Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Guaranteed continuous delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

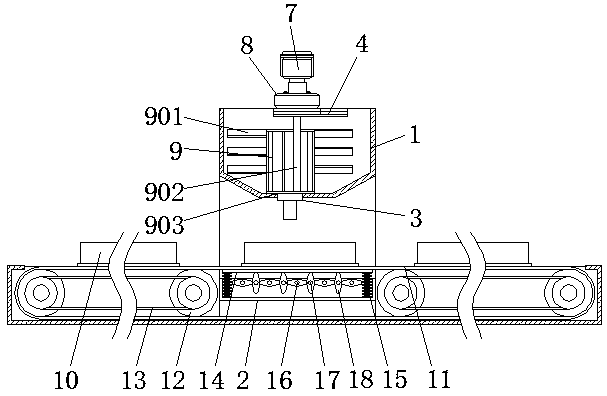

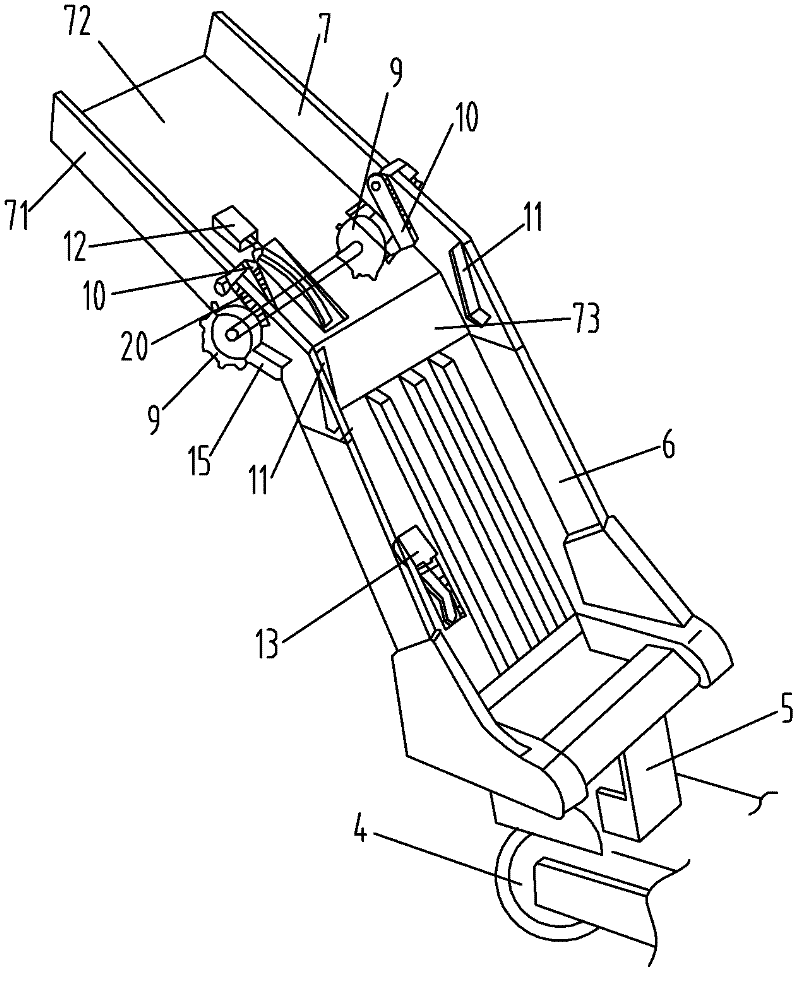

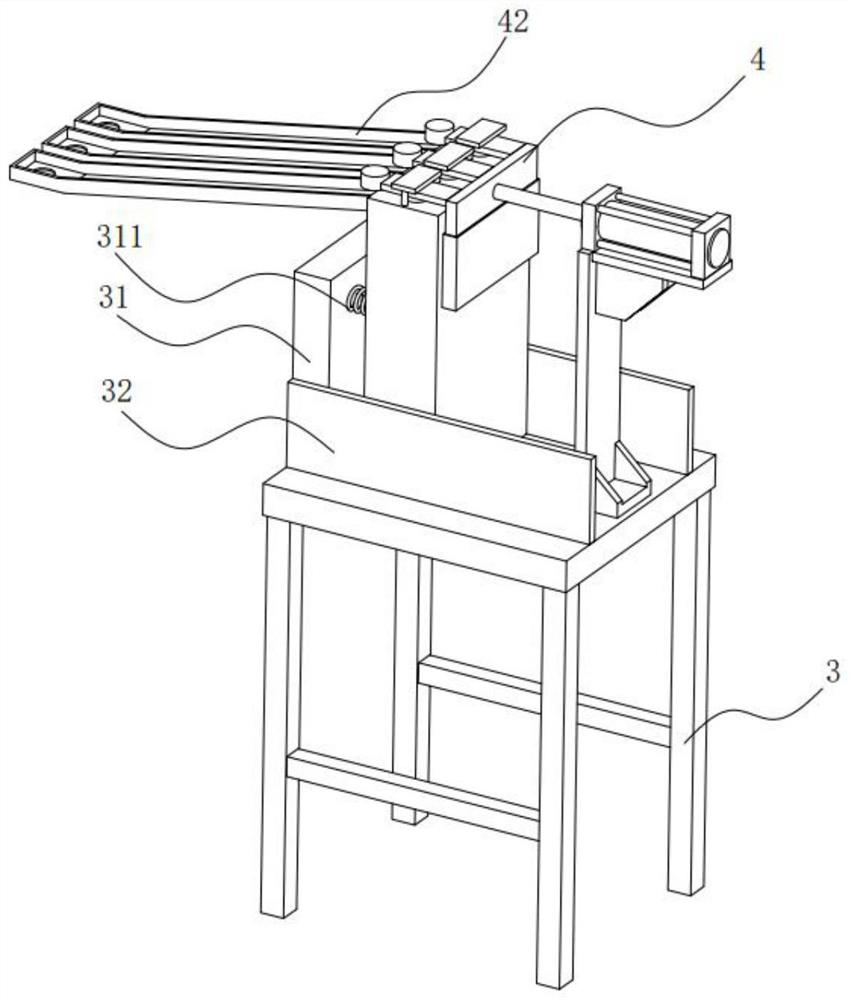

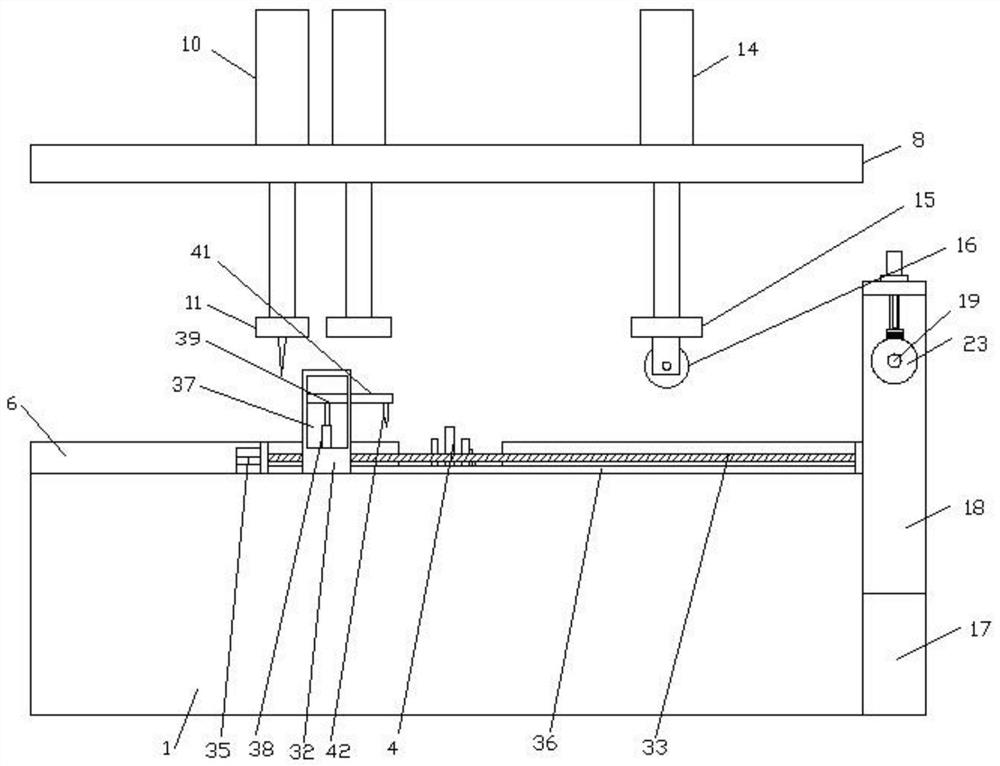

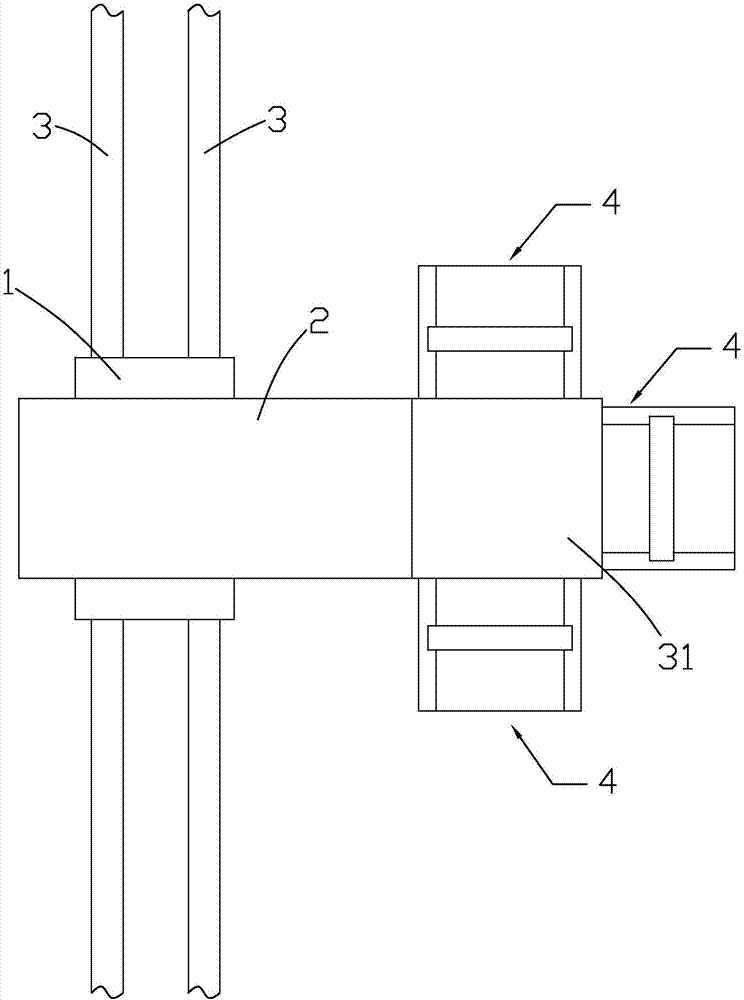

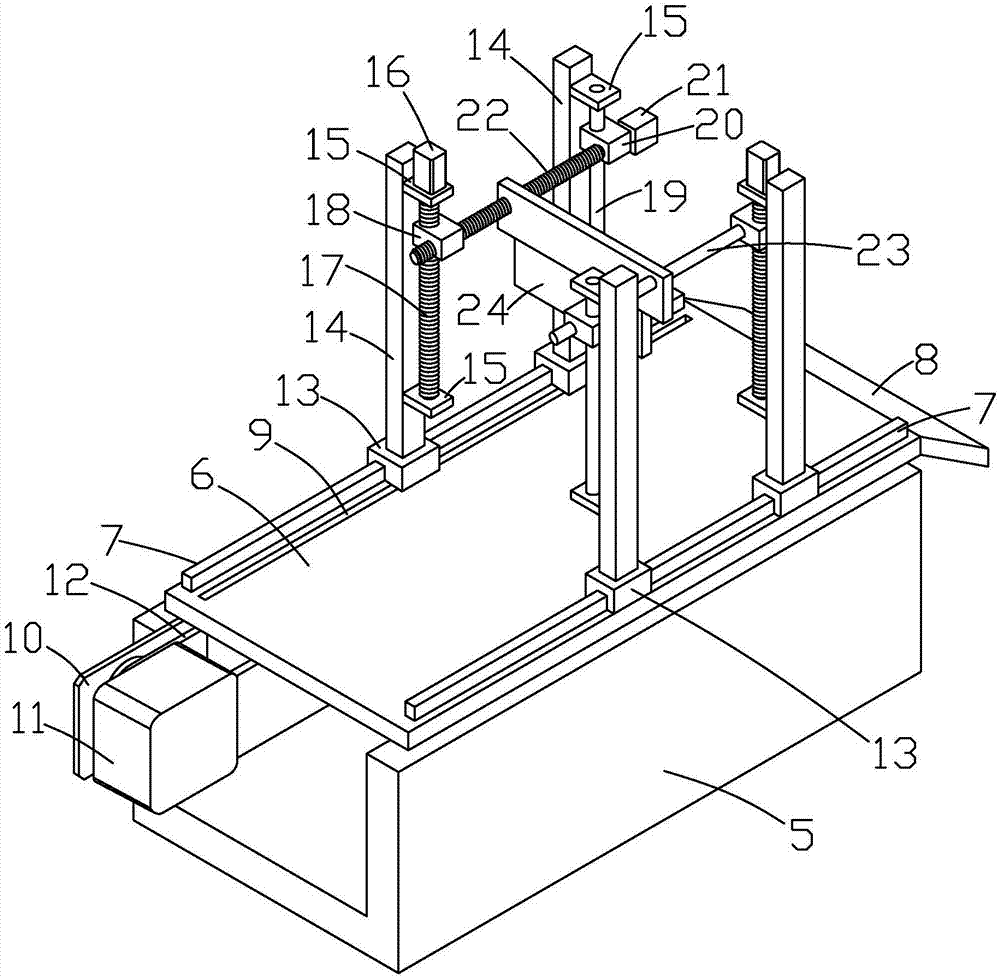

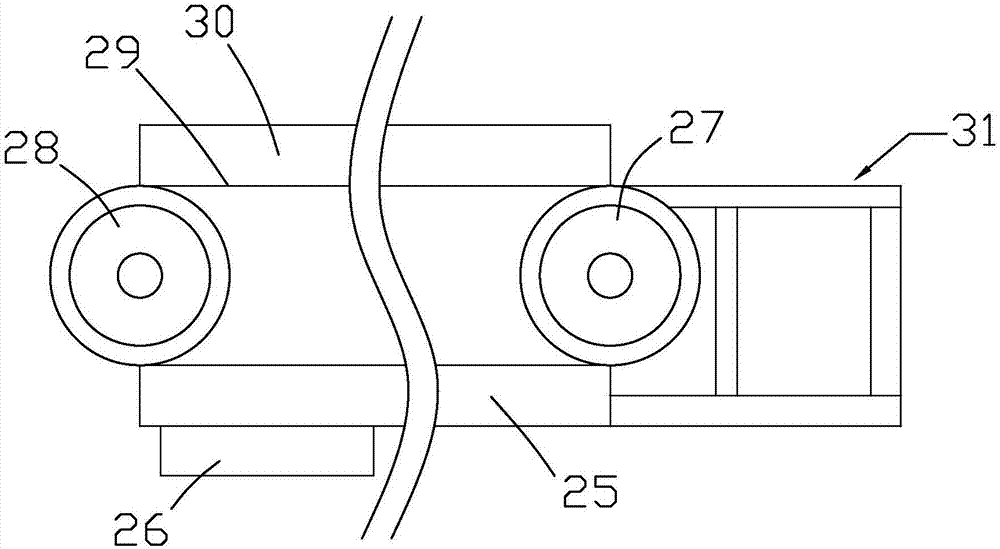

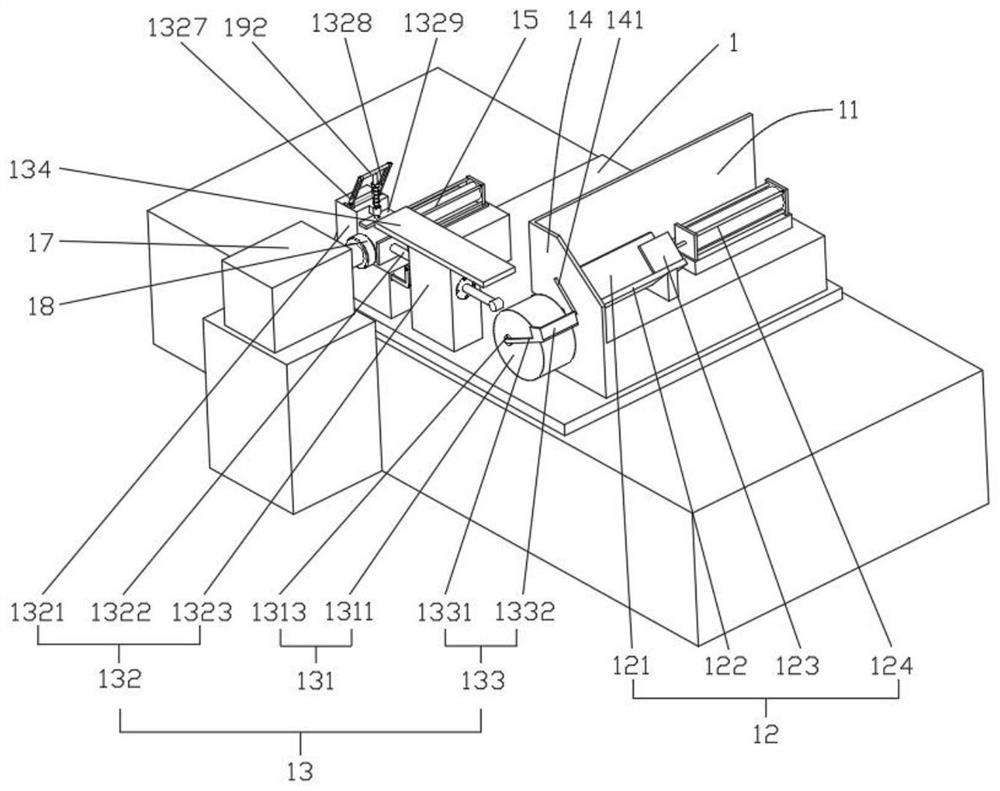

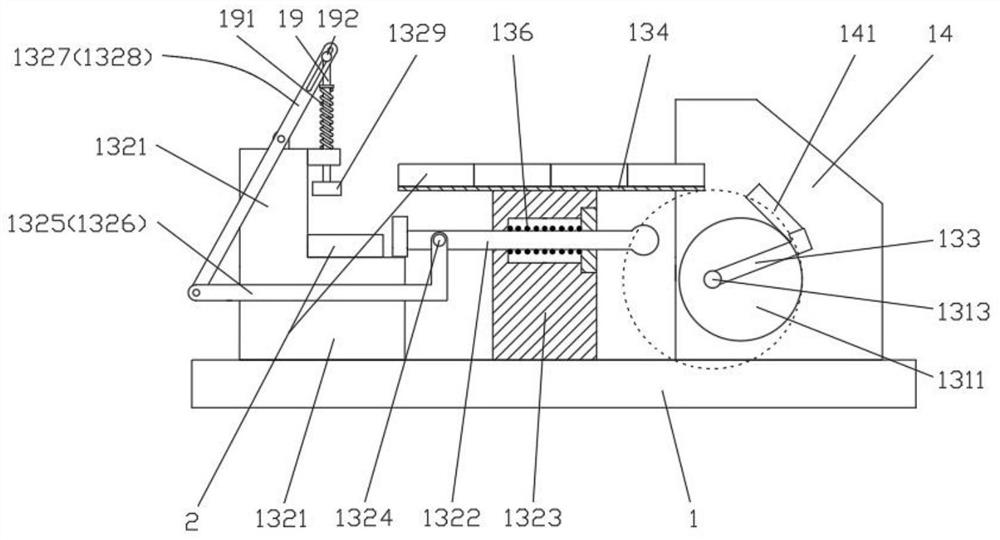

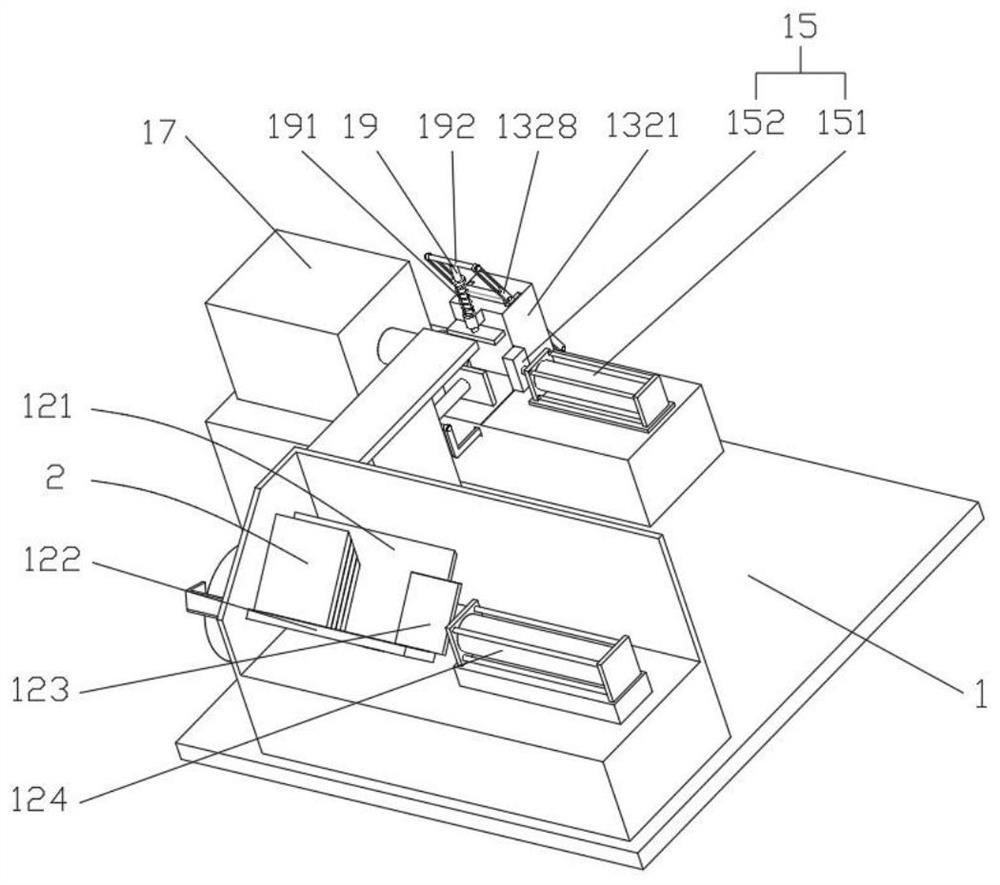

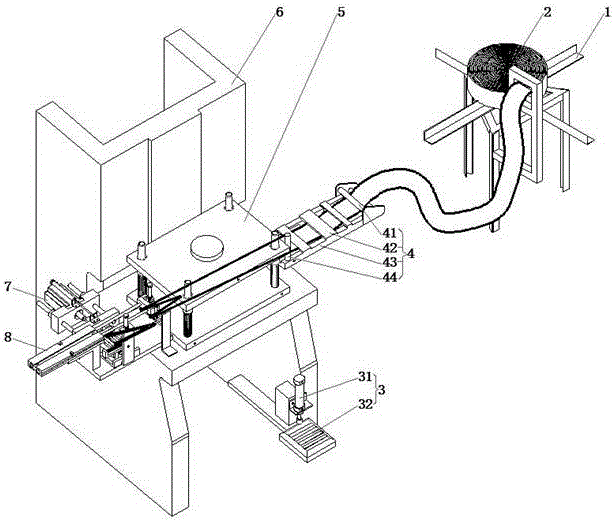

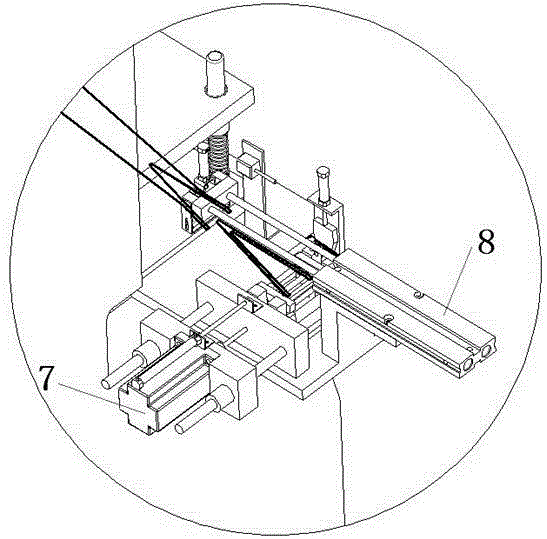

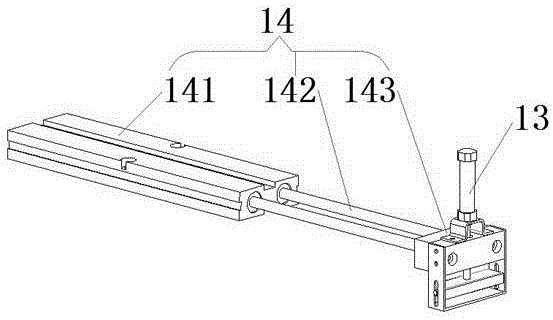

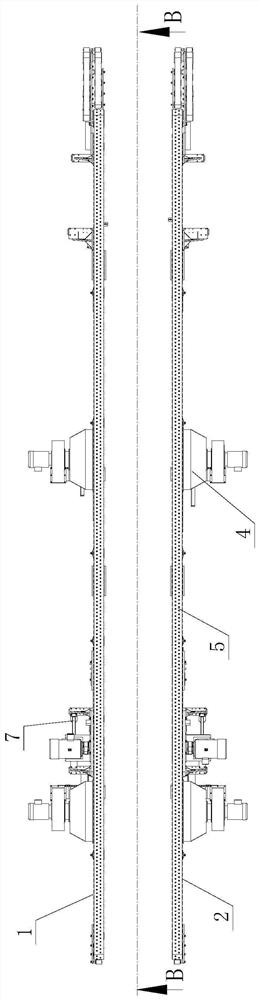

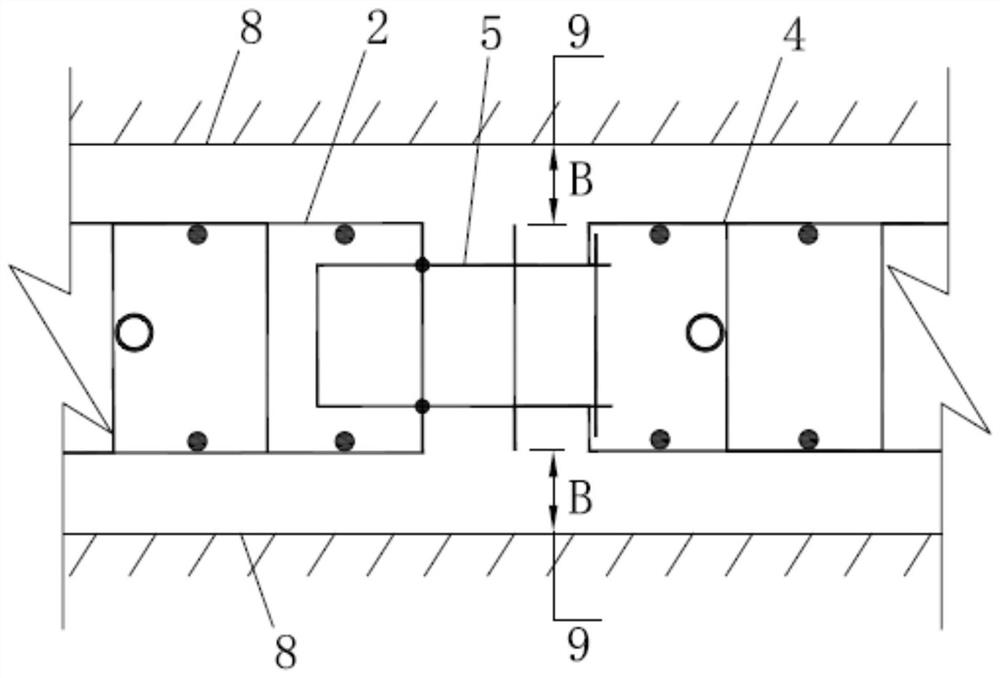

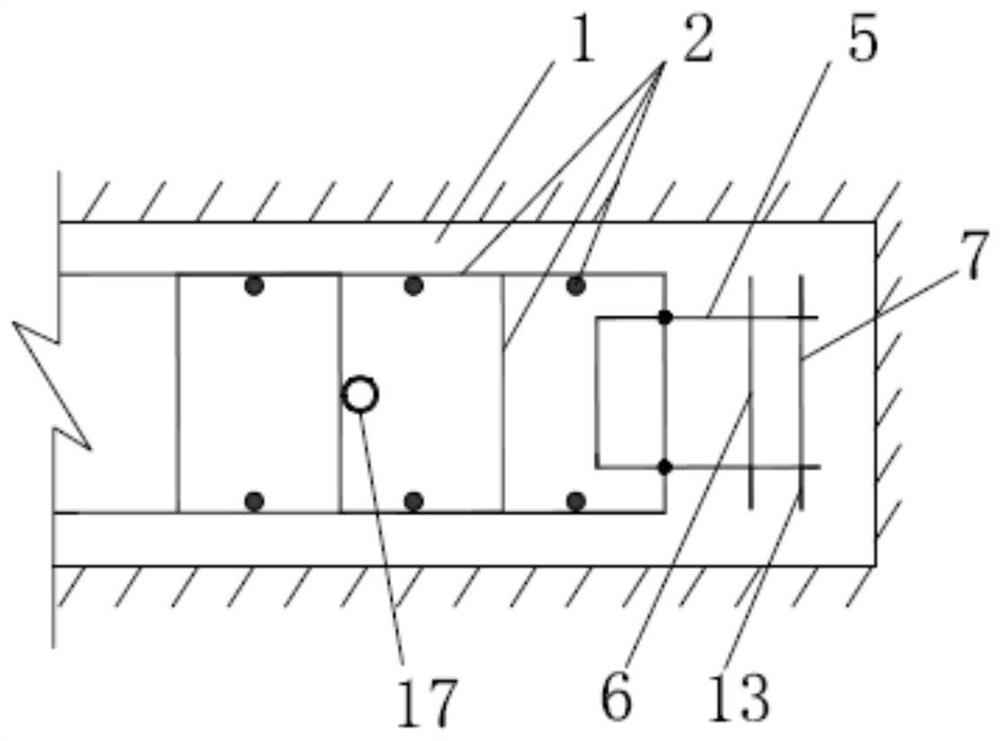

Minimally invasive vascular intervention surgical robot catheter and guide wire propulsion mechanism

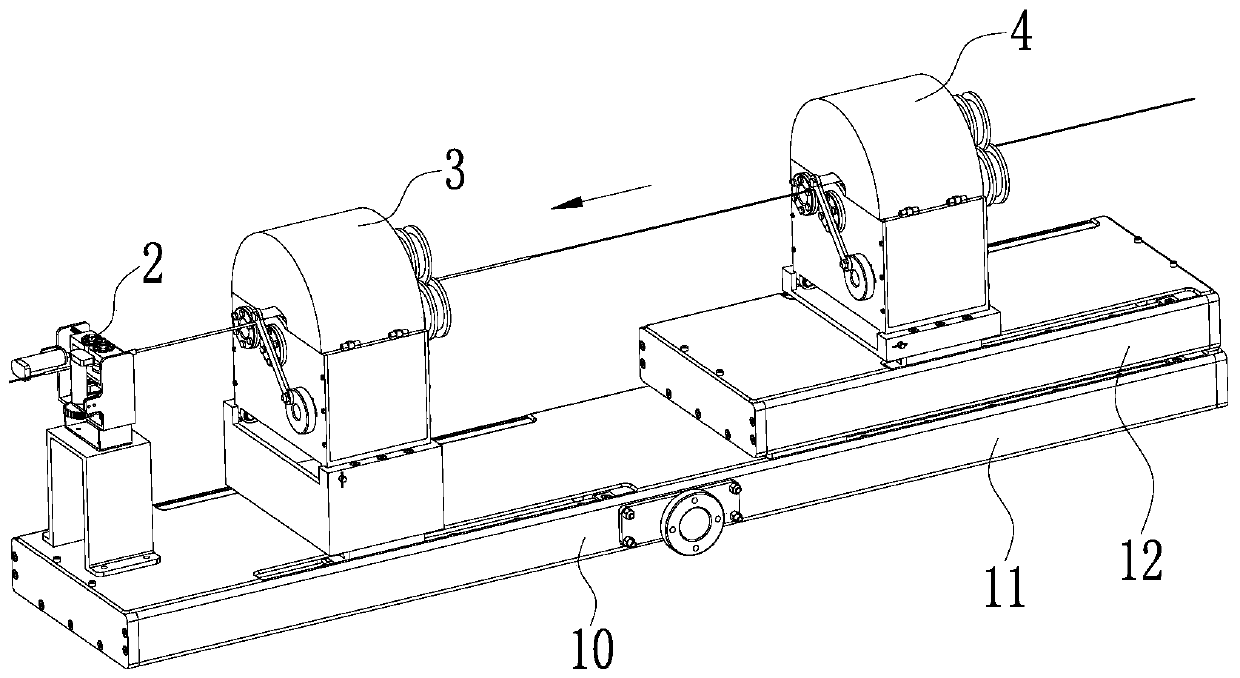

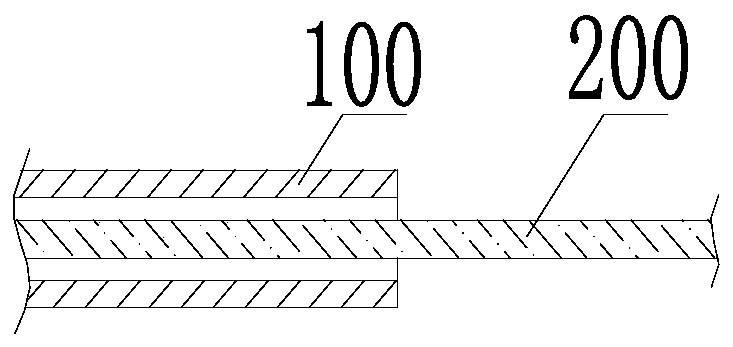

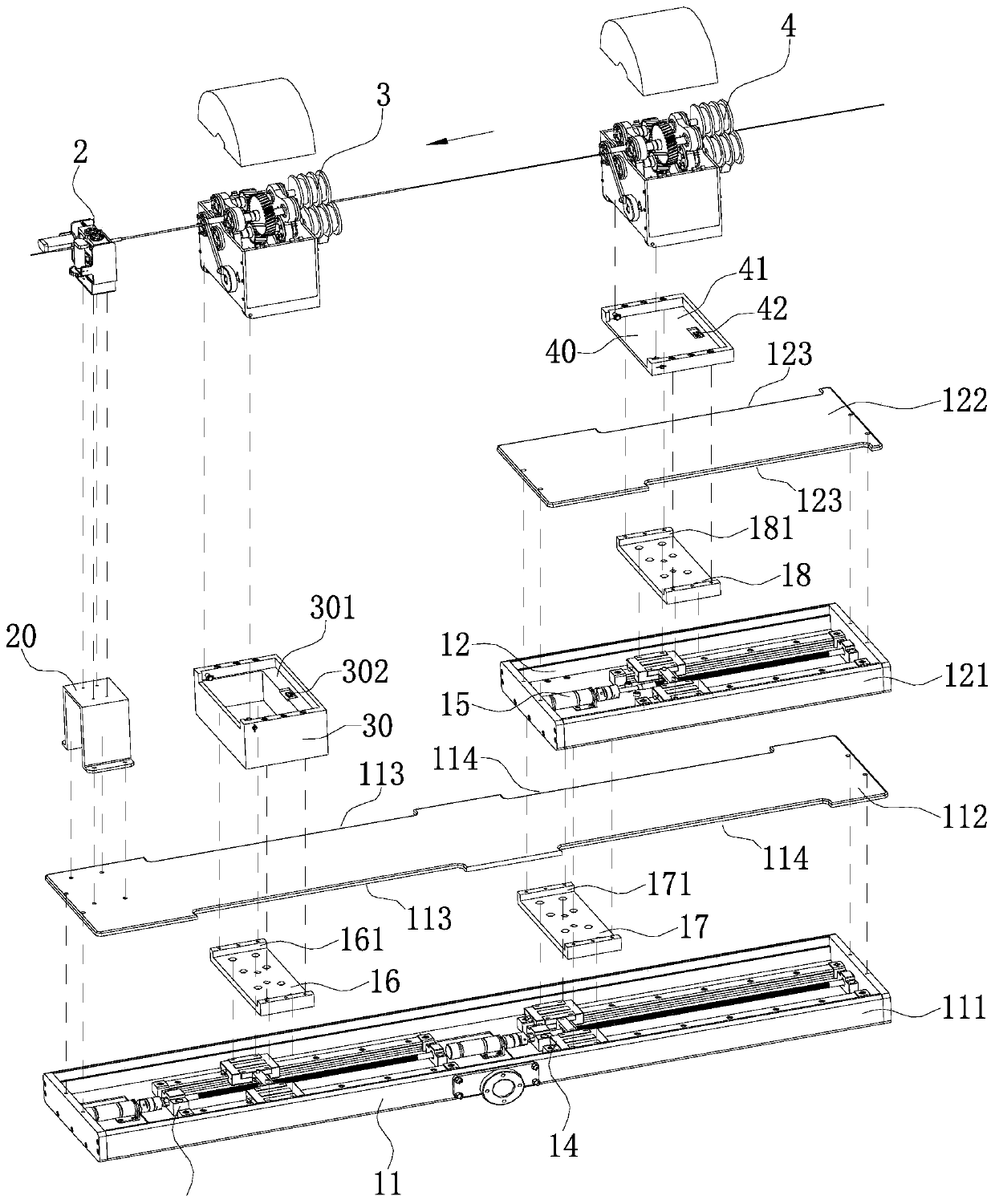

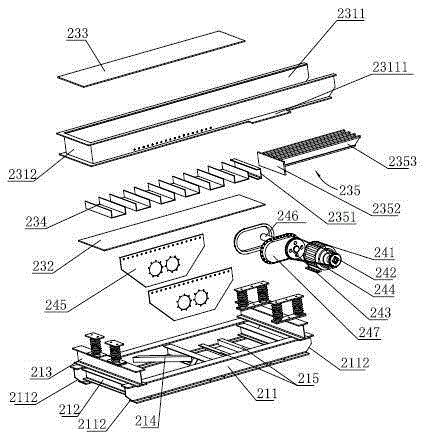

The invention discloses a minimally invasive vascular intervention surgical robot catheter and guide wire propulsion mechanism. The minimally invasive vascular intervention surgical robot catheter andguide wire propulsion mechanism comprises a displacement platform, a fine adjustment device, a catheter clamping and spin-twisting device and a guide wire