Rapid drivage-anchoring integrated equipment for coal road under instable surrounding rock condition

A technology of surrounding rock and conditions, applied in mining equipment, drilling equipment, drilling equipment and methods, etc., can solve problems such as mismatch between tunneling and anchoring capabilities, low overall tunneling efficiency, instability, etc., and improve comprehensive anchoring Efficiency, improved support efficiency, and convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

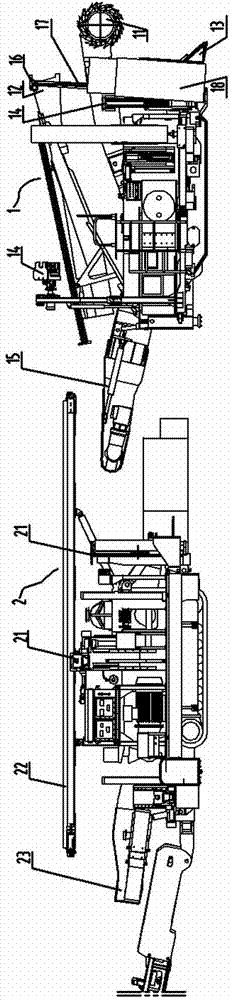

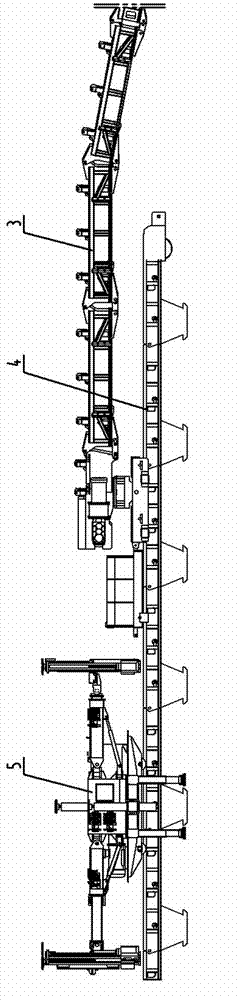

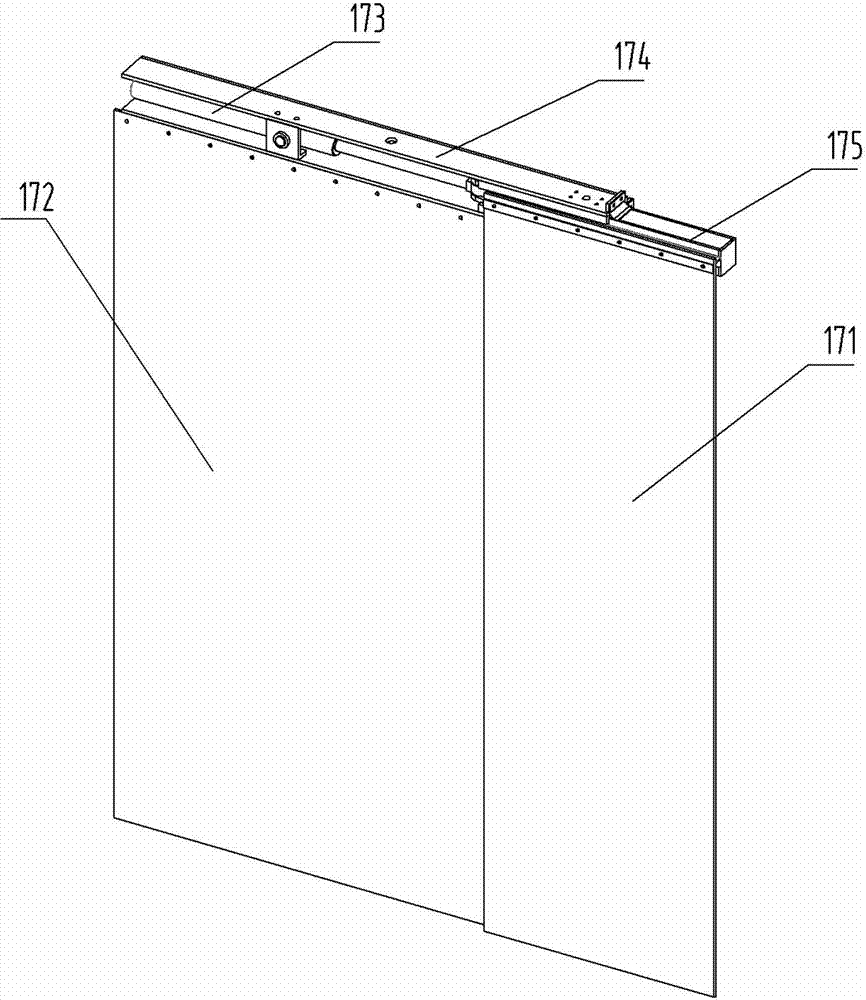

[0022] Embodiment one: if figure 1 As shown in and 2, in the present embodiment, the coal roadway rapid bolting integrated equipment under unstable surrounding rock conditions includes a bolter 1, a bolter 2, and the bolter 1 includes a cutting drum 11, a draft Pipeline 12, material collector 13, rock bolter unit 14 and scraper conveyor 15, described rocker drill 2 includes rocker drill unit 21 and scraper conveyor 23, and described rocker drill 2 is arranged at the excavation The rear of the windlass 1 and the rear of the scraper conveyor 15 of the bolter 1 is above the front of the scraper conveyor 23 of the bolter 2, and the bolter 1 is provided with an anti-roof fall device 16, The bottom of the anti-roofing device 16 is connected with a sealing device 17, and the sealing device 17 is composed of a movable sealing rubber 171, a fixed sealing rubber 172, a telescopic oil cylinder 173, a beam 174, and a telescopic beam 175, and the beam 174 is connected to the telescopic oi...

Embodiment 2

[0025] Embodiment 2: Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that: the bolter 1 is symmetrically provided with two anti-chip side devices 18, and the anti-chip side The device 18 is composed of a lower guard plate 181, an upper guard plate 182, a telescopic oil cylinder 183 and an adjustment oil cylinder 184. Both sides of the upper end of the lower guard plate 181 are provided with chute, and the upper guard plate 182 is slidably connected to the lower guard plate 181. In the chute, the lower guard plate 181 is connected to the cylinder barrel of the telescopic oil cylinder 183, the upper guard plate 182 is connected to the piston rod of the telescopic oil cylinder 183, and the lower guard plate 181 is also connected to the piston rod of the adjustment oil cylinder 184, so The cylinder barrel of the adjustment oil cylinder 184 is hinged on one side of the collector 13 .

[0026] The middle part and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com