Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Extend evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

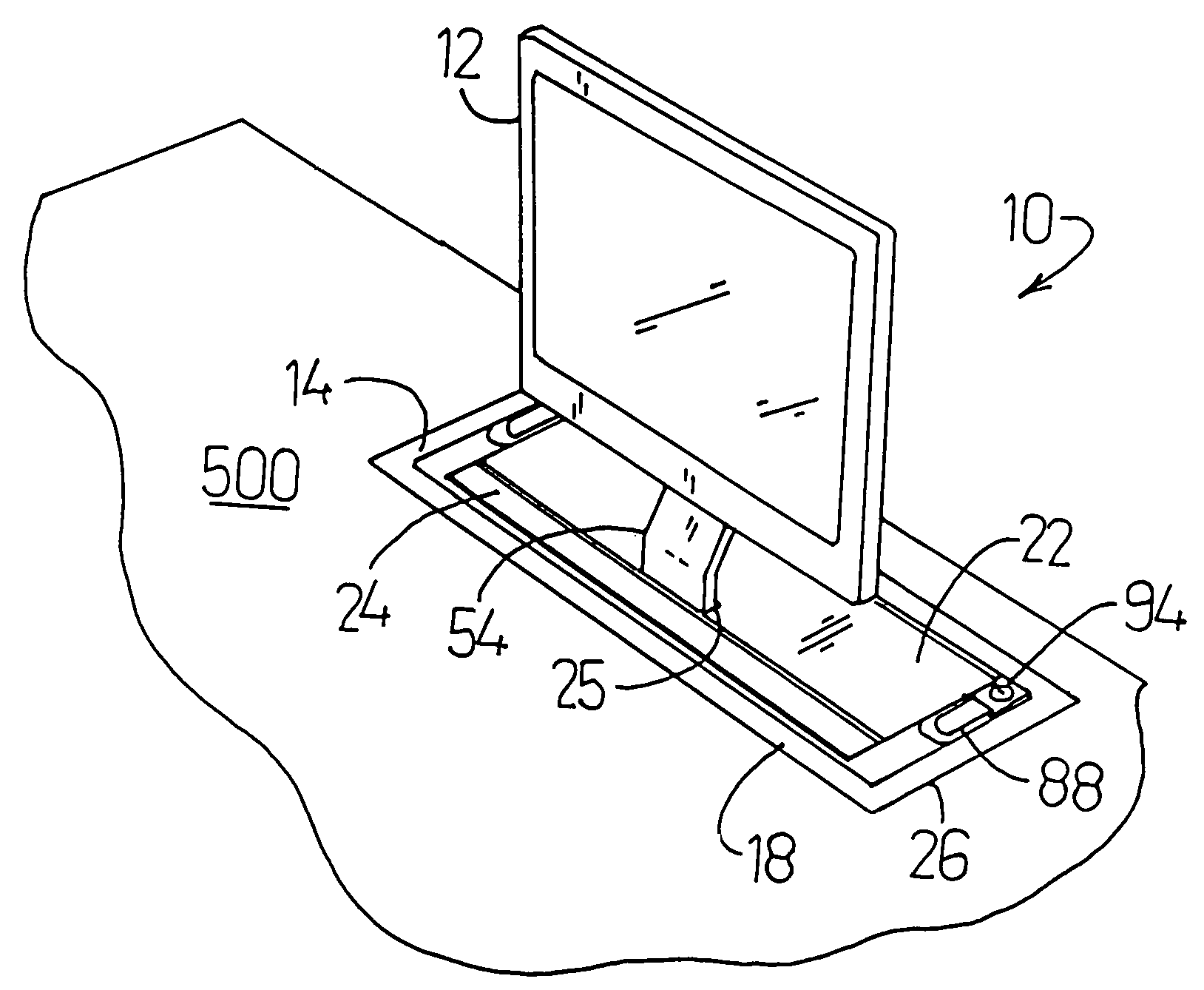

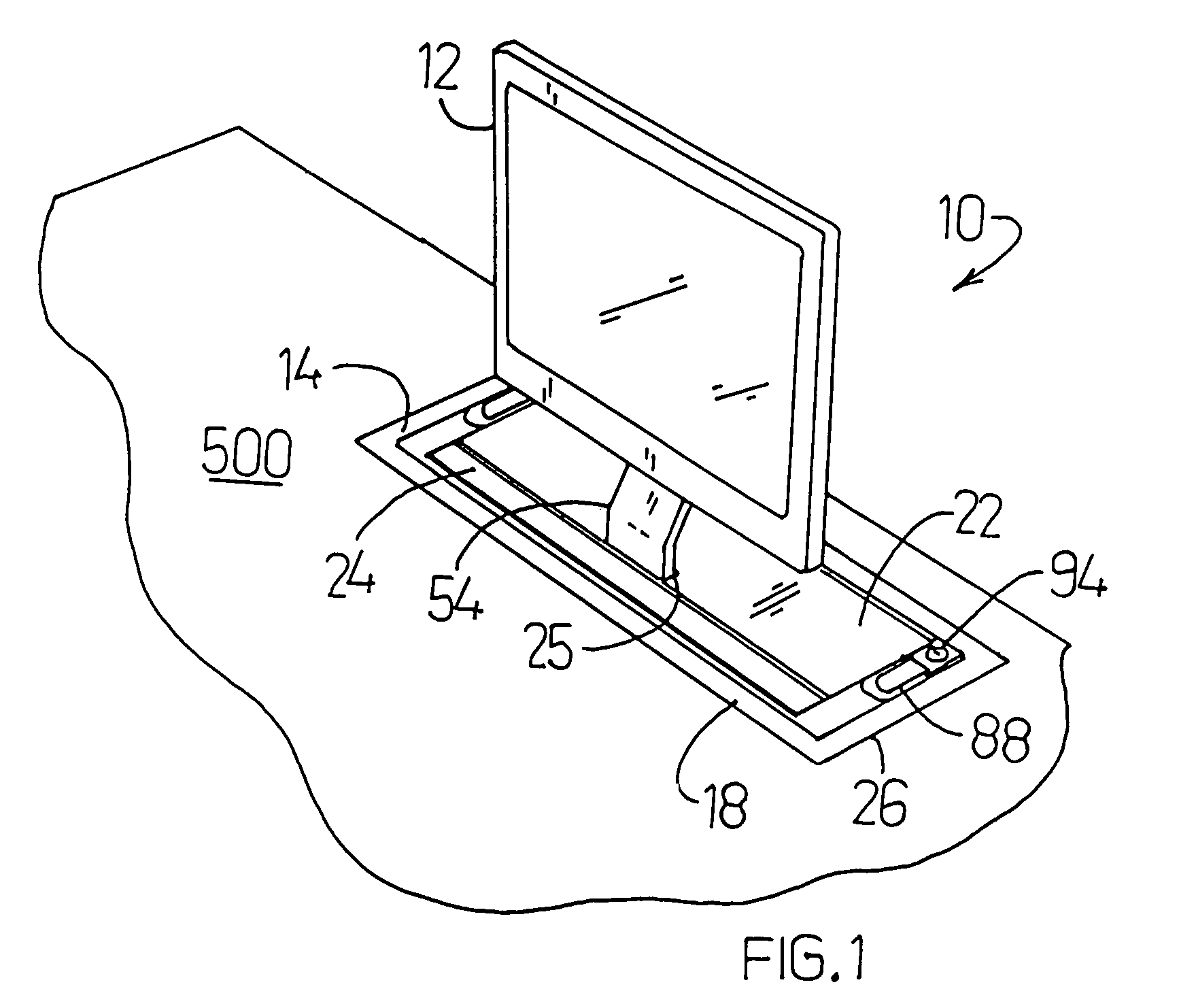

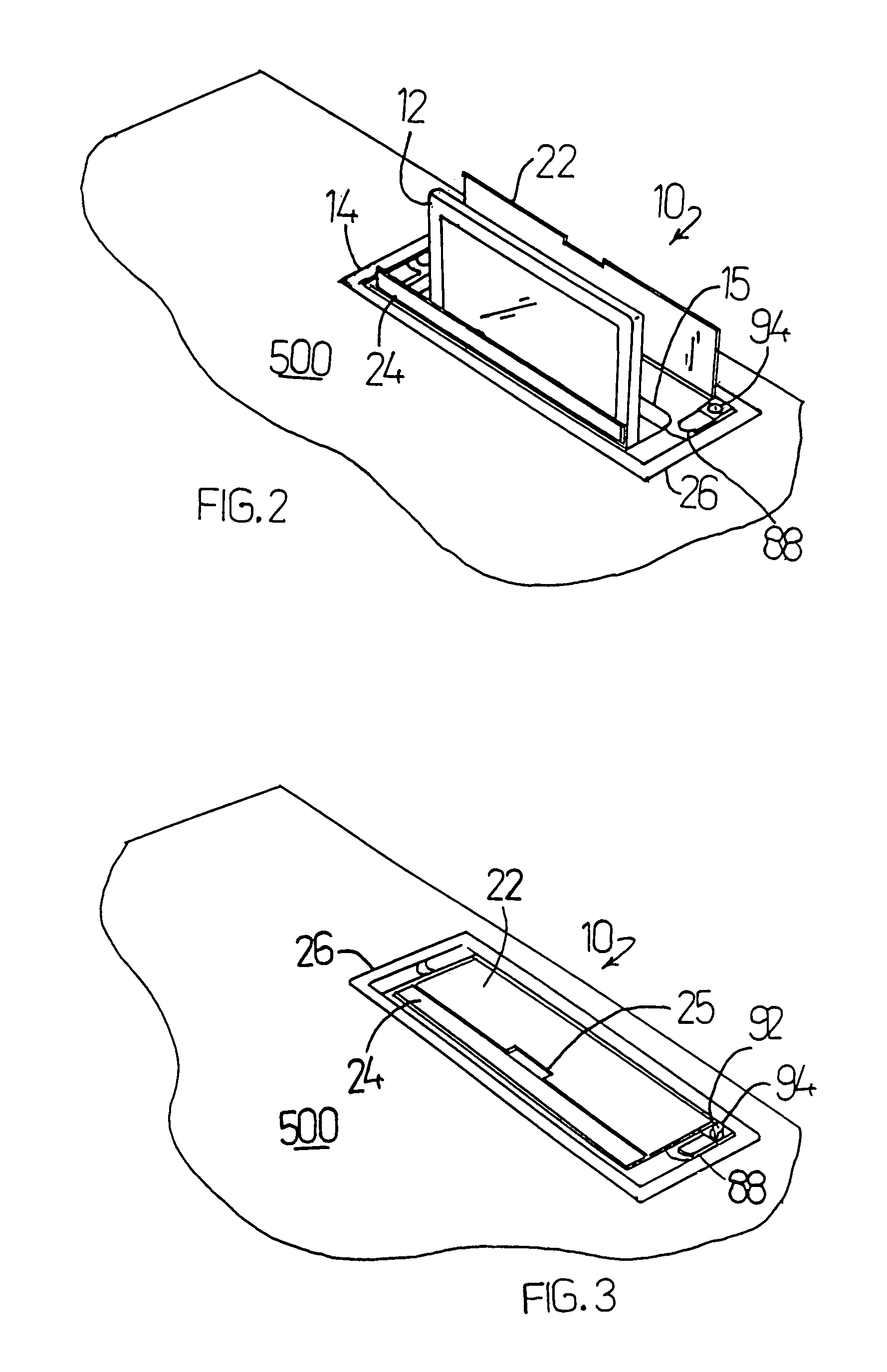

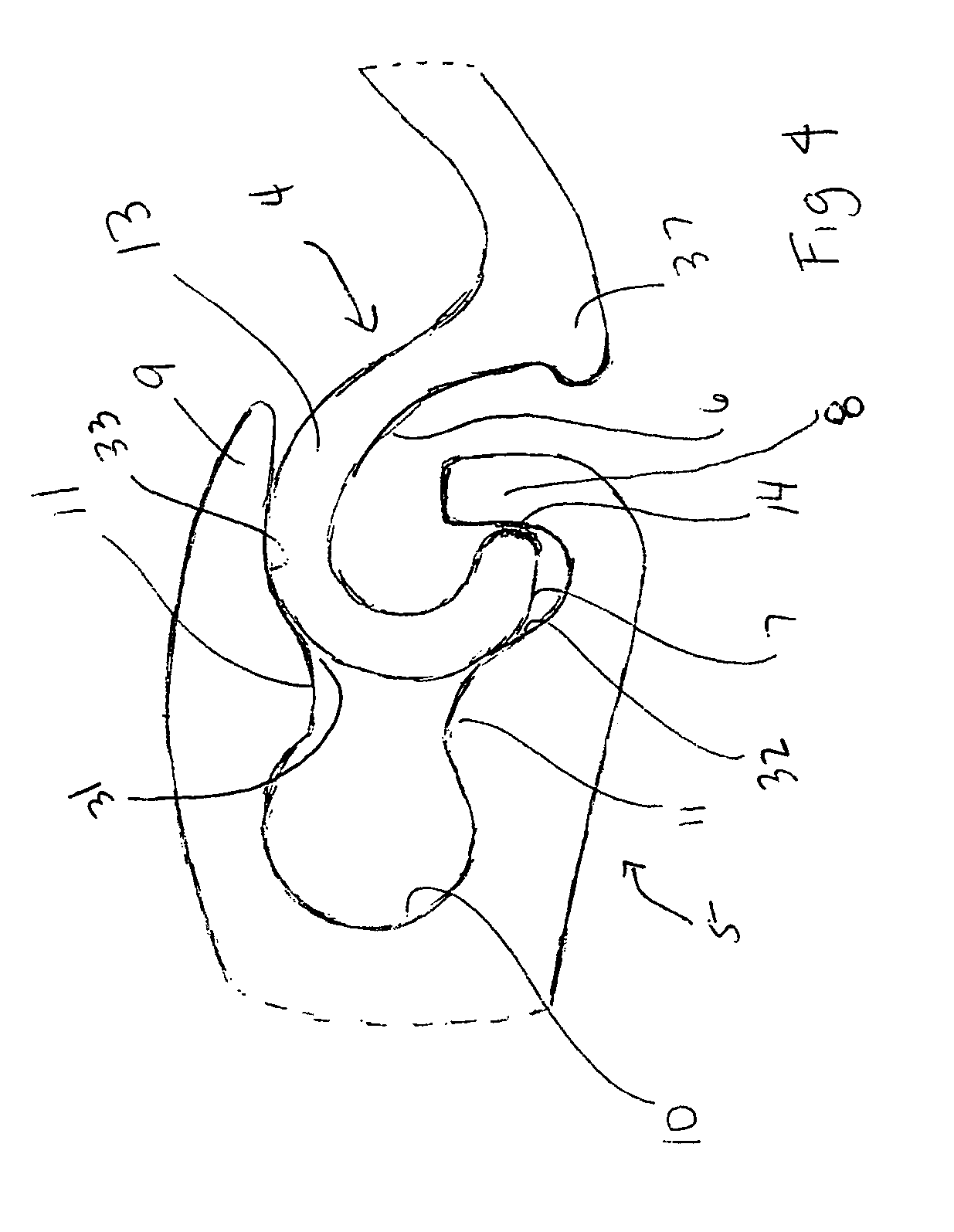

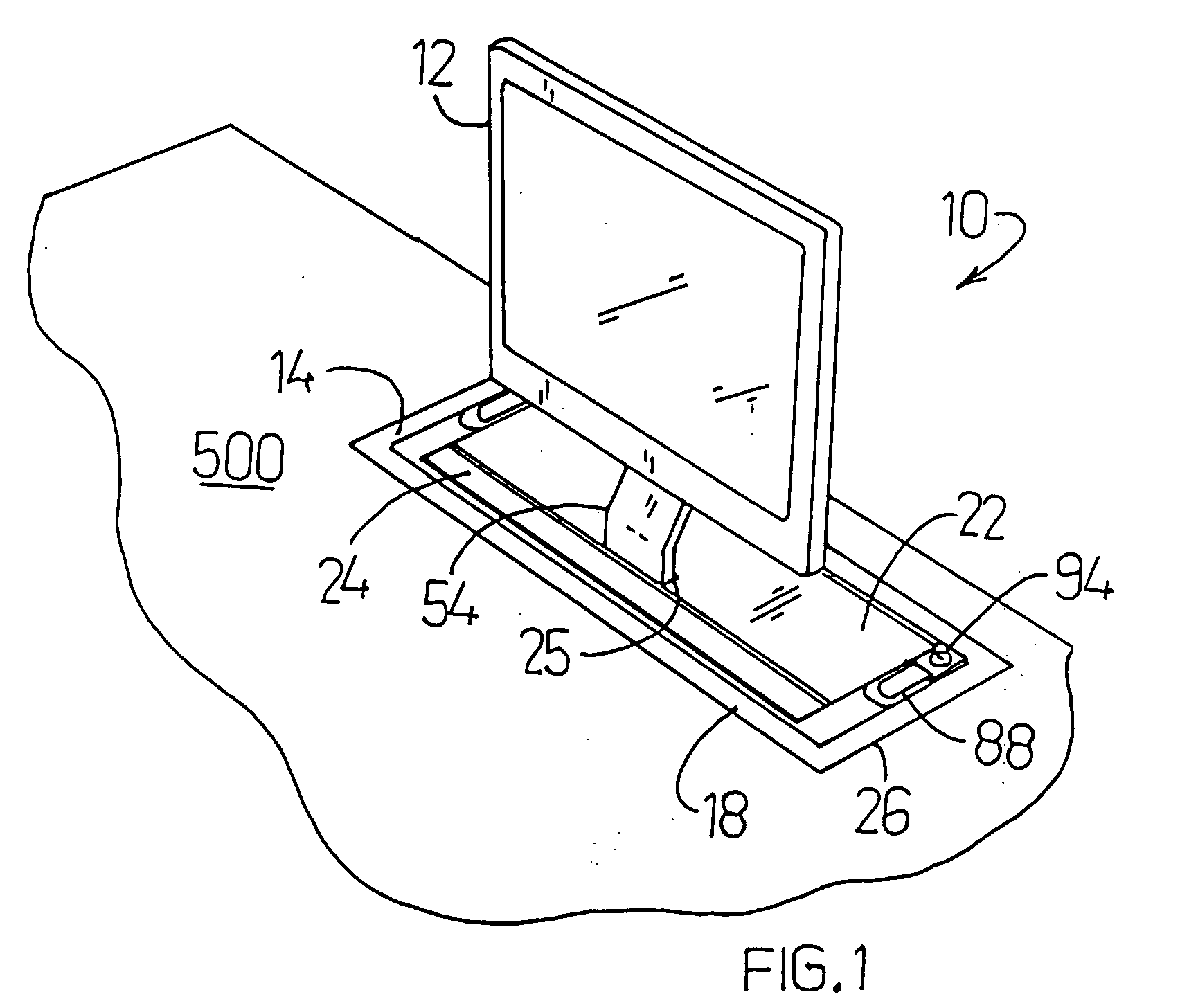

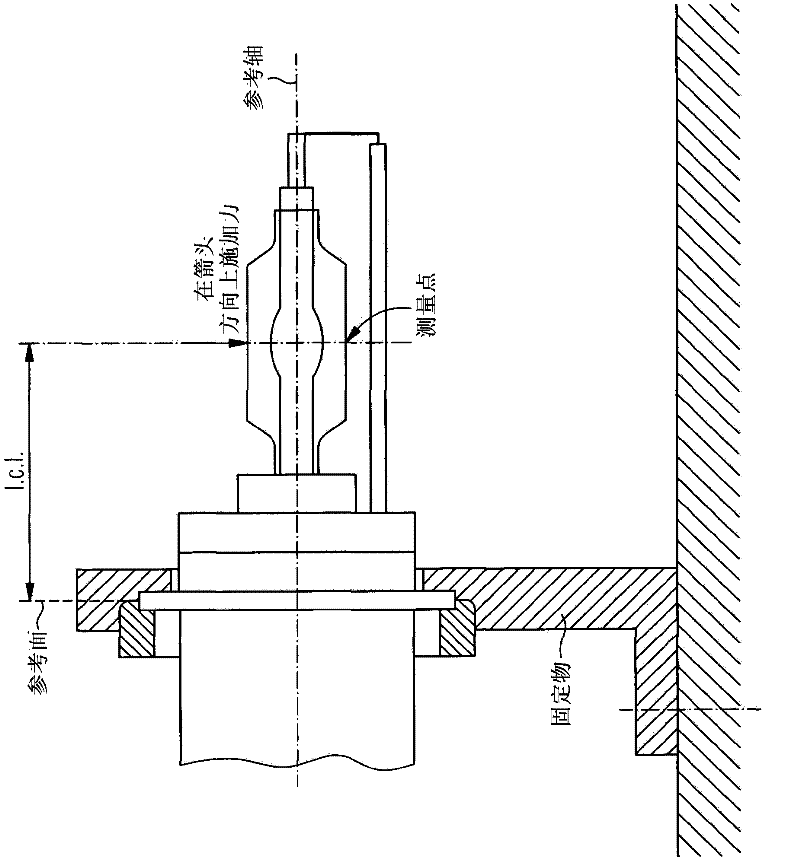

Extension and retraction arrangements

InactiveUS20060000955A1Without risk of damage to the article or an inadvertent retraction thereofExtend evenlyOffice tablesStands/trestlesConstant-force springConstant force

An extension and retraction arrangement for retaining a supported article, such as a monitor, in relation to a trolley structure that is retained for axial extension and retraction in relation to an elongate support arrangement. A support arm, which can be unitary, articulated, pivoting, or non-pivoting, can be coupled to the trolley structure. The trolley structure can have a centrally disposed alcove disposed inboard of first and second rail members of the elongate support arrangement. A subsurface enclosure can retain the rail members, and first and second doors can selectively close an