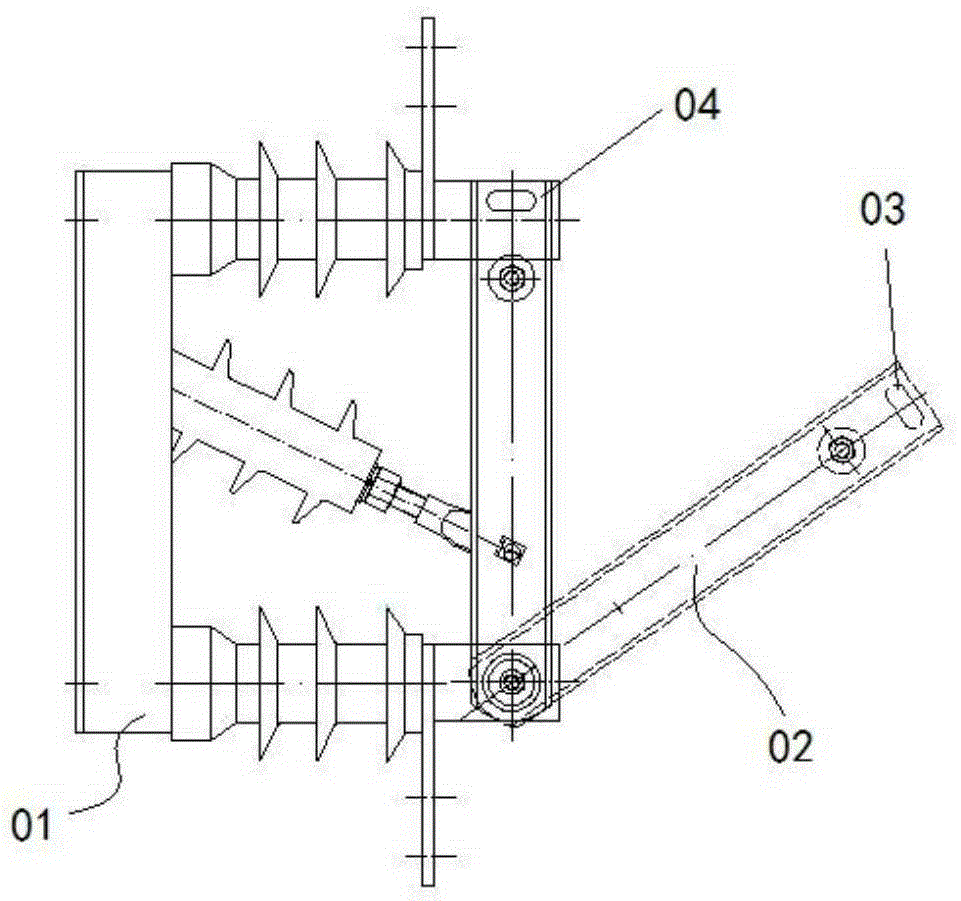

Isolating switch

ActiveCN105374610ANo electric shockImprove securityHigh-tension/heavy-dress switchesAir-break switchesEngineeringElectrical and Electronics engineering

The invention provides an isolating switch. The isolating switch comprises a first contact arm which is suitable for being electrically connected with a first contact and which is provided with a first contact part, a second contact arm which is suitable for being electrically connected with a second contact and which is provided with a second contact part, a grounding structure and a drive mechanism; the first contact and the second contact are a pair of movable and static contacts which are oppositely disposed; and the drive mechanism is used to drive the first contact arm so that the first contact part and an incoming line bus are connected or disconnected, and, after the first contact part and the incoming line bus are disconnected, the first contact arm is continuously driven until the first contact arm is connected with the grounding structure, and then the first contact arm is grounded; and the drive mechanism is used to drive the second contact arm so that the second contact part and an outgoing line bus are connected or disconnected, and, after the second contact part and the outgoing line bus are disconnected, the second contact arm is continuously driven until the second contact arm is connected with the grounding structure, and then the second contact arm is grounded. After the isolating switch is opened, the first contact arm and the second contact arm are not electrified, and people are very safe when repair and maintenance are performed.

Owner:HUAYI ELECTRIC CO LTD

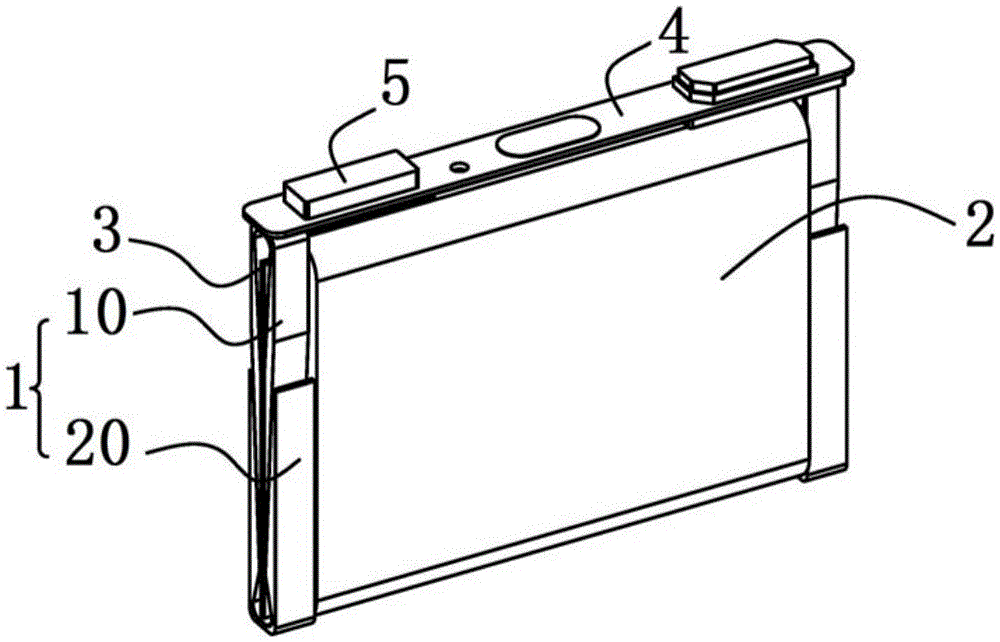

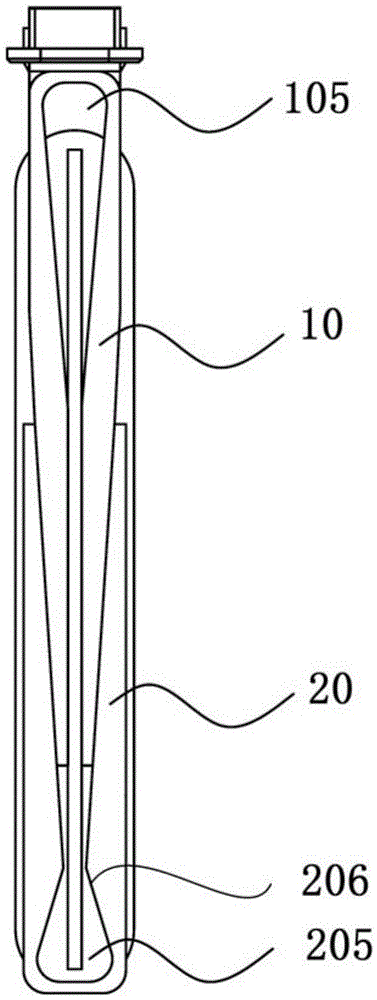

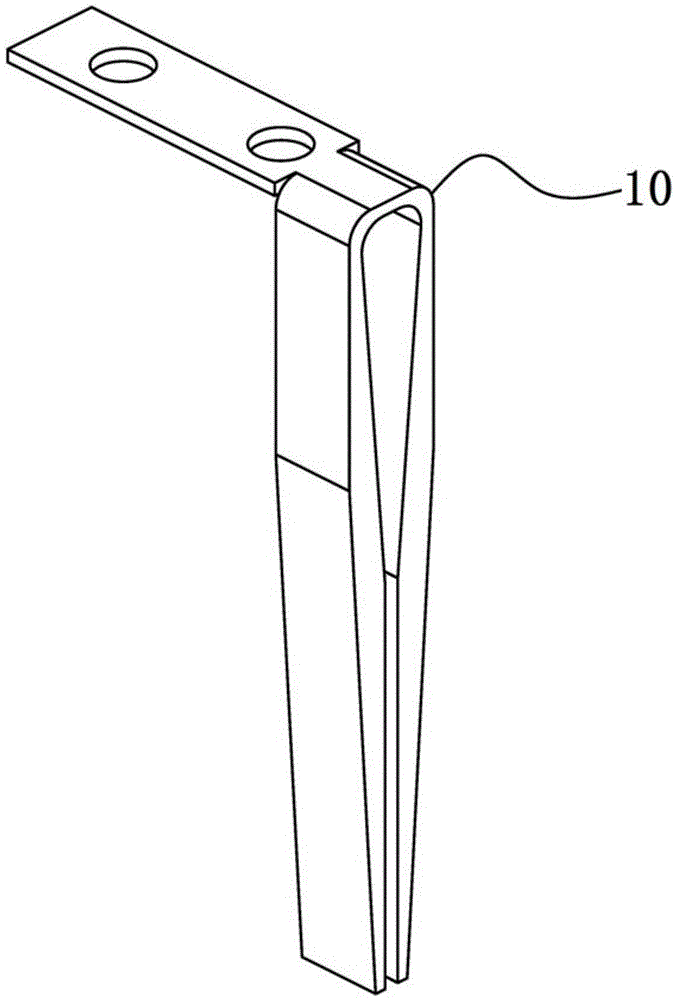

Tab connection assembly and secondary battery

ActiveCN105591061AGuaranteed electrical connection performanceControl thicknessFinal product manufactureSecondary cells manufactureElectrical and Electronics engineering

The invention relates to the production field of secondary batteries and particularly relates to a tab connection assembly and a secondary battery. The tab connection assembly comprises a pin and a clamping part, wherein the pin comprises a connection part and two conductive parts; the two conductive parts are arranged on the two sides of the connection part and are connected with the connection part; fitting regions are arranged on opposite side faces of the two conductive parts; the conductive parts can rotate around connected parts of the conductive parts and the connection part so that the distance between the two conductive parts is changed; when the fitting regions are fitted with the side face of a tab, the conductive parts are prone to be retracted towards the direction of the tab; the clamping part comprises a fixed part and two clamping parts; the two clamping parts are arranged on the two sides of the fixed part and are connected with the fixed part; one end, which is far away from the connection part, of each of the two conductive parts can stretch into the space between the two clamping parts and is tightly clamped by the two clamping parts; and the clamping parts are prone to be retracted towards the direction of the conductive parts. The tab connection assembly is simple and reliable in structure, and has no limitation on the pin thickness.

Owner:JIANGSU CONTEMPORARY AMPEREX TECHNOLOGY LIMITED

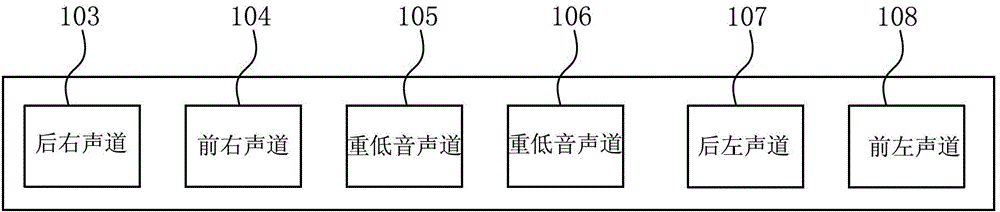

Method for preventing loudspeaker connecting wire from being incorrectly inserted and connection system for compound type plug and loudspeaker in method

InactiveCN102882106AGood effectSimple and fast operationTransducer detailsIncorrect coupling preventionLoudspeakerMulti channel

The invention discloses a method for preventing a loudspeaker connecting wire from being incorrectly inserted, which is simple and has an ideal effect, and a connection system for a compound type plug and the loudspeaker in the method. The method comprises the following steps of: providing a plurality of plug connectors which are connected with a loudspeaker connecting wire, wherein structures of at least two plug connectors at an inserting end part are different; providing a compound type socket, wherein the compound type socket is provided with a plurality of corresponding multi-channel systems and slots for inserting the plug connectors and the structures of at least two slots are different; and enabling each plug connector to be only capable of being inserted into the slot in a socket connector corresponding to the plug connector so as to accurately connect each loudspeaker into the corresponding channel systems. The compound type plug is at least formed by the two plug connectors; and two insulating bodies of the adjacent plug connectors are integrally connected through an engaging block. The connection system for the loudspeaker comprises the compound type plug and the compound type socket. The connection system for the compound type plug and the loudspeaker has the advantages of compact structure, stable and firm connection and convenience for use.

