Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Eliminate fold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

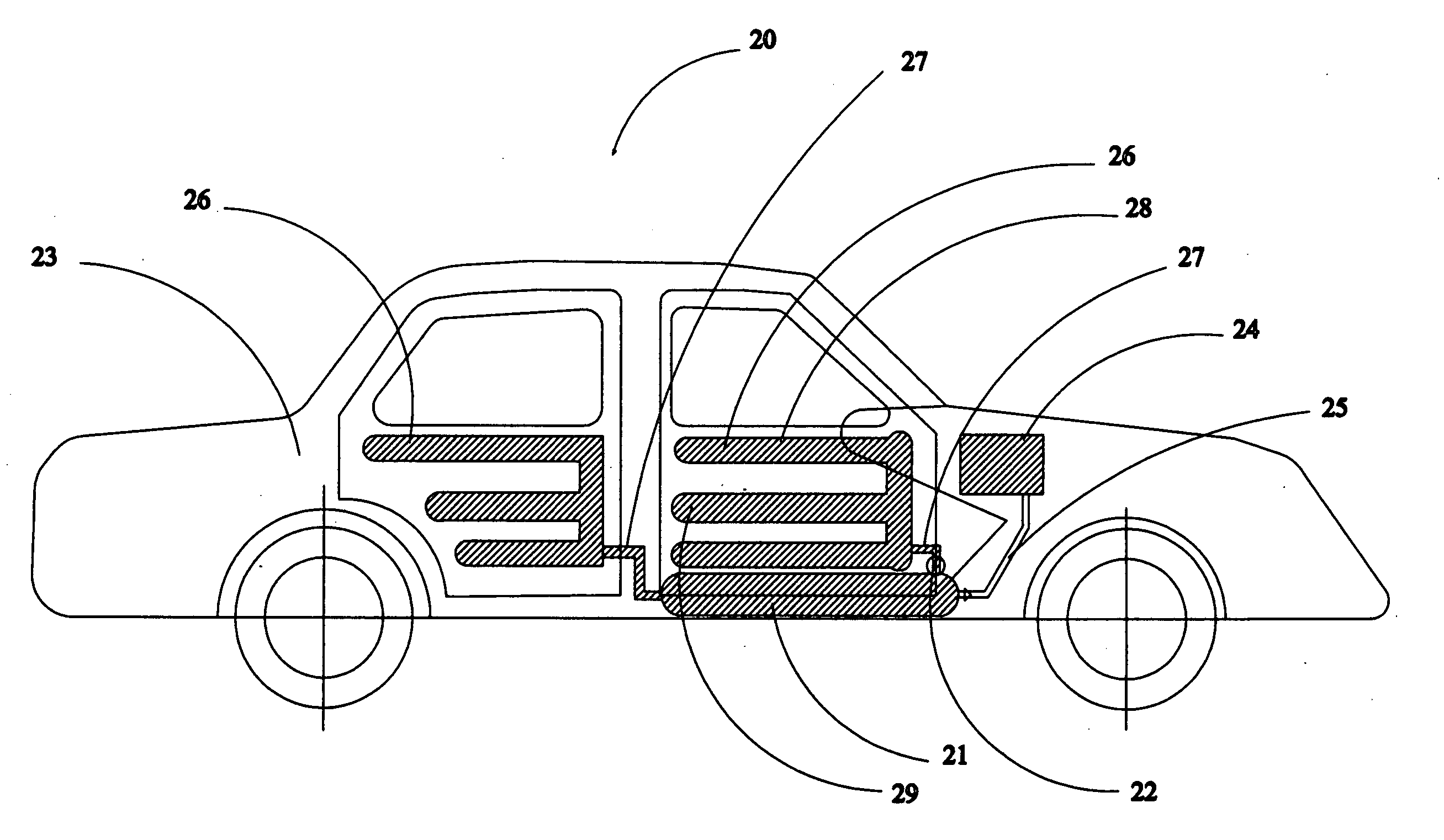

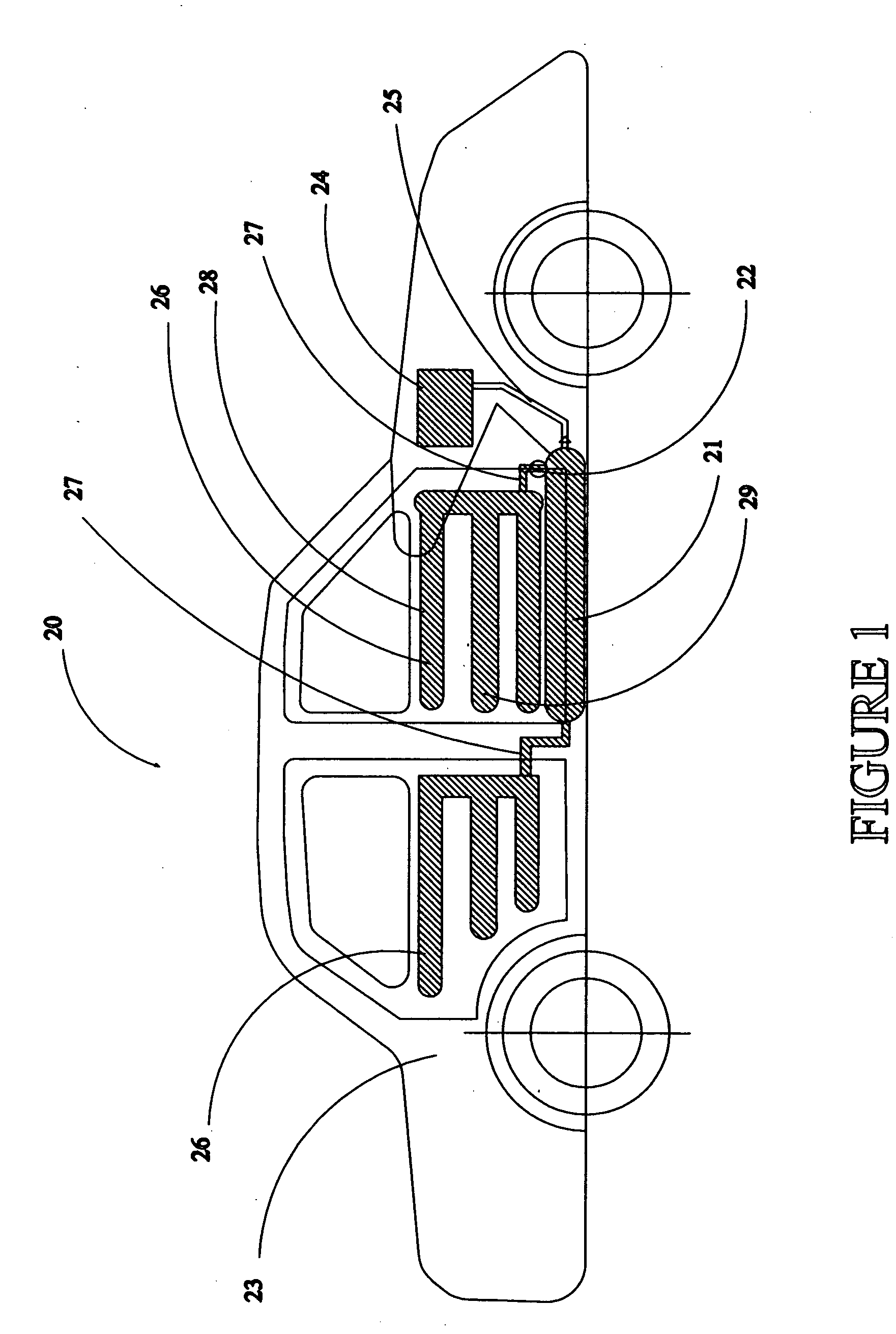

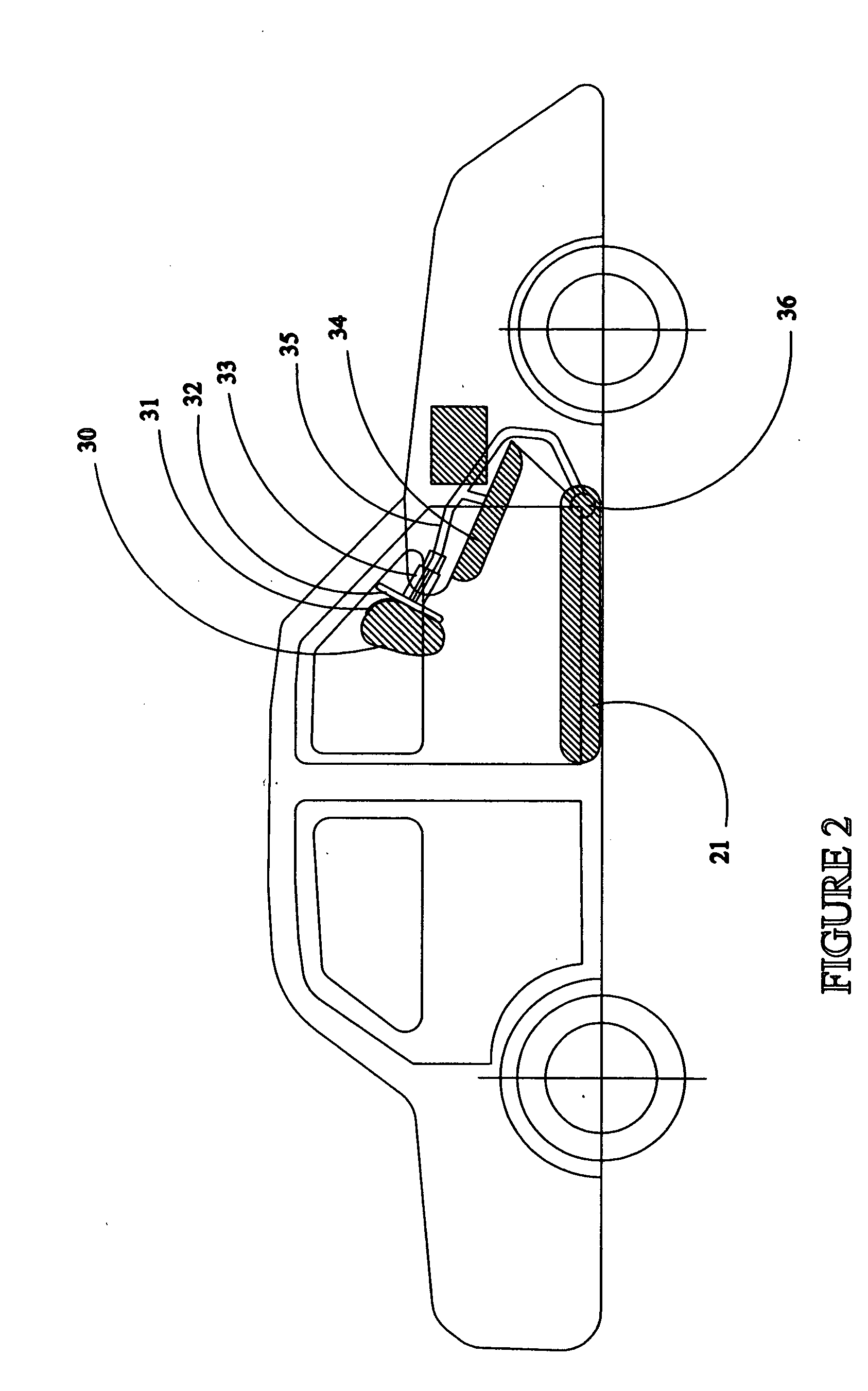

Restorable vehicle occupant safety system

InactiveUS20050218632A1Safer environmentReduce ratePedestrian/occupant safety arrangementRolloverDriver/operator

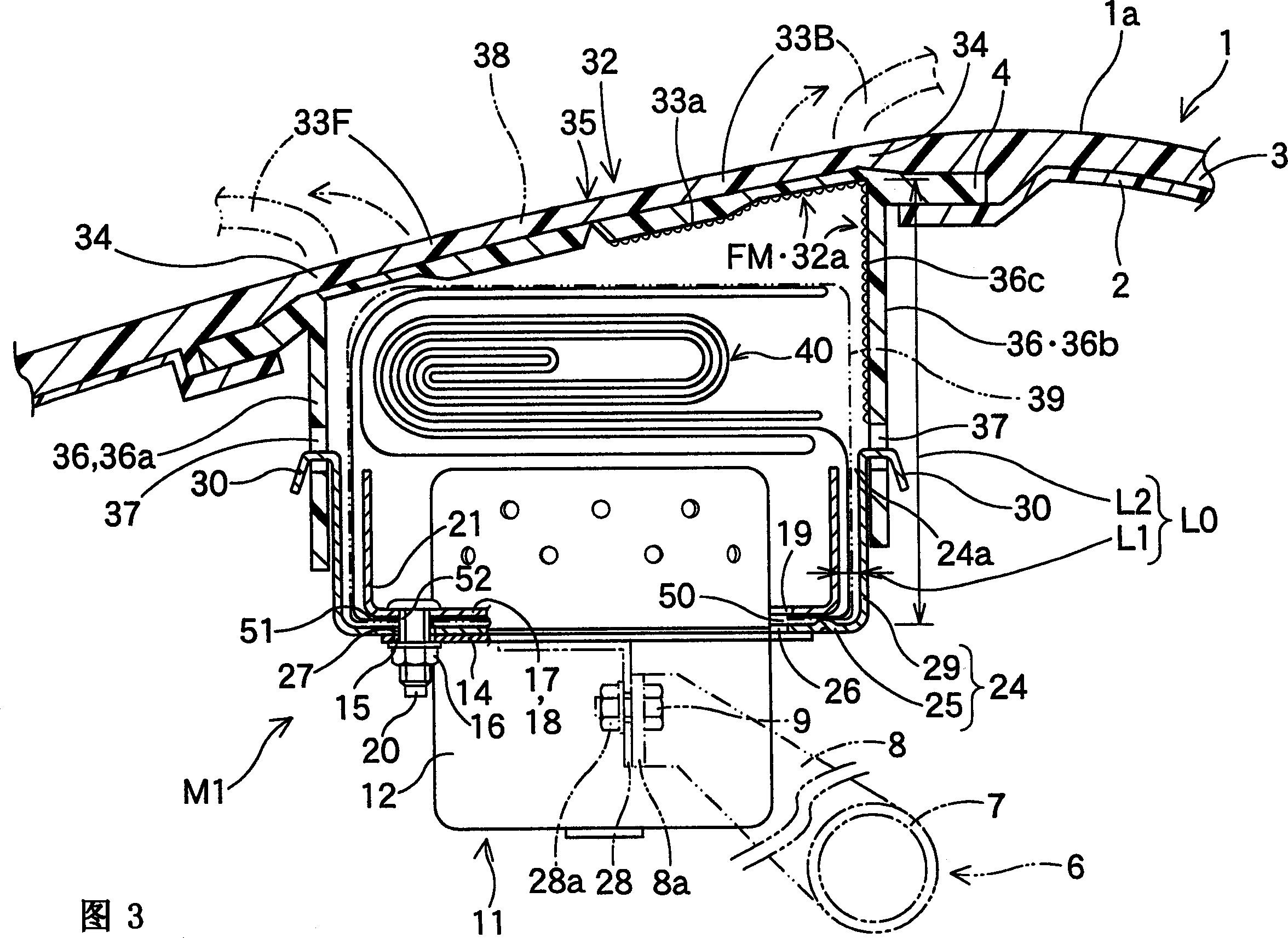

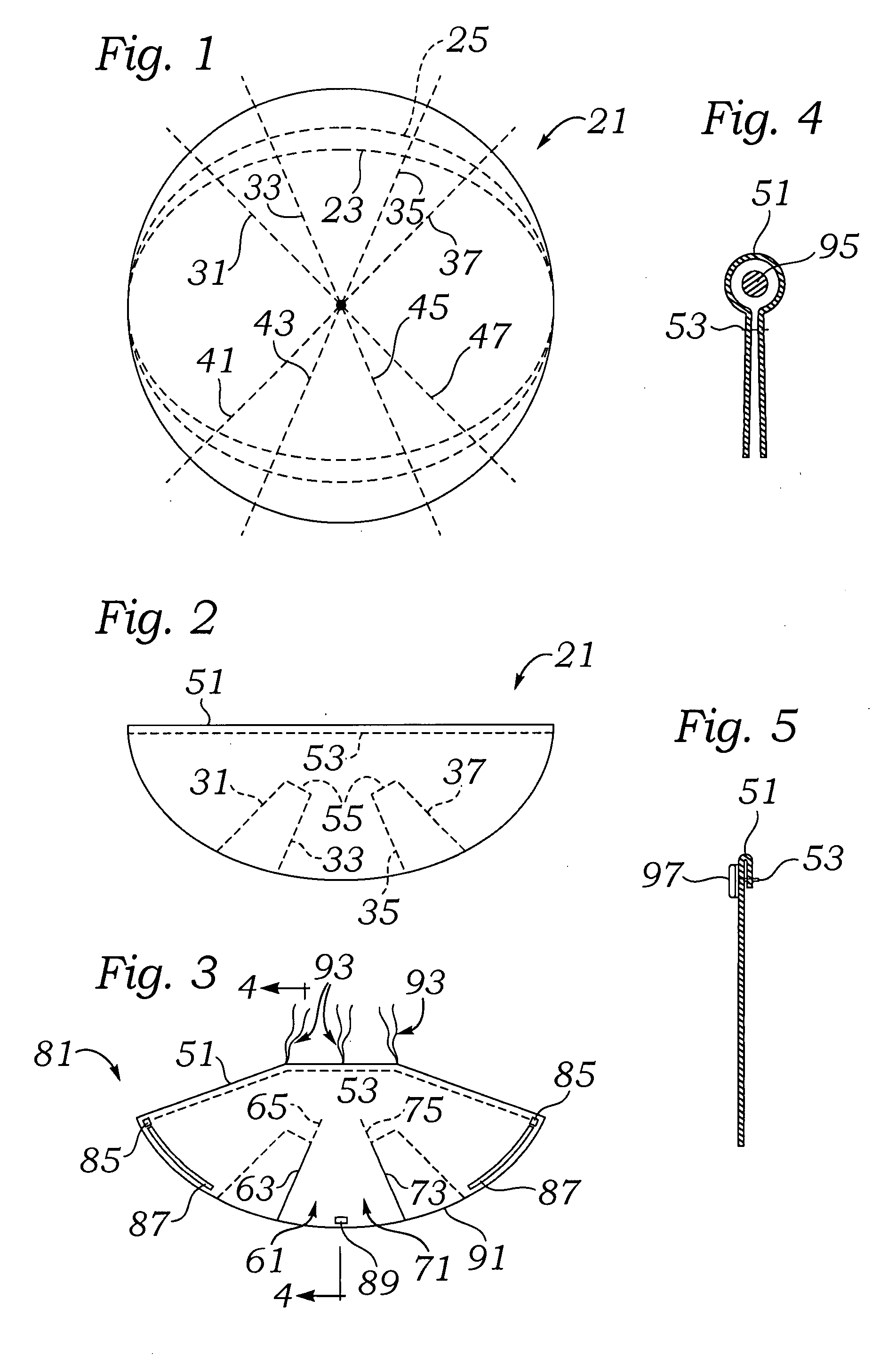

A Restorable Vehicle Occupant Safety System to replace present pyrotechnic airbag systems. The system is comprised of an air pressure storage vessel 21 that is fluidly connected to an air distribution manifold 36, electronic sensors that preclude an impending crash, valves which are sensor activated to inflate airbags for driver, passenger, knee bolster, side impact, and rollover units as well as seatbelt pre-tensioning units. The present system will safely deploy the airbags in a substantially safe increment of time before a crash condition and restore the airbags to their original position in the event the crash condition does not occur.

