Looping and welding integrated machine for mesh enclosure machining

An all-in-one machine and grille technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as sagging deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

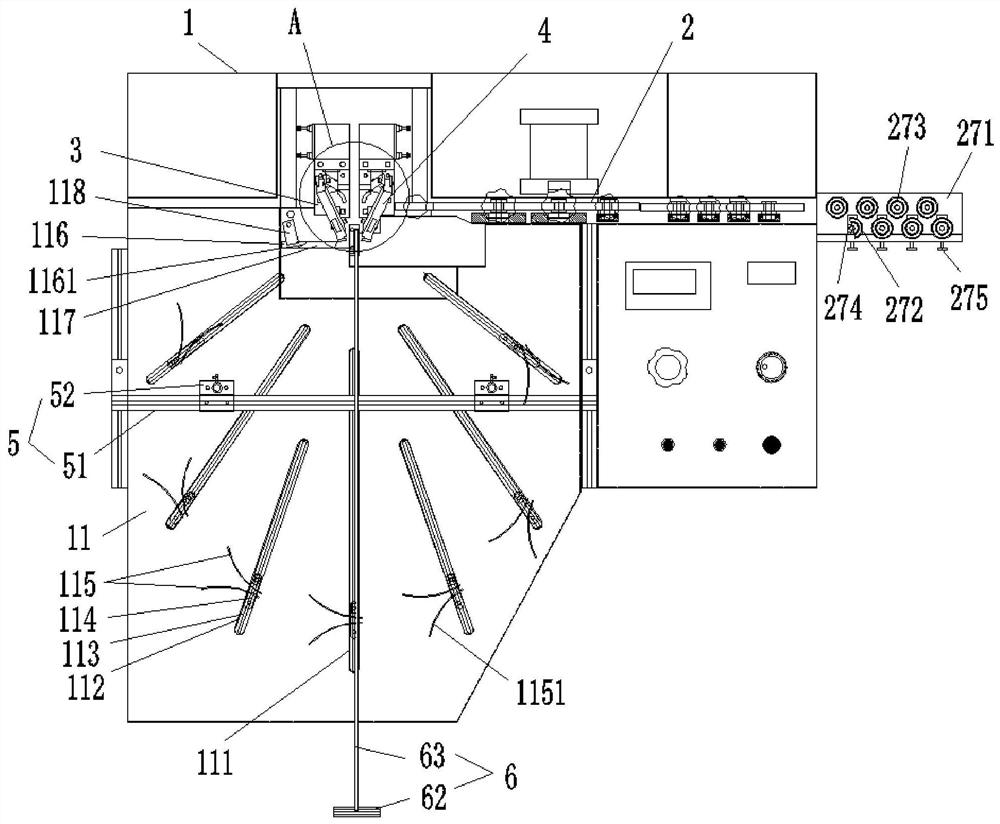

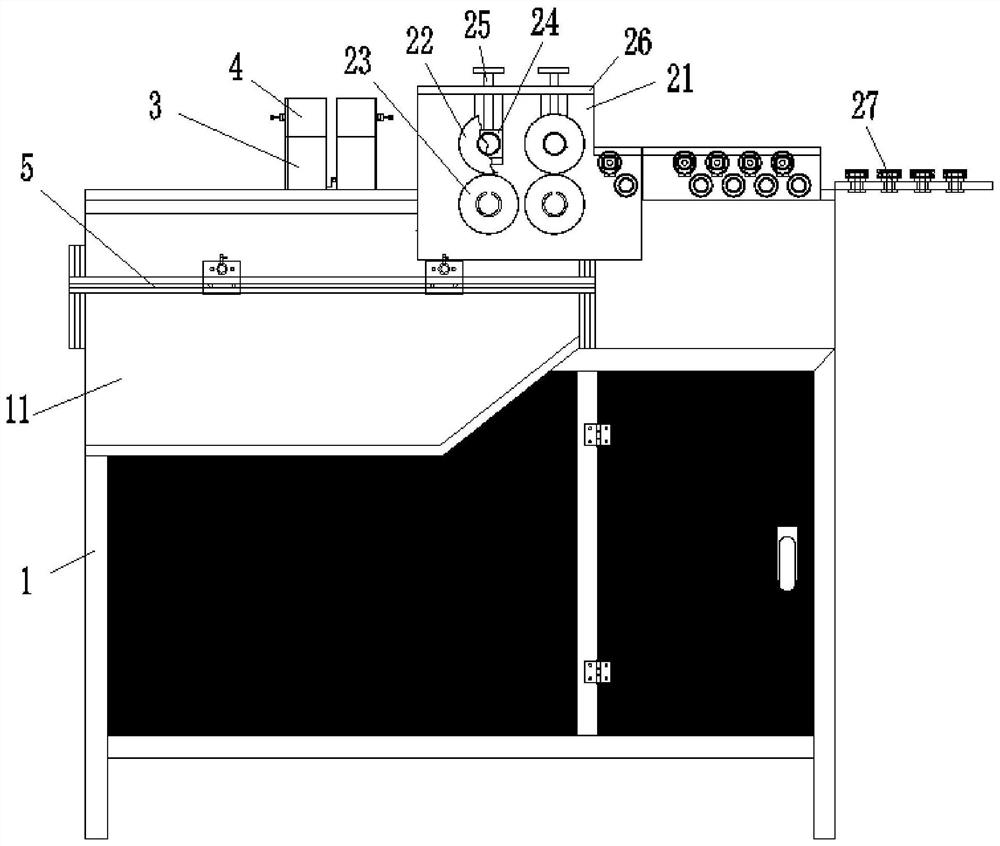

[0029] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach image 3 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0030] figure 1 It is a structural diagram of an embodiment of a circle welding all-in-one machine for mesh cover processing of the present invention; figure 2 for figure 1 Enlarged view of part A in the middle; image 3 It is a structural diagram of another perspective of a preferred embodiment of the present invention. Such as figure 1 , figure 2 as well as image 3 As shown, the all-in-one loop welding machine for mesh cover processing provided in this embodiment includes: a bracket 1 , a loop assembly 2 , a welding assembly 3 , a cutting assembly, a welding gripper 4 , an auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com