Owner:DONGGUAN YUQIU ELECTRONICS CO LTD

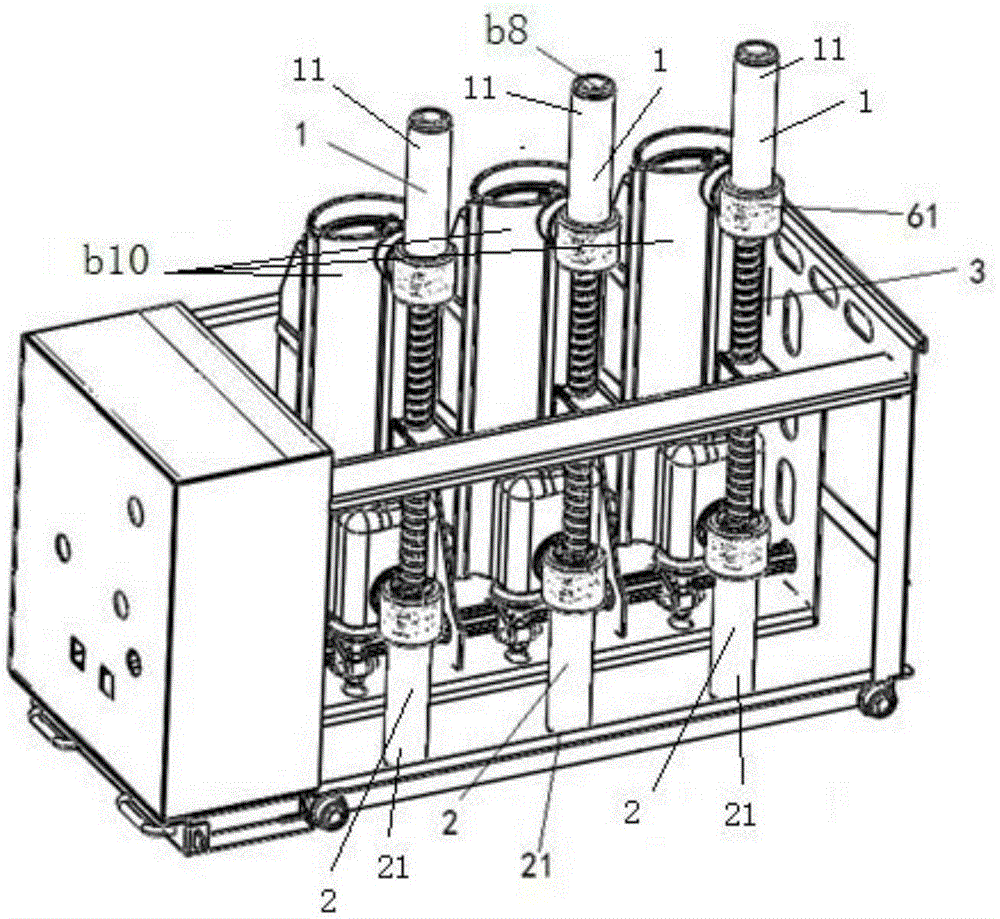

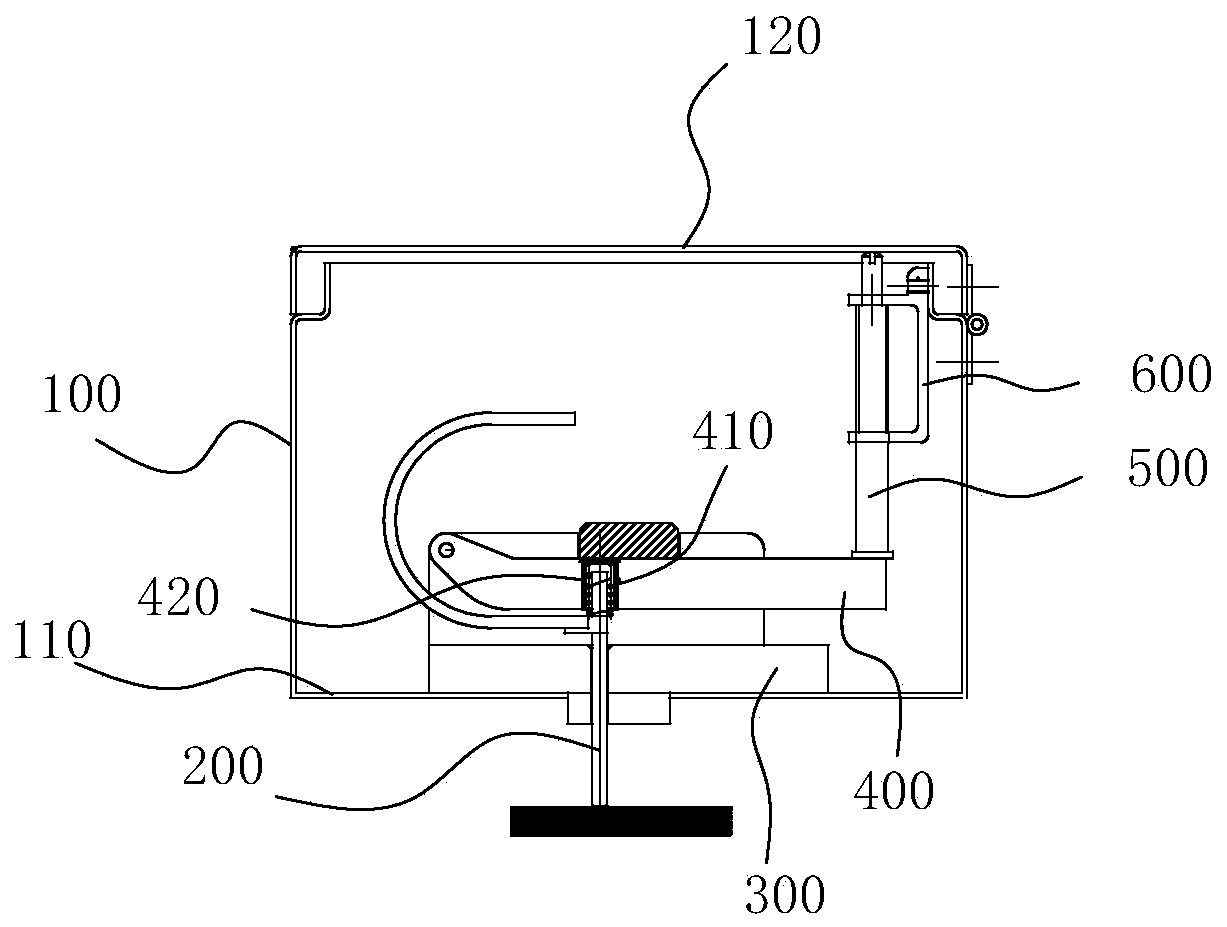

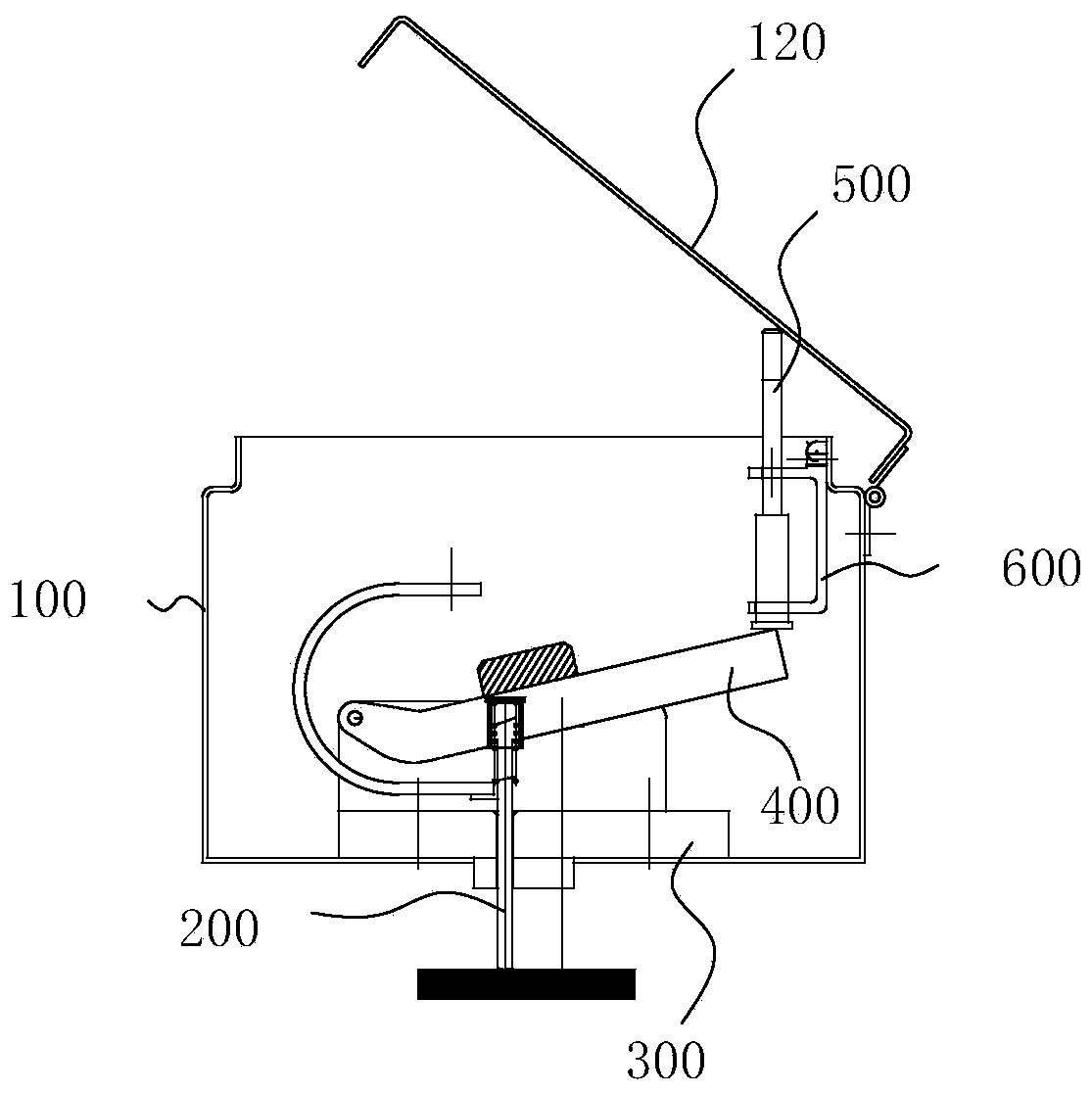

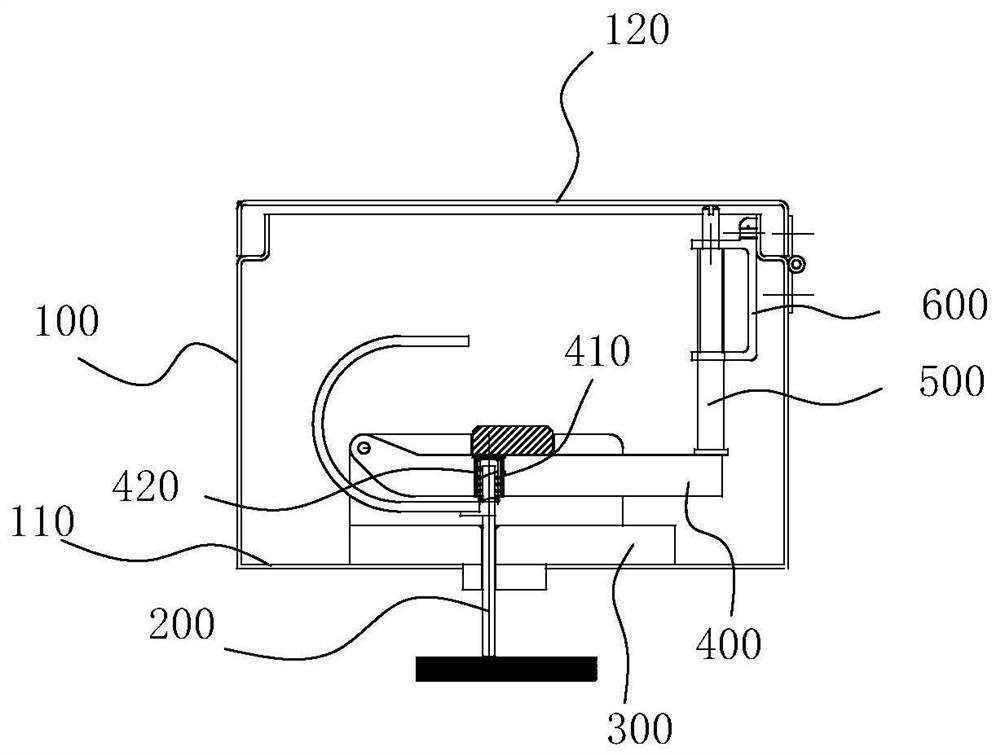

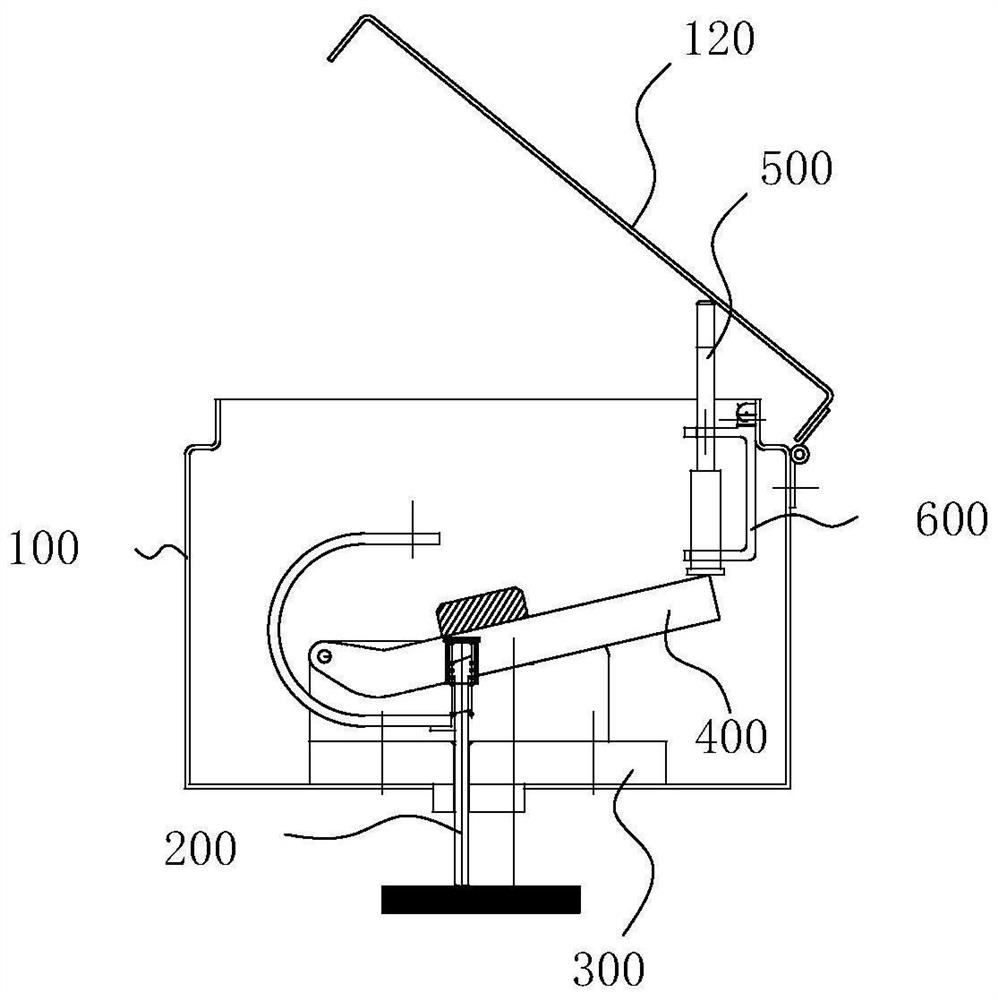

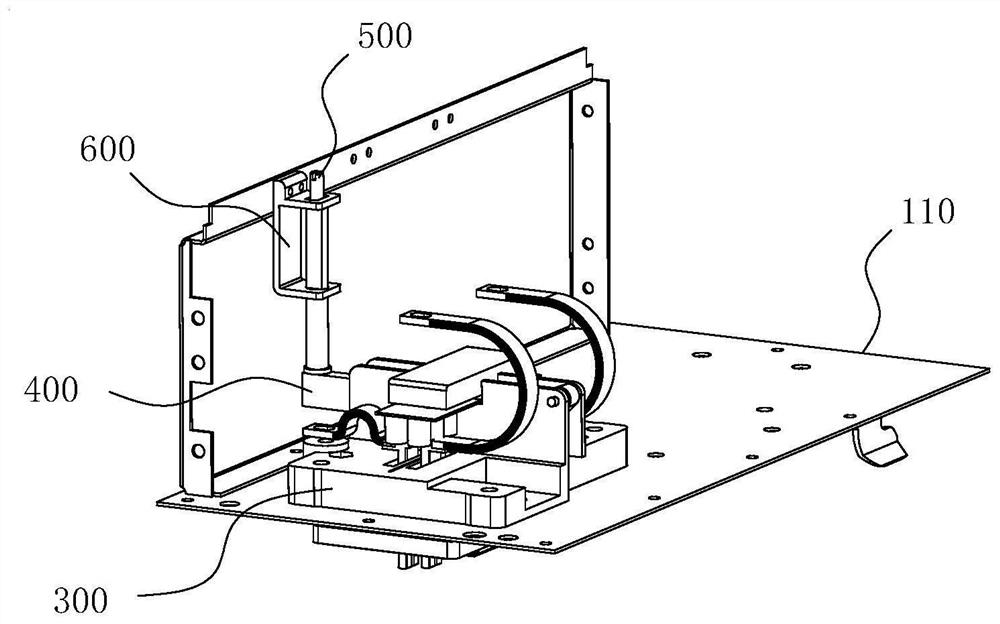

Plug-in box pin pressing and interlocking device

ActiveCN110739587AEffective contactGuaranteed electrical connection performanceCoupling device detailsElectrical connectionStructural engineering

The invention discloses a plug-in box pin pressing and interlocking device which comprises a plug-in box body which is provided with a a box body back plate facing a bus duct and a door cover arrangedopposite to the box body back plate; an elastic pin which is movably arranged in the plug-in box body, wherein the end part of the elastic pin extends from the box body back plate to the outside of the plug-in box body to be connected with the bus duct; and a plug-in interlocking assembly which can selectively press the elastic pin against the bus duct, wherein the end part away from the elasticpin hinders the closure of the door cover when the plug-in interlocking assembly does not press the elastic pin. The plug-in interlocking assembly is used for applying preset pressure to the elastic pin, thereby ensuring effective contact between the elastic pin and the bus duct and ensuring electrical connection performance.