clamping and spin-twisting device, wherein the fine adjustment device, the catheter clamping and spin-twisting device and the guide wire clamping and spin-twisting device are sequentially arranged on the displacement platform; the displacementplatform comprises a first displacement workbench and a second displacement workbench, the fine adjustment device and the catheter clamping and spin-twisting device are installed on the first displacement workbench, and the guide wire clamping and spin-twisting device is installed on the second displacement workbench; the first displacement workbench is provided with a catheter displacement mechanism for driving the catheter clamping and spin-twisting device to move and a platform displacement mechanism for driving the second displacement workbench to move, and the second displacement workbench is provided with the guide wire displacement mechanism for driving the guide wire clamping and spin-twisting device to move. The catheter displacement mechanism, the platform displacement mechanismand the guide wire displacement mechanism can move synchronously or independently, so that synchronous or independent delivery of catheters and / or guide wires into blood vessels can be facilitated.

Owner:YANSHAN UNIV

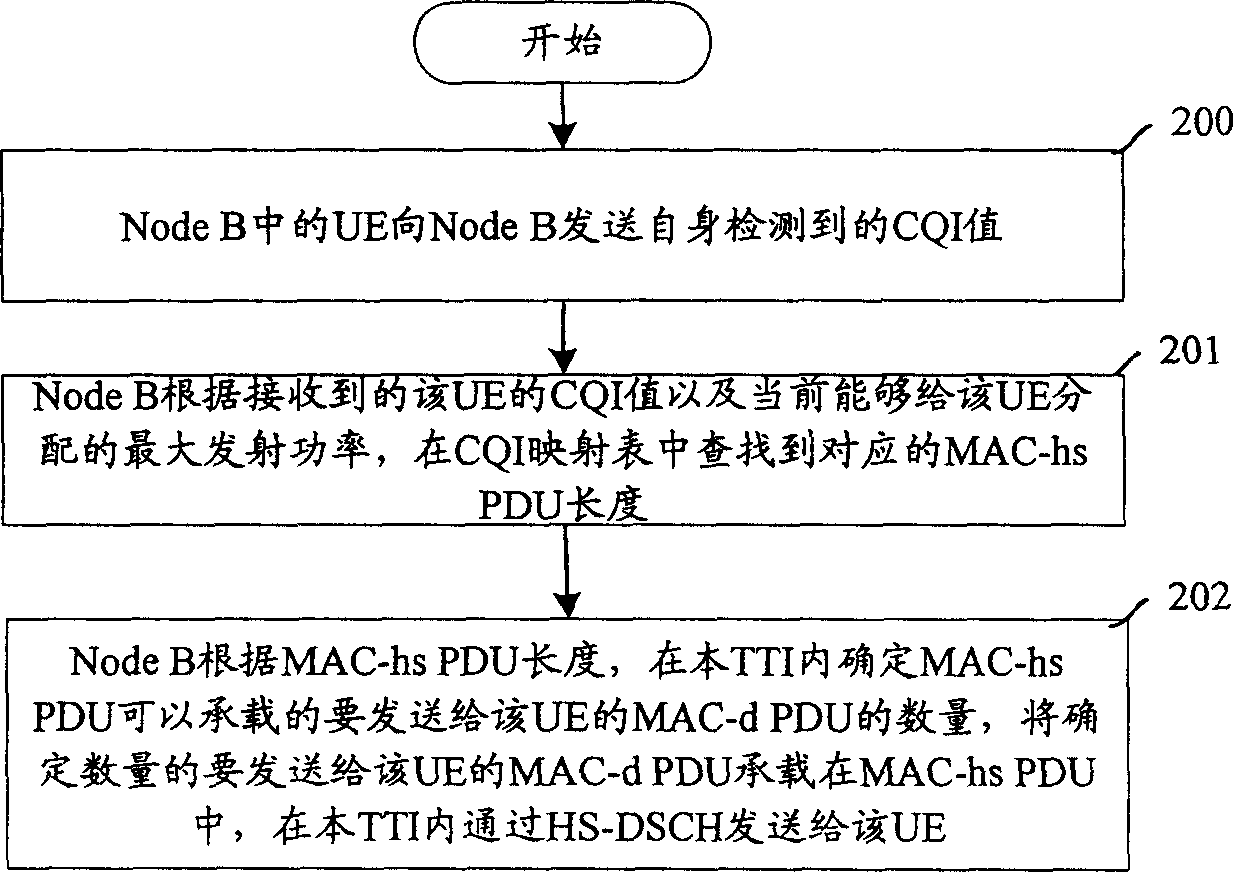

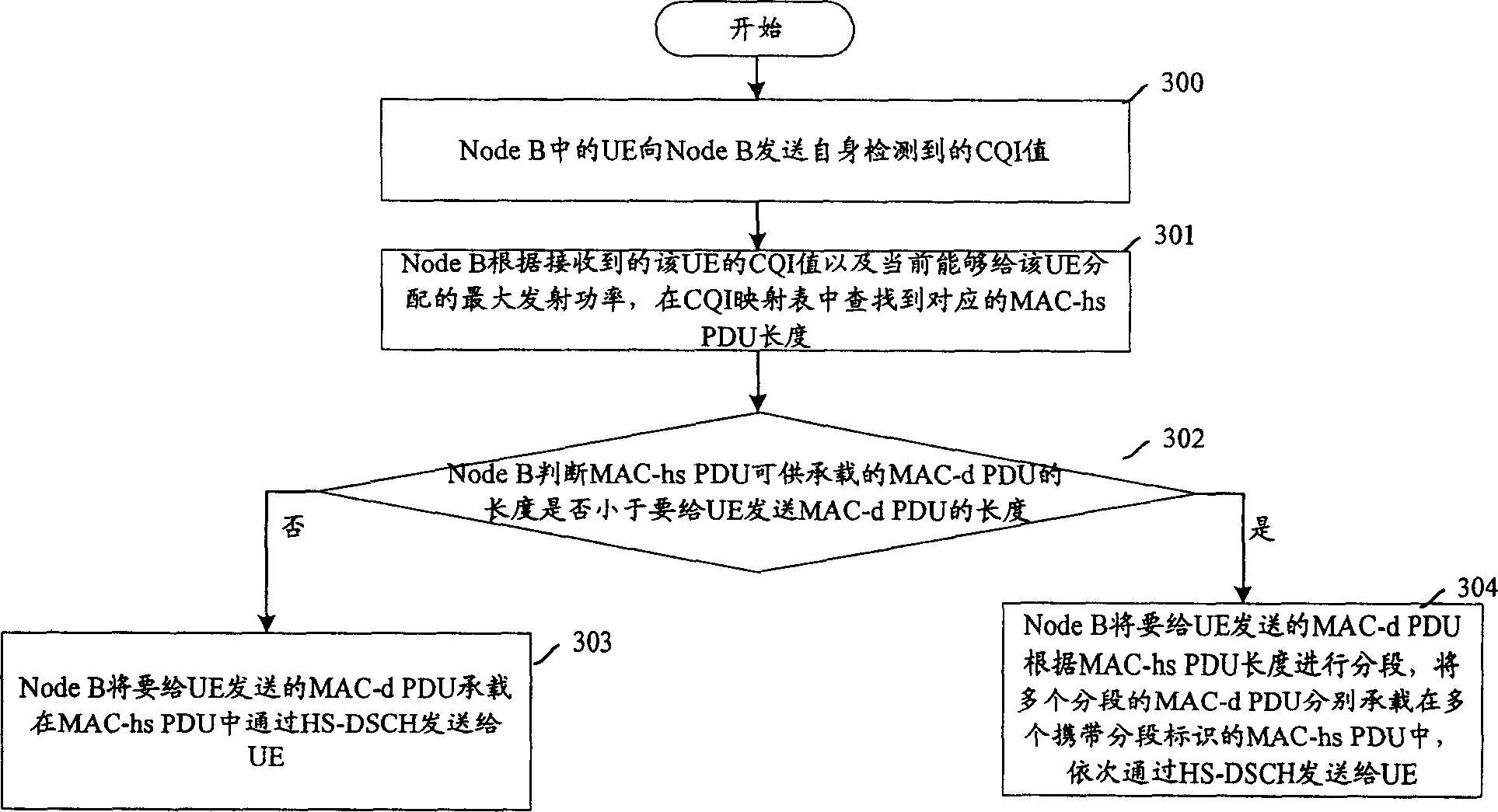

Transmitting and receiving method for high speed medium cut-in control grouping data unit