aperture in a framework coupled adjacent to an end of the subsurface enclosure. Constant force springs can assist travel of the trolley structure and an arcuate braking member or compressing spring can provide a braking effect to the trolley structure

Owner:CVEK SAVA

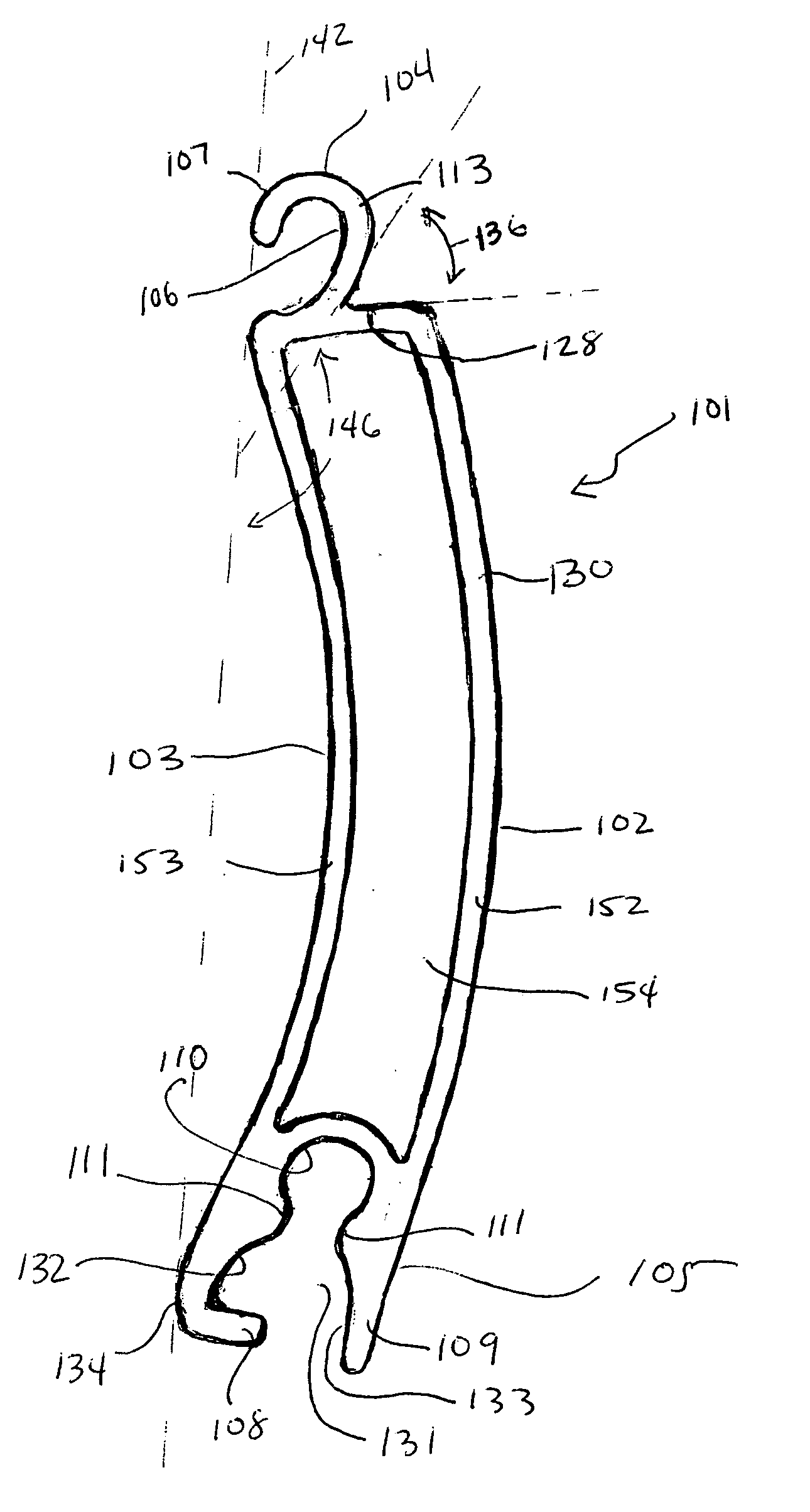

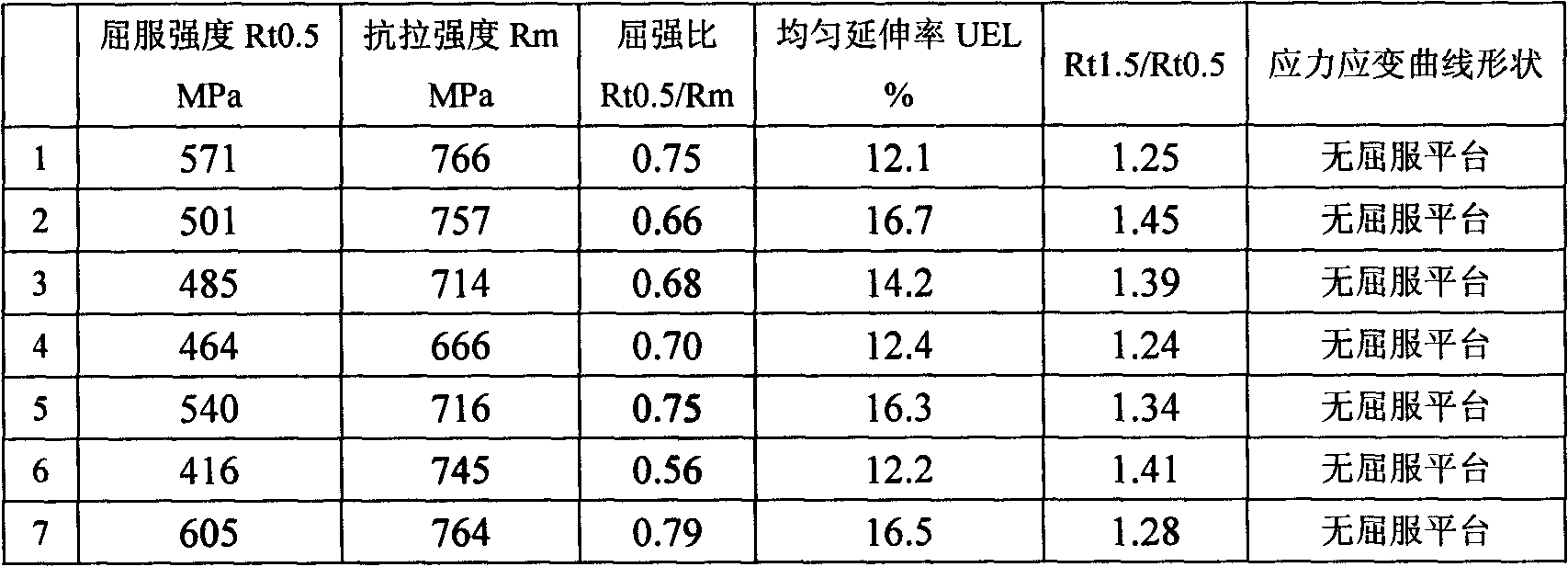

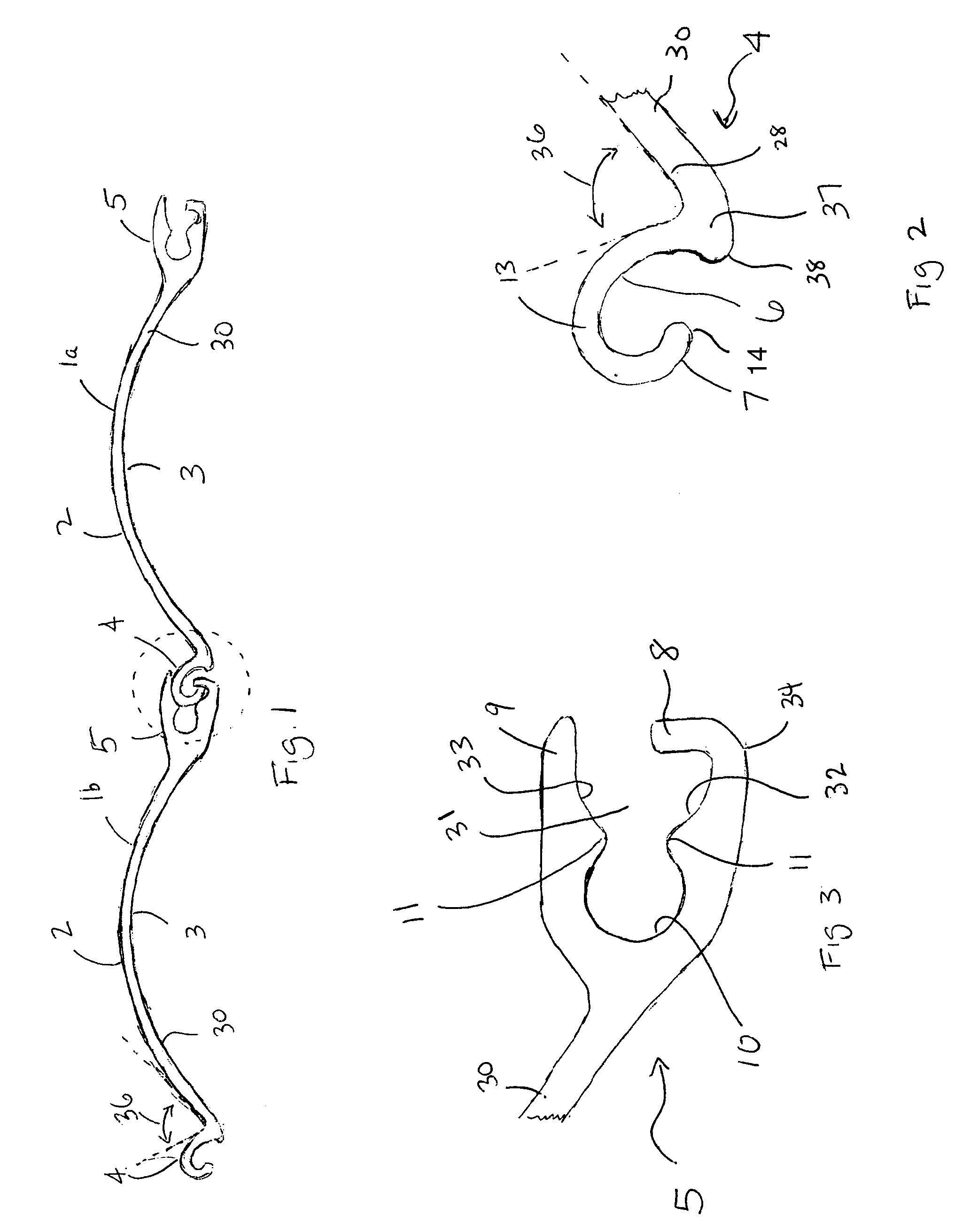

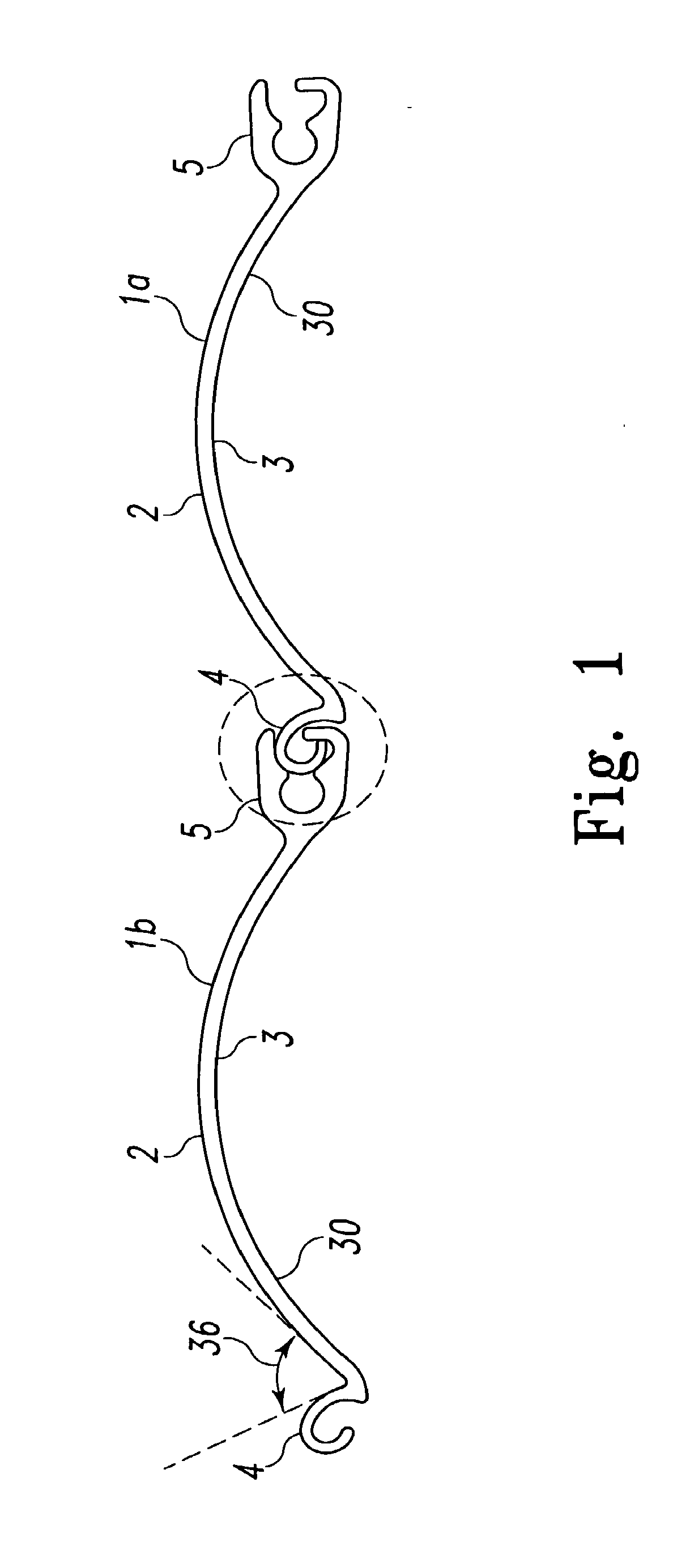

Locator and shutter slat

InactiveUS20050205223A1Less effortExtend evenlyShutters/ movable grillesWing framesAcute angleEngineering

A rolling shutter and a slat for use in a rolling shutter are provided. The slat comprises an engaging track located at a first edge and a receptacle track located at a second edge. Illustratively, the engaging track has a hook-shaped profile and is disposed at an acute angle relative to an adjacent part of the body portion, is disposed at an angle of less than 180° relative to a vertical axis of the slat, or has a hook-shaped profile that curves for more than 180°, and the receptacle track comprises a lip and a guard defining a space adapted to receive therein an engaging track of an adjacent slat.

