Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Facilitate automatic welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic end socket welding method of automatic welding device based on large-curved-surface end socket welding

InactiveCN104014945AEasy assembly, positioning and clampingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesBall screwEngineering

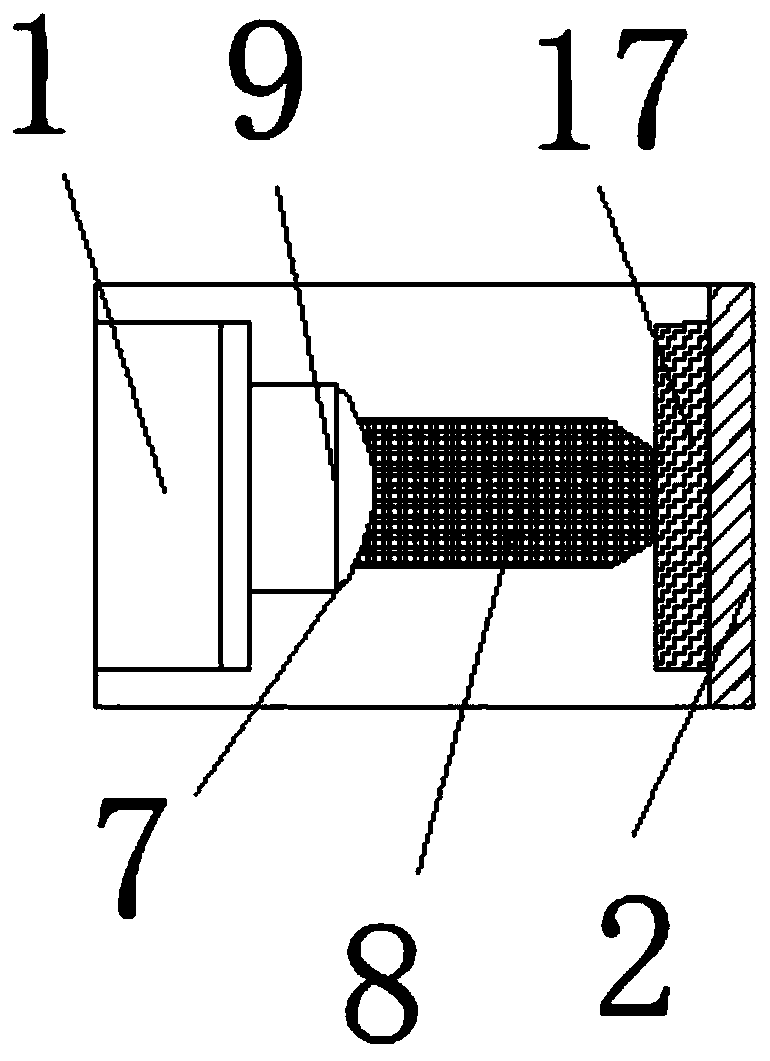

The invention discloses an automatic end socket welding method of an automatic welding device based on large-curved-surface end socket welding. The device comprises a support base plate, a ball screw, a group of rolling bearings, an external locating block, an internal locating block, a rotary handle, a calibrated scale, a welding positioner, and a welding head realizing automatic welding, and the end socket comprises a plurality of claw end sockets and a segment. The method is characterized by comprising following steps of end socket fixation, welding of external welding line, welding of internal welding line, and annealing heat treatment. The method can be used for automatic welding of large end sockets of various sizes, thus lowering labor intensity of workers, shortening the manufacturing cycle of products, and lowering production cost.

Owner:NANJING INST OF TECH

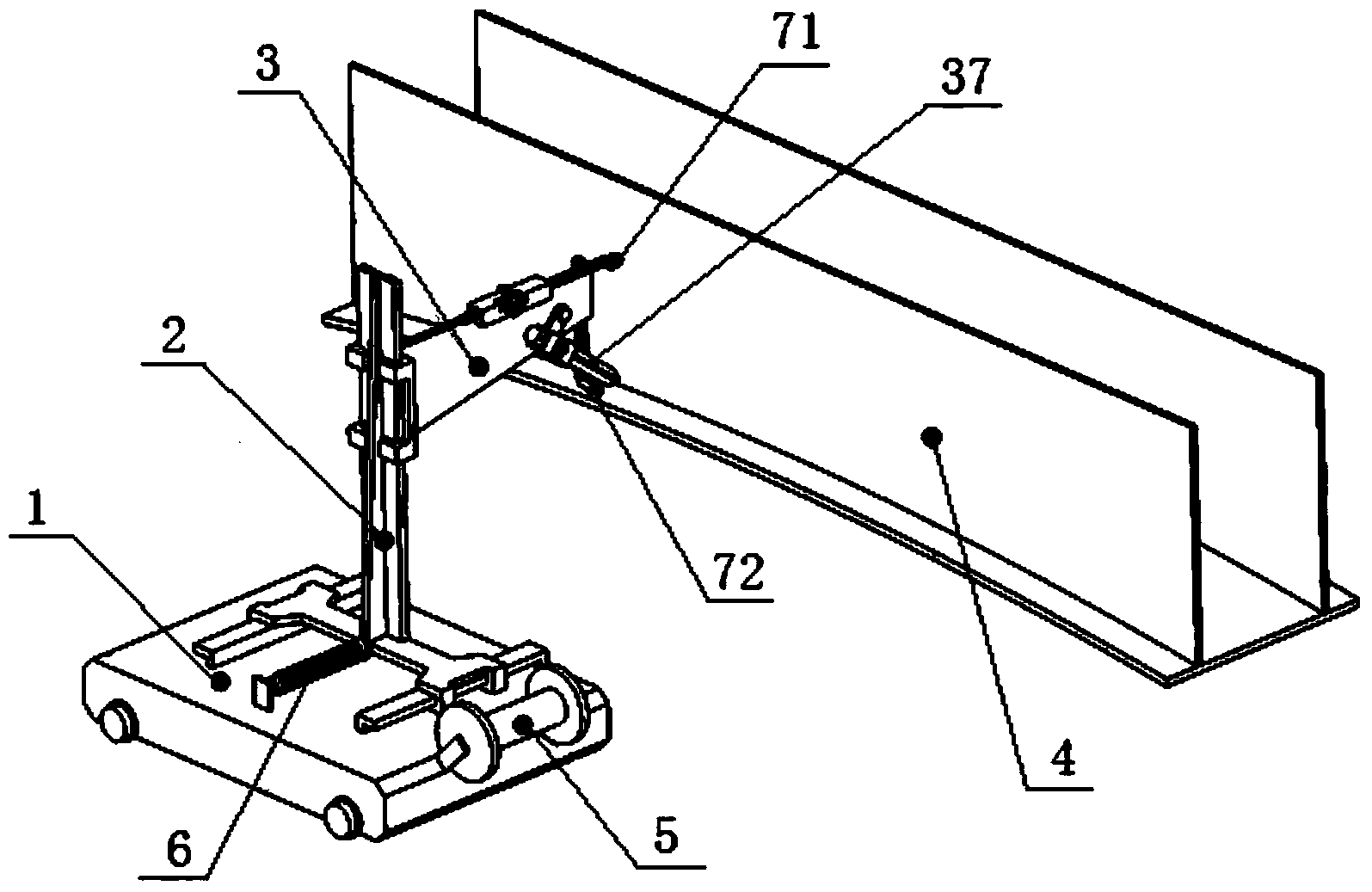

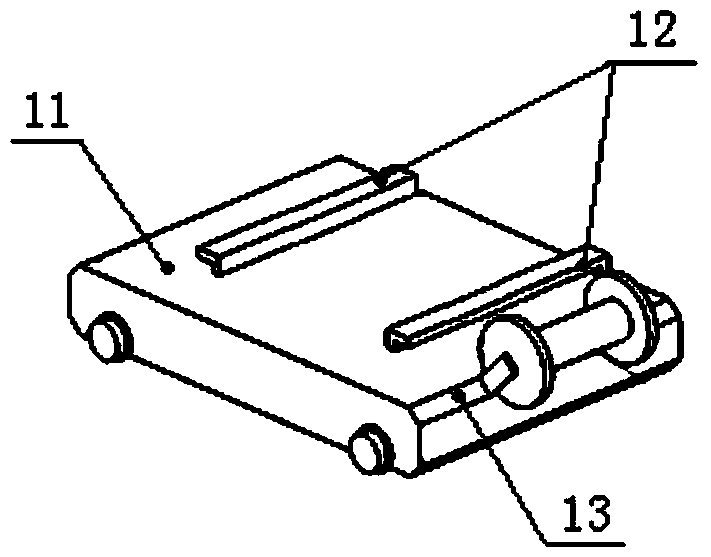

Device and method for automatically welding box beam

ActiveCN104175038AFacilitate automatic weldingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a device and method for automatically welding a box beam. The device comprises a walking trolley, a main support, a welding gun supporting arm and a welding gun. The welding gun is arranged on the welding gun supporting arm through a hinge shaft, and the welding gun supporting arm is arranged on a vertical rectangular guide rail of the main support. The main support is matched with a horizontal rectangular guide rail of the walking trolley through a rectangular guide rail groove below the main support, and the welding gun can move along the horizontal rectangular guide rail and the vertical rectangular guide rail. In the welding process, the height and the angle of the welding gun are well adjusted according to the camber of the box beam and the positions of a flange plate and a box beam web, and therefore automatic welding can be achieved. According to the device and method for automatically welding the box beam, the structure is simple, adjustment is easy, box beams of various sizes can be conveniently and automatically welded, the labor intensity of welding personnel is lowered, rigidity is high, the bearing capability is high, machining and maintaining are easy, and cost is saved. The box type beam is automatically welded, besides, H-shaped steel used in a steel structure workshop can be automatically welded, and the accuracy of a profiling outline can be effectively ensured.