InactiveCN1859037AGuaranteed continuous deliveryGuaranteed to continuously send downlink dataError preventionRadio transmission for post communicationComputer hardwareMedia access control

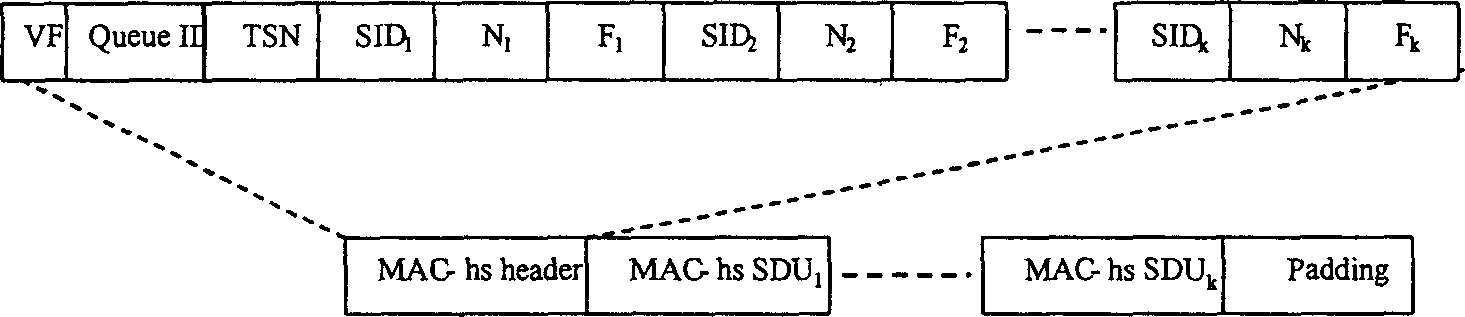

This invention discloses a transmission and receiving method for MAC-hs PDU of a high speed media access control packet data unit, in which, the method includes: A, when the MAC-d PDU length for loading of the MAC-hs PDUprovided to the UE by Node B is shorter than that of the MAC-d PDU of the special channel media access control packet data unit being sent to the UE, Node B segments the MAC-d PDU based on the length of the MAC-hs PDU, B, Node B loads one or more than one segments of MAC-d PDU on one or more than one MAC-hs PDU to send them to the UE via the high speed down share channel HS-DSCH, in which, when the length of the MAC-hs PDC is smaller than that of the MAC-d PDU to be sent, the MAC-d PDU can be loaded on the MAC-hs PDU and transmitted to the UE via HS-DSCH.

Owner:HUAWEI TECH CO LTD

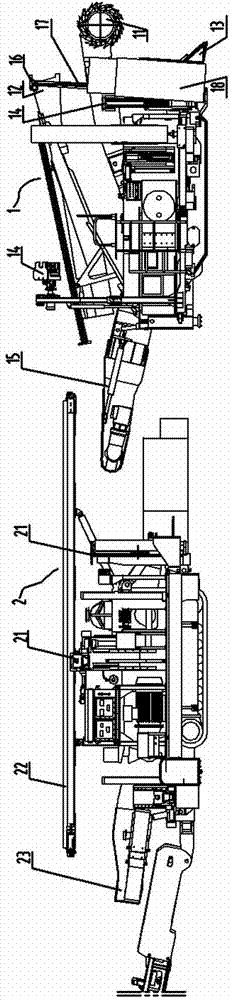

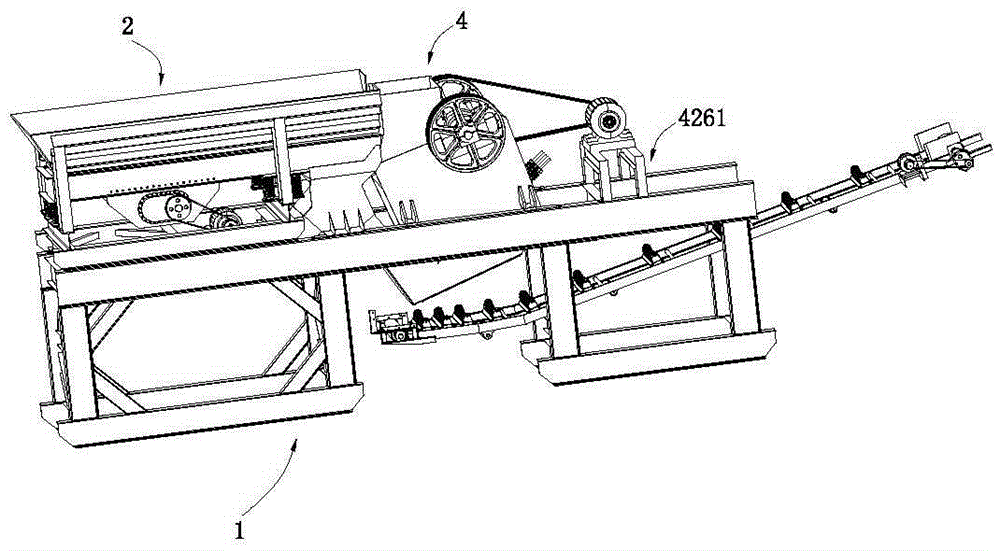

Rapid drivage-anchoring integrated equipment for coal road under instable surrounding rock condition

ActiveCN104747201AImprove efficiencyAvoid destructionTunnelsAnchoring boltsRubber sheetDrilling machines

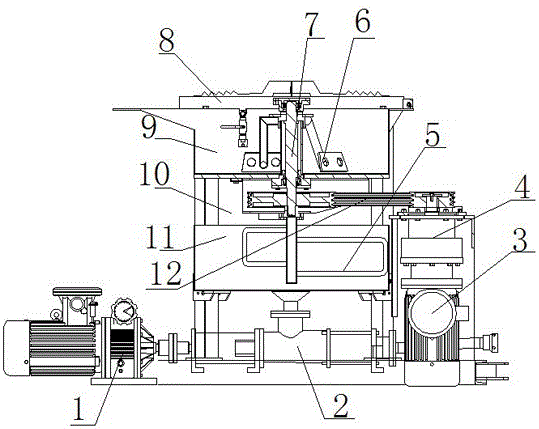

The invention discloses rapid drivage-anchoring integrated equipment for a coal road under an instable surrounding rock condition. The equipment comprises a drivage-anchoring machine and an anchor rod drill carriage, the drivage-anchoring machine comprises a cutting roller, an air draft pipeline, a material collector, an anchor rod drilling machine set and a scraper conveyor, the anchor rod drill carriage comprises an anchor rod drill drilling machine set and a scraper conveyor, the anchor rod drill carriage is arranged behind the drivage-anchoring machine, the rear portion of the scraper conveyor of the drivage-anchoring machine is located over the front portion of the scraper conveyor of the anchor rod drill carriage, a roof-caving-preventing device is arranged on the drivage-anchoring machine, a sealing device is connected below the roof-caving-preventing device, the sealing device is composed of a moving sealing rubber sheet, a fixed sealing rubber sheet, a telescopic oil cylinder, a cross beam and a telescopic beam, the cross beam is connected with one end of the telescopic oil cylinder, the other end of the telescopic oil cylinder is connected with the telescopic beam, the fixed sealing rubber sheet is connected below the cross beam, and the moving sealing rubber sheet is connected below the telescopic beam. By means of the equipment, the anchoring efficiency can be matched with the drivage efficiency, and the comprehensive drivage-anchoring efficiency is promoted.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

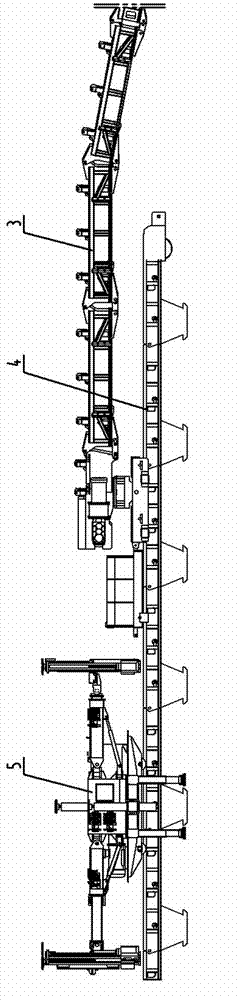

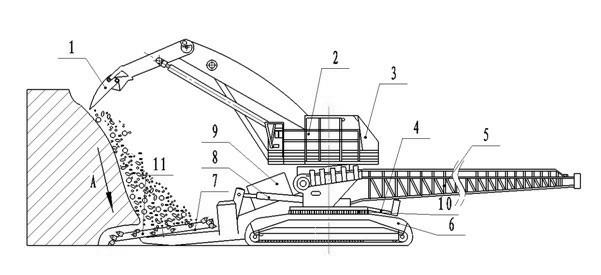

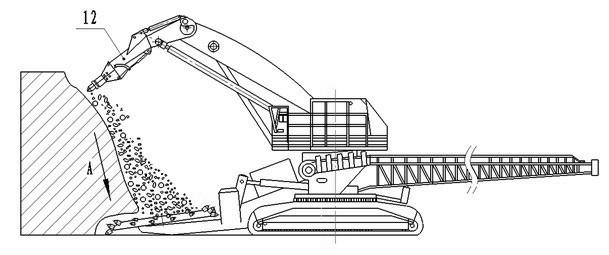

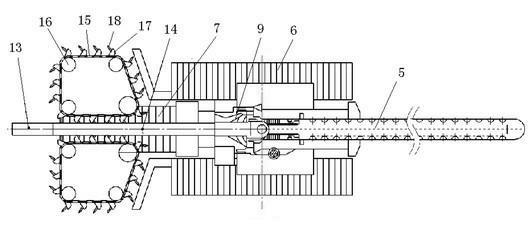

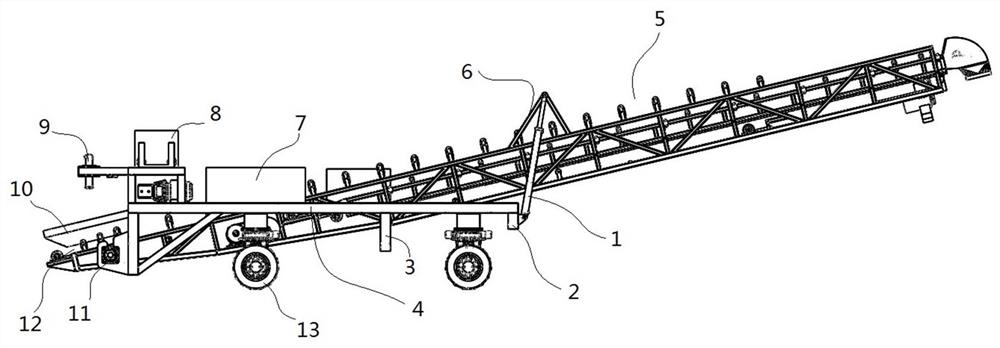

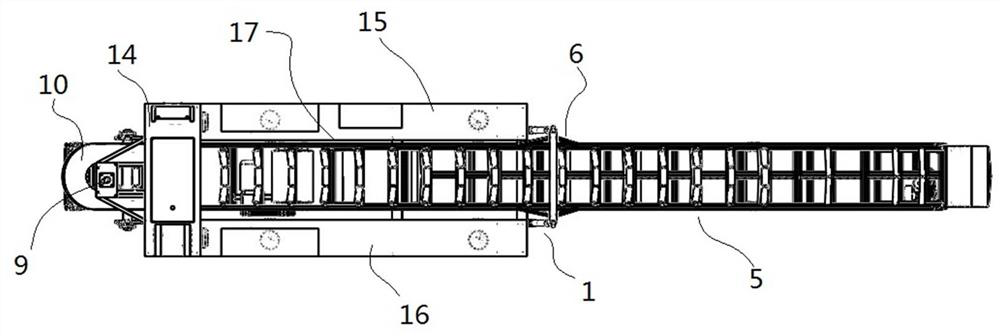

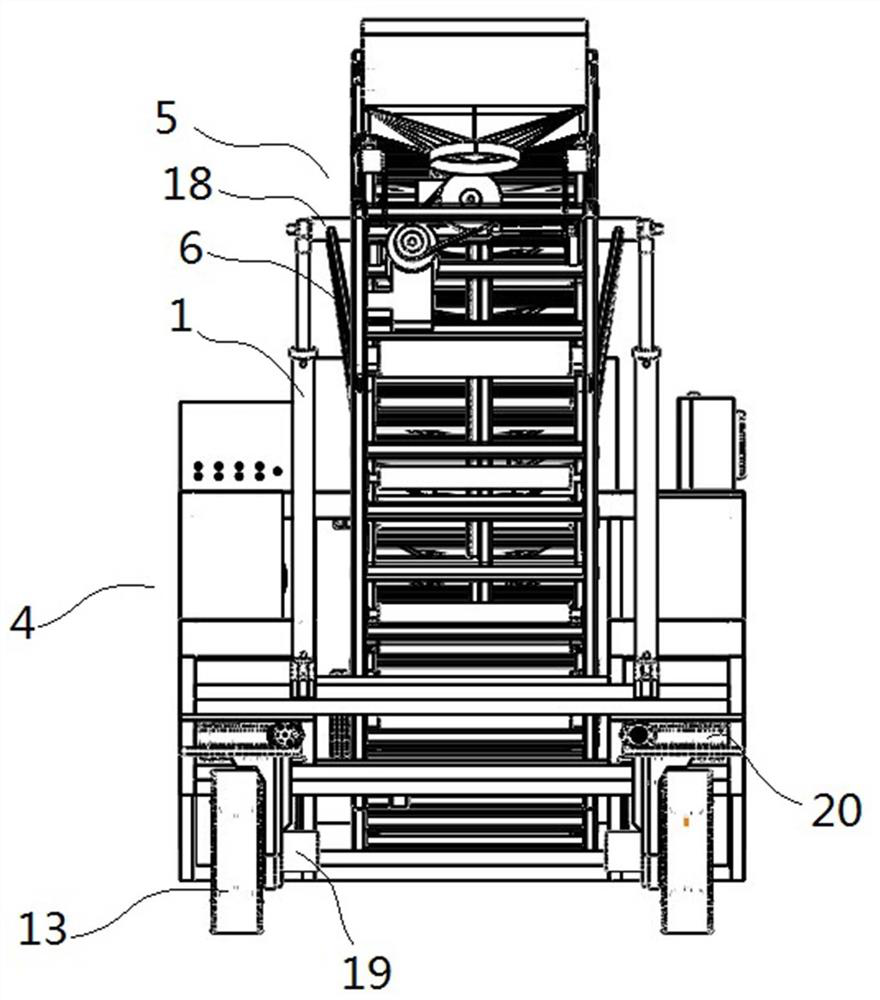

Strip mining machine for mine

InactiveCN102691503AImprove stabilityImprove compactnessSlitting machinesOpen-pit miningIntegrated operationsMechanical engineering

A strip mining machine for a mine belongs to technical field of mining equipment, and is applied to integral strip mining of surrounding rock and mineral of an open-pit mine. The technical scheme is that the strip mining machine comprises a cutting, slotting and scraper type loading part, a raking down part, a scratch board transporting device, a crushing device, a rubber belt transporting device, a rotating and elevating system, a walking part and a rotating part, wherein the cutting, slotting and scraper type loading part is arranged at the front end of the strip mining machine; the scratch board transporting device is mounted at the lower part of the cutting, slotting and scraper type loading part; the back end of the scratch board transporting board device is connected to the crushing device; the crushing device is connected to the rubber belt transporting device; the rotating and elevating system is mounted at the lower part of the rubber-belt transporting device; the transporting belt of the rubber belt transporting device is mounted in the middle of the track of the walking part; the raking down part is arranged above the cutting, slotting and scraper type loading part; and the rotating part is mounted above the walking part. The strip mining machine can realize the integrated operation of continuous strip mining, crushing, transshipping and transporting for the open-pit mine, thereby greatly improving the strip mining efficiency and the productivity of the mine.