Owner:QUALITAS MFG

Extension and retraction arrangements with control systems

ActiveUS7517029B2Without risk of damage to the article or an inadvertent retraction thereofExtend evenlyStands/trestlesKitchen equipmentRemote controlControl system

An extension and retraction arrangement with a trolley structure retained for axial extension and retraction relative to a rail arrangement and a control system with an actuating arrangement and a mechanism for selectively controlling a travel of the trolley structure. In a manual control system, the trolley structure can be mechanically engaged and disengaged in extended and retracted configurations by first and second locking projections respectively. An actuating rod can be actuated by a trigger to pivot the locking projections into and out of engagement with the trolley structure. The trigger can additionally enable a selective release of first and second doors from closed positions. A motorized control system can propel the trolley structure and open and close the doors. A lock and key, an access card and access card reader, or a remote control and remote control receiver can selectively enable operation of the control system.

Owner:CVEK SAVA

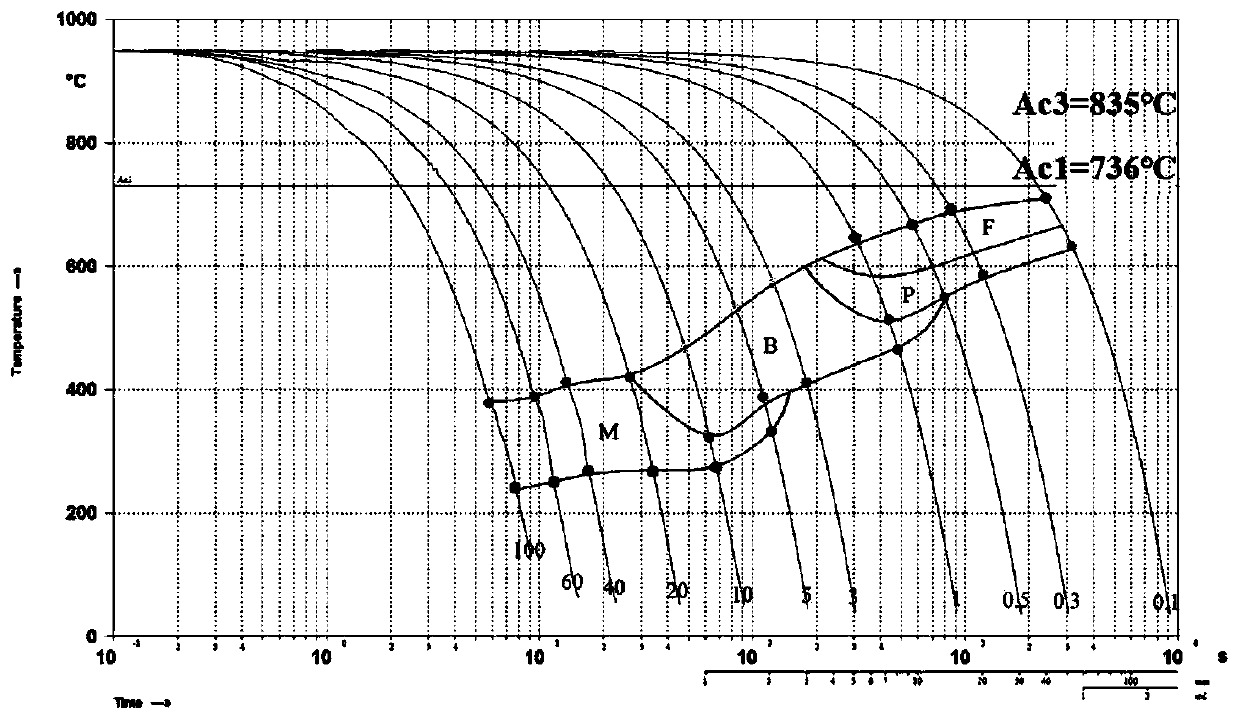

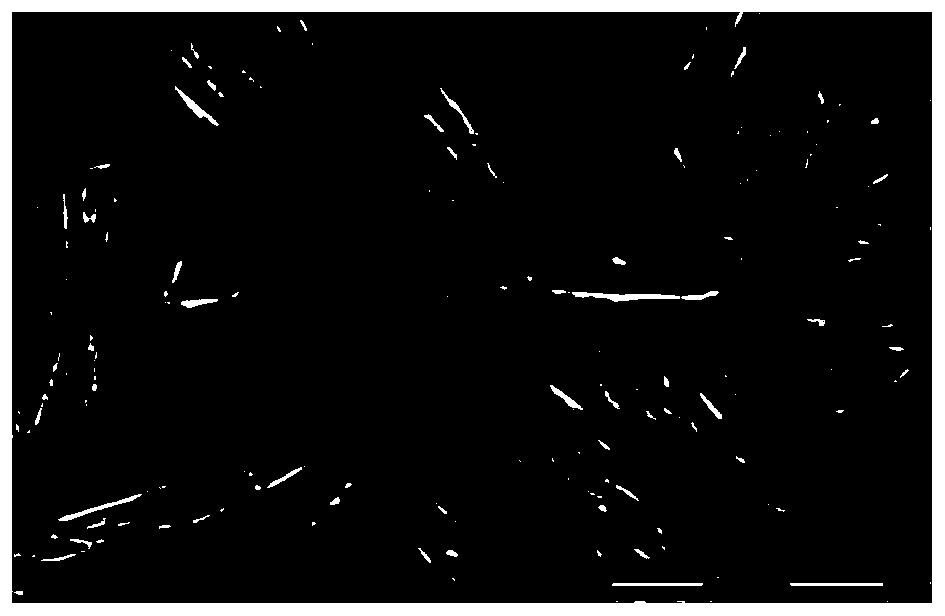

Nbc nanoparticle reinforced X80 plastic pipe steel plate and production method thereof

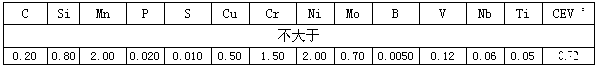

The invention provides an Nbc nanoparticle reinforced X80 plastic pipe steel plate and a production method of the Nbc nanoparticle reinforced X80 plastic pipe steel plate. The steel plate comprises, by weight percentage, 0.06%-0.12% of C, 0.10%-0.30% of Si, 0.60%-1.40% of Mn, 0.07%-0.15% of Nb, 0.001%-0.004% of N, 0.01%-0.04% of Ti, 0.025%-0.045% of Al, not larger than 0.010% of P, not larger than0.005% of S, not larger than 0.30% of Cu, not larger than 0.30% of Mo, 0.12%-0.30% of Cr, 0.12%-0.30% of Ni and the balance Fe and inevitable impurity elements. The production method comprises the steps of material preparation, converter or electric furnace smelting, secondary refining, casting, slab reheating, controlled rolling and controlled cooling. By the adoption of the produced steel plate, the safety of oil and gas transmission pipelines laid in geological complex areas is ensured, and the purposes of high-pressure transportation of natural gas and oil and the like are met.

Owner:ANGANG STEEL CO LTD

Polyvinyl alcohol film for diffuser

ActiveCN101033320AHigh strengthIncreased durabilityPolarising elementsLiquid-crystal displayPlasticizer

The invention relates to a polyvinyl alcohol membrane for the polarizing film, which is used to solve the problem of high-performance PVA film. The composition and weight of shares of the polyvinyl alcohol membrane: 10-30 units of PVA polymer, 5-25 units of plasticizer, 1-5 units of surfactant, 50 - 200 units of solvent. The PVA membrane has a high strength, good extension, which can be widely applied to liquid crystal display (LCD).

Owner:乐凯光电材料有限公司

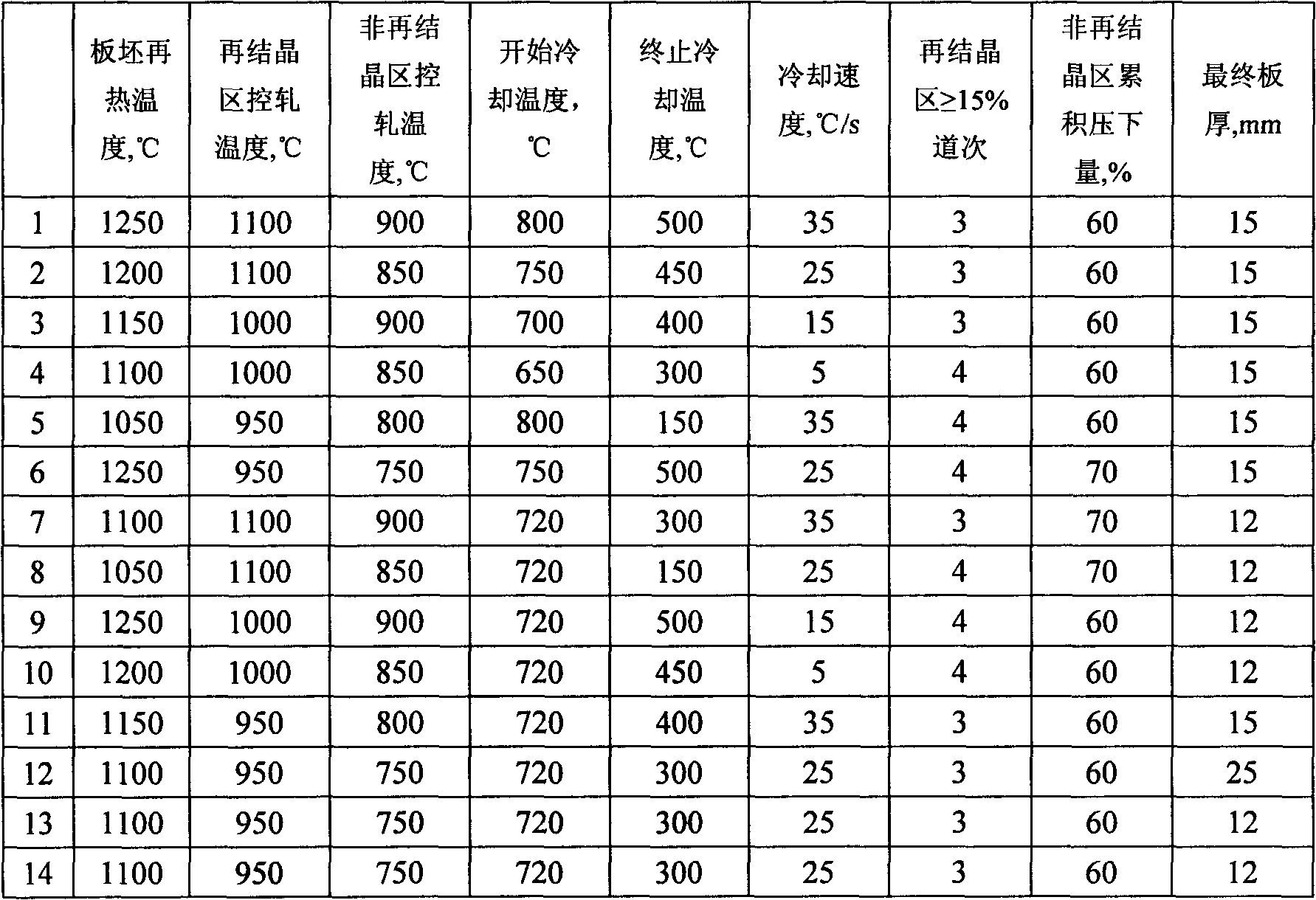

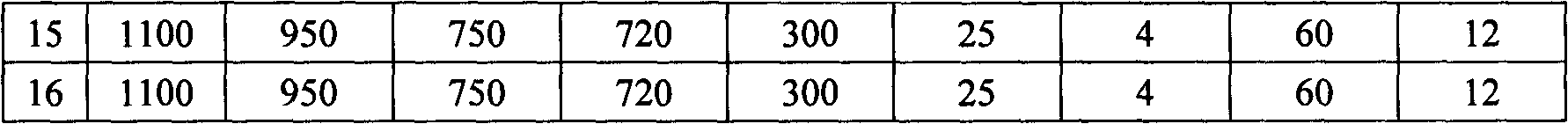

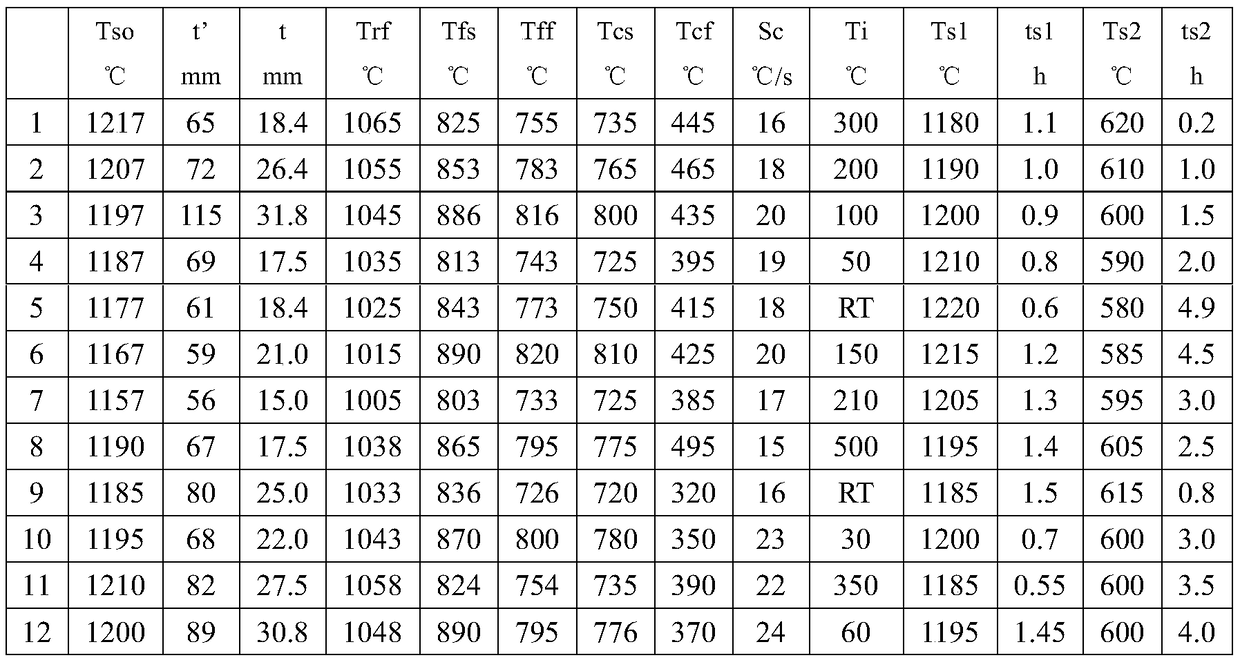

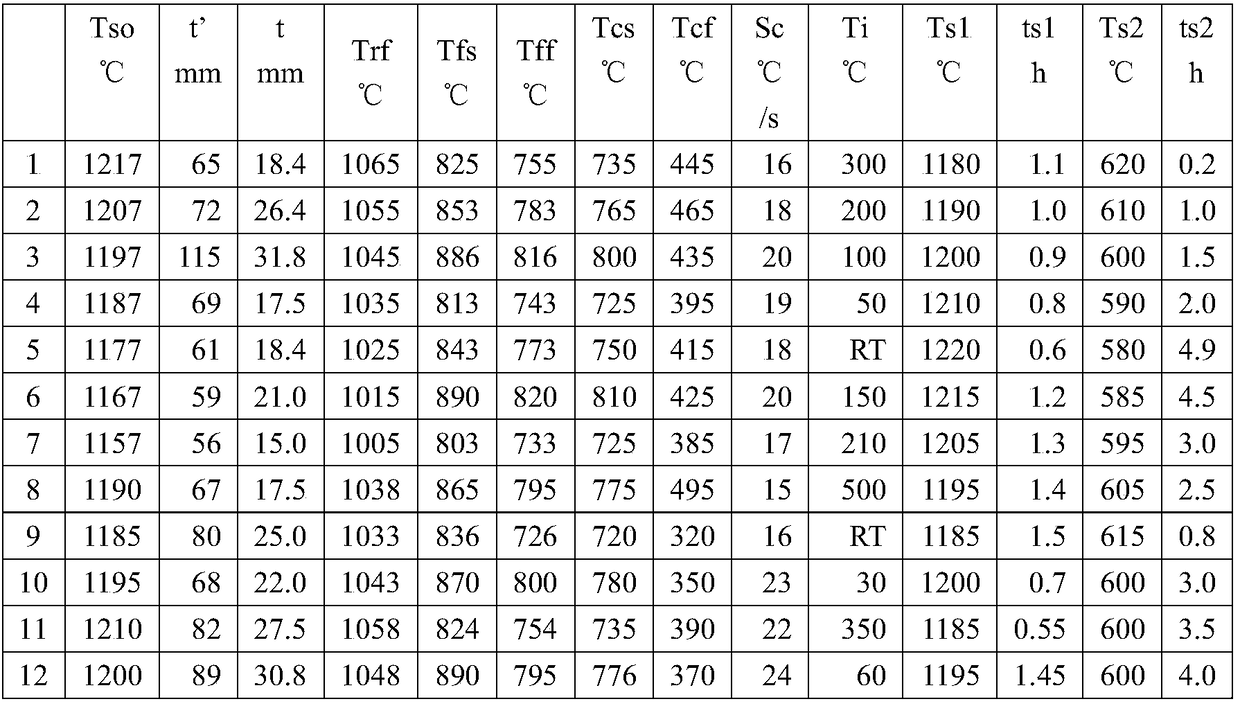

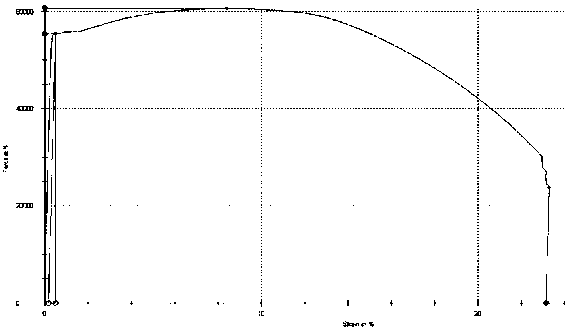

Strain design based pipe line steel X70 and its manufacturing method

ActiveCN102828125AExtend evenlyProper extensionTemperature control deviceImpurityHeating temperature

The invention discloses strain design based pipe line steel X70 and its manufacturing method. the steel comprises the following ingredients of: by weight, 0.06-0.10% of C, 0.1-0.6% of Si, 1.0-2.5% of Mn, P being less than or equal to 0.015%, S being less than or equal to 0.003%, Cr being less than 0.1%, 0.05-0.35% of Mo, 0.01-0.15% of Nb, 0.005-0.03% of Ti, 0.01-0.06% of Al, one or two components selected from 0-0.5% of Cu and 0-0.5% of Ni, and the balance Fe and unavoidable microscale impurities. The manufacturing method is characterized in that slab heating temperature is 1050-1280 DEG C by a controlled rolling and controlled cooling method; the temperature for controlled rolling in a recrystallization zone is controlled within the range of 900-1250 DEG C; the temperature for controlled rolling in a non-recrystallization zone is controlled within the range of 700-950 DEG C; initial cooling temperature is 650-800 DEG C; finish cooling temperature is 100-500 DEG C; and cooling rate is 5-35 DEG C / s. According to the invention, elements of V, B and the like are not added, and the total amount of Mo, Cu, Cr and Ni is low. In addition, subsequent heat treatment is not required, the process is simple and requires low cost, and production efficiency is high.

