Display substrate and manufacturing method thereof, display panel and display device

A display substrate and display panel technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of ACF bubbles, ACF difficult to compress, etc., and achieve the effect of avoiding bubbles and ensuring electrical connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] In order to facilitate the description later, the following will be combined with the attached figure 1 The OLED panel Bonding involved in the embodiment of the present invention is explained:

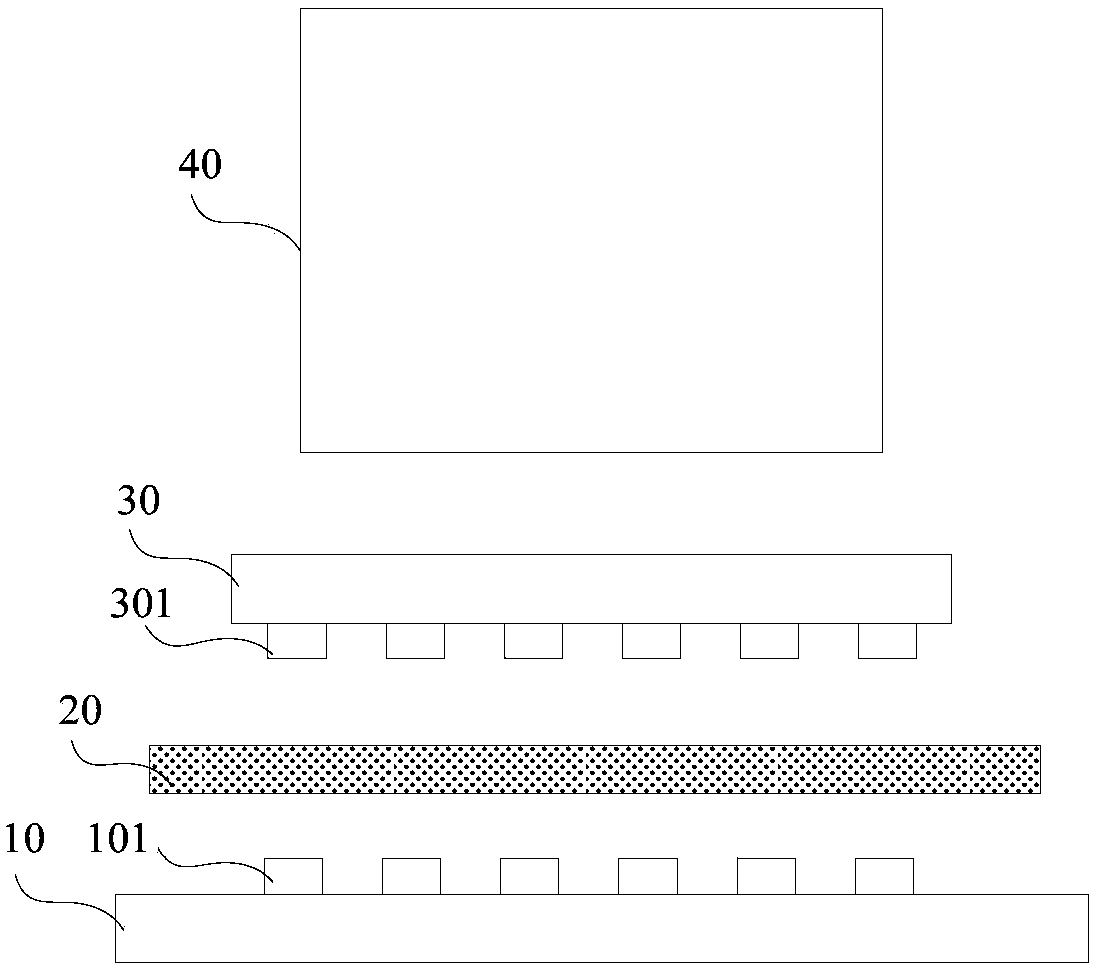

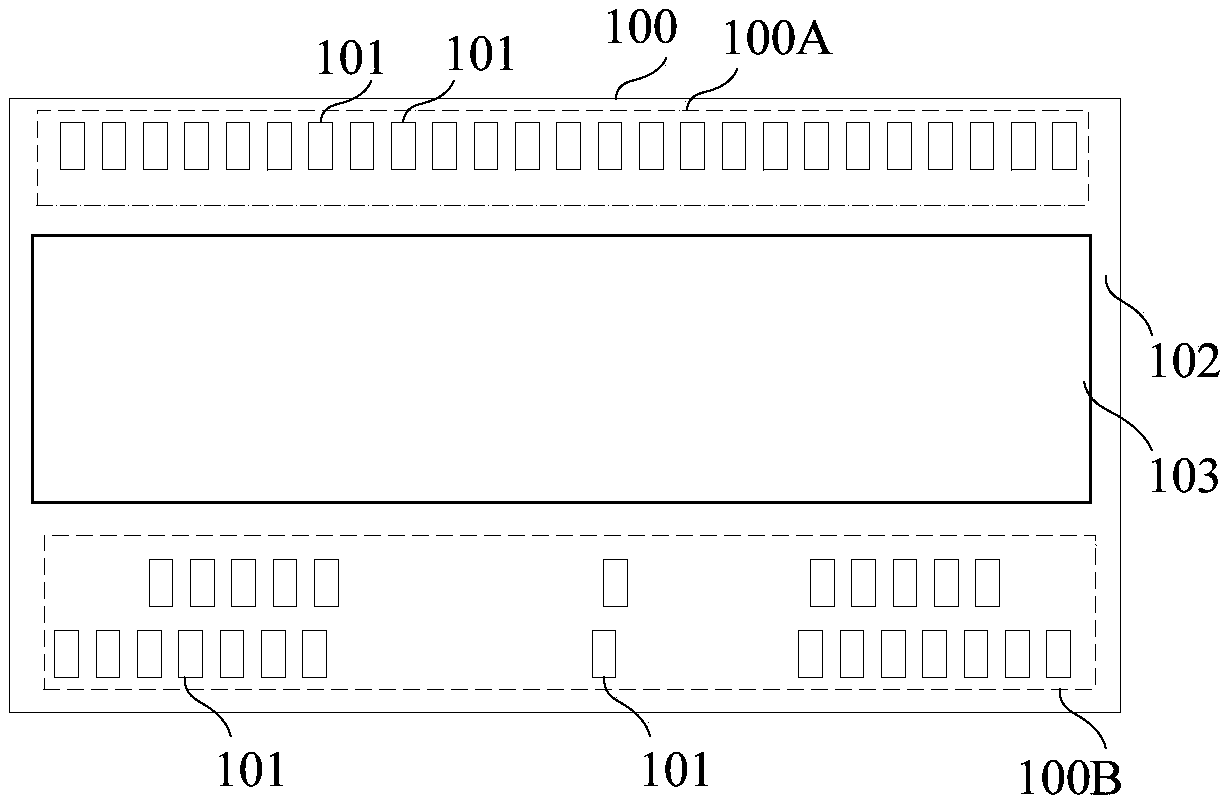