Owner:CUEVAS JESS +1

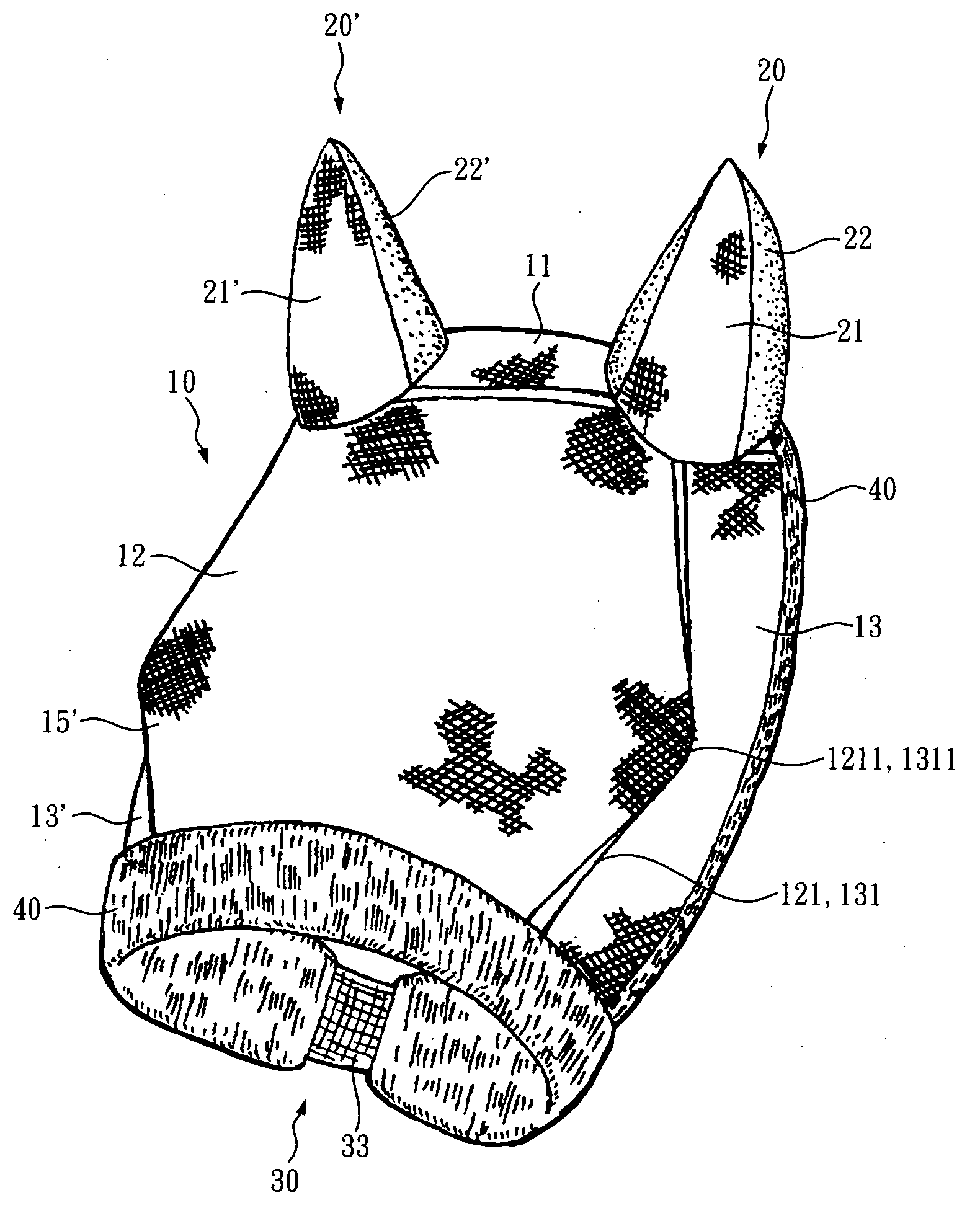

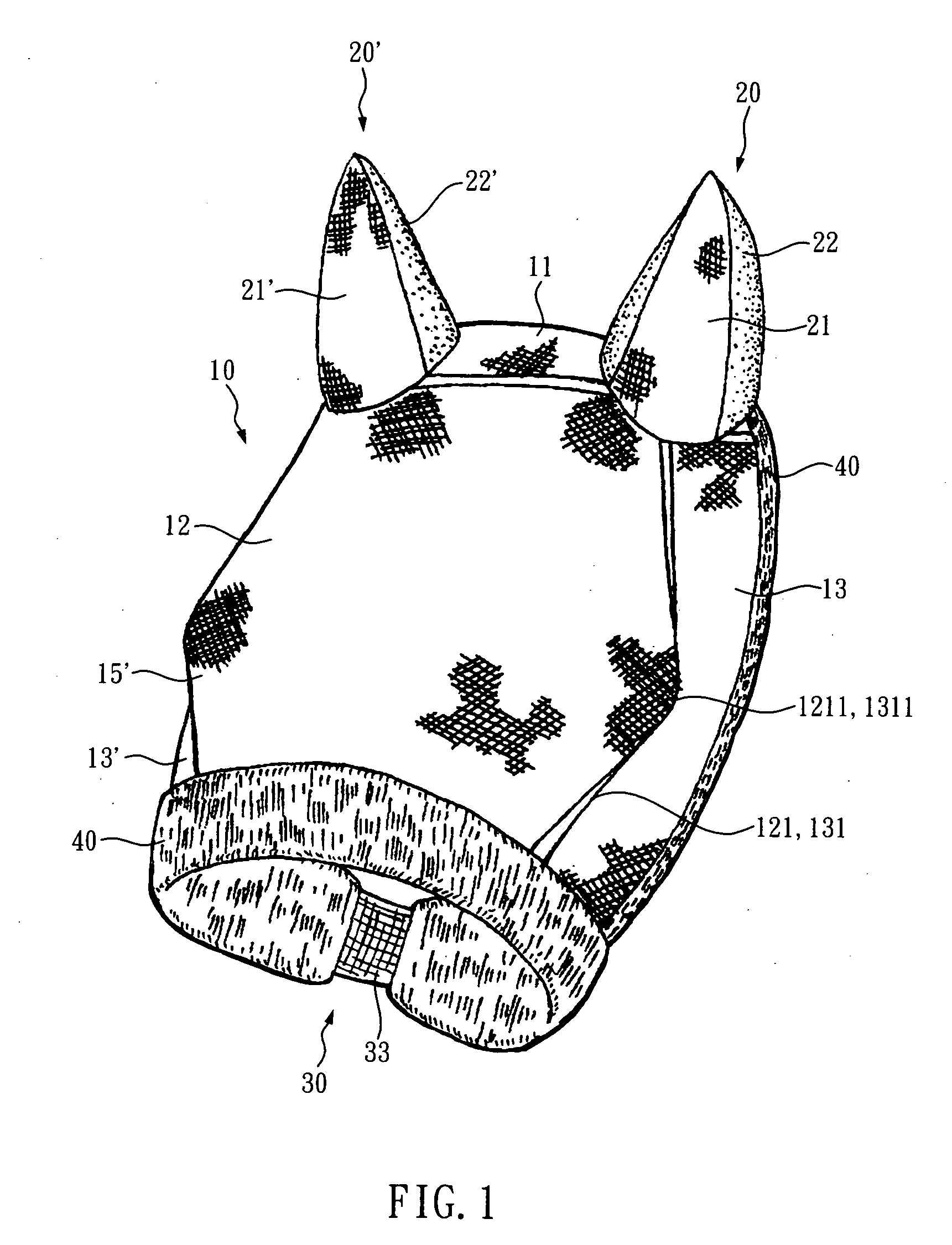

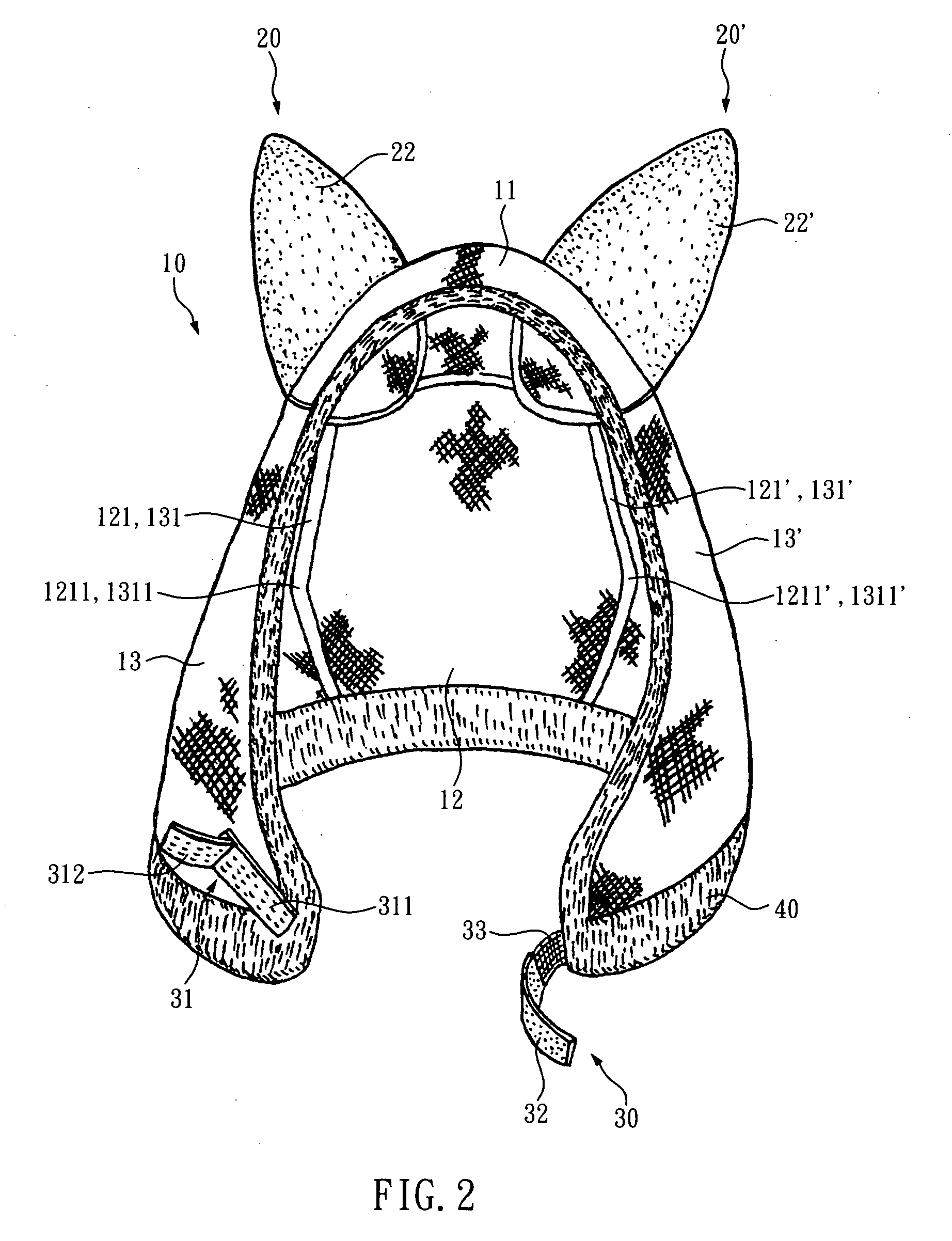

Fly shield to protect the head of a horse

Owner:HUNG KUEI YIN

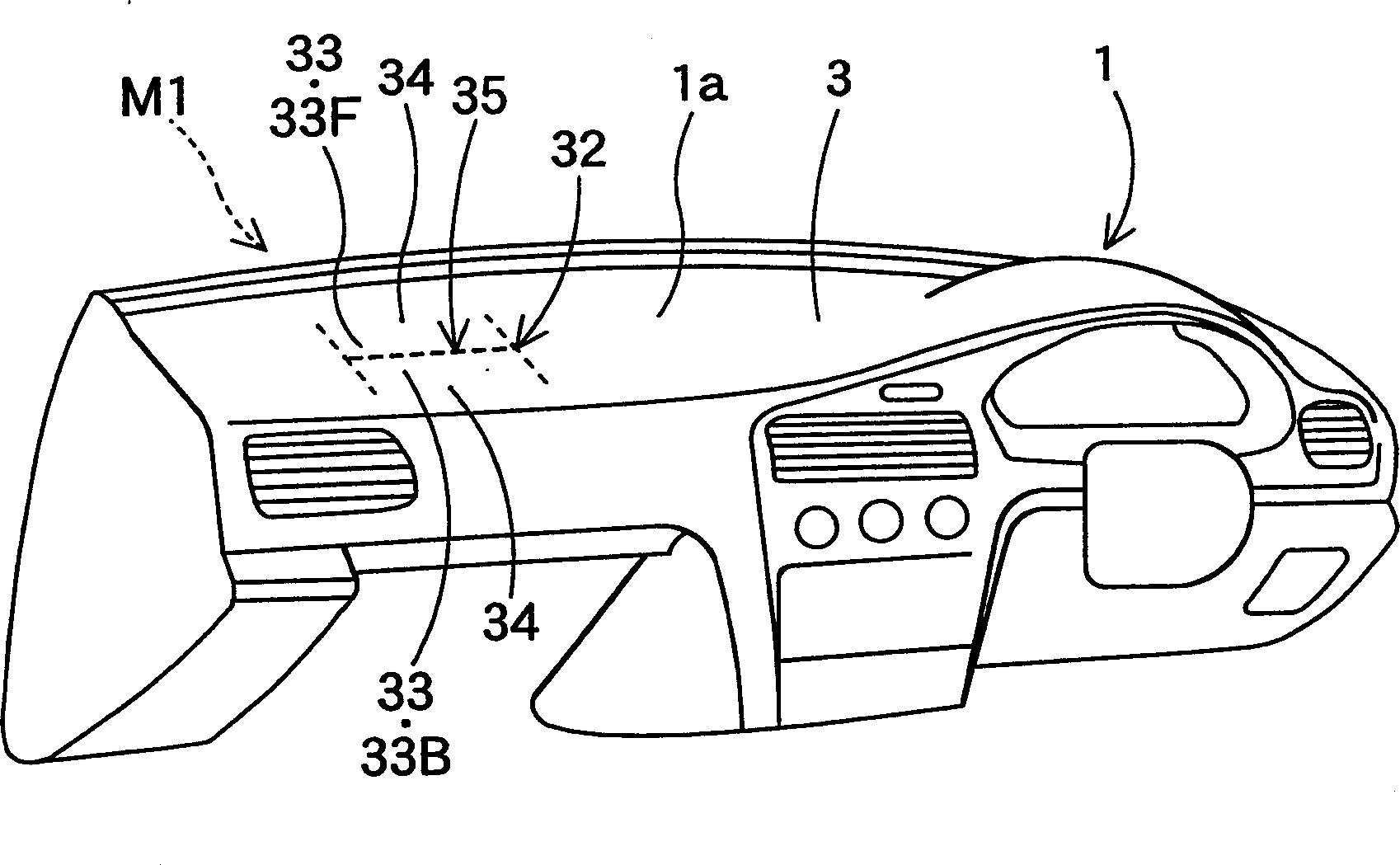

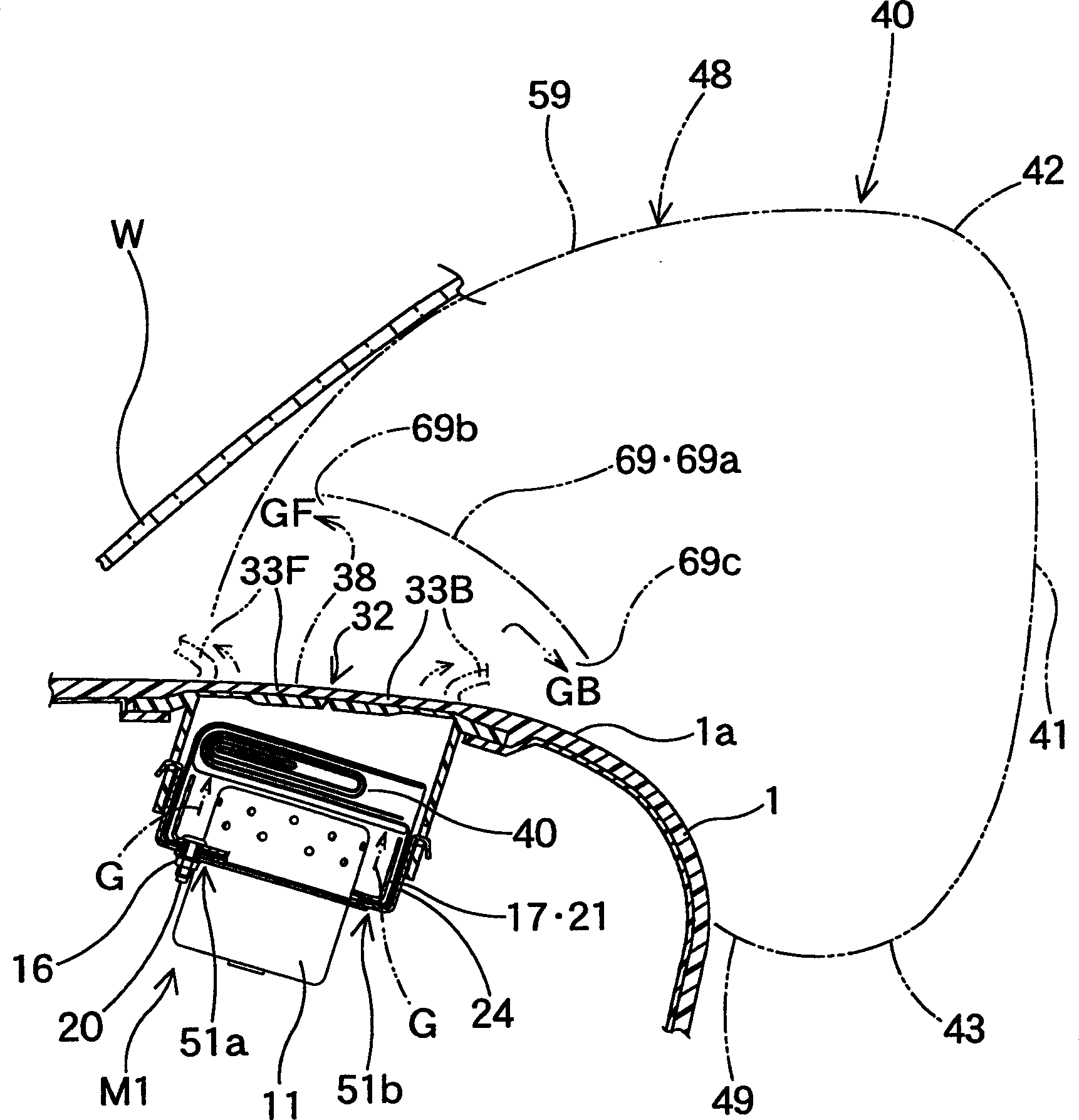

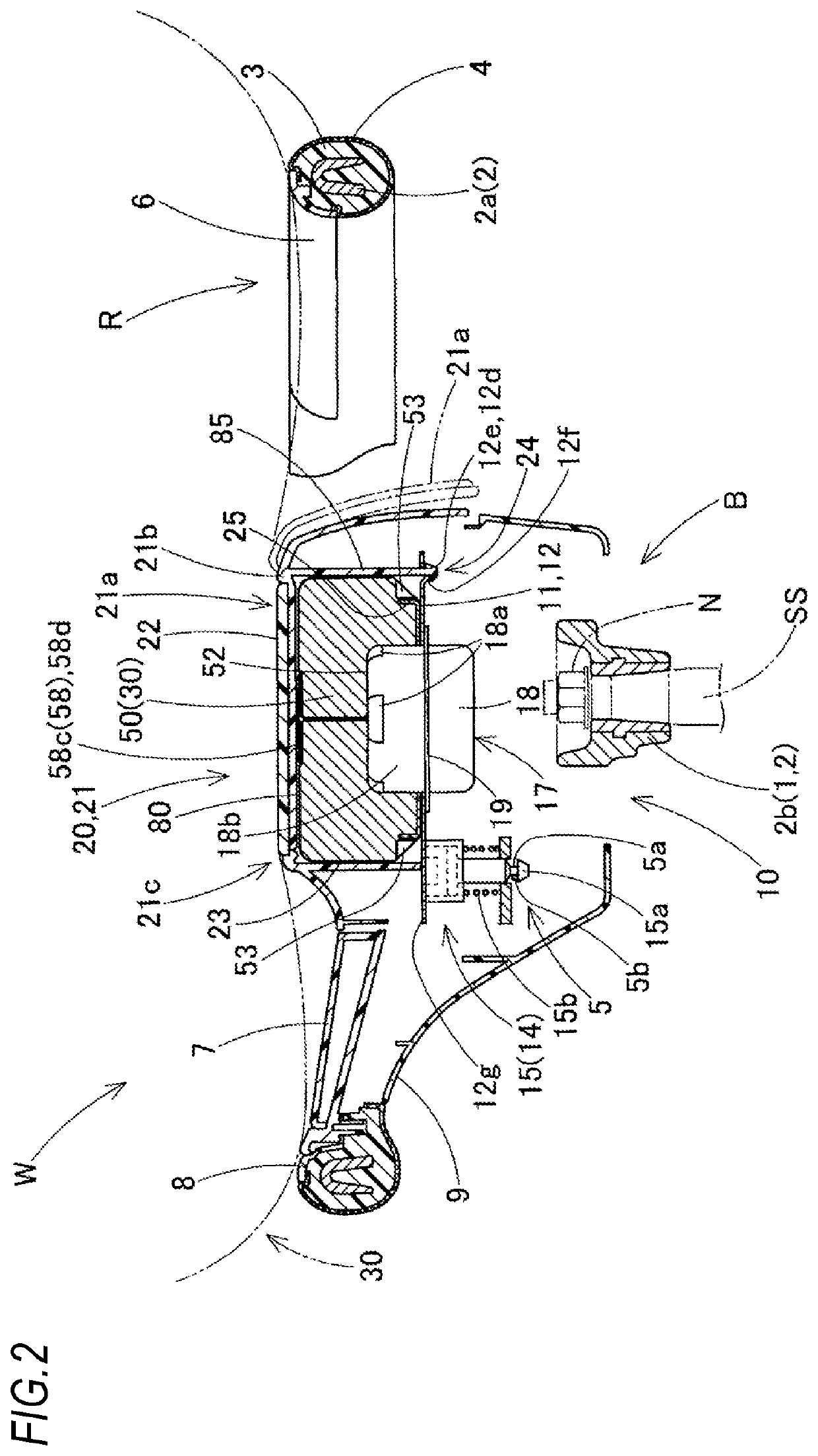

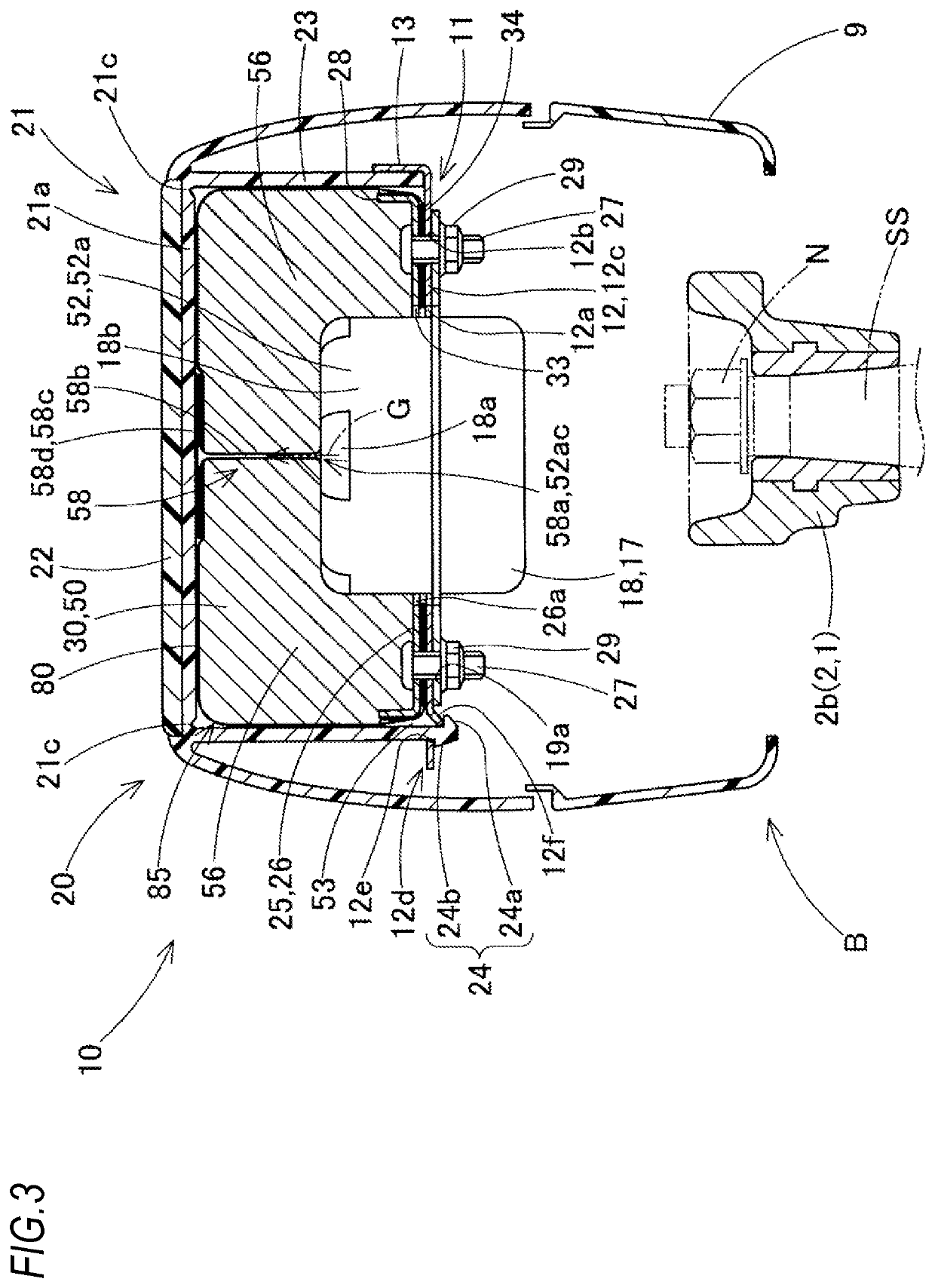

Airbag device for front passenger's seat

InactiveCN1651284AReduce vertical foldEliminate foldPedestrian/occupant safety arrangementEngineeringPerpendicular direction

The invention provides a gasbag device for co-driver seats, which is formally folded after prefolded composed of a cross folding and a longitudinal folding and held in a housing arranged on the vehicle. The shape of the gasbag after prefolding is that: the upper margin of the sidewall part of the passengers is positioned on the gas inlet, and the sidewall part of the passengers is folded under the circumferential wall forming a flat shape. When the gasbag is cross folded while the formal folding, the rear lateral part of the gas inlet after the prefolding is cross folded at a state of two parts folded, enabling the lower side of the rear end under the circumferential wall next to the gas inlet. The gasbag has an advantage that the whole area of the rear sidewall of the gasbag during the expanding can move backward along an approximately perpendicular direction.

