Slurry mixing conveyor for combined type wet concrete sprayer

A concrete sprayer and combined technology, which is applied to cement mixing devices, earth square drilling, clay preparation devices, etc., can solve the problems of easy falling into the mixing drum, inconvenient feeding and sundries, so as to avoid random distribution of materials and avoid The effect of uneven transmission and slowing down of solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

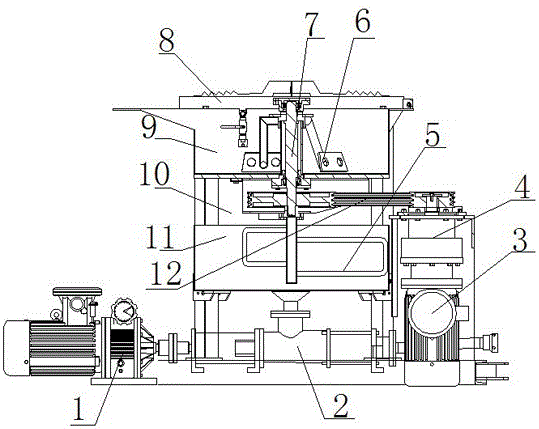

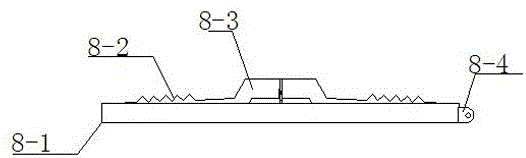

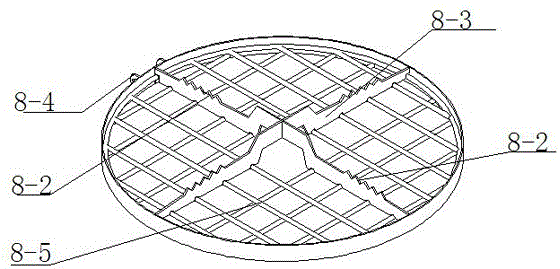

[0018] Figure 1-3 As shown, the specific implementation is as follows:

[0019] A slurry mixing conveyor for a combined wet concrete sprayer, comprising a mixing drum, a power shaft 7, a drive motor 3 for driving the power shaft to rotate, a water supply pipe for providing water for mixing slurry, and a cover arranged at the opening of the mixing drum The upper cylinder cover 8, the water supply pipe is installed on the cylinder cover 8, the mixing cylinder is the cylinder body of the mixing chamber 9, the power chamber 10 and the material storage chamber 11 arranged in sequence from top to bottom, the mixing chamber 9 and the material storage chamber 11 Both are isolated from the power chamber 10, and the stirring chamber 9 communicates with the storage chamber 11 so as to store the slurry stirred by the stirring chamber 9 in the storage chamber 11. One end of the power shaft 7 is rotated and installed on the cylinder cover 8, and the other end is After passing through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com