Owner:SHANDONG FENGHUI EQUIP TECH

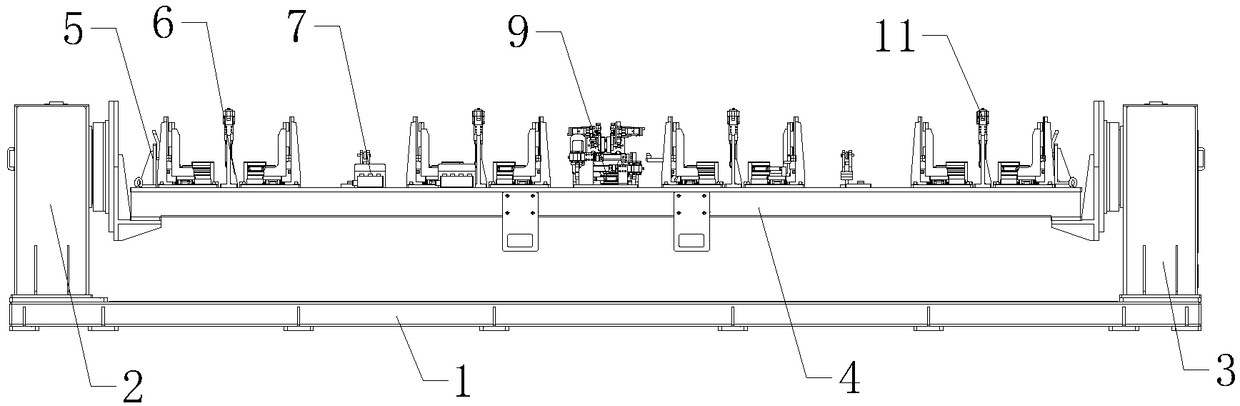

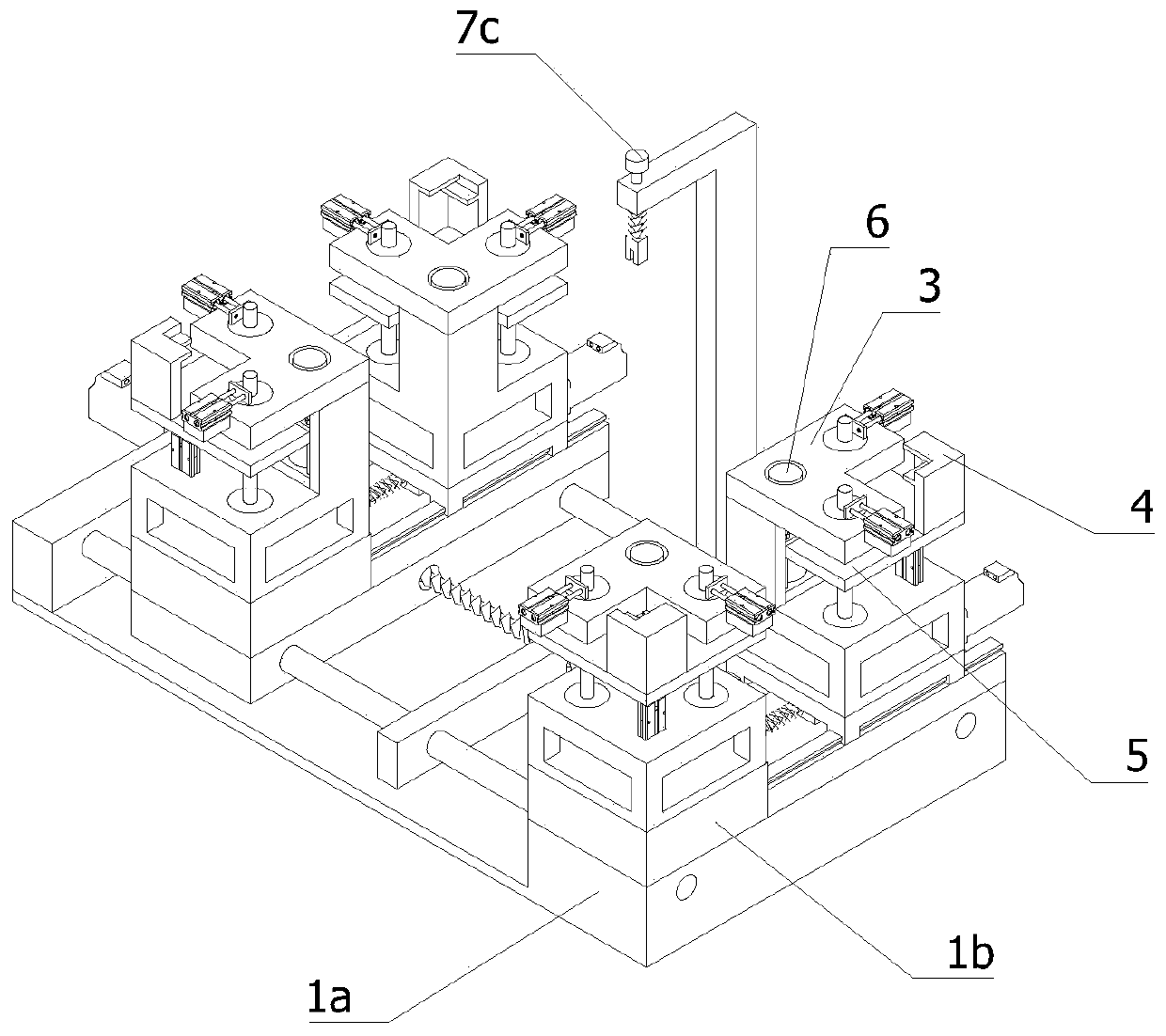

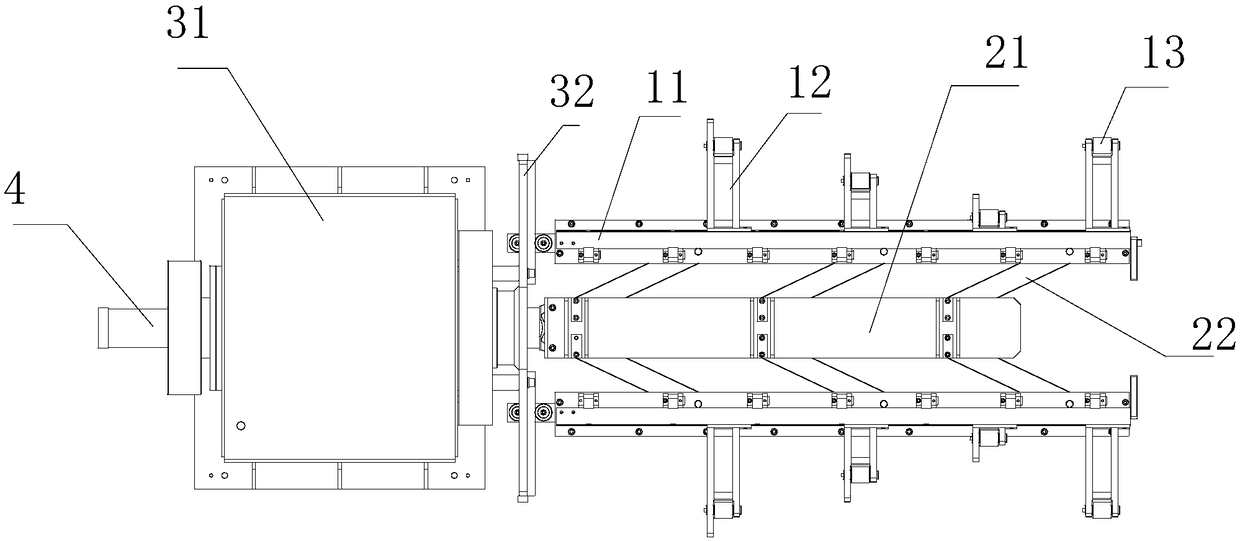

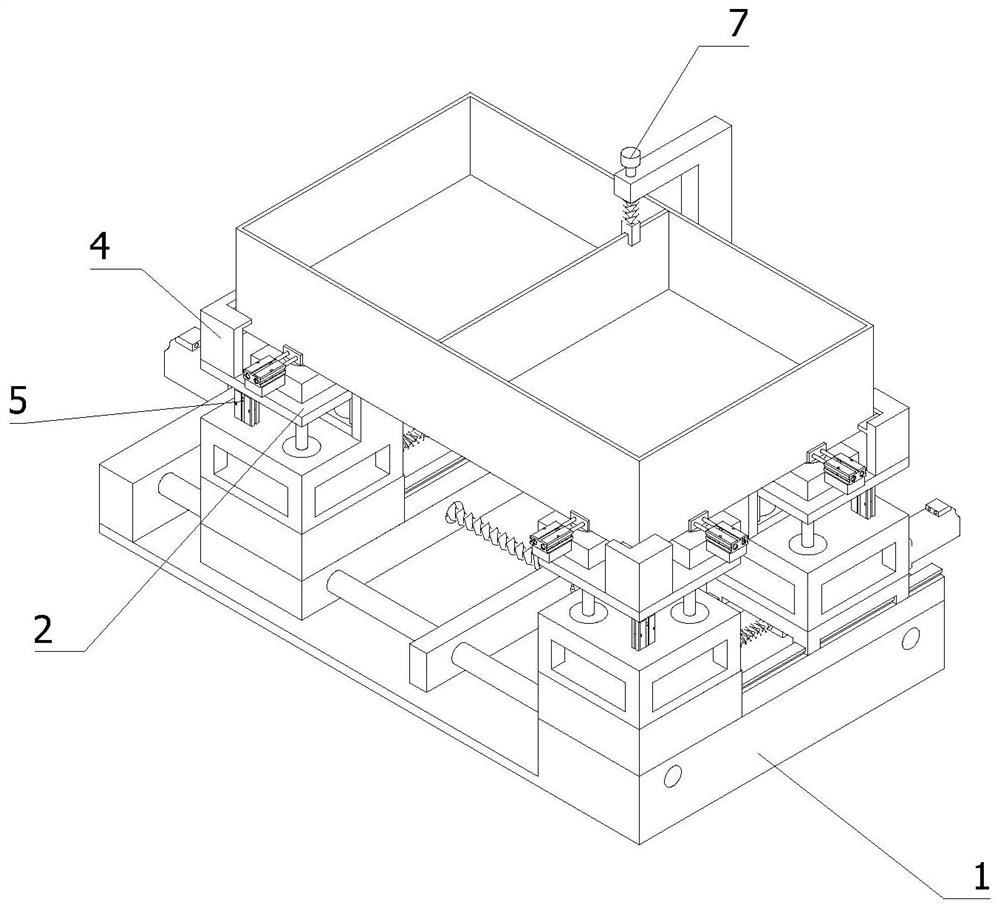

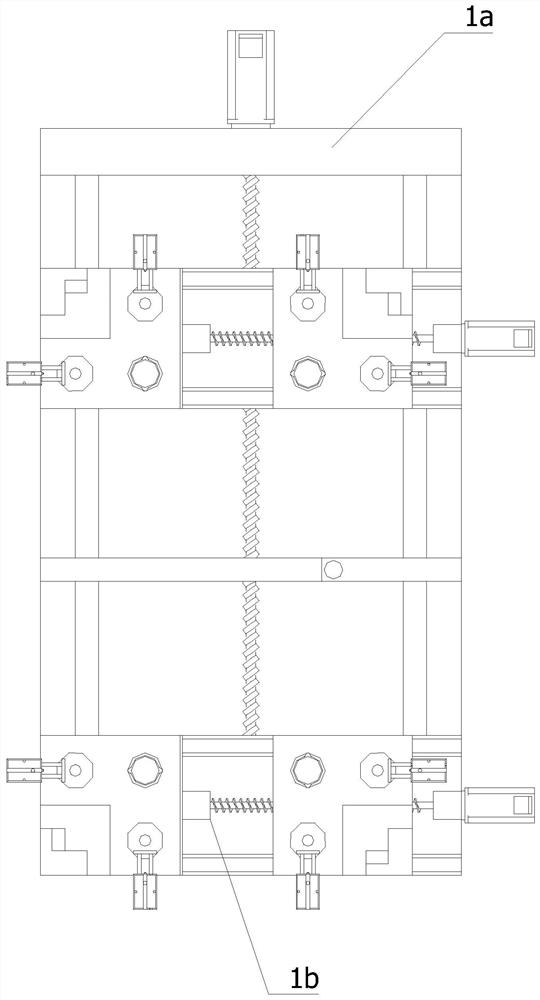

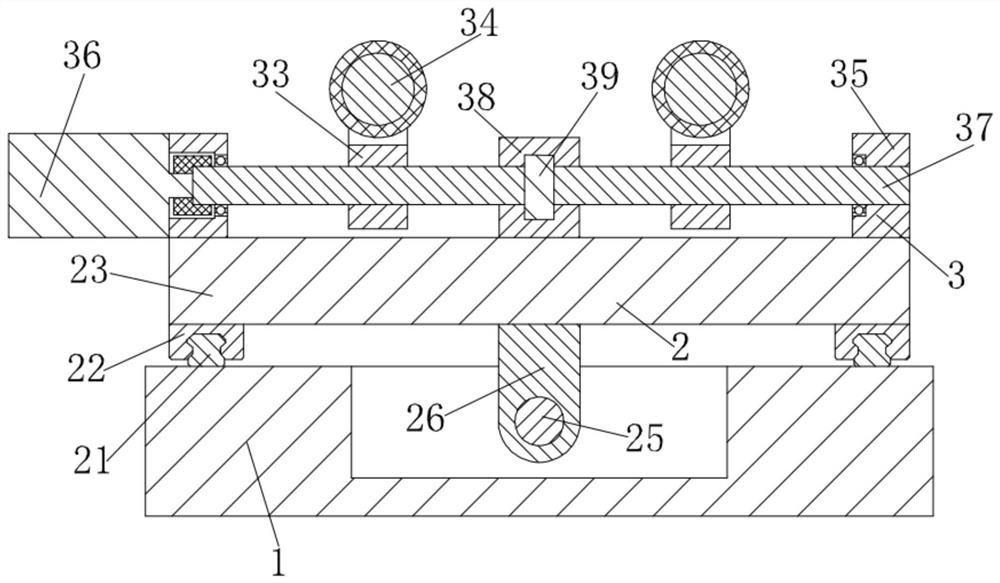

Main beam welding clamp tool

ActiveCN109158823AAvoid displacementEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesDowelRobot

The invention relates to the field of welding clamps, in particular to a main beam welding clamp tool. The main beam welding clamp tool comprises a base, a drive positioner, a driven positioner and aclamping fixing assembly, wherein the clamping fixing assembly comprises a bearing plate, two main beam end surface limiting mechanisms which are arranged on the top of the bearing plate, four supporting beam positioning clamping mechanisms, two main beam supporting mechanisms, a main beam dowel pin, a main beam supporting base clamp and a pushing rod supporting base clamp; the bearing plate is ofa horizontally arranged rectangular structure, and the two ends of the bearing plate are fixedly connected with the drive positioner and the driven positioner separately; the main beam supporting base clamp and the pushing rod supporting base clamp are positioned on the middle position of the bearing plate; and each supporting beam positioning clamping mechanism comprises a first pressing air cylinder which can press a main beam from the above. The main beam welding clamp tool can precisely and stably fix the main beam and a welding component thereof, so that a welding robot automatically welds.