Owner:WETOWN ELECTRIC GRP CO LTD

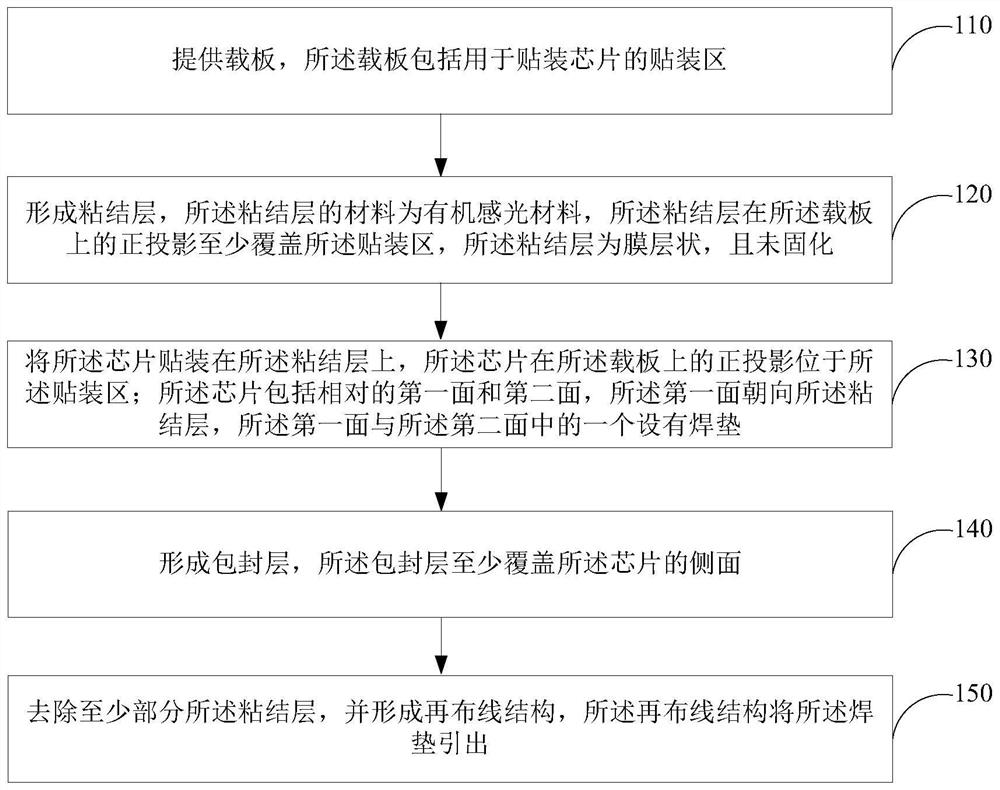

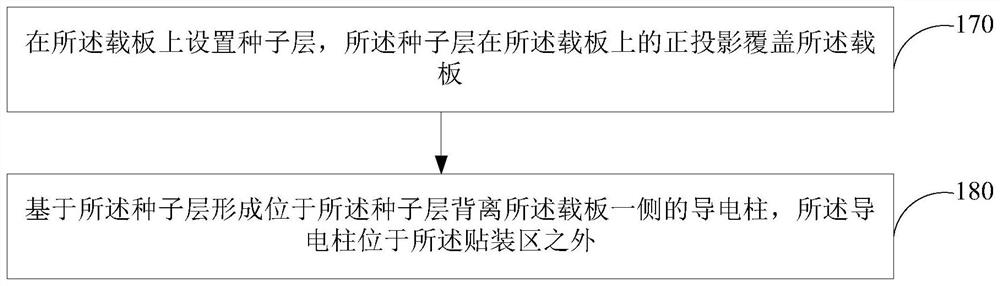

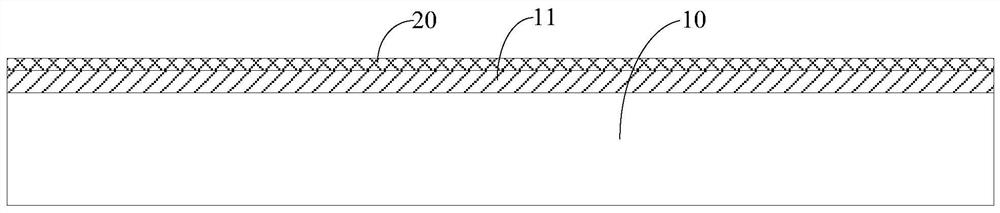

Semiconductor packaging method

PendingCN113436979AGood removal effectPrevent movementSemiconductor/solid-state device manufacturingSemiconductor/solid-state device detailsSemiconductor packageEngineering

The invention provides a semiconductor packaging method. The semiconductor packaging method comprises the following steps: providing a carrier plate, wherein the carrier plate comprises a mounting area for mounting a chip; forming a bonding layer, wherein the material of the bonding layer is an organic photosensitive material, the orthographic projection of the bonding layer on the carrier plate at least covers the mounting area, and the bonding layer is in a film layer shape and is not cured; mounting the chip on the bonding layer, wherein the orthographic projection of the chip on the carrier plate is located in the mounting area, wherein the chip comprises a first surface and a second surface which are opposite to each other, the first surface faces the bonding layer, and one of the first surface and the second surface is provided with a welding pad; forming an encapsulation layer, wherein the encapsulation layer at least covers the side surface of the chip; and removing at least part of the bonding layer, forming a rewiring structure, and leading out the welding pad through the rewiring structure.

Owner:SIPLP MICROELECTRONICS CHONGQING CO LTD

Current carrier and design method thereof

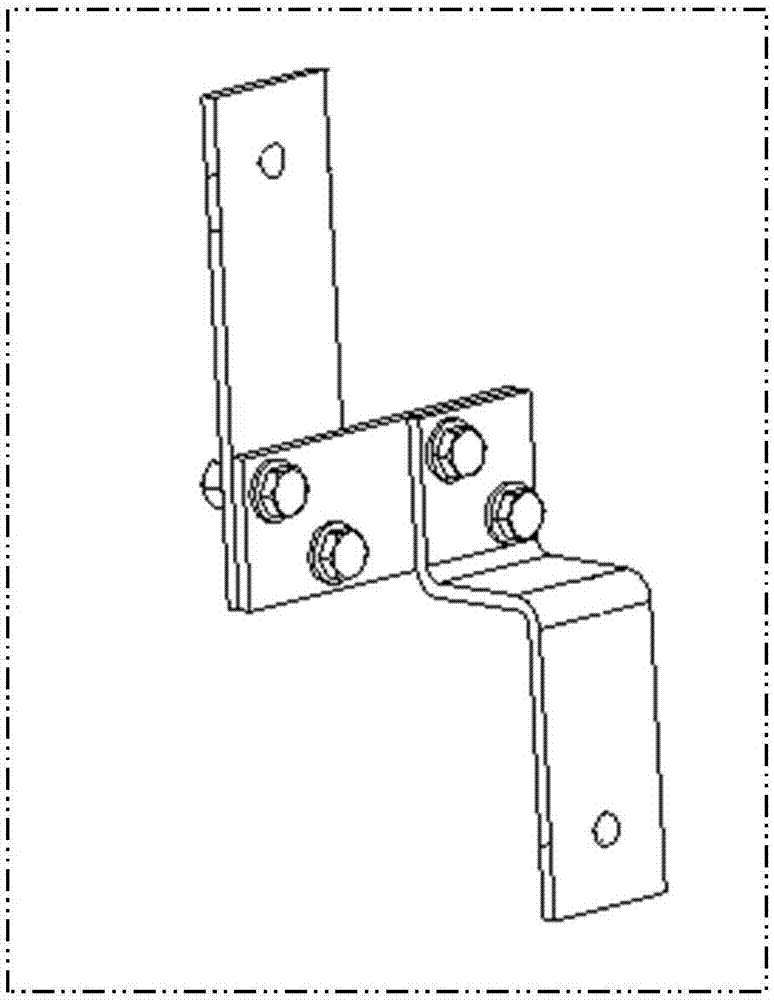

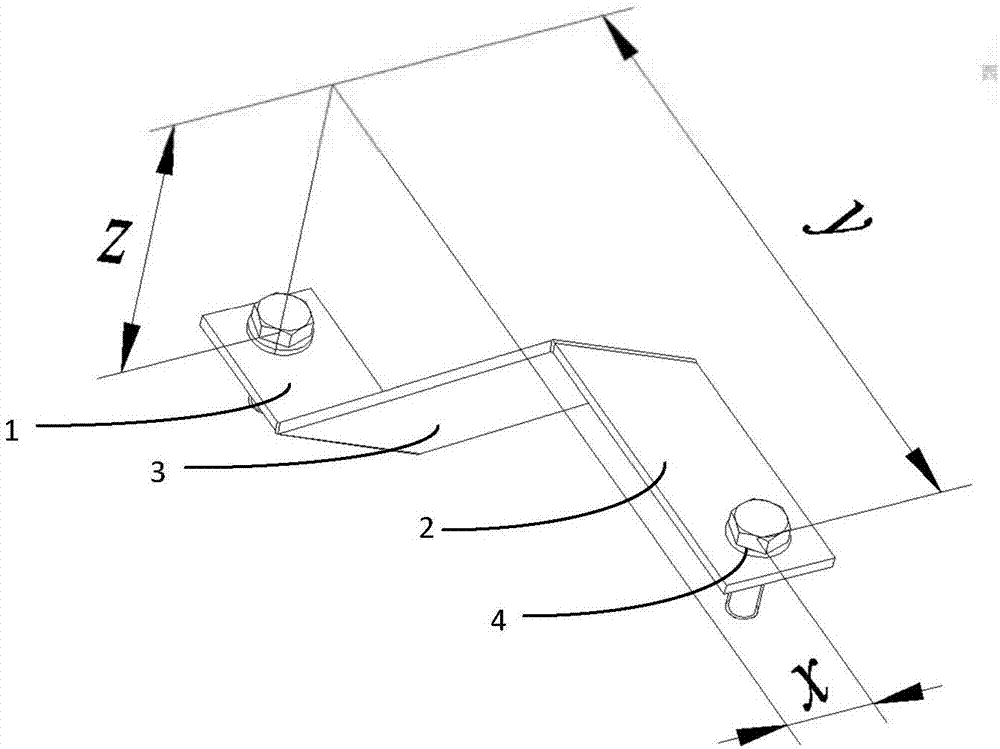

InactiveCN107230515AGuaranteed electrical connection performanceImprove stabilitySingle bars/rods/wires/strips conductorsCable/conductor manufactureDistribution systemFastener

The invention discloses a current carrier and a design method thereof, comprising a flat metal strip, the metal strip comprises a first bent part, a second bent part and a middle oblique bent section, the first bent part and the second bent part The folding parts are respectively located at both ends of the middle oblique section, the middle oblique section includes a front and a back side, the first bending part is bent toward the front of the middle oblique section, and the second bending part is bent toward the middle oblique section The back side is bent, and the first bent part and the second bent part both have through holes. The invention is suitable for the connection of high-current electrical appliances, especially for the electrical connection occasions where there are distance differences in all directions; the integrally formed structure completely solves the hidden danger of reliability caused by splicing carriers of fasteners, and ensures the connection between electrical appliances. The electrical connection performance effectively improves the stability of the power transmission and distribution system; there is no need for a large number of manpower to participate in assembly maintenance and a large amount of fastener consumption, saving costs.

Owner:NARI TECH CO LTD +1

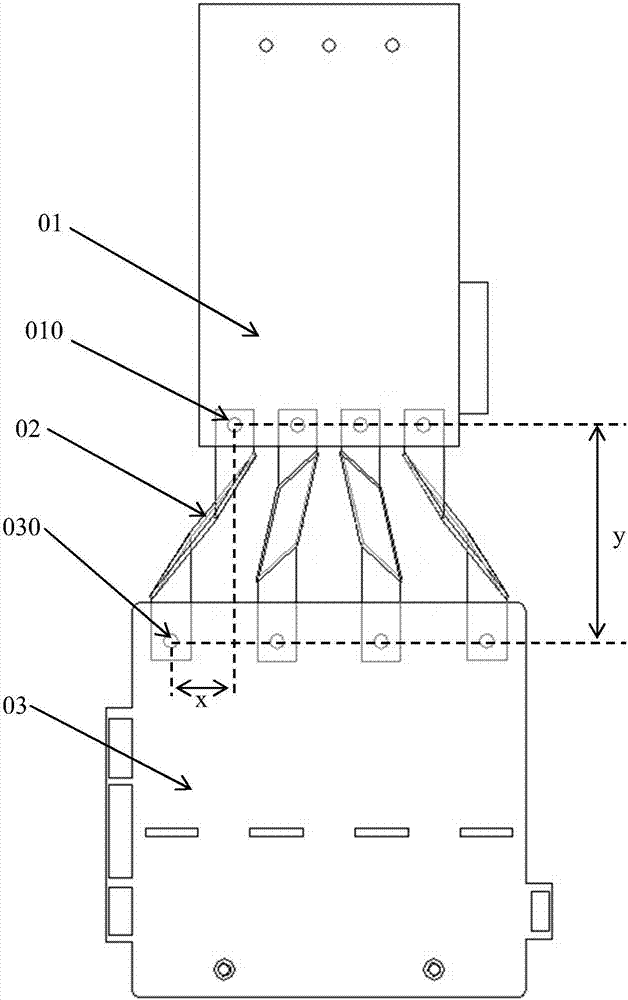

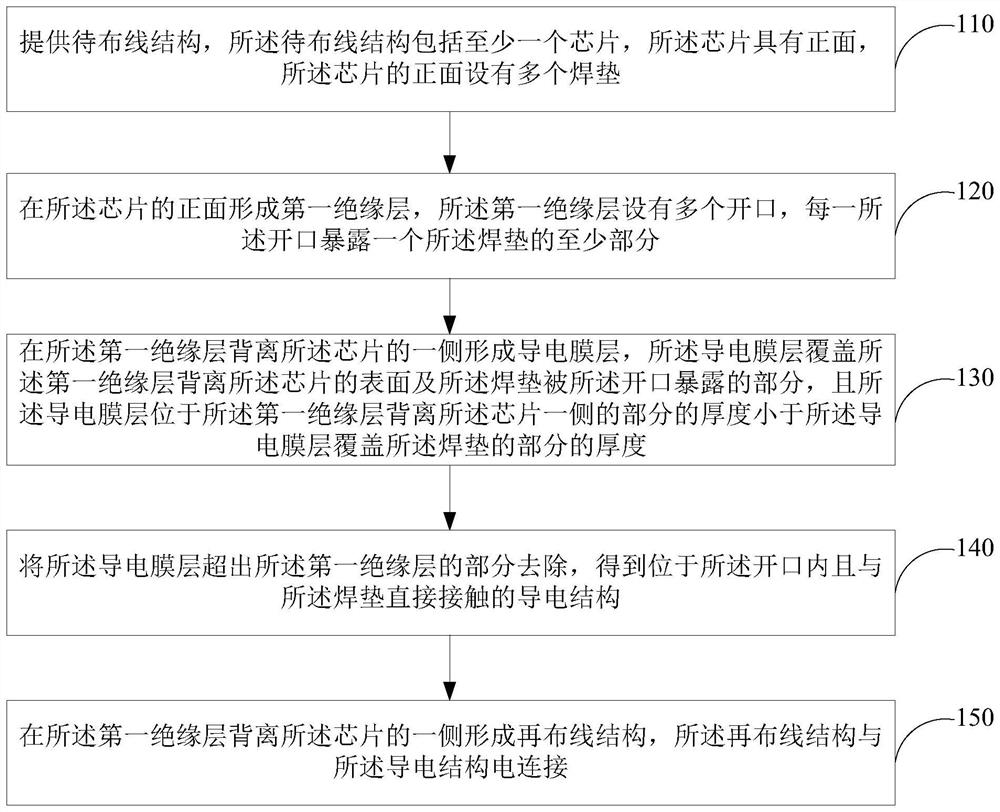

Manufacturing method of semiconductor structure, and semiconductor structure

PendingCN113707566AAvoid misalignmentGuaranteed electrical connection performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureElectrical connection

The invention provides a manufacturing method of a semiconductor structure, and the semiconductor structure. The manufacturing method comprises the steps that a to-be-wired structure is provided, wherein the to-be-wired structure comprises at least one chip, the chip is provided with a front face, and the front face of the chip is provided with a plurality of welding pads; a first insulating layer is formed on the front face of the chip, the first insulating layer is provided with a plurality of openings, and each opening exposes at least part of one welding pad; a conductive film layer is formed on the side, deviating from the chip, of the first insulating layer, the conductive film layer covers the surface, deviating from the chip, of the first insulating layer and the part, exposed by the opening, of the welding pad, and the thickness of the part, located on the side, deviating from the chip, of the conductive film layer is smaller than that of the part, covering the welding pad, of the conductive film layer; the part, exceeding the first insulating layer, of the conductive film layer is removed to obtain a conductive structure which is located in the opening and is in direct contact with the welding pad; and a re-wiring structure is formed on one side, deviating from the chip, of the first insulating layer, and the re-wiring structure is electrically connected with the conductive structure.

Owner:SIPLP MICROELECTRONICS CHONGQING CO LTD

Semiconductor package device and manufacturing method thereof

PendingCN114284242AGuaranteed electrical connection performanceAvoid excessive wear and tearSemiconductor/solid-state device detailsSolid-state devicesPhysicsElectrically conductive

The invention relates to a semiconductor packaging device and a manufacturing method thereof. The semiconductor packaging device includes: a molding material; the bridging chip is wrapped in the molding material, the bridging chip is provided with a conductive pad and a first conductive hole, the conductive pad is located on the first surface of the bridging chip, and the first conductive hole is located in the bridging chip and electrically connected with the conductive pad; the buffer layer is arranged on the first surface of the bridging chip, a second conductive hole is formed in the buffer layer, the first end of the second conductive hole is electrically connected with the conductive pad, and the second end of the second conductive hole is exposed out of the buffer layer. According to the semiconductor packaging device, the problem that the silicon through hole is excessively abraded or is difficult to expose due to warping of the semiconductor packaging device in the grinding process can be avoided, and the electrical connection performance between the semiconductor packaging device and the outside can be guaranteed.