Owner:TIANDI TANGSHAN MINING TECH

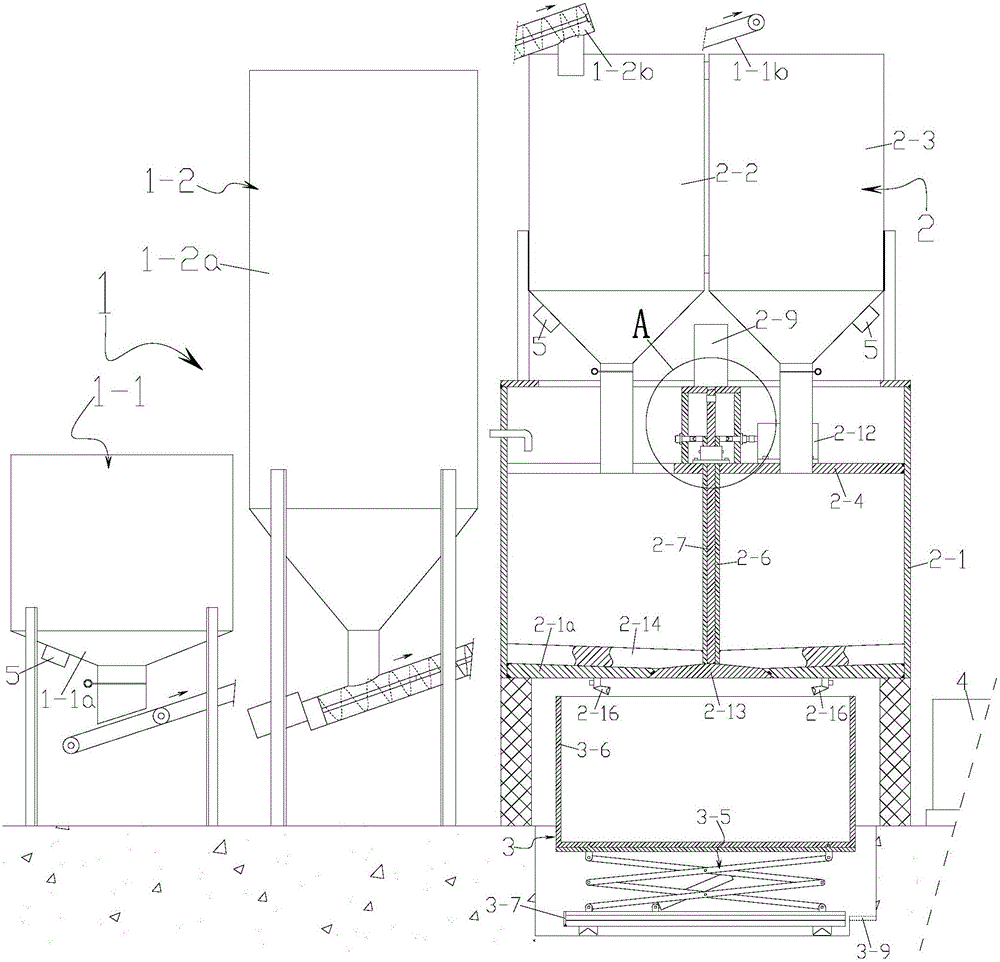

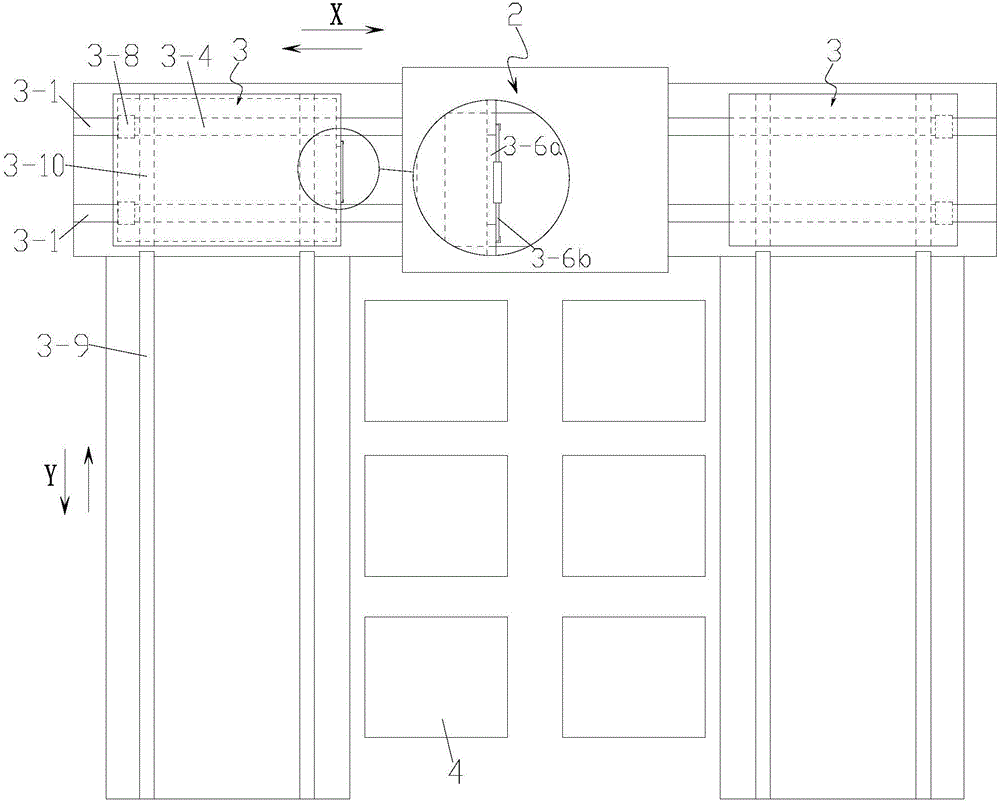

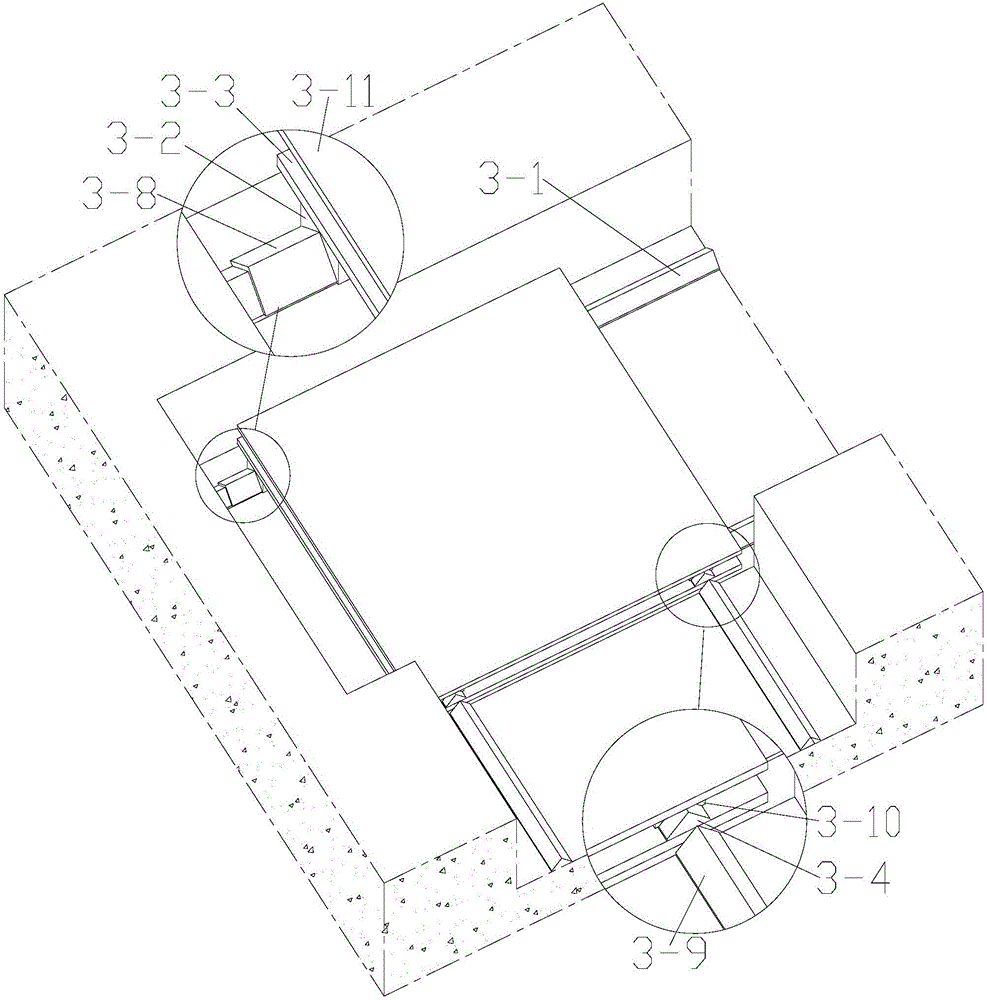

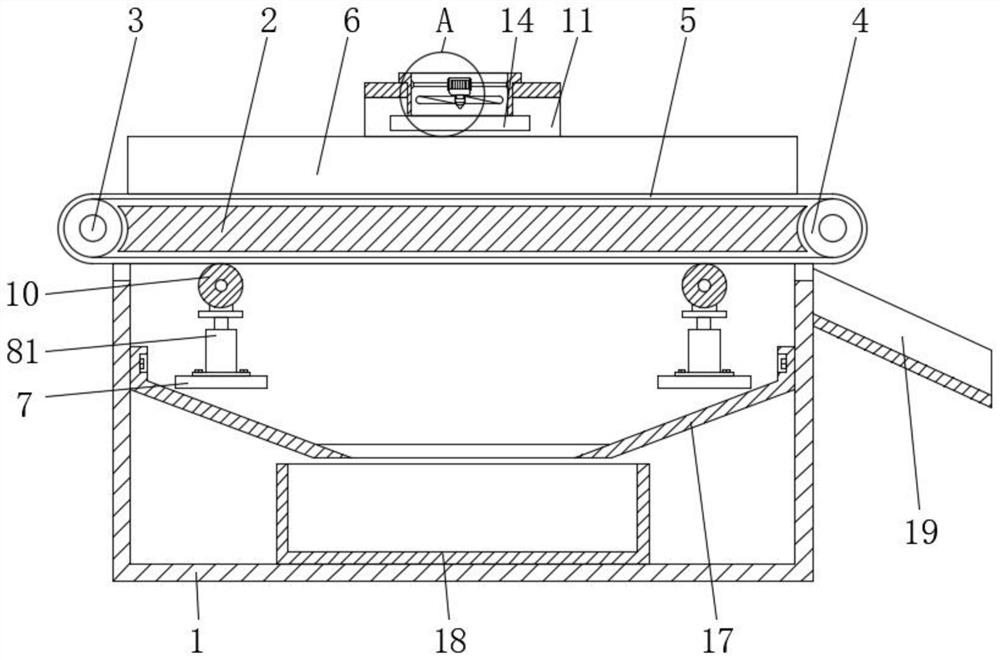

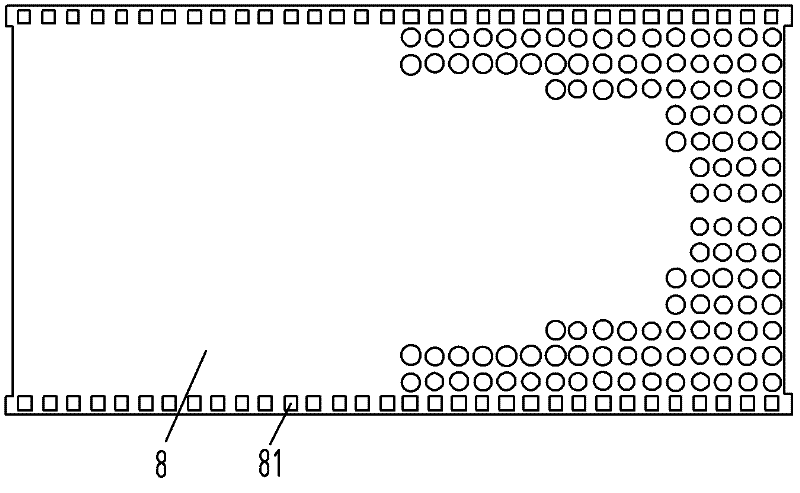

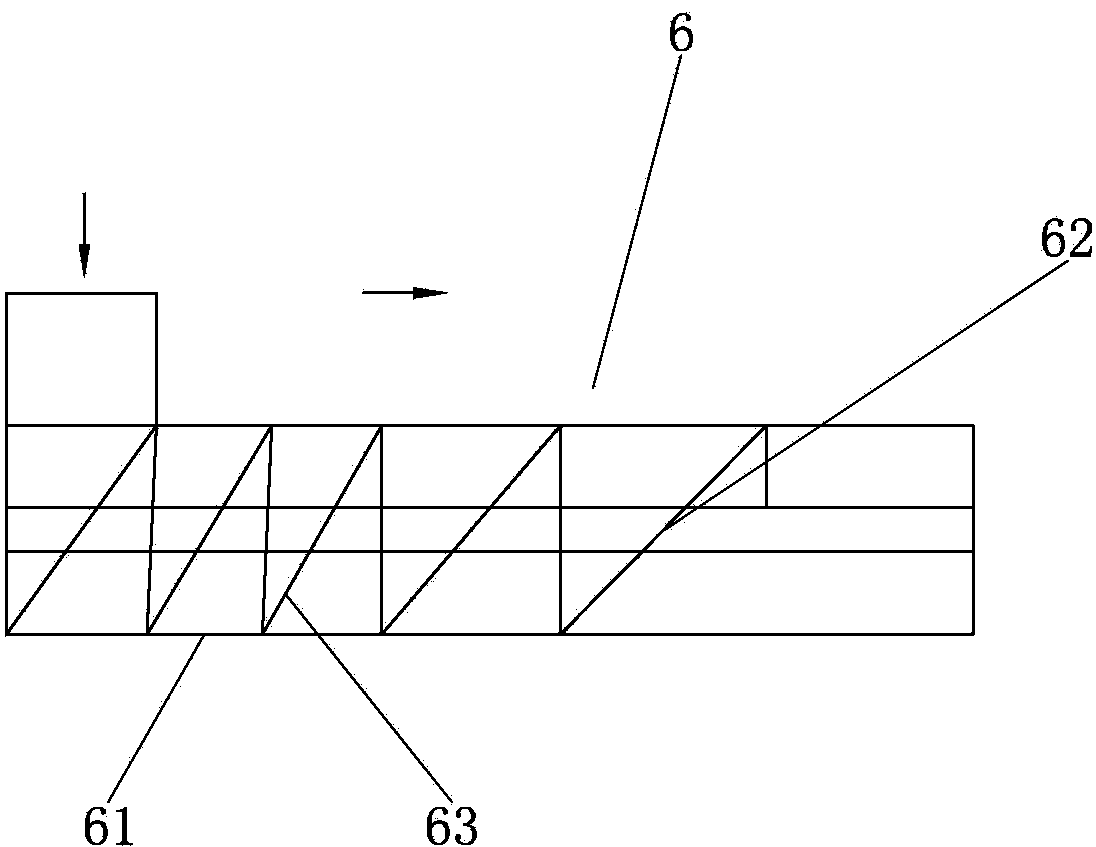

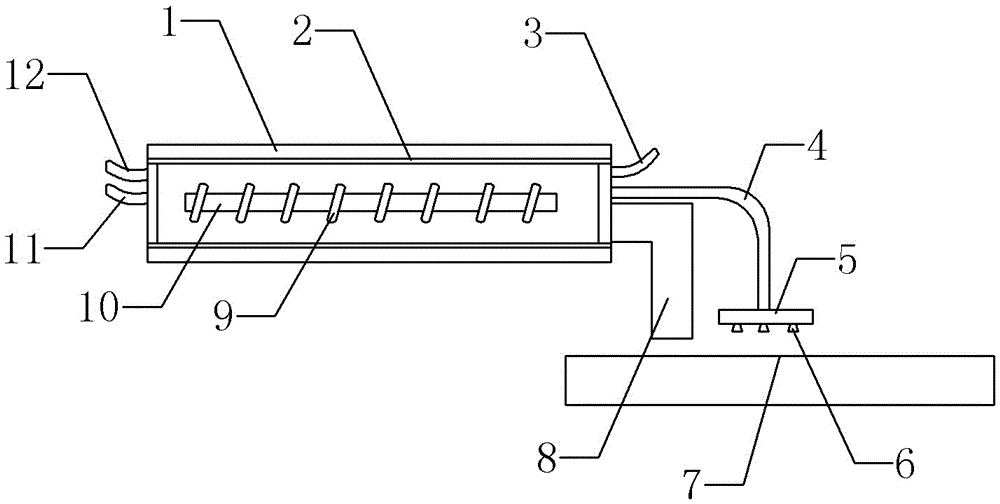

Process and equipment for producing ceramsite aerated building blocks

ActiveCN105690564AGuaranteed continuous deliveryReduce laborFeeding arrangmentsCement mixing apparatusExpanded clay aggregateEngineering

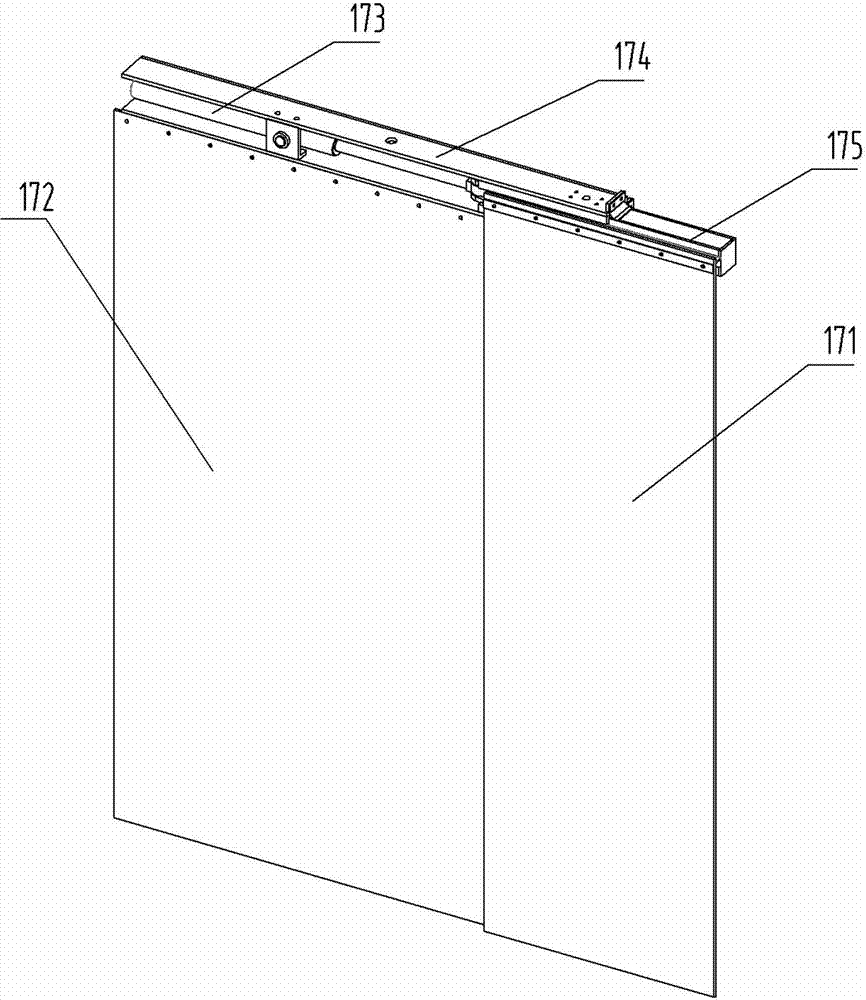

A process for producing ceramsite aerated building blocks comprises the step A of conveying raw materials, the step B of stirring the raw materials, the step C of discharging stirred materials, and the step D of conveying the stirred materials. Equipment for producing the ceramsite aerated building blocks comprises a raw material conveying device, and a raw material stirring device is fixed to the lateral portion of the raw material conveying device. The equipment for producing the ceramsite aerated building blocks is ingenious and reasonable in structural design. The raw material conveying device can be used for conveniently and continuously conveying the raw materials to a first storage hopper and a second storage hopper. The raw material stirring device can mix ceramsite and cement and stir the ceramsite and the cement with water added therein, and the stirred materials are formed. A closing plate moves so as to open a discharging hole, and the stirred materials fall into a receiving hopper below the discharging hole through the discharging hole. The receiving hopper is moved to the position stopped by a second stopping block in the X direction, then moved to a third guide rail in the Y direction and lifted under the action of a lifting table. The stirred materials in the receiving hopper are fed into ceramsite aerated building block moulds through an inserting and connecting plate. The process and equipment for producing the ceramsite aerated building blocks are worthy of being applied and popularized.

Owner:利川市大山新型建材有限公司

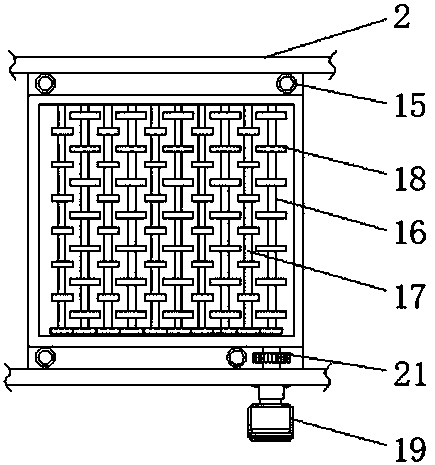

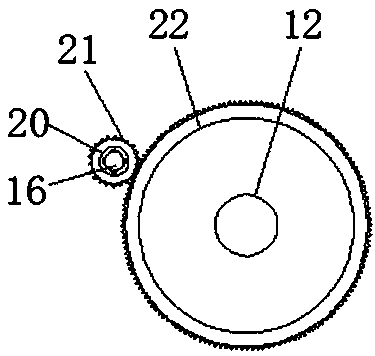

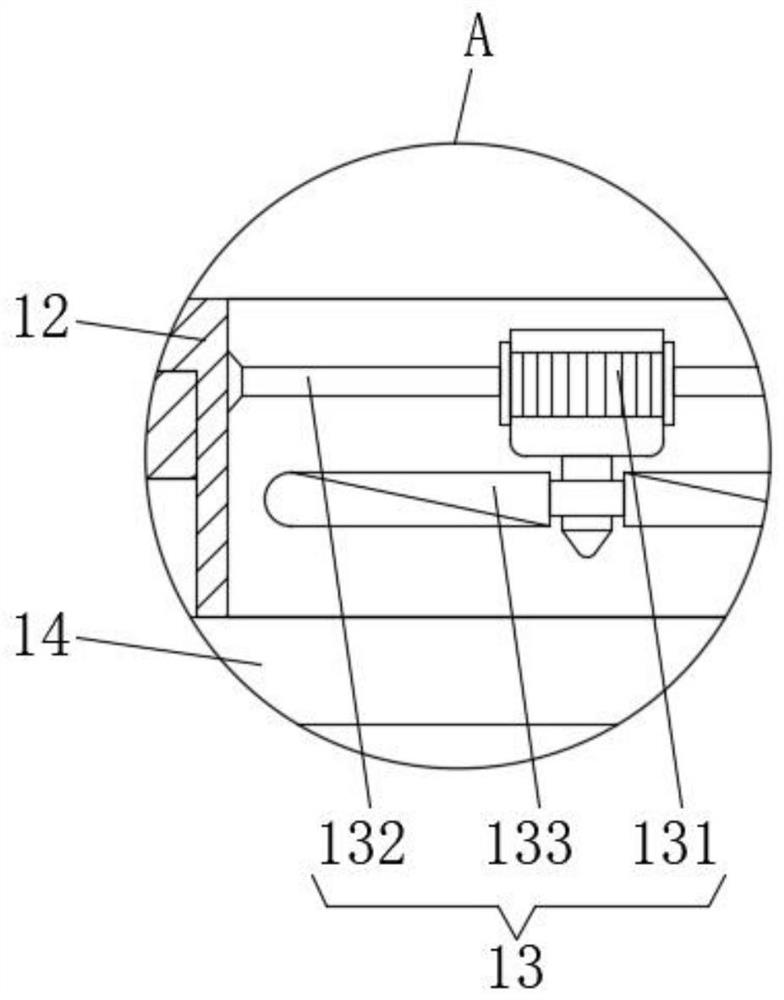

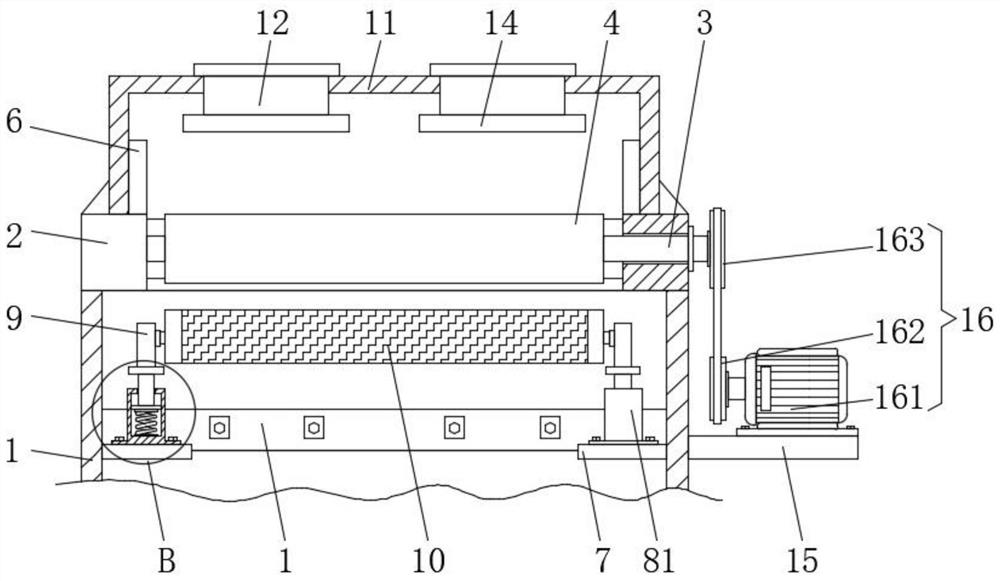

Intermittent filler uniform pouring equipment for fabricated building precast concrete component processing

InactiveCN111283845AFlexible control of intermittent feedingFlexible control of feeding volumeFeeding arrangmentsDrive shaftGear wheel

The invention discloses intermittent filler uniform pouring equipment for fabricated building precast concrete component processing. The intermittent filler uniform pouring equipment for the fabricated building precast concrete component processing comprises a concrete filler box and a pouring die, and a discharging hole is formed in the bottom of the concrete filler box; a movable mounting frameis arranged on the upper part of the concrete filler box, a first driving motor and a speed reducer are mounted on the upper part of the movable mounting frame, and an eccentric movable frame is arranged at the output end of the speed reducer; a movable bearing plate is arranged on the inner side of the middle part of a conveyor belt in an attached mode; and movable cams are uniformly distributedon the outer sides of a first transmission shaft and a second transmission shaft correspondingly, a driving shaft is arranged at the output end of a second driving motor, and a reduction gear is arranged on the side edge of the driving shaft in an attached mode. According to the intermittent filler uniform pouring equipment for the fabricated building precast concrete component processing, conveying pouring and uniform vibration of batched components can be carried out continuously and stably, and uniform pouring of batched small components is facilitated in cooperation with the stirring of the eccentric movable frame and intermittent uniform discharging.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Powder coating pulverizer

ActiveCN105363545AEasy to set upIncrease vibration amplitudeSievingScreeningPowder coatingMaterials science

Owner:广东阳河涂料制造有限公司

Slurry mixing conveyor for combined type wet concrete sprayer

InactiveCN105128147AReduce solidificationPrevent solidificationUnderground chambersCement mixing apparatusDrive motorWater supply

The invention discloses a slurry mixing conveyor for a combined type wet concrete sprayer. The slurry mixing conveyor comprises a stirring cylinder, a power shaft, a driving motor for driving the power shaft to rotate, a water supply pipe for supplying water for stirring slurry, and a cylinder cover covering an opening of the stirring cylinder, wherein the water supply pipe is mounted on the cylinder cover; the stirring cylinder is a cylinder body which is sequentially provided with a stirring cavity, a power cavity and a storage cavity from top to bottom; the stirring cavity and the storage cavity are insulated from the power cavity; the stirring cavity communicates with the storage cavity, so that the slurry stirred in the stirring cavity can be conveniently stored in the storage cavity. A stirring machine in the slurry mixing conveyor disclosed by the invention is provided with three cavities, and the slurry mixing operation and the slurry storage operation are separated, so that the continuous conveyance of the slurry is guaranteed, and the solidification of the slurry is delayed; besides, the stirring machine is provided with an upper stirring blade and a lower stirring blade, so that the slurry can also be always in a stirred state and prevented from being solidified; besides, the stirring machine is provided with the power cavity, and in the power cavity, the driving shaft is transmitted by the middle part of the power cavity, so that uneven transmission of the power shaft is avoided.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

Food processing finished product conveying device

PendingCN112623638AImprove efficiency and processing qualityReduce the difficulty of cleaningConveyorsCleaningProcess engineeringWorkbench

The invention relates to the technical field of food processing, in particular to a food processing finished product conveying device which comprises a box body and a workbench. Rotating shafts are rotatably connected to the two sides of the workbench, conveying rollers are fixedly installed on the surfaces of the rotating shafts, the surfaces of the conveying rollers are sleeved with a conveying belt, the conveying rollers are in transmission connection through the conveying belt, and baffles are connected to the top of the workbench in a bolted mode. Through the arrangement of the rotating shafts, the conveying belt, extrusion mechanisms, cleaning rollers, an air blowing mechanism, a heating frame and a driving mechanism, the food processing finished product conveying device has the advantages that the conveying device can be rapidly cleaned, it is guaranteed that food can be continuously conveyed, dust and moisture on the surface of the food can be removed, and then the food processing efficiency and the food processing quality can be improved. The problems that an existing conveying device used for food processing is poor in practicability and not convenient to repair and maintain in the later period, and the conveying device needs to be stopped to be cleaned are solved.