Owner:浙江摩科机器人科技有限公司

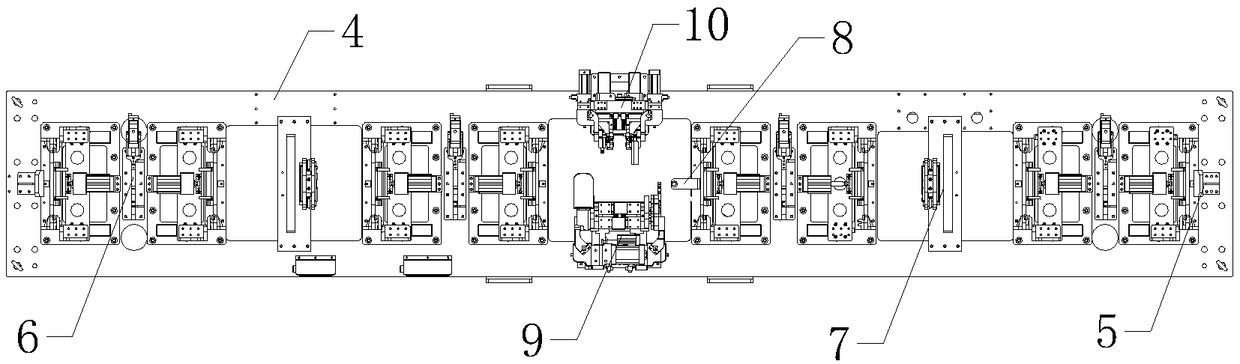

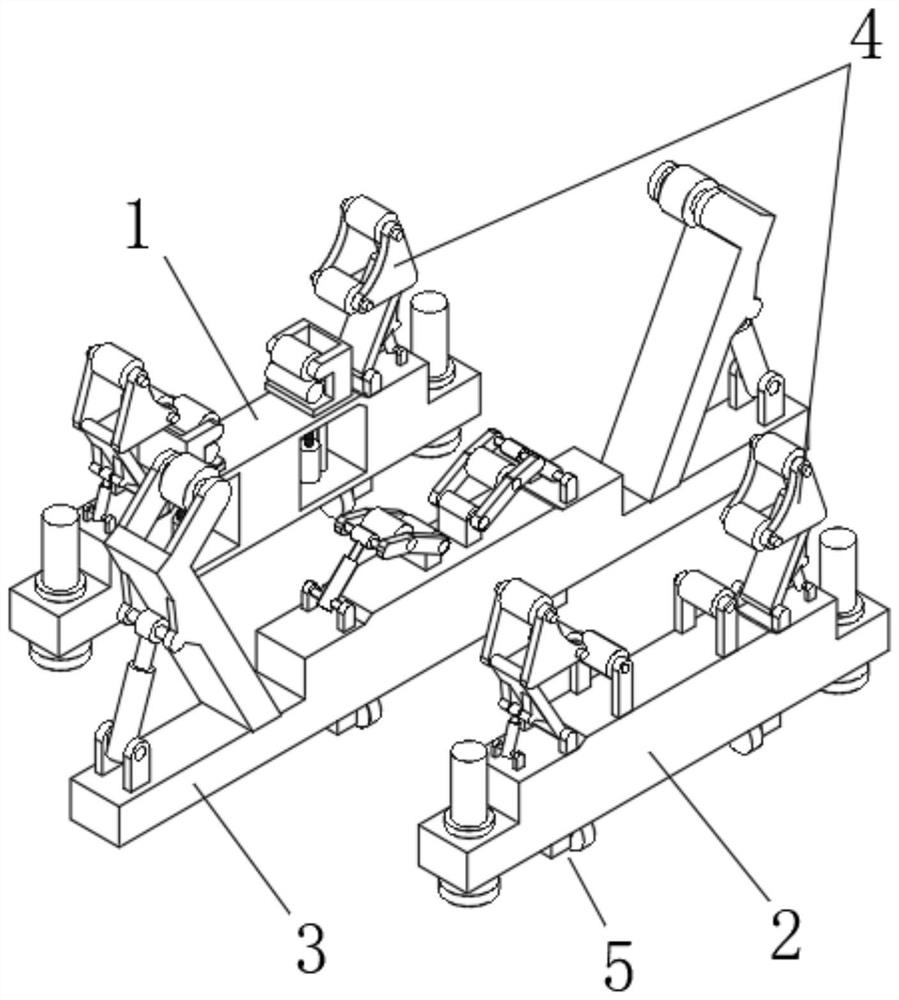

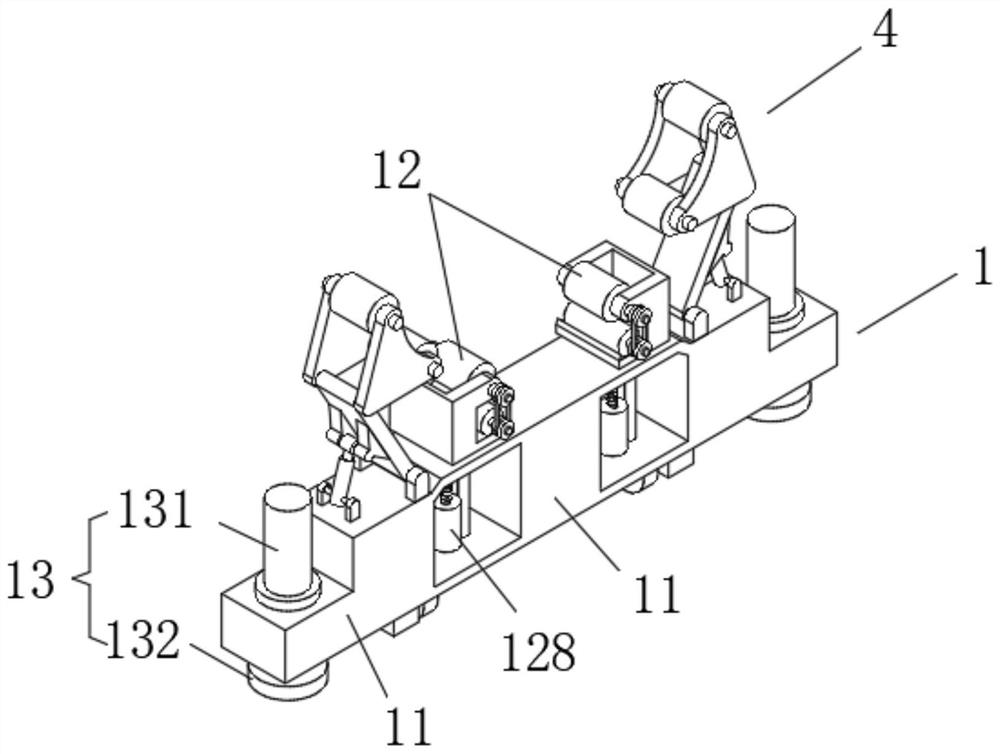

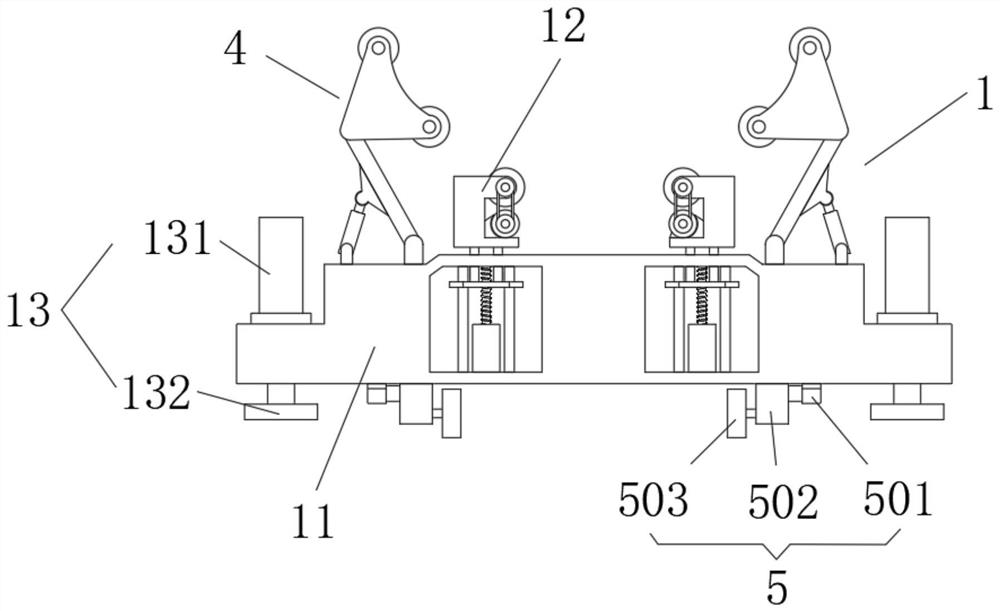

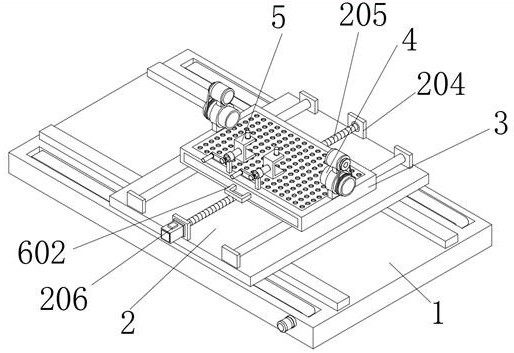

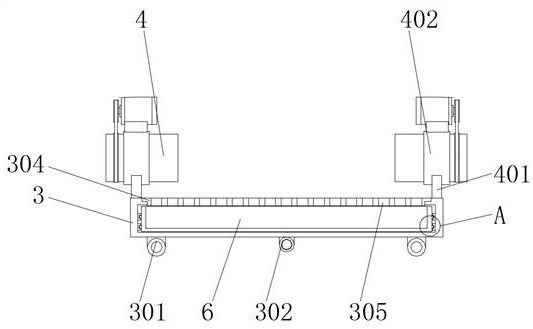

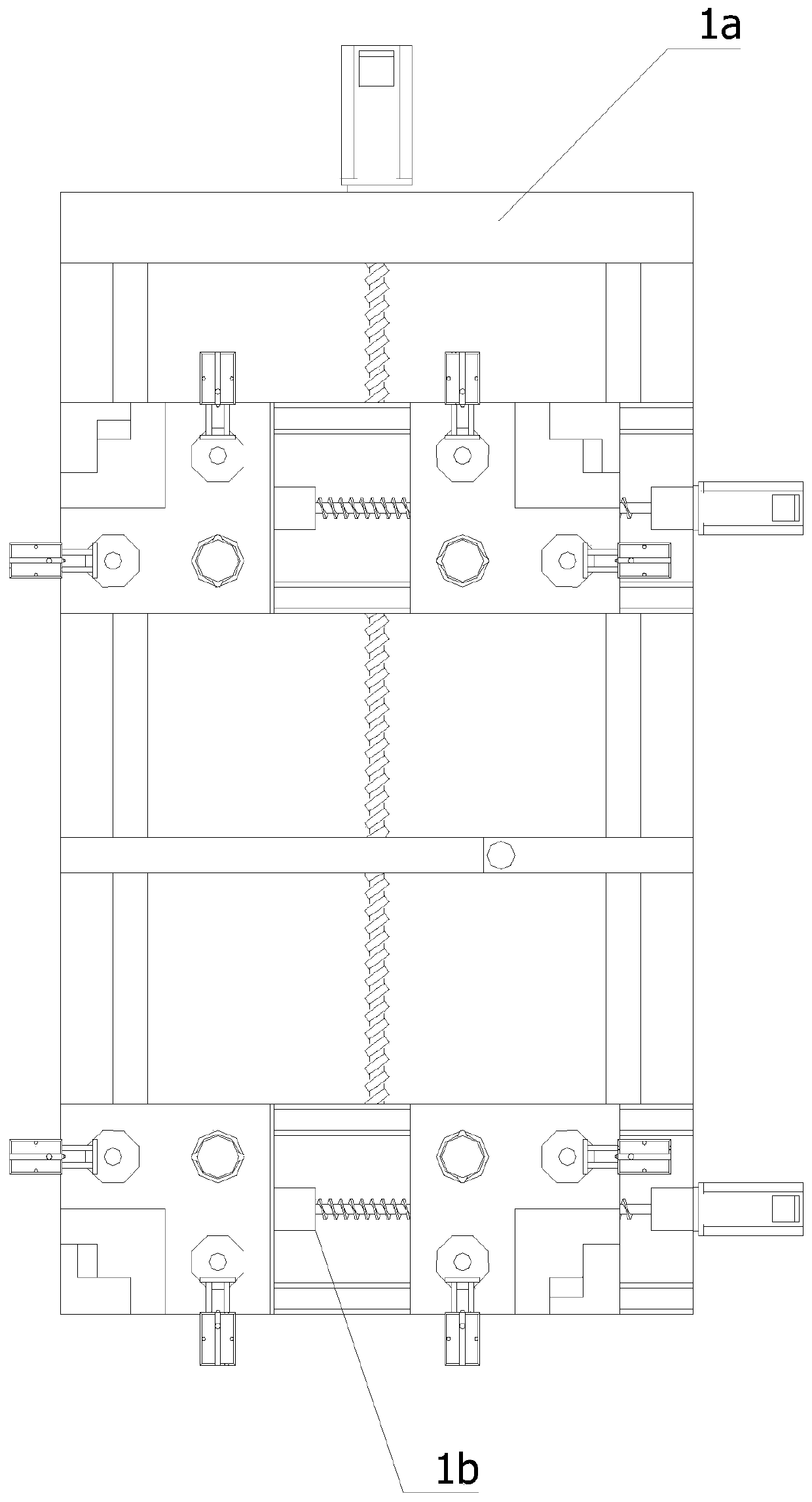

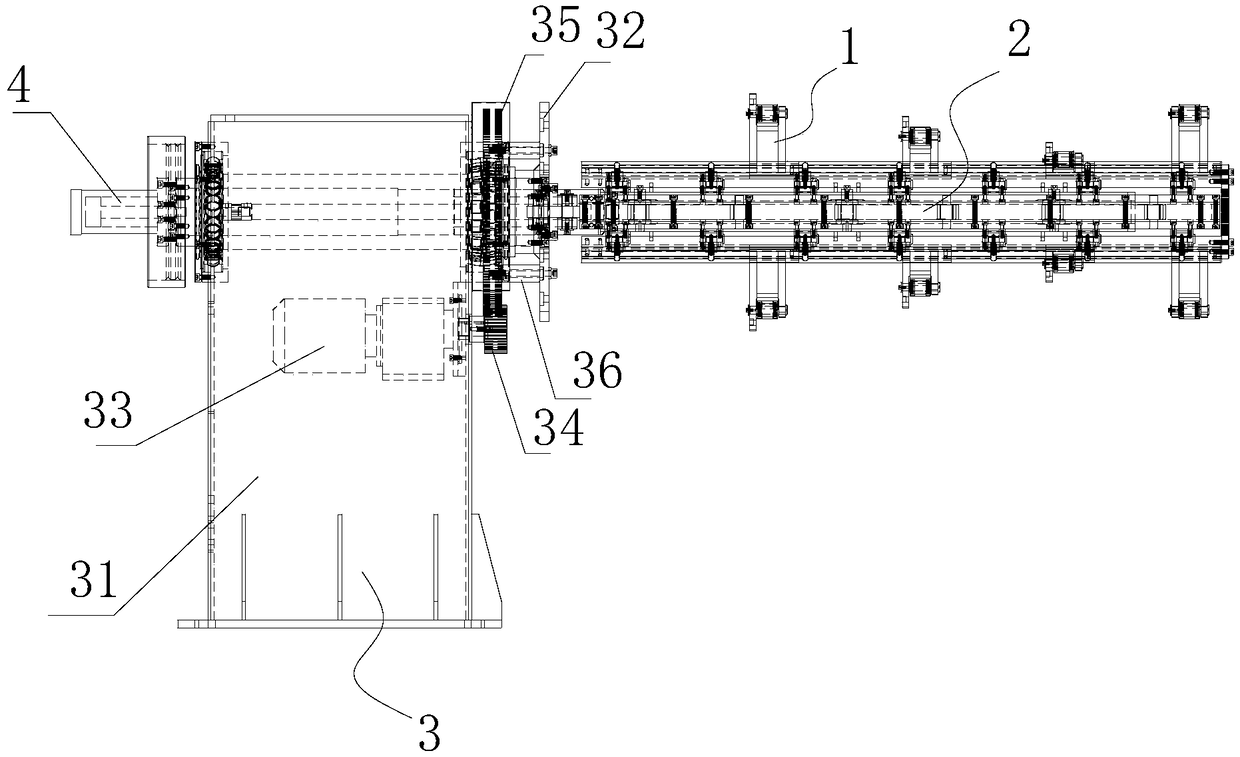

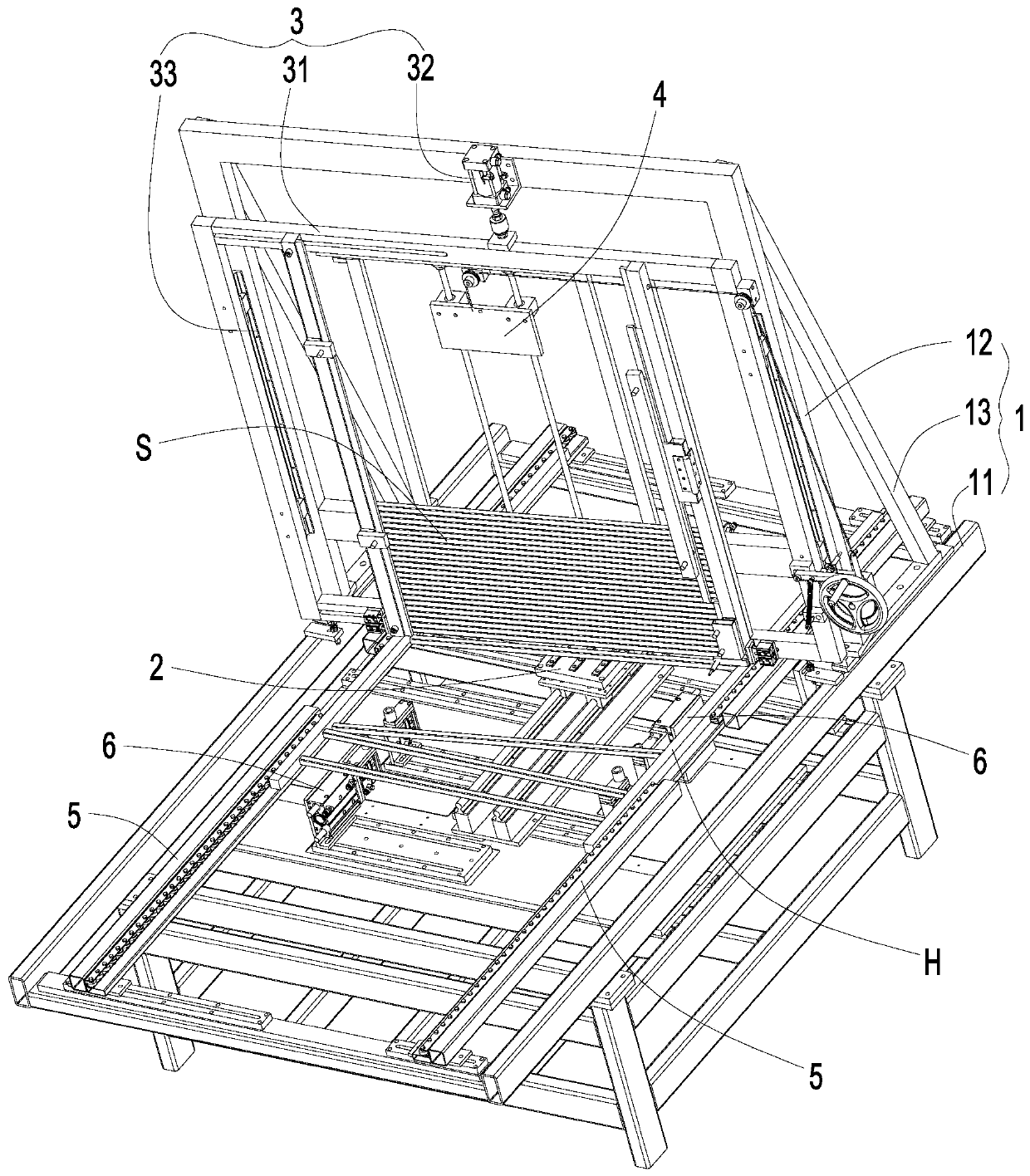

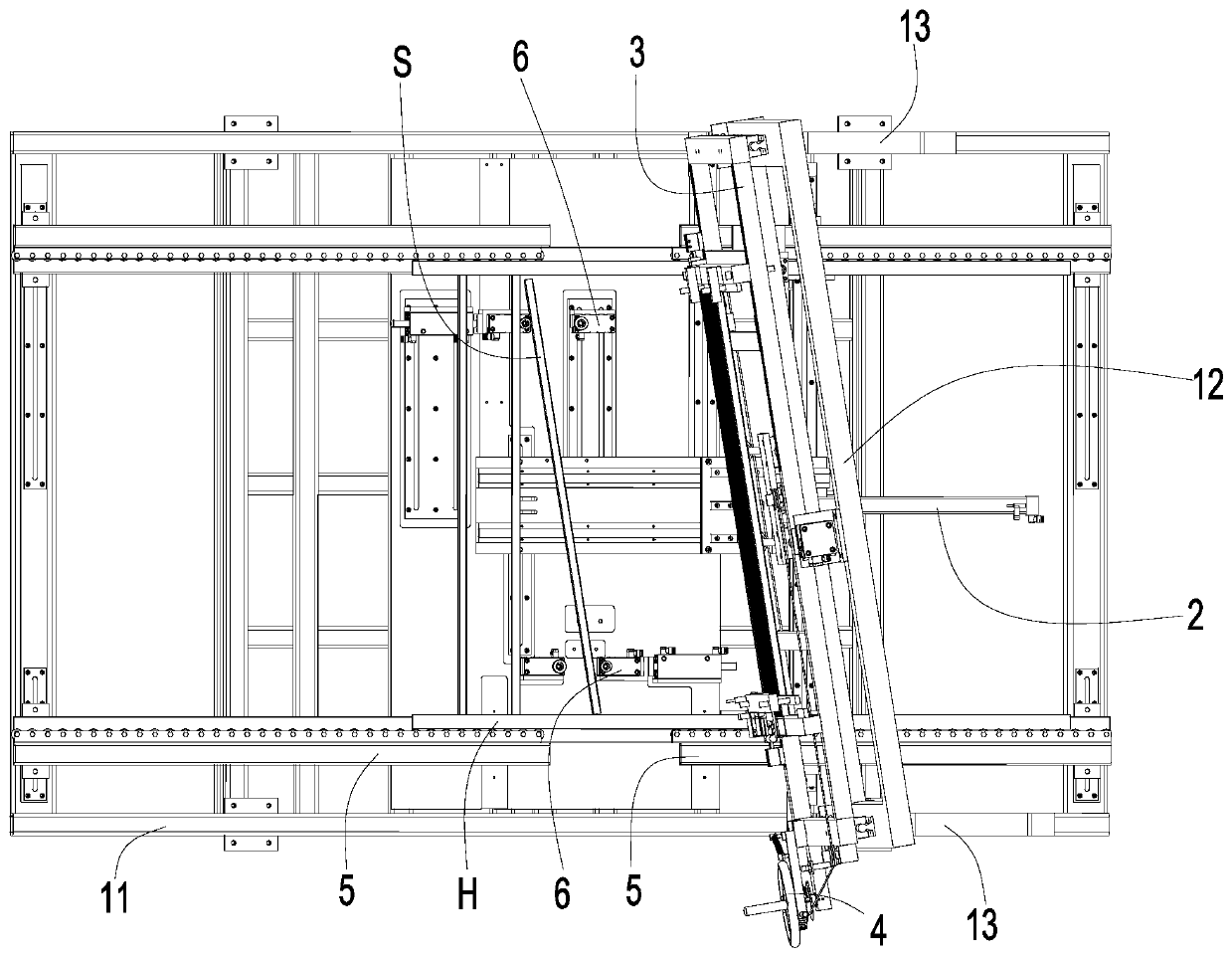

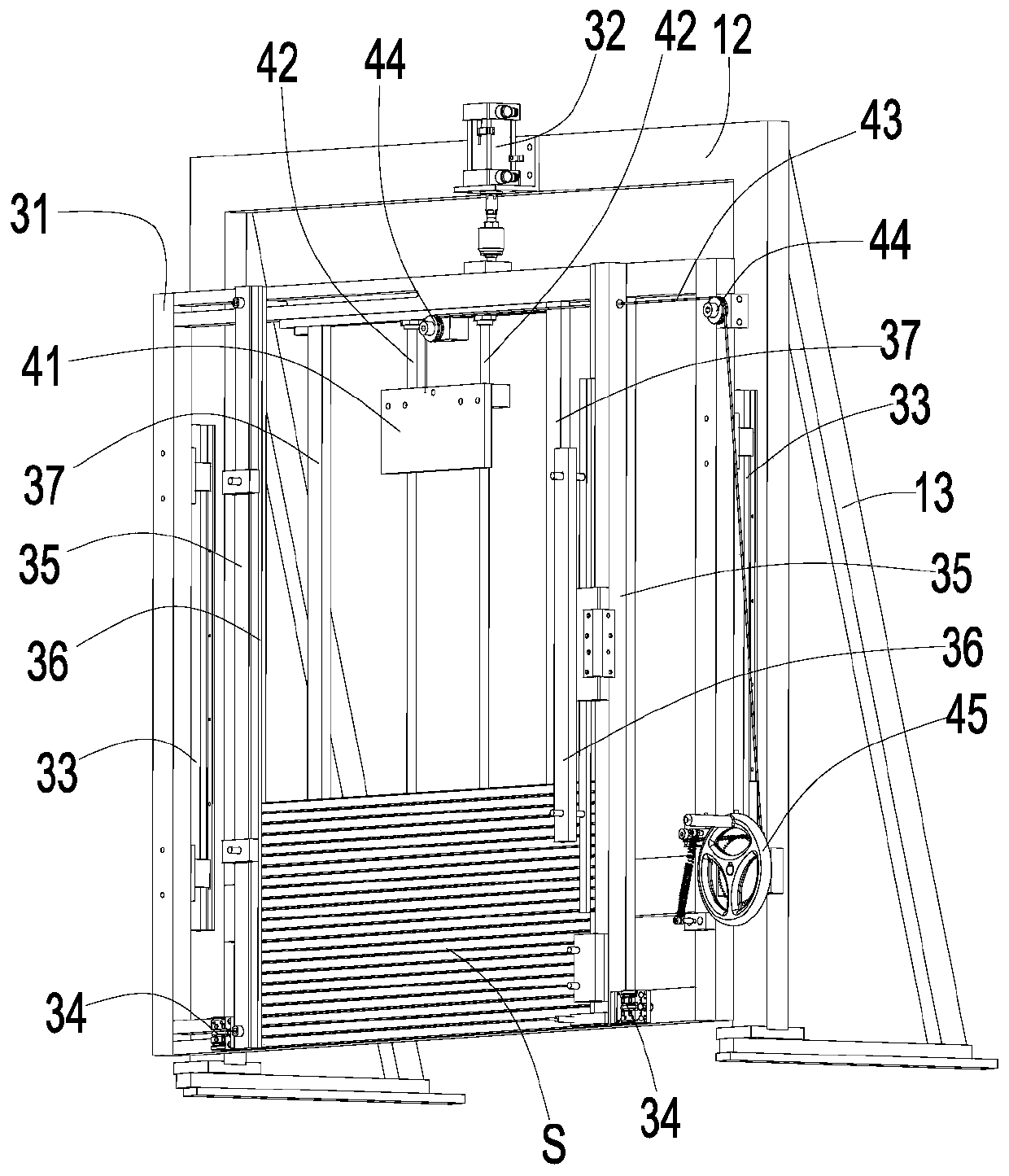

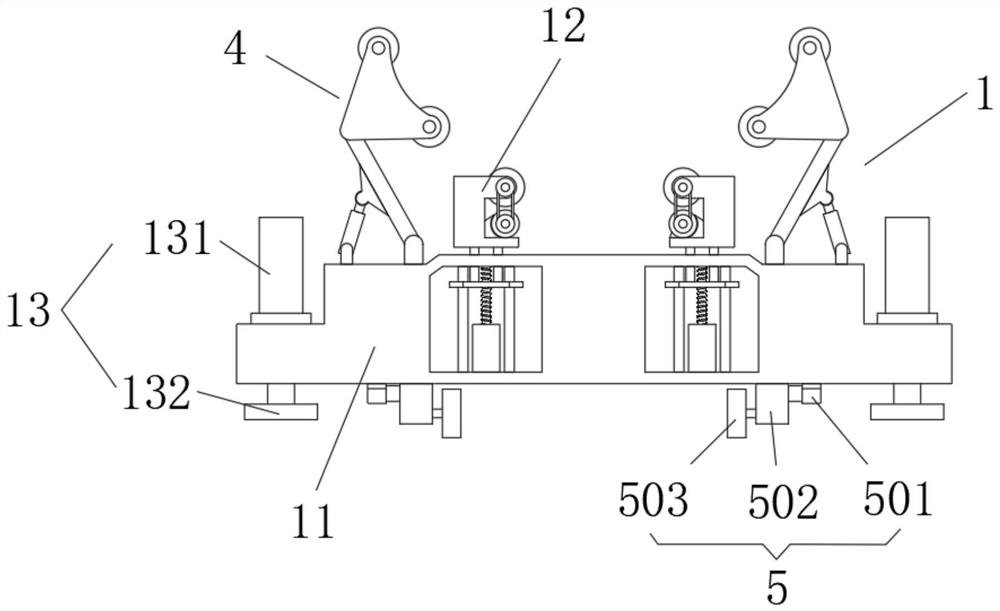

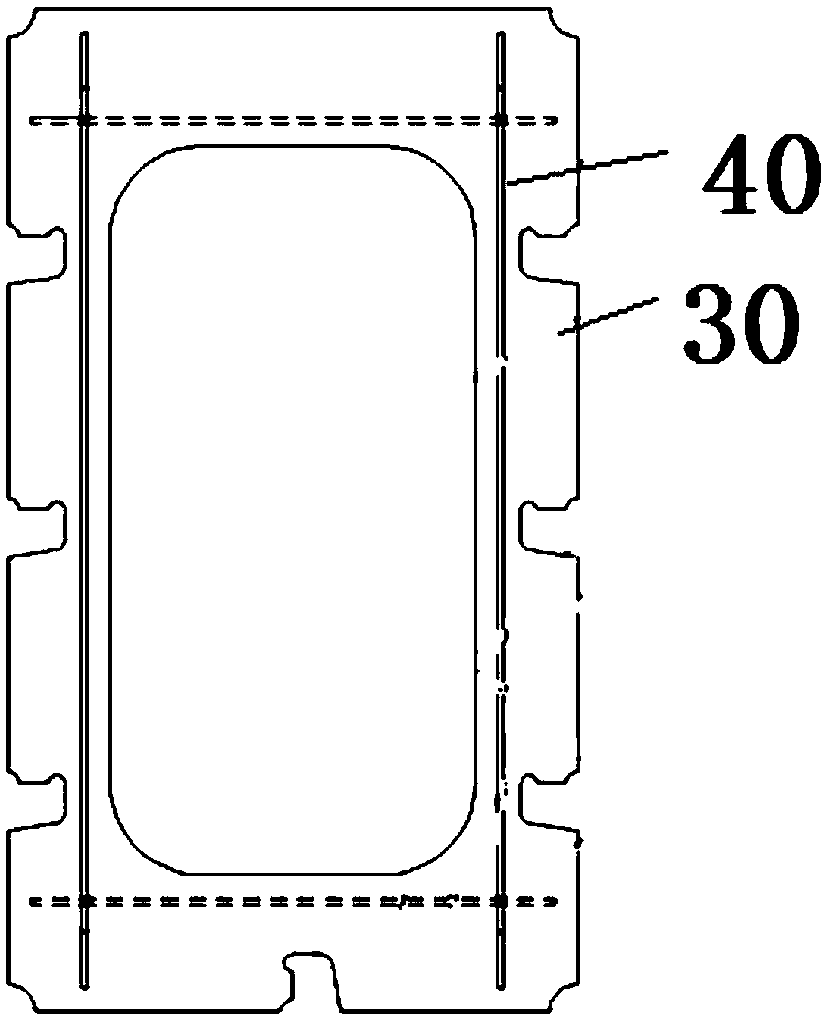

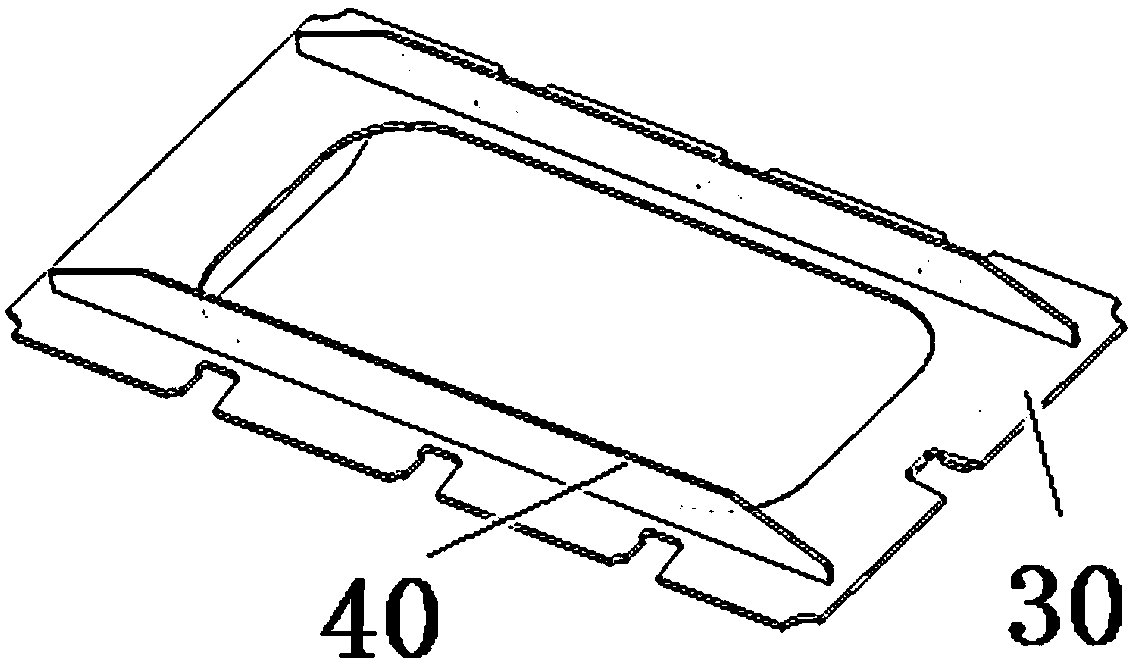

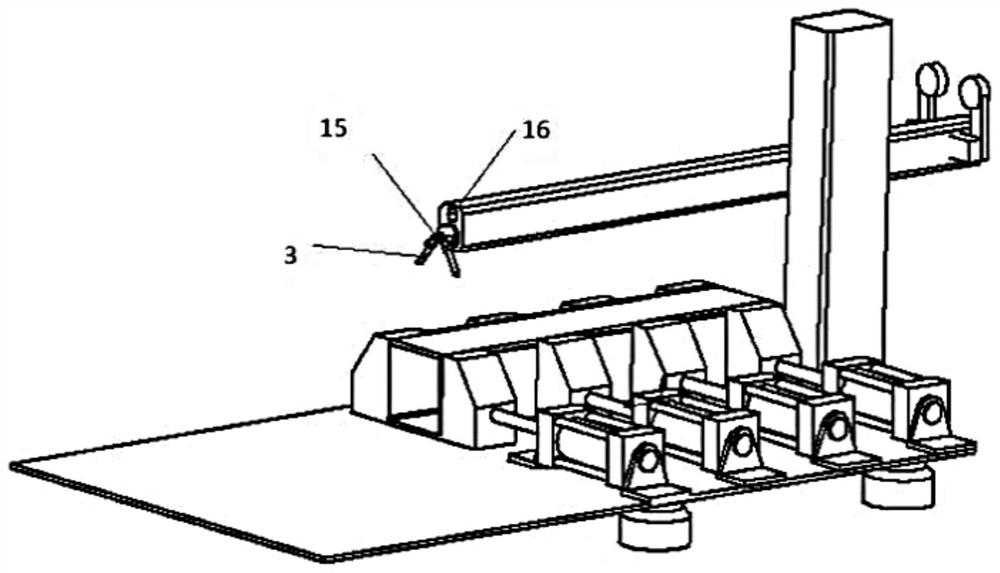

Welding platform and building formwork welding system with same

ActiveCN112620999AReduce labor intensityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsElectric machinery

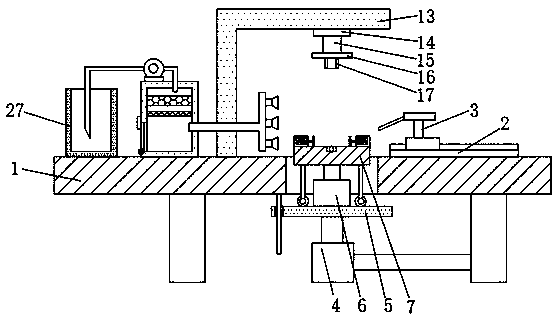

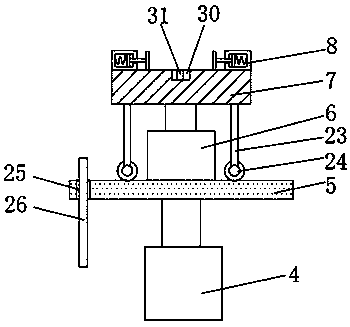

The invention discloses a welding platform and a building formwork welding system with the same. The building formwork welding system with the welding platform comprises a portal frame (1), a feeding device (2), a material taking and moving device (3), the welding platform (4) and a welding robot (5). The welding platform (4) comprises a sliding rail (401), welding platform racks (402), a welding platform moving mechanism (403), conveying rollers (404), a conveying motor (405), a transmission mechanism, blocking mechanisms (406) connected with the welding platform racks (402), guide mechanisms (407) connected with the welding platform racks (402), clamping mechanisms (411) connected with the welding platform racks (402), clamping beams (412) connected with the clamping mechanisms (411) and connected with the welding platform racks (402) in a sliding mode, clamping cylinders (408) connected with the clamping beams (412), floating guide mechanisms (409) connected with the clamping cylinders (408), and a plurality of wedge-shaped clamping mechanisms (410) connected with the welding platform racks (402) and the clamping beams (412).

Owner:长沙中创海通智能科技有限公司

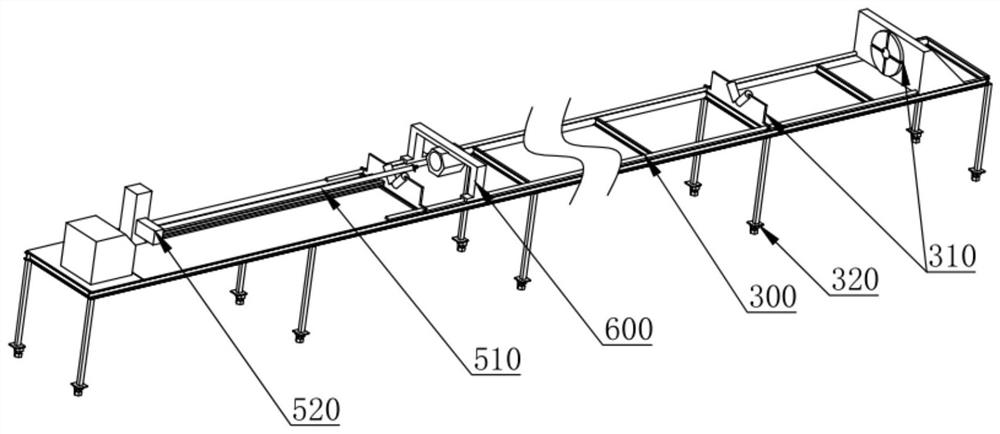

Welding operation track, large pipeline girth welding device and welding method

ActiveCN113210920AEasy to fixFacilitate automatic weldingMetal working apparatusWelding apparatusEngineeringWeld seam