Owner:ADVANCED SEMICON ENG INC

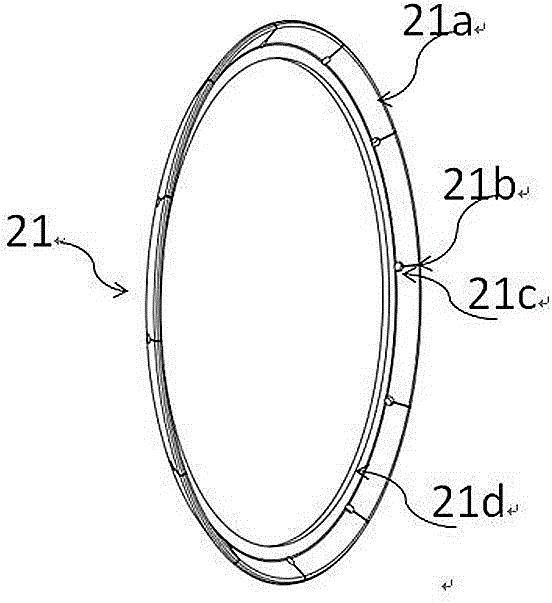

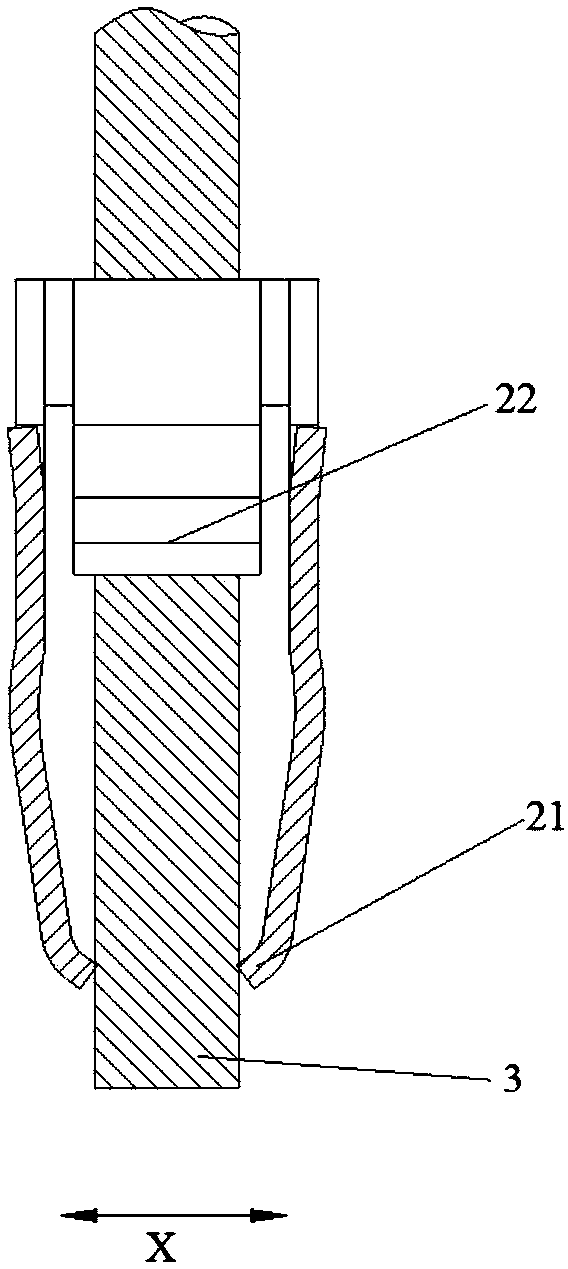

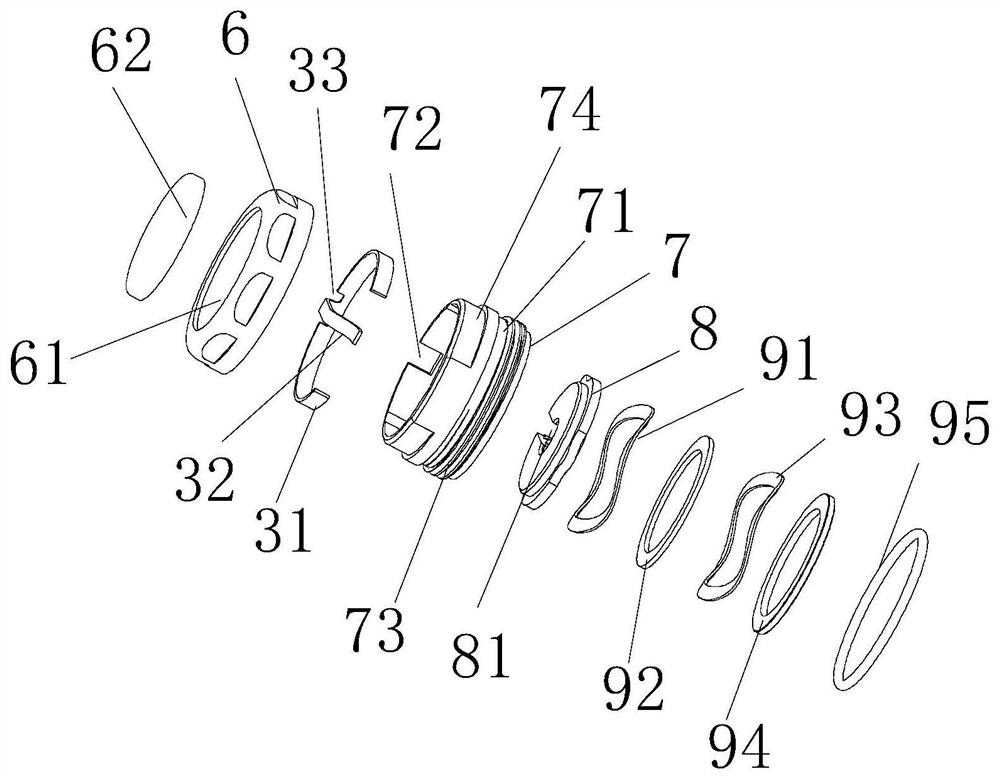

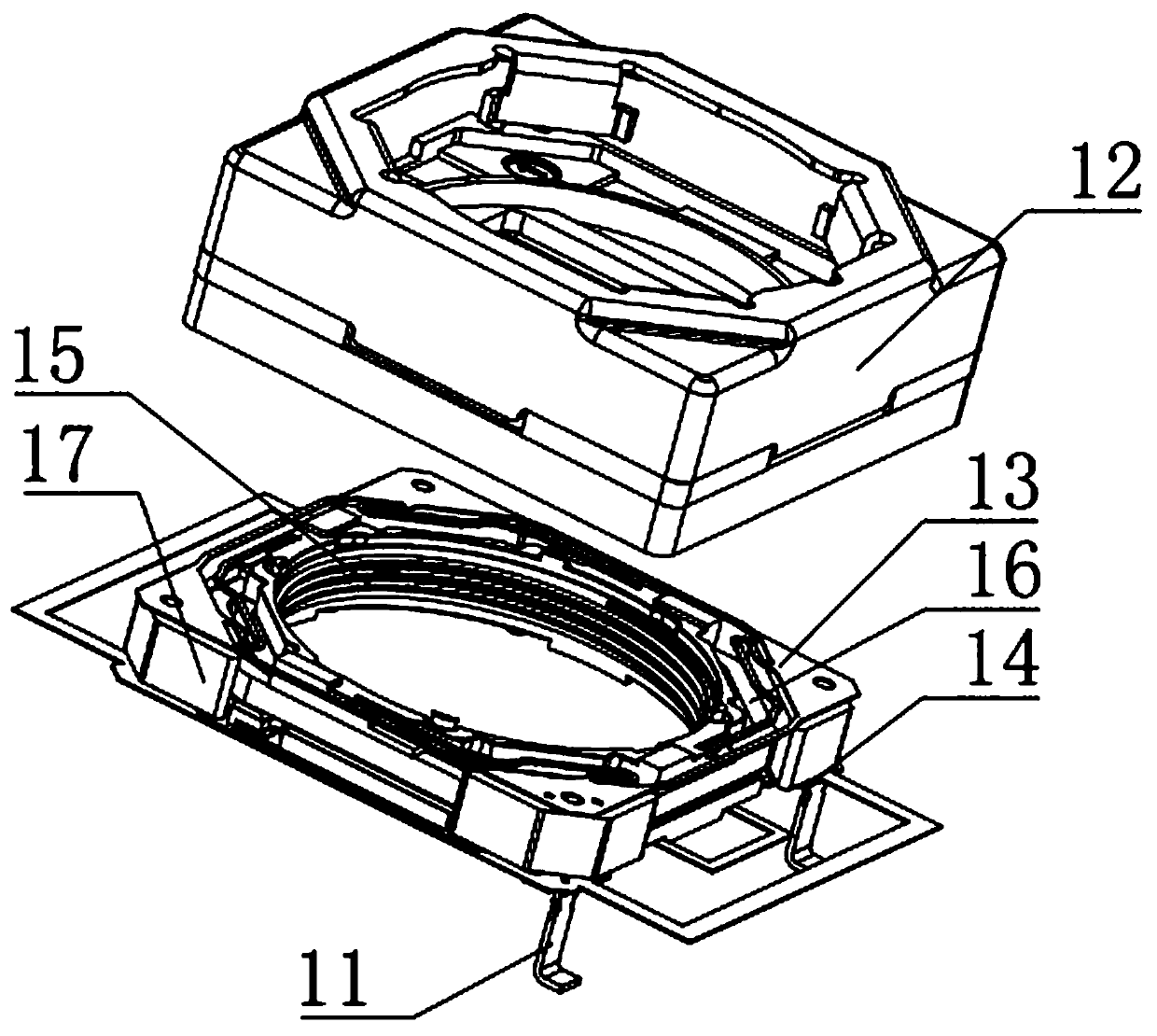

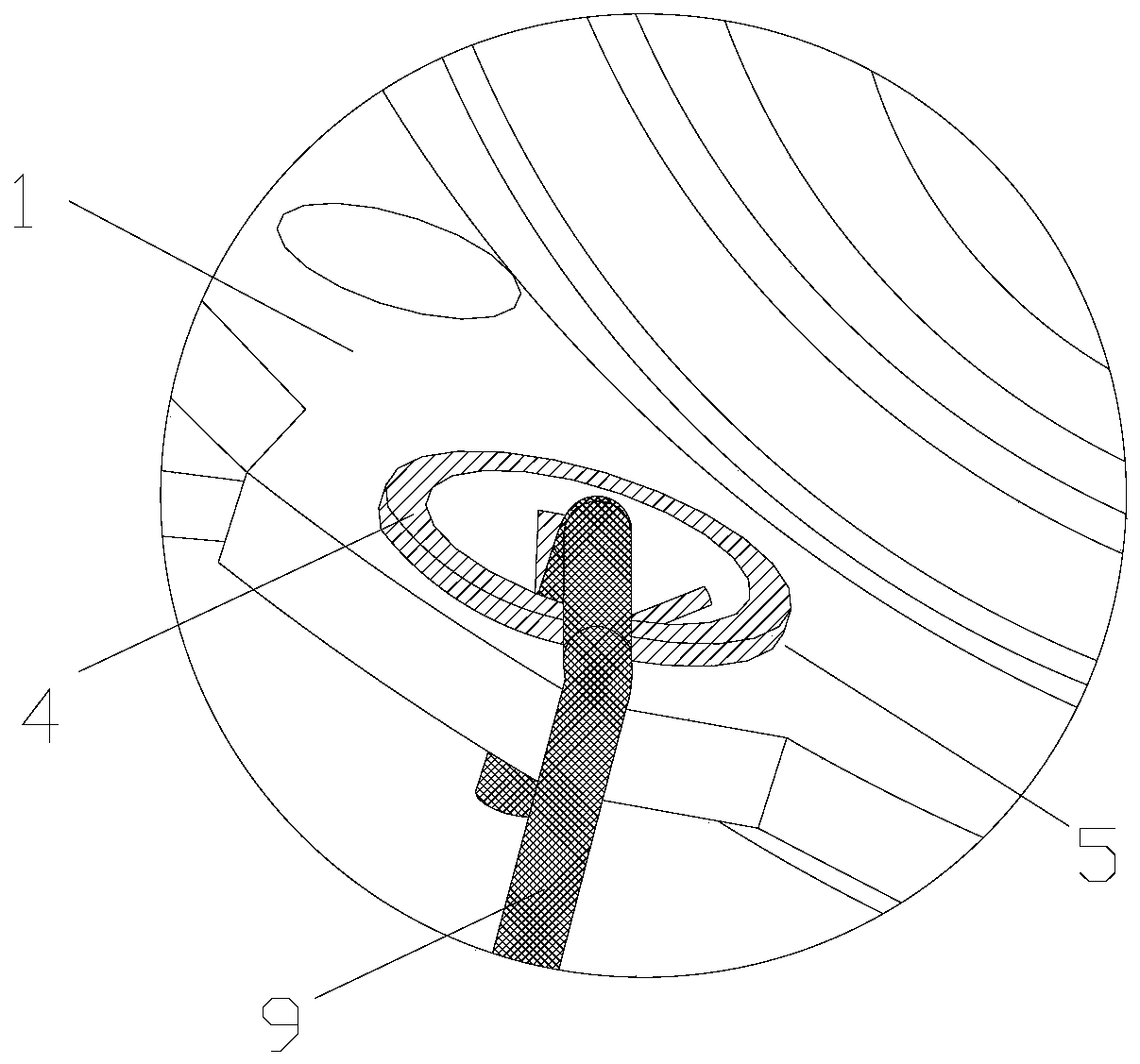

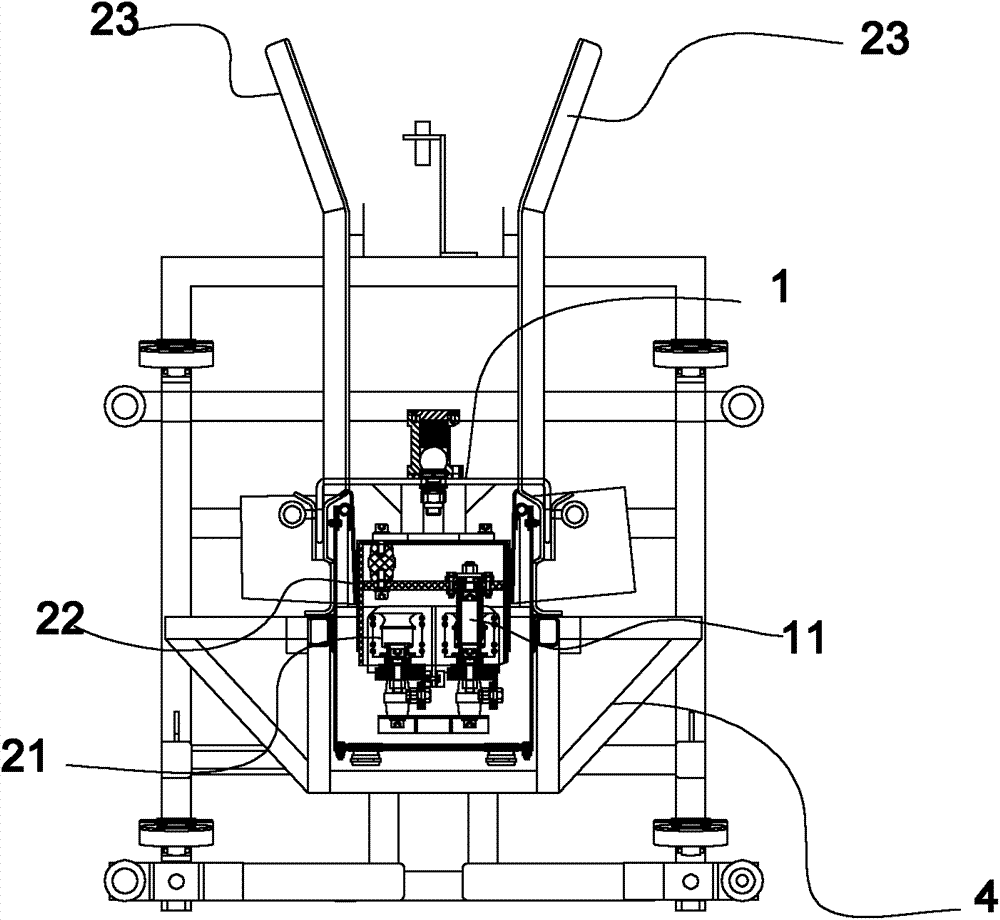

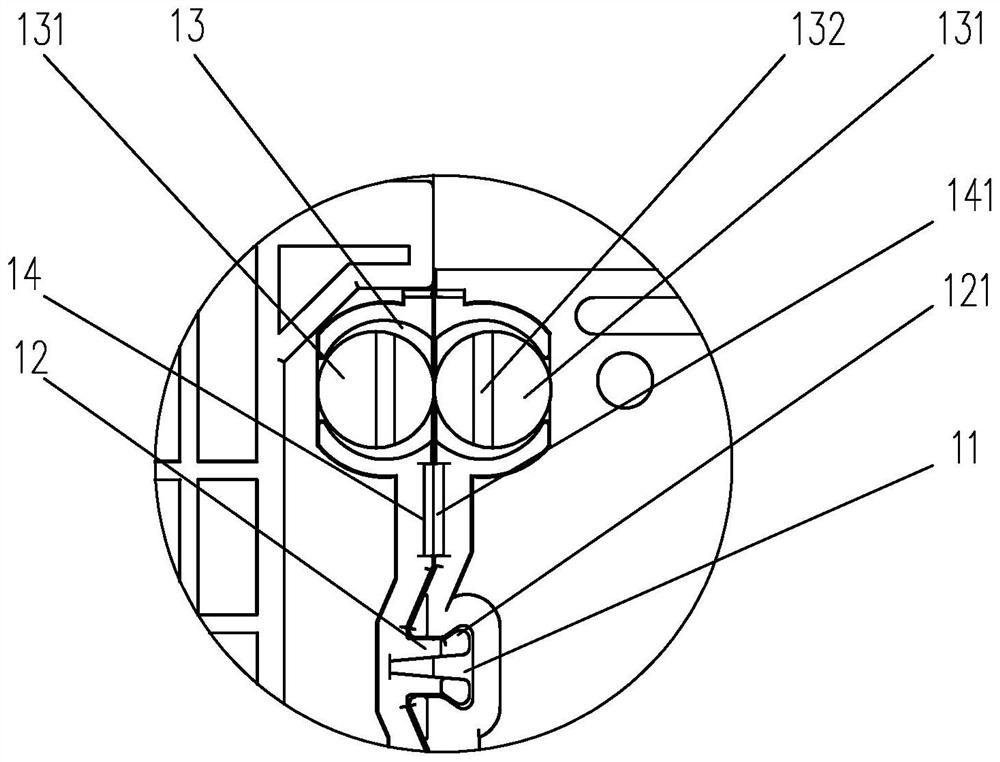

Contra-angle handpiece with conducting strip arranged in rear cover and root canal preparation machine