Owner:湖南上优食品科技有限公司

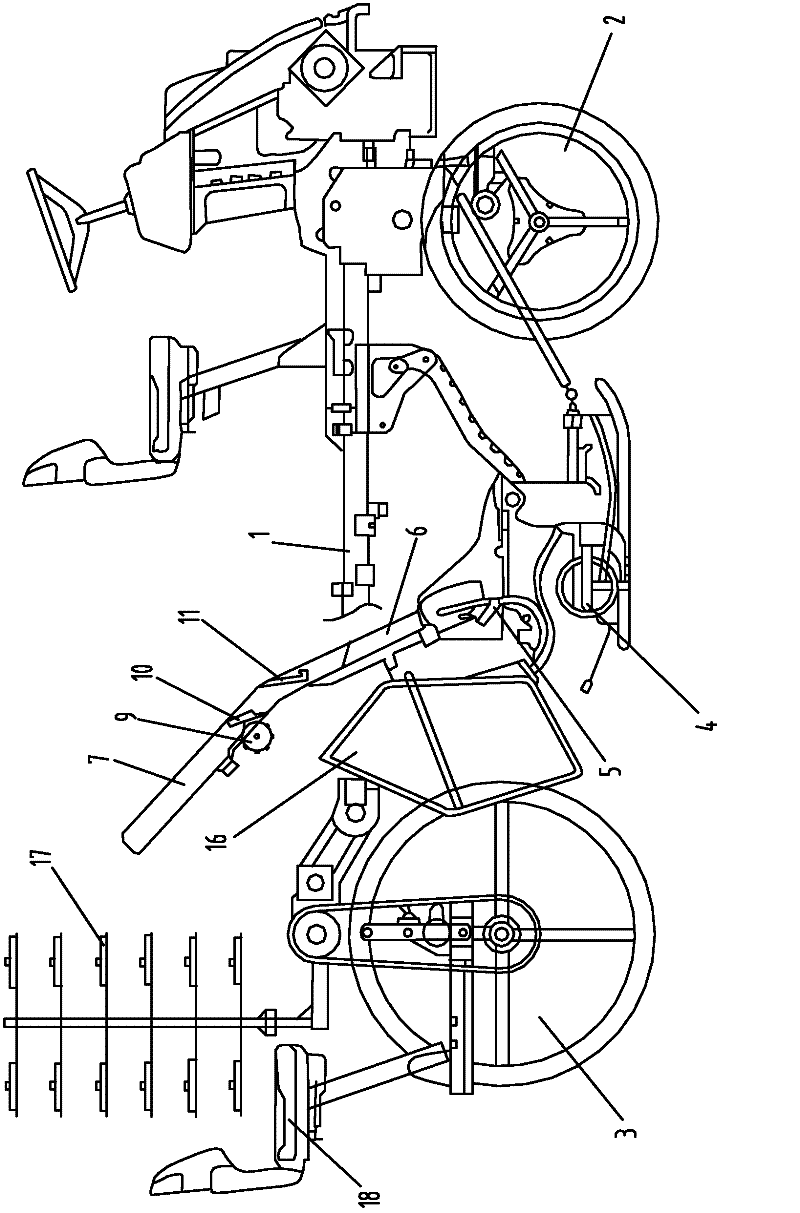

Riding-type rice seedling transplanting machine

The invention discloses a riding-type rice seedling transplanting machine, which is characterized in that a planting device is arranged below the middle part of a machine body between a front wheel and a rear wheel, a rice seedling pressing device is installed above the planting device, a rice seedling carrying platform is connected above the rice seedling pressing device, a rice seedling supply part above the rice seedling carrying platform is obliquely connected with the rice seedling carrying platform, a rice seedling tray is conveyed to the rice seedling pressing device from the rice seedling supply part through the rice seedling carrying platform, a conveying roller is arranged at the rice seedling supply part, the conveying roller is provided with convex teeth, and a rice seedling pressing plate which is used for pressing the edge of the rice seedling tray towards the conveying roller is arranged on a guide wall plate corresponding to the rice seedling supply part above the conveying roller. By downwards pressing the rice seedling tray through the rice seedling pressing plate to be matched with the conveying roller for conveying the rice seedling tray, since no many conveying rollers are used, the structure is simple, the cost is reduced and the maintenance of the machine is facilitated; and when the rice seedling tray is taken out, even though the rice seedling tray is at the positions of the rice seedling supply part and the rice seedling carrying platform, the rice seedling tray can be rapidly and conveniently taken out without conducting any other operation.

Owner:常州亚美柯机械设备有限公司 +2

Full-automatic beer bottle capping device and using method thereof

The invention discloses a full-automatic beer bottle capping device which comprises a conveying frame. A conveying belt and a driving mechanism used for driving the conveying belt to run are arrangedon the conveying frame, a plurality of placement mechanisms used for placing beer bottles are arranged on the conveying belt, and a capping mechanism is arranged over the conveying belt. The capping mechanism comprises a pressing air cylinder and a cover suction assembly fixed to a piston rod of the pressing air cylinder. A supporting frame is arranged on one side of the conveying frame, and a bottle cap supply mechanism is arranged at the top of the supporting frame. The bottle cap supply mechanism comprises a bottle cap storage base, wherein bottle cap storage cavities are formed in the bottle cap storage base. Bottle cap conveying assemblies are arranged on the bottle cap storage base and arranged above the bottle cap storage cavities correspondingly. The invention further discloses a using method. According to the beer bottle capping device, manual capping operation is not needed, the labor intensity of workers is reduced, meanwhile, a plurality of beer bottles can be capped at a time, the working efficiency is improved, and therefore the beer bottle capping device has good market popularization prospects.

Owner:段洪永

Winding device used in cutting process of fireproof thermal insulation material

The invention discloses a winding device used in the cutting process of a fireproof thermal insulation material. The winding device comprises a workbench, a cutting groove is formed in the upper end of the workbench, conveying belts are arranged at the positions, located on the two sides of the cutting groove, of the upper end of the workbench correspondingly, a first mounting frame is arranged above the workbench, a punching mechanism is fixed to the first mounting frame, a first hydraulic cylinder is fixed to the first mounting frame, the first hydraulic cylinder and the punching mechanism are located on the two sides of the cutting groove correspondingly, a piston rod of the first hydraulic cylinder is fixed to a first mounting plate, a pressing roller is mounted at the lower end of the first mounting plate, a lifting table is arranged on one side of the workbench, a second mounting frame is fixed to the upper end of the lifting table, a winding roller is mounted on the second mounting frame and fixedly sleeved with a winding barrel, a gluing mechanism is arranged on the second mounting frame and used for gluing the upper end face of the winding barrel, and a traction mechanism is installed at the upper end of the workbench and used for pulling cut-off materials to the winding barrel. By means of the winding device, the cut materials can be automatically wound.

Owner:安徽省绩溪县华宇防火滤料有限公司

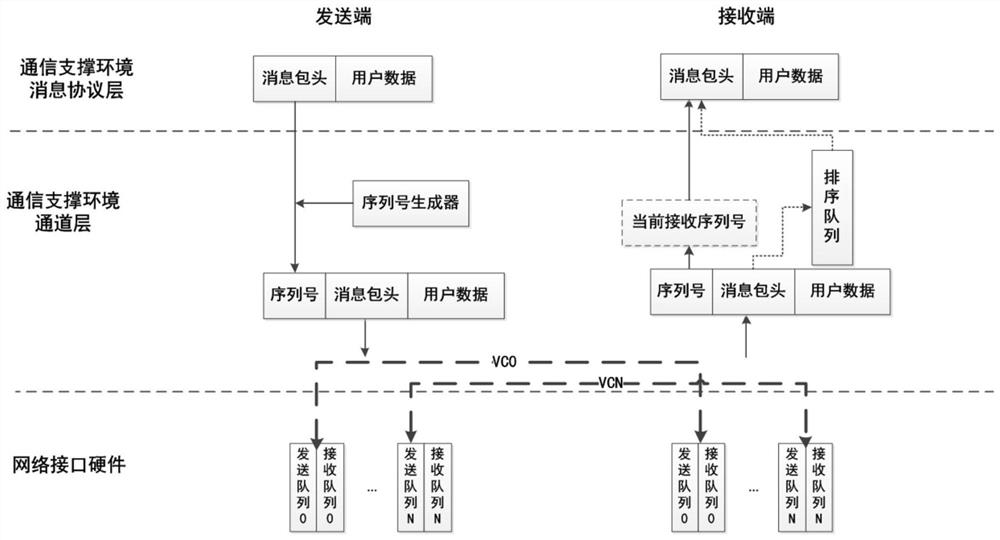

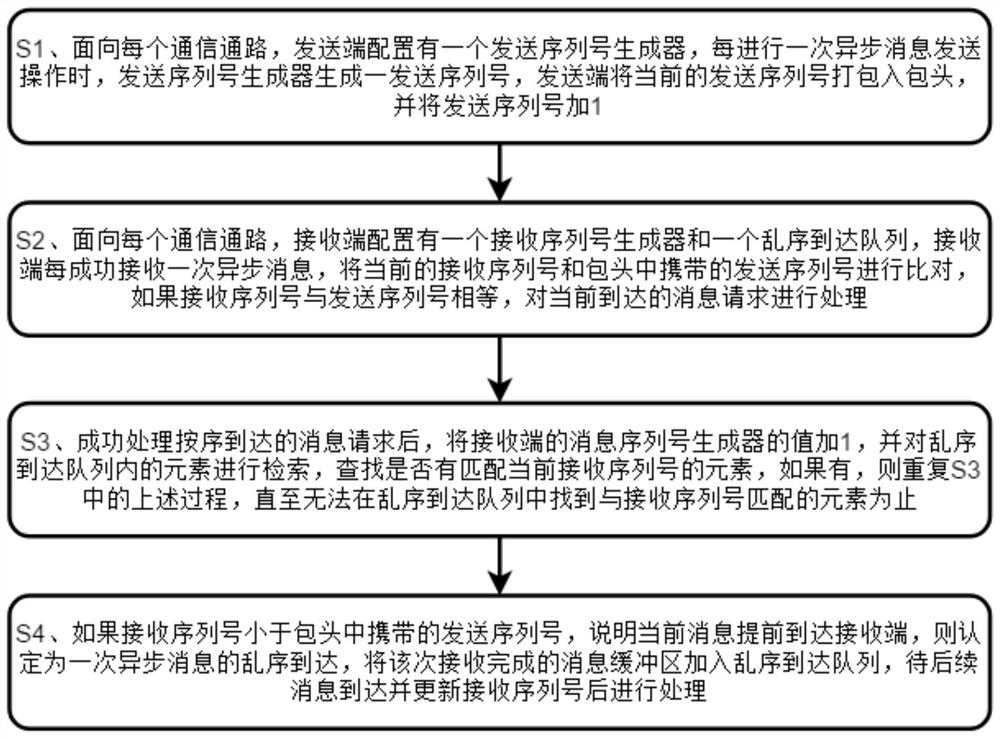

Message order preserving method based on serial number mechanism

PendingCN112448898AGuaranteed concurrent transfersGuaranteed concurrencyData switching networksEngineeringInterconnection

The invention discloses a message order preserving method based on a serial number mechanism, which comprises the following steps that: S1, when asynchronous message sending operation is carried out each time, a sending end packages a current sending serial number into a packet header, and adds 1 to the sending serial number; S2, a receiving end compares the current receiving serial number with the sending serial number carried in the packet header every time the receiving end successfully receives the asynchronous message; S3, after the message requests arriving in sequence are successfully processed, 1 is added to the value of a message serial number generator at the receiving end, and whether elements matched with the current receiving serial number exist in the elements arriving in a out-of-sequence queue or not are determined; and S4, if it is determined that the asynchronous message arrives out of order once, the message buffer area which finishes receiving this time is added into an out-of-order arrival queue, and processing is performed after the subsequent message arrives and the receiving serial number is updated. Concurrency of communication paths can be effectively guaranteed, the problem of message sequences caused by a bottom-layer interconnection framework can be effectively solved, and meanwhile influences of serial number generation and matching on performanceare very low.

Owner:JIANGNAN INST OF COMPUTING TECH

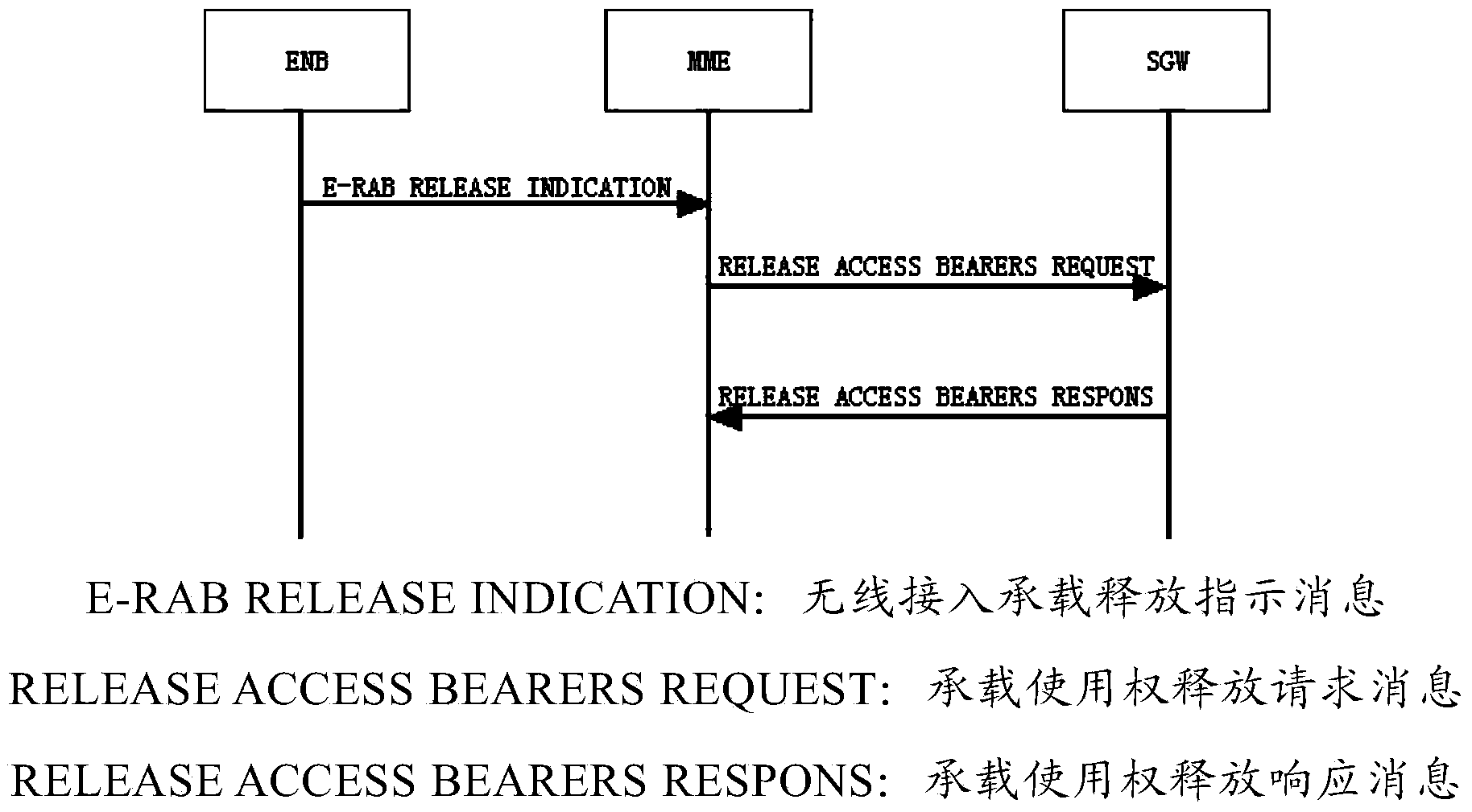

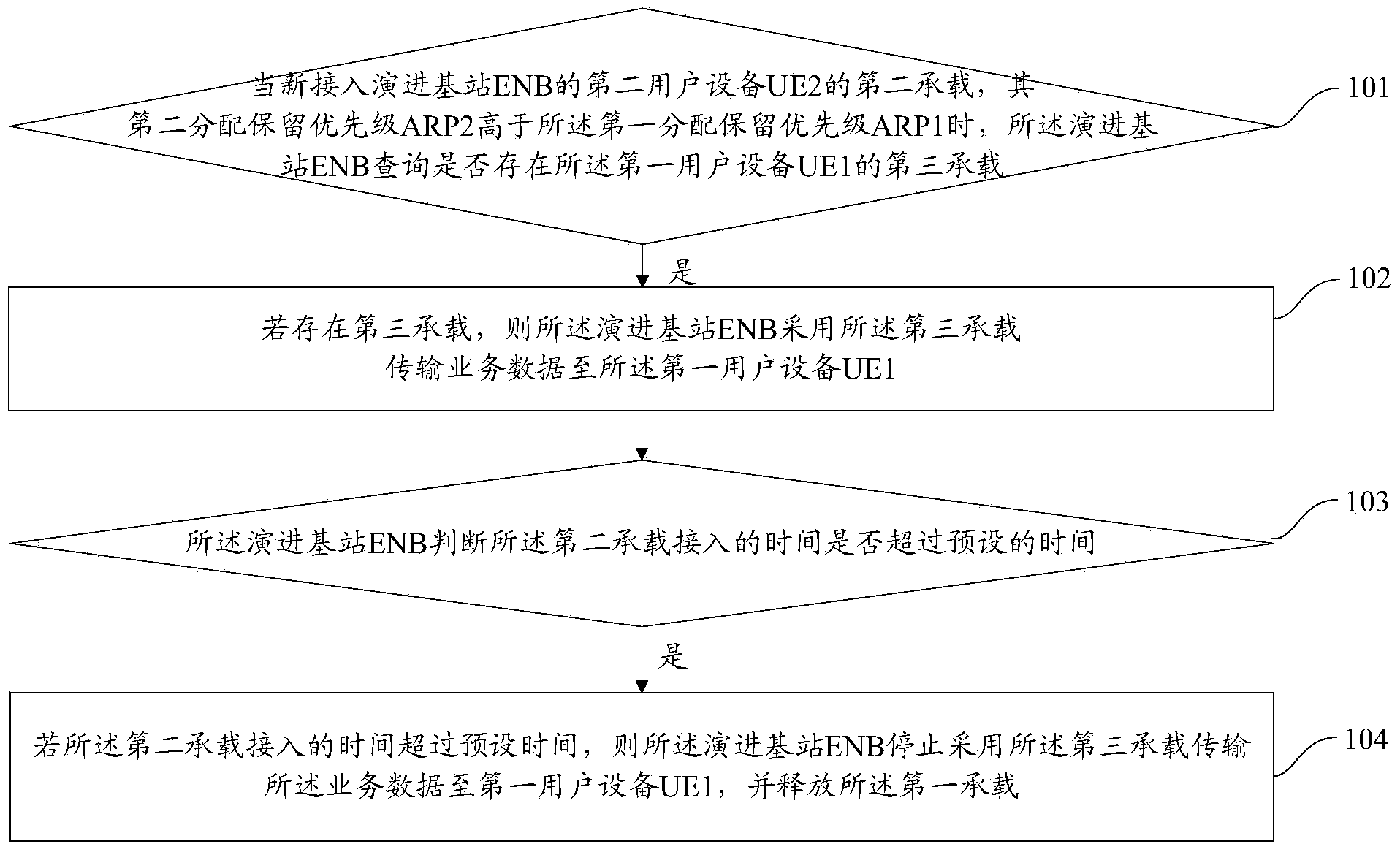

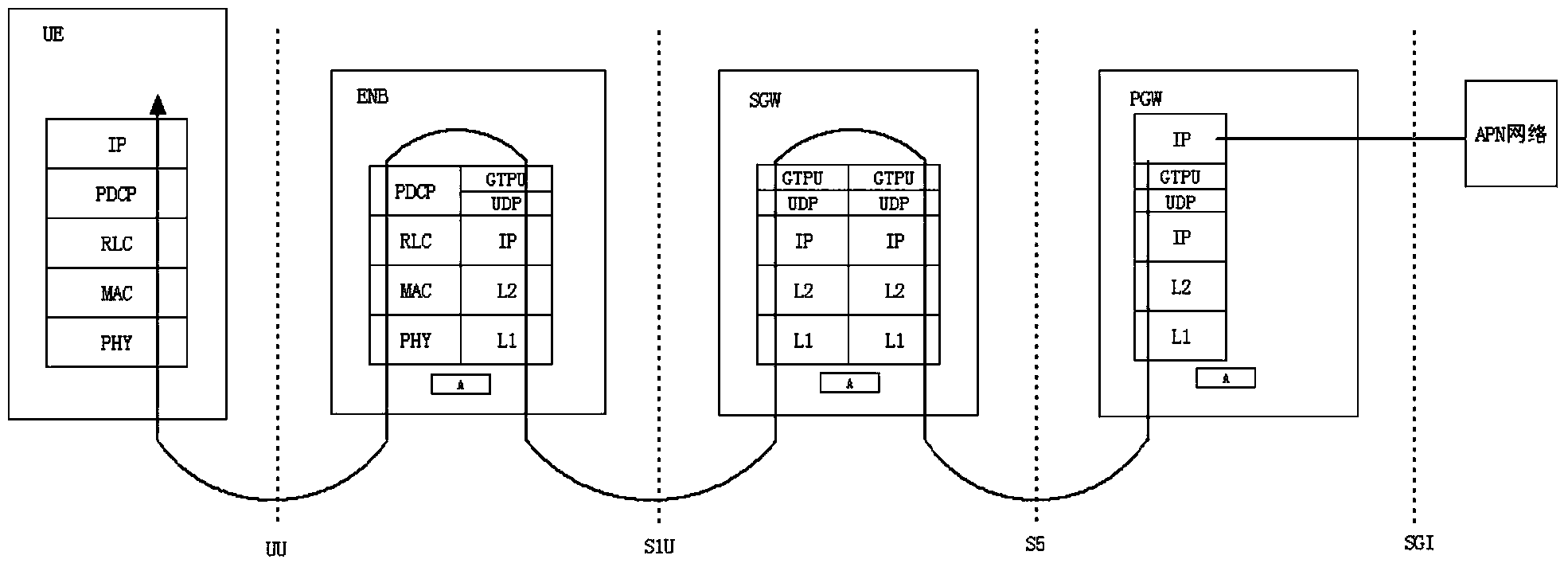

Method and device for processing service data during bearing and preemption in LTE