The invention provides a welding operation track, a large pipeline girth welding device and a welding method, and relates to the technical field of welding devices. The technical problems that the large pipeline girth welding device is manually taken and fixed, and time and labor are wasted are solved. The welding operation track comprises a frame body, an electromagnetic gripper and a welding adjusting device, and the frame body is of an annular structure and is fixed to a circular seam of a to-be-welded pipeline through the electromagnetic gripper; a welding gun for welding is movably mounted on the frame body through the welding adjusting device; and the frame body is of a reconfigurable flexible structure and comprises a plurality of sections of track units made of elastic steel plates, and part of or all the track units are connected end to end and spliced together to form the frame bodies with different diameters so as to be suitable for welding operation of pipelines with different diameters. The automatic welding device is used for automatically welding the welding seam of the large round pipeline, and has the advantages of simple structure, easiness in mounting, convenience in operation, full automation in the whole welding process after the mounting is completed, and high automation degree.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

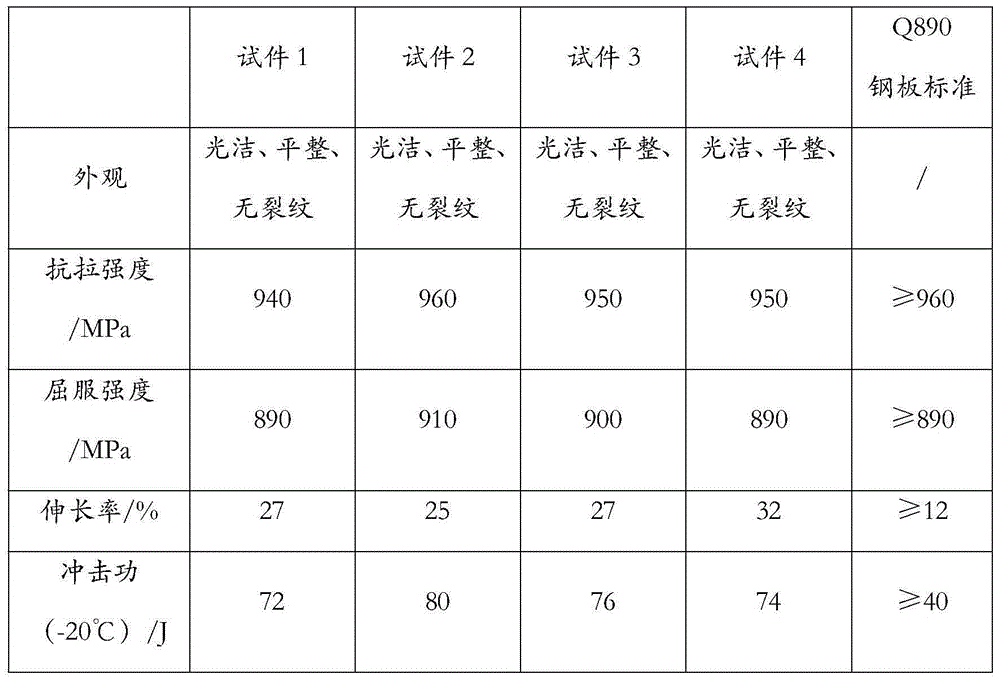

Welding method of high-strength steel of 900 MPa level

InactiveCN105014208AReduce processSimple welding equipmentArc welding apparatusWelding/cutting media/materialsSpot weldingHeat treated

The invention discloses a welding method of high-strength steel of the 900 MPa level and belongs to the technical field of high-strength steel welding. The method sequentially comprises the steps of clearing, chamfering, spot welding, overall preheating, bottoming welding, filling welding, cover face welding and heat treatment. All welding wires are welding wires of the 90 kg level. By means of the method, large scale automatic welding in a factory is facilitated, procedures are saved, and the method can be popularized to the welding field of automated robots.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP CO LTD

