One-time cold-rolled continuous annealing packaging steel and preparation method thereof

A continuous annealing technology for packaging, applied in the field of primary cold rolling and continuous annealing packaging steel and its preparation, can solve the problem of low transverse elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

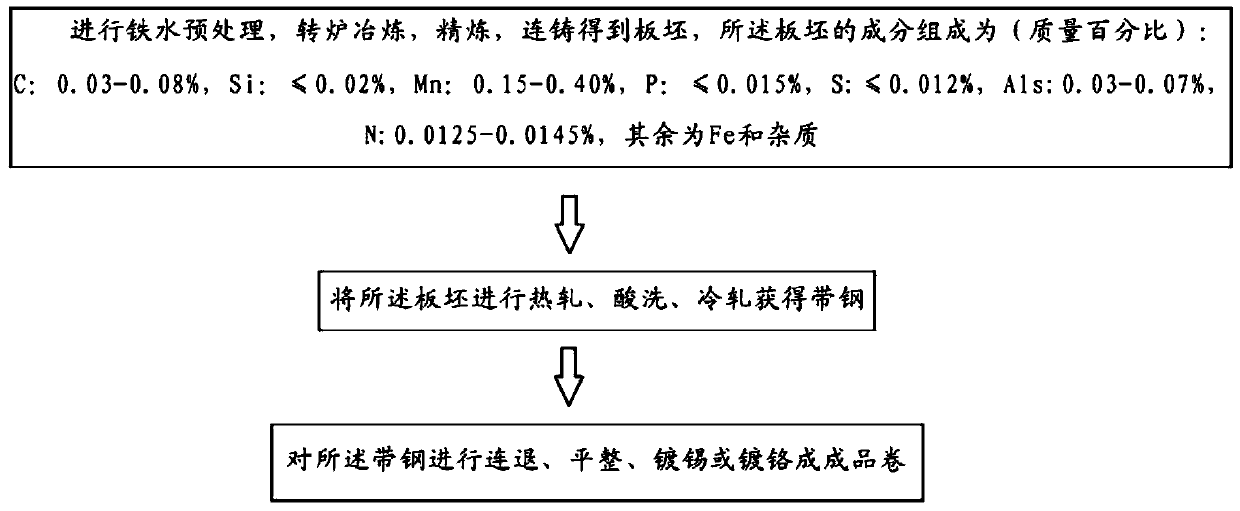

[0027] see figure 1 , based on the same inventive concept, the present application also provides a preparation method of one-time cold-rolled continuous unpacking steel, comprising the following steps:

[0028] Step 1, carry out molten iron pretreatment, converter smelting, refining, and continuous casting to obtain slabs. P: ≤ 0.015%, S: ≤ 0.012%, Als: 0.03-0.07%, N: 0.0125-0.0145%, and the rest are Fe and impurities.

[0029] In step 2, the slab is subjected to hot rolling, pickling and cold rolling to obtain strip steel.

[0030] In step 3, the strip is continuously withdrawn and leveled, and then tinned or chrome-plated to form a finished coil.

[0031] The specific implementation of this application will carry out hot metal pretreatment, converter smelting, refining, and continuous casting to obtain slabs. %, P: ≤ 0.015%, S: ≤ 0.012%, Als: 0.03-0.07%, N: 0.0125-0.0145%, the rest are Fe and impurities, the slab is subjected to hot rolling, pickling and cold rolling to o...

Embodiment 1

[0040]Hot metal pretreatment, converter smelting, refining, and continuous casting are carried out to obtain slabs. The chemical composition mass percentages of the slabs are C: 0.07%, Si: 0.01%, Mn: 0.35%, P: 0.011%, S: 0.008%, Als: 0.066%, N: 0.125%, and the rest are slabs of Fe and impurities. Then, the slab passes through the hot continuous rolling unit, that is, heating, rough rolling and descaling, rough rolling, head and tail cutting, finishing rolling and descaling, finishing rolling, laminar cooling, and coiling for hot continuous rolling. Among them, the heating furnace The heating temperature is 1190°C, the rough rolling adopts 1+5 passes, the finishing rolling temperature of the finishing mill is 878°C, and the coiling temperature is 577°C. In this way, after rough rolling, finishing rolling and laminar cooling, it is coiled by a coiler.

[0041] Then, make the hot-rolled coil go through the combined pickling unit, continuous unwinding unit and tinning unit, that ...

Embodiment 2

[0043] Hot metal pretreatment, converter smelting, refining, and continuous casting are carried out to obtain slabs. The chemical composition mass percentages of the slabs are C: 0.04%, Si: 0.015%, Mn: 0.23%, P: 0.011%, S: 0.005%, Als: 0.043%, N; 0.0135%, the rest are slabs of Fe and impurities. Then, the slab passes through the hot continuous rolling unit, that is, heating, rough rolling and descaling, rough rolling, head and tail cutting, finishing rolling and descaling, finishing rolling, laminar cooling, and coiling for hot continuous rolling. Among them, the heating furnace The heating temperature is 1235°C, the rough rolling adopts 3+3 passes, the finishing rolling temperature of the finishing mill is 897°C, and the coiling temperature is 575°C. In this way, after rough rolling, finishing rolling and laminar cooling, it is coiled by a coiler.

[0044] Then, make the hot-rolled coil go through the combined acid rolling unit, continuous withdrawal unit and tin-plating uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com