PendingCN112057183AExtended service lifeReduce wearTeeth fillingTeeth cappingRoot Canal PreparationsEngineering

The invention relates to a contra-angle handpiece with a conducting strip arranged in a rear cover and a root canal preparation machine. The contra-angle handpiece with the conducting strip arranged in the rear cover comprises a handpiece, the rear cover, and a cutting tool; a handpiece core assembly used for driving the cutting tool to rotate is arranged inside the handpiece; the conducting stripis arranged inside the rear cover, and the conducting strip comprises a semi-ring body and an elastic part; the semi-ring body is sleeved by the rear cover; the tail end of the elastic part is connected with the middle of the semi-ring body; the front end of the elastic part extends to the center of the semi-ring body; and the front end of the elastic part is in contact with the center of the endface of the cutting tool when the rear cover is fixed to the handpiece.

Owner:CHANGZHOU SIFARY MEDICAL TECH CO LTD

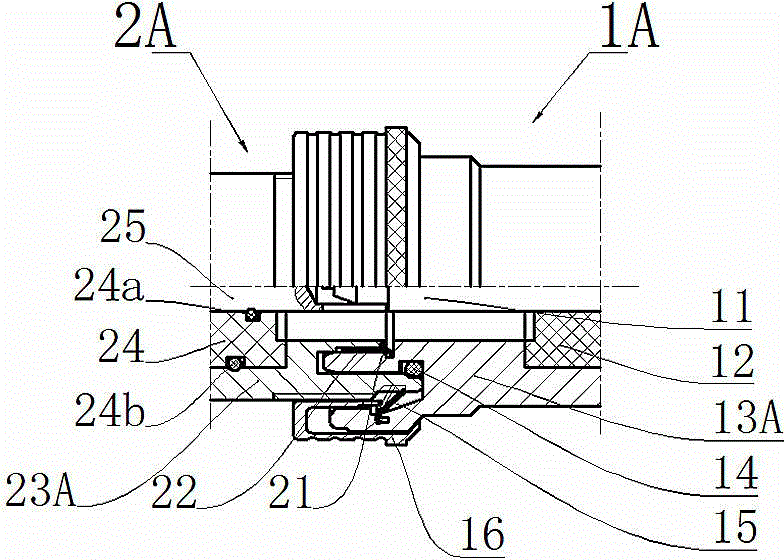

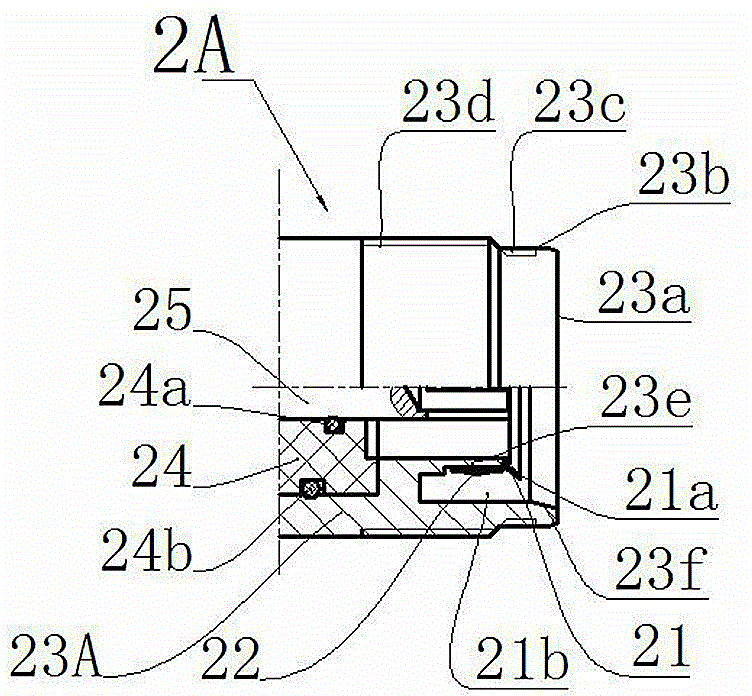

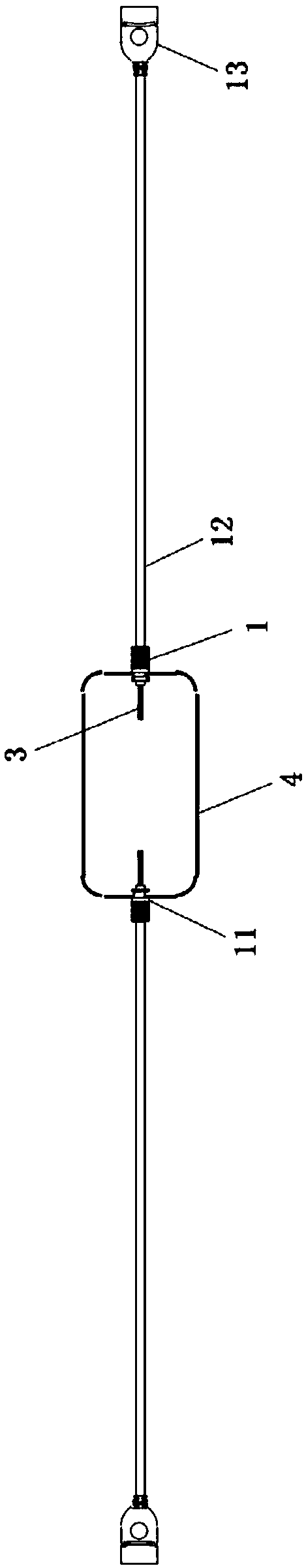

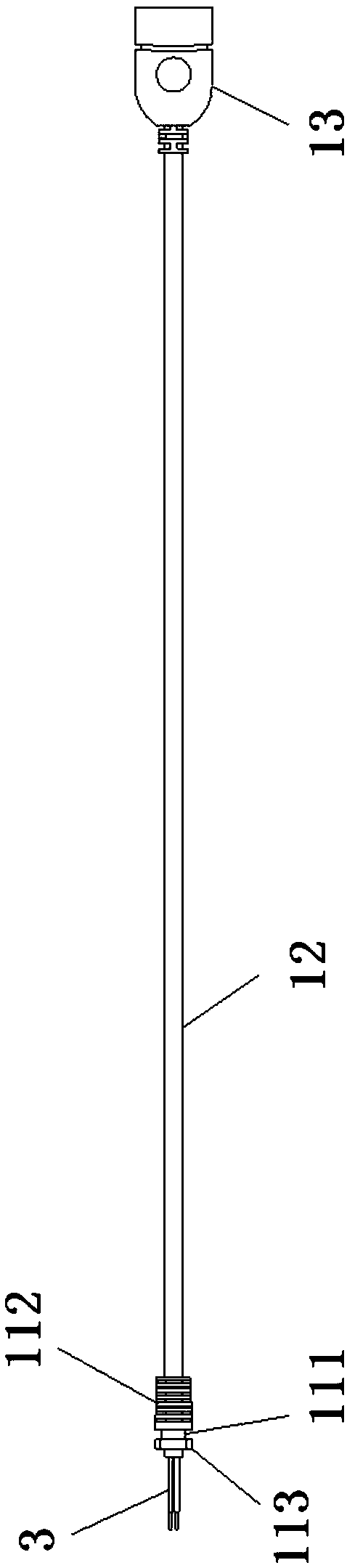

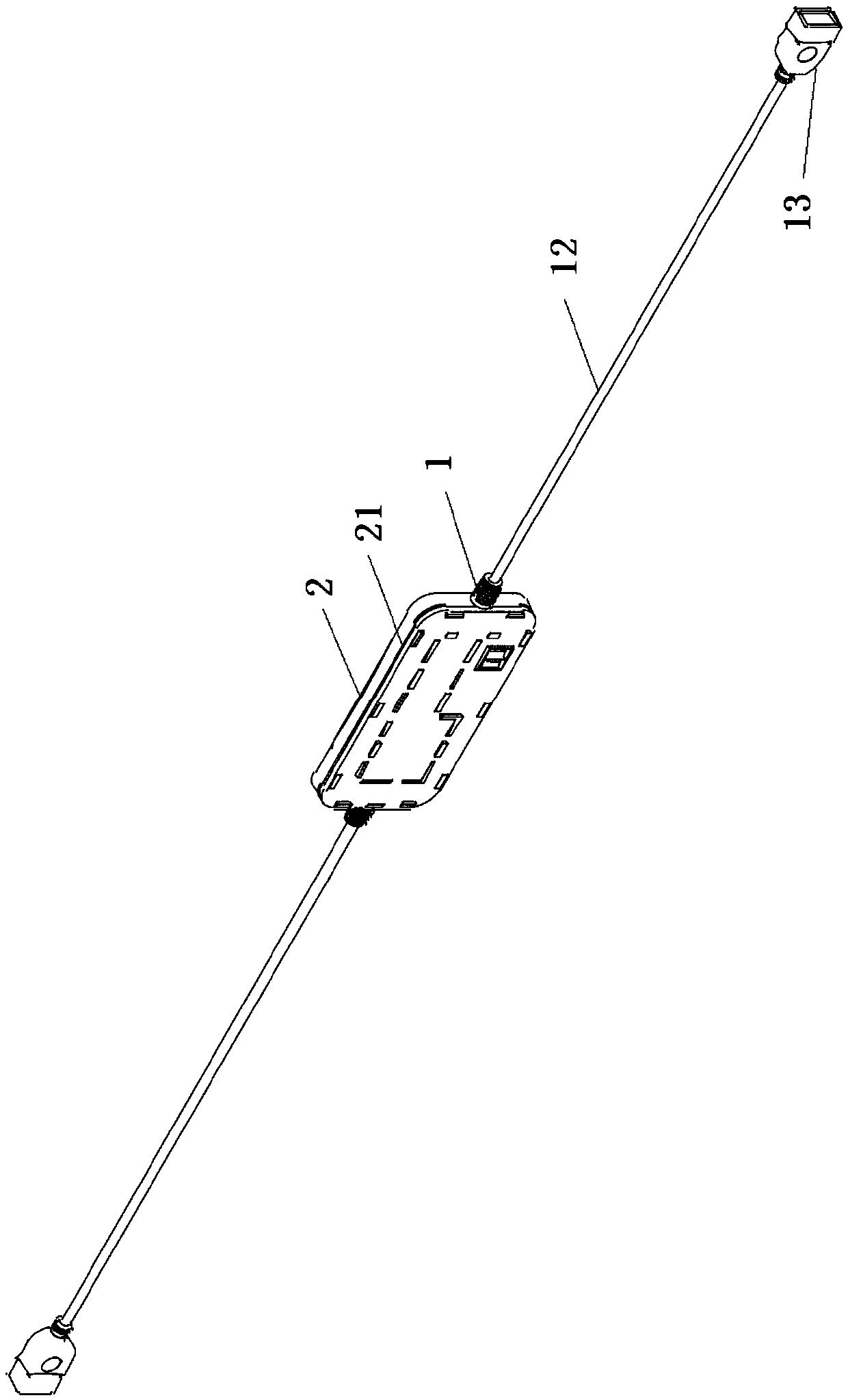

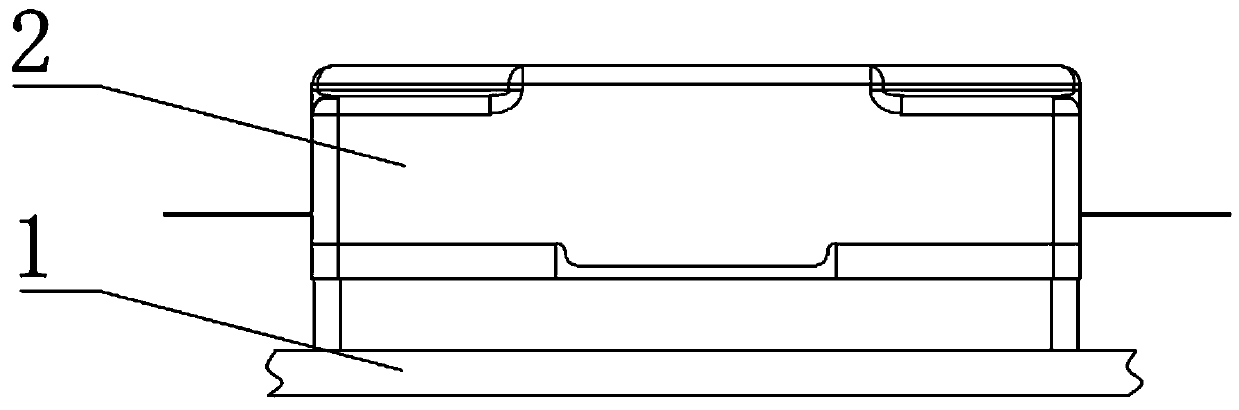

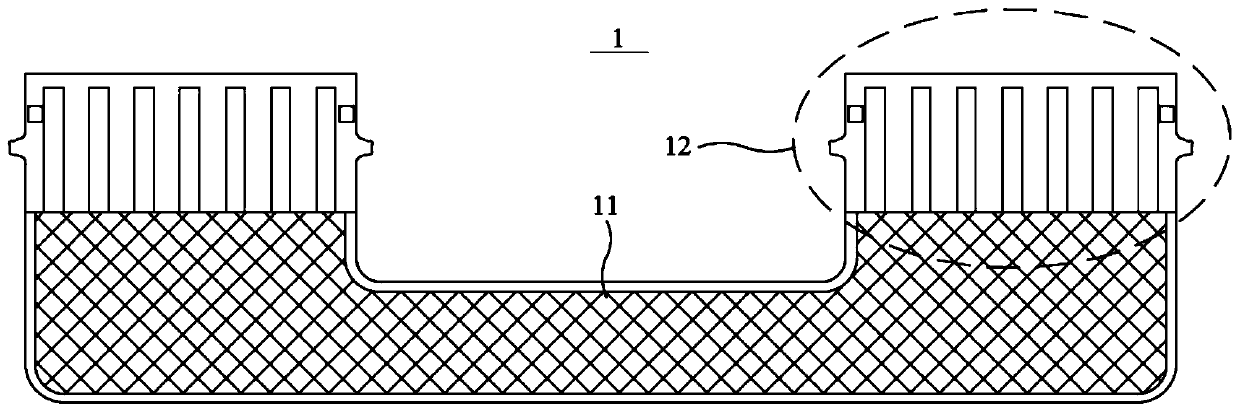

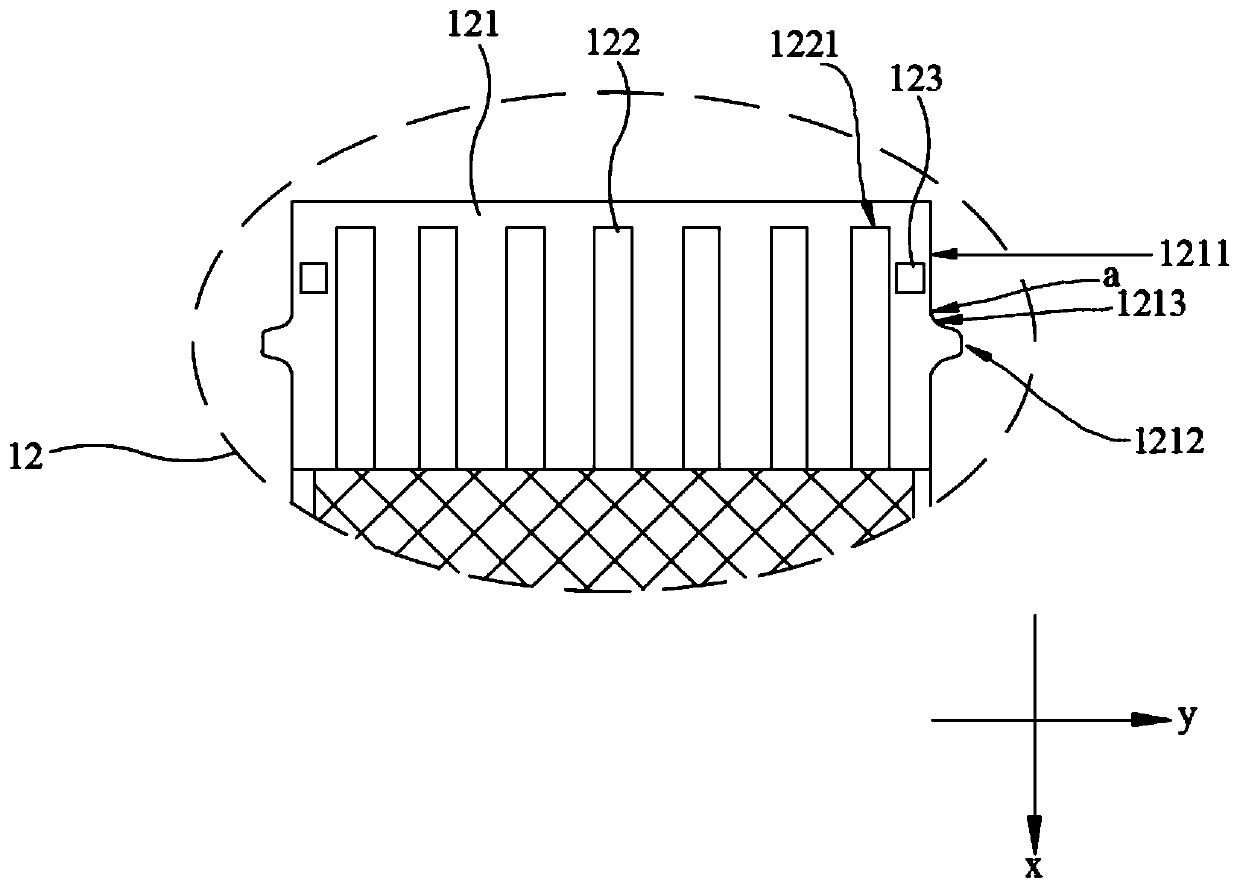

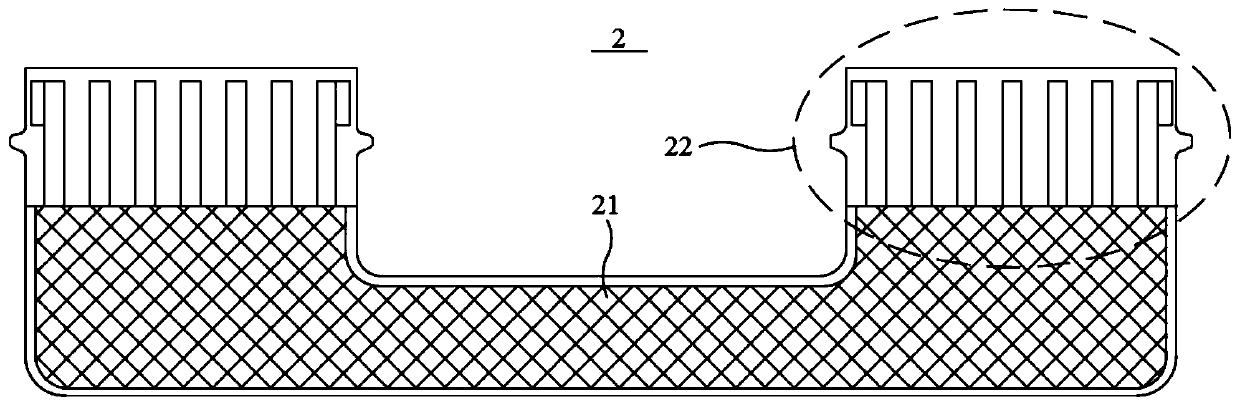

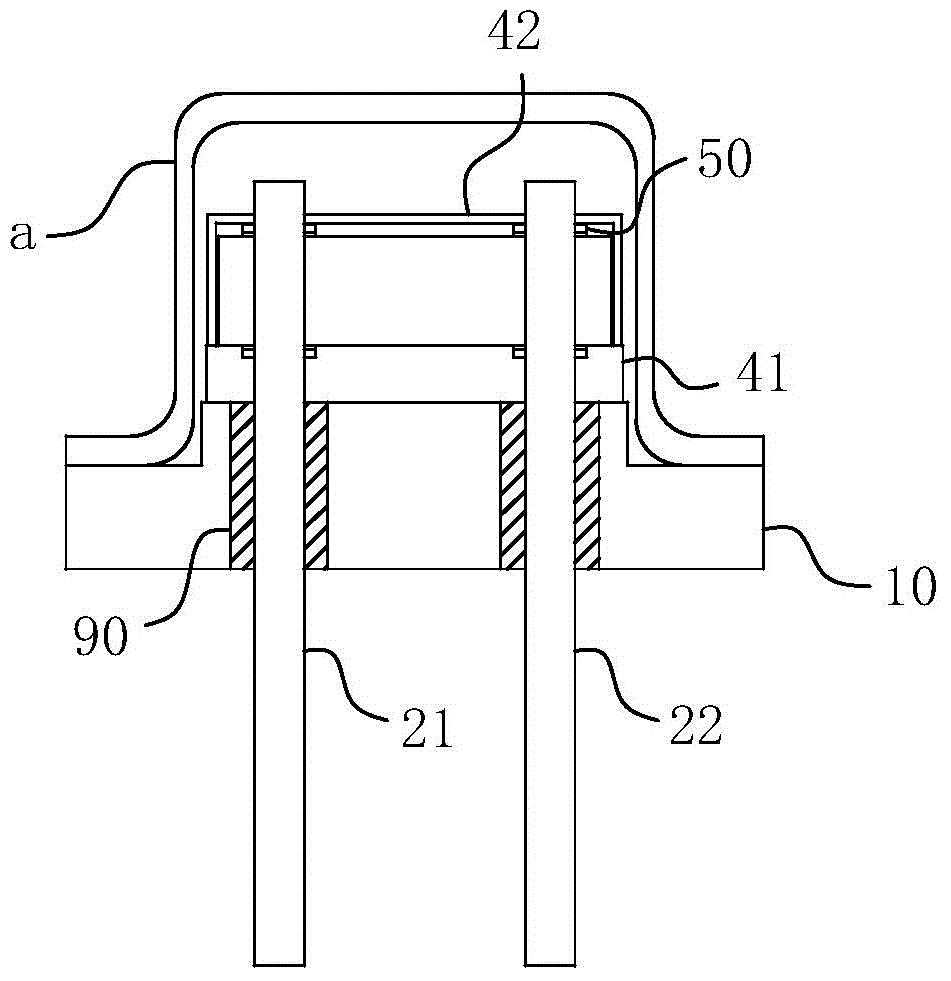

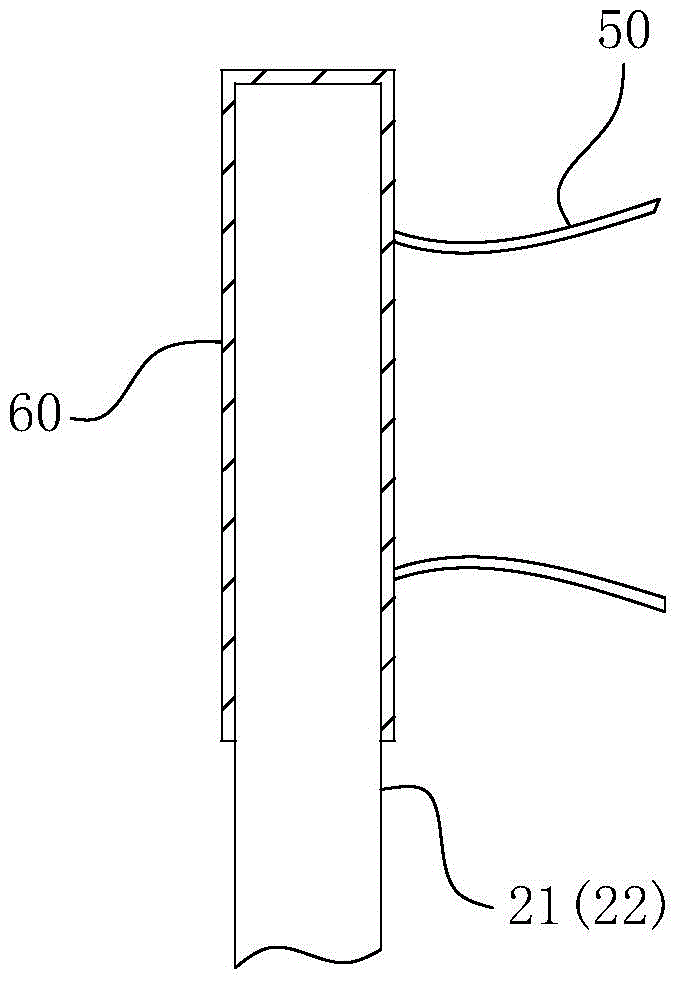

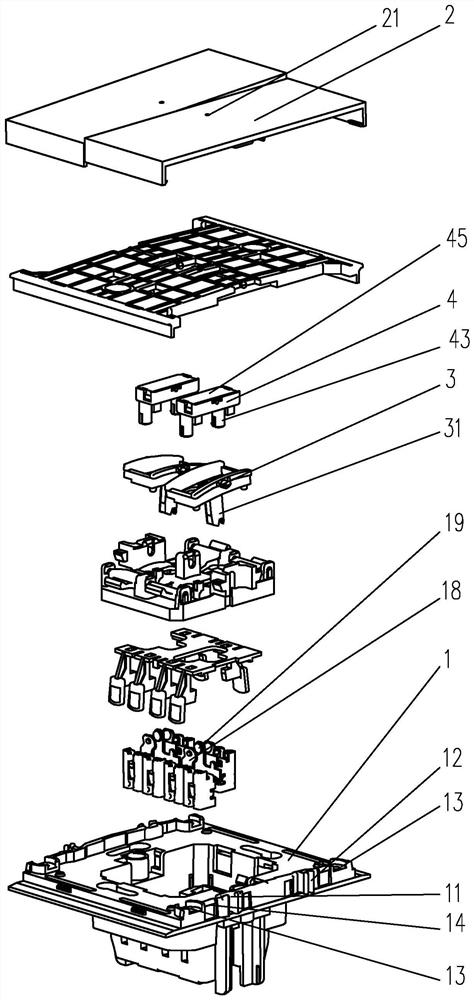

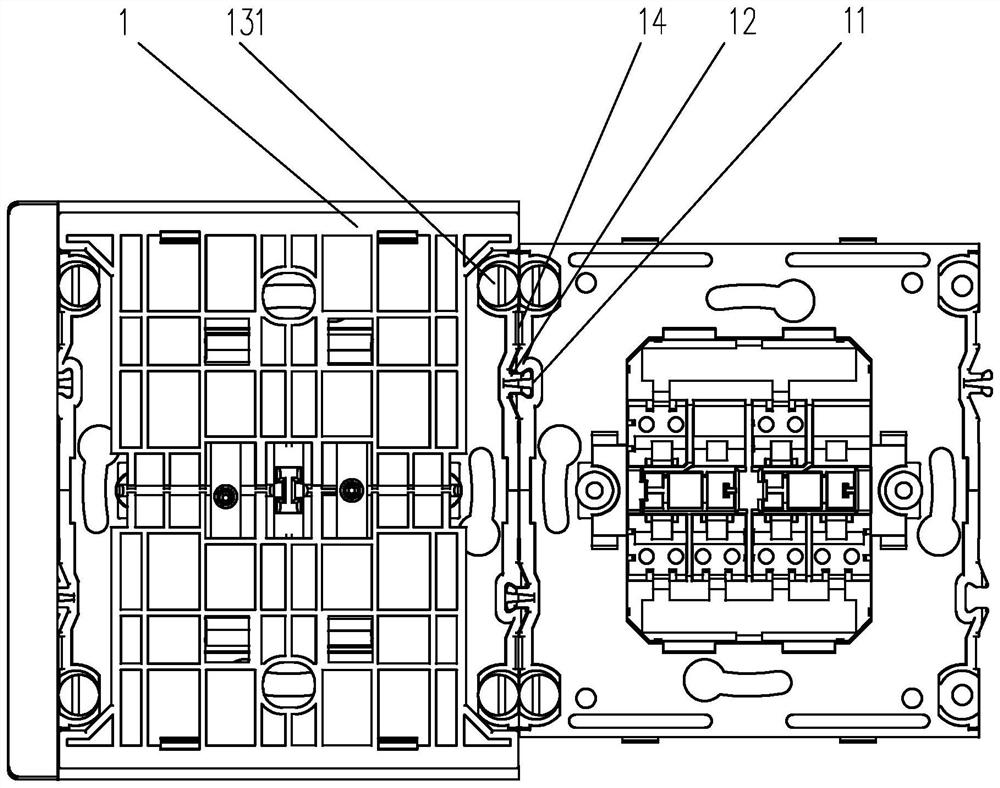

Joint with sealing structure and junction box with joint

PendingCN111327003AImprove anti-staticImprove dustproofElectrical apparatusClassical mechanicsEngineering

The invention relates to the technical field of joints, and particularly relates to a joint with a sealing structure and a junction box with the joint. The joint (1) is provided with an installation part (11) matched with a to-be-assembled part of a shell (2) and a connecting wire (12) connected with the installation part (11), wherein the installation part (11) is provided with an annular sealingpiece (4) matched with the periphery of the shell (2). According to the joint with the sealing structure and the junction box with the joint, due to the arrangement of the annular sealing piece, theanti-static, dustproof and waterproof performance is good, and the actual use requirement can be met.