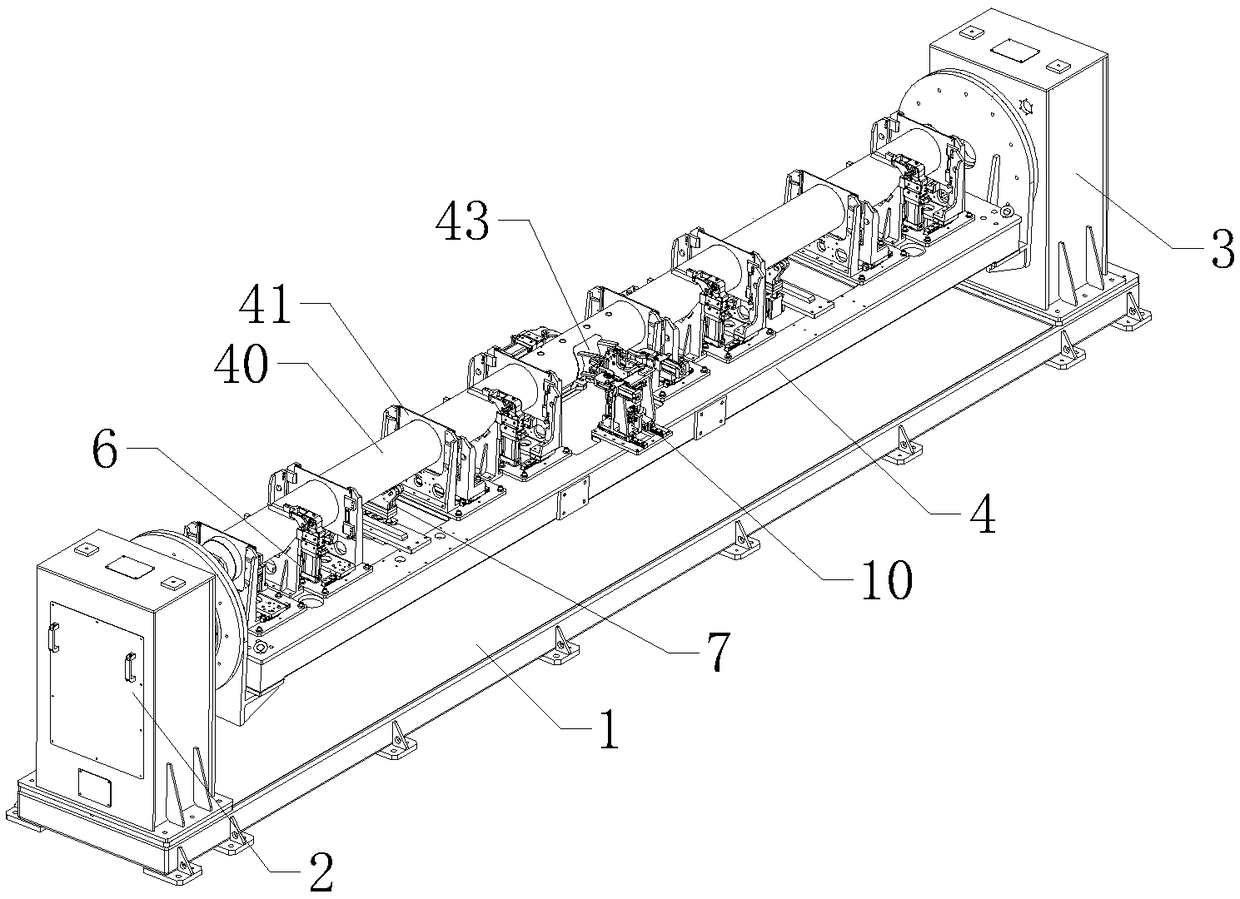

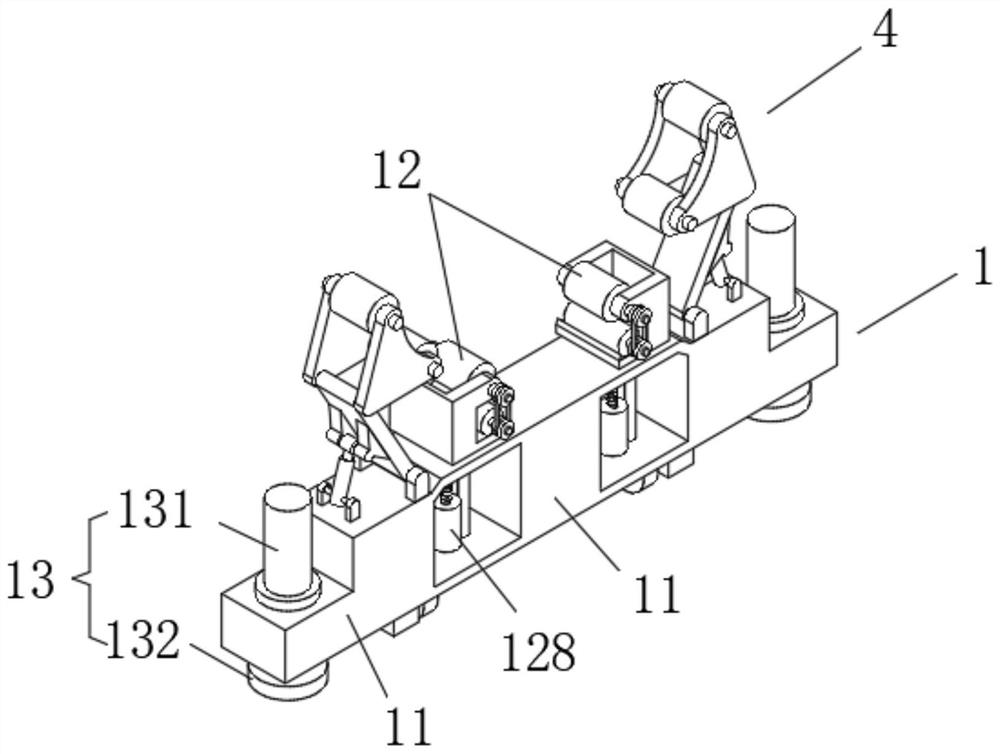

Straight seam welding and grouping welding equipment for large-diameter barrel

PendingCN112935697AImprove welding efficiencyPrevent collapseWelding/cutting auxillary devicesAuxillary welding devicesSeam weldingStructural engineering

The invention provides straight seam welding and grouping welding equipment for a large-diameter barrel, and relates to the technical field of welding equipment. The straight seam welding and grouping welding equipment for the large-diameter barrel comprises a driving welding walking roller carrier, a driven welding walking roller carrier, a hydraulic jacking grouping roller carrier and hydraulic supporting arm mechanisms, wherein the two groups of the hydraulic support arm mechanisms are arranged; the number of each group of hydraulic support arm mechanisms is at least two; one group of hydraulic support arm mechanisms is symmetrically distributed on the driving welding walking roller carrier; and the other group of hydraulic support arm mechanisms is symmetrically distributed on the driven welding walking roller carrier. The hydraulic support arm mechanisms are adjusted to abut against a barrel from the two side faces of the barrel; and the hydraulic support arm mechanisms are used for correcting and lifting a workpiece with the large barrel diameter to prevent the workpiece with the large barrel diameter from collapsing, and the roundness of the workpiece with the large barrel diameter is corrected, so that more time and labor can be saved when workpieces with the large barrel diameter are welded and grouped, and the welding efficiency is improved.

Owner:郑州越达科技装备有限公司

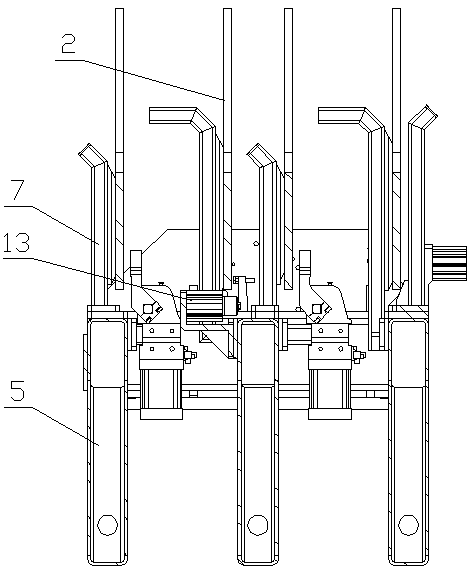

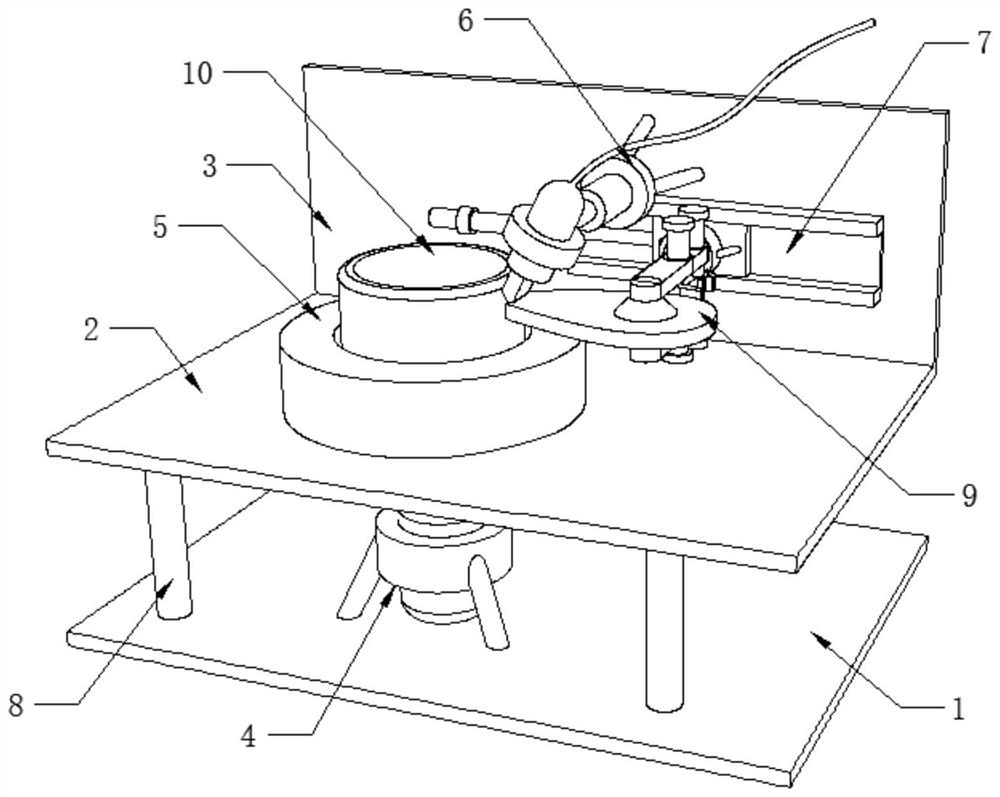

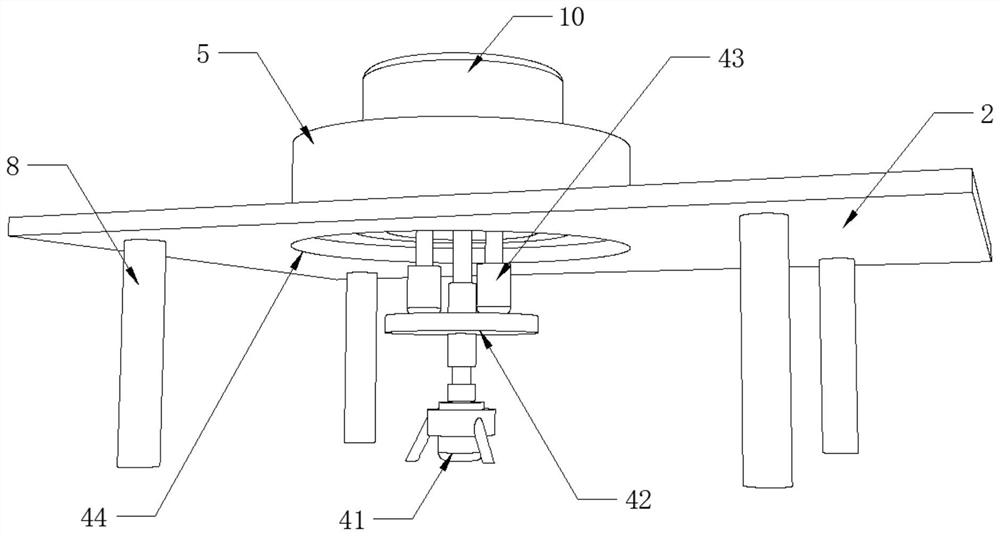

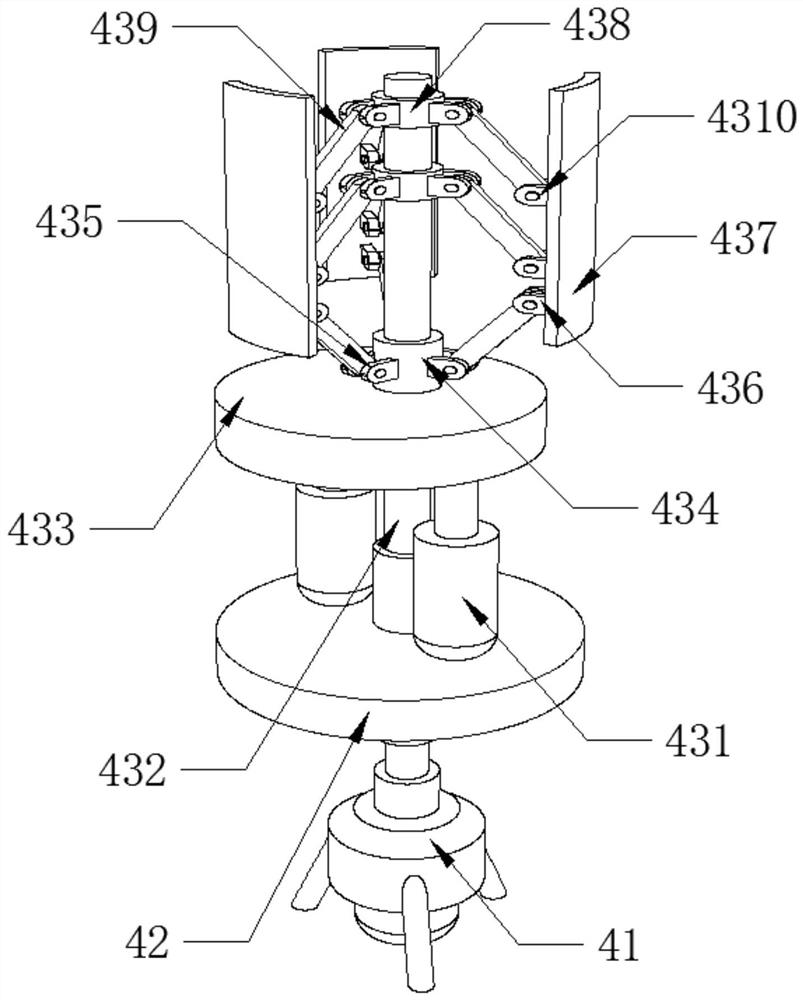

Automatic welding equipment for inner wall of pipeline

PendingCN112404831AAchieve translationAchieve rotationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSpot welding

The invention discloses automatic welding equipment for the inner wall of a pipeline. The automatic welding equipment comprises a supporting base, a welding gun, a welding gun moving device used for adjusting the position and posture of the welding gun, a pipeline preheating device used for preheating a welding area and a workpiece positioning tool used for fixing a to-be-welded workpiece to the inner wall of the to-be-welded pipeline; and the welding gun moving device comprises a welding gun connecting rod used for being connected with a welding gun, a straight moving mechanism used for enabling the welding gun to horizontally move in the length direction of the to-be-welded pipeline, a rotary moving mechanism used for enabling the welding gun to rotate on the cross section of the to-be-welded pipeline, and an inclination angle adjusting mechanism used for adjusting the inclination angle between the welding gun and the inner wall of the to-be-welded pipeline. According to the automatic welding equipment, operation such as positioning, pressing, preheating, spot welding and welding can be conducted in the pipeline, and automatic welding of the workpiece on the inner wall of the pipeline with the inner diameter ranging from 50 mm to 200 mm is achieved.

Owner:WUHAN YUANFANG SCI & TECH CO LTD OF CHINA SANJIANG SPACE GRP

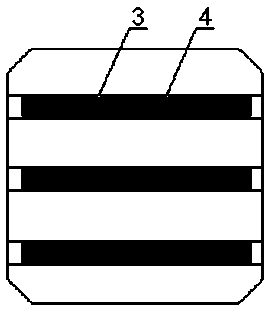

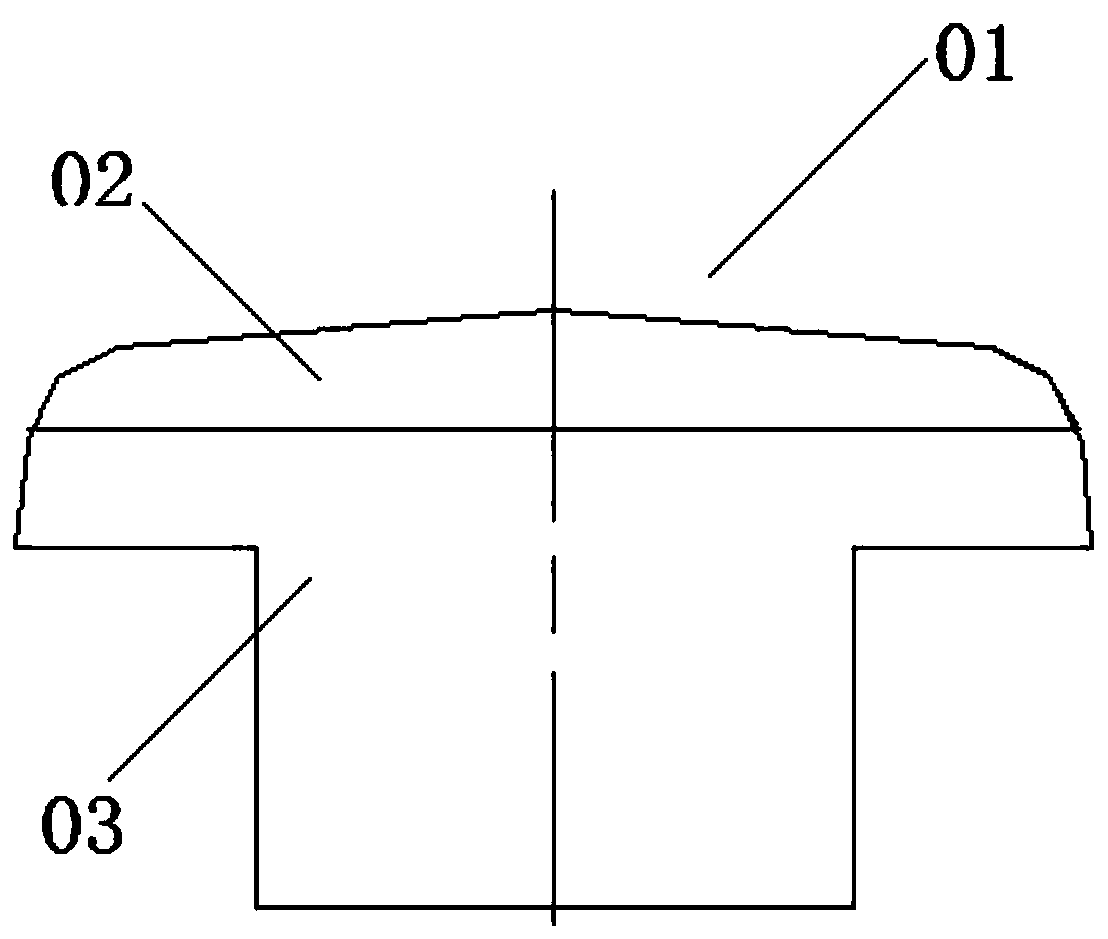

A web used for h-shaped steel and a plate forming machine for processing the web

InactiveCN102261161AHigh degree of automationFast processingConstruction materialProduction lineMetal forming

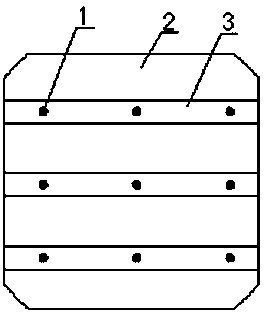

The invention discloses a web used for H-shaped steel and a plate forming machine for processing the web. The technical solution adopted is: the web is a wave web, and the cross-sectional outline of the wave web is is the curve. The plate forming machine includes an input part, a forming part and an output part. The forming part includes a lower roll and an upper roll installed in parallel. The lower roll and the upper roll rotate at the same speed and turn in opposite directions. between. The beneficial effects of the present invention are: the H-shaped steel adopts the corrugated web, and under the condition that the size and thickness of the web remain unchanged, the overall bearing capacity increases, and the corrugated web facilitates the realization of the automatic welding process in use, and is more suitable for For the construction and construction of large-scale building steel frame structures, the forming machine used in the processing and production of corrugated webs has a high degree of automation and fast processing speed. It can be used alone or in a large-scale automated production line.

