Vertical wallboard and multi-rib plate assembly welding fixture

A vertical wall and rib panel technology, which is applied in the field of vertical wall panel and multi-rib panel group tailor welding fixture, can solve the problems of large manpower consumption and large working area, so as to reduce production cost and facilitate large-scale production , Improve product quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

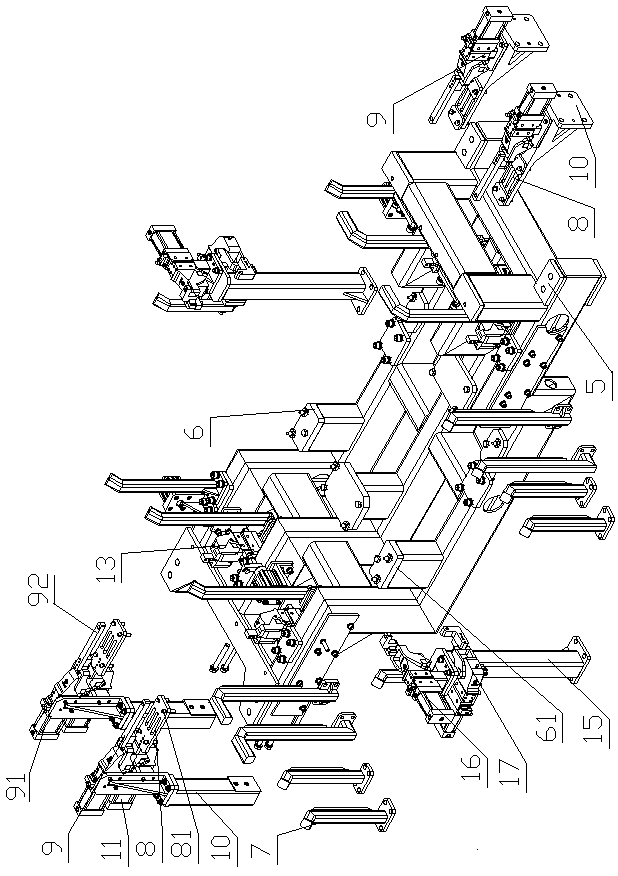

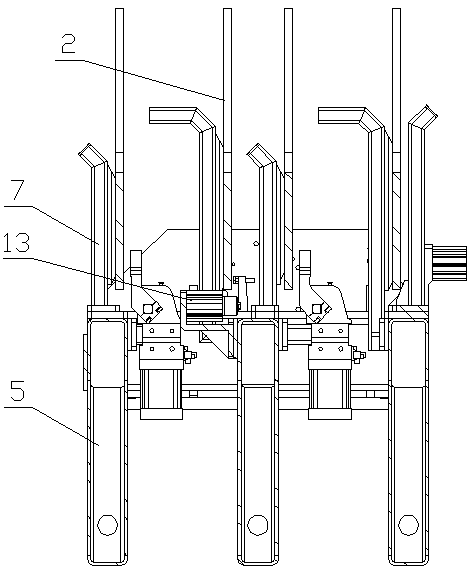

[0018] Such as Figure 1-3 As shown, the present invention discloses a vertical wall panel and multi-reinforced panel group tailor-welding fixture, which is used for the gap between two bottom plates 1, four horizontal vertical wall panels 2, one longitudinal wall panel 3, and four rib panels 4. Clamping includes a clamping platform 5 with a cross section that matches the shape of the lower end surface of the horizontal vertical wall panel 2. The middle of the clamping platform 5 is provided with two sets of supporting components 6, and the supporting components 6 include three supporting platforms arranged longitudinally 61. The bottom plate 1 is respectively supported on a set of supporting components 6, the horizontal vertical wall panel 2 is supported on the supporting component 6 from front to back, and the clamping platform 5 at one end of the horizontal vertical wall panel 2 is provided with an end limit seat 30, One side of the two ends of the horizontal vertical wall p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com