Owner:DONGJUN NEW ENERGY CO LTD

Camera module and assembling method

ActiveCN110248062AReduce layoutIncrease contact areaTelevision system detailsColor television detailsElectrical connectionCamera module

The invention provides a camera module, which comprises a circuit board and a voice coil motor arranged on the circuit board, the voice coil motor is provided with a connecting pin extending towards the circuit board, and the connecting pin is provided with a contact surface which is consistent with the arrangement direction of the circuit board; the side, facing the circuit board, of the contact surface is kept flush with the lower surface of the side, facing the circuit board, of the voice coil motor; and the voice coil motor is electrically connected with the circuit board through the contact between the contact surface of the connecting pin and the circuit board. The invention further provides an assembling method of the camera module. The assembling method comprises the following steps that 1, the voice coil motor and the circuit board are provided; and step 2, the voice coil motor is fixed on the circuit board through an SMT process and electrical connection between the voice coil motor and the circuit board is realized. According to the camera module and the assembling method, the structure is simplified, the mounting procedures can be effectively reduced, the production efficiency is effectively improved, and the product quality is ensured.

Owner:TRULY OPTO ELECTRONICS

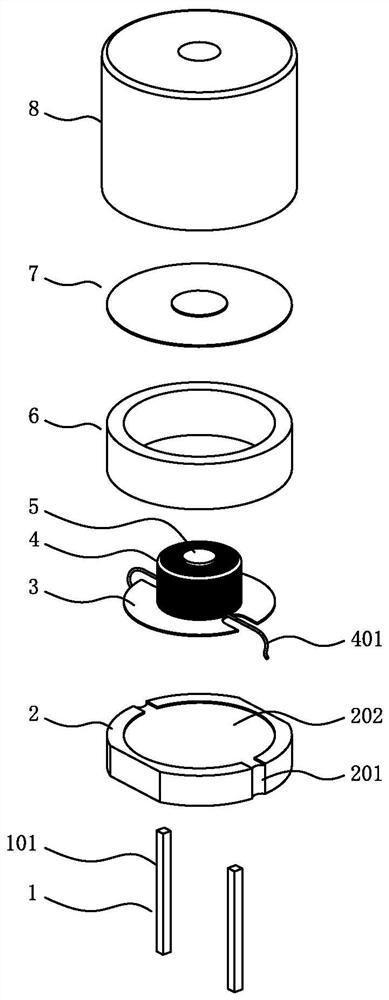

Improved buzzer and manufacturing process thereof

PendingCN113539220AIncrease productivityUninterrupted productionSound producing devicesElectrical connectionEngineering

The invention relates to an improved buzzer and a manufacturing process thereof. The improved buzzer comprises a pins, a bottom cover and a coil assembly, the pins and the coil assembly are respectively arranged on the bottom cover; and the starting end and / or the tail end of the coil assembly are / is directly and electrically connected with the corresponding pins. The buzzer is simple and reasonable in structure, the production process can be simplified, and the production efficiency can be improved.