Owner:ANGANG STEEL CO LTD

Locator and shutter slat

InactiveUS7784522B2Less effortExtend evenlyShutters/ movable grillesWing framesAcute angleEngineering

A rolling shutter and a slat for use in a rolling shutter are provided. The slat comprises an engaging track located at a first edge and a receptacle track located at a second edge. Illustratively, the engaging track has a hook-shaped profile and is disposed at an acute angle relative to an adjacent part of the body portion, is disposed at an angle of less than 180° relative to a vertical axis of the slat, or has a hook-shaped profile that curves for more than 180°, and the receptacle track comprises a lip and a guard defining a space adapted to receive therein an engaging track of an adjacent slat.

Owner:QUALITAS MFG

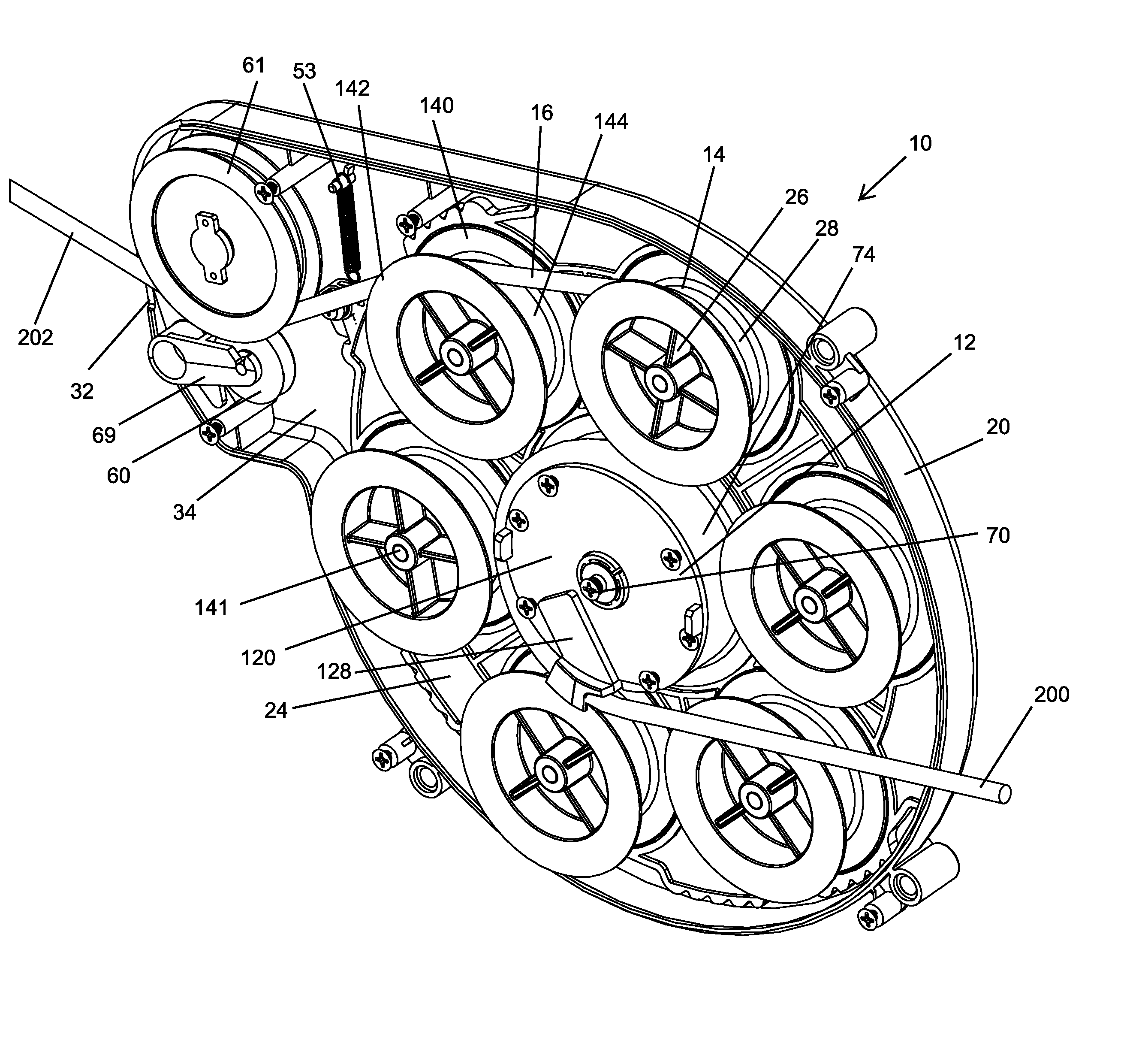

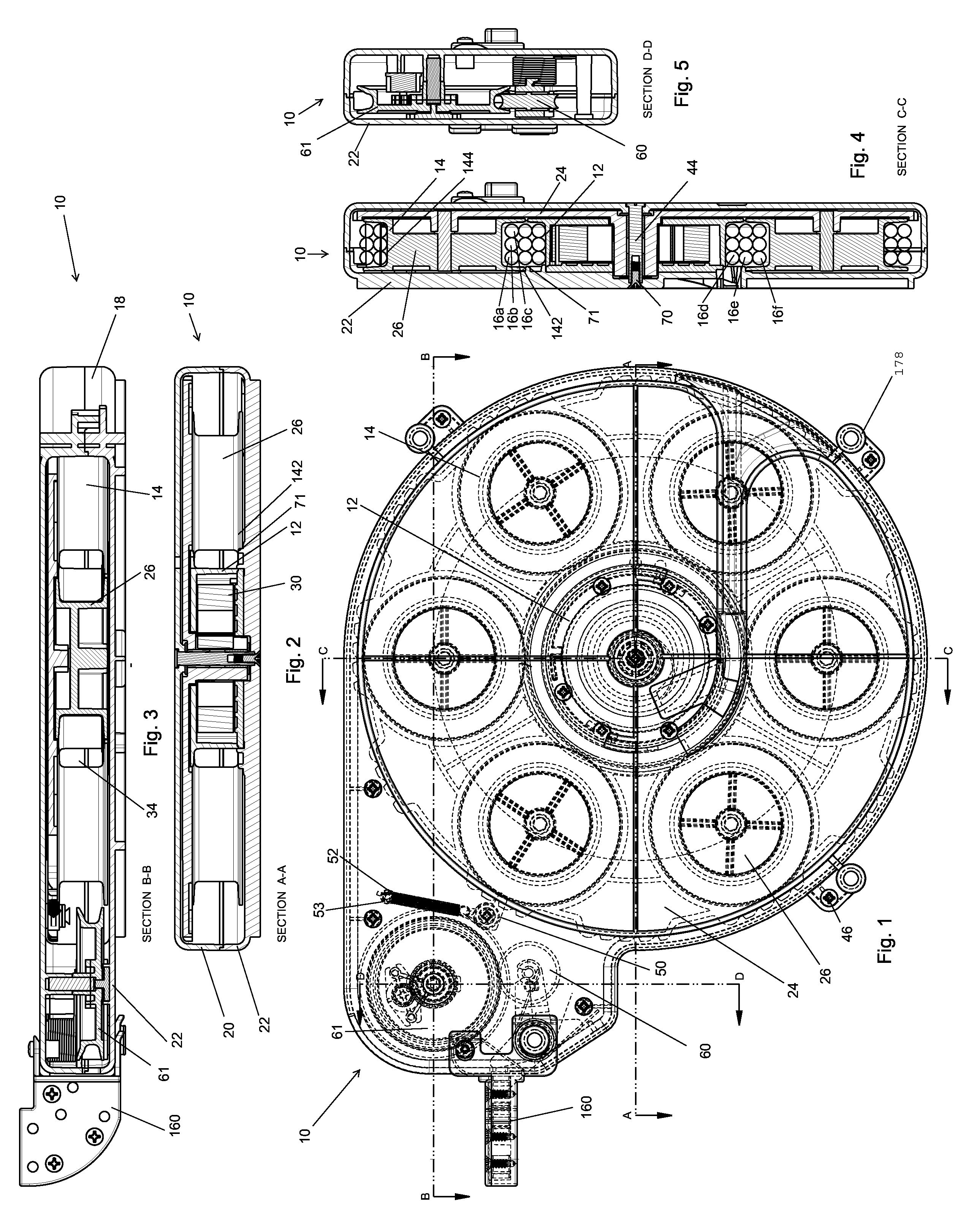

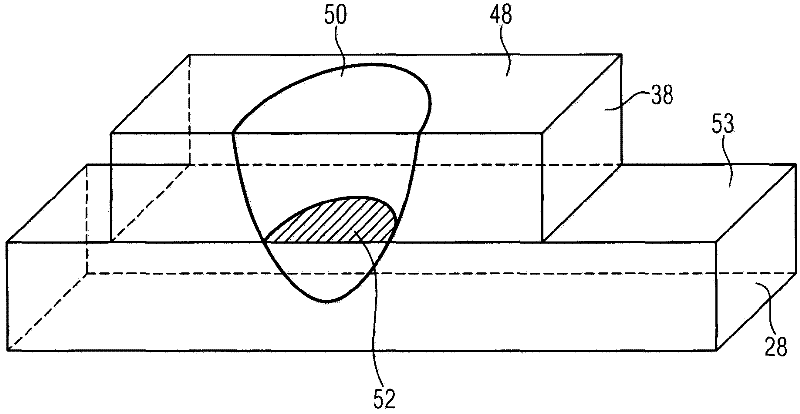

Trolley and rail systems for extension and retraction arrangements

InactiveUS20060102812A1Without risk of damage to the article or an inadvertent retraction thereofExtend evenlyPortable framesInstrument housingConstant forceEngineering

A trolley and rail system for use in relation to an extension and retraction arrangement with a trolley structure retained for axial extension and retraction along a body portion of a rail arrangement comprising first and second rails disposed in substantially parallel spaced orientation. The trolley structure can have a central portion and first and second wing portions with load bearing wheels for rolling along rigid bearing surfaces of the first and second rails. The bearing surfaces and the wheels can have correspondingly contoured profiles. The trolley structure can have a ventrally disposed alcove. Constant force springs can assist in a travel of the trolley structure in relation to the rail arrangement. The trolley structure or a support arm coupled thereto can have threaded mounting holes for retaining a flat panel monitor.