Owner:TOYODA GOSEI CO LTD

Flexible dual skin wall and device for tensioning a dual skin flexible wall

Owner:TISSAGE & ENDUCTION SERGE FERRARI SA

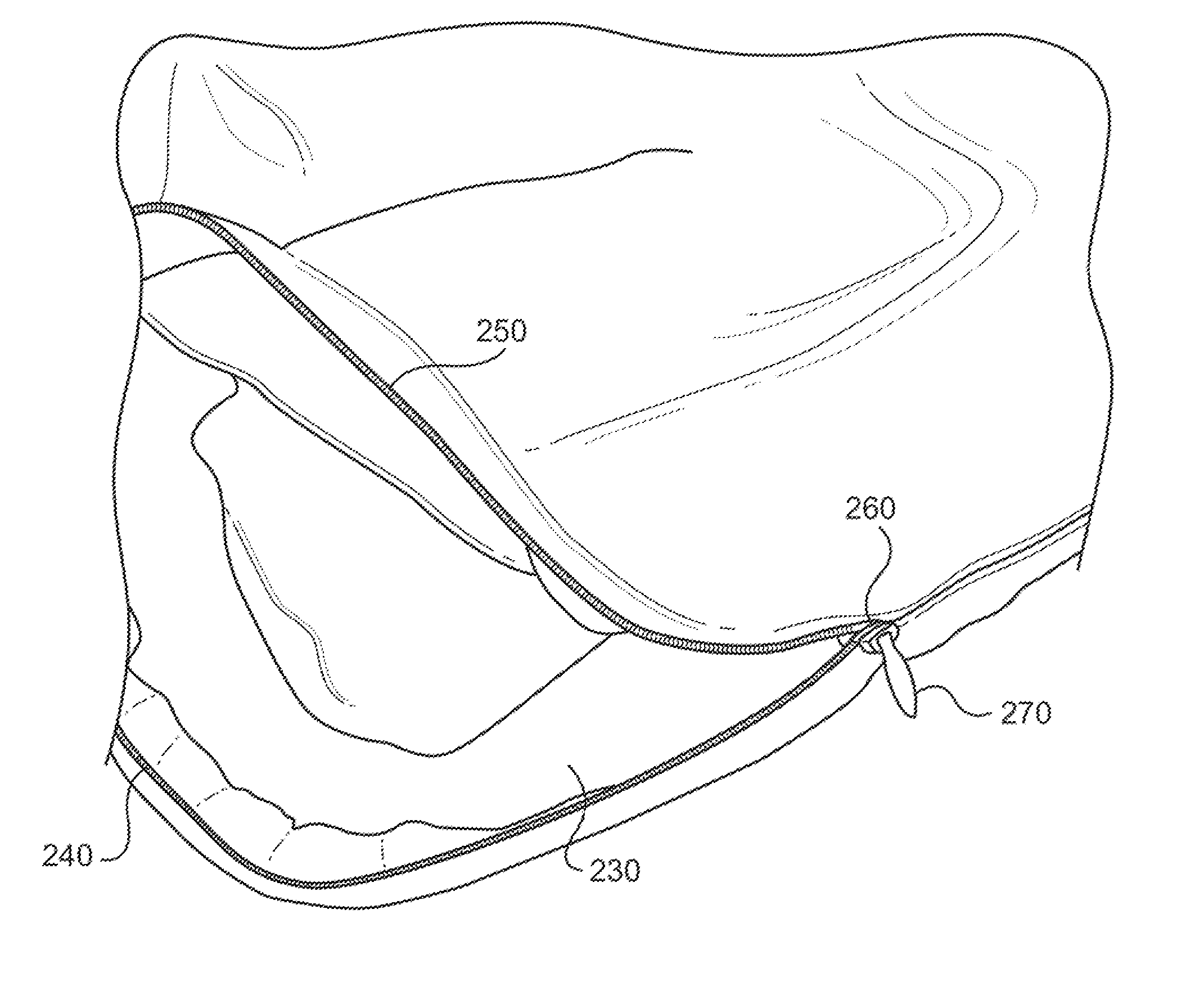

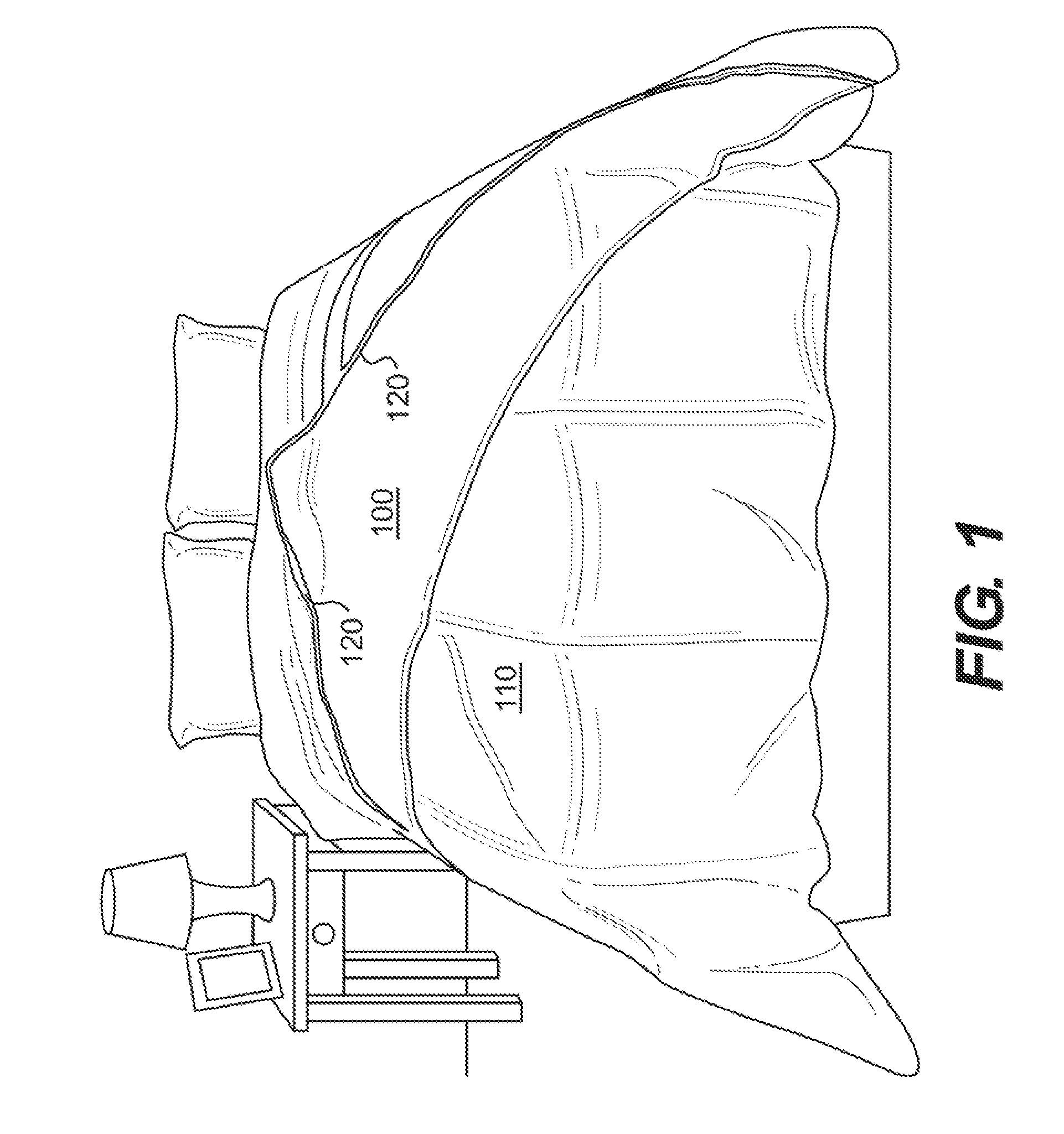

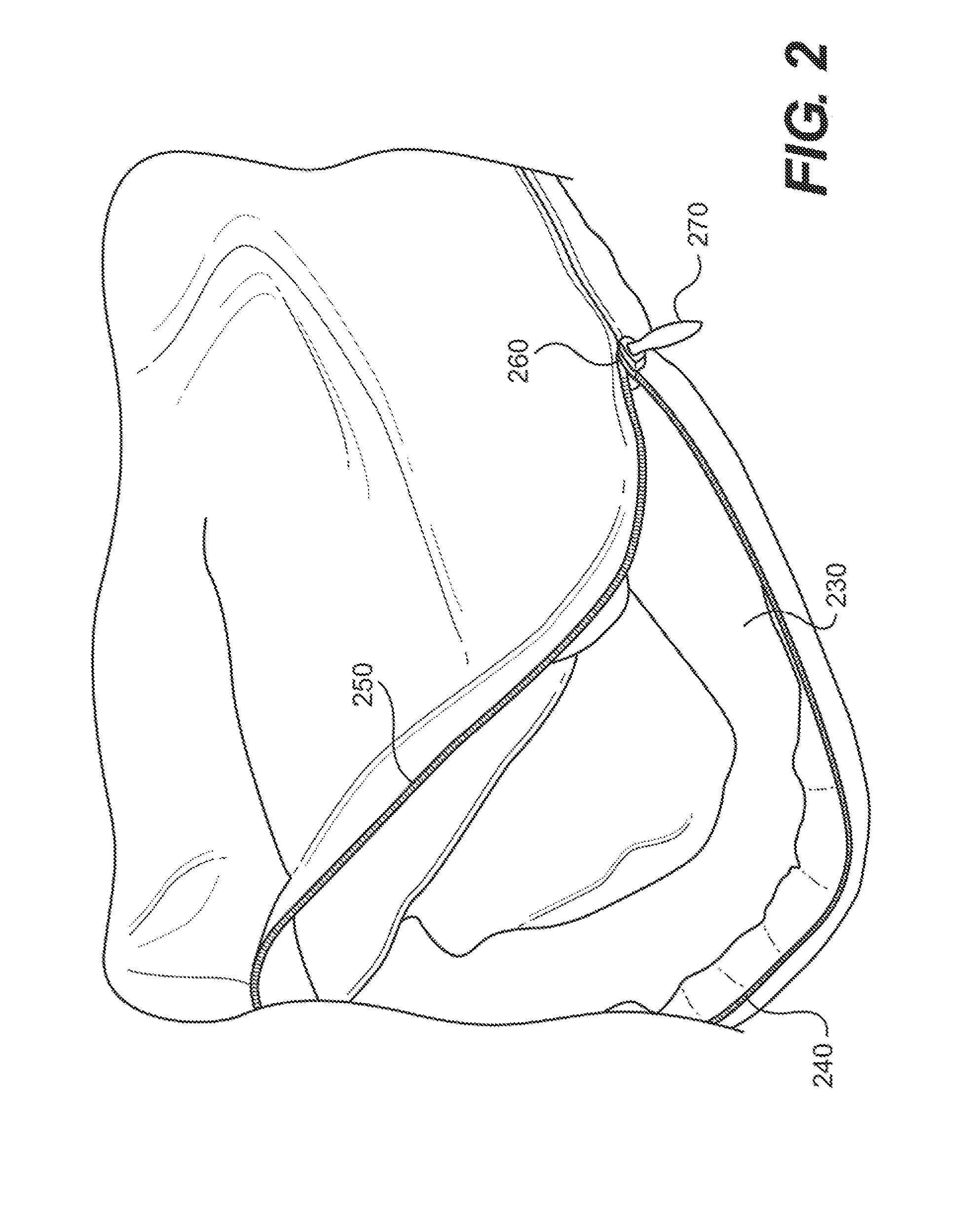

Two sided hidden zipper for removable cover

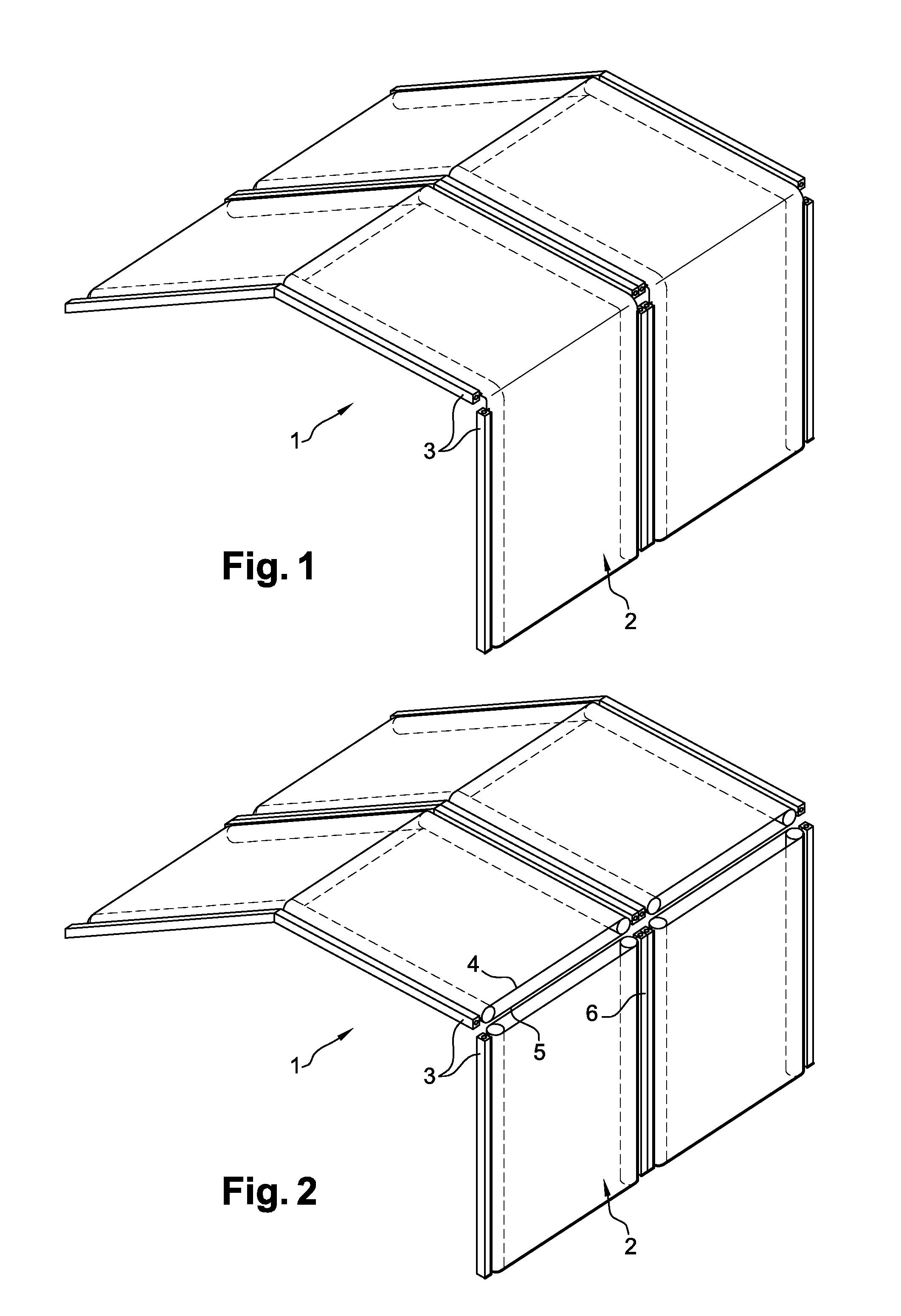

InactiveUS20110023235A1Easy to insertEasily enclosingSnap fastenersSlide fastenersEngineeringMechanical engineering

The invention relates to an improved removable cover for a duvet, comforter, or other bedding material that includes an opening along at least two adjacent sides that may further include a hidden closure mechanism running along the length of the opening, and a method for effectively arranging and enclosing the bedding material within the removable cover.