Owner:广东疆海五音电子科技有限公司

Self-locking type electric connector

InactiveCN102882064BFirmly connectedGuaranteed electrical connection performanceElectric discharge tubesCoupling device detailsElectricitySelf locking

The invention relates to a self-locking type electric connector, comprising a first middle sleeve sleeved on a first rubber head, a second middle sleeve sleeved on a second rubber head, a first outer sleeve sleeved on the first middle sleeve and a second outer sleeve sleeved on the second middle sleeve; and the first middle sleeve and the second middle sleeve are in self-locking type connection through a locking ring. According to the electric connector disclosed by the invention, the locking ring is driven to rotate and reset by inserting locking springs after two connecting ends are abutted and inserted in place and pass over critical points so as to realize automatic locking; the connecting ends are inserted in place and the automatic locking is realized so that the connection electric performance of the two connecting ends is good, the connection is stable and firm, the two connecting ends do not automatically cut off and are connected on a straight line, and the self-locking type electric connector is rapid and convenient; furthermore, the sealing and waterproof performances are good; and the structure is simple and the weight is light.

Owner:SHENZHEN CHOGORI TECH CO LTD

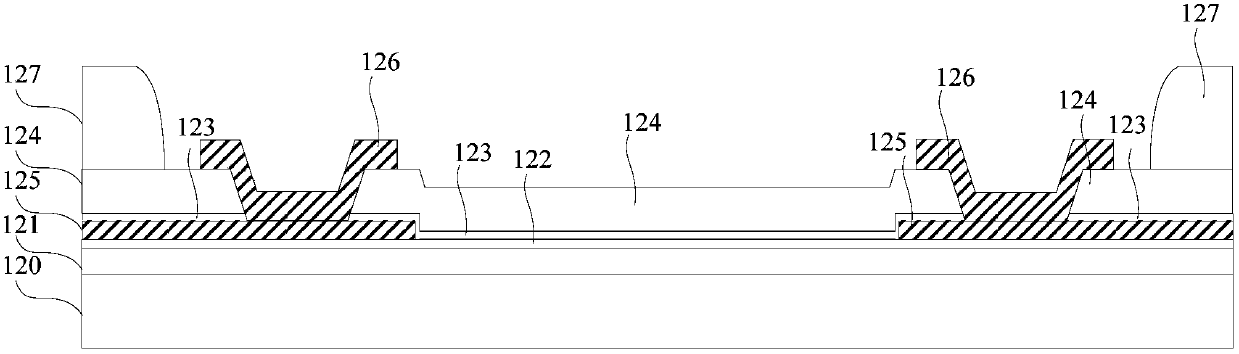

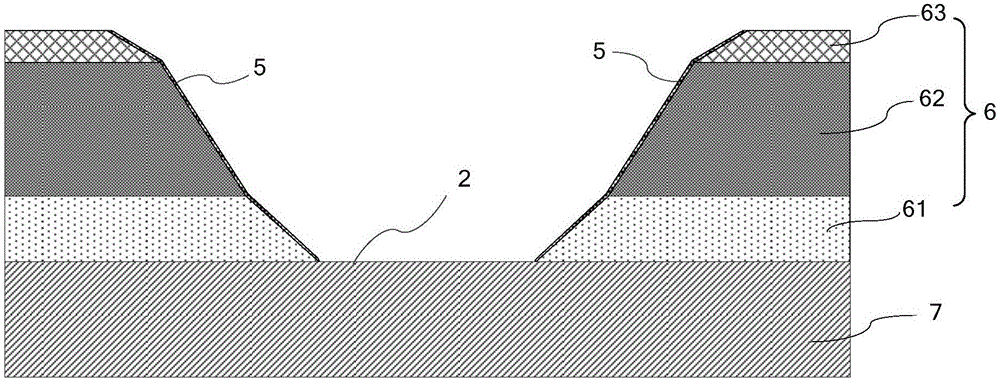

Array substrate, display panel and preparation method of array substrate

ActiveCN106531748AGuaranteed electrical connection performanceImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineering

The invention provides an array substrate, a display panel and a preparation method of the array substrate. A protective film layer is formed at the position, at least corresponding to a first insulating layer, on the side wall of a via hole which penetrates through the first insulating layer, a second insulating layer and a third insulating layer, and an undercut chamfer at the bottom of the via hole can be avoided, so that the electric connection property between two layer structures connected through the via hole is ensured, and the yield and the display effects of the array substrate and the display panel are improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

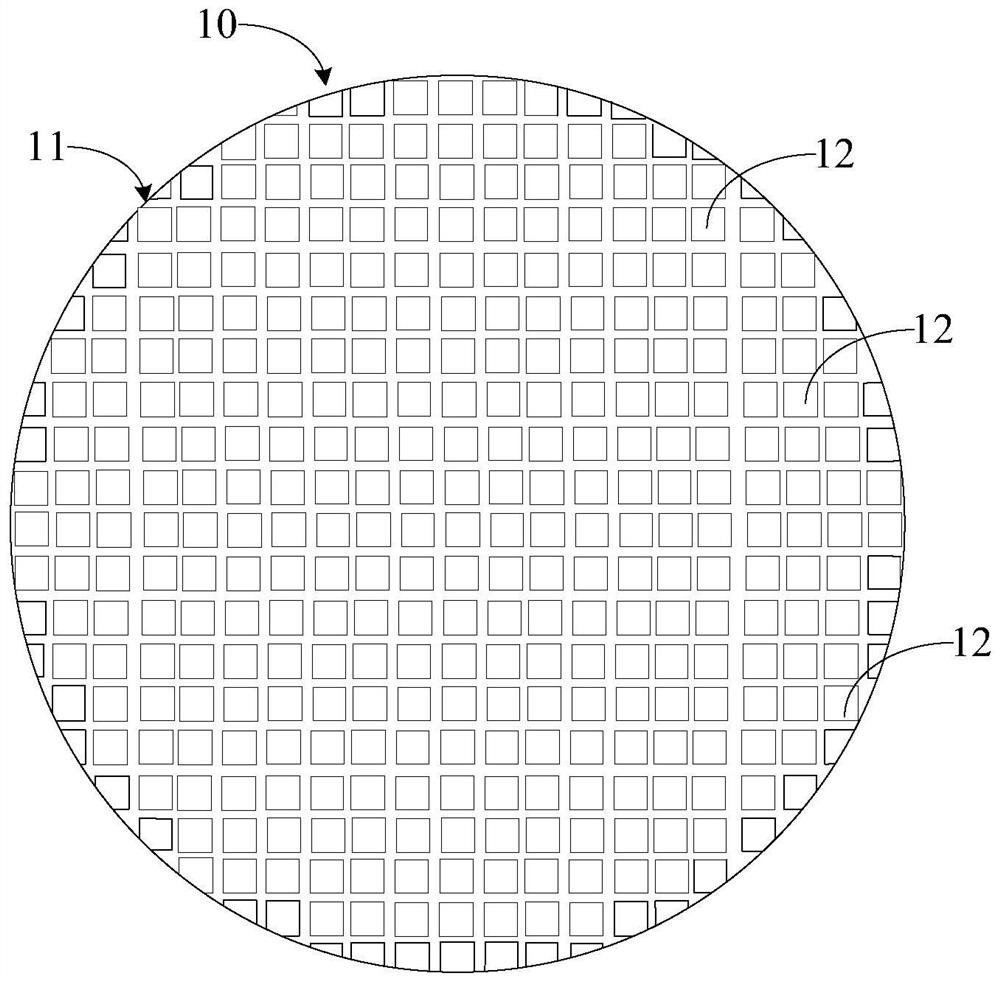

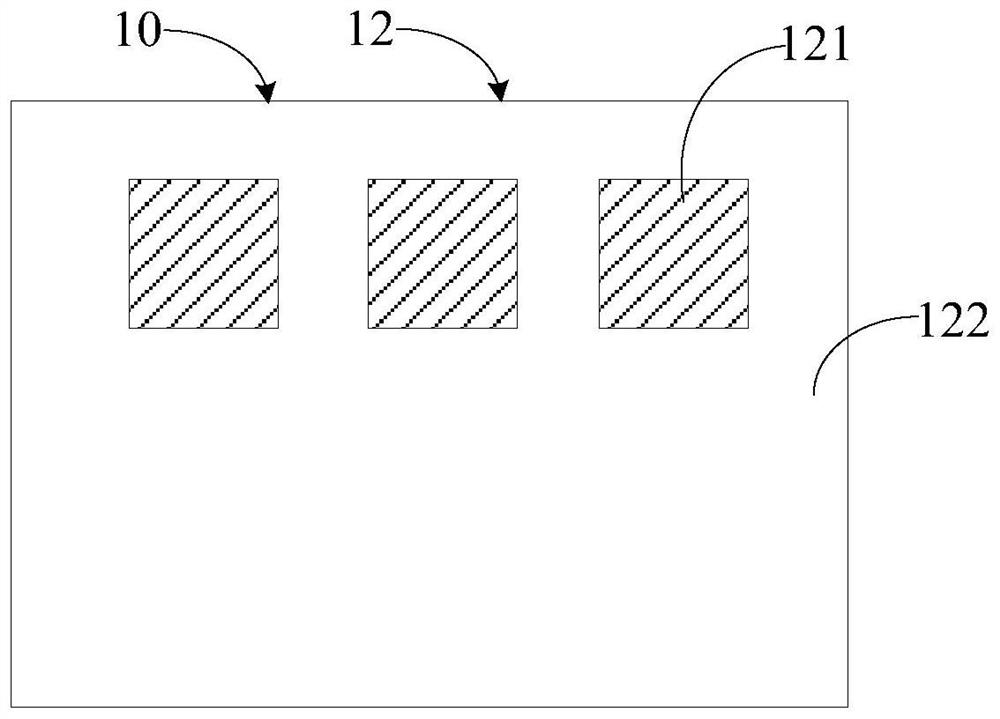

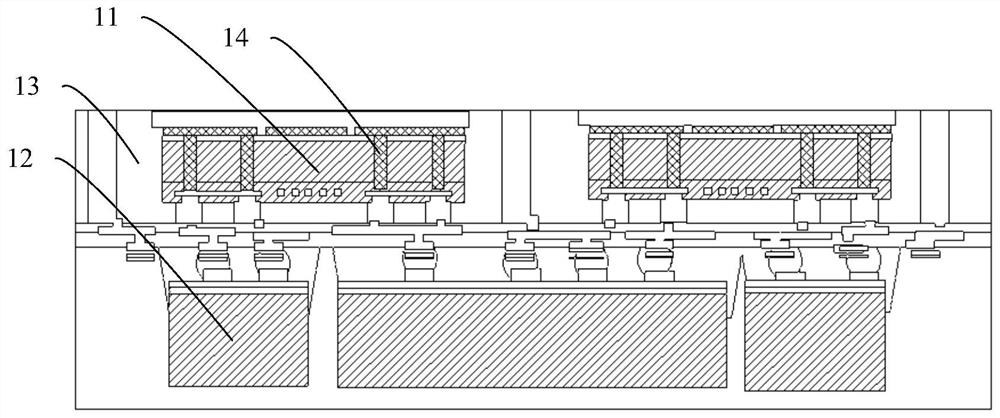

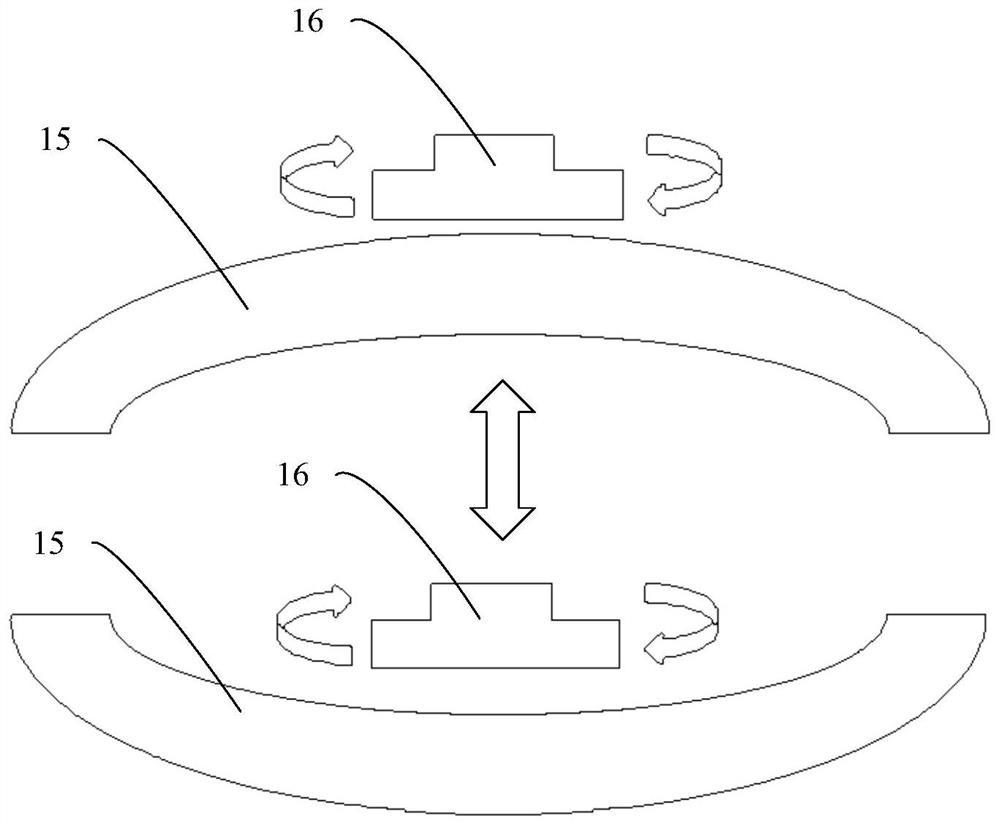

Wafer connector

InactiveCN1841860AGuaranteed electrical connection performanceElectric discharge tubesCoupling device detailsElectrical and Electronics engineeringCrystal

The invention provides a crystal chip connector which is used to electric connect a crystal chip. It comprises a base with a plurality of terminal grooves and a crystal chip position area, wherein the elastic device is positioned on the rear end of the base; a plurality of terminals are positioned in the plurality of terminal grooves; there are a touching part, an upper cover whose rear end is connected with the base and the front end has a projection, a first raising jack and a second raising jack; when the upper cover covers the base, it can press the crystal chip and the second raising jack can be on the front end of the crystal chip; the bell crank has vertical first crank and second crank, when the first crank bells to the rear end of the base, the projection crank can press the projection of the upper cover and pull the first raising jack of the upper cover so that the upper cover shifts to the rear end and pulls the second raising jack to let the crystal chip to move to the rear part.