ActiveCN103716894AGuaranteed continuous deliveryAvoid user experienceConnection managementAccess timeData processing

Owner:DATANG MOBILE COMM EQUIP CO LTD

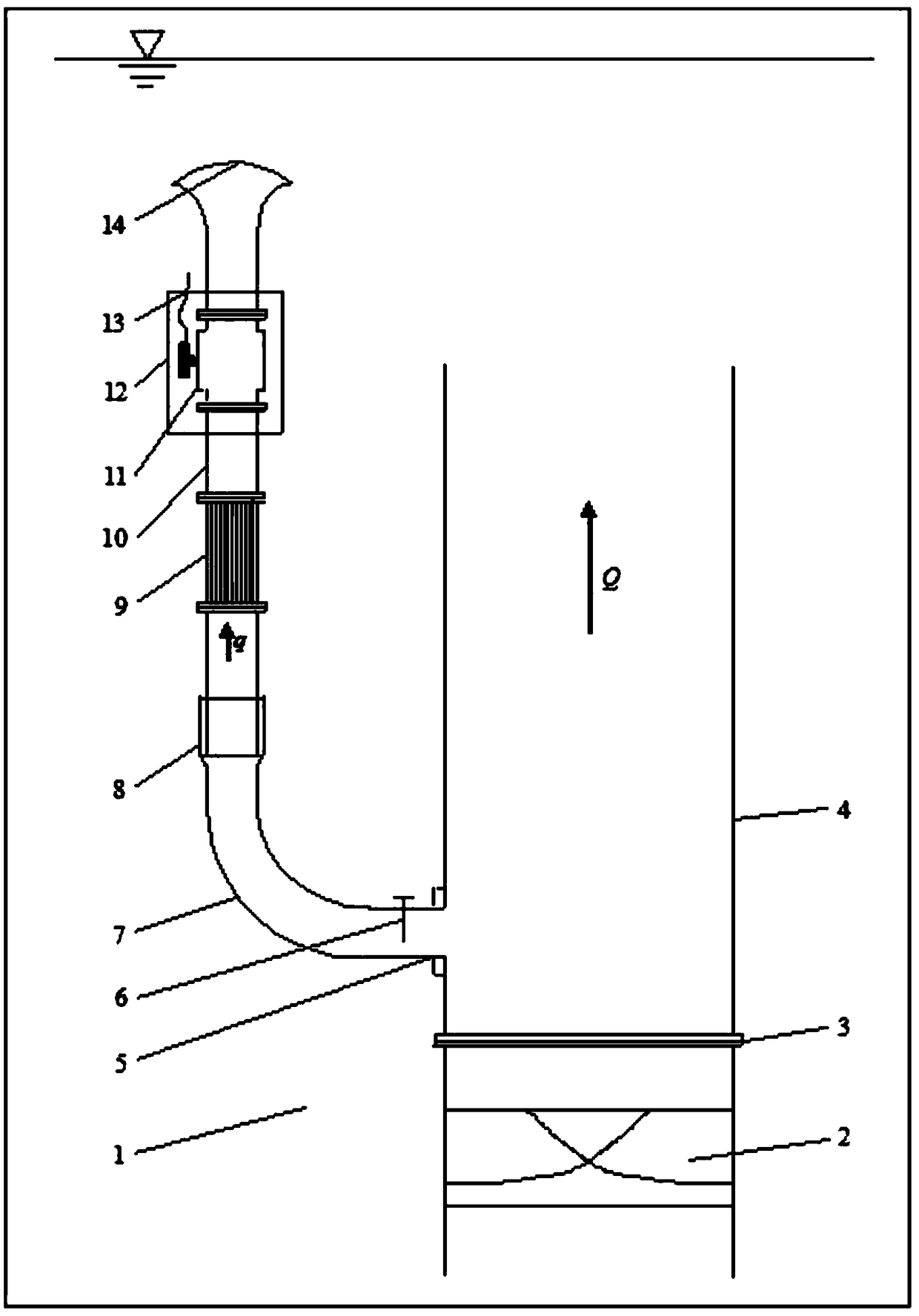

Kiln feeding system for directly injecting refuse-derived fuel into cement kiln

ActiveCN104279570AImprove delivery capacitySmall footprintIncinerator apparatusLump/pulverulent fuel feeder/distributionRefuse-derived fuelEngineering

The invention discloses a kiln feeding system for directly injecting refuse-derived fuel into a cement kiln. The kiln feeding system comprises a pyrolyzing furnace with a high-position feeding port, a vertical continuous hoist, a horizontal continuous conveyor and a buffer bin, the vertical continuous hoist and the pyrolyzing furnace are adjacent to each other and are arranged side by side, a discharging port is formed in one upper side of the vertical continuous hoist and positioned above the feeding port of the pyrolyzing furnace, a feeding port is formed in the other side of the lower end of the vertical continuous hoist, a discharging port is formed in one end of the horizontal continuous conveyor and positioned above the feeding port of the vertical continuous hoist, a feeding port is formed in the other end of the horizontal continuous conveyor, the buffer bin is arranged above the feeding port of the horizontal continuous conveyor, and a feeding device is arranged at the bottom of the buffer bin. The kiln feeding system for directly injecting the refuse-derived fuel into the cement kiln is capable of improving conveying capacity of refuse-derived fuel greatly, and the occupied area of the kiln feeding system can be decreased greatly.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Discharging platform for refuse landfill and discharging method thereof

The invention discloses a discharging platform for a refuse landfill and a discharging method thereof. The discharging platform comprises a sliding trolley, first guide rails, a refuse conveying mechanism, a distributing table and refuse discharging mechanisms, wherein the sliding trolley is movably connected to the two first guide rails, the refuse conveying mechanism is rotationally connected above the sliding trolley, the distributing table is arranged at the end of the refuse conveying mechanism, and the refuse discharging mechanisms are arranged on three side faces of the distributing table. The discharging method of the discharging platform includes the steps that (1) the first guide rails are laid; (2) the sliding trolley is installed; (3) the refuse conveying mechanism is installed; (4) the refuse discharging mechanisms are installed; and (5) refuse discharging treatment is conducted. According to the discharging platform for the refuse landfill and the discharging method thereof, the structure is simple, the practicality is high, different types of refuse are piled in corresponding positions according to the size of the refuse landfill, and rapid classified landfilling ofrefuse is achieved; and use is flexible and convenient, refuse can be uniformly piled in the refuse landfill, the degree of automation is high, and the labor intensity of manual operation is relieved.

Owner:浙江永安工程咨询集团有限公司

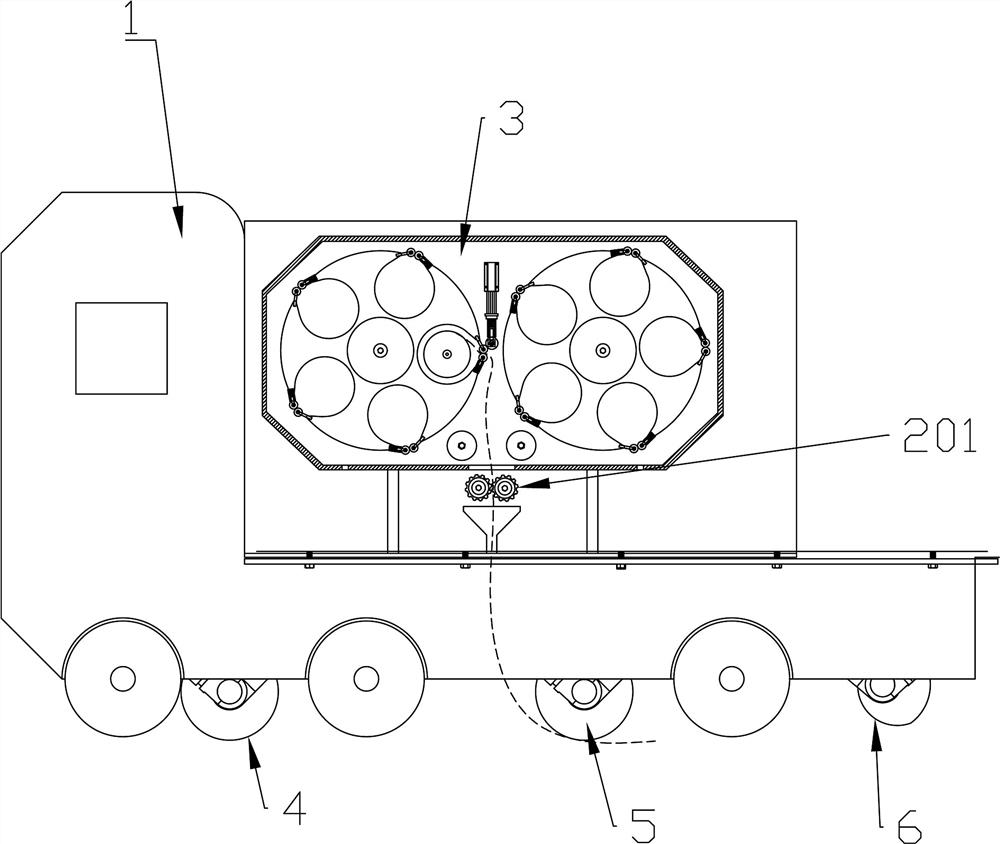

Horizontal warehouse bulk grain warehousing and distributing method

PendingCN112456162AReduce the number of movesReliable feedingConveyorsLoading/unloadingThermodynamicsVehicle frame

The invention relates to a horizontal warehouse bulk grain warehousing and distributing method. Grains are distributed into a granary through a grain distributing vehicle, and the grain distributing vehicle comprises a grain distributing vehicle frame and a grain conveying mechanism arranged on the grain distributing vehicle frame. The grain conveying mechanism comprises a fixed conveying mechanism body with the length extending in the front-back direction and at least one movable conveying mechanism body capable of moving front and back relative to the fixed conveying mechanism body, the front end portion of the movable conveying mechanism body forms the discharging end of the grain conveying mechanism, and the rear end of the fixed conveying mechanism body is provided with a feeding end.The rear end of the grain distributing vehicle frame is provided with a rotating connection structure with the rotating axis extending in the vertical direction. The granary grain distributing methodis provided so that position movement of the grain distributing vehicle can be reduced as much as possible, and therefore the grain distributing efficiency is improved.

Owner:郑州工大粮安科技有限公司

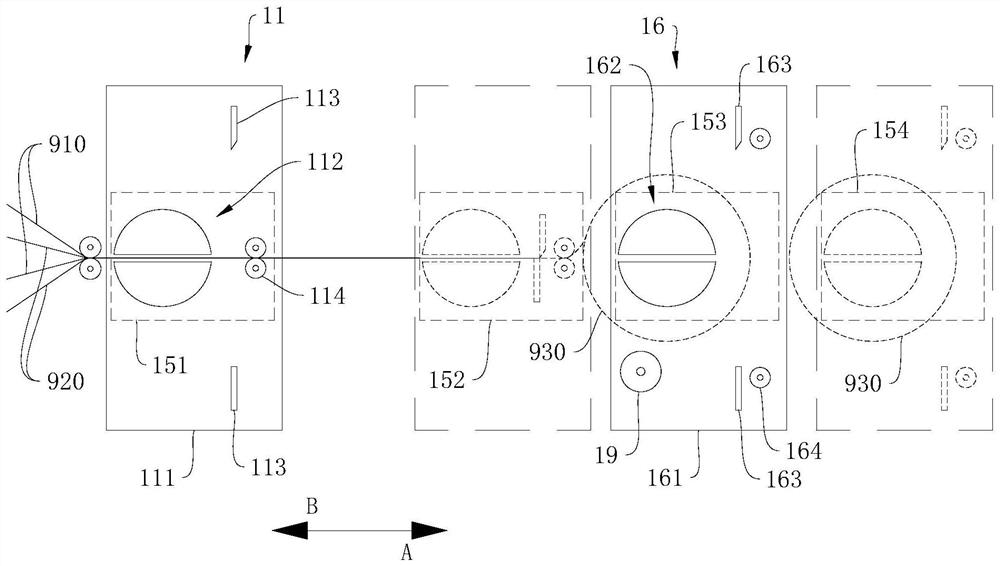

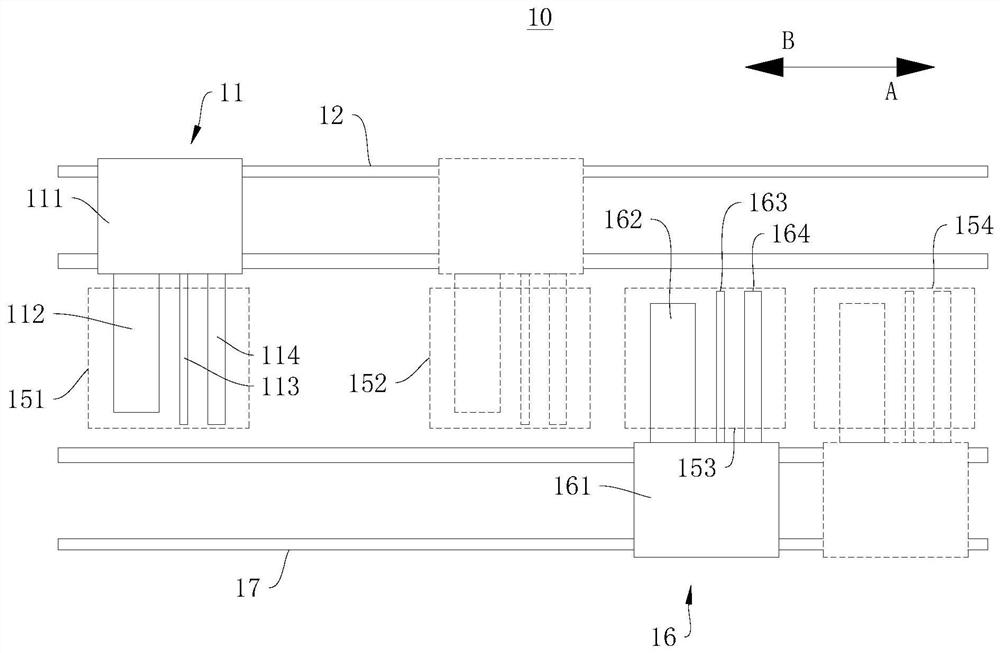

Battery core continuous winding device and battery core continuous winding method

InactiveCN111740169AReduce winding auxiliary timeGuaranteed continuous deliveryAssembling battery machinesFinal product manufactureControl theoryMechanical engineering

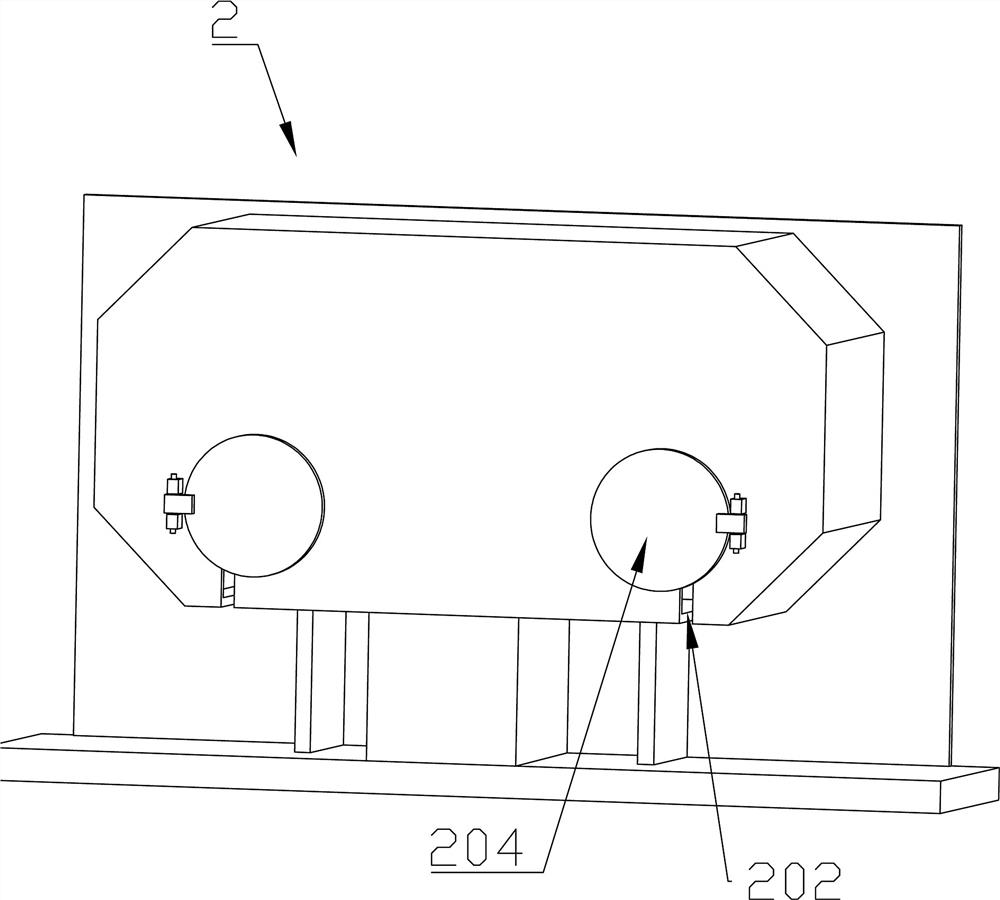

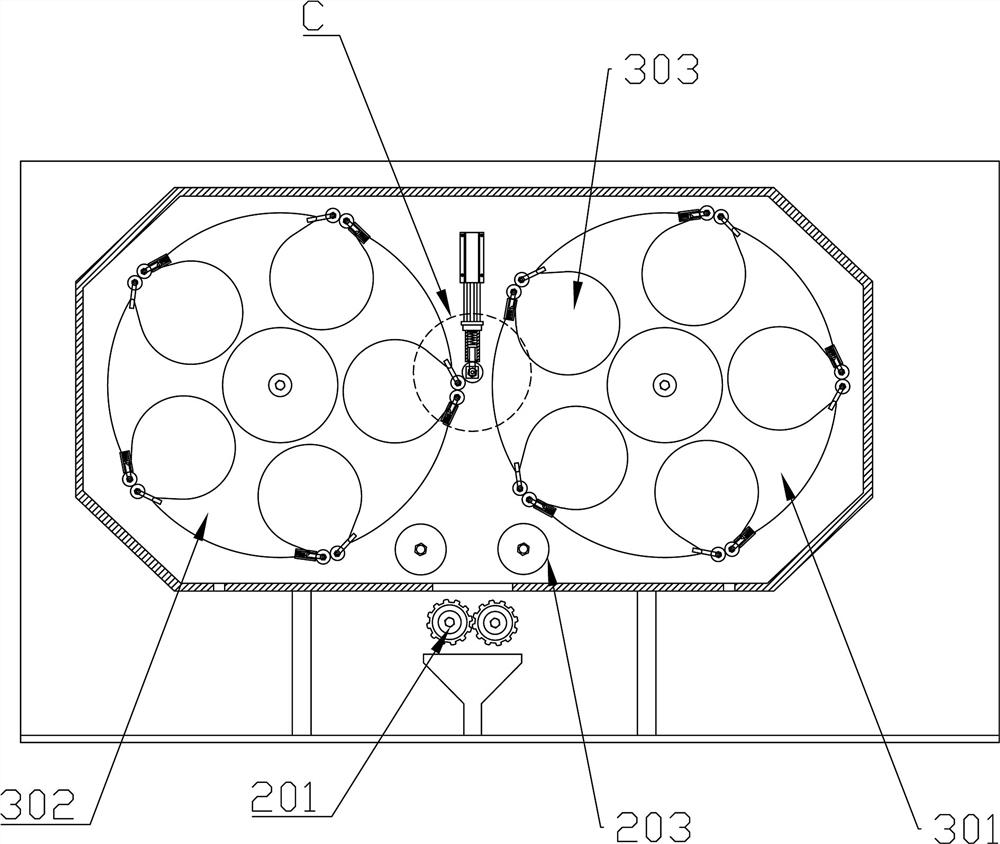

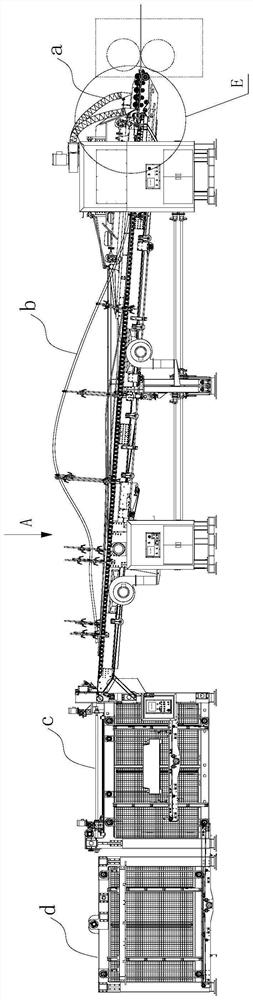

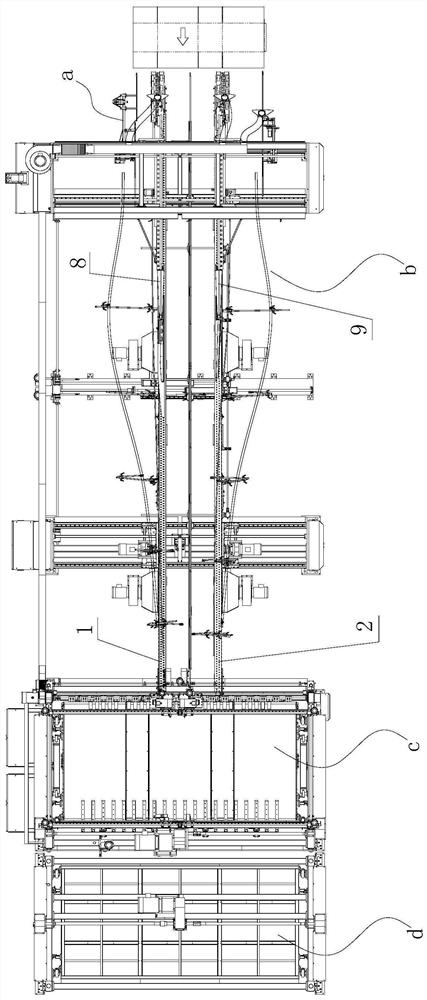

The invention discloses a battery core continuous winding device and a battery core continuous winding method, and relates to the technical field of battery core production. The battery core continuous winding device comprises a first winding mechanism, a first guide rail, a second winding mechanism and a second guide rail, wherein the first guide rail and the second guide rail extend along a winding channel, and are positioned at the two sides of the winding channel respectively; the winding channel is provided with a winding preparation section and a winding station; the first winding mechanism and the second winding mechanism can move along the first guide rail and the second guide rail respectively, can move to the winding preparation section and the winding station respectively and can conduct winding work at the winding station to form a battery core piece and conduct winding preparation work at the winding preparation section; and the first winding mechanism and the second winding mechanism can alternately move to the winding section to alternately conduct winding preparation work and winding work. The battery core continuous winding device and the battery core continuous winding method have the characteristic of relatively high winding efficiency.