Owner:THE MITCHELL GOLD

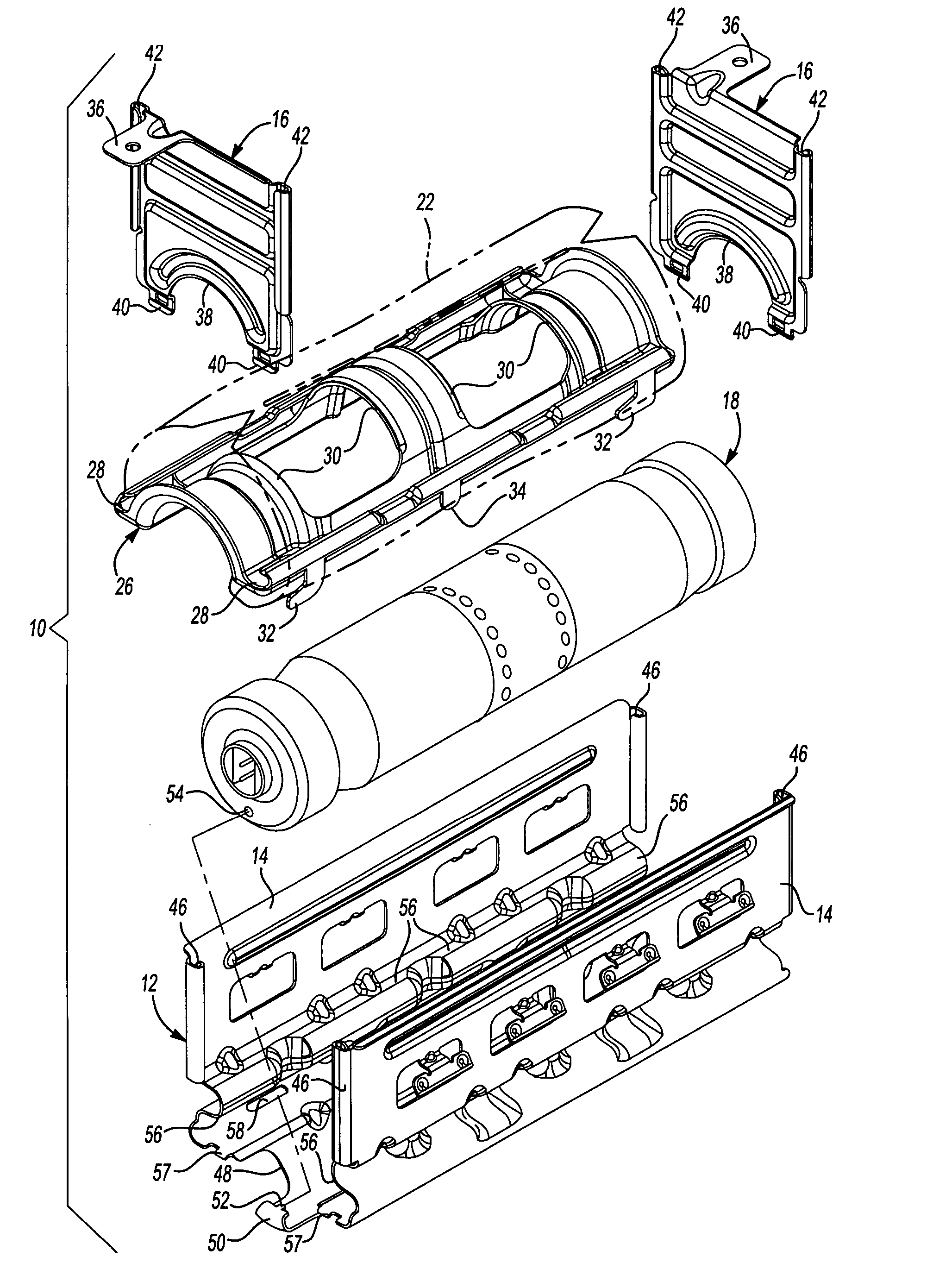

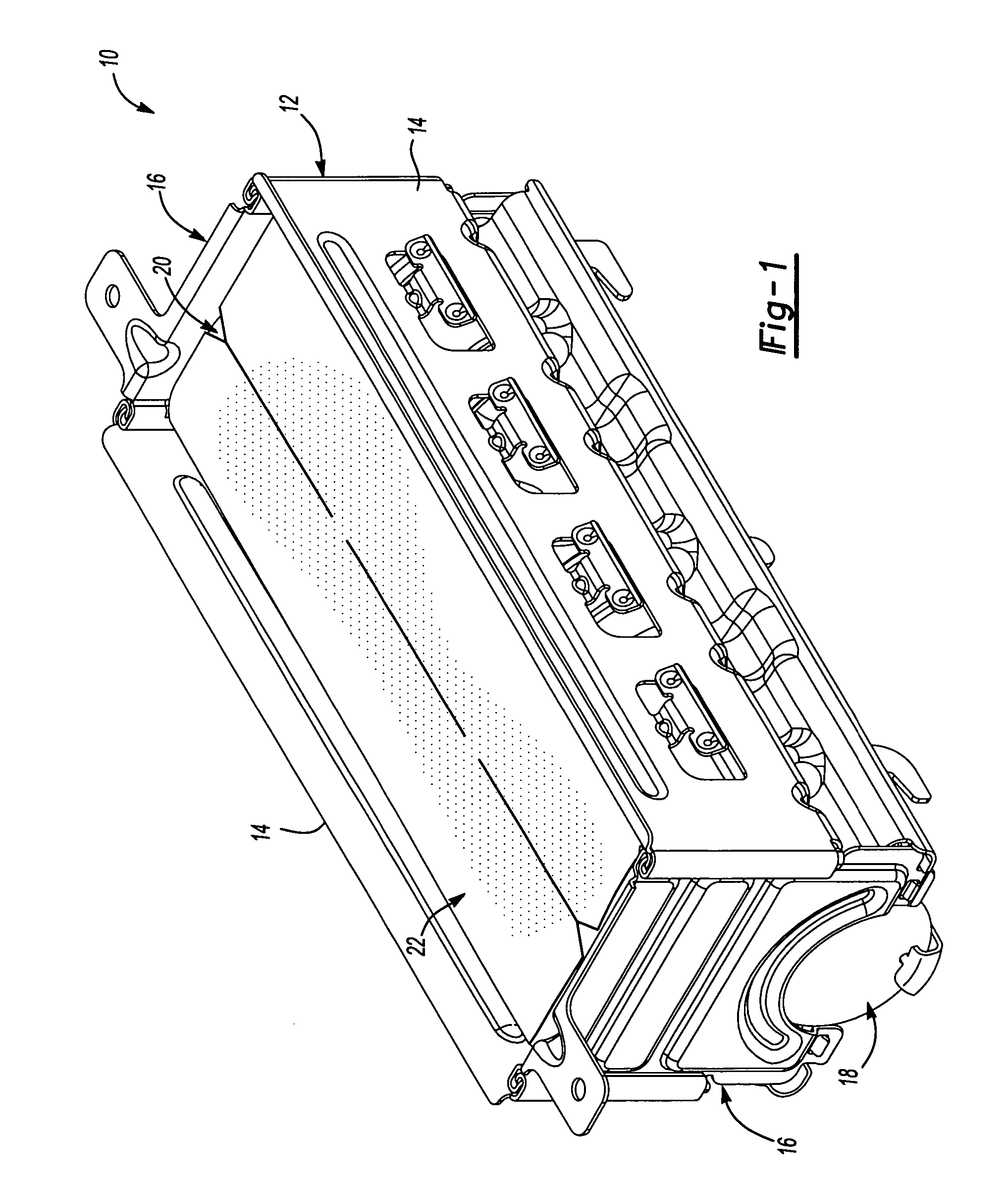

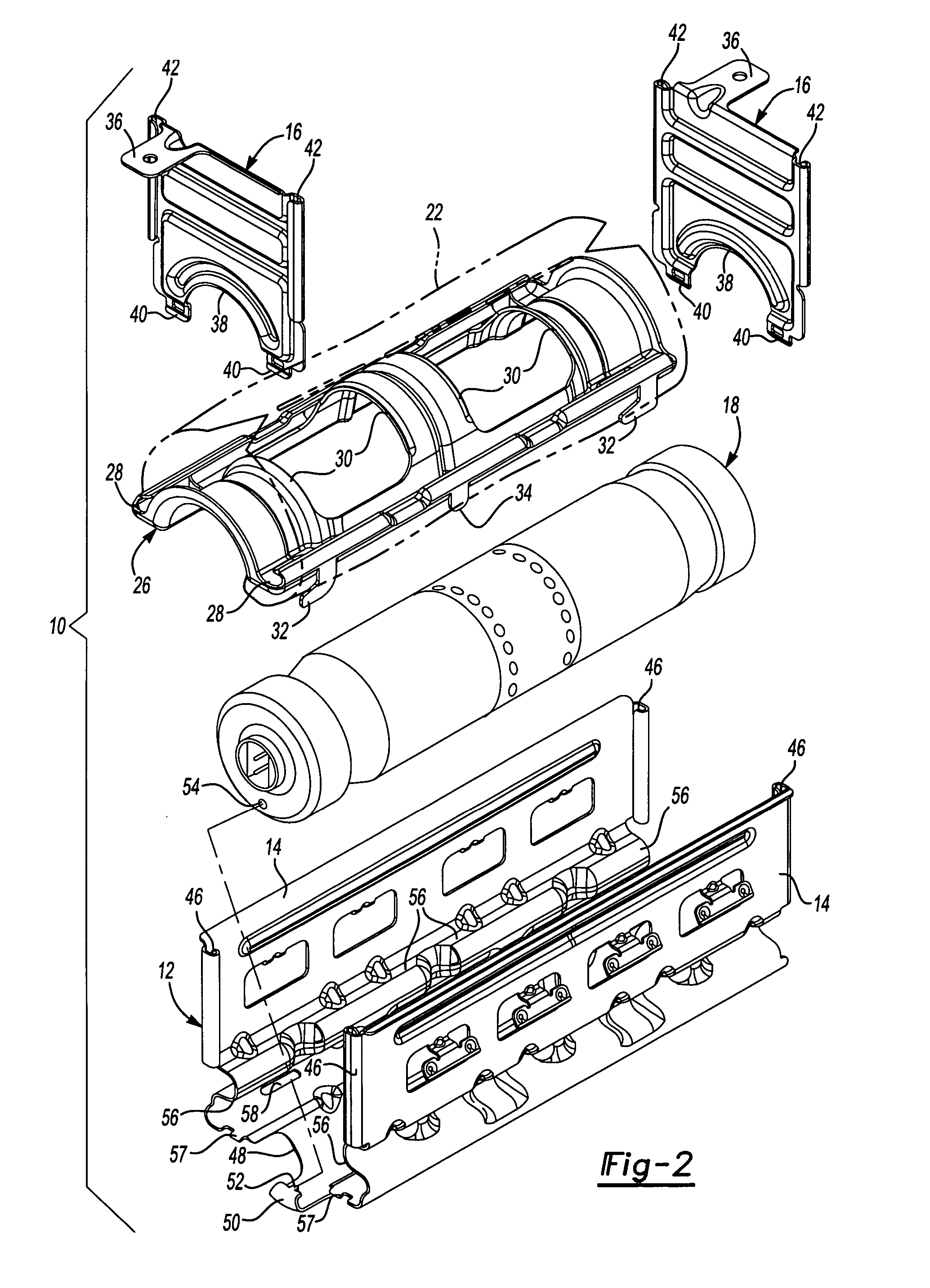

Passenger airbag module

InactiveUS20070176398A1Eliminating bunchingEliminate foldPedestrian/occupant safety arrangementEngineeringAirbag

A passenger airbag module includes opposite side walls connected by a rear wall. The side walls each include at least one inward projection that traps a semi-cylindrical retainer between the projections and the rear wall. The retainer holds the inflator and airbag within the housing. End walls connect the side walls with interlocking channels thereby preventing the side walls from releasing the retainer, inflator and airbag.