Owner:CVEK SAVA

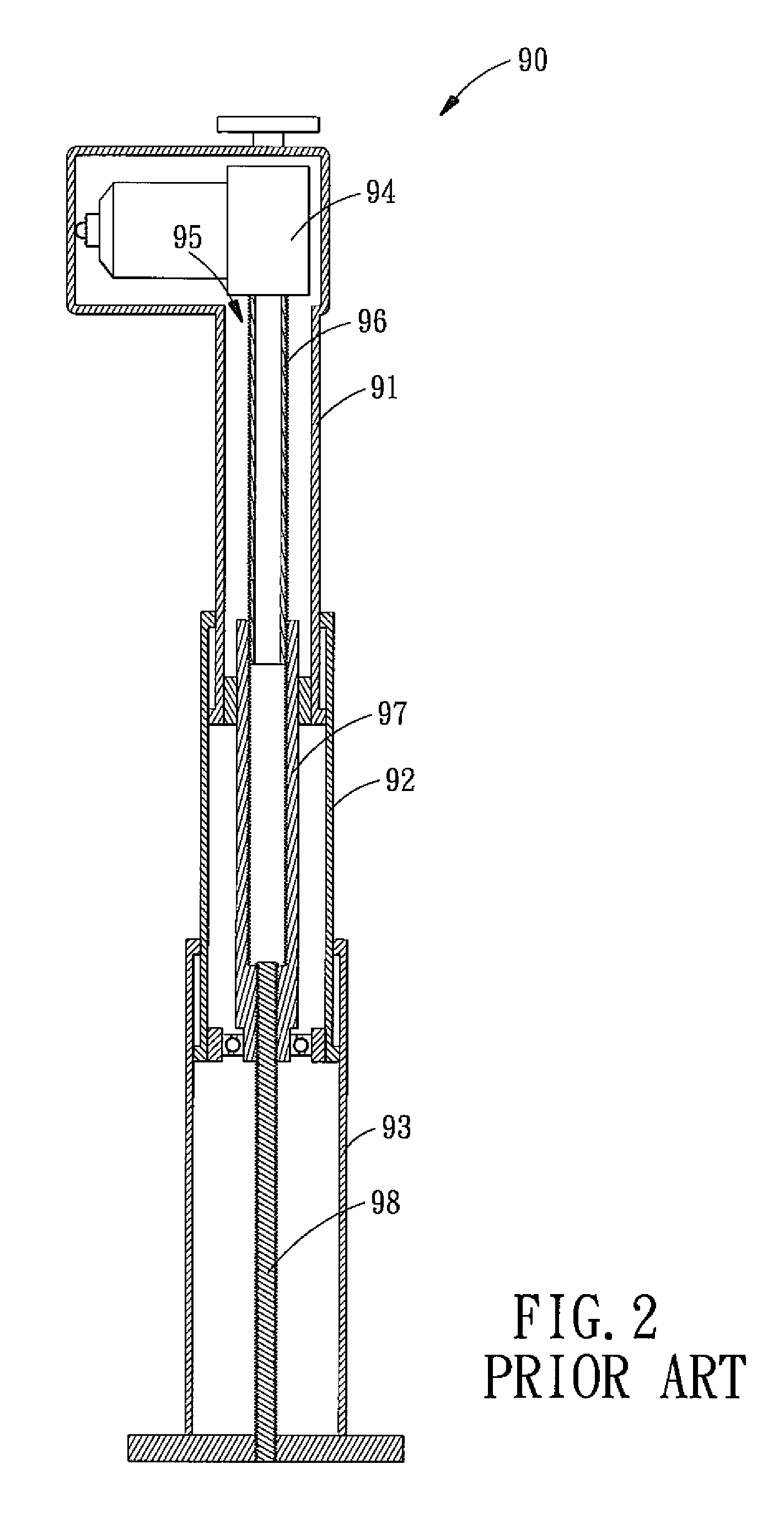

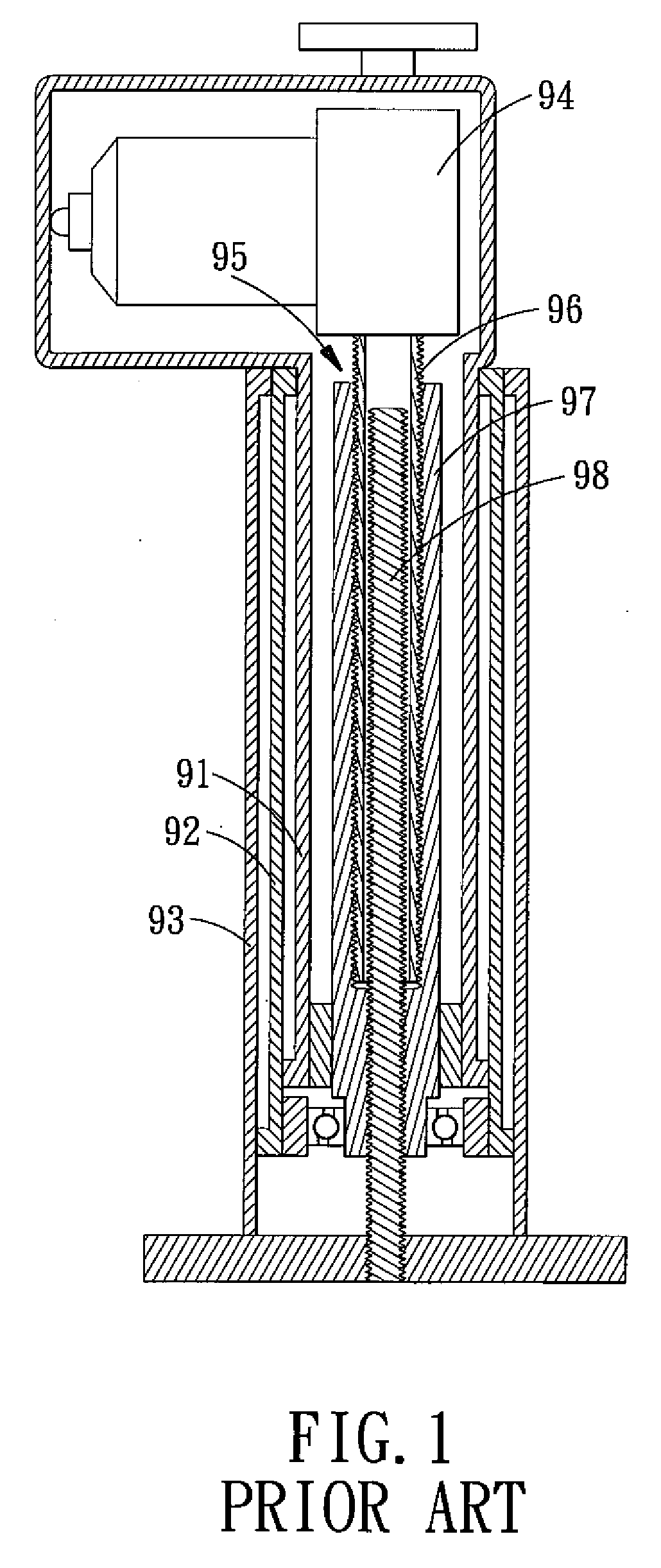

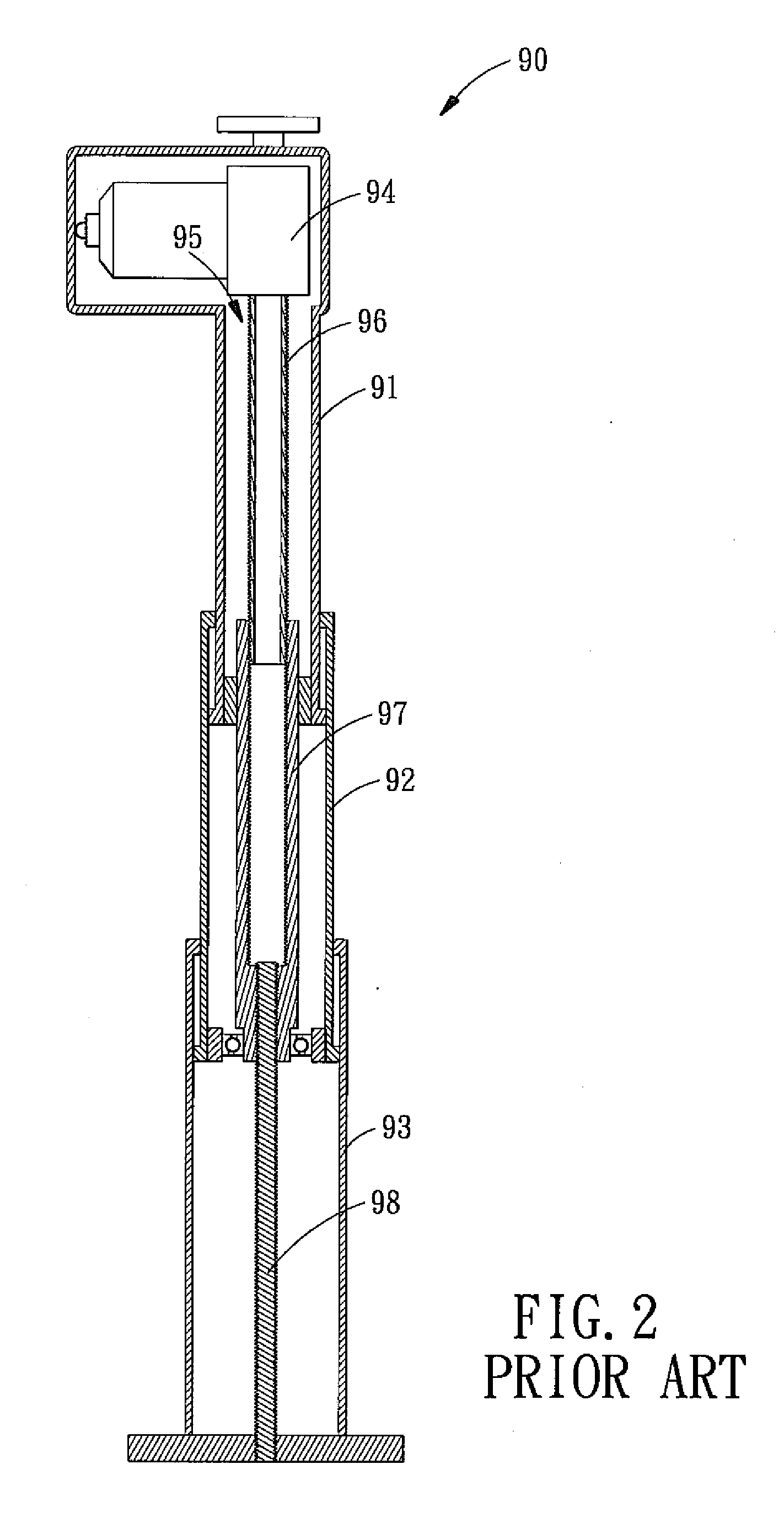

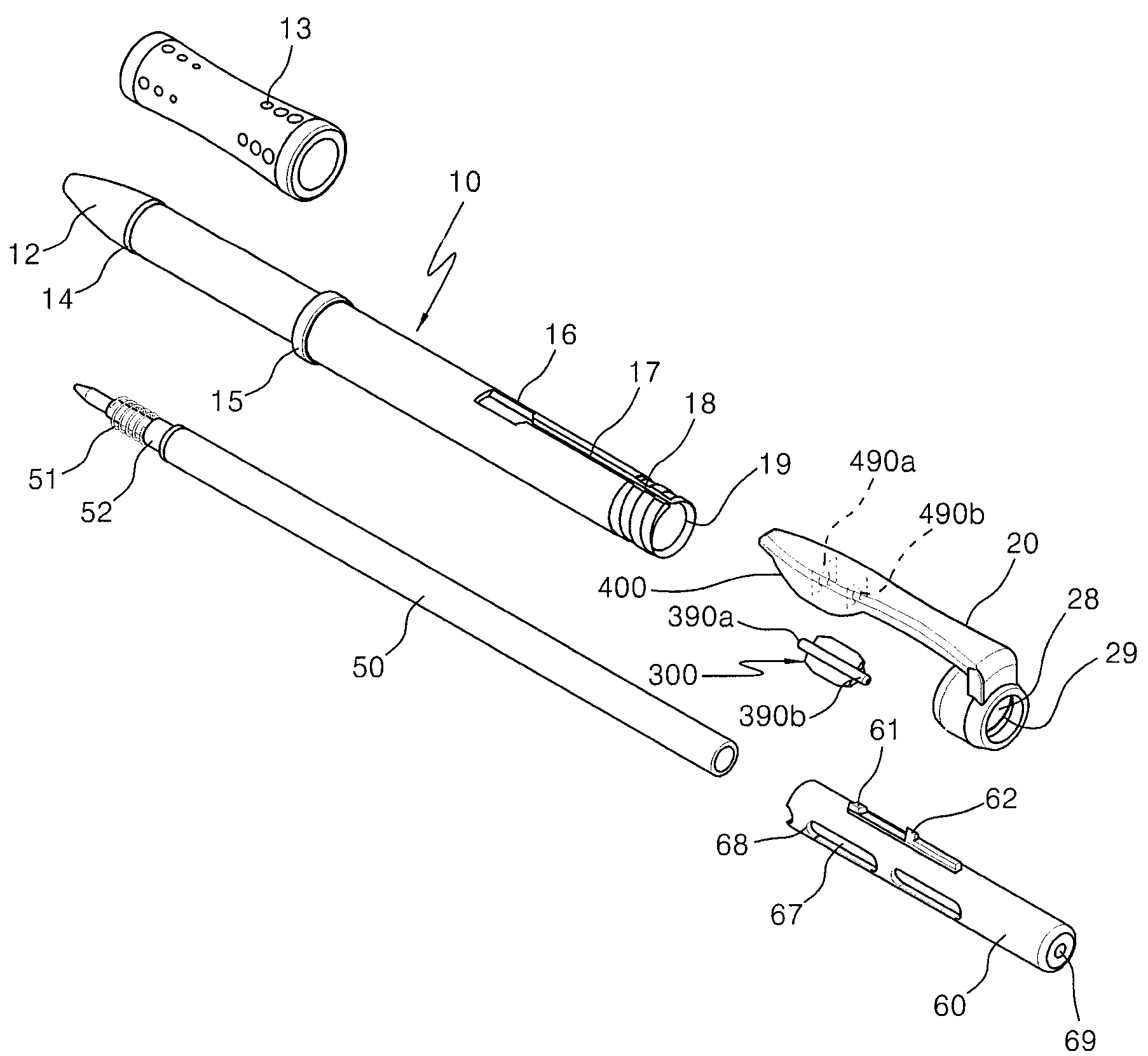

Linear actuator

InactiveUS7752932B2Easy to moveExtend evenlyToothed gearingsStands/trestlesEngineeringLinear actuator

A linear actuator is provided with an outer tube, an intermediate tube and an inner tube, and the tubes are all polygonal in cross section and are mounted orderly. The outer tube is disposed at the bottom thereof with a push device which has a screw and a nut that are screwed with each other. The nut is engaged in the intermediate tube and is linked to move axially by the screw. The intermediate tube can be movably equipped with a pulling member, and the pulling member can link the inner tube to synchronously move in the axial direction. By such arrangements, the linear actuator allows the respective tubes to extend and retract axially relative to one another while preventing them from moving relative to one another in radial direction, thus achieving the stable and smooth axial movement.

Owner:HIWIN MIKROSYST

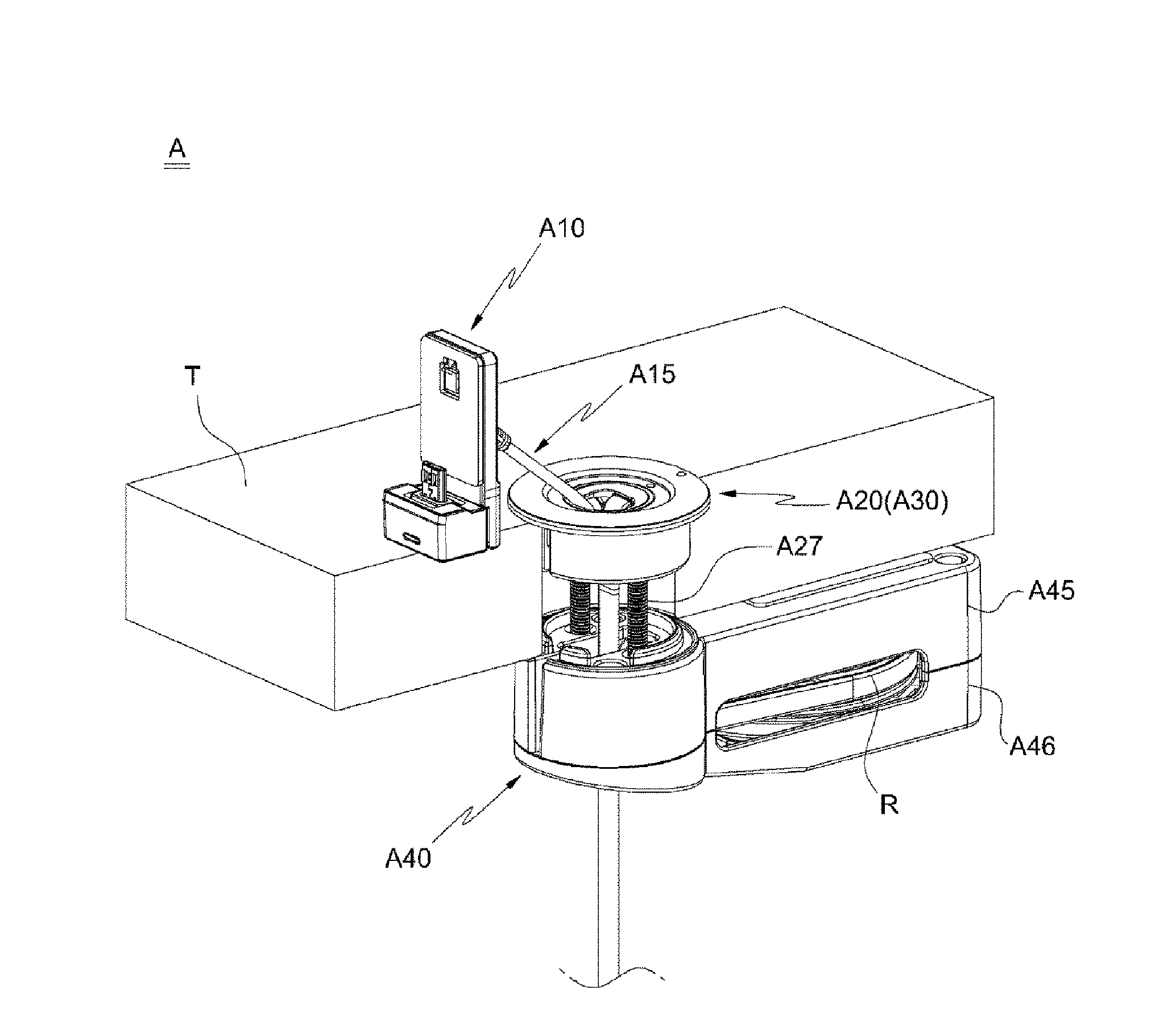

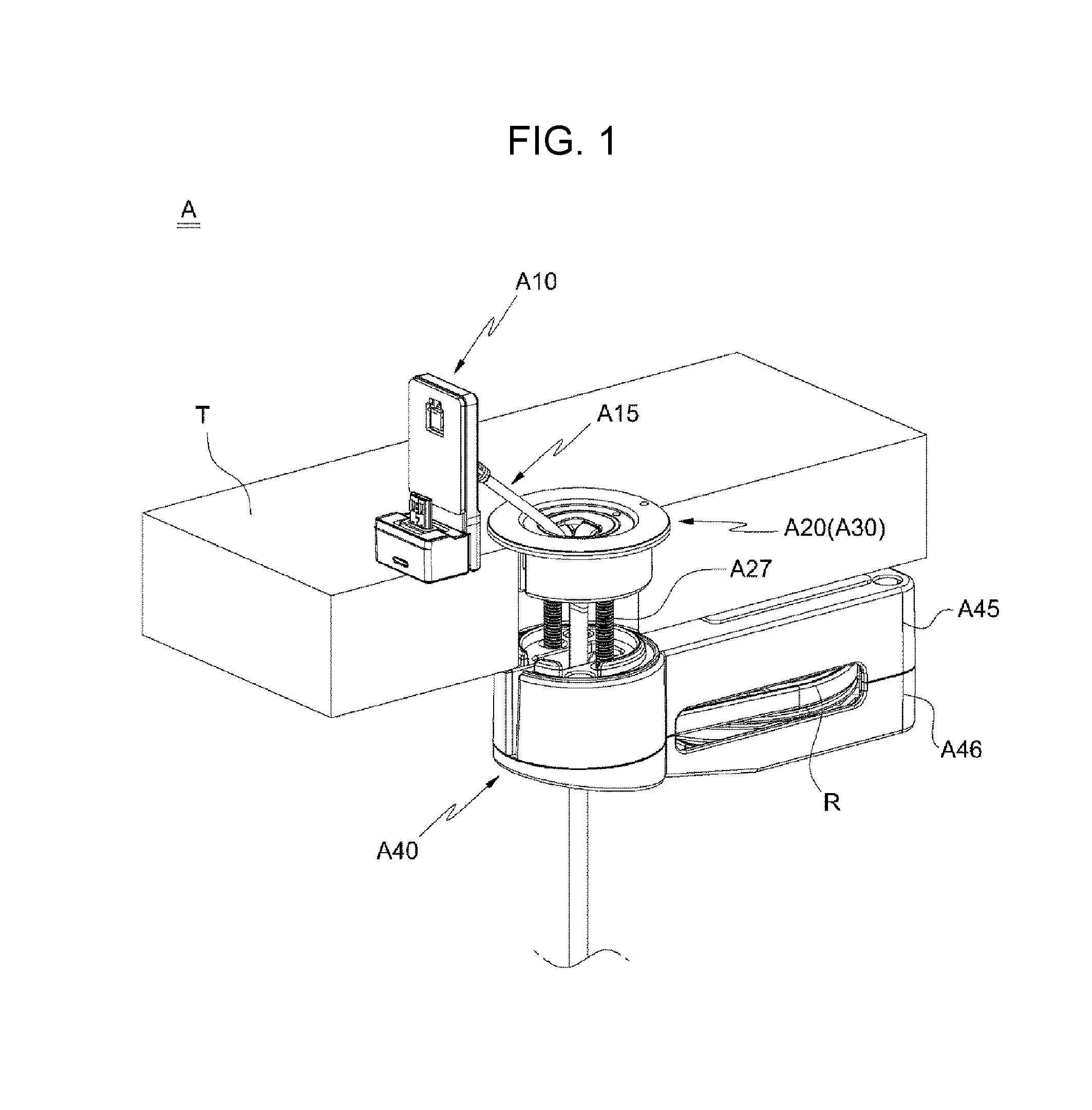

Cable retraction unit assembly

ActiveUS9499373B1Prevent twistingAvoid breakingArrangements using take-up reel/drumBurglar alarmMobile deviceElectric cables

Provided is a cable retraction unit assembly connected to a table for displaying a mobile device. The cable retraction unit assembly includes: a cable connected to a mobile device; a guide housing and a withdrawal unit respectively mounted to an upper portion and a lower portion of a table, with the cable penetrating through the guide housing and the withdrawal unit; and a guide unit rotatably provided within the guide housing, wherein the guide unit is configured to rotate in response to a rotating direction of the cable when the cable rotates, thereby being capable of preventing twisting or breaking of the cable.

Owner:KUM OH ELECTRONICS

Linear Actuator

InactiveUS20090249905A1Easy to moveExtend evenlyToothed gearingsStands/trestlesEngineeringLinear actuator

A linear actuator comprises an outer tube, an intermediate tube and an inner tube, and the tubes are all polygonal in cross section and are mounted orderly. The outer tube is disposed at the bottom thereof with a push device having a screw and a nut that are screwed with each other. The nut is engaged in the intermediate tube and is linked to move axially by the screw. The intermediate tube can be movably equipped with a pulling member, and the pulling member can link the inner tube to synchronously move in the axial direction. By such arrangements, the linear actuator allows the respective tubes to extend and retract axially relative to one another while preventing them from moving relative to one another in radial direction, thus achieving the stable and smooth axial movement.

