Plastic motor

A plastic-encapsulated motor and conductive connection technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as low reliability, weak connection of anti-electric corrosion structure, affecting bearing lubricity and service life, etc., to improve stability performance and reliability, and the effect of improving the anti-corrosion function of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

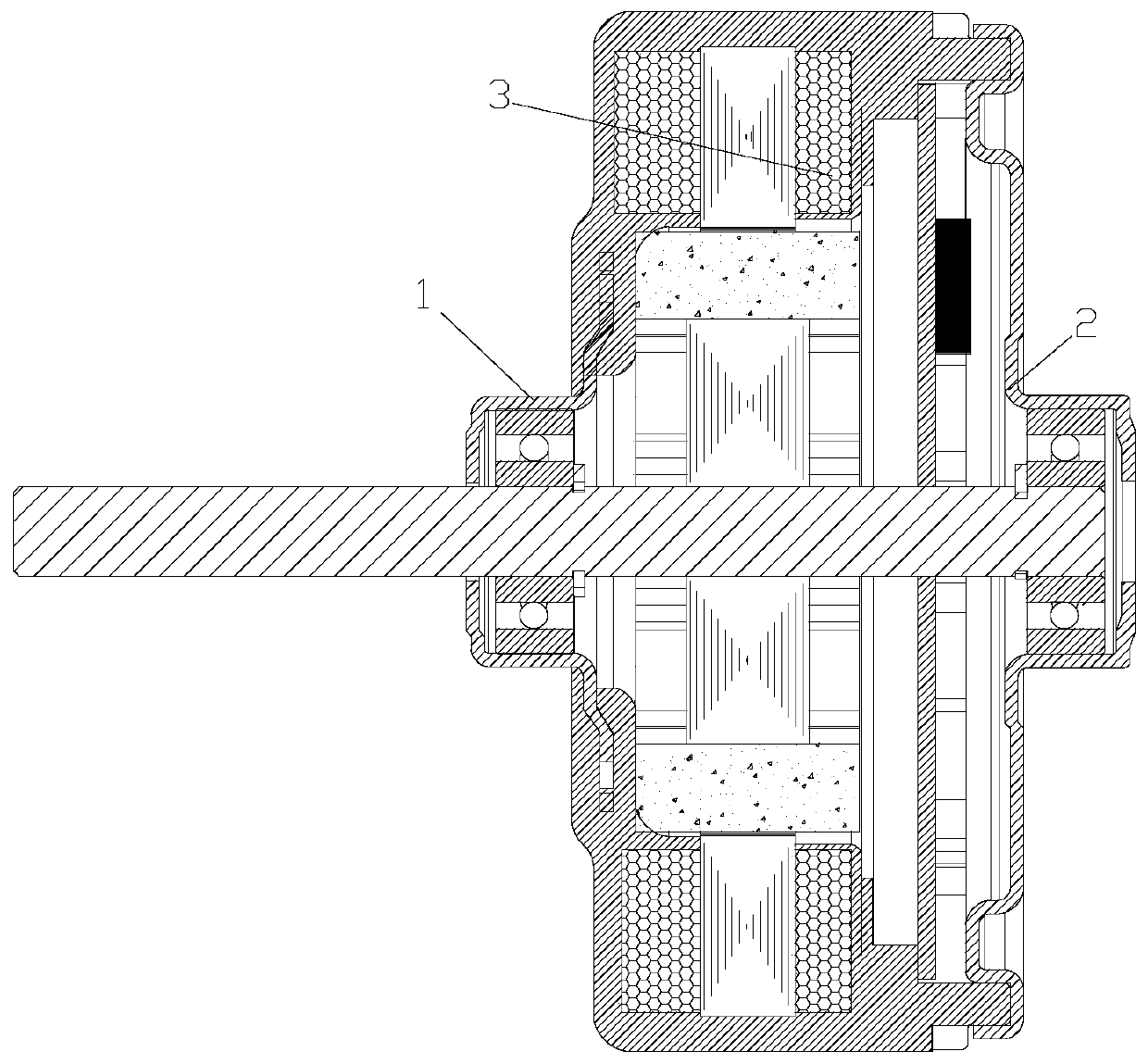

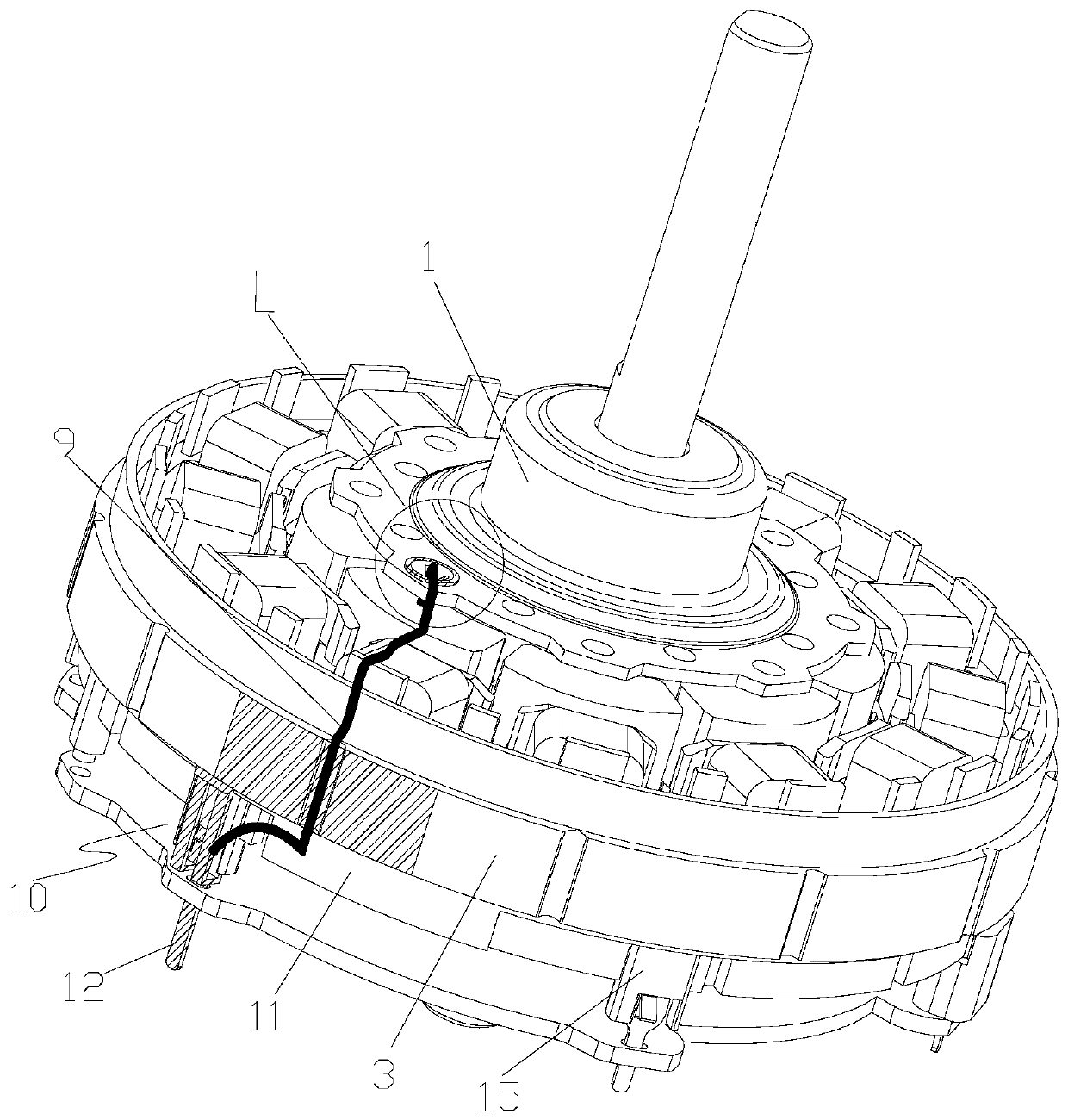

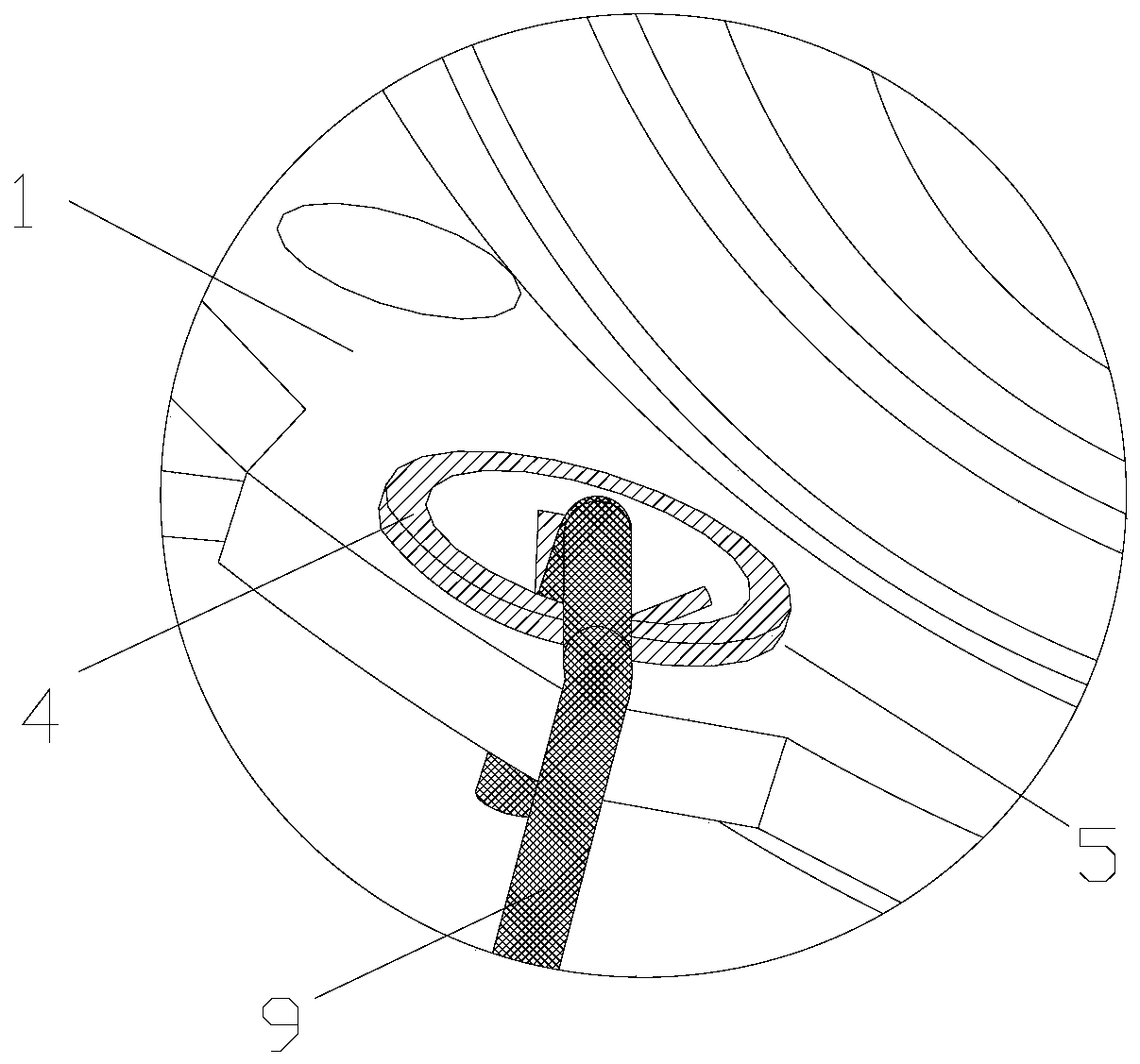

[0036] see in conjunction Figure 1 to Figure 16 As shown, according to the embodiment of the present invention, the plastic-encapsulated motor includes a front end cover 1, a rear end cover 2, a stator core 3 and an anti-galvanic corrosion structure. The anti-galvanic corrosion structure includes conductive connectors and h-shaped lugs 10, and the h-shaped wiring The piece 10 is in contact with the stator core 3, the protruding end of the h-shaped lug 10 is in conductive contact with the rear end cover 2, one end of the conductive connector is electrically connected to the h-shaped lug 10, and the other end of the conductive connector is connected to the front end cover 1 Conductive connection.

[0037] The h-shaped lug 10 is connected between the stator core 3 and the rear end cover 2, and is connected to the conductive connector at the same time. Therefore, the structure of the h-shaped lug 10 can be used to realize the connection between the stator core 3 and the rear end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com