Owner:TOYODA GOSEI CO LTD

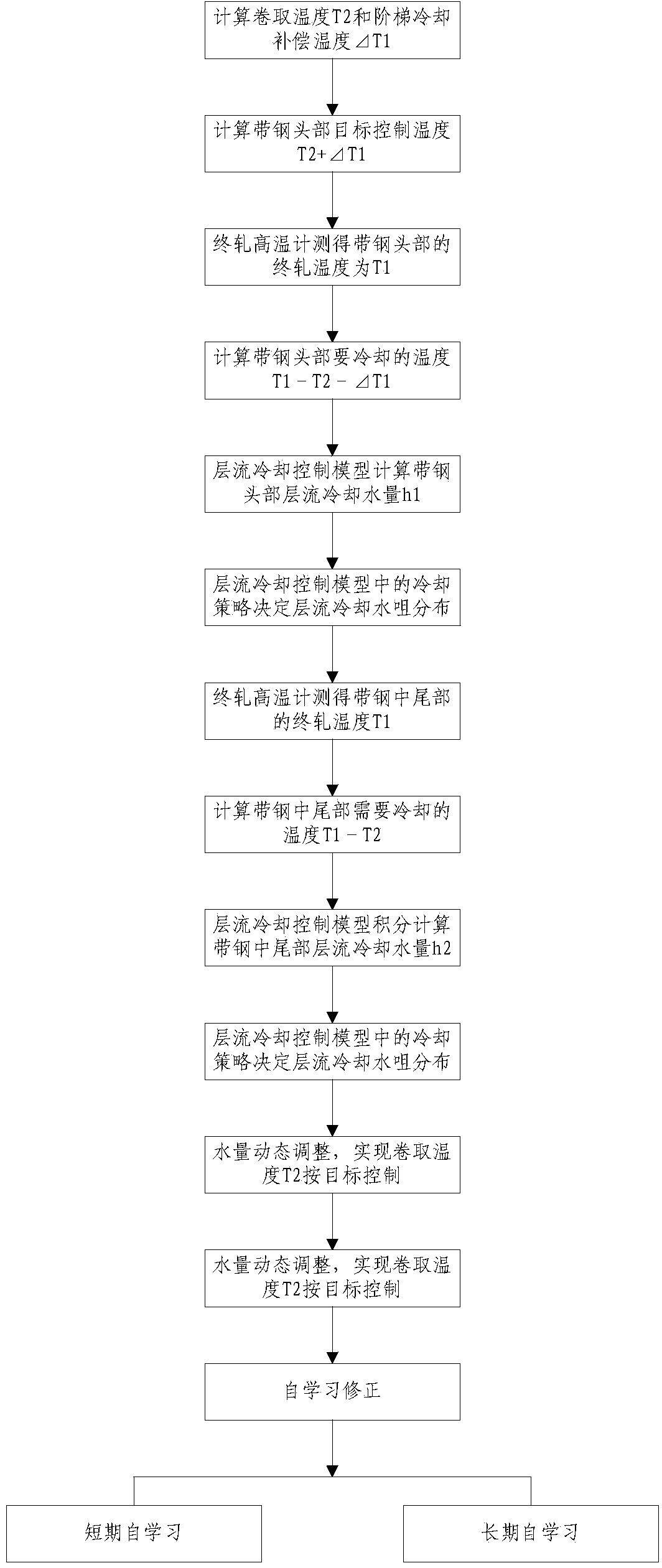

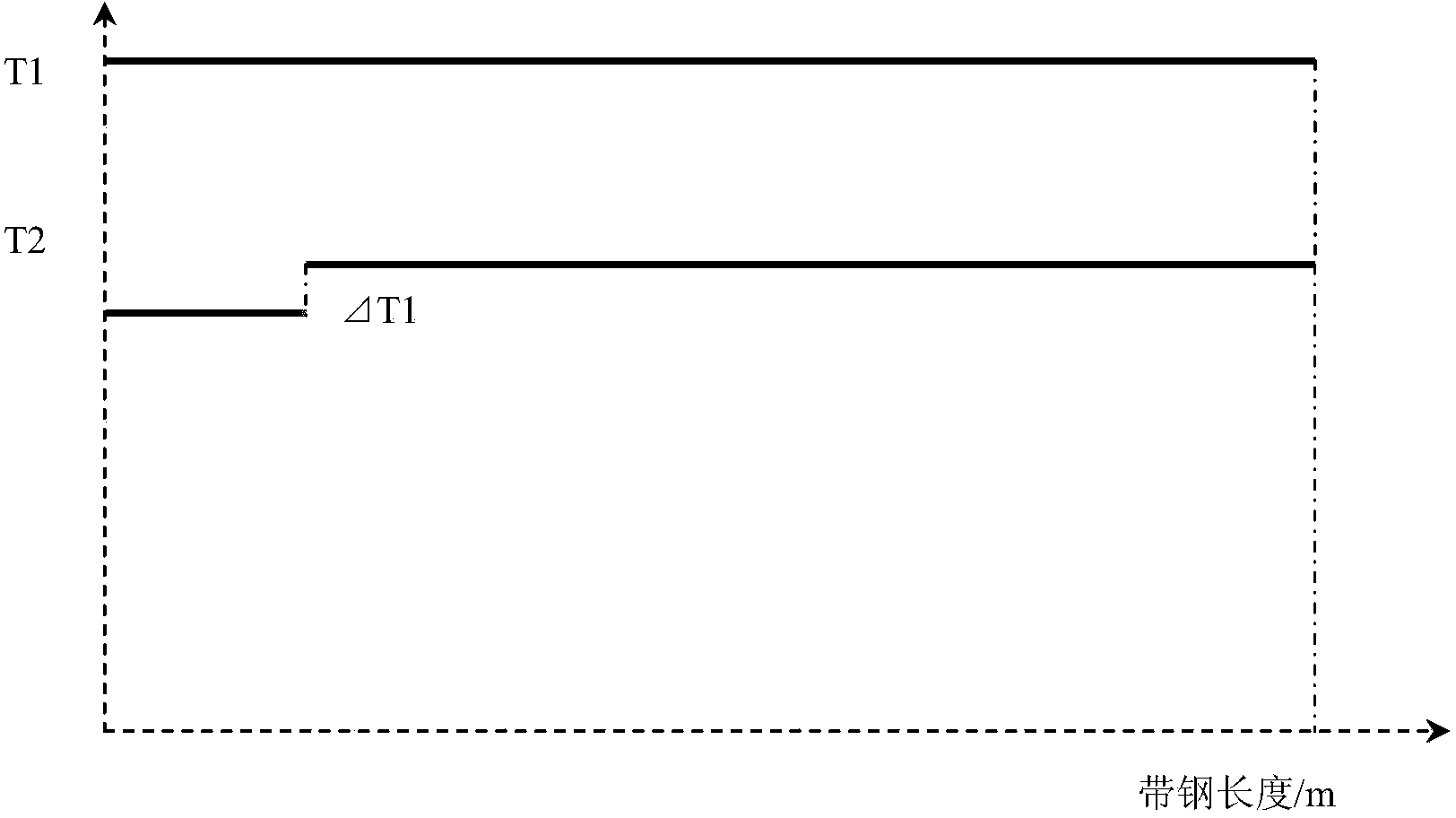

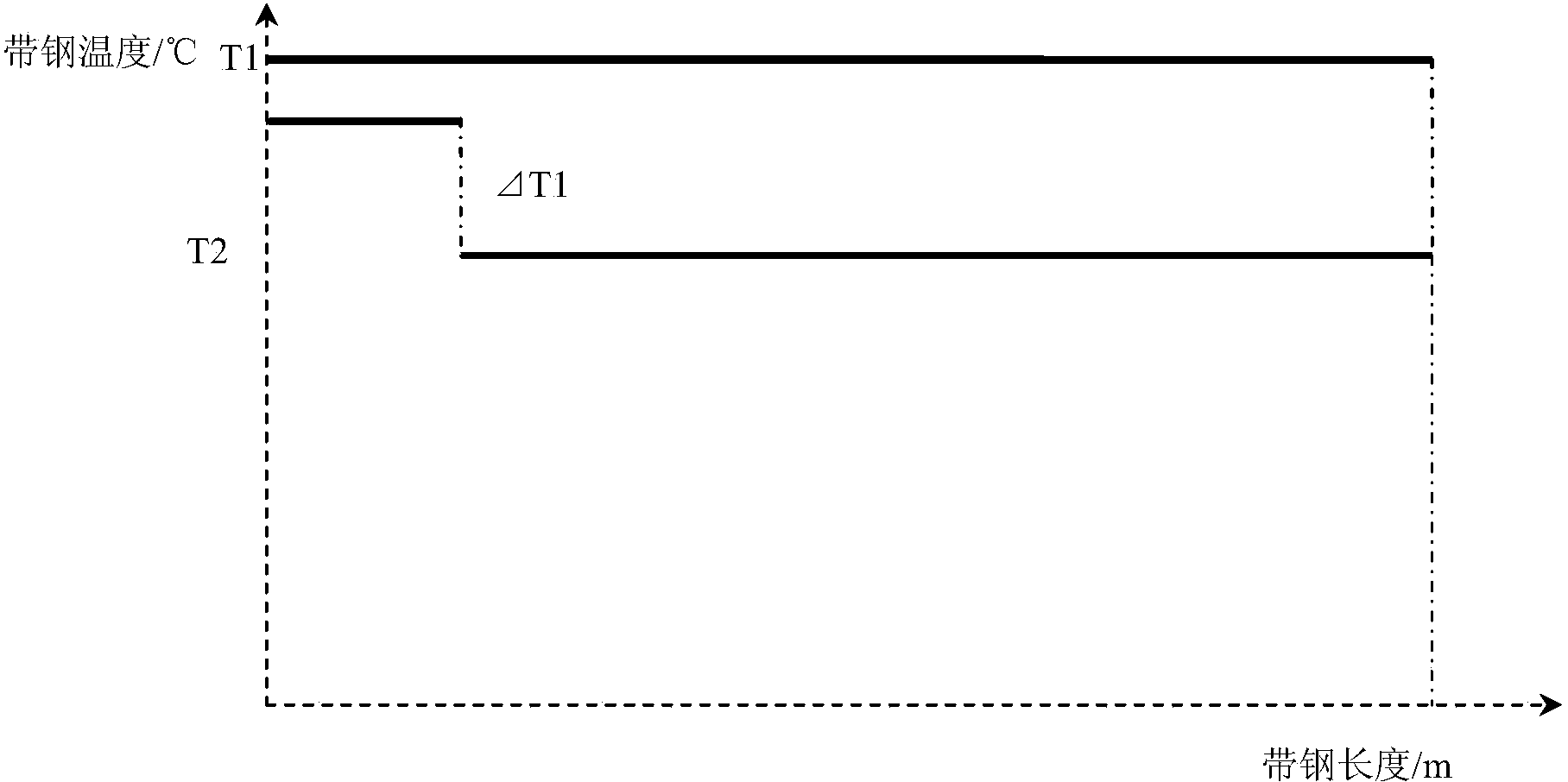

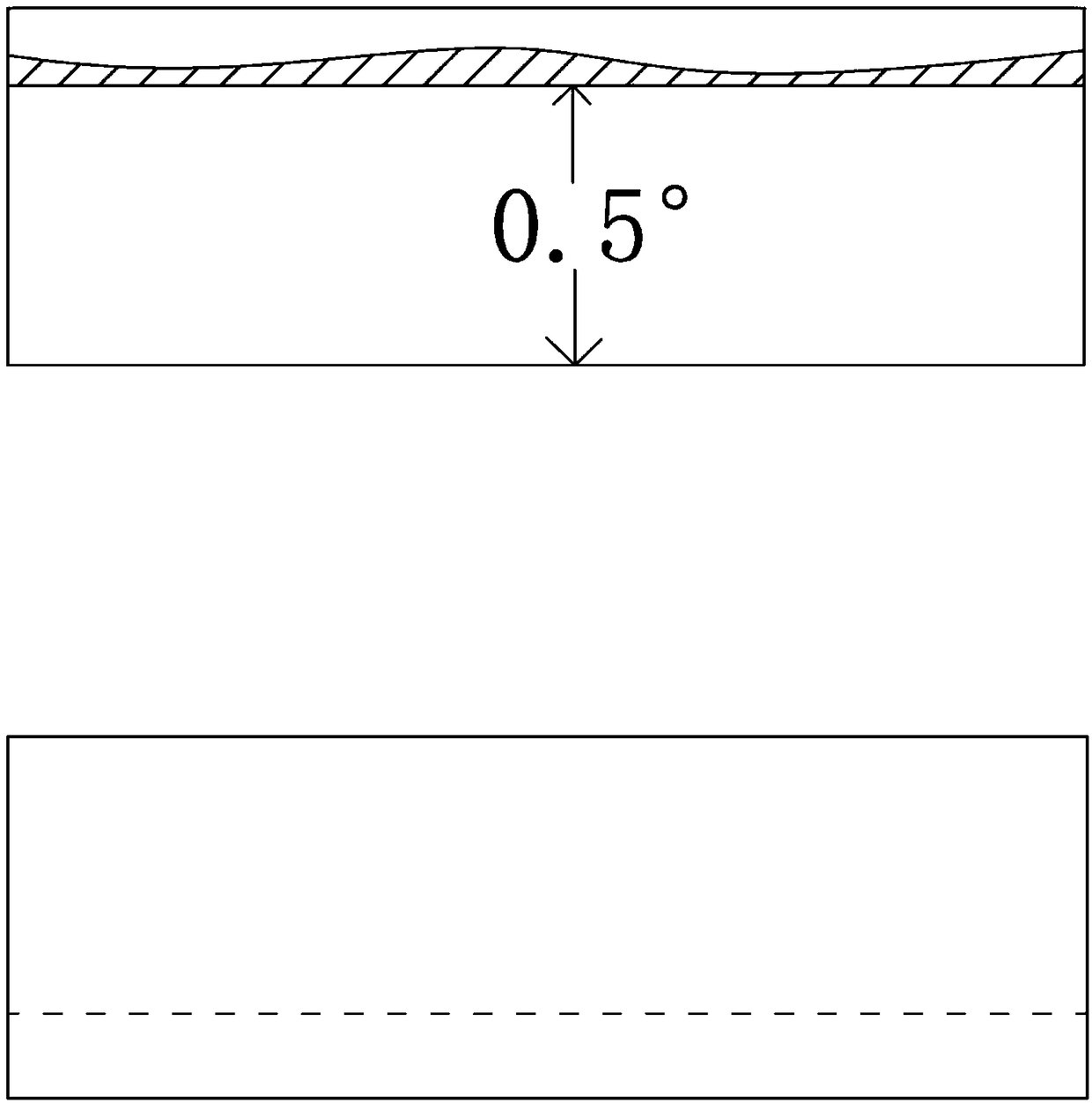

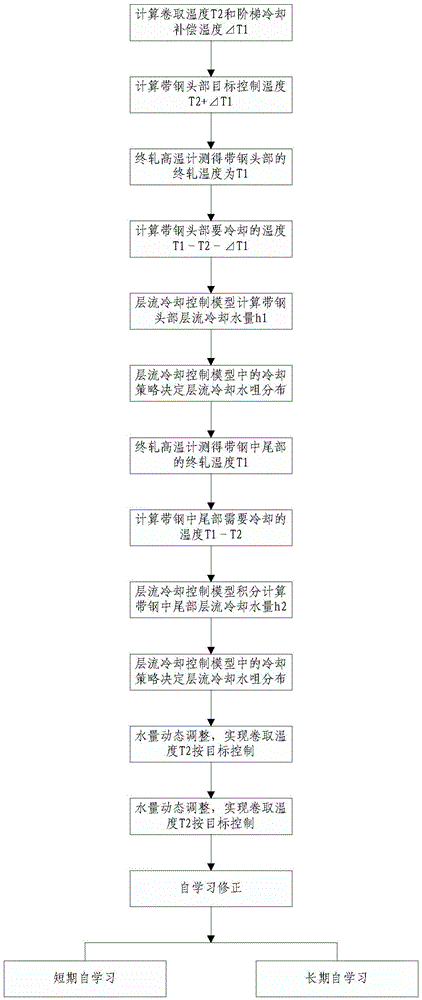

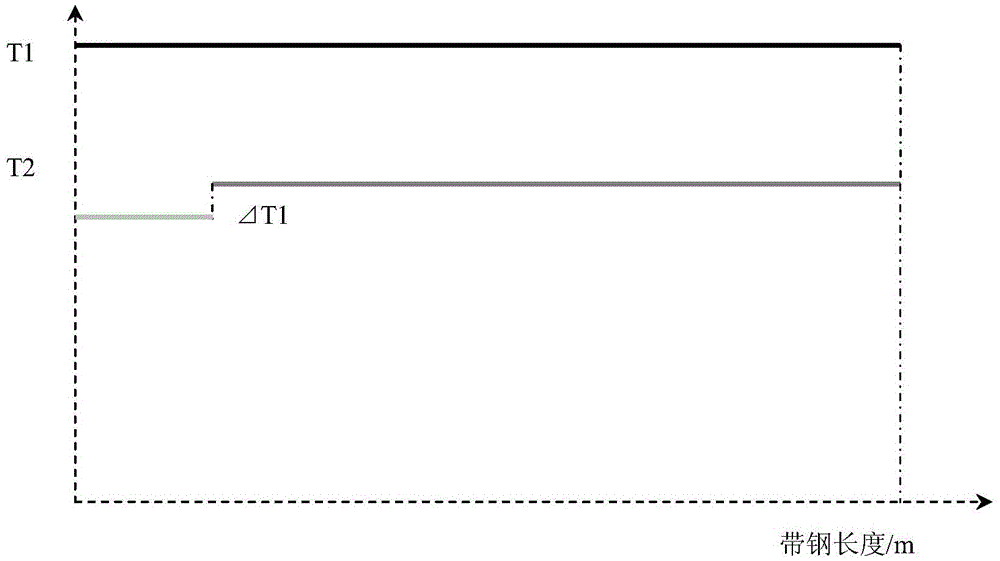

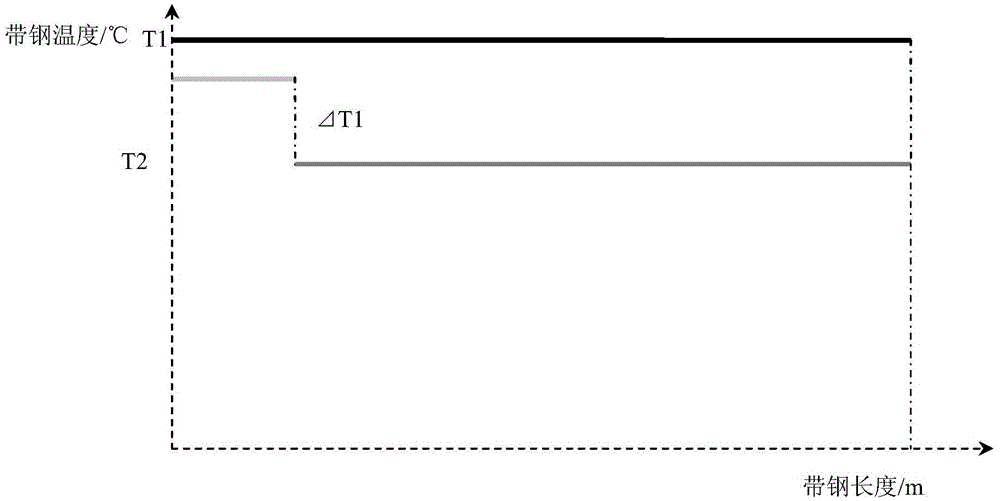

Stepped hot rolled strip production line laminar flow cooling control method

ActiveCN104307891AModerate straightness and hardnessRun smoothlyTemperature control deviceHot rolledStrip steel

The invention discloses a stepped hot rolled strip production line laminar flow cooling control method. The method comprises the following steps: I, setting the temperature of the head of strip steel: calculating temperature to be cooled of the head of the strip steel by a laminar flow cooling control model through rolling temperature, stepped cooling compensation temperature and strip steel head finish rolling temperature; II, setting a strip steel head cooling scheme: calculating cooling water quantity of the laminar flow of the head of the strip steel by the laminar flow cooling control model according to the temperature to be cooled of the head of the strip steel and the speed of the strip steel, and then determining the cooling water nozzle distribution of the laminar flow according to a cooling strategy in the laminar flow cooling control model; III, setting the temperature of the tail part in the strip steel: calculating the temperature to be cooled of the tail part in the strip steel by the laminar flow cooling control model through the finish rolling temperature of the tail part in the strip steel; IV, setting the cooling scheme of the tail part in the strip steel. The method has the characteristics that the turn-up of the head of the strip steel on a track is prevented and folding and unwinding are prevented from occurring on the inner ring of a steel coil, and can be widely applied to the field of production of hot rolled strips.

