Kiln feeding system for directly injecting refuse-derived fuel into cement kiln

A technology for waste fuel and cement kiln, which is applied in the field of kiln entry system that directly injects waste fuel into cement kiln, can solve the problems of long conveying stroke and no-load return journey, large area and high cost, so as to improve the conveying capacity and reduce the cost. The effect of manufacturing cost and footprint reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

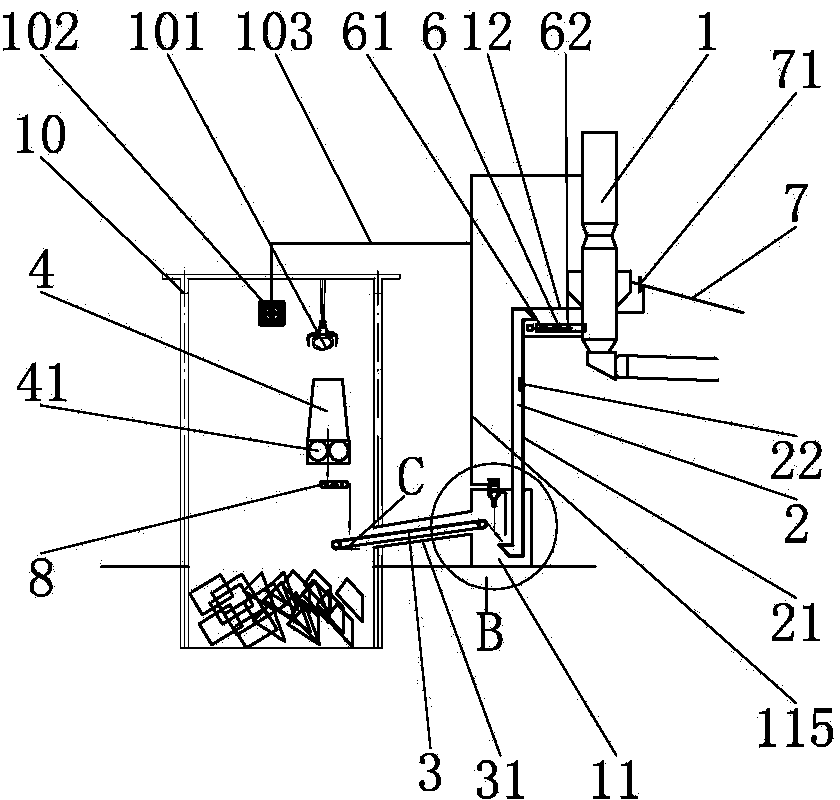

[0034] Such as Figure 1 to Figure 9 As shown, this embodiment provides a kiln entry system for directly injecting garbage fuel into a cement kiln. The system includes a pyrolysis furnace 1 with a feed inlet located at a high place, and the feed inlet is upward. The system also includes garbage fuel. Vertical continuous hoist 2, garbage fuel horizontal continuous conveyor 3 and garbage fuel buffer bin 4; the garbage fuel vertical continuous hoist 2 is adjacent to and juxtaposed with the pyrolysis furnace 1, and the garbage fuel One side of the upper end of the vertical continuous hoist 2 is provided with a discharge port, the discharge port faces downward and is positioned above the feed port of the pyrolysis furnace 1, and the other side of the lower end of the vertical continuous hoist 2 for waste fuel is There is a feed port on the side, the feed port faces upwards, from figure 1 and Figure 9 It can be seen from the figure that the discharge port at the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com