Owner:GEESUN AUTOMATION TECH

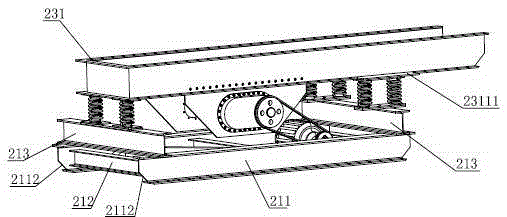

Vibratory conveying equipment of pulverizing machine of powder coatings

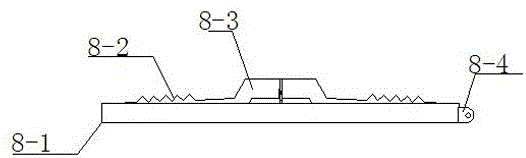

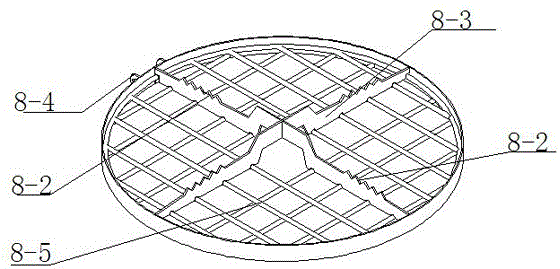

The invention discloses vibratory conveying equipment of a pulverizing machine of powder coatings. The vibratory conveying equipment comprises a machine frame and a vibratory conveying device. The vibratory conveying device comprises a vibratory conveying fixed support, an elastic device, a vibratory conveying mechanism and a vibrating device, wherein the vibratory conveying fixed support is installed on the machine frame, the elastic device is installed on the vibratory conveying fixed support, the vibratory conveying mechanism is installed on the elastic device, and the vibrating device is installed between the vibratory conveying fixed support and the vibratory conveying mechanism. According to the vibratory conveying equipment, the machine frame facilitates the layout of other components, the strength of the vibratory conveying fixed support can be improved, the structural stability of the vibratory conveying fixed support can be improved, and the amount of elastic deformation of the vibratory conveying fixed support can be increased; the vibratory conveying device vibrates drastically and promotes continuous conveying of materials, and the rotation speed of a vibrating motor can be easily controlled according to the conveying requirement of the materials.

Owner:佛山市汇友装饰材料有限公司

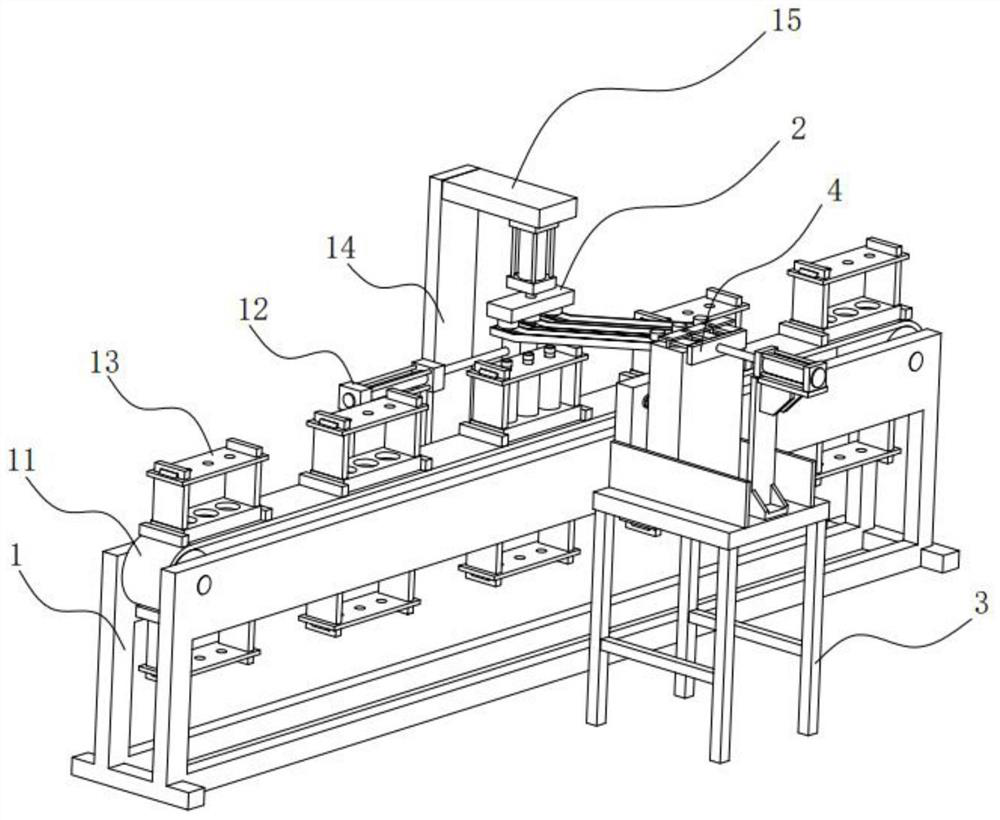

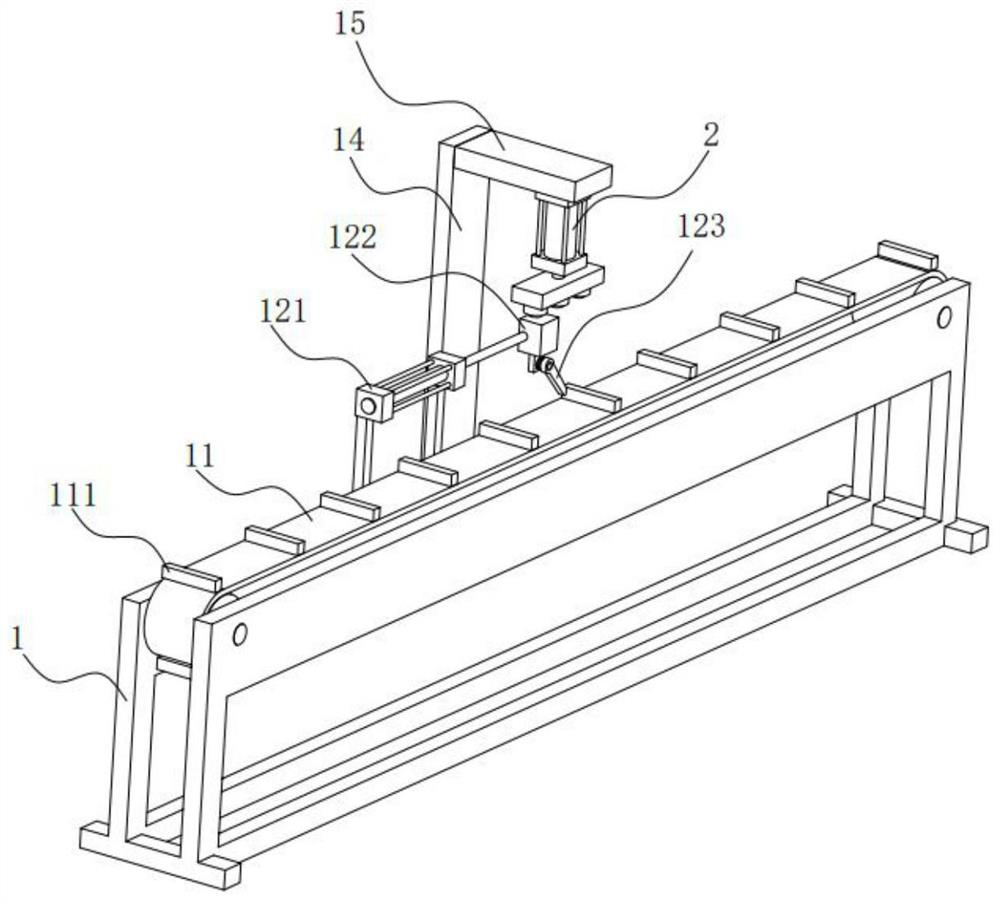

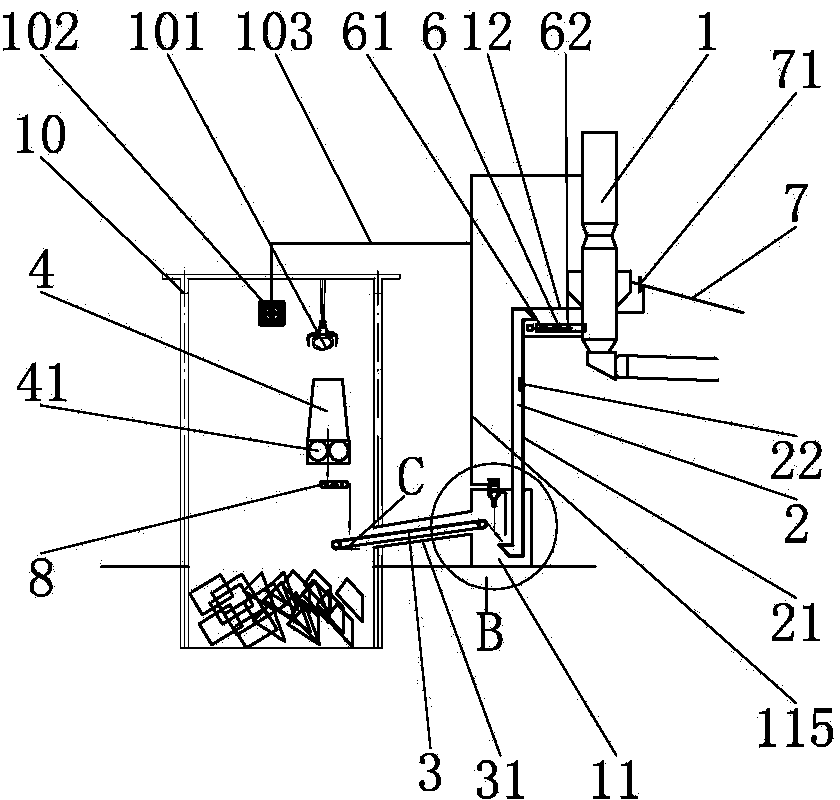

Automatic feeding device for end face machining

ActiveCN112720032AHigh degree of automationImprove processing efficiencyPositioning apparatusMetal working apparatusEngineeringPower equipment

The invention relates to the technical field of part machining, and discloses an automatic feeding device for end face machining. The automatic feeding device for end face machining comprises a pushing device, an automatic positioning device and a discharging device, wherein workpieces to be machined are continuously conveyed to the automatic positioning device through the pushing device so as to be positioned and clamped, and discharging is conducted through the discharging device, so that the continuous and automatic end face machining procedure is achieved, the automation degree is high, and the working efficiency is high; in addition, a conveying mechanism in the automatic positioning device drives a conveying wheel to do eccentric rotating motion through an eccentric shaft, so that clamping of the workpieces is achieved; in the workpiece conveying motion process of the conveying wheel, on one hand, the workpiece conveying path is increased, and the diameter of the conveying wheel needed for conveying the workpieces with the same size is reduced, so that the equipment size is reduced, and the equipment cost is reduced; on the other hand, the conveying wheel can drive a positioning mechanism to position the workpieces in the eccentric movement process, so that the synchronism between the positioning mechanism and the conveying mechanism is guaranteed; and the positioning mechanism does not need extra power, so that the equipment cost is low.

Owner:襄阳鼎超机械制造有限公司

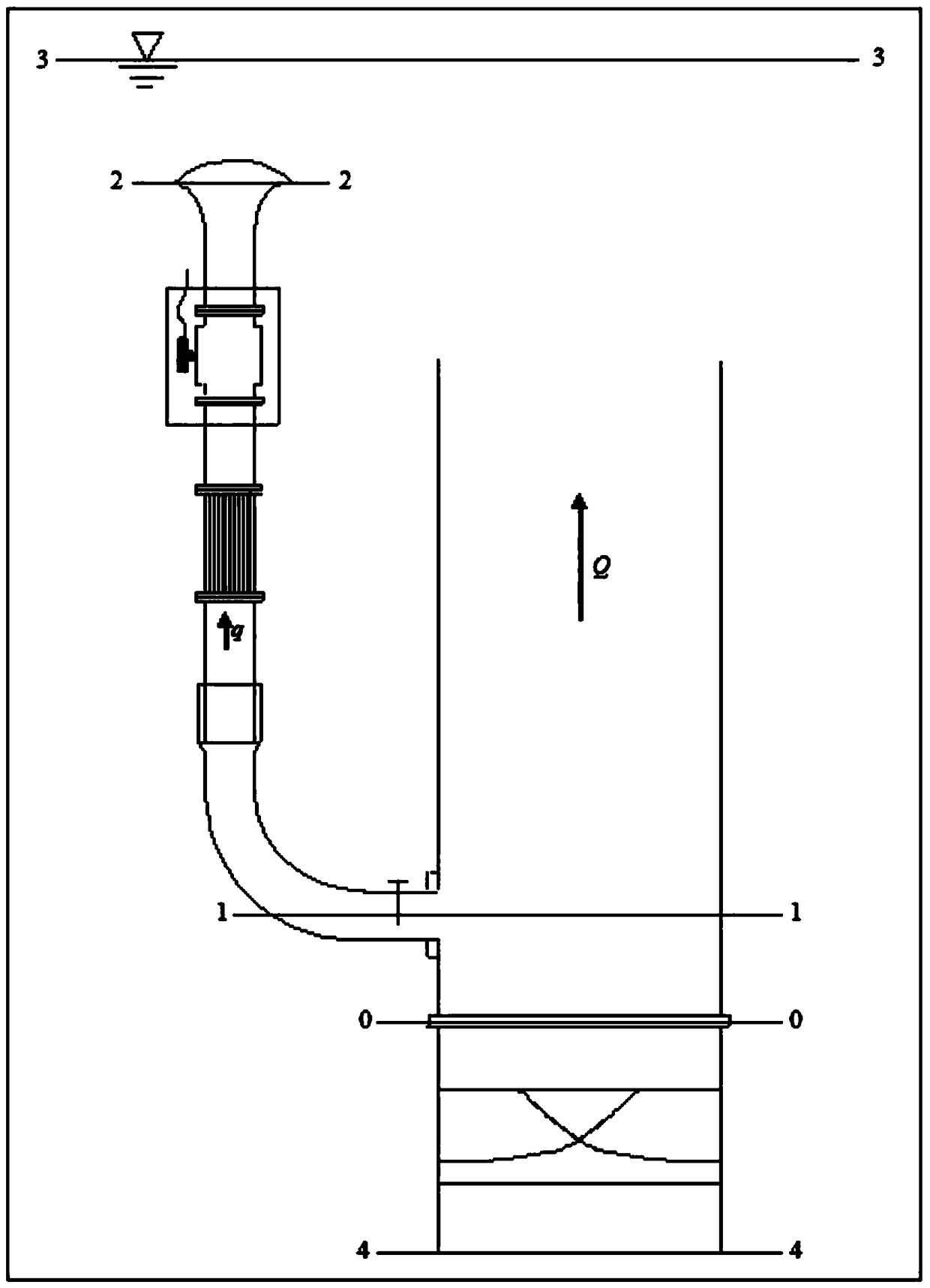

Flow measuring device and method

ActiveCN109341791AEasy loading and unloadingExtended service lifeVolume/mass flow by electromagnetic flowmetersEngineeringStreamflow

The invention discloses a flow measuring device and method. When a main pipeline and a pump arranged on the main pipeline are immersed in a liquid medium and work, a branch pipe which is communicatedwith the main pipeline and has the inner diameter smaller than that of the main pipeline is arranged and connected to the wall face, close to an output port of the pump, of the main pipeline, an overflow pipe which is immersed in the liquid medium is connected to an outlet of the branch pipe, a flowmeter is arranged on the overflow pipe, and the overflow pipe flow value which is actually measuredby the flowmeter is converted into the main pipeline flow value in the main pipeline. According to the flow measuring device and method, the flowmeter can be convenient to maintain and replace, the main pipeline does not need to be cut off, continuous normal conveying of the main pipeline can be guaranteed, normal work is not influenced, and the flow measuring device and method are suitable for situations in which the pump and the main pipeline need to continuously work for a long term.