Owner:武汉钢铁有限公司

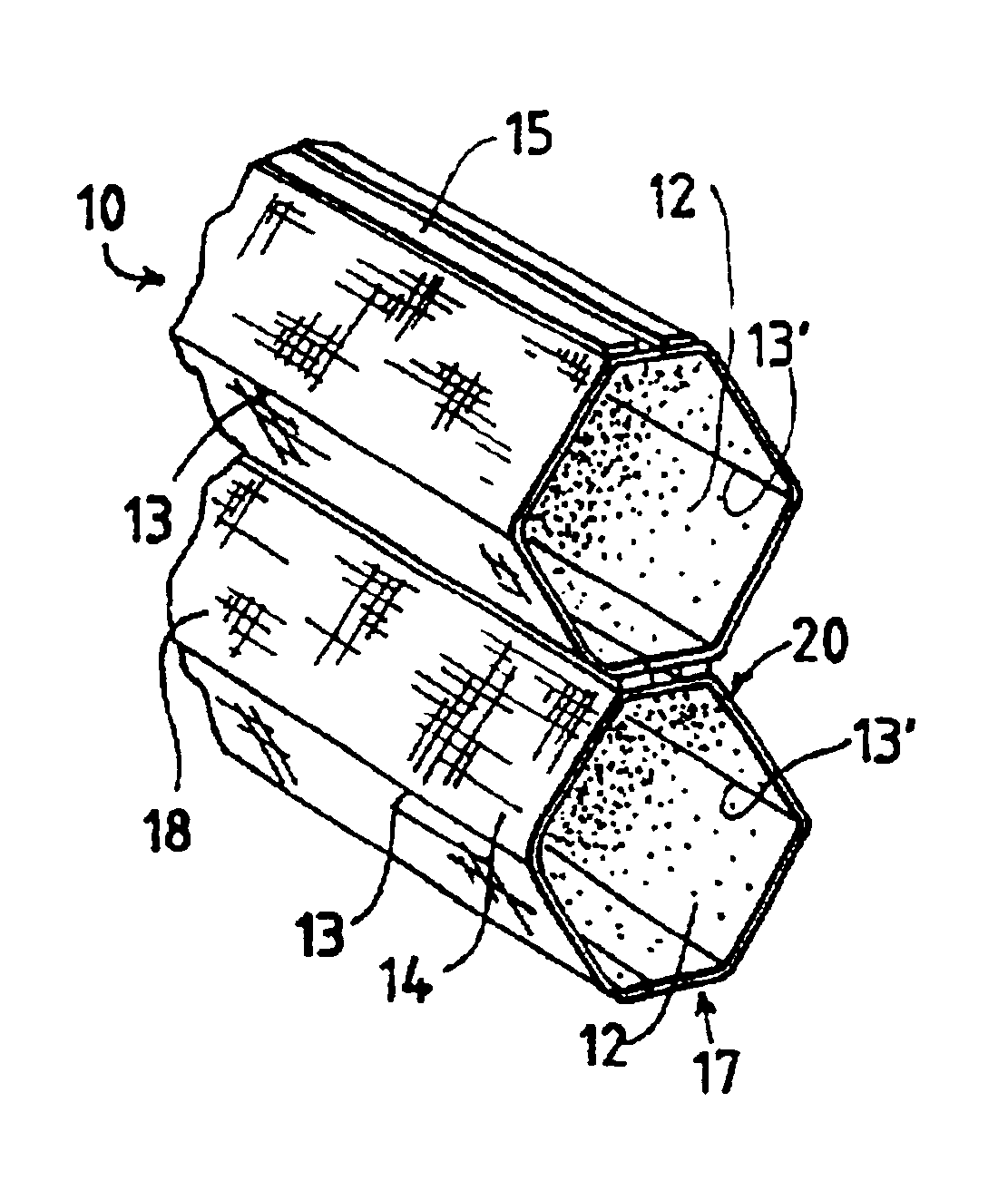

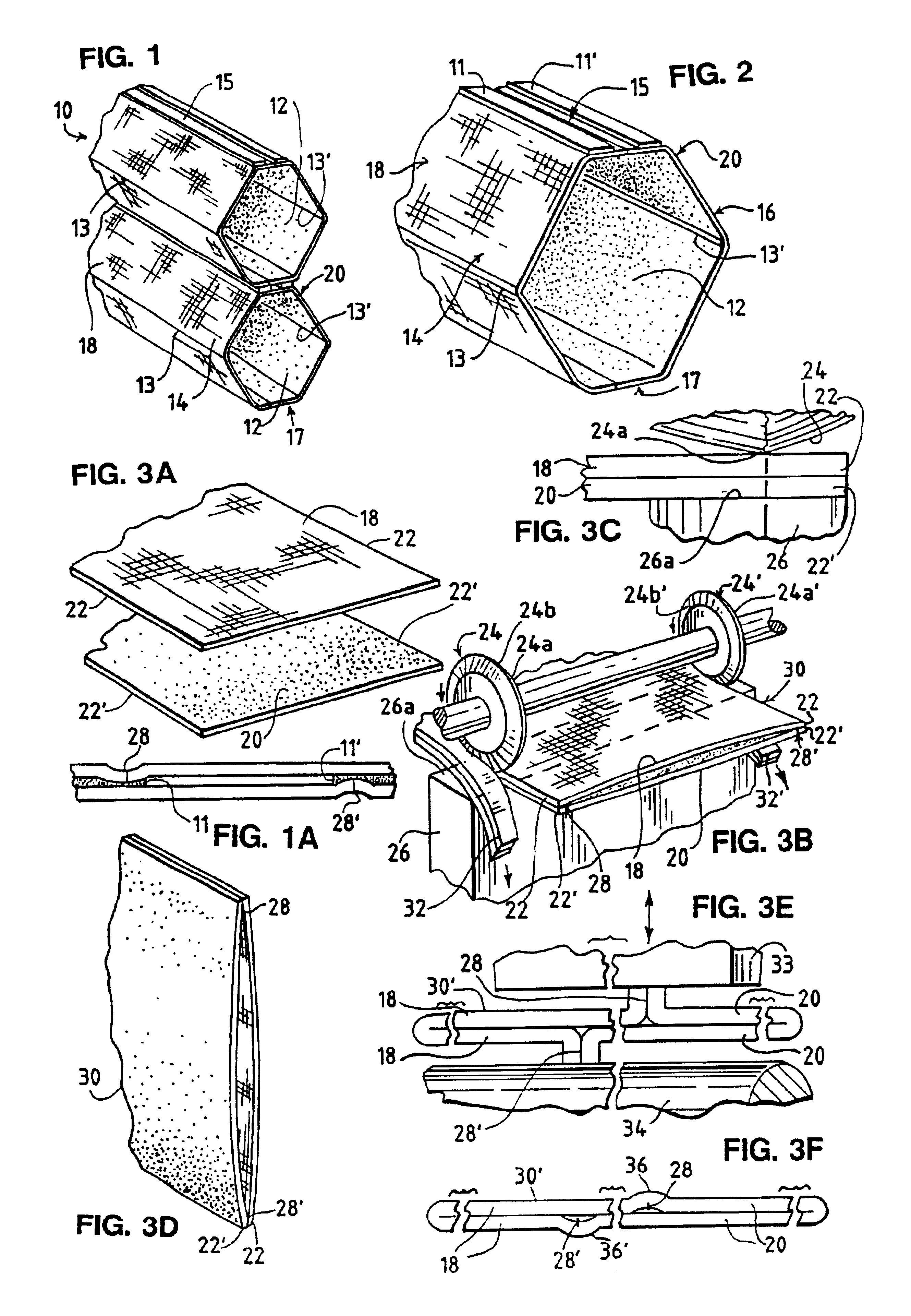

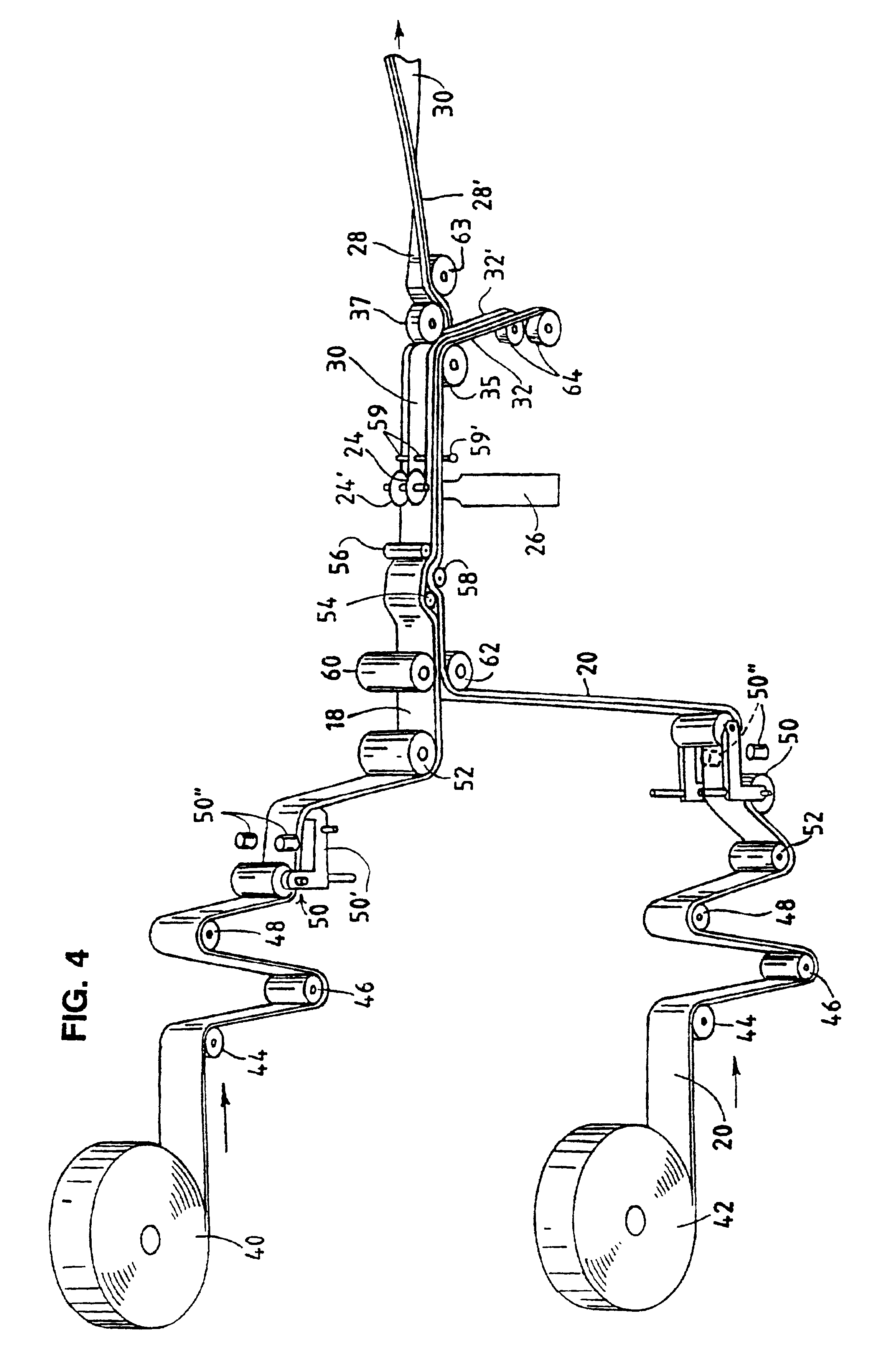

Cellular panel and method and apparatus for making the same

InactiveUS6908661B2Efficient mass productionReduce thicknessLayered productsLight protection screensSheet material

An expandable and contractible cellular panel 10 comprises a plurality of parallel, aligned, elongated tubular sections 12 secured together at the median region of their adjacent longitudinal margins to form the panel 10. The adjacent tubular sections 12 of the panel 10 are made of a pair of substantially identical separate strips of sheet material from those forming the other adjacent tubular sections 12. The various adjacent pairs of strips are laminated together along their confronting longitudinal margins. Each strip is made of at least two separate flexible substrate sheets 18,20 having completely different appearances, and are secured together by welding together their longitudinal margins. The corresponding substrate sheets 18,20 of all the strips have corresponding positions in the panel 10, so that all the substrate sheets having one appearance are on one side of the panel 10 and those having a different appearance are on the other side of the panel 10, and the welded portions 28,28′ are located in the laminated portion of the strips where they are hidden from view.