Owner:TOP YANG TECH ENTERPRISE CO LTD

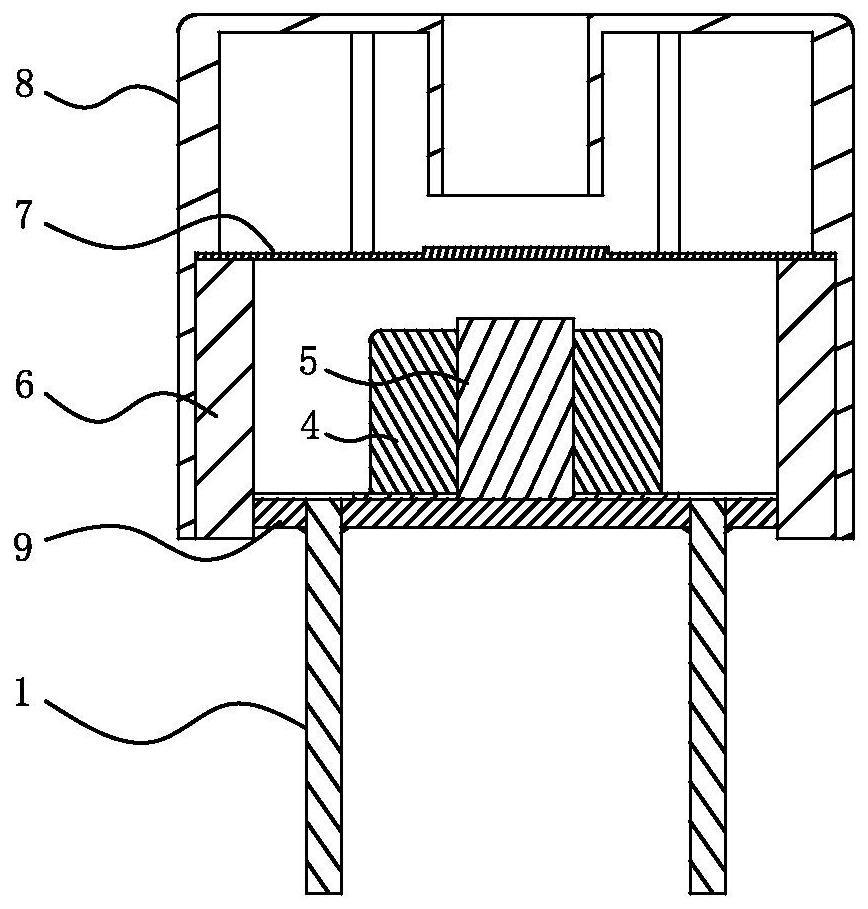

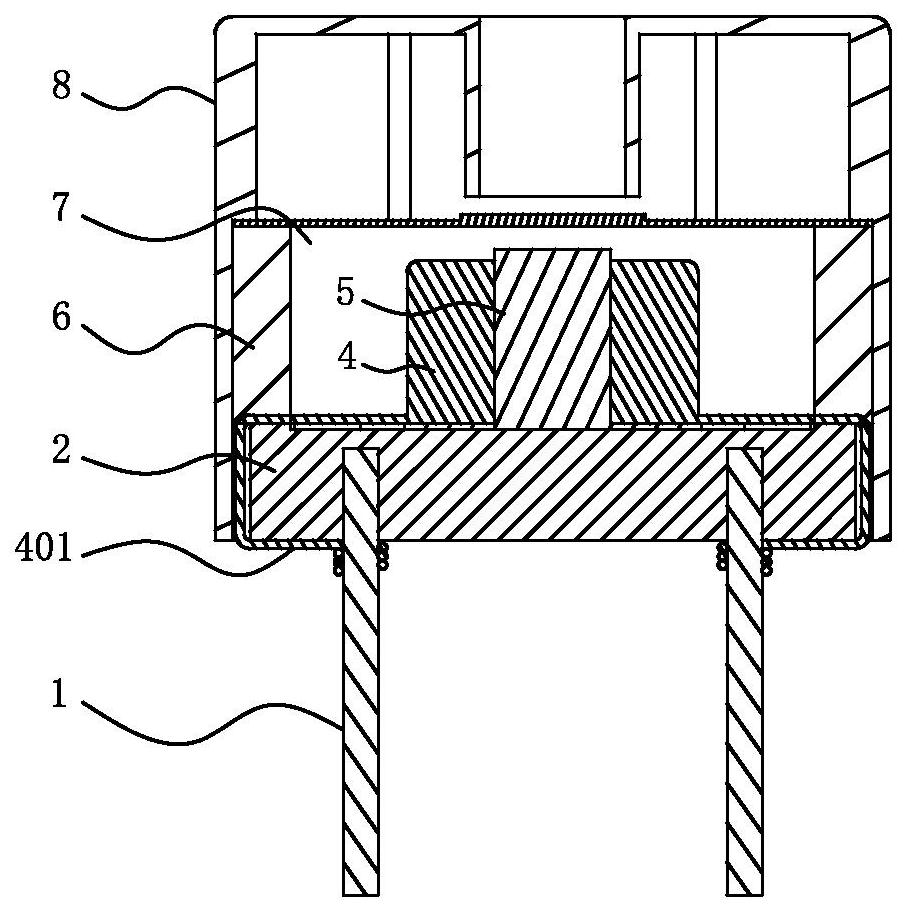

Plastic motor

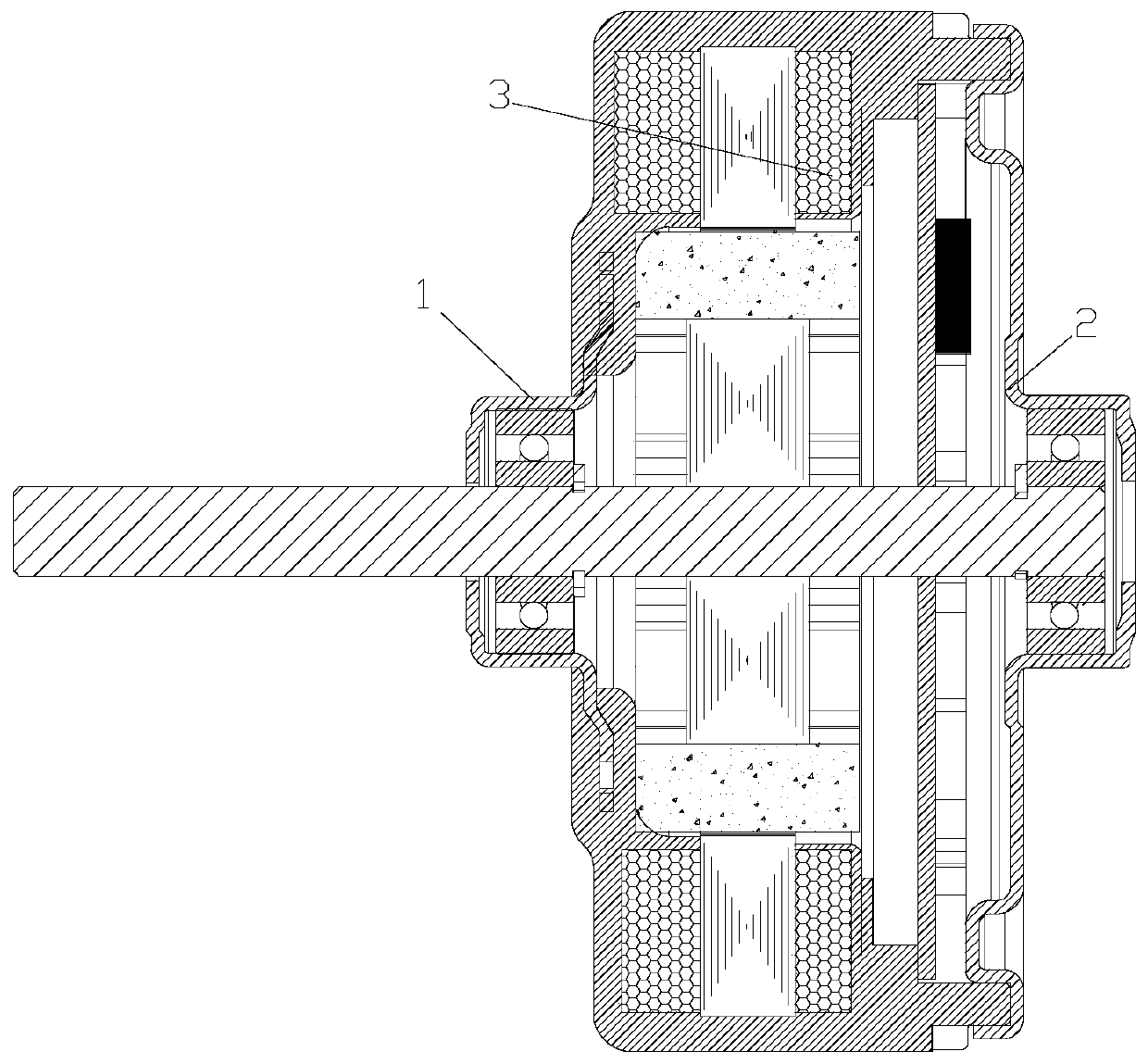

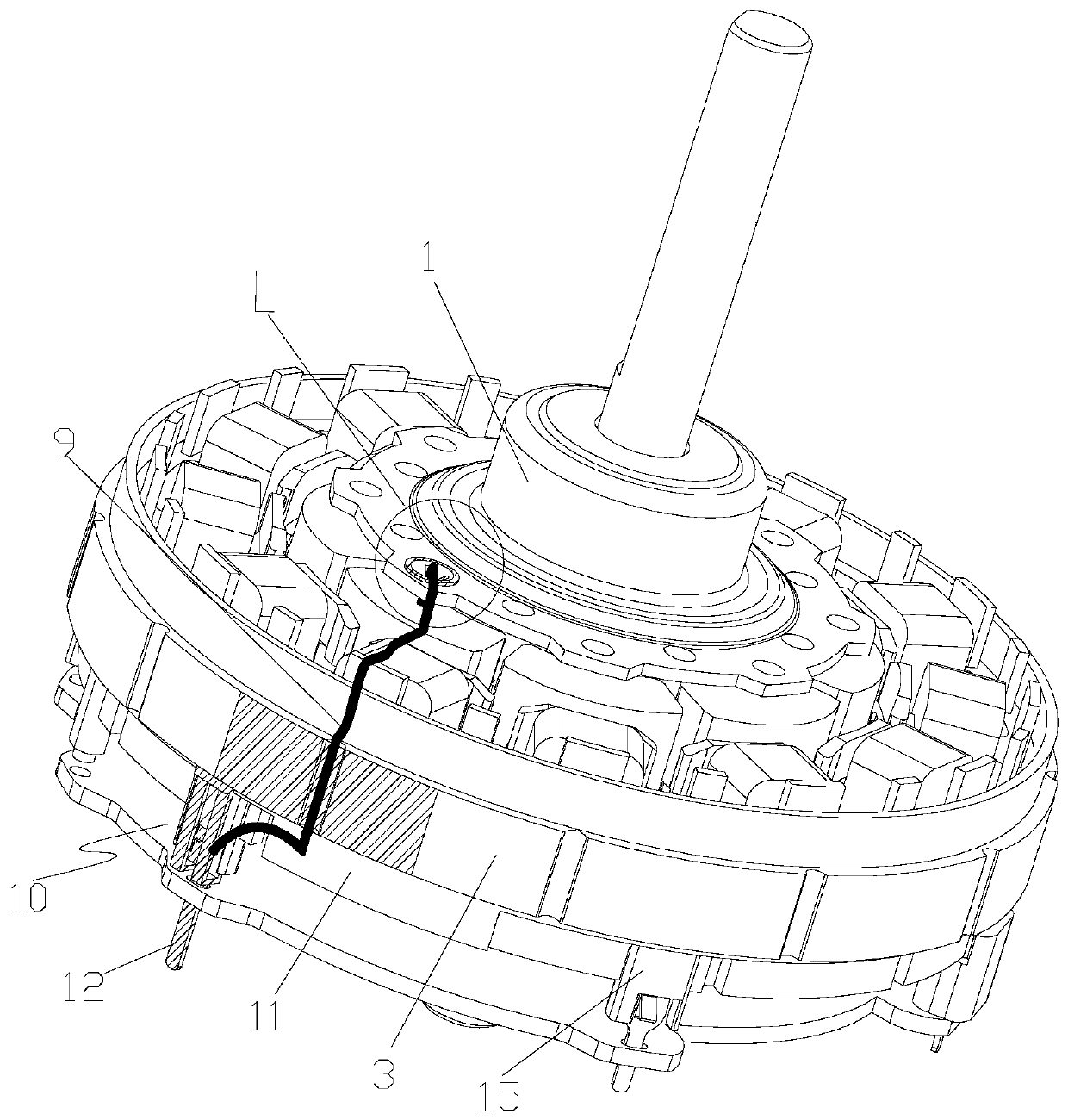

ActiveCN109038910BImprove bearing anti-corrosion functionImprove EMC performanceAssociation with grounding devicesWindingsElectric machineStructural engineering

The invention provides a plastic package motor. The plastic package motor comprises a front cover (1), the rear end cover (2), the stator core (3), the conductive connector and the h-shaped terminal piece (10), the h-shaped terminal piece (10) is in contact with the stator core (3), the protruding end of the h-shaped terminal piece (10) is in conductive contact with the rear end cover (2), one endof the conductive connector is in conductive connection with the h-shaped terminal piece (10), and the other end of the conductive connector is in conductive connection with the front end cover (1).The plastic package motor according to the invention can improve the reliability of the electric erosion prevention structure of the motor, so that the electric erosion prevention structure of the motor is firm and is not easy to fall off.

Owner:GREE ELECTRIC APPLIANCES INC +1

Flexible printed circuit board and display device

PendingCN111479381AIncrease productivityGuaranteed electrical connection performanceInspection/indentification of circuitsElectrical connection printed elementsDisplay deviceElectrical connection

The invention provides a flexible printed circuit board and a display device. The flexible printed circuit board comprises a circuit wiring part, a golden finger end connected with the circuit wiringpart, and a detection bonding pad. The golden finger end comprises a substrate and a plurality of conductive contact pieces arranged on the substrate in an array mode. The substrate comprises a side punching edge; the detection bonding pad is positioned between the conductive contact piece and the side punching edge; a flexible printed circuit board is punched and molded; by observing and detecting whether the bonding pad is punched, whether the flexible printed circuit board has punching deviation can be judged, so that whether the flexible printed circuit board is qualified can be judged more quickly and accurately, the production efficiency of the flexible printed circuit board is improved, and the electrical connection performance of the flexible printed circuit board is guaranteed.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Automatic electricity conversion apparatus for rubber-tyred crane transmission

ActiveCN102363504BHigh protection levelReduce quality problemsLoad-engaging elementsElectricitySliding contact

Owner:NINGBO WEILONG PORT MASCH CO LTD

Anti-vibration impact type quartz crystal resonator

ActiveCN104901646AAvoid breakingExtended service lifeImpedence networksQuartz crystal resonatorEngineering

The invention belongs to the field of electronic resonant elements, and particularly relates to an anti-vibration impact type quartz crystal resonator. The anti-vibration impact type quartz crystal resonator at least comprises a base and a shell covering on the base. The base is also provided with a positive lead post and a negative lead post, which penetrate through the base and are insulating to each other. Both the positive lead post and the negative lead pose are arranged at the same side of a quartz crystal wafer. Jaw-shaped clamping parts for clamping and fixing the quartz crystal wafer are arranged on the positive lead post and the negative lead post at the same height so as to enable the quartz crystal wafer to be at a horizontal suspension state. The jaw-shaped clamping parts at corresponding lead posts are respectively electrically connected with corresponding electrodes on the quartz crystal wafer. Relative to a fixing clamping end of the fixing lead post of the quartz crystal wafer, a support part for supporting a suspension end is arranged on the base where the suspension end is. While guaranteeing the normal working performance, the anti-vibration impact type quartz crystal resonator can achieve the purpose of efficient assemble, and both the assemble efficiency and service life of the resonator can be further improved.

Owner:HEFEI JINGWEITE ELECTRONICS CO LTD

Wall switch

A wall switch disclosed by the present invention comprises a switch base and a toggle, the toggle is rotatably arranged on the switch base, a swing base is arranged on the switch base in a swing manner, the swing base is in transmission connection with the toggle, the switch base is also provided with a lamp holder, a light-emitting unit is arranged in the lamp holder, and the light-emitting unit is arranged on the switch base. The swing seat is further provided with a contact used for changing the state of the light-emitting unit when the toggle switch is switched on and switched off, a display groove is formed in the position, corresponding to the lamp holder, of the toggle switch, a connecting groove and a connecting piece are arranged on the side edge of the switch seat, and the connecting groove is clamped with the connecting piece of the adjacent switch seat to be connected with the adjacent switch seat side by side. The switch base is provided with a mounting groove in the side direction of the connecting groove and the connecting piece, and an eccentric wheel is rotationally arranged in the mounting groove. The structure is simple, the installation time interval is convenient to adjust, connection is stable, and meanwhile the prompt identification function is achieved.

Owner:WENZHOU GUANGTAI ELECTRICAL APPLIANCE

Pin pressing interlocking device for plug-in box

ActiveCN110739587BEffective contactGuaranteed electrical connection performanceCoupling device detailsBusbarInterlock

The invention discloses a pin pressing interlocking device for a plug-in box, which comprises: a box body of a plug-in box, with a backboard of the box body facing a bus duct and a door cover opposite to the backboard of the box body; elastic pins can The mobile device is installed in the box body of the plug-in box, and its end protrudes from the back plate of the box body to the outside of the box body of the plug-in box to connect with the bus duct; the interlocking component can be selectively squeezed The elastic pin is pressed to be pressed against the busbar groove, and when it is not pressed against the elastic pin, the end of the elastic pin far away from the elastic pin hinders the closing of the door cover. The plug-in interlocking component is used to exert a preset pressure on the elastic pins, so as to ensure effective contact between the elastic pins and the bus duct, and ensure electrical connection performance.

Owner:WETOWN ELECTRIC GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com