Discharging platform for refuse landfill and discharging method thereof

A landfill and unloading platform technology, applied in loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problems of pollution, labor-intensive manual operation, and inability to classify and landfill different types of garbage, etc. To achieve the effect of improving accuracy and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

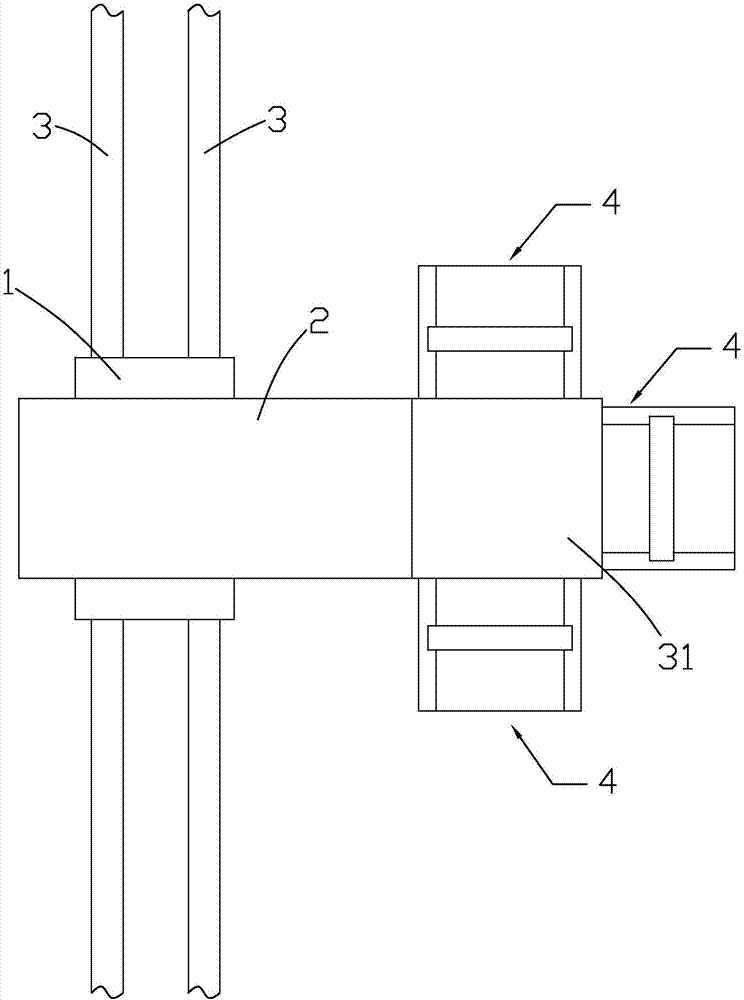

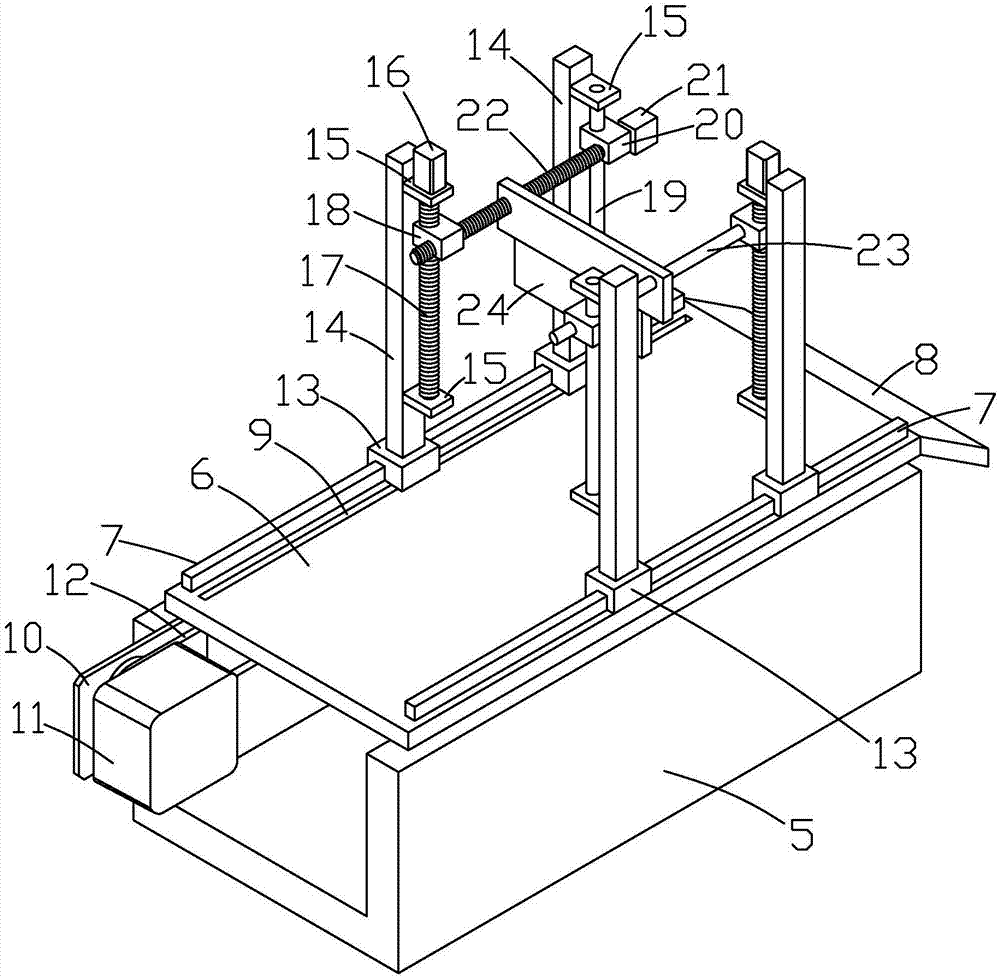

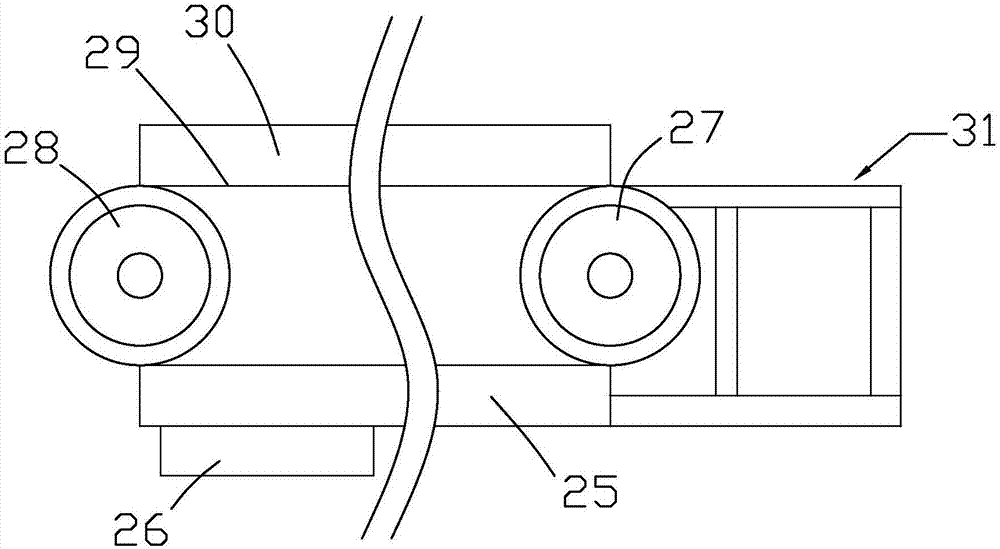

[0041] Such as Figure 1 to Figure 5 As shown, it is an unloading platform for a garbage landfill of the present invention, including a sliding trolley 1, a first guide rail 3, a garbage conveying mechanism 2, a material distribution platform 31 and a garbage unloading mechanism 4, two mutually parallel first Guide rail 3 is arranged on the outside of refuse landfill, and sliding trolley 1 is mobile and connected on two first guide rails 3, and sliding trolley 1 comprises car body 32, and the top surface of car body 32 is provided with turntable 33, and the top surface of turntable 33 Groove 34 is arranged on the top, and the bottom of turntable 33 is provided with positioning column 36, and the bottom end of positioning column 36 is connected with the 3rd motor 35 through gear set, and the bottom of car body 32 is evenly provided with guide wheel 37, and guide wheel 37 is connected with the first A guide rail 3 is matched, and the guide wheel 37 is connected with a driver 38,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com