Welding method of high-strength steel of 900 MPa level

A welding method and high-strength steel technology, applied in welding media, welding equipment, welding equipment and other directions, can solve problems such as restricting production efficiency, and achieve the effect of simplifying welding equipment, reducing costs, and improving mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

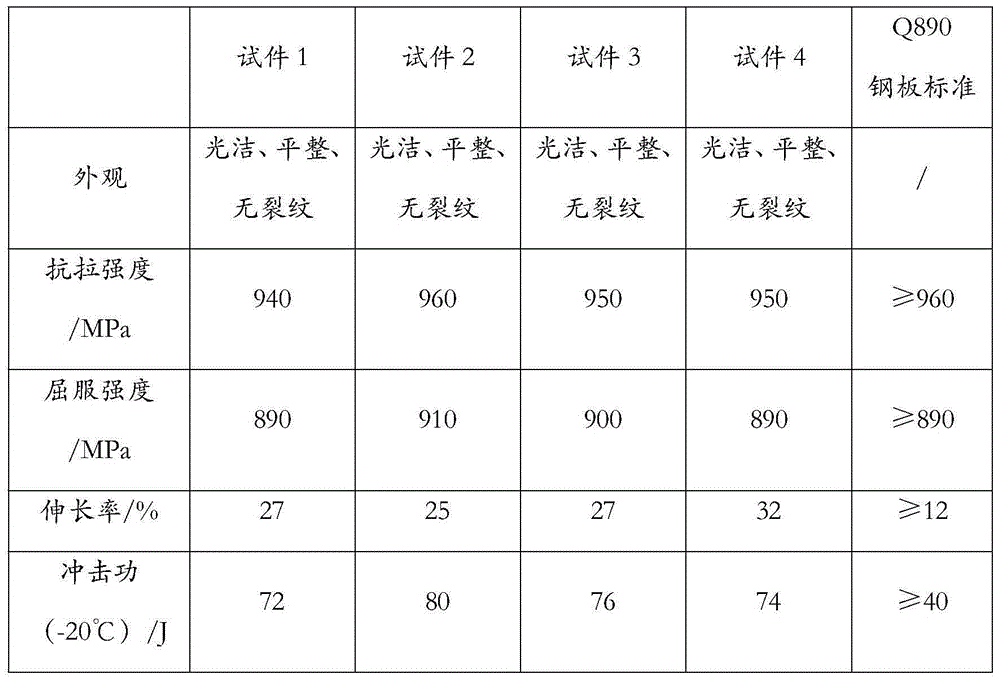

Examples

Embodiment 1

[0031] The steel plate to be welded is: Q890 high-strength steel, the size is 350mm×150mm×25mm, and the welding wire is: GHS-90.

[0032] A welding method for 900MPa grade high-strength steel, comprising the following steps:

[0033] (1) Shot blasting is performed on the surface of the high-strength steel until the metallic luster is exposed, and then a K-shaped bevel is made with a bevel angle of 30° and a blunt edge of 3mm. After beveling, the oxide layer on the bevel surface is manually removed;

[0034] (2) Preheat the high-strength steel to be welded, the preheating temperature is 150°C, and then spot welding is formed, the spot welding length is 80mm, and the spacing is 200mm;

[0035] (3) Preheating the formed high-strength steel obtained in step (2) as a whole, and the temperature is 180° C.;

[0036] (4) 90kg grade welding wire and gas shielded welding are used for bottom welding, and the shielding gas is Ar+CO 2 Mixed gas, the volume ratio is Ar:CO 2 =70%: 30%, us...

Embodiment 2

[0044] The steel plate to be welded is: Q890 high-strength steel, the size is 350mm×150mm×30mm, and the welding wire is: GHS-90.

[0045] A welding method for 900MPa grade high-strength steel, comprising the following steps:

[0046] (1) Shot blasting is performed on the surface of the high-strength steel until the metallic luster is exposed, and then a K-shaped bevel is made with a bevel angle of 30° and a blunt edge of 2mm. After beveling, the oxide layer on the bevel surface is manually removed;

[0047] (2) Preheat the high-strength steel to be welded, the preheating temperature is 160°C, and then spot welding is formed, the spot welding length is 100mm, and the spacing is 200mm;

[0048] (3) Preheating the formed high-strength steel obtained in step (2) as a whole, and the temperature is 160° C.;

[0049](4) 90kg grade welding wire and gas shielded welding are used for bottom welding, and the shielding gas is Ar+CO 2 Mixed gas, the volume ratio is Ar:CO 2 = 80%: 20%, u...

Embodiment 3

[0057] The steel plate to be welded is: Q890 high-strength steel, the size is 350mm×150mm×35mm, and the welding wire is: GHS-90.

[0058] A welding method for 900MPa grade high-strength steel, comprising the following steps:

[0059] (1) Shot blasting is performed on the surface of the high-strength steel until the metallic luster is exposed, and then a K-shaped bevel is made with a bevel angle of 30° and a blunt edge of 3mm. After beveling, the oxide layer on the bevel surface is manually removed;

[0060] (2) Preheat the high-strength steel to be welded, the preheating temperature is 120°C, and then spot welding is formed, the spot welding length is 120mm, and the spacing is 200mm;

[0061] (3) Carry out overall preheating to the formed high-strength steel obtained in step (2), and the temperature is 200° C.;

[0062] (4) 90kg grade welding wire and gas shielded welding are used for bottom welding, and the shielding gas is Ar+CO 2 Mixed gas, the volume ratio is Ar:CO 2 =8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com