Automatic welding equipment for inner wall of pipeline

A technology of automatic welding and piping, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Adjust, facilitate automatic welding, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

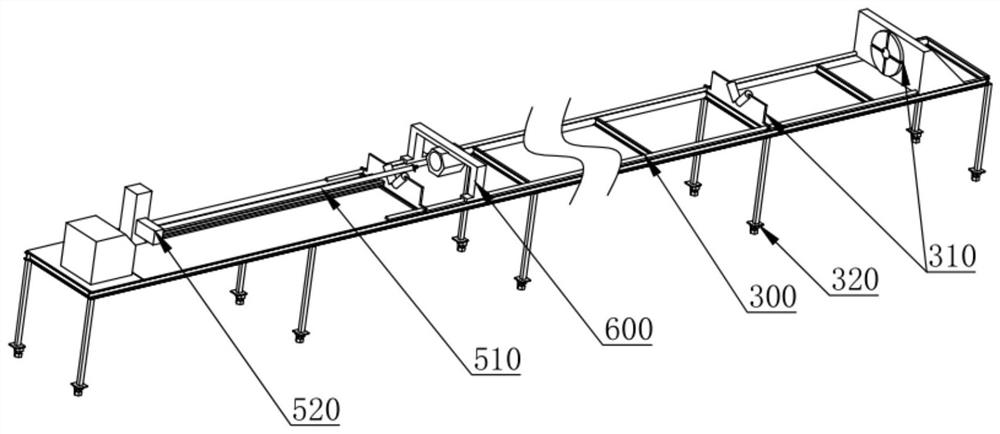

[0027] Such as Figure 1-7 As shown, the automatic welding equipment for the inner wall of the pipeline designed by the present invention includes a support base 300, a welding torch 400, a welding torch moving device 500, a pipeline preheating device 600 and a workpiece positioning tool 700; wherein:

[0028] The upper part of the supporting base 300 is provided with a plurality of height-adjustable rod tube brackets 310 , by adjusting the rod tube brackets 310 , the pipe to be welded 100 and the welding torch connecting rod 510 are parallel and in a suitable relative position. Part of the pipe support 310 is provided with a V-shaped support portion 311 , and rollers 312 that can roll are provided on both sides of the V-shaped support portion 311 to facilitate the movement of the welding torch connecting rod 510 and the pipe 100 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com