Owner:NEWELL OPERATING COMPANY

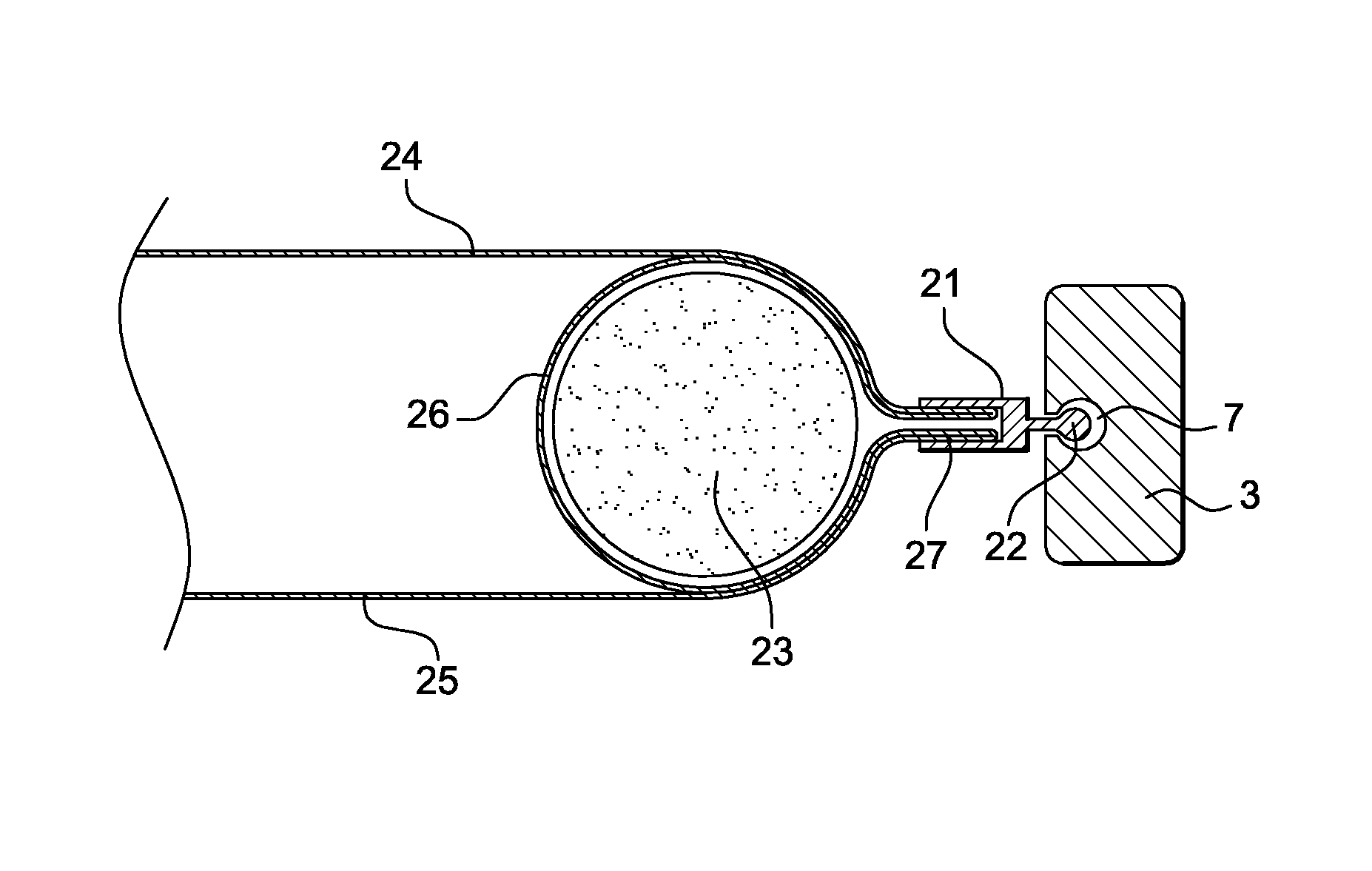

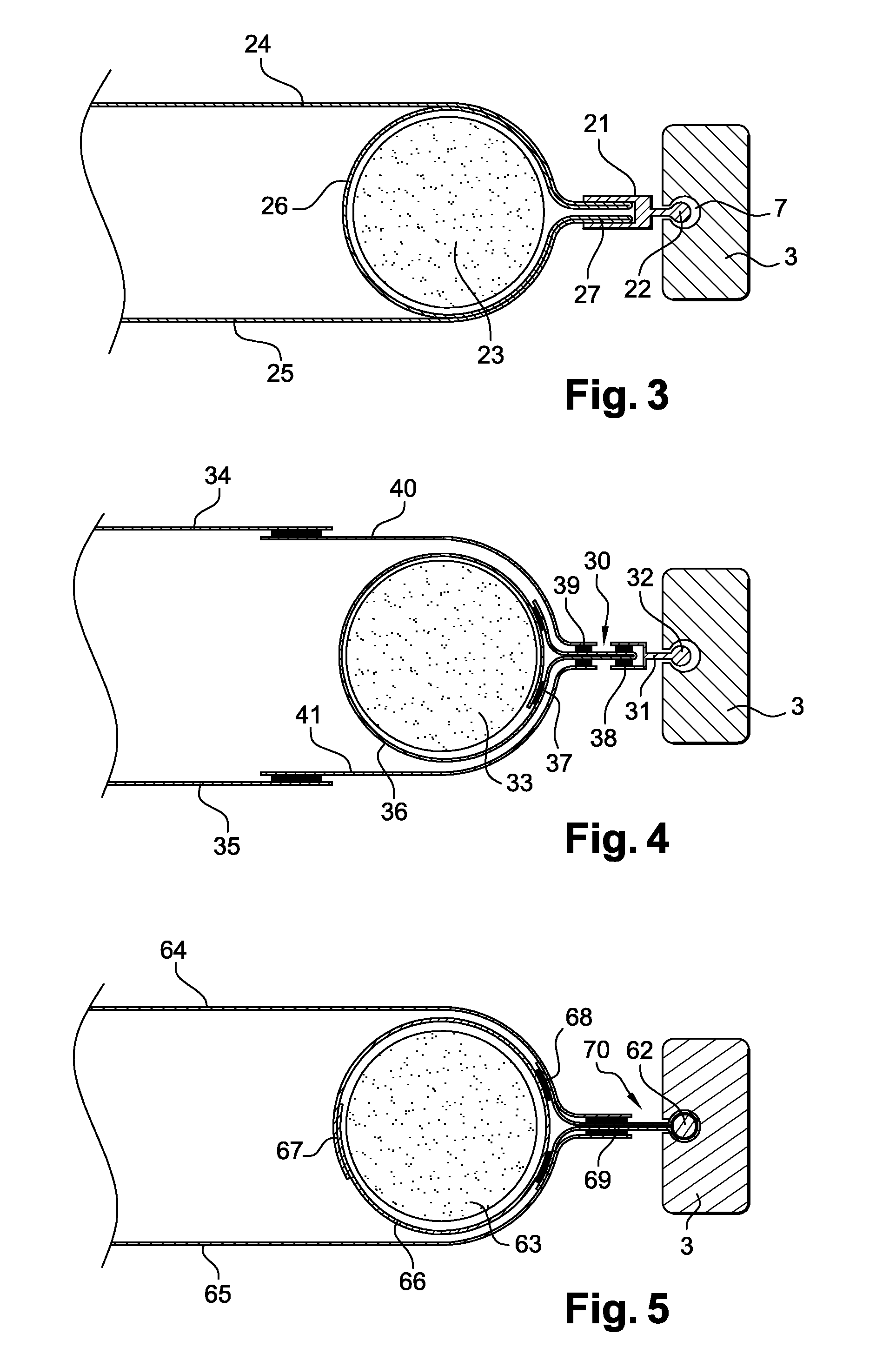

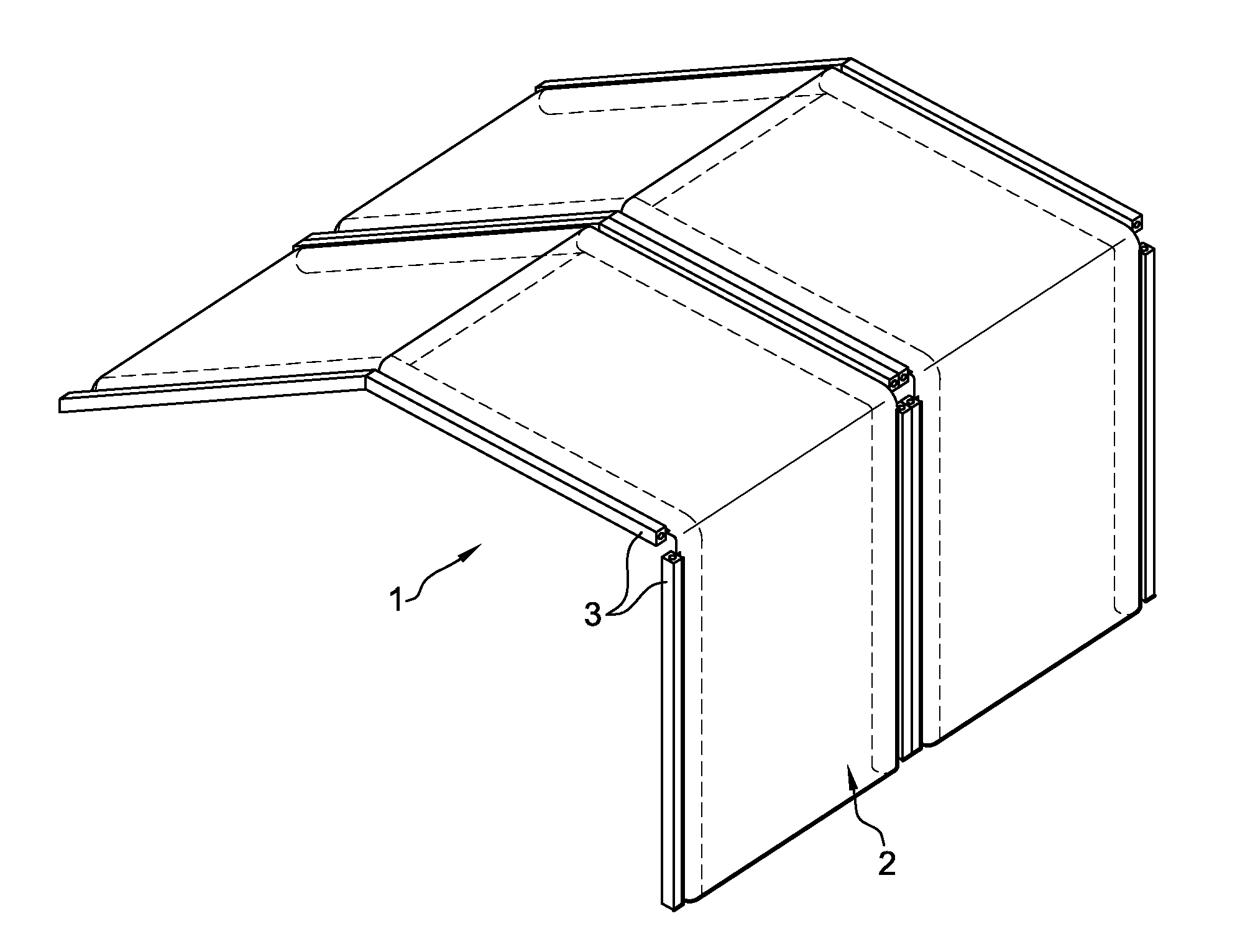

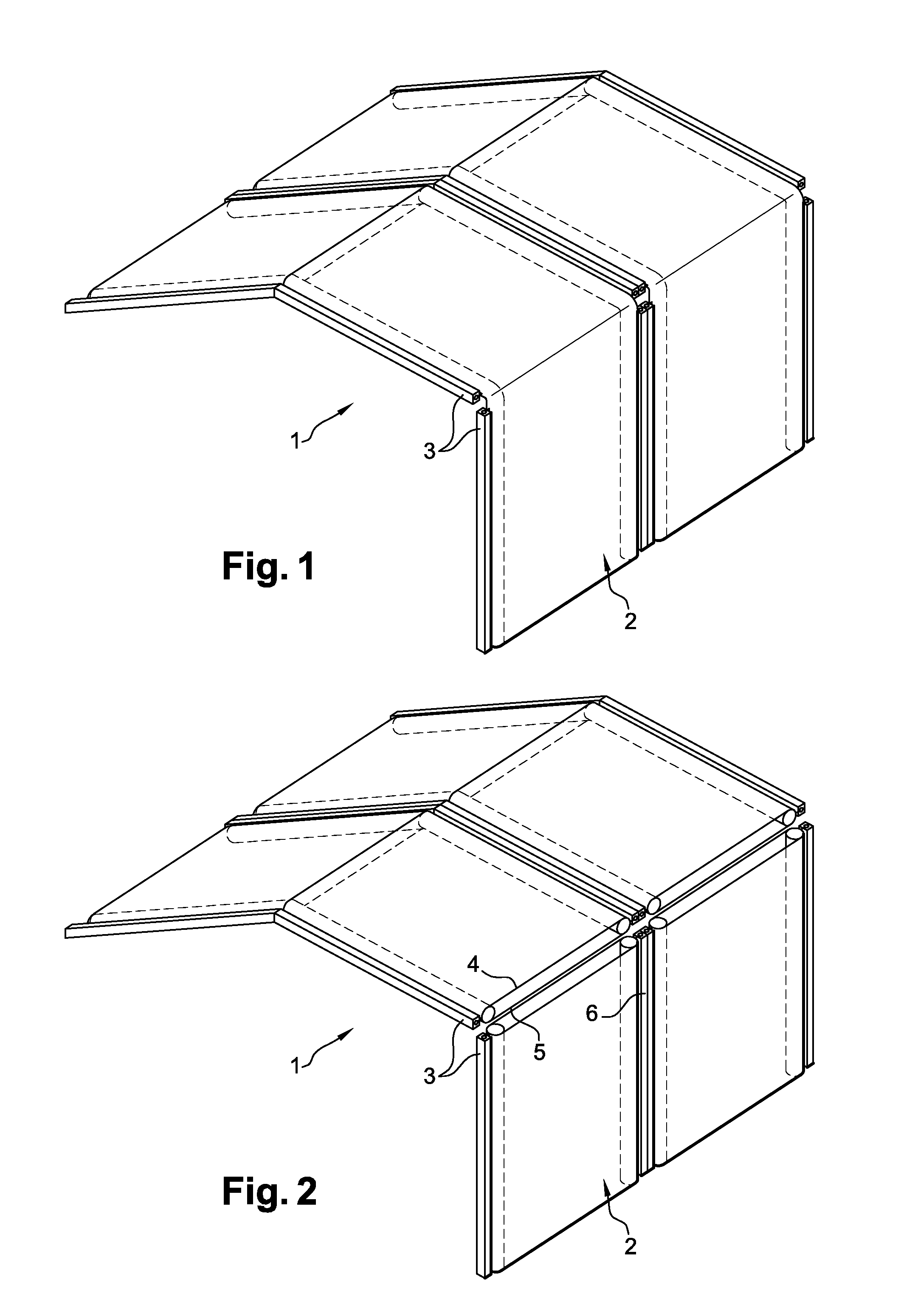

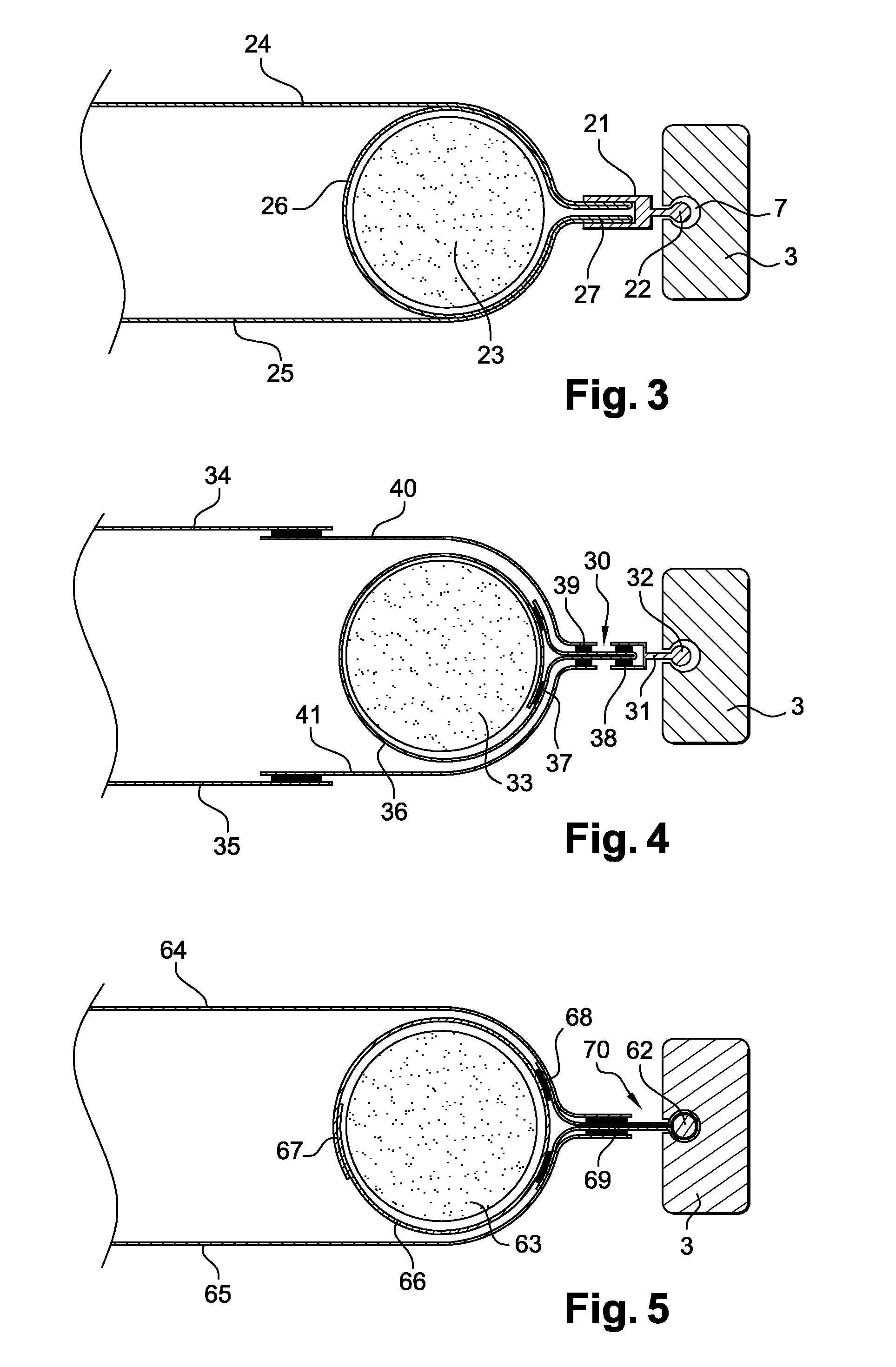

Flexible dual skin wall and device for tensioning a dual skin flexible wall

A device for tensioning a dual-skin flexible wall capable of interaction with at least one rigid mount, the device being mounted at the opposite edges of two skins to be retained by the rigid mount. The device includes a cord designed to interact with a groove formed in the rigid mount, and an inflatable bead capable of spacing the two skins away from and parallel to each other. Once inflated, the inflatable bead has a substantially cylindrical shape and remains confined outside the volume occupied by the rigid mount.

Owner:TISSAGE & ENDUCTION SERGE FERRARI SA

Infant food & debris catcher

An easily attachable, washable food, utensil and debris catcher device is easily fitted to all types of commercially available high chairs using a wide variety of attachment structures and operates to hold any small items or food spilled in the area of the child's seat and legs which would otherwise pass through to the floor. The catcher is designed to be attached to and detached from the high chair quickly and easily, yet can be attached for long periods of time especially where it is employed to catch dry objects such as toys or dry food such as whole peas or cereal. The catcher can be made from a wide range of material and can employ a wide range of attachment systems, including snap members, hook and loop members, hook and eyelet members, and latch members to name a few. Construction of the catcher is illustrated as well as variations in the construction which may enable the shape of the deployed catcher to be altered as well as one and two ply versions.

Owner:ROMANIUK JOHANNA LOUISE

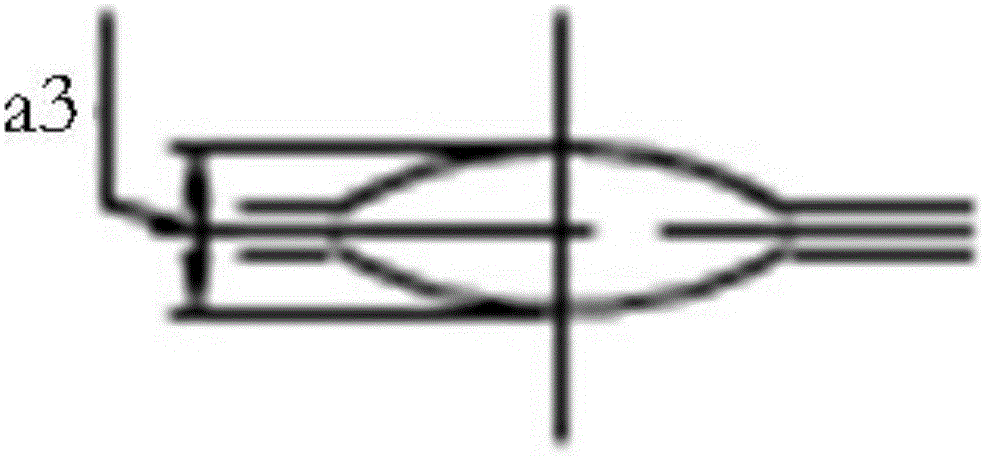

Forging forming process of rotating shafts for locomotive

InactiveCN108160905AReduce wearReduce manufacturing costRailway componentsForging/hammering/pressing machinesDiameter ratioForming processes

The invention provides a forging forming process of rotating shafts for a locomotive. The forging forming process comprises the following steps of a, blanking, wherein raw materials are selected by taking appropriate specifications of the drawing length of a small-diameter rod and the upsetting height-diameter ratio of a large-diameter end as references; b, machining, wherein the raw materials areheated, the length of the raw materials which need to be drawn are positioned through a positioning device, and a preformed billet is formed by drawing the rod through a clamping die; and c, forging,wherein the preformed billet is put into a forming die and subjected to upsetting, and then a final forged part is obtained. According to the forging forming process of the rotating shafts for the locomotive, a distributed forging and local forming forging method is adopted, that is to say, a drawing process is adopted for the rod of the forged part, and an upsetting process is adopted for an endround cake, so that the production cost is low, and the die abrasion loss is low.

