Universal tailor welding tooling device and method for large curved surface head of pressure vessel

A pressure vessel and curved surface technology, applied in the field of pressure vessel head manufacturing, can solve problems such as difficulty in ensuring the dimensional accuracy of the head, affecting the aesthetics of the head surface, and increasing the labor intensity of workers, so as to ensure accuracy and facilitate positioning and adjustment. , the effect of preventing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

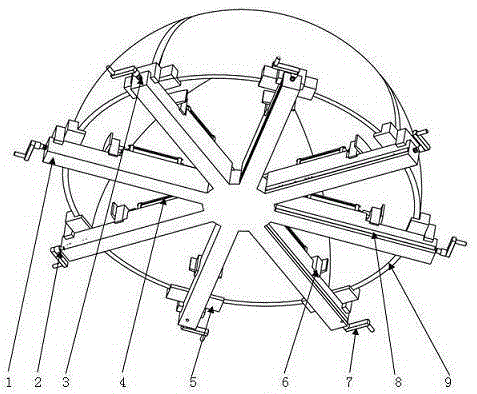

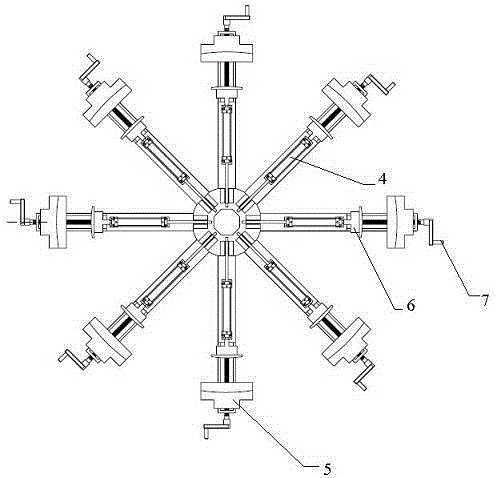

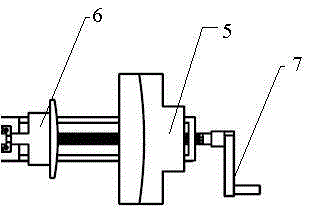

[0042] At first this inventive device is used for the manufacture of hemispherical head, and when using, the inventive device is placed in the workshop, and is used for the manufacture of the head on the deasphalting tower of 400,000 tons / year catalytic oil slurry supercritical extraction unit, this The thickness of the upper head is δ=42min, the hemispherical head with the radius R=2000mm, the material used is Q345R, because Q345R material welding tends to be hardened in the heat affected zone, it is easy to form a quenched structure - martensite, so that The hardness of the seam area increases and the plasticity decreases, which will easily lead to cracks after welding. Therefore, ensuring a reasonable tooling and welding process is the key to welding manufacturing. When manufacturing the head, first place eight curved heads on the device one by one, and then place them on the device. Put the balls on the top of all melon petals and assemble them, rotate the manual rocker to ...

Embodiment 2

[0044] The semi-ellipsoidal head is an important part of the deasphalting tower of the 400,000 tons / year catalytic oil slurry supercritical extraction device. Compared with the hemispherical head, the welding curve is more complicated when the ellipsoidal head is manufactured, so the deformation is more serious. The patented device of the present invention is placed in the working workshop, and the lower head of the deasphalting tower is manufactured. The thickness of the lower head is δ=42 (38) mm, and the semi-ellipsoidal head with radius R=2000mm is made of Q345R. , because Q345R material welding is prone to hardening tendency in heat-affected zone, it is easy to form quenched structure-martensite, which increases the hardness of the near-seam area and reduces the plasticity, which is easy to cause cracks after welding. Therefore, it is necessary to ensure reasonable tooling and welding process The key to welding the lower head is to manufacture the head by first placing eig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com