Owner:HIWIN MIKROSYST

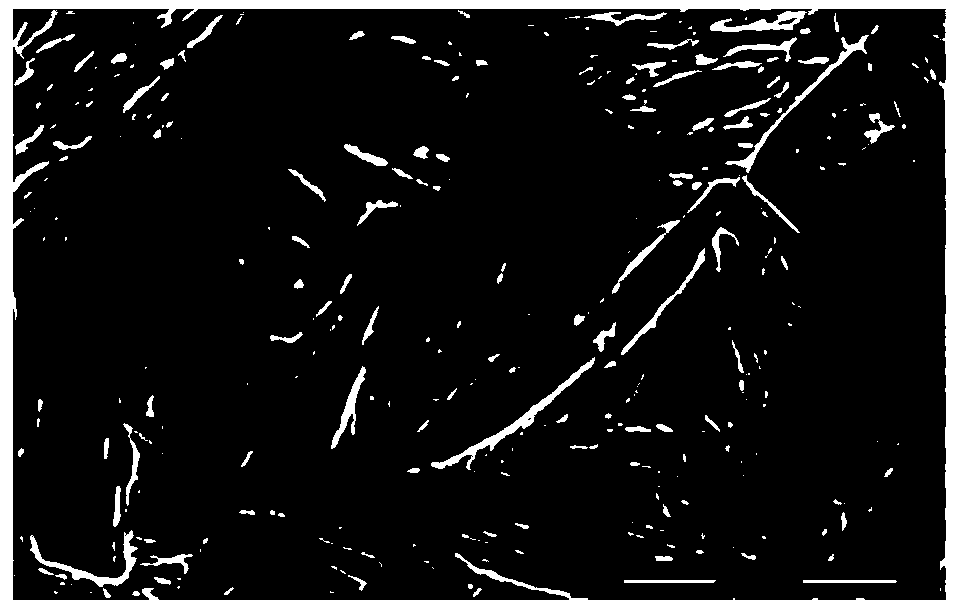

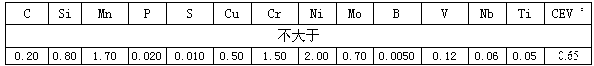

Wear-resistant steel with good forming performance for dumper carriage body and production method thereof

ActiveCN110964979AGood molding performanceEnsure consistencySteel platesMechanical properties of carbon nanotubes

The invention discloses wear-resistant steel with good forming performance for a dumper carriage body. Weight percentages of chemical components of the wear-resistant steel are as follows, 0.16-0.22%of C; 0.15-0.35% of Si; 0.90-1.30% of Mn; less than or equal to 0.018% of P, less than or equal to 0.010% of S, 0.020-0.060% of Als; 0.020-0.060% of Nb; 0.012-0.028% of Ti, 0.30-0.70% of Cr, 0.10-0.20% of Mo, 0.0005-0.0018% of B, less than or equal to 0.0025% of O, less than or equal to 0.0050% of N, less than or equal to 1.8 ppm of H and the balance of Fe and inevitable impurities. In the production method, the controlled rolling process comprises the rough rolling process, and austenite recrystallization zone deformed austenite grain uniformity control is carried out in the rough rolling process, and the pass reduction rate is controlled to gradually increase. The wear-resistant steel is advantaged in that the microstructure of the base plate is mainly composed of fine lath martensite, martensite lath size and mechanical property through plate distribution are uniform, a steel plate uniformly extends in all directions during stretching, cutting and U-shaped bending, consistency of machining and forming is guaranteed, straightness of the steel plate ranges from 1 mm / 2 m to 4 mm / 2 m after the steel plate is cut into narrow strips, straightness of a bent end is not larger than 3 mmafter the steel plate is bent in a U shape, and good forming performance is achieved.

Owner:HANDAN IRON & STEEL GROUP +2

Locator and shutter slat

A rolling shutter and a slat for use in a rolling shutter are provided. The slat comprises an engaging track located at a first edge and a receptacle track located at a second edge. Illustratively, the engaging track has a hook-shaped profile and is disposed at an acute angle relative to an adjacent part of the body portion, is disposed at an angle of less than 180° relative to a vertical axis of the slat, or has a hook-shaped profile that curves for more than 180°, and the receptacle track comprises a lip and a guard defining a space adapted to receive therein an engaging track of an adjacent slat.

Owner:QUALITAS MFG

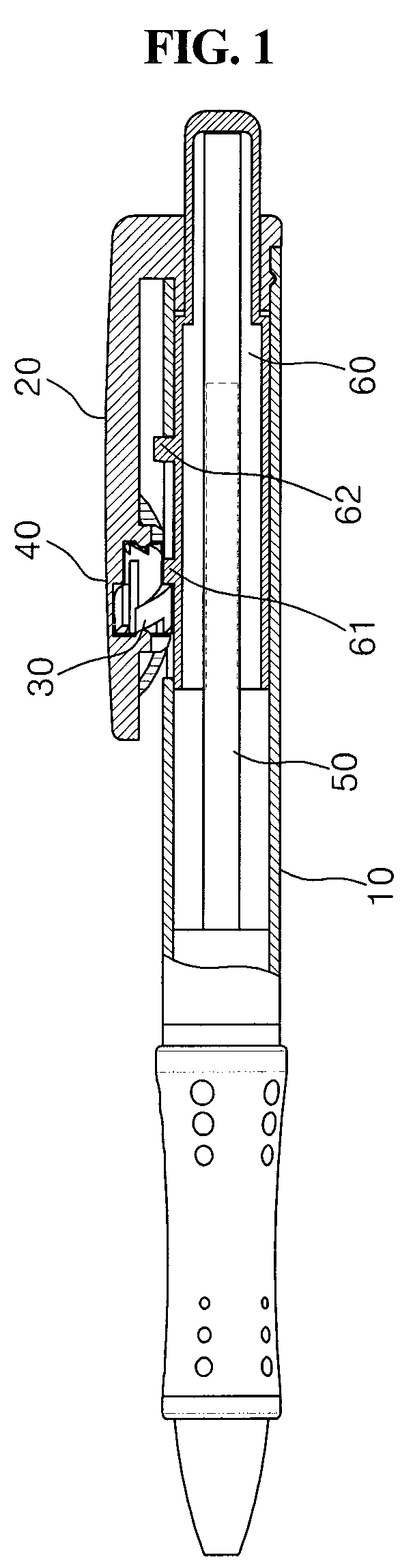

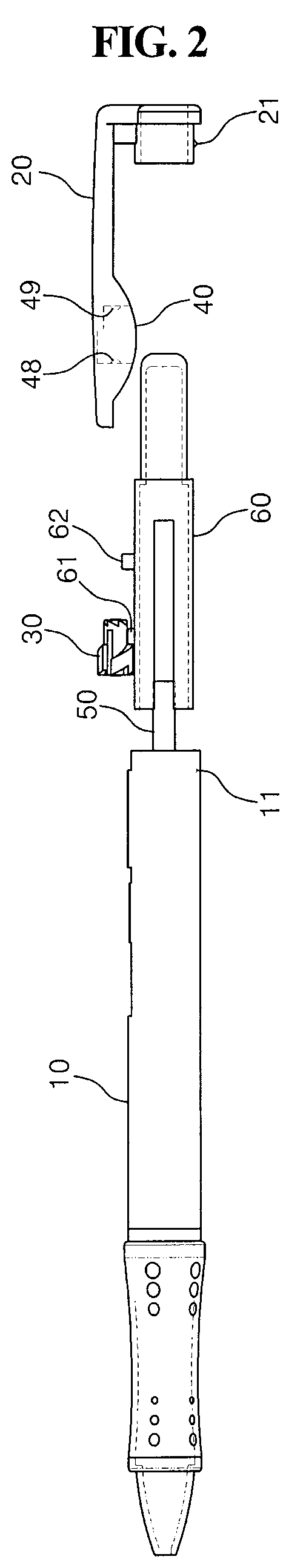

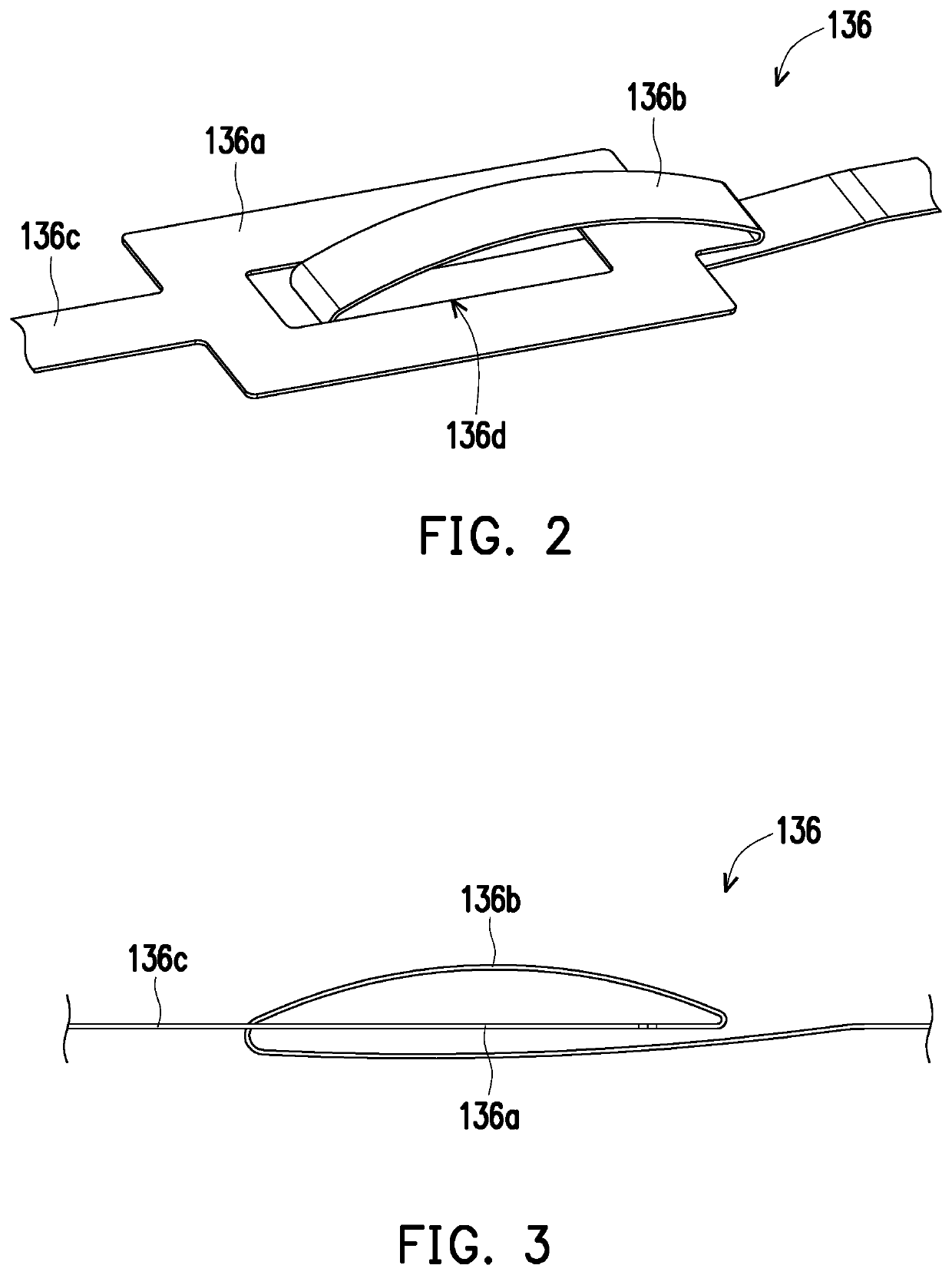

Safety knock-type writing instrument

InactiveUS7581896B2Increase contact areaEnhanced couplingBall-point pensInk reservoir pensMechanical engineering

The object of this invention is to provide a safety knock-type writing instrument. The writing instrument includes a barrel (10) with a cartridge (50), a gear unit (30), and a knock unit (60). The gear unit (30) is positioned on an exterior of the barrel (10) and rotatably seated on a clip (20). The knock unit (60) is provided in the barrel (10), and includes first and second protrusions (61, 62) to engage with the gear unit (30), thus operating the gear unit. In this writing instrument, when the first protrusion (61) of the knock unit disengages from the gear unit (30), the cartridge is retracted into the barrel. Thus, although a user puts the writing instrument, with the cartridge extended, in a pocket without first retracting the cartridge, the cartridge is automatically retracted into the barrel, thus preventing his / her clothing from being stained by the cartridge.