Owner:山东金瑞诺华兴机械有限公司

Welding operation table with welding position capable of being adjusted in real time for machining mechanical mold parts

PendingCN114453815AAvoid offsetGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelTransmission belt

The invention discloses a mechanical mold part machining welding operation table capable of adjusting the welding position in real time, which comprises a base, two groups of adjusting grooves are formed in the inner side of the base, a transmission rod is mounted on the inner side of the base in a penetrating manner, the transmission rod penetrates through the interiors of the two groups of adjusting grooves, and two groups of transmission rollers are mounted on the outer side of the transmission rod. The transmission roller is located on the inner side of the adjusting groove, and a conveying belt is movably installed on the outer side of the transmission roller. The movable inner pipe is installed, a motor is controlled to operate to drive a driving wheel at the output end to rotate, the driving wheel rotates to drive a transmission belt on the outer side to rotate, the transmission belt rotates to drive a driven wheel on the inner side to rotate, and the driven wheel rotates to drive the movable inner pipe on the inner side to rotate on the inner side of a fixed outer ring; the movable inner pipe rotates to drive the adjusting rod and the clamping plate on the inner side to rotate, the clamping plate rotates to drive the tubular workpiece on the inner side to rotate, the device can conveniently and automatically adjust the angle of a welding seam during welding, and the workpiece is comprehensively welded.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

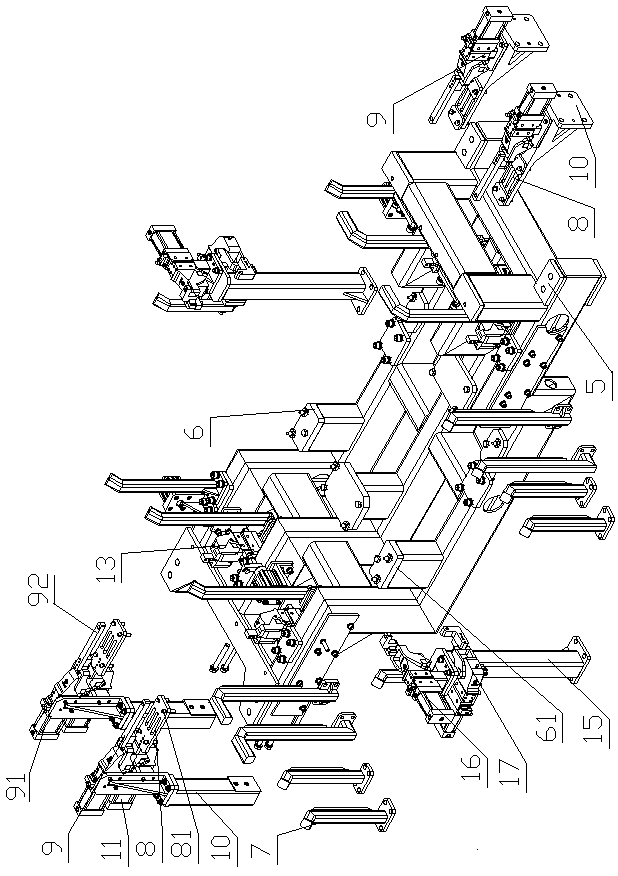

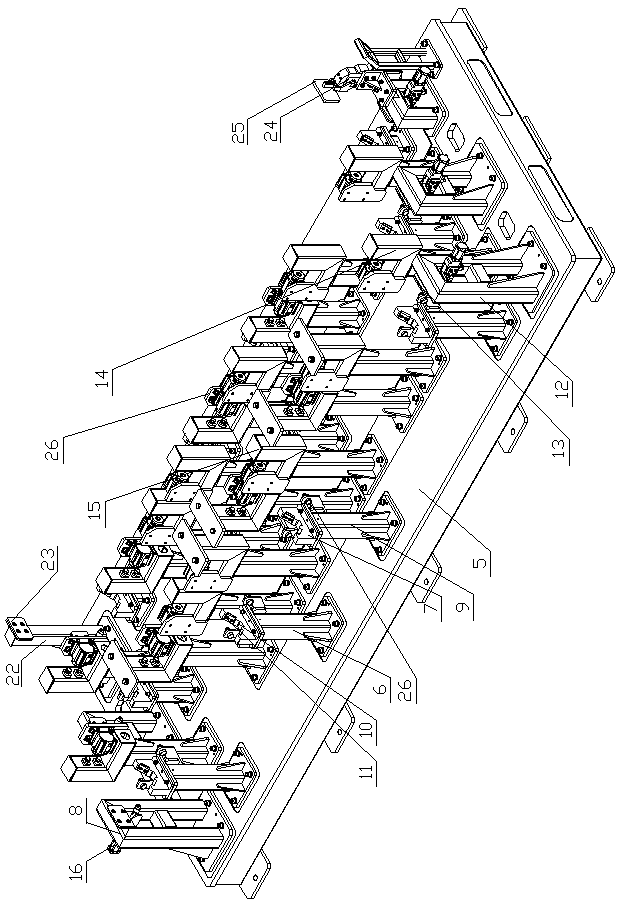

Vertical wallboard and multi-rib plate assembly welding fixture

PendingCN107803622AFacilitate automatic weldingImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWall plate

The invention discloses a vertical wallboard and multi-rib plate assembly welding fixture, and relates to the field of fixtures. The vertical wallboard and multi-rib plate assembly welding fixture comprises a clamping platform whose section is matched with the lower end surface of a transverse vertical wallboard in shape; multiple sets of support modules corresponding to baseplates in number are arranged at the middle part of the clamping platform; one baseplate is supported on each set of support modules; end limiting bases are arranged on the clamping platform at one end of the transverse vertical wallboard; backers are arranged on one sides of two ends of the transverse vertical wallboard, and pressing cylinders are arranged on the other sides; each rib plate is provided with a supportplate at the bottom and a pressing rod mechanism on the upper side; and the support plate and the pressing rod mechanism corresponding to each rib plate are mounted on the clamping platform through first mounting bases. The vertical wallboard and multi-rib plate assembly welding fixture can assemble and clamp multiple baseplates, multiple transverse vertical wallboards and multiple rib plates as awhole, so that a welding robot is convenient to automatically weld, the product quality and the working efficiency are effectively improved, the production cost is reduced, and the large-scale production is convenient to realize.

Owner:HAIAN JIAORUI ROBOT TECH +1

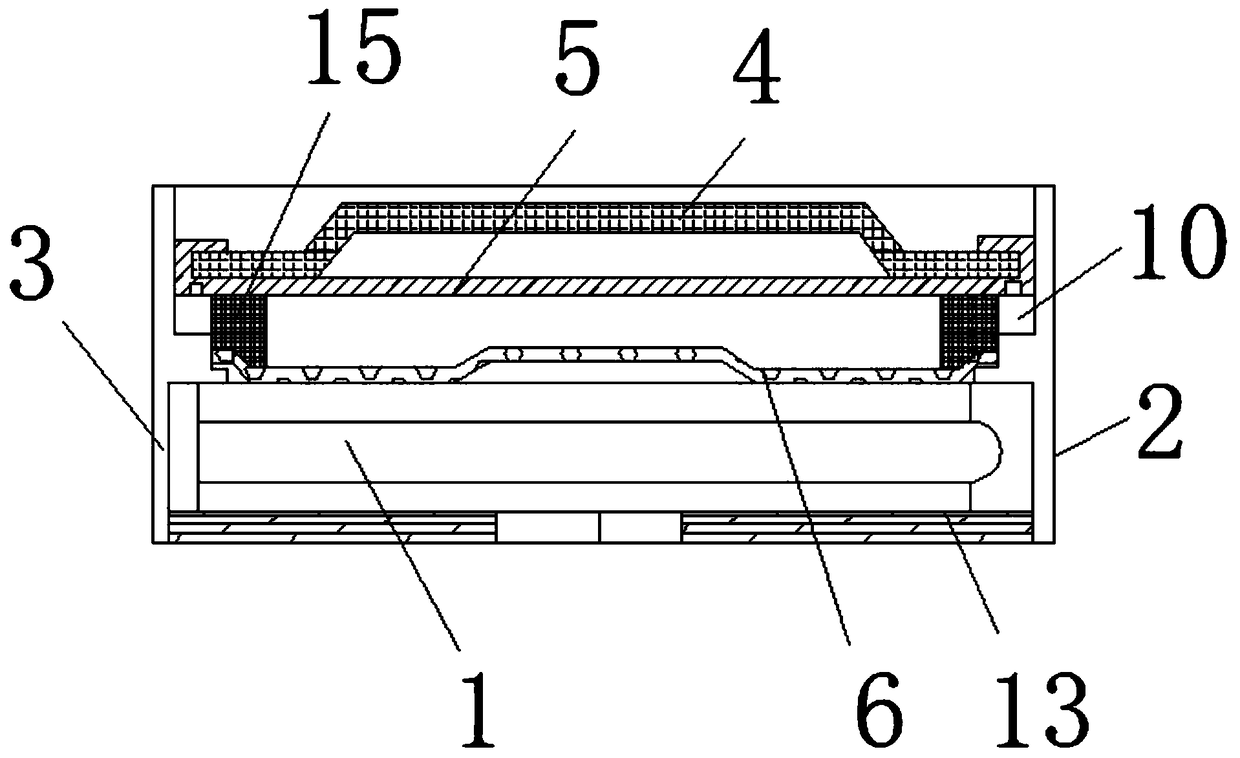

An explosion-proof notebook battery

PendingCN109148783AExtended service lifePrevent extensionBattery isolationSecondary cellsInternal pressurePull force

The invention discloses an explosion-proof notebook battery, include a battery body and a housing, A shell is fixedly connected with that external wall of the battery, the shell is composed of an explosion-proof shell and a top cover, and the top cover is fixedly connected with the top end of the explosion-proof shell through bolts; an explosion-proof sheet is arrange at the joint of the explosion-proof shell and the top cover; the explosion-proof sheet and the two ends of the top cover are welded; a pressure plate is arranged at the bottom end of the explosion-proof sheet, and a pressure relief hole is arranged on the pressure plate. As that explosion-proof shell is use for preventing damage to other component inside the computer when the battery explodes, the top cover relieves the pressure generated by the heating of the battery, The explosion-proof sheet avoids the extension of the battery body to the inner part of the shell barrel, reduces the occupancy of the inner space of the shell barrel, has a pressing plate at the bottom end, and breaks away from the explosion-proof sheet when the pressing plate is deformed due to tensile force, thereby ensuring that when the internal pressure of the battery exceeds the standard value, the pressure is dredged to prevent overload.

Owner:东莞市海拓伟电子科技有限公司

Automatic welding machine

InactiveCN110561023AFacilitate automatic weldingQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderMotor drive

The invention discloses an automatic welding machine. The automatic welding machine comprises a rack, a linear sliding table is installed on one side of the top of the rack, a welding gun is installedon a sliding table body of the linear sliding table, a hydraulic cylinder is installed at the bottom of the rack, a fixed plate is welded to an output shaft of the hydraulic cylinder, a motor is mounted at the top of the fixed plate, and a rotating plate is fixedly connected to an output shaft of the motor. The automatic welding machine is mainly composed of the rack, the linear sliding table, the hydraulic cylinder, the motor, a support and other components, in the welding process, a base of a bar chair is placed on the rotating plate, the base bears squeezing force of a spring in a cylinderbody and is fixed to the rotating plate, then a steel pipe of the bar chair is inserted into a sleeve at the bottom of a top plate, and the base is driven by the hydraulic cylinder to move upwards, so that the base and the steel pipe are in butt joint and clamped between the top plate and the rotating plate, and the linear sliding table drives the welding gun to weld the base and the steel pipe.Meanwhile, the motor drives the base to rotate, automatic welding of the bar chair is facilitated, and the welding quality and efficiency are improved.

Owner:安吉腾飞家具有限公司

Metallization method for back contact solar battery

ActiveCN103872181ASmall diameterReduce consumptionFinal product manufacturePhotovoltaic energy generationP type dopingElectricity

The invention discloses a metallization method for a back contact solar battery. The metallization method for the back contact solar battery includes the following steps that firstly, a through hole electrode is manufactured, at least one N type metal contact column is formed, and the diameter of the N type metal contact is 0.5-1 mm; secondly, a metal layer is arranged in a P type doping area or a P+ doping area of the back face of a semiconductor substrate; thirdly, the position, opposite to the N type meal contact column, on the metal layer of the back face is provided with bar-shaped insulating medium layers; fourthly, second metal layers are arranged on all the insulating medium layers, and the second metal layers are electrically connected with N type metal contacts below the second metal layers, and a welding electrode is formed. The invention discloses a metallization preparing method of the back contact solar battery, the insulating medium layers and the second metal layers are led in, the maximum efficiency is achieved, electric leakage caused by contact between metal and a semiconductor is reduced, and meanwhile consumption of Ag metal slurry is reduced. The battery efficiency obtained before and after with the method is promoted by 0.4 percent, and an unexpected effect is obtained.

Owner:CSI CELLS CO LTD

Locating frame for welding laboratory cabinet

ActiveCN110434535AFacilitate automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWorkbench

The invention relates to the technical field of cabinet assembling, in particular to a locating frame for welding a laboratory cabinet. The locating frame comprises a movable workbench and four cornerlocating devices; the four corner locating devices are installed on the movable workbench; the movable workbench comprises a first linear movement device and two second linear movement devices; one second linear movement device is installed at the working end of the first linear movement device; the other second linear movement device is fixed to the side of the end point of the output directionof the first linear movement device; the two second linear movement devices are arranged side by side; two corner locating devices are installed on one second linear movement device side by side; onecorner locating device is installed at the working end of one second linear movement device; and the other corner locating device is fixed to the side of the end point of the output direction of one second linear movement device. The locating frame can adapt to cabinets which are in different sizes and are unequal in the number of partition plates, and automatic welding of a welding robot is facilitated.