Owner:XIHUA UNIV

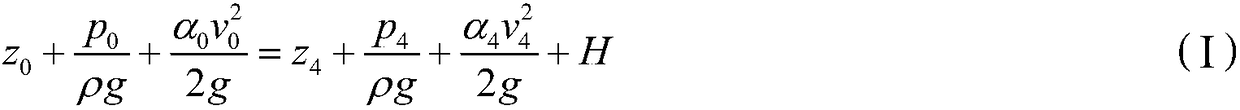

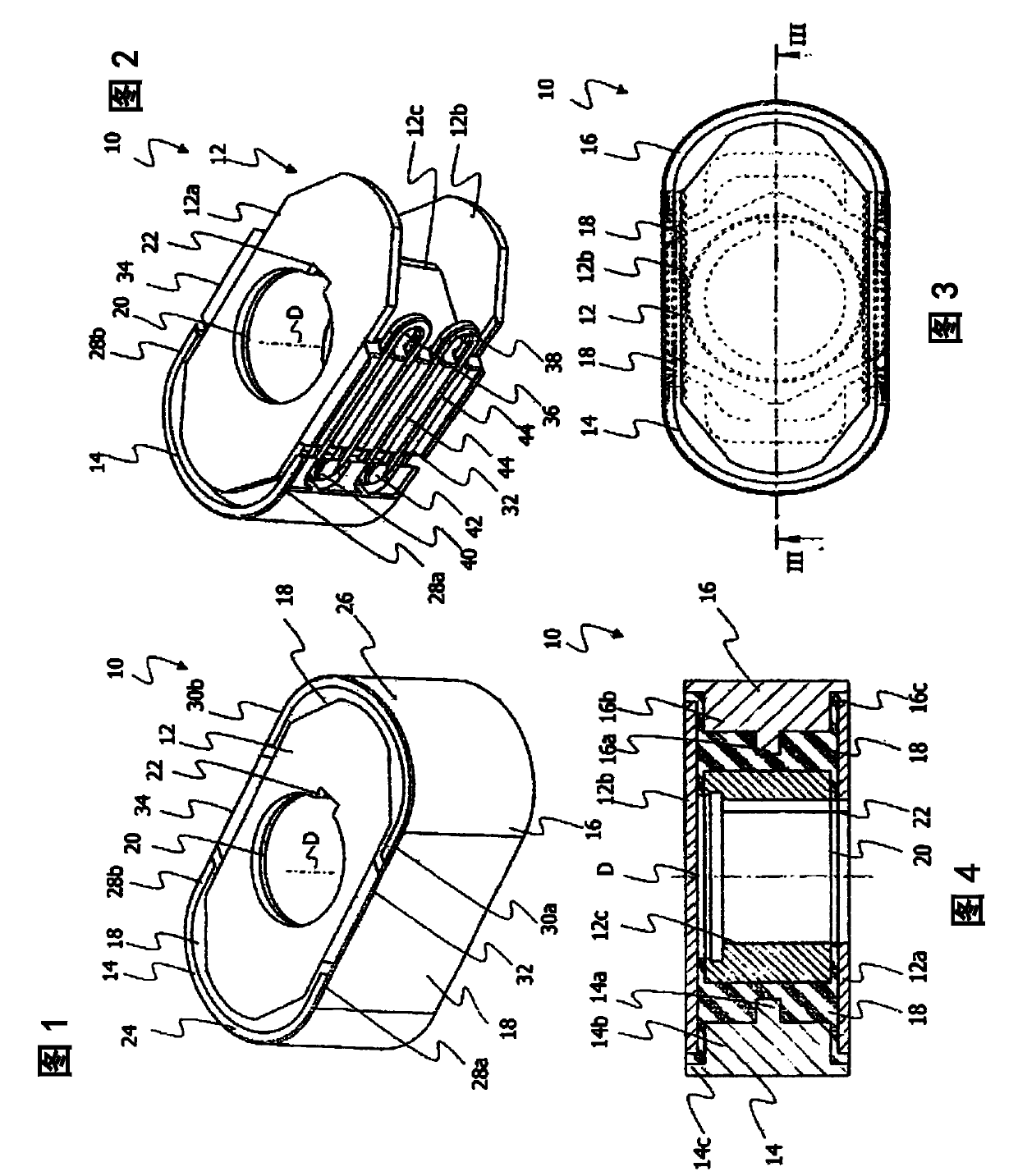

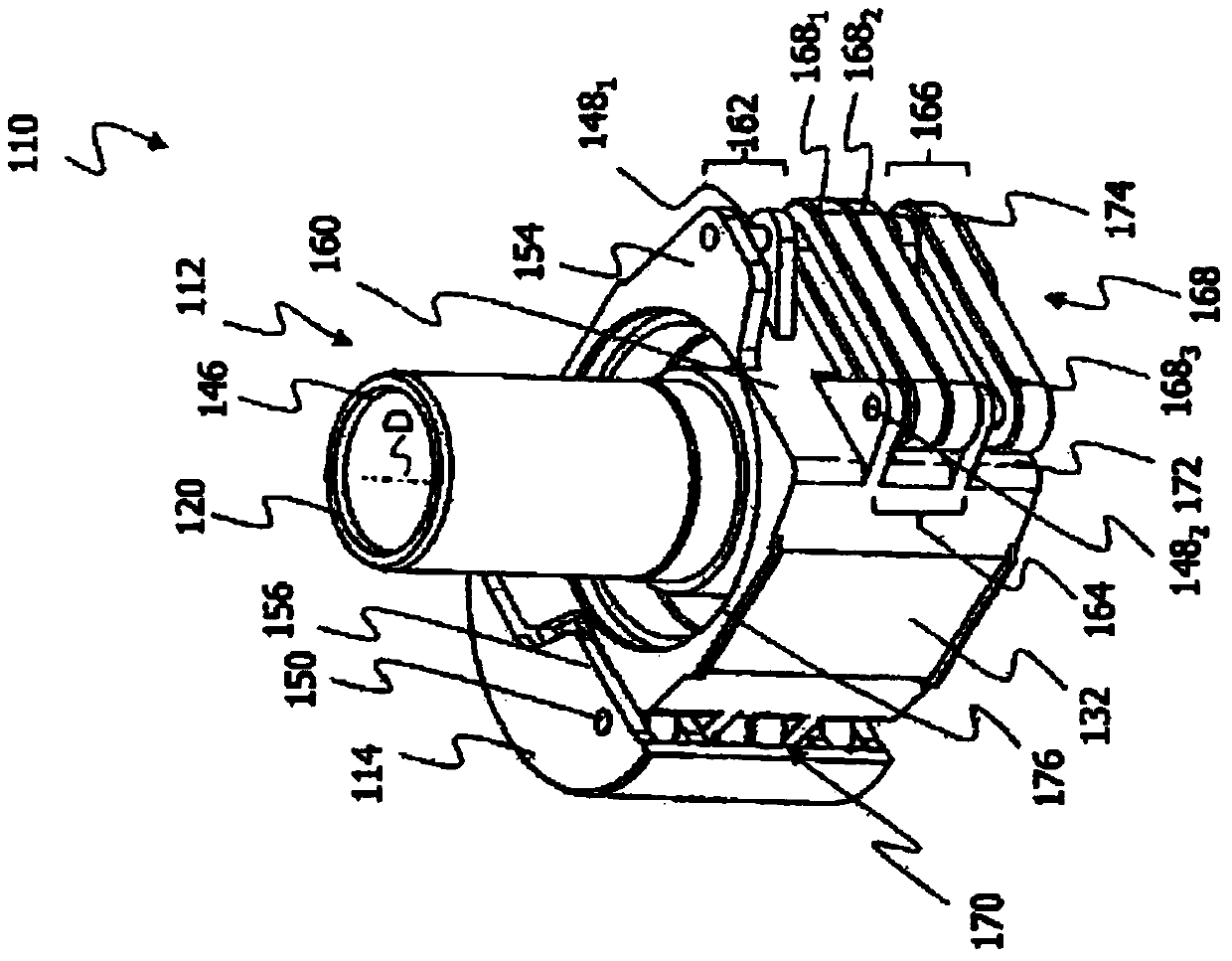

Rotary piston

The present invention relates to a rotary piston 10 for a rotary piston pump, wherein the rotary piston 10 comprises at least one supporting body 12, through which the axis of rotation D of the rotary piston 10 extends, and at least one end cap portion 14, 16 which is arranged radially outwards of the at least one supporting body 12 and is connected flexibly, preferably elastically, to the at least one supporting body 12.

Owner:NETZSCH PUMPEN & SYST +1

Bagging system for sponge inner sleeve

PendingCN111731565AReduce manual laborImprove work efficiencyWrapper twisting/gatheringYarnIndustrial engineering

The invention relates to a bagging system for a sponge inner sleeve. The bagging system comprises a feeding unit, a bagging unit, a cutting and overseam unit and a discharging unit sequentially arranged. The bagging system has the following advantages: through mutual cooperation of the feeding unit, the bagging unit, the cutting and overseam unit and the discharging unit, automatic conveying and bagging of sponge and automatic cutting and overseam unit of a yarn bag are realized, manual labor is greatly reduced during the entire process, effectively saves the labor force and correspondingly improves the working efficiency.

Owner:南通恒康数控机械股份有限公司

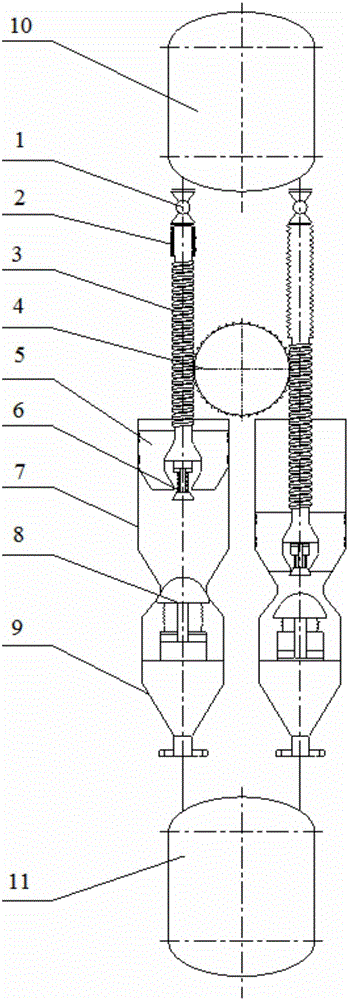

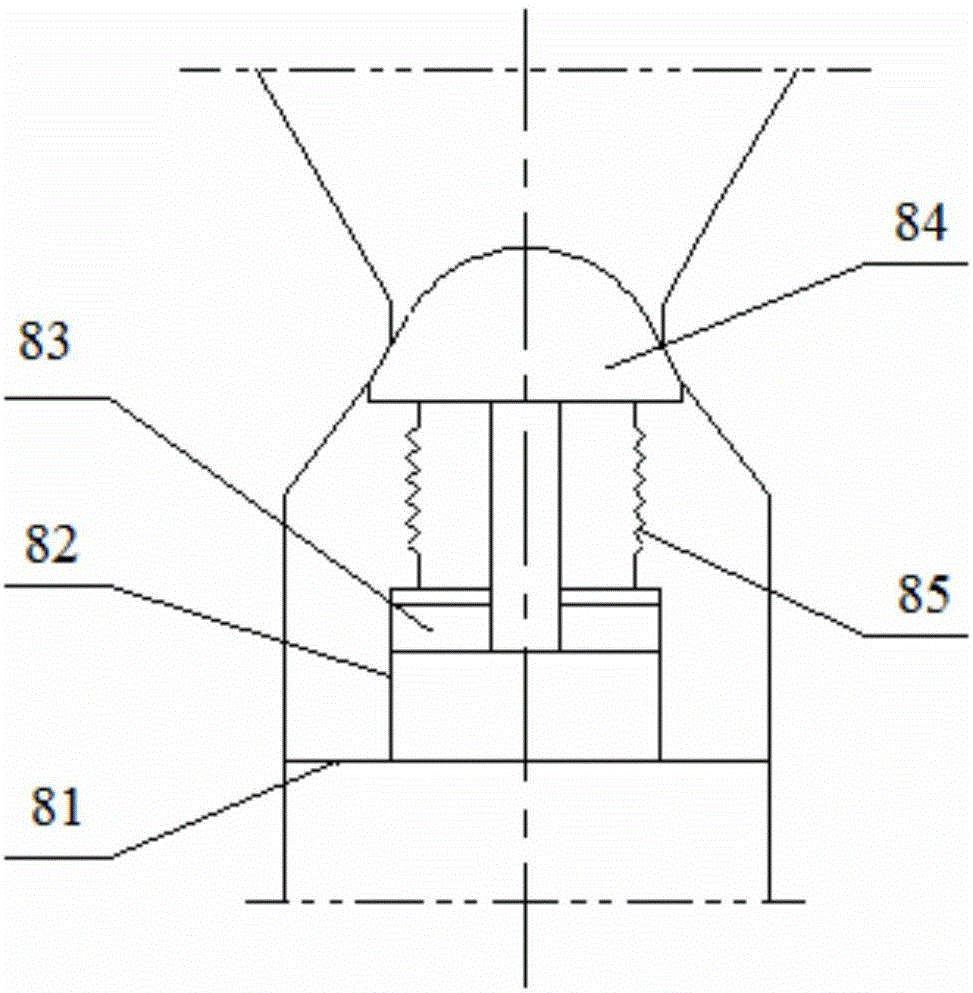

Plunger type coal ash pressurized conveying device

PendingCN106516752AIncrease pressureGuaranteed continuous deliveryBulk conveyorsEngineeringMechanical engineering

The invention provides a plunger type coal ash pressurized conveying device and belongs to the technical field of coal chemical engineering for solving the problems that an existing coal ash pressurized conveying technology is low and the like. The device provided by the invention comprises a driving part and two conveying channels which are arranged in parallel; the upper and lower ends of each of the conveying channels are connected to a constant pressure storage tank and a coal ash feeding tank, respectively; a constant pressure feeding valve is arranged at the upper end of each of the conveying channels, the lower end outlet of the constant pressure feeding valve is connected to a stretchable coal ash conveying pipeline, the lower end of the stretchable coal ash conveying pipeline is connected to a worm coal ash conveying pipeline, the lower end of the worm coal ash conveying pipeline is connected to a coal as feeding valve in a piston part, the piston part is located in a coal ash conveying cavity, the lower end output port of the coal ash conveying cavity is connected to the upper end inlet of a blanking section, the lower end outlet of the blanking section is connected to a coal ash feeding tank, and a coal ash blanking valve is arranged at the connection of the coal ash conveying cavity and the blanking section; the driving part is used for driving the piston rod to do a reciprocating rectilinear movement. The device has the characteristic of being low in energy consumption.

Owner:CHANGZHENG ENG

Milk sterilizer

InactiveCN105410176ASimplify the sterilization processGuaranteed continuous deliveryMilk preservationBottleCow milk

The invention discloses a milk sterilizer which can simultaneously sterilize the feeding bottle and the milk. The milk sterilizer comprises a horizontal sterilizing tube; a liquid inlet pipe and a steam inlet pipe are respectively connected to one side of the sterilizing tube; a liquid outlet pipe and a steam outlet pipe are respectively connected to the other side of the sterilizing tube; the milk sterilizer is characterized in that a bottle inlet is further arranged on the sterilizing tube at the side of the liquid inlet pipe; a bottle outlet pipe is further arranged on the sterilizing tube at the side of the liquid outlet pipe; a horizontal rotor shaft is arranged in the sterilizing tube; the rotor shaft is bound by a spiral sterilizing pipe; the sterilizing pipe is respectively connected to the liquid inlet pipe and the liquid outlet pipe; and the a special conveyor for conveying the feeding bottles is formed by the sterilizing pipe and the rotor shaft when the rotor shaft rotates.

Owner:CHONGQING LONGYUE FOOD

Novel spring coiling system

ActiveCN106734441ARealize automated productionIncrease productivityMetal-working feeding devicesPositioning devicesPunch pressCoil spring

The invention discloses a novel spring coiling system, and belongs to the field of specially-shaped spring processing. The novel spring coiling system comprises a working platform and further comprises a feeding mechanism, a forming mechanism and a spring coiling mechanism, wherein the feeding mechanism comprises a material frame, a feeder and a feeding machine; the feeder and the feeding machine are separately arranged at the two ends of the working platform; the forming mechanism comprises a blanking mould and a punching machine; the blanking mould and the punching machine are positioned on the middle part of the working platform; the spring coiling mechanism comprises a spring coiling machine which is matched with the feeding machine to work; coiled materials are arranged on the material frame; the coiled materials are transmitted to a blanking station through the feeder, and the coiled materials on the blanking station are prepared into a coil spring semi-finished product through the forming mechanism; the coiled spring semi-finished product is transmitted to a spring coiling station through the feeding machine; the coil spring semi-finished product on the spring coiling station is processed into a coil spring finished product; and the working platform is further equipped with a control unit. The novel spring coiling system can realize automatic production of coil springs; and the scheme obviously improves production efficiency, product quality and consistency.

Owner:中山市鹏耀五金制品有限公司

Continuous grass roll laying device for grass checkered sand barrier

ActiveCN114698511AGuaranteed continuous deliveryReduce frictionHops/wine cultivationClimate change adaptationAgricultural engineeringControl theory

The invention relates to a grass grid sand barrier grass roll continuous laying device which comprises a vehicle body, a ditching wheel, a grass pressing wheel and a gathering device are arranged at the lower end of the vehicle body and are sequentially arranged in the advancing direction of the vehicle body, a traction wheel set and a continuous feeding device are further arranged on the vehicle body, and the continuous feeding device comprises a first rotating wheel and a second rotating wheel. The traction wheel set is arranged below the position between the first rotating wheel and the second rotating wheel, the first rotating wheel and the second rotating wheel are each provided with a plurality of storage bins in the circumferential direction, the storage bins are used for containing grass rolls, the side walls of the storage bins are provided with notches used for discharging grass roll stub bars out of the bins, and the first rotating wheel and the second rotating wheel rotate to the discharging position in turn so that grass can be connected. The traction wheel set is used for pulling straw roll stub bars, and the problem of continuous conveying of straw rolls of the straw grid laying device is solved.

Owner:YANGTZE UNIVERSITY

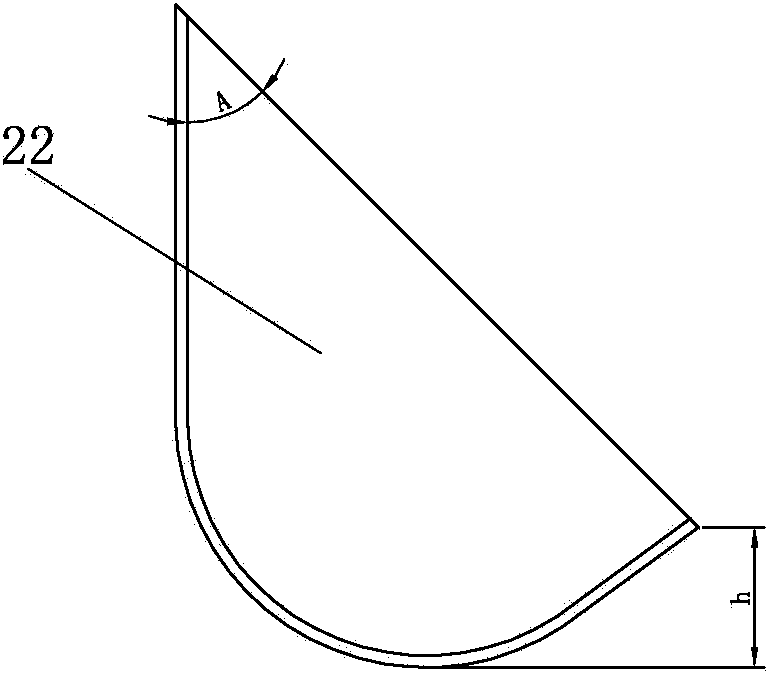

Box pasting and folding device for ultra-large type corrugated paper printing linkage line

ActiveCN111605243AHigh-speed automatic productionIncrease productivityPaper-makingBox making operationsPaperboardManual handling

The invention discloses a box pasting and folding device for an ultra-large type corrugated paper printing linkage line. The box pasting and folding device comprises a box pasting part, a box foldingpart, a counting and discharging part and a press fit part which are connected in sequence. The box folding part comprises a paperboard conveying mechanism and a folding mechanism, and the box pastingpart and the folding mechanism are sequentially arranged above the paperboard conveying mechanism in the paperboard conveying direction. The counting and discharging part is connected with the outputend of the paperboard conveying mechanism, and the press fit part is connected with the output end of the counting and discharging part. The box pasting and folding device is designed aiming at the printing process of ultra-large type corrugated paper; after the printing and die cutting process is completed, the ultra-large type corrugated paper can directly enter a subsequent process to be subjected to box pasting, box folding, counting and discharging, press fitting and other processes; traditional manual operation can be replaced, the defect that a traditional printing linkage line can beonly suitable for small paperboard printing and cannot be suitable for large or ultra-large type paperboard printing, high-speed automatic production of the ultra-large type corrugated paper is achieved in cooperation with printing equipment, the production efficiency is improved, and the production safety is also improved.

Owner:GUANGZHOU KESHENGLONG CARTON PACKING MACHINE

Underground cast-in-place continuous wall construction method and connecting structure thereof

PendingCN114411695AImprove performanceImprove anti-seepage performanceBulkheads/pilesUltimate tensile strengthJoint (building)

The invention discloses an underground cast-in-place continuous wall construction method and a connecting structure thereof, belongs to the technical field of building construction, and provides the underground cast-in-place continuous wall construction method which is continuous in stress and higher in bearing strength and the formed connecting structure. By arranging the corresponding first nesting joint and the second nesting joint and adopting an effective movable buckling connection structure, concrete walls constructed in different hole sequences are connected into an effective whole, and particularly, effective connection between steel trusses in different hole sequences in the construction in different hole sequences is achieved; by means of the structure, continuity of stress in the continuous wall body is guaranteed, continuous transmission of force and deformation is facilitated, the overall performance and the anti-seepage effect of the concrete wall body can be greatly improved, the important guarantee effect is achieved for guaranteeing the quality and safety of the continuous wall body structure, and the practical application effect is quite obvious.

Owner:梁军

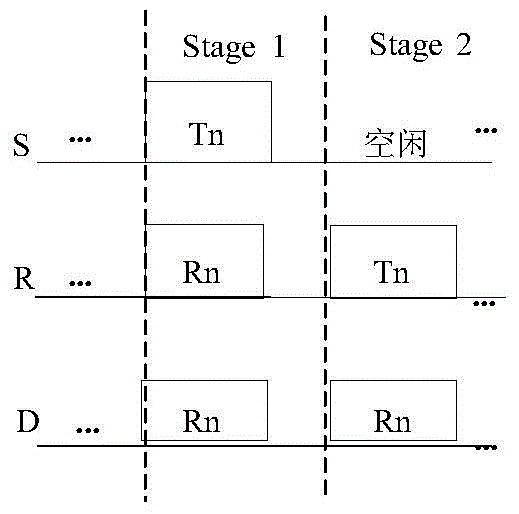

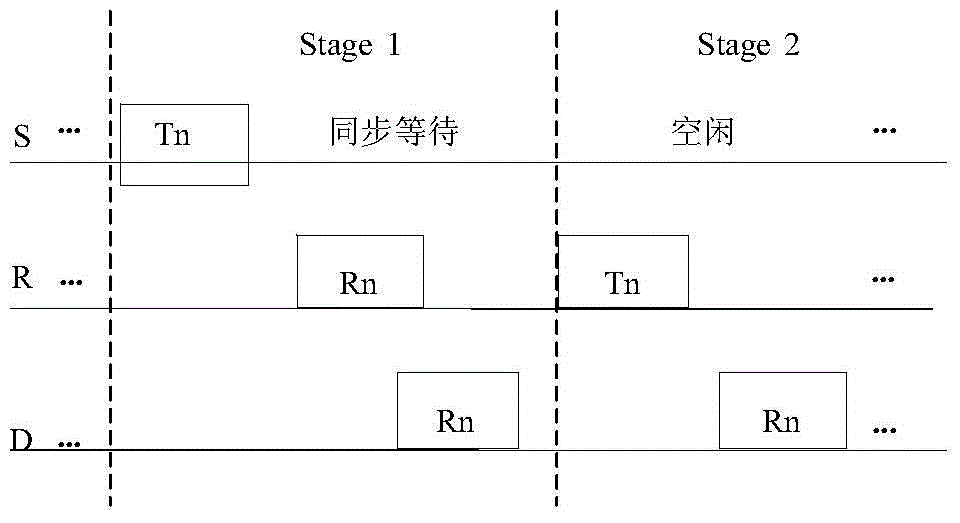

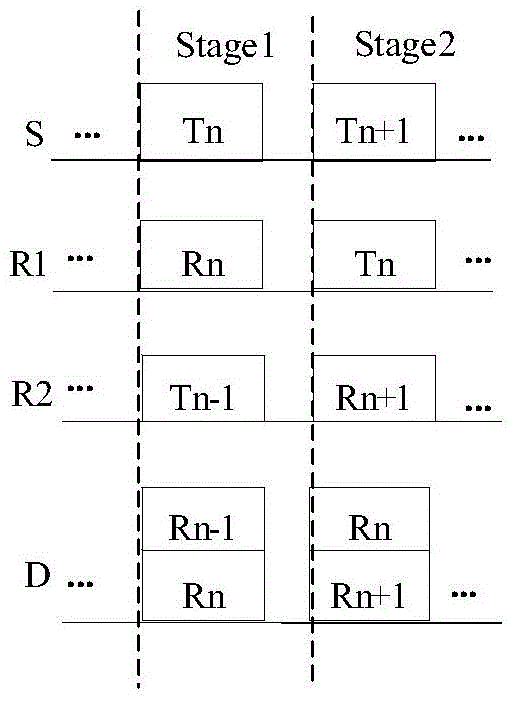

An asynchronous underwater full-rate cooperative communication method

InactiveCN103580815BGuaranteed continuous deliveryIncrease transfer rateTransmission path multiple useHigh level techniquesTransfer modeFull Rate

The invention discloses an asynchronous underwater full-rate cooperative communication method. The method includes the following steps that first, a source node acquires the right to use a channel and sends data; second, when the number of relay nodes capable of being used in the current transmission is larger than or equal to two, a full-rate cooperative communication mode is started; third, the relay nodes capable of being used are divided into N groups, the relay nodes in all the groups monitor data frames sent by the source node, when the nth group of relay nodes monitor the ith frame of data, if the remainder generated by dividing i by N is n, the group of relay nodes receive the frame of data, and if not, the monitoring is continued; a target node receives the data frames sent by the source node and the data frames forwarded by all the groups of relay nodes; after data transmission of the source node is completed, a stop signal is sent, the relay nodes receive the stop signal, forward the stop signal and then stop relay transmission, and the target node stops receiving after receiving the stop signal. The method has the advantages that the transmission rate is improved, and cost and power consumption are low.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com