Owner:ZHUZHOU TIANLI FORGING IND

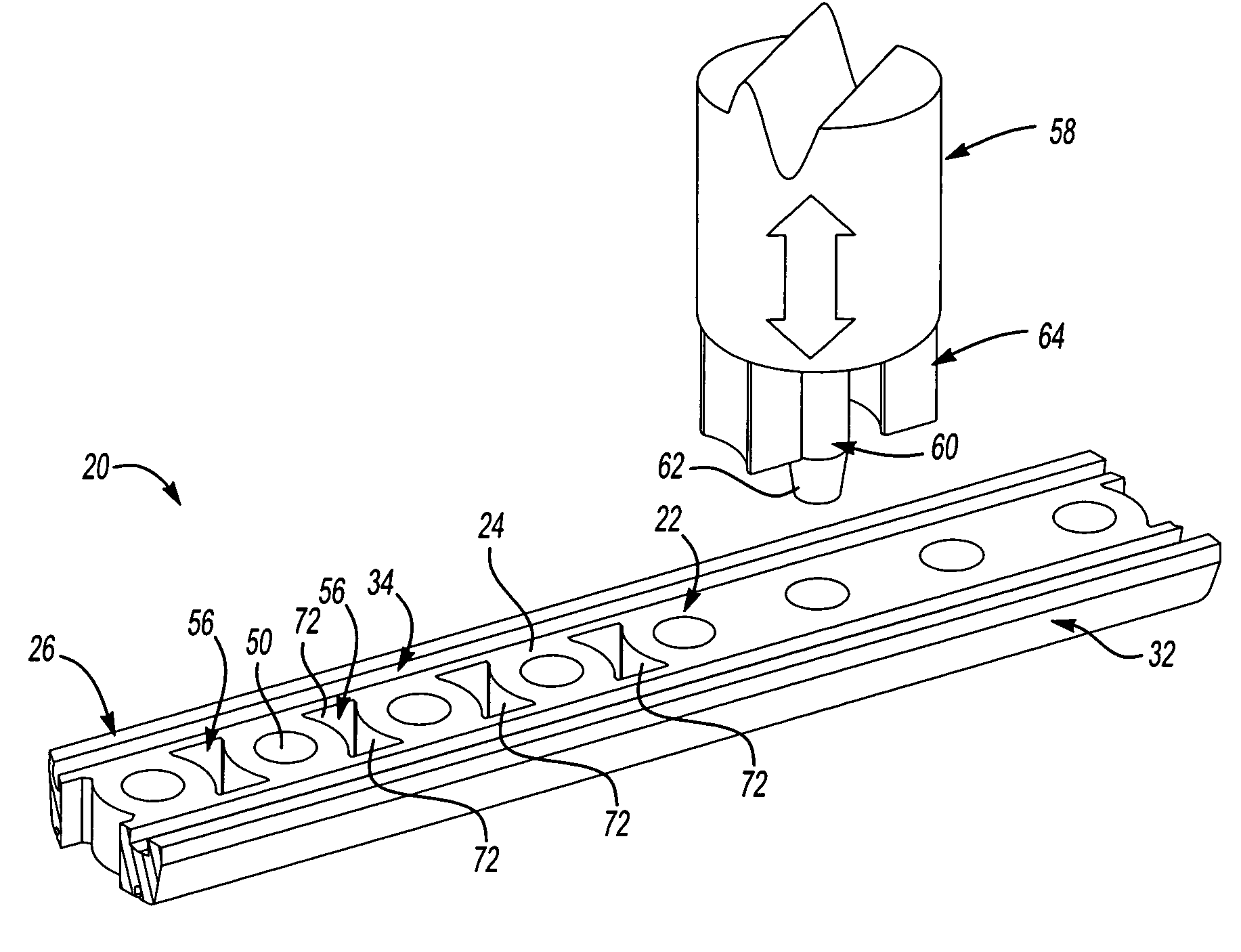

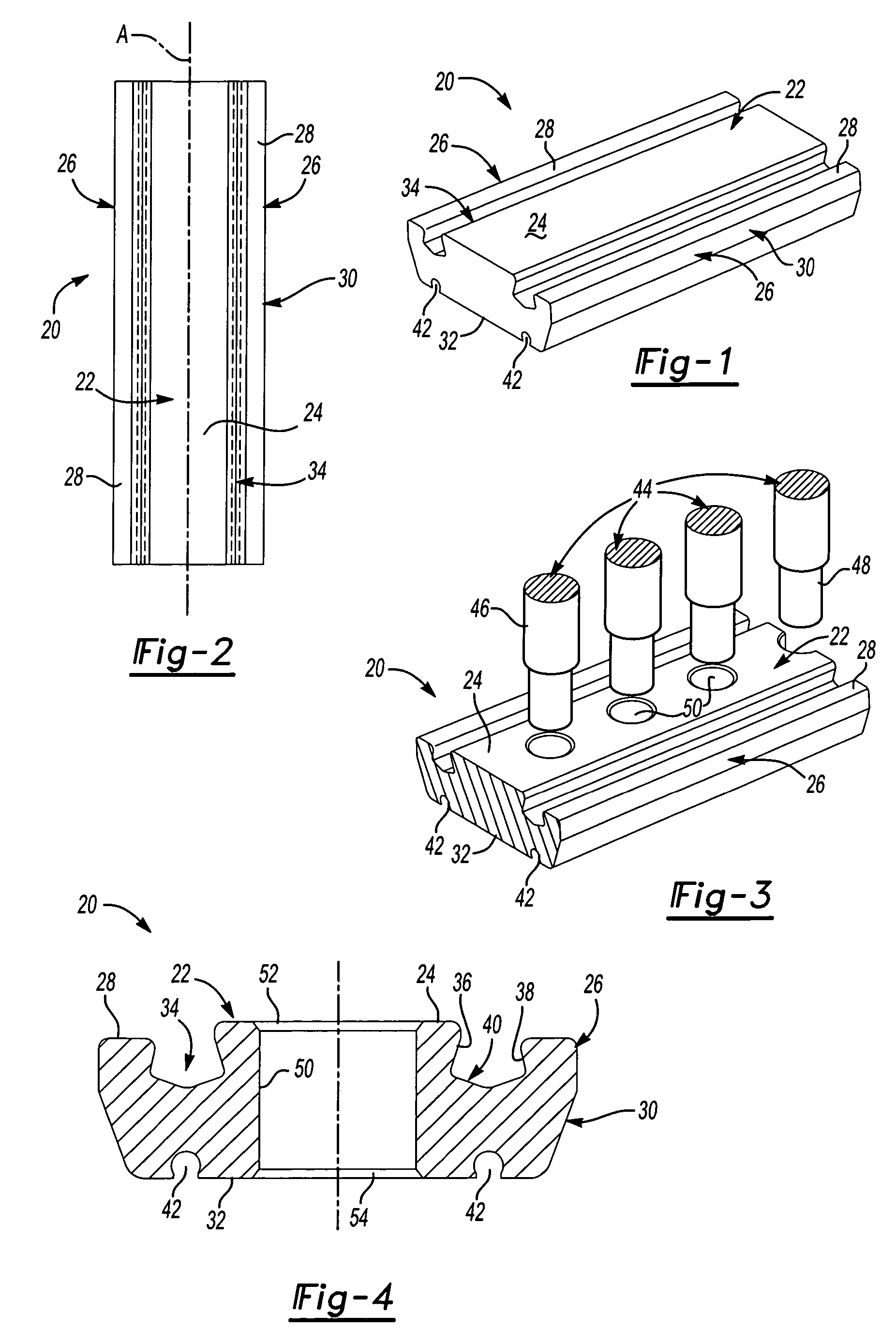

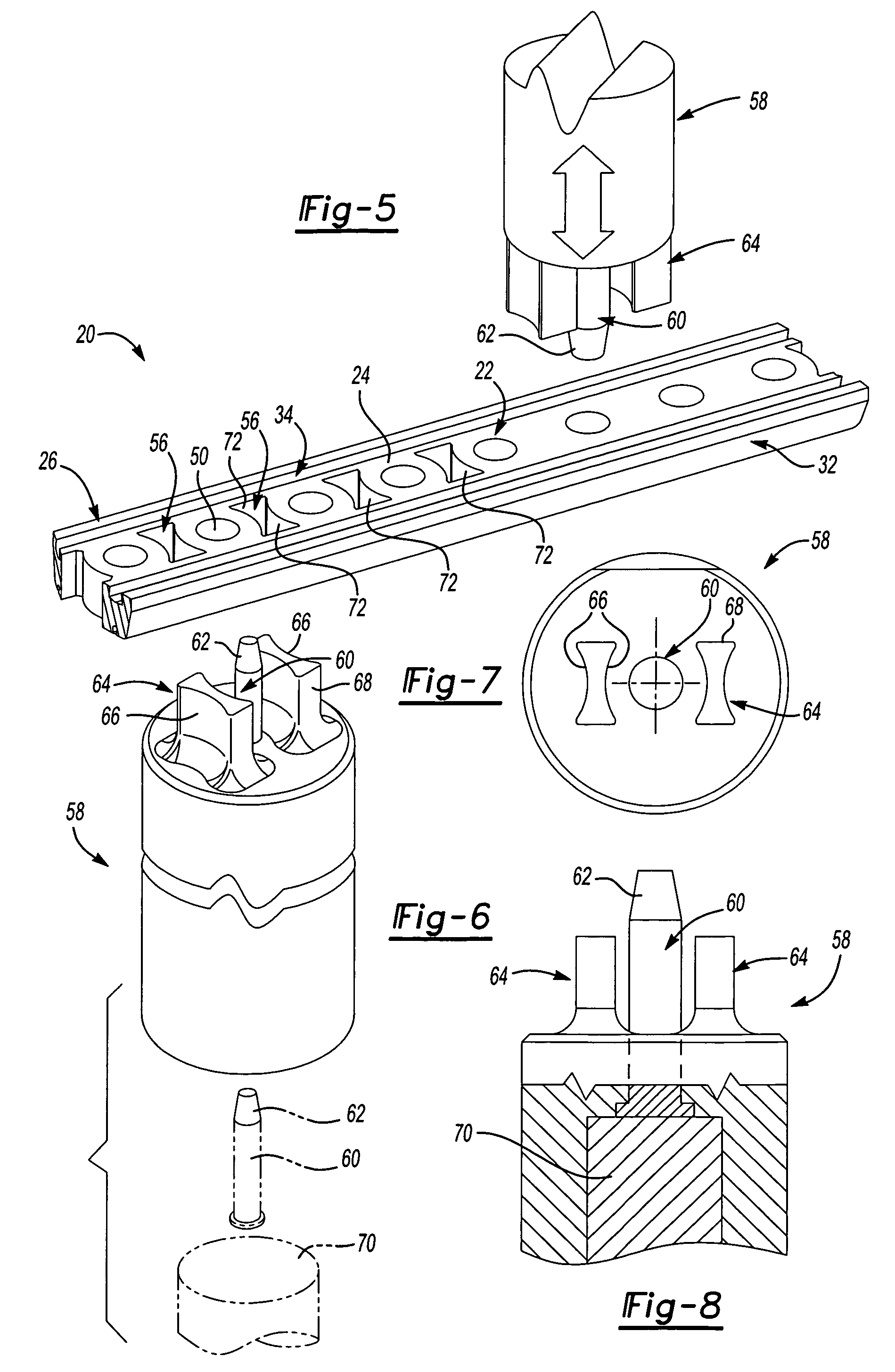

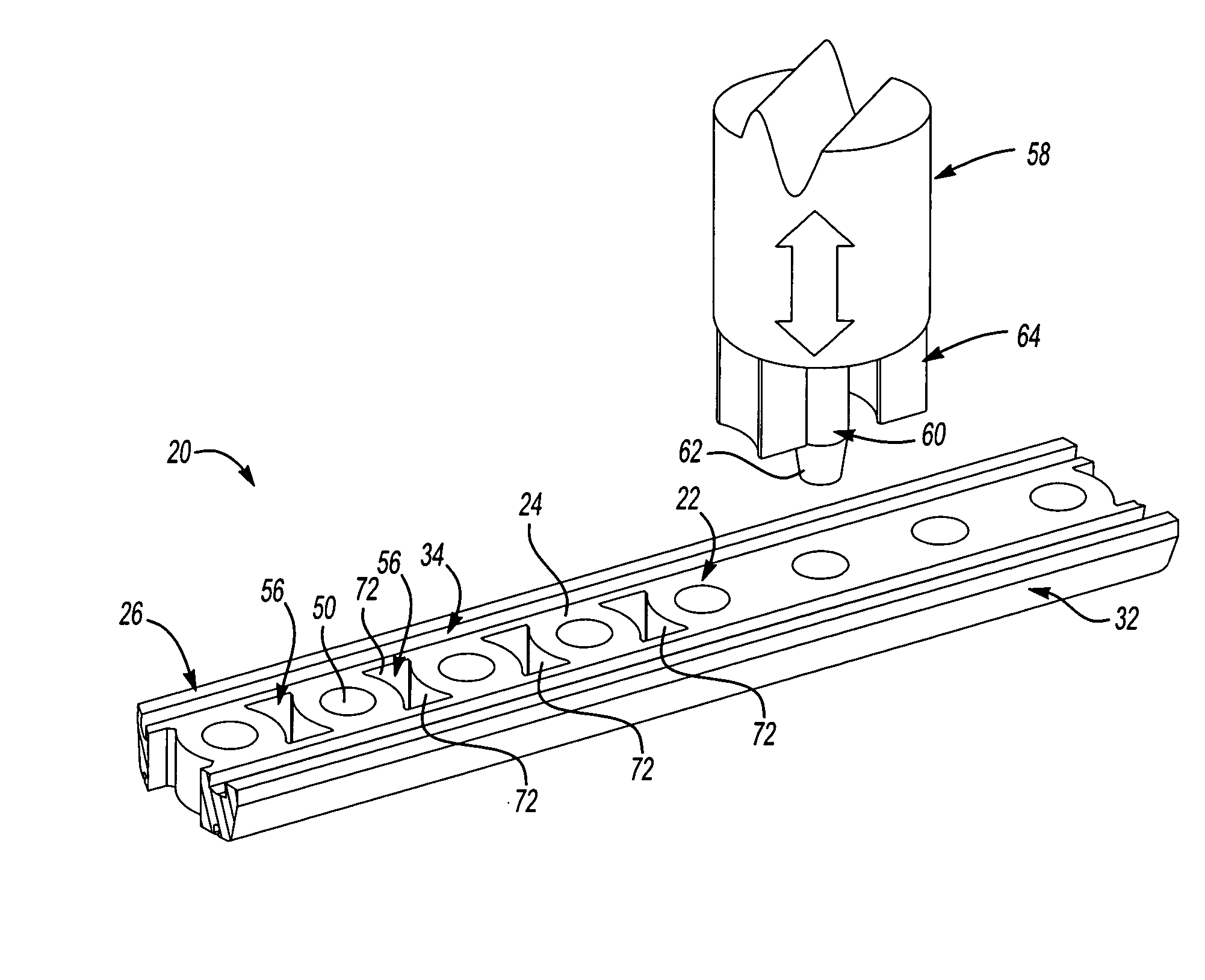

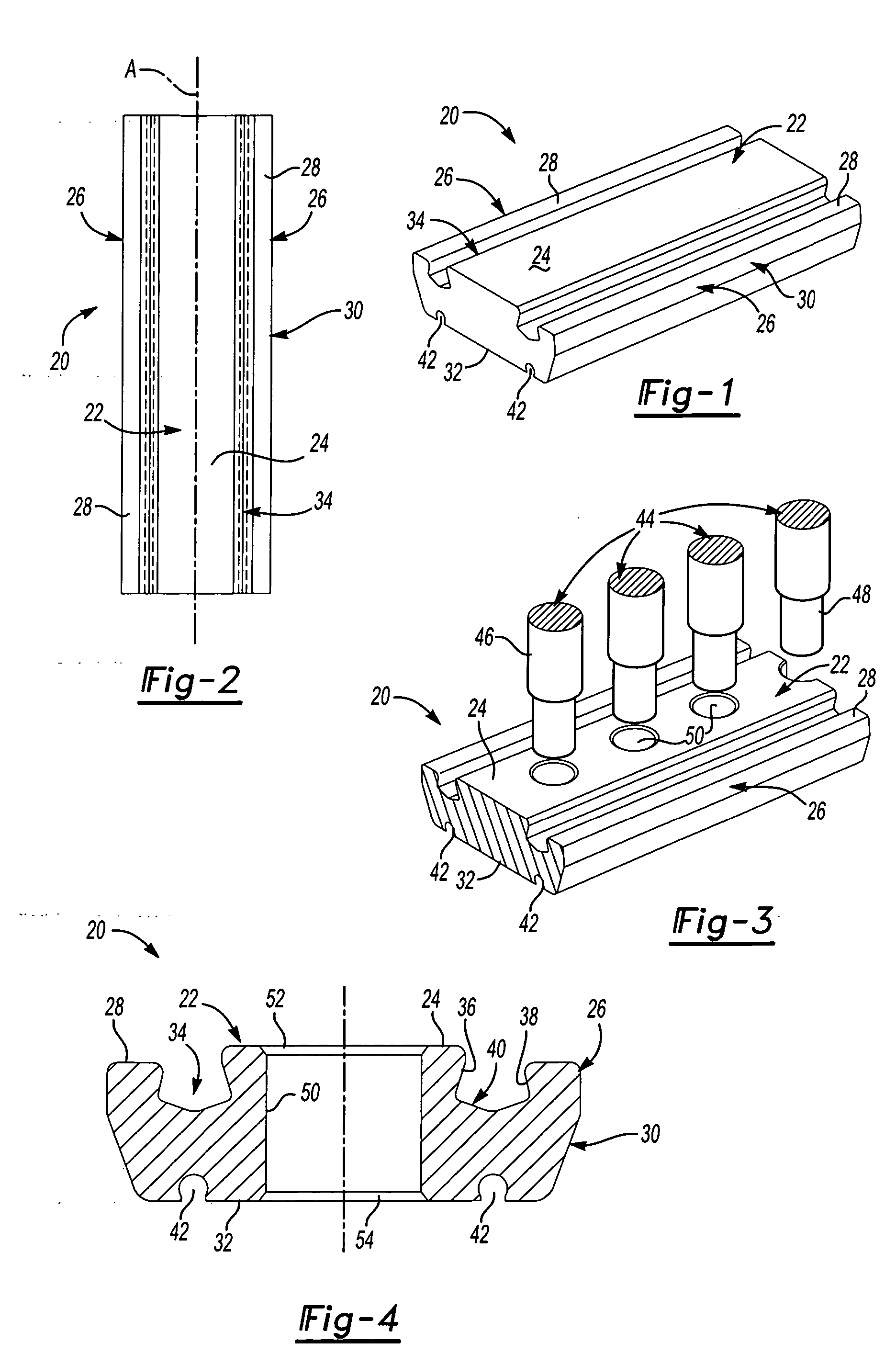

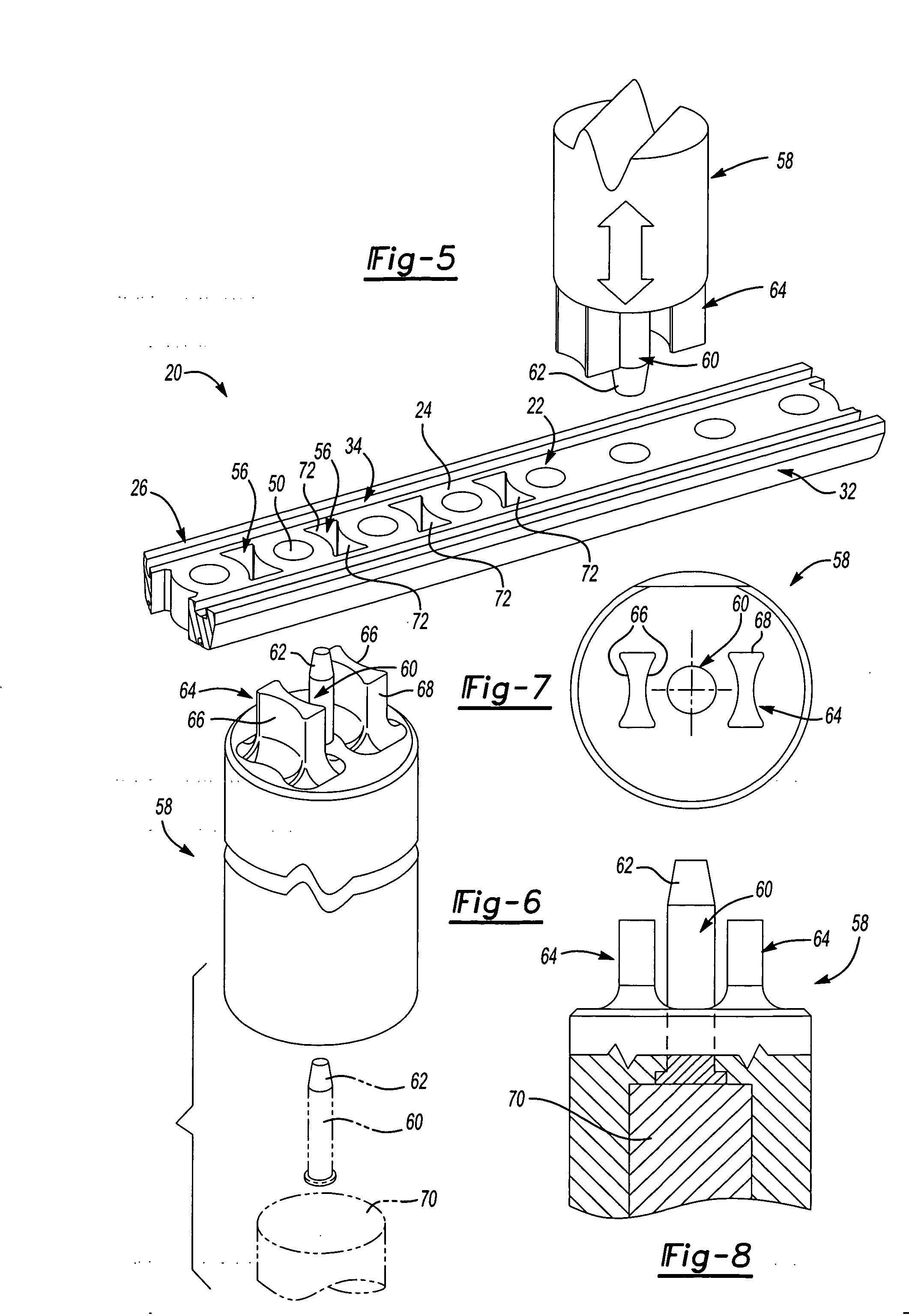

Self-attaching female fasteners, method of forming same and strip of interconnected fasteners

A method of forming pierce and clinch nuts by rolling a section having the desired cross-section, punching equally spaced bores through the central pilot portion and then punching configured openings through the central pilot portion having convex arcuate surfaces and eliminating sharp corners. The strip of interconnected self-attaching fasteners may be installed directly from the strip in a panel, fed in bulk or separate fasteners interconnected by frangible connectors. The resultant self-attaching nut includes a central pilot portion having a bore through the top face, integral flange portions extending from opposed sides and the pilot portion includes convex arcuate faces reducing or eliminating stress cracking and propagation of stress cracks.

Owner:WHITESELL FORMED COMPONENTS