Owner:北京戴纳实验科技有限公司

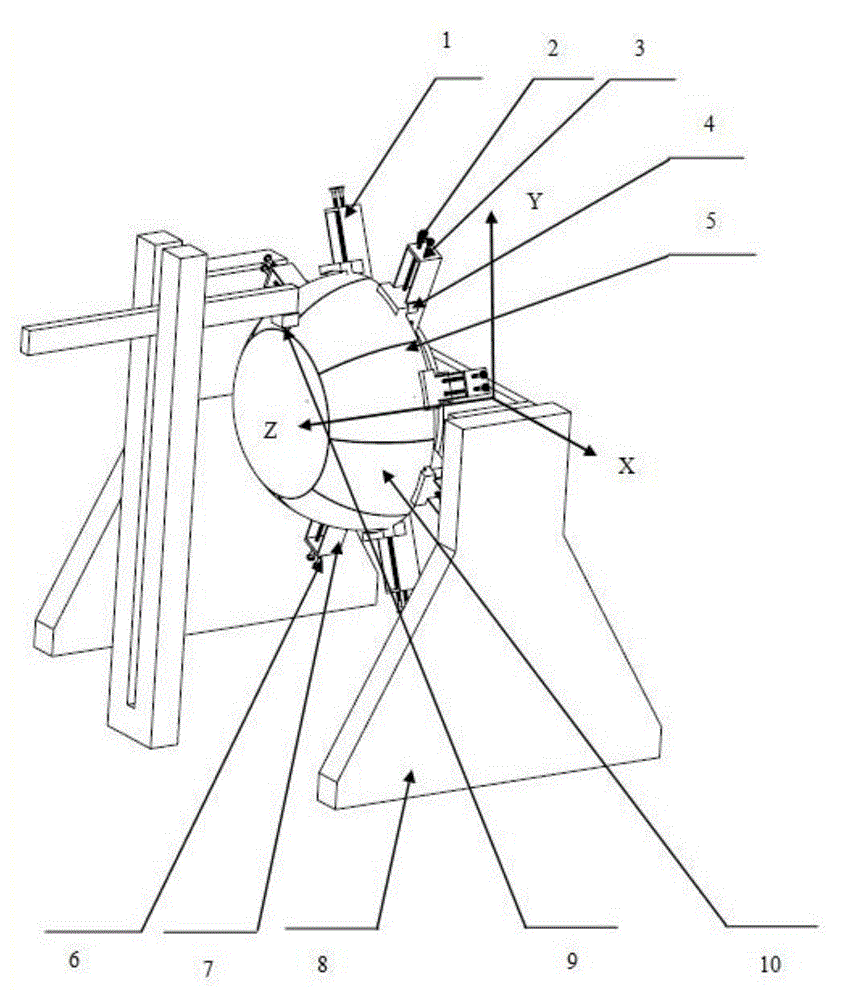

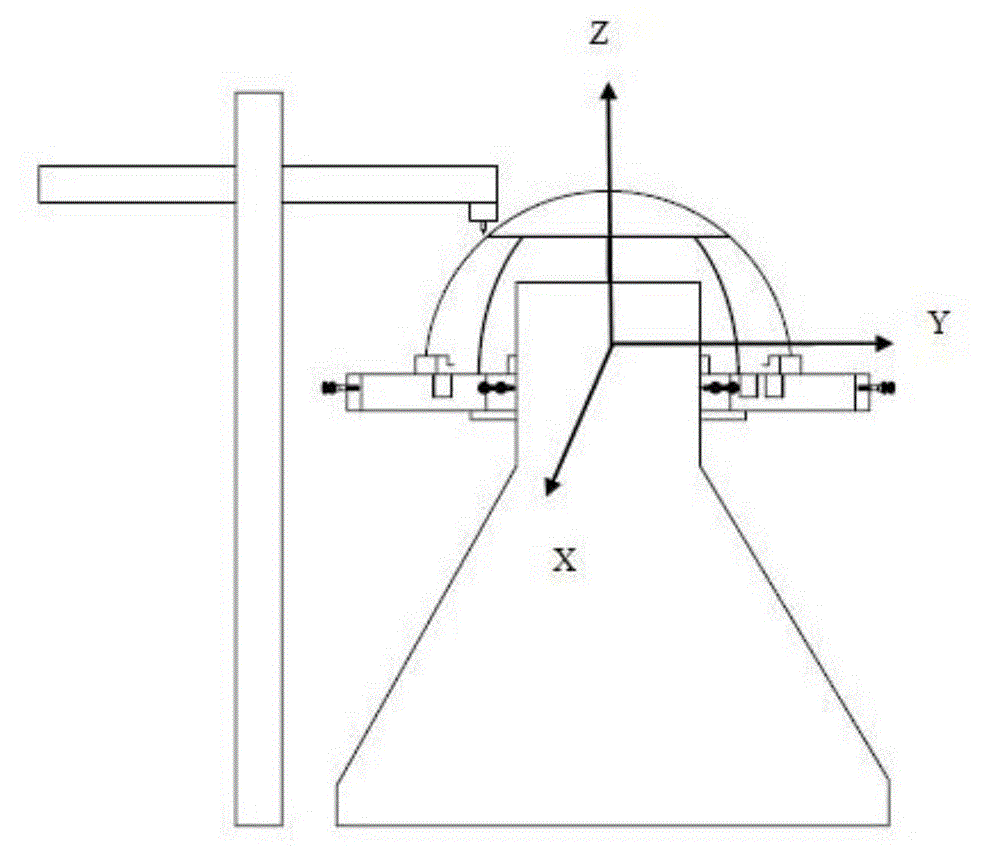

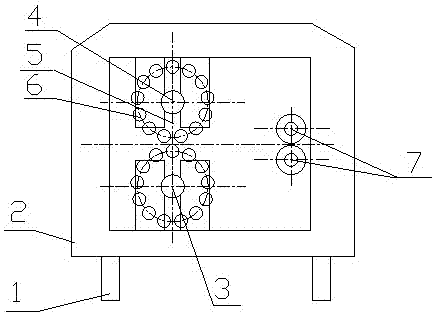

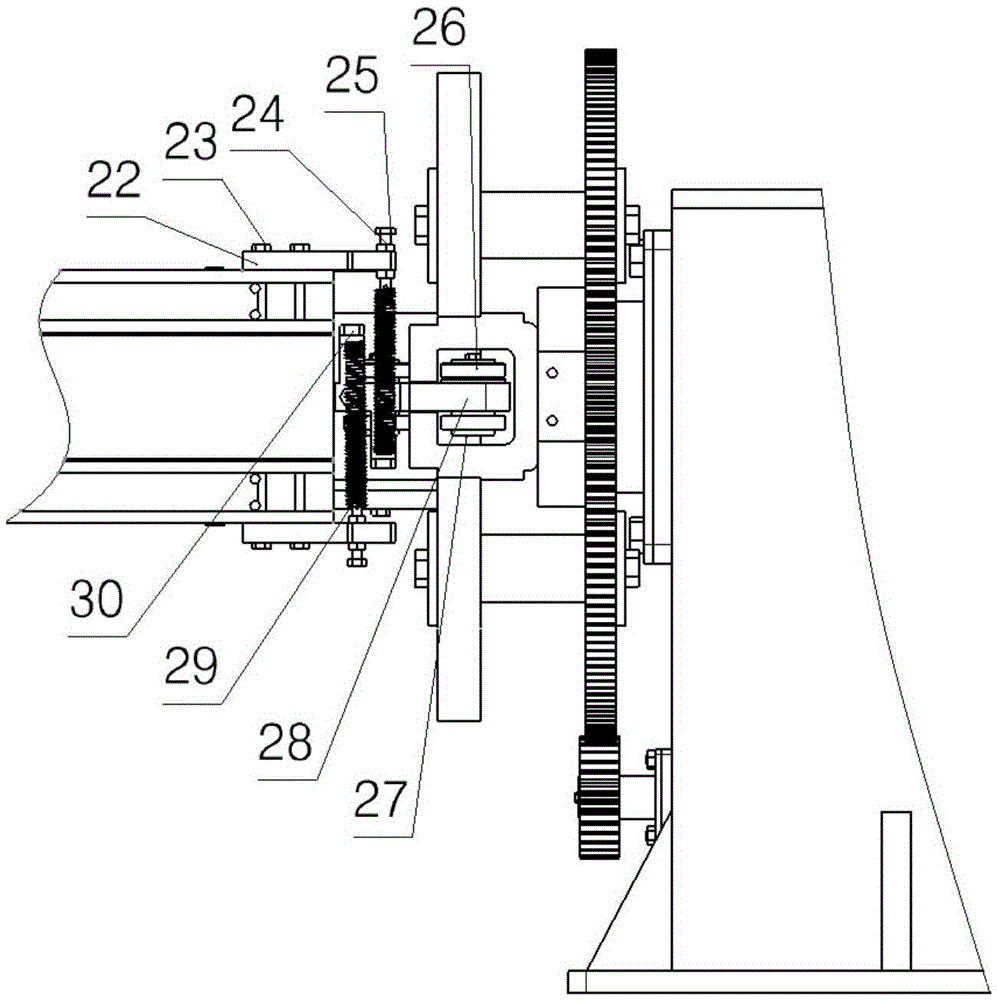

A positioner suitable for welding transformer oil tank

ActiveCN104607857BCompact structureAchieve positioningWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderDrive shaft

The invention relates to a positioner suitable for transformer oil tank welding. The positioner comprises a base, a clamp device, a rotating device and a connecting device. The clamp device mainly comprises a hydraulic cylinder, a connecting rod, a connecting block, a thrust bearing, a push rod, first connection rods, supporting rods, positioning rods, positioning blocks and positioning rollers. The rotating device mainly comprises a servo motor, a coupler, a driving shaft, a driving gear, a large gear ring, a rotating shaft and tapered roller bearings. The connecting device mainly comprises a connecting plate, a connecting pin, a supporting plate, upper supporting rolling wheels and lower supporting roll wheels. The eight positioning rollers of the clamp device move to appropriate positions, so that positioning and clamping of a transformer oil tank supporting frame are achieved; rotation of the transformer oil tank supporting frame can be achieved through the large gear ring of the rotating device, and it is guaranteed that cooling fins on the four sides of a transformer can be installed and welded at a horizontal position. Thus, welding quality is guaranteed, and labor intensity of workers is relieved.

Owner:WUHU ANPU ROBOT IND TECH RES INST

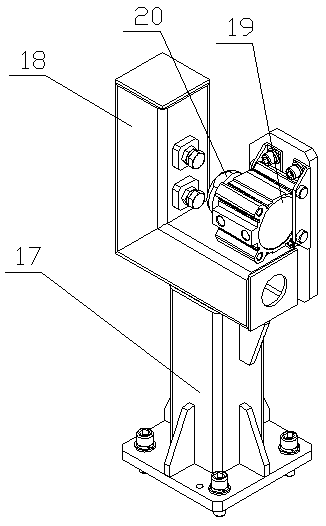

Single-shaft positioning machine clamp

InactiveCN109175868AFacilitate automatic weldingImprove securityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a single-shaft positioning machine clamp which comprises a plurality of support components, telescopic components and a rack, wherein the telescopic components are connected with the inner sides of the support components; and the end parts of the support components are in sliding fit with the rack. The single-shaft positioning machine clamp drives the support components toexpand outwards through the telescopic components to fixedly clamp a rectangular corrugated box, so that automatic welding by a robot is facilitated, the staff operating safety is improved and the production efficiency is improved.

Owner:NANTONG HUINING MECHANICAL & ELECTRICAL TECH CO LTD

Special clamp suitable for assembling and welding of multiple specifications of vertical plates and multiple round pipes

PendingCN107695595AFacilitate automatic weldingImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesCoaxial lineWelding

The invention discloses a special clamp suitable for assembling and welding multiple specifications of vertical plates and multiple round pipes and relates to the field of tool clamps. The special clamp comprises a supporting platform. Multiple supporting pipe assemblies are arranged on the supporting platform in parallel in a spaced manner. The supporting pipe assemblies are used for supporting first round pipes. The supporting platform is provided with multiple columns of vertical plate positioning assemblies at intervals, and round holes coaxially arranged are formed between vertical plates. Second round pipes penetrate in the round holes of the vertical plates. End portion limiting seats used for positioning one ends of the second round pipes are arranged at the positions, located at one ends of the second round pipes, on the supporting platform, and end portion limiting air cylinders used for positioning the other ends of the second round pipes are arranged at the positions, located at the other ends of the second round pipes, of the supporting platform. By means of the special clamp, multiple specifications of vertical plates and multiple round pipes can be assembled and clamped into a whole, automatic welding of a welding robot is facilitated, the product quality and work efficiency are effectively improved, the production cost is reduced, and scale production is betterachieved.

Owner:HAIAN JIAORUI ROBOT TECH

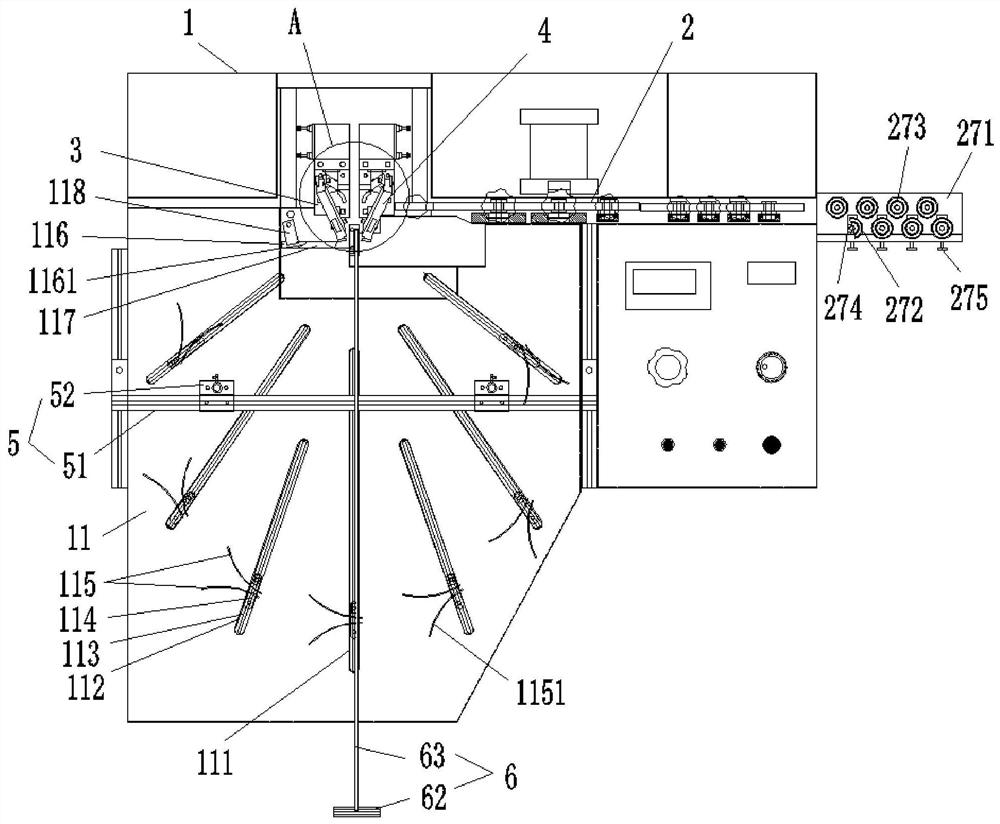

Looping and welding integrated machine for mesh enclosure machining

InactiveCN112108876AEasy to processAchieve alignmentOther manufacturing equipments/toolsMachining processWelding deformation

The invention provides a looping and welding integrated machine for mesh enclosure machining, and belongs to the technical field of mesh enclosure machining equipment. The looping and welding integrated machine for mesh enclosure machining comprises a support, a looping assembly, a welding assembly, a cutting-off assembly, a welding gripper, an auxiliary gripper and a storage rack. According to the looping and welding integrated machine, the looping assembly and the welding assembly are arranged on the support with an inclined table plate, looping and welding procedures are completed at a time, transferring is not needed, the workload is low, and the machining efficiency is high; in addition, the inclined table plate can provide support for an open type annular ring body, so that the drooping deformation problem caused by gravity in the machining process is prevented, and therefore the mesh enclosure machining quality is guaranteed; in addition, the welding gripper and the auxiliary gripper are further arranged, so that automatic grabbing and welding can be realized, and therefore alignment of the ends is guaranteed, and welding deformation is prevented; and in addition, the storage rack is further arranged, so that automatic arrangement and collection of the annular ring body can be achieved, and therefore the machining efficiency is further improved, the workload is reduced,and mesh enclosure machining is facilitated.

Owner:宁波市鄞州叶仕金属制品有限公司

Positioning frame for welding laboratory cabinet body

ActiveCN112621068AFacilitate automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesWorkbenchPhysics

The invention relates to the technical field of cabinet body assembly, in particular to a positioning frame for welding a laboratory cabinet body, which comprises a movable workbench and four corner positioning devices arranged on the movable workbench; the movable workbench comprises a first linear moving device and two second linear moving devices; wherein one second linear moving device is installed at a working end of the first linear moving device, and the other second linear moving device is fixed beside the terminal point of the output direction of the first linear moving device; the two second linear moving devices are arranged side by side, and the two angle positioning devices are installed on the second linear moving devices side by side; and wherein one angle positioning device is installed at the working end of the second linear moving device, and the other angle positioning device is fixed beside the terminal point of the output direction of the second linear moving device. The positioning frame can adapt to cabinet bodies with different specifications and different numbers of partition plates, and a welding robot can conduct automatic welding conveniently.

Owner:BEIJING DAINA SHIYAN SCI & TECH CO LTD

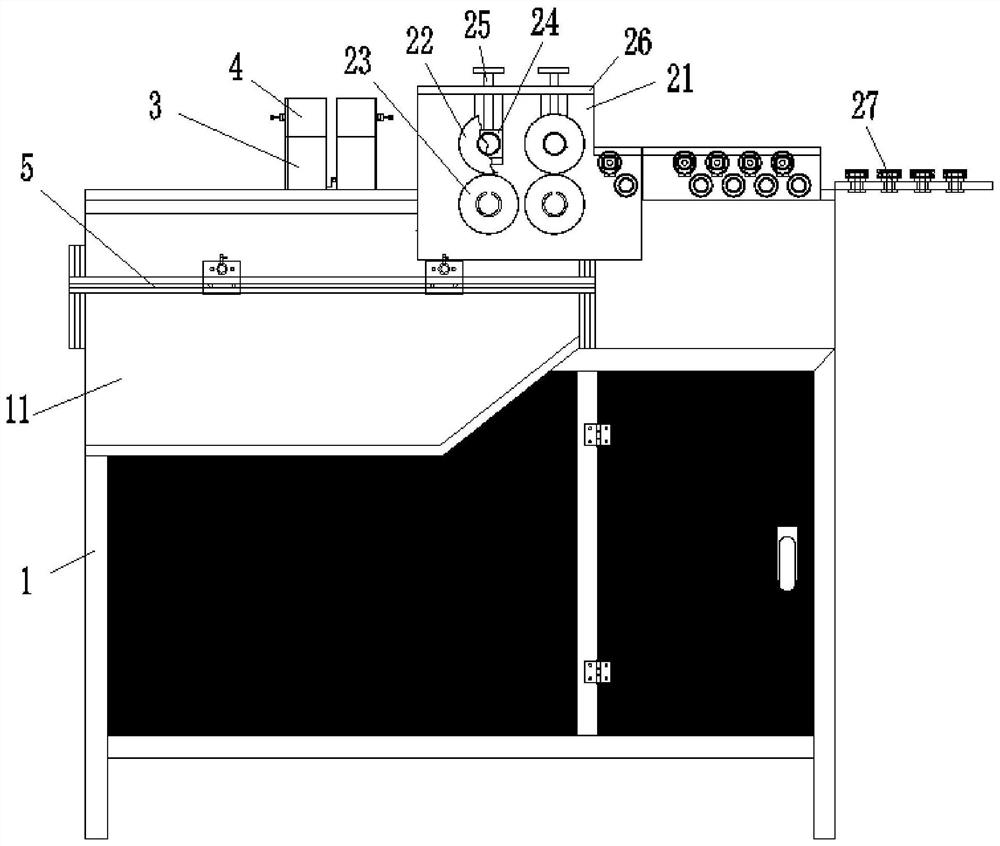

Large-flow low-noise brushless electronic fan and automatic machining equipment thereof

InactiveCN112727791AImprove location accuracyFacilitate automatic weldingPump componentsWelding/cutting auxillary devicesLow noiseImpeller

The invention discloses a large-flow low-noise brushless electronic fan and automatic machining equipment thereof. The large-flow low-noise brushless electronic fan comprises a base plate, a mounting plate, a side plate, a positioning body, a supporting column, fan blades and an impeller, wherein the supporting column is fixedly mounted on the upper surface of the base plate, the mounting plate is fixedly mounted on the upper surface of the supporting column, the side plate is fixedly mounted on one side of the upper surface of the mounting plate, the impeller is movably arranged on the upper surface of the mounting plate, the positioning body is fixedly mounted on the inner wall of the mounting plate, the positioning body is movably connected with the impeller in an inserted mode, the fan blades are movably arranged on the upper surface of the mounting plate, and a limiting device for movably clamping the impeller in a retractable mode is arranged at the position, corresponding to the impeller, of the upper surface of the base plate. According to the large-flow low-noise brushless electronic fan and the automatic machining equipment thereof, the position accuracy during welding of the fan blades and the impeller is improved, automatic welding of the fan blades and the impeller is achieved, the labor intensity of workers is reduced, the working efficiency of products is improved, and the large-flow low-noise brushless electronic fan is convenient to use by a user.

