Automatic end socket welding method of automatic welding device based on large-curved-surface end socket welding

An automatic welding and automatic welding technology, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of cumbersome automatic welding for economic benefits, high labor intensity of workers, and unsuitability for automatic welding, etc., so as to reduce labor intensity of workers, tooling Simple, reliable, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

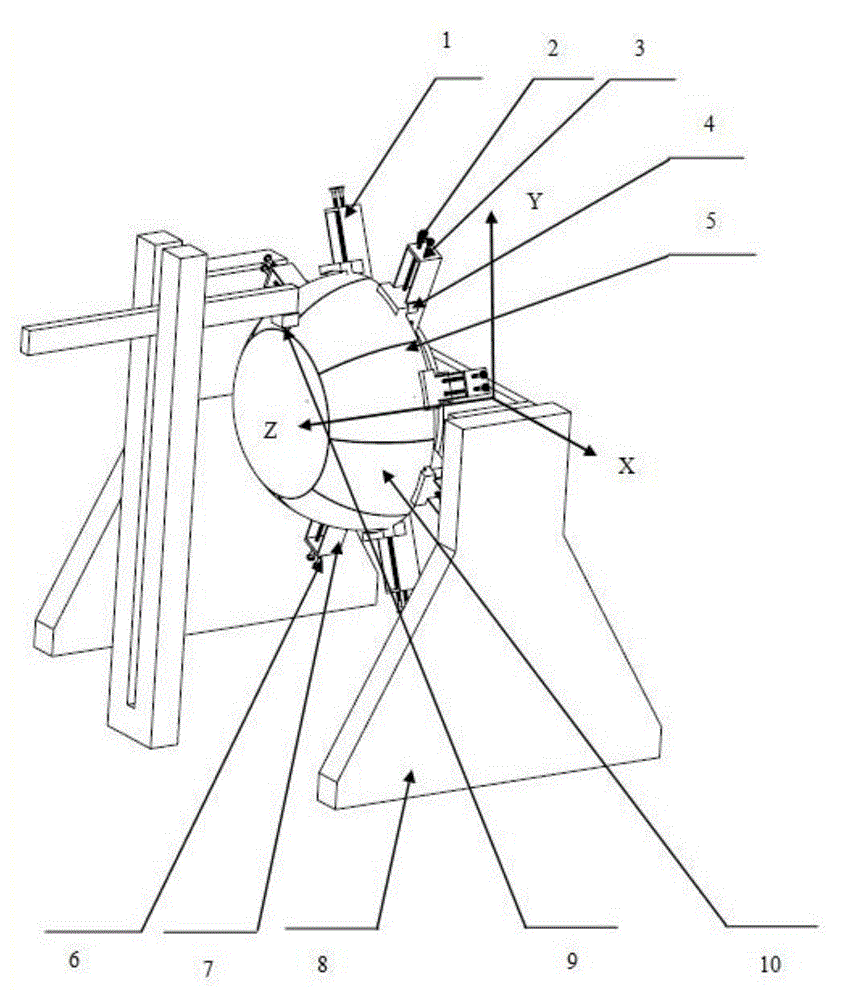

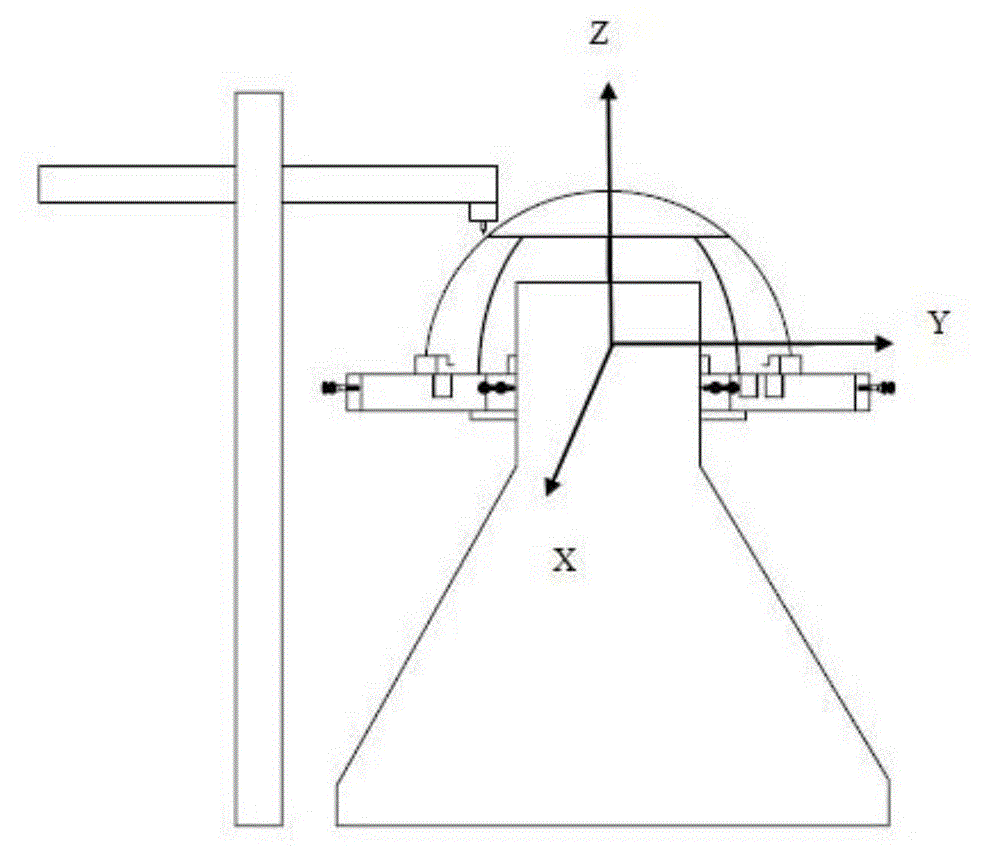

[0021] The first embodiment: the automatic welding method of the hemispherical head. When in use, the device is placed in the working workshop for the manufacture of the upper head of the dealkylation tower of the 400,000 tons / year catalytic oil slurry supercritical extraction device. The upper head has a hemispherical head with a thickness of δ=85min and a radius of R=2100mm. The material used is Q345R. This material is prone to hardening tendency in the heat-affected zone when welding, and it is easy to form a quenched structure-martensite, making it close to The hardness of the seam area increases and the plasticity decreases, which easily leads to cracks after welding. Therefore, ensuring a reasonable tooling and welding process is the key to welding manufacturing. When the head is manufactured, the eight melon petal heads are placed on the device one by one, and then the ball is placed on the top of all the melon petals to be assembled for clamping. After the clamping is c...

no. 2 example

[0022] The second embodiment: the automatic welding method of the semi-ellipsoidal head. The semi-ellipsoidal head is an important part of the dearomatization tower of the 400,000 tons / year catalytic slurry supercritical extraction device. The upper head of the dearomatization tower is an ellipsoidal head, and the welding curve is more complicated than that of a hemispherical head during manufacture. When in use, the device is placed in the manufacturing of the head of the dearomatization tower of the working plant. The thickness of the upper head is δ=50(48)mm, the long axis radius R=2500mm, the short axis radius r=1500mm, and the semi-ellipsoidal head, the bottom half section is circular with radius r=2000mm. The material used is Q345R. When the head is manufactured, 6 pieces of melon petal heads are placed on the device one by one, and then the oval ball is placed on the top of all melon petals for assembly, and the dimensions are clamped and positioned according to the draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com