A web used for h-shaped steel and a plate forming machine for processing the web

A sheet metal forming machine, H-beam technology, applied in building materials, building components, buildings, etc., can solve the problems of low production efficiency, increased cost, single specifications, etc., and achieves fast processing speed, high degree of automation, and increased overall bearing capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

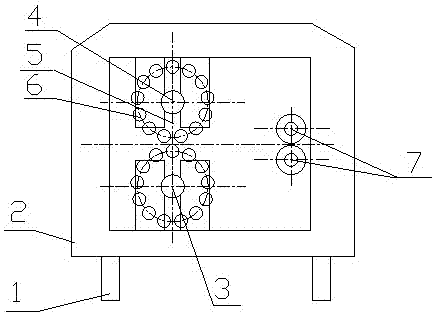

[0014] The H-shaped steel disclosed by the present invention is composed of two flange plates 8 and a web 9, the flange plates 8 are upright welded to the two ends of the web 9, wherein the web 9 is a corrugated web, and the profile curve of its cross section It is a sinusoidal curve. A plate forming machine is used to process this kind of web 9. The plate forming machine is composed of an input part, a forming part and an output part. The input part can input the flat plate to the forming part. The plate can be input manually or conveyed With automatic delivery. The forming part includes the following structures: a base 1, a frame 2, a lower roll 3, an upper roll 4, a plate thickness adjustment device 5 and a traction roll set 7. Among them, the base 1 and the frame 2 play a supporting role, the axes of the lower roll 3 and the upper roll 4 are parallel, opposite to each other, and the rotation speed is the same. The corrugated web 9 is formed after being bent and deformed u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com