Owner:杭州松浦电器有限公司

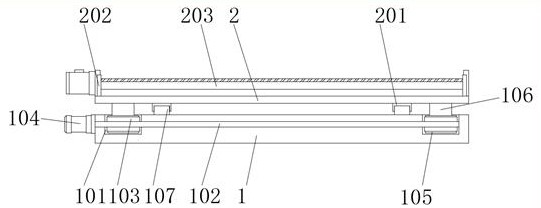

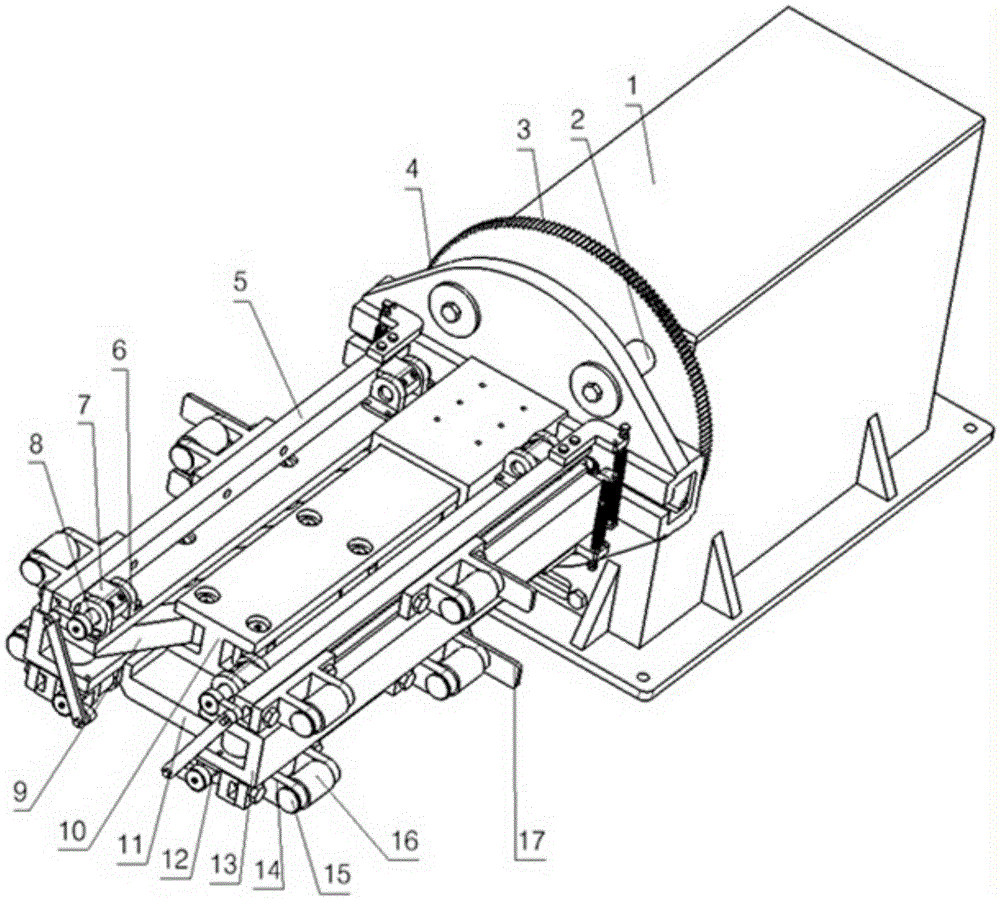

Pipe welding automatic feeding device

ActiveCN109108533BConvenient blankingEasy to compressWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe

The invention provides a pipe welding automatic feeding device. Automatic pipe discharging is controlled by forming a pipe discharging channel, with a bottom opening, in the middle of a sliding frameand further arranging discharging air cylinders; furthermore, by arranging an air cylinder and vertical slide rails, the distance between the pipe discharging channel and a pipe conveying mechanism iscontrolled, accordingly, it is guaranteed that only one pipe drops at a time, meanwhile, the sliding frame is shaken when material blocking occurs, and material dropping is facilitated; by arranginga movable discharging mechanism, bundles of pipes can be loaded conveniently, the movable discharging mechanism adapts to incoming pipes with different lengths, furthermore, by arranging a pressing mechanism, the pipes can be pressed and put in order conveniently, and the discharging accuracy is guaranteed; an included angle which is greater than 0 degree and smaller than 90 degrees is formed between the pipe discharging channel and welding frame feeding guide rails, and the pipes can move inside a welding frame conveniently; and a positioning mechanism is arranged, the pipes are clamped within the welding frame and positioned, and subsequent automatic welding is facilitated.

Owner:HUBEI WEISHENG ROBOT TECH CO LTD

Low-resistance bimetallic temperature controller

PendingCN110993437ASimple structureLow costHeating/cooling contact switchesThermal switch detailsComposite structureBimetal

The invention discloses a low-resistance bimetal temperature controller. The low-resistance bimetal temperature controller comprises a shell, an end cover, a base and a metal elastic sheet assembly, the shell covers one end of the base, the end cover covers the other end of the base, the metal elastic piece assembly comprises a static piece and an elastic piece, one end of the static piece is provided with a static piece contact, the other end of the static piece is fixed to the bottom of the base, one end of the elastic piece is provided with an elastic piece contact, the other end of the elastic piece is fixed to the bottom of the base, an ejector rod is fixed to the base, and the ejector rod abuts against a disc in the vertical direction at one end and abuts against the elastic piece atthe other end. The elastic sheet and the elastic sheet contact are fixed through welding, and the static sheet and the static sheet contact are fixed through welding. According to the invention, unstable contact and unstable resistance caused by riveting are avoided, the contact structure is simplified, and the cost is low; and the contact adopts a three-layer composite structure, so that the weldability is effectively improved, and the welding on substrates of the static sheet and the elastic sheet is facilitated.

Owner:太平洋电子(昆山)有限公司

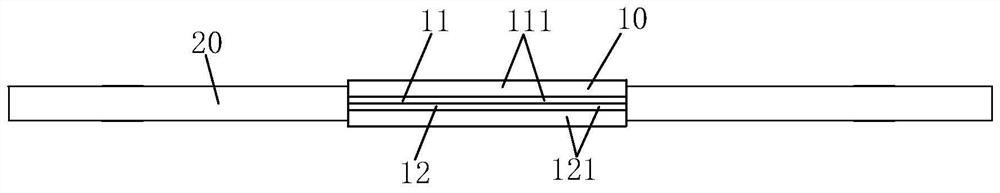

Automatic welding material belt for brocade silk threads

PendingCN113070617AOrderly rowsFacilitate automatic weldingNon-insulated conductorsElectrical transducersYarnEngineering

The invention provides an automatic welding material belt for brocade silk threads. The automatic welding material belt comprises at least one bonding belt assembly and the at least three brocade silk threads arranged in parallel, the bonding belt assembly comprises an upper bonding belt and a lower bonding belt, the upper bonding belt comprises an upper material belt and an upper bonding layer bonded to the lower surface of the upper material belt, the lower bonding belt comprises a lower material belt and a lower bonding layer adhered to the upper surface of the lower material belt, the upper bonding belt vertically wraps the upper portions of the at least three brocade silk threads, the upper bonding layer adheres to the upper portions of the brocade silk threads, the lower bonding belt vertically wraps the lower portions of the at least three brocade silk threads, the lower bonding layer adheres to the lower portions of the brocade silk threads, the upper bonding belt is right opposite to the lower bonding belt, the upper bonding layer adheres to the lower bonding layer, and the bonding belt assembly is located between the two ends of the brocade silk threads. Brocade silks of the automatic brocade silk yarn welding material belt are arranged in order, and automatic welding is facilitated.

Owner:陈敏

Polishing device for connectors of automatically welded oil and gas pipes

ActiveCN113579897AGuaranteed flatnessPlace stableEdge grinding machinesGrinding carriagesThermodynamicsPolishing

The invention relates to the technical field of polishing device for welding of oil and gas pipes, in particular to a polishing device for connectors of automatically welded oil and gas pipes. The polishing device for the connectors of the automatically welded oil and gas pipes comprises a base. A feeding structure is arranged on the base. An adjusting structure is arranged on the feeding structure. A rotating structure is mounted on the adjusting structure. A conversion structure is further mounted on the feeding structure. A polishing structure is mounted at the top end of the base. A protection structure is further mounted on the base. A sweeping structure is arranged in the protection structure. A collecting structure is arranged in the protection structure. Through the arrangement of the feeding structure, the oil and gas pipes can be precisely fed and polished, so that the flatness of welding connectors of the oil and gas pipes is ensured, and accordingly, subsequent automatic welding work is facilitated; and through the arrangement of the adjusting structure, the oil and gas pipes with different external diameters can be stably placed, and accordingly, the circumstance that the oil and gas pipes with the different external diameters shake during placement is avoided.

Owner:四川庆达实业集团有限公司

Straight seam welding and grouping welding method for large-diameter cylinder

ActiveCN113070632APrevent collapseImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSeam welding

The invention provides a straight seam welding and grouping welding method for a large-diameter cylinder, and relates to the technical field of welding equipment. The straight seam welding and grouping welding method for the large-diameter cylinder comprises the following steps that firstly, rolling wheels on a driving welding walking rolling wheel frame, a driven welding walking rolling wheel frame and at least two hydraulic jacking grouping rolling wheel frames are placed on two parallel rails which are arranged on the ground in advance, wherein the hydraulic jacking grouping rolling wheel frames are located between the driving welding walking rolling wheel frame and the driven welding walking rolling wheel frame; and the driving welding walking rolling wheel frame is placed close to the end, needing to be welded, of the cylinder. A hydraulic supporting arm mechanism is adjusted, the cylinder can be jacked from the two side faces of the cylinder, the hydraulic supporting arm mechanism is used for correcting and lifting a workpiece with the large cylinder diameter to prevent the workpiece with the large cylinder diameter from collapsing, the roundness of the workpiece with the large cylinder diameter is corrected, more time and labor can be saved when the workpiece with a large cylinder diameter is welded and assembled, and the welding efficiency is improved.

Owner:郑州越达科技装备有限公司

Special welding positioner capable of performing position rotating and switching

PendingCN107627068ARealize assembly weldingRealize individual transpositionWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention discloses a special welding positioner capable of performing position rotating and switching, and relates to the field of clamping jigs. The positioner comprises a first welding clampingmechanism and a second welding clamping mechanism which are arranged side by side, wherein fixed bases are arranged at the two ends of the first welding clamping mechanism and the second welding clamping mechanism; rotating bases which are arranged oppositely are mounted on the fixed bases through first bearing seats; the two ends of the first welding clamping mechanism and the second welding clamping mechanism are rotationally mounted on the rotating bases through second bearing seats; two first driving mechanisms respectively driving the first clamping mechanism and the second welding clamping mechanism to rotate are mounted on the rotating bases on one side; second driving mechanisms driving the corresponding rotating bases to rotate are mounted on the fixed bases on one side. The positioner can realize the splicing and welding of two work piece components, can further realize single displacement and synchronous displacement of the two work piece components, and effectively enhances the production efficiency and productivity.

Owner:HAIAN JIAORUI ROBOT TECH +1

Fusion reactor cooling pipe connection special solder for ultra-low temperature environment

ActiveCN103286474BLow melting pointLower melting temperatureWelding/cutting media/materialsSoldering mediaManganeseCopper

Owner:SOUTHWESTERN INST OF PHYSICS +1

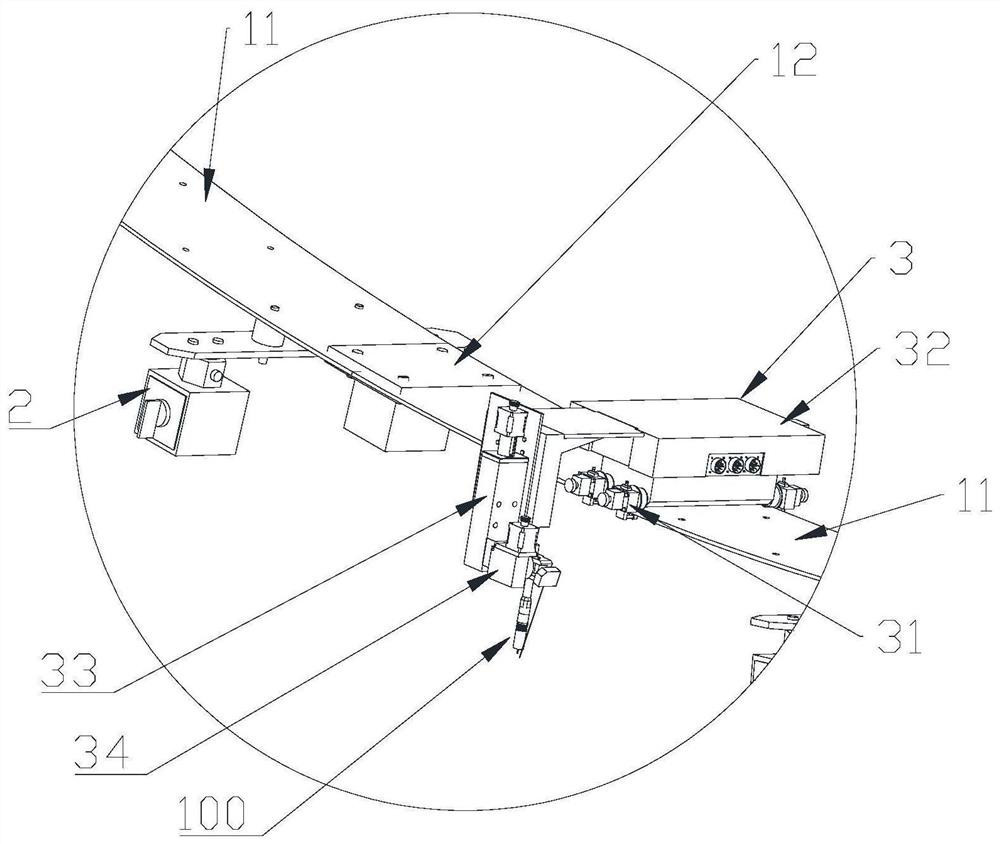

Auxiliary tool, welding system with auxiliary tool and welding method

InactiveCN109648231AImprove efficiencyFacilitate automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention provides an auxiliary tool, a welding system with the auxiliary tool and a welding method. The auxiliary tool is used for welding a port crane box beam partition plate and reinforcing ribs, the auxiliary tool comprises a base face plate which is used for cooperating with the partition plate in a coplanar mode, a pedal face plate which is connected with the base face plate and is usedfor cooperating with the reinforcing ribs in a coplanar mode, and a fixing portion which is connected with the pedal face plate and is used for being connected with the partition plate. Through the auxiliary tool, the partition plate can be extended, when a trolley walks to the end, trolley wheels can be supported to walk, so that the reinforcing ribs are extended, when the trolley walks to the end, the trolley is allowed for attracting and walking, so that rapid installing and positioning are facilitated, full-length welding is achieved, welding of the welding trolley is facilitated, so thatthe efficiency of the welding trolley is improved; through the welding system, trolley automatic welding of the partition plate and the reinforcing ribs can be realized, the welding angle is uniformin size, the welding seam is continuous, the weld seam grinding workload is remarkably reduced, continuous welding can be realized, the labor intensity is remarkably reduced, and the welding efficiency is improved.

Owner:SHANGHAI ZHENHUA HEAVY IND

Box girder automatic welding device and using method

ActiveCN109366028BFacilitate automatic weldingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The invention belongs to the field of welding, and particularly relates to an automatic welding device for a box girder and an application method thereof. The automatic welding device for the box girder comprises a box girder fixing unit and a welding unit for fixing the box girder; the box girder fixing unit comprises a base, a fixed clamping block on one side of the base, a movable clamping block on the other end of a bottom plate and an auxiliary sliding frame inside the box girder; the welding unit comprises a welding wire gun supporting arm, a welding wire gun on the welding wire gun supporting arm and a supporting block used to support the welding wire gun supporting arm; one end of the welding wire gun supporting arm is provided with a mating hole engaging with the auxiliary slidingframe, the auxiliary sliding frame can dynamically adjust a box girder support during welding. The automatic welding device for the box girder and the application method thereof have the advantages of simple structure and easy adjustment and can conveniently automatically weld the box girders of various sizes, so that the labor intensity of box girder welders is reduced.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com