Owner:MORRIS CORP

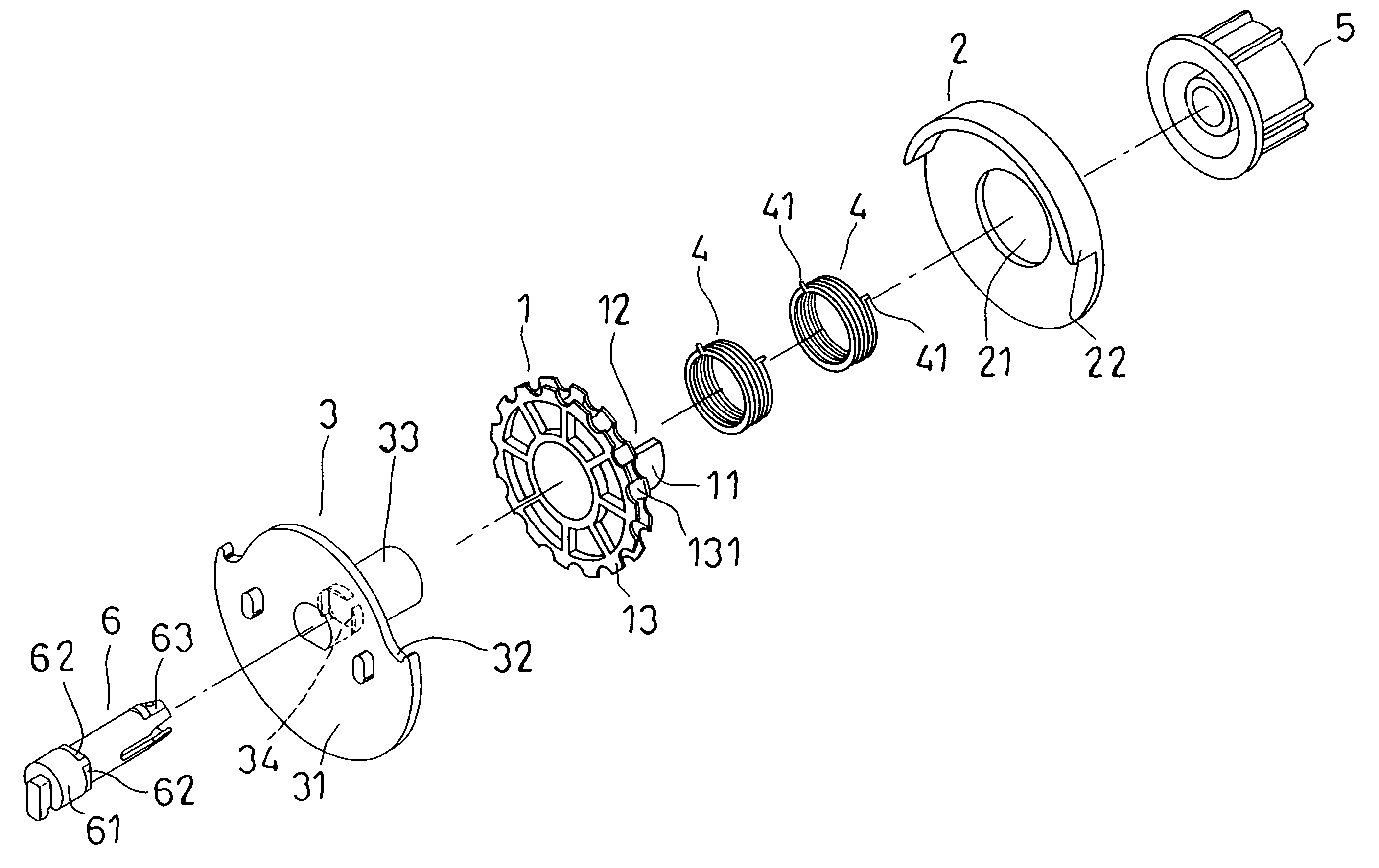

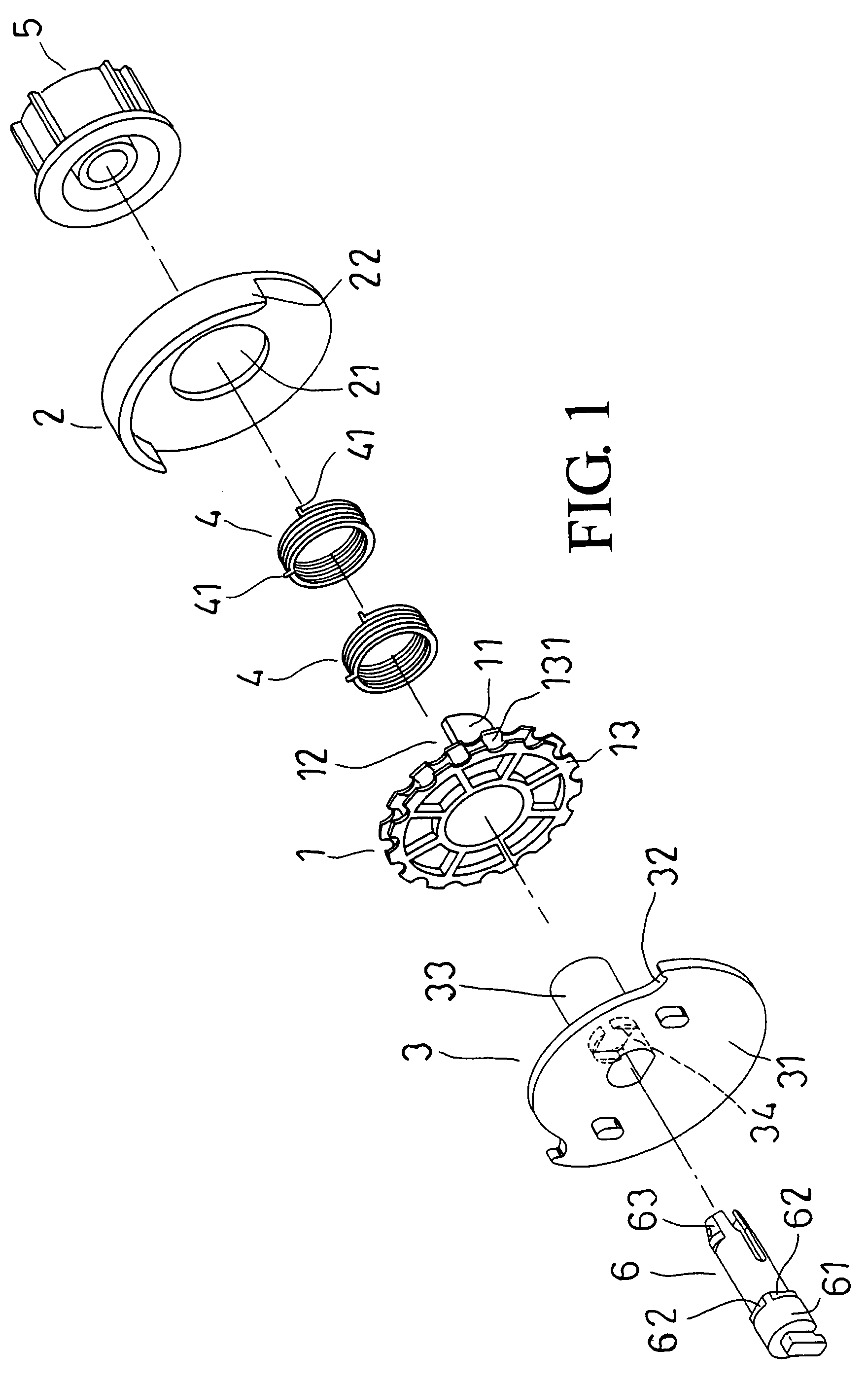

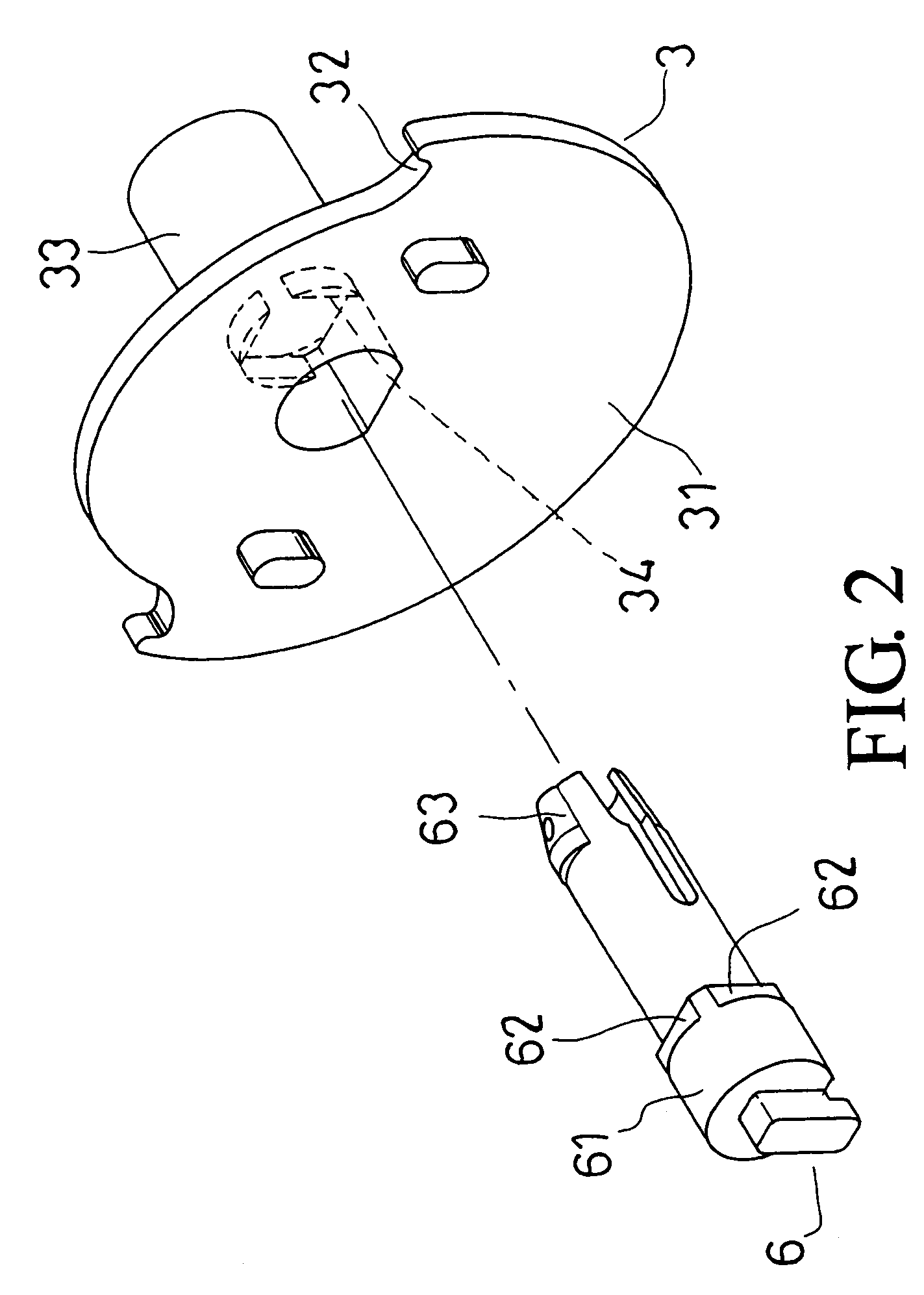

Roll screen control member

InactiveUS8156993B2Extended or retractedDrive precisionScreensShutters/ movable grillesSprocketEngineering

Owner:UNI-SOLEIL ENT CO LTD

VC nanoparticle-strengthened X90 steel plate for plastic pipe, and manufacturing method thereof

ActiveCN109023068AReduce manufacturing costGood anti-HIC performanceSteel platesMaterials preparation

The invention provides a VC nanoparticle-strengthened X90 steel plate for a plastic pipe, and a manufacturing method thereof. The steel plate comprises the following components in percentage by weight: 0.06%-0.12% of C, 0.10%-0.30% of Si, 0.60%-1.40% of Mn, 0.07%-0.15% of V, 0.001%-0.004% of N, 0.01%-0.04% of Ti, 0.025%-0.045% of Al, not greater than 0.010% of P, not greater than 0.005% of S, 0.10%-0.30% of Cu, 0.10%-0.30% of Mo, 0.10%-0.30% of Cr, 0.10%-0.30% of Ni and the balance Fe and inevitable impurity elements. The manufacturing method comprises the following steps: material preparation, converter or electric furnace smelting, external refining, casting, plate blank reheating, controlled rolling and controlled cooling. The steel plate produced by the manufacturing method meets the various mechanical property requirements of the X90 steel plate for the plastic pipe, and is especially high in low-temperature toughness and anti-HIC property.

Owner:ANGANG STEEL CO LTD

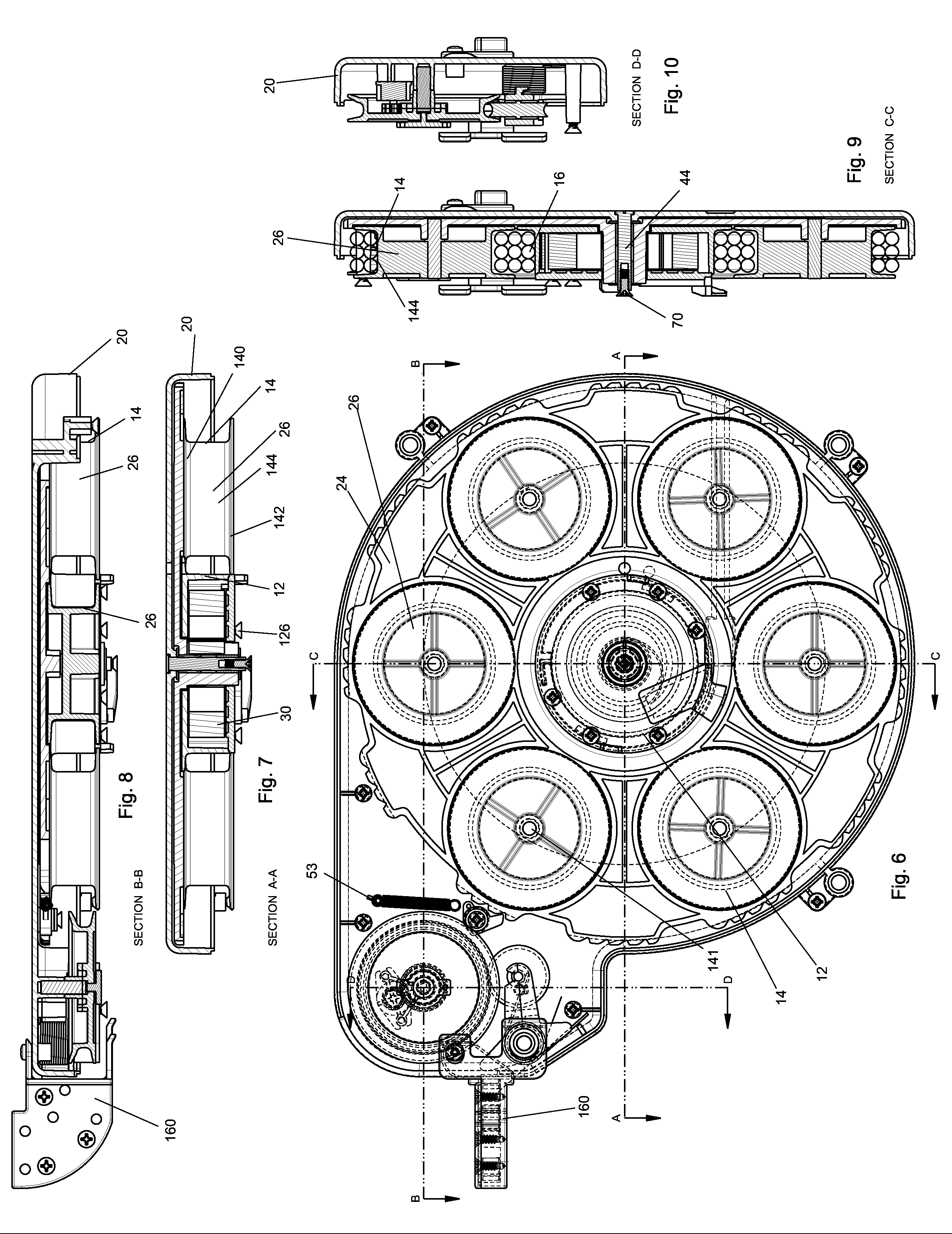

Cable retractor

InactiveUS20140224913A1A large amountPay outArrangements using take-up reel/drumEngineeringMechanical engineering

A cable retractor for use in a variety of applications includes a housing forming an internal chamber, and first and second drums within the chamber for winding of the cable. The first drum may include a stationary outer surface, and the second drum may be formed by a plurality of rollers mounted on a rotatable frame. The rollers may orbit about the first drum upon rotation of said frame, with each of the rollers also rotating about its own roller axis. The first and second drums may be sized to enable wrapping of the cable both side-by-side and in multiple layers about at least one of the first drum and the second drum. The cable retractor may include structure to urge the rollers to rotate with respect to the frame as the frame rotates. For example, a portion of the rollers may be frictionally engaged with a track, and capable of slipping with respect to the track to provide smooth extension and retraction of the cable even as multiple layers of cable are wound about the first and second drums.

Owner:HAWORTH SPA

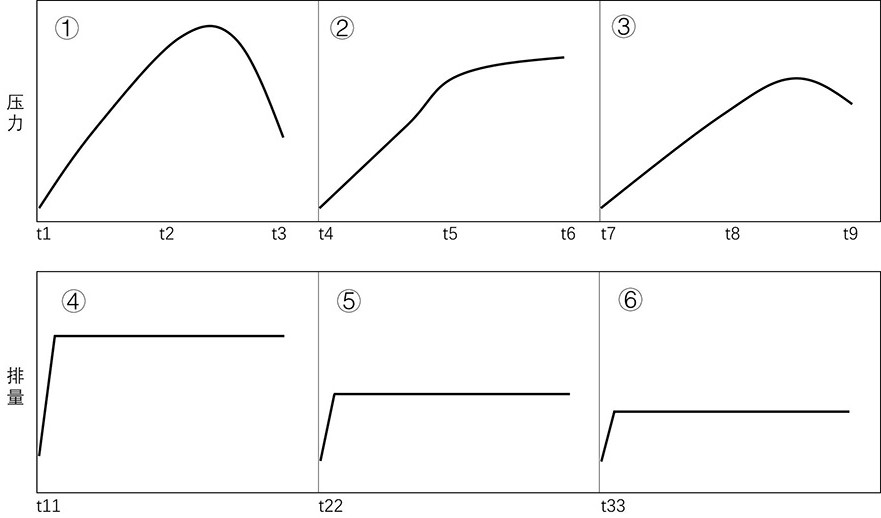

Step displacement increasing fracturing automatic control method used for hole opening

ActiveCN111997579AGood cracking effectIncrease production capacityFluid removalAutomatic controlFracturing fluid

The invention discloses a step displacement increasing fracturing automatic control method used for hole opening. The method includes the following steps that S1, fracturing liquid with the first preset displacement is injected into a shaft; S2, the pressure value and the pumping displacement of the fracturing liquid in the shaft are obtained in real time; S3, the pressure feature value in a timewindow is calculated in real time, and a pressure changing feature is analyzed; S4, the displacement increasing amount and the displacement increasing time are determined according to the pressure feature value in the time window and the pressure changing feature; S5, when the displacement increasing condition is met, displacement increasing operation is executed; and S6, the steps S2-S5 are defined as one stage, and when the pumping displacement is smaller than the designed final displacement value, at least one stage is repeated. By means of the step displacement increasing fracture automatic control method used for hole opening, the fracturing effect of the fracturing liquid on an oil / gas reservoir is effectively improved, the utilization rate of a perforation hole is increased, the complexity degree of cracks close to the shaft is lowered, and multiple sets of fractures in the fracturing process can evenly extend; and in addition, the reservoir is increased, the volume and the fracture diversion capability are effectively transformed, and therefore the oil / gas well productivity is increased.

Owner:SICHUAN HONGHUA ELECTRIC

Nbc nano-particle reinforced steel plate for X90 plastic pipes and manufacturing method of steel plate

The invention provides an Nbc nano-particle reinforced steel plate for X90 plastic pipes and a manufacturing method of the steel plate. The steel plate comprises, by weight, 0.06-0.12% of C, 0.10-0.30% of Si, 0.60-1.40% of Mn, 0.07-0.15% of Nb, 0.01-0.004% of N, 0.01-0.04% of Ti, 0.025-0.045% of Al, not greater than 0.010% of P, not greater than 0.005% of S, 0.10-0.30% of Cu, 0.10-0.30% of MO, 010-0.30% of Cr, 0.10-0.30% of Ni and the balance being Fe and other inevitable impurity elements. The manufacturing method includes the steps of preparing of materials, smelting in converter or electric furnace, external refining, casting, reheating of plates, controlled rolling and controlled cooling. The steel plate produced by the method has good plastic deformation capacity, and can guarantee safety of oil and gas transmission pipelines laid in zones with complex geological conditions.

Owner:ANGANG STEEL CO LTD

Production method of easily formable high-strength medium-thick steel plate

The invention relates to a production method of an easily formable high-strength medium-thick steel plate. The method comprises the following process steps: converter steelmaking, ladle furnace refining, vacuum treatment vacuum treatment, continuous casting, heating, rolling, pre-straightening, on-line quenching and tempering heat treatment. The mass percent composition of the steel is as follows: C = 0.06-0.08, Si = 0.15-0.30, Mn = 1.40-1.60, P <= 0.015, S <= 0.005, Nb + V + Ti <= 0.16, Cr + Mo <= 0.4, Alt = >0.020, and Pcm <= 0.21. The Q620E steel plate with a thickness of 200mm produced by the method is good in cold bending, and the cold bending property of the steel plate real object meets the easily forming requirement of users; the yield ratio of the steel plate is smaller than 0.92, and the uniform elongation rate is larger than 8%, which meets the use requirements of relevant designs; the product of strength and elongation is increased by more than 35%, the capacity of resisting dynamic loading of the high strength steel plate is increased, and the equipment safety is improved; through hot charging and on-line quenching of the continuous casting, the production cost is reduced; and with the component design in which Pcm is smaller than 0.21%, the welding properties welding property of the high strength steel plate is improved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

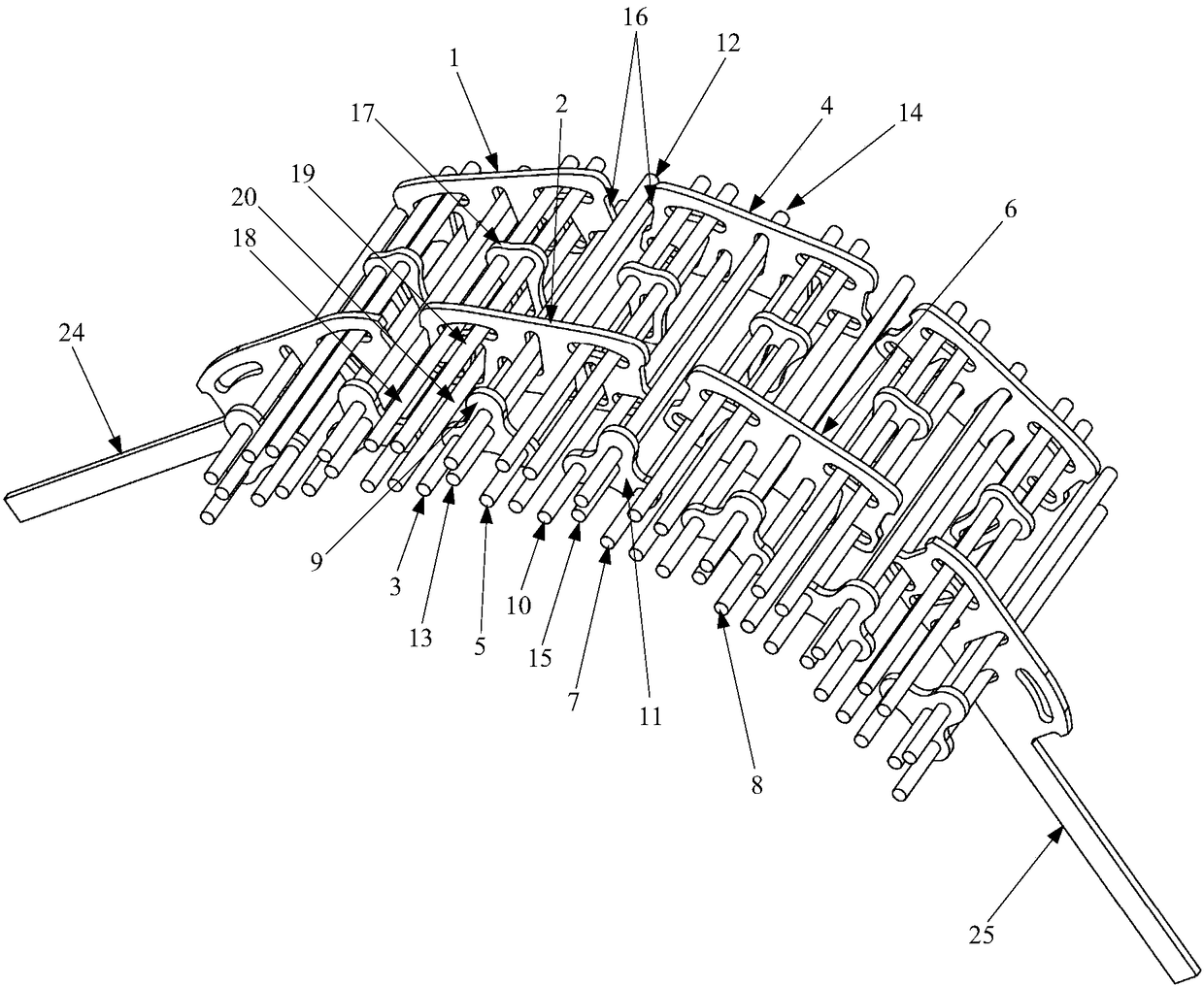

Cable retractor

InactiveUS9327938B2A large amountPay outArrangements using take-up reel/drumEngineeringMechanical engineering

A cable retractor for use in a variety of applications includes a housing forming an internal chamber, and first and second drums within the chamber for winding of the cable. The first drum may include a stationary outer surface, and the second drum may be formed by a plurality of rollers mounted on a rotatable frame. The rollers may orbit about the first drum upon rotation of said frame, with each of the rollers also rotating about its own roller axis. The first and second drums may be sized to enable wrapping of the cable both side-by-side and in multiple layers about at least one of the first drum and the second drum. The cable retractor may include structure to urge the rollers to rotate with respect to the frame as the frame rotates. For example, a portion of the rollers may be frictionally engaged with a track, and capable of slipping with respect to the track to provide smooth extension and retraction of the cable even as multiple layers of cable are wound about the first and second drums.