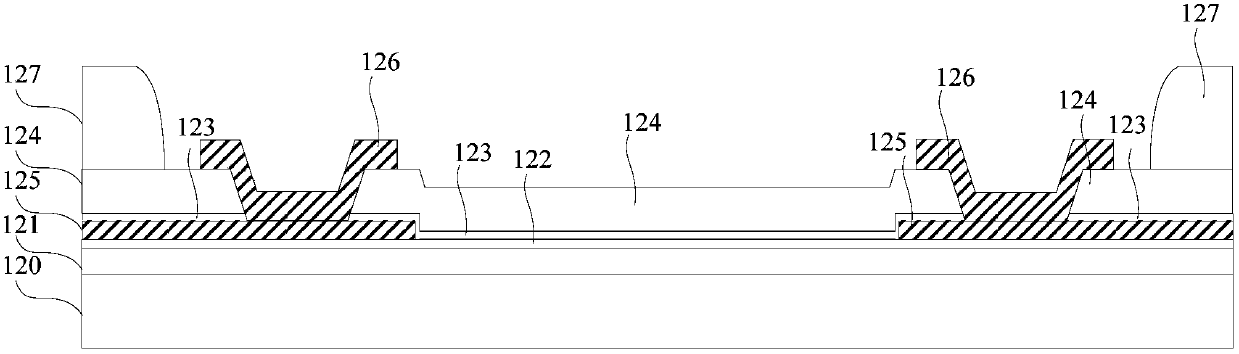

[0037] figure 1 It is a schematic diagram of Bonding of the OLED panel, see figure 1 , wherein the label 10 is the display substrate (that is, the OLED substrate), 20 is the ACF, and 30 is the driver IC. During Bonding, ACF 20 is coated on the bonding area of the display substrate 10, and then, under the action of the heater 40, the driver IC 30 is pressed onto the display substrate 10 , and the pad 101 of the display substrate 10 and the pad 301 of the driving IC 30 are conducted under the action of the ACF 20 .

[0038] However, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com