Owner:HAWORTH SPA

Electronic equipment and rotating shaft mechanism thereof

ActiveCN108156777ACurved arc smoothExtend evenlyCasings/cabinets/drawers detailsEngineeringElectric equipment

The invention discloses a rotating shaft mechanism, and the rotating shaft mechanism comprises a plurality of connection units which are connected sequentially. Each connection unit comprises a firstconnecting part and a second connecting part; a first rotating shaft passing through the first connecting part and the second connecting part; a third connecting part; a second rotating shaft passingthrough the second connecting part and the third connecting part; a fourth connecting part; a third rotating shaft passing through the third connecting part and the fourth connecting part; a fourth rotating shaft passing through the fourth connecting part, wherein all rotating shafts are parallel to each other, and through holes which are disposed on all connecting parts and respectively allow thecorresponding rotating shafts to pass through are strip-shaped holes. According to the rotating shaft mechanism, because the rotating shafts are disposed in the strip-shaped holes, the rotating shafts can move and rotate, thereby achieving the uniform extending of the connection units, enabling a neutral layer of the rotating shaft mechanism to be transferred to the surface of a bent inner side to be closer to the neutral layer of a flexible curtain at the inner side of the rotating shaft mechanism, and reducing the damages to the flexible curtain. The invention also provides an electronic equipment with the above rotating shaft mechanism.

Owner:LENOVO (BEIJING) CO LTD

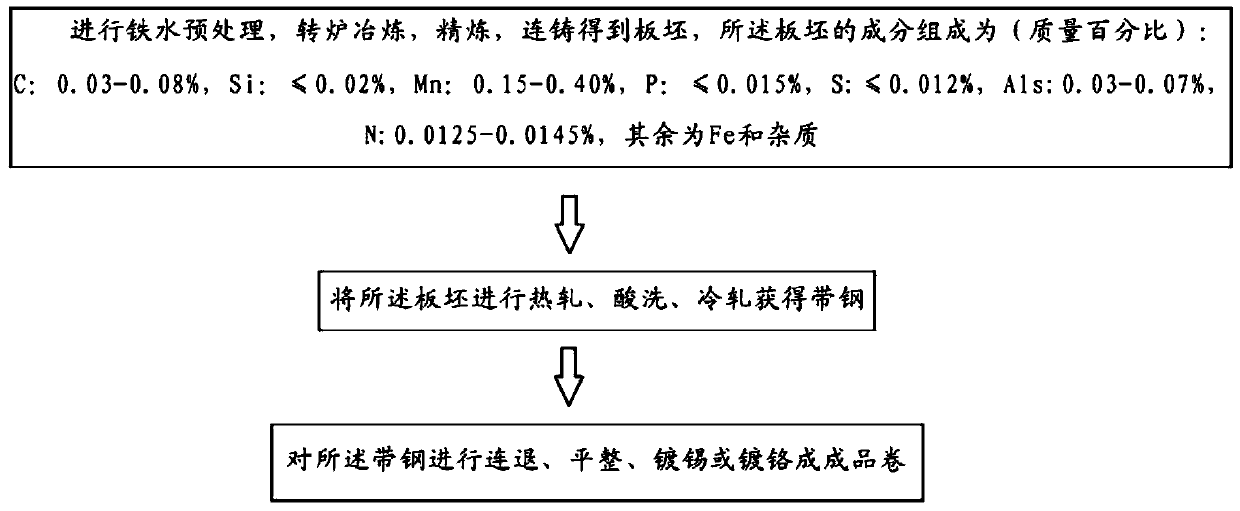

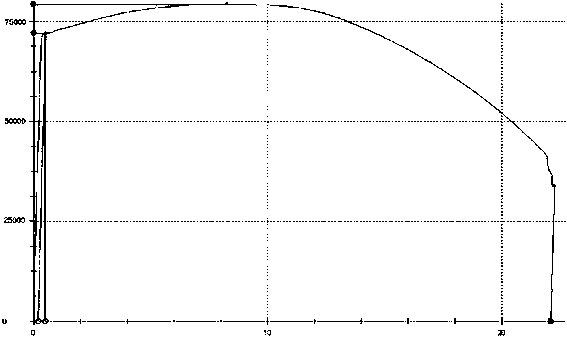

One-time cold-rolled continuous annealing packaging steel and preparation method thereof

The invention discloses one-time cold-rolled continuous annealing packaging steel and a preparation method thereof, and belongs to the technical field of steel preparation. The one-time cold-rolled continuous annealing packaging steel comprises, by mass, 0.03%-0.08% of C, smaller than or equal to 0.02% of Si, 0.15%-0.40% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.012%of S, 0.03%-0.07% of Als, 0.0125%-0.0145% of N and the balance Fe and impurities. According to the one-time cold-rolled continuous annealing packaging steel and the preparation method thereof, the packaging steel with the ferrite+cementite structure and the high forming property can be produced, and the high transverse elongation after baking is achieved.

Owner:SHOUGANG CORPORATION

Production method of easily formable high-strength medium-thick steel plate

ActiveCN103215504AReduce dislocation densityLow yield ratioProcess efficiency improvementSteelmakingTempering

The invention relates to a production method of an easily formable high-strength medium-thick steel plate. The method comprises the following process steps: converter steelmaking, ladle furnace refining, vacuum treatment vacuum treatment, continuous casting, heating, rolling, pre-straightening, on-line quenching and tempering heat treatment. The mass percent composition of the steel is as follows: C = 0.07-0.09, Si = 0.15-0.30, Mn = 1.55-1.80, P <= 0.015, S <= 0.005, Nb + V + Ti <= 0.10, Cr + Mo <= 0.5, Alt= > 0.020, and Pcm <= 0.23. The Q800F steel plate with a thickness of 200mm produced by the method is good in cold bending, and the cold bending property of the steel plate real object meets the easily forming requirement of users; the yield ratio of the steel plate is smaller than 0.92, and the uniform elongation rate is larger than 8%, which meets the use requirements of relevant designs; the product of strength and elongation is increased by more than 35%, the capacity of resisting dynamic loading of the high strength steel plate is increased, and the equipment safety is improved; through hot charging and on-line quenching of the continuous casting, the production cost is reduced; and with the component design in which Pcm is smaller than 0.23%, the welding properties welding property of the high strength steel plate is improved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Non-quenched and non-tempered 980 MPa grade high-strength strapping steel and production method thereof

The invention discloses non-quenched and non-tempered 980 MPa grade high-strength strapping steel and a production method thereof. The production method comprises work procedures of hot rolling, cooling, cold rolling and bluing. The non-quenched and non-tempered 980 MPa grade high-strength strapping steel is characterized in that chemical components of the non-quenched and non-tempered 980 MPa grade high-strength strapping steel comprise, by weight percentage, 0.17%-0.23% of C, 1.15%-1.35% of Mn, smaller than or equal to 0.35% of Si, smaller than or equal to 0.015% of S, smaller than or equal to 0.025% of P, larger than or equal to 0.015% of Als, smaller than or equal to 0.0060% of N and the balance iron and inevitable impurities. According to the method, medium low C is adopted, compared with conventional Mn component design, by means of control over a cooling path of the cooling work procedure, the partition of C in the phase change process of the steel is adjusted, medium temperature reeling is controlled, the pearlite transformation organization conversion is avoided, a ferrite bainite organization with the performance better than that of ferrite pearlite can be obtained, and ferrite bainite steel has high tensile strength, good uniform elongation performance and high n value. By means of the method, the high-strength strapping steel with the tensile strength larger than or equal to 980 Mpa and the elongation rate A30 larger than or equal to 10% can be obtained.

Owner:TANGSHAN STAINLESS STEEL +1

Discharge lamp, and method for the production of such a discharge lamp

InactiveCN102473565AReduce plastic deformationReduce mechanical stressElectric discharge tubesElectric discharge lampsGas-discharge lampEngineering

A discharge lamp is disclosed, comprising a bulb that is mounted on a base. Four metal fastening brackets which are arranged in an approximately regular fashion around a longitudinal axis of the lamp and are offset relative to each other protrude from the base. Said fastening brackets are welded to a metal clamp which firmly embraces the base. Each fastening bracket has a holding section and an adjacent welded section. A welded cross-section in a joining plane located between the metal clamp and the welded section has a minimum area of 0.5 mm2, and / or the holding section has at least one recess.

Owner:OSRAM GMBH

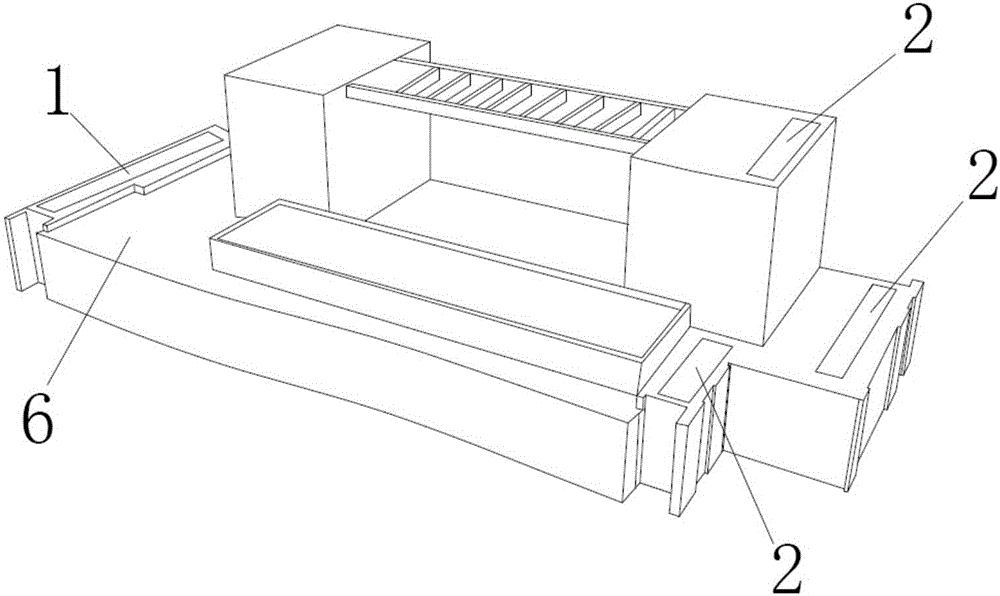

Pushing-sliding installation device and method for sail type box steel beam

ActiveCN105908981AEconomical and reasonable cross-sectional shapeImprove mechanical propertiesBuilding material handlingArchitectural engineeringWelding

The invention provides a pushing-sliding installation device and method for a sail type box steel beam. The installation device comprises a support, a first sliding way, a second sliding way and a pusher. The first sliding way and the second sliding way are horizontally arranged in parallel. The support is arranged between the first sliding way and the second sliding way. The pusher is arranged along the first sliding way and the second sliding way. The installation method comprises the steps that the two ends of the steel beam are hoisted to the first sliding way and the second sliding way at first, then, the steel beam is supported by the support, then the pusher is used for pushing the steel beam to enable the steel beam to slide to a preset position, the same operation is implemented on multiple steel beams, and installation and fixing of a roof steel structure can be completed. According to the pushing-sliding installation device and method for the sail type box steel beam, the construction engineering of a large number of scaffolds is avoided, the redundant welding workload is omitted, and the high-altitude in-place installation precision of components and the installation efficiency of the sail type box steel beam roof structure are improved.

Owner:LONGXIN CONSTR GRP

Flexible printed circuit board and electronic device using the same

ActiveUS20210029827A1Easy to useExtend evenlyCircuit bendability/stretchabilityPrinted circuit aspectsEngineeringFlexible electronics

Owner:PEGATRON

Polyvinyl alcohol film for diffuser

ActiveCN101033320BHigh strengthIncreased durabilityPolarising elementsLiquid-crystal displayPlasticizer

Owner:乐凯光电材料有限公司

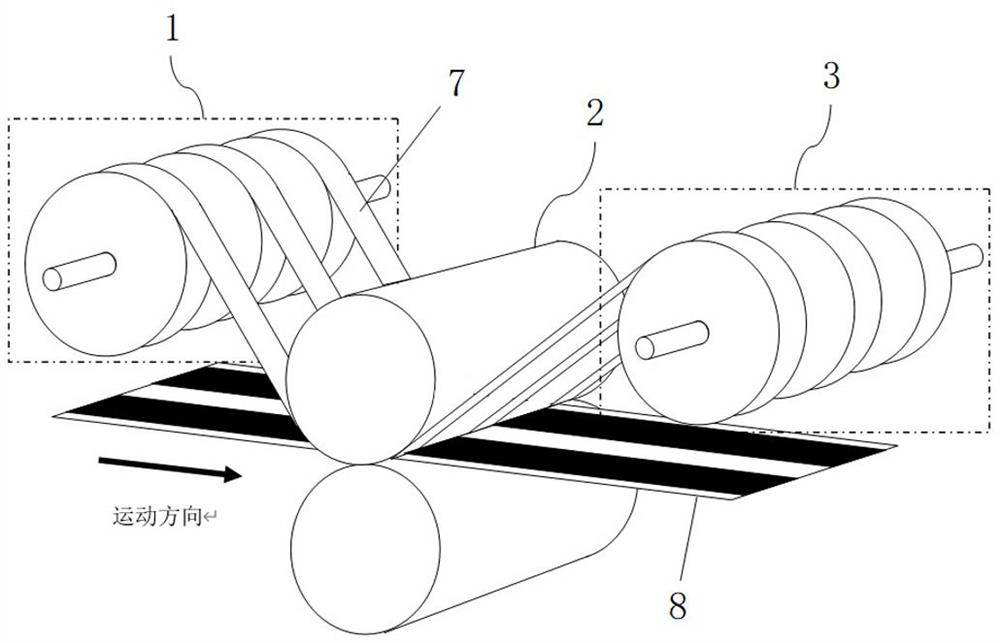

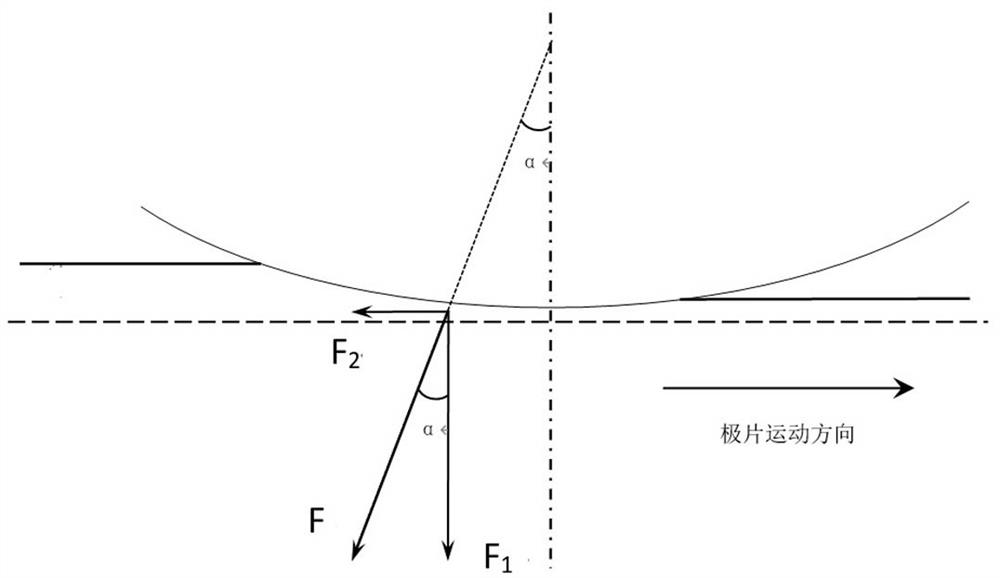

Double-roller compaction equipment of battery pole piece and compaction method for battery pole piece

InactiveCN113078280AIncreasing the thicknessIncrease pressureElectrode rolling/calenderingEngineeringStructural engineering

The invention relates to double-roller compaction equipment for a battery pole piece and a compaction method for the battery pole piece, and belongs to the technical field of lithium ion batteries. The invention mainly solves the problem that after the current battery pole piece is compacted, wrinkles are generated between a coating part and a non-coating part, so that the subsequent production of a battery is very unfavorable. The equipment is mainly characterized by comprising paired compression rollers and a filling belt auxiliary device, and the filling belt auxiliary device comprises filling belts and a filling belt winding and unwinding mechanism which are distributed between the paired compression rollers at intervals. According to the invention, when the battery pole piece with a plurality of coating parts and non-coating parts in the width direction is rolled, wrinkles at the boundaries of the coating parts and the non-coating parts can be inhibited. The double-roller compaction equipment has the characteristics that when the battery pole piece passes through the paired compression rollers, the coated part and the uncoated part are simultaneously pressed and extend, so that the uncoated part does not generate wrinkles, and the compaction device is mainly used for compacting the battery pole piece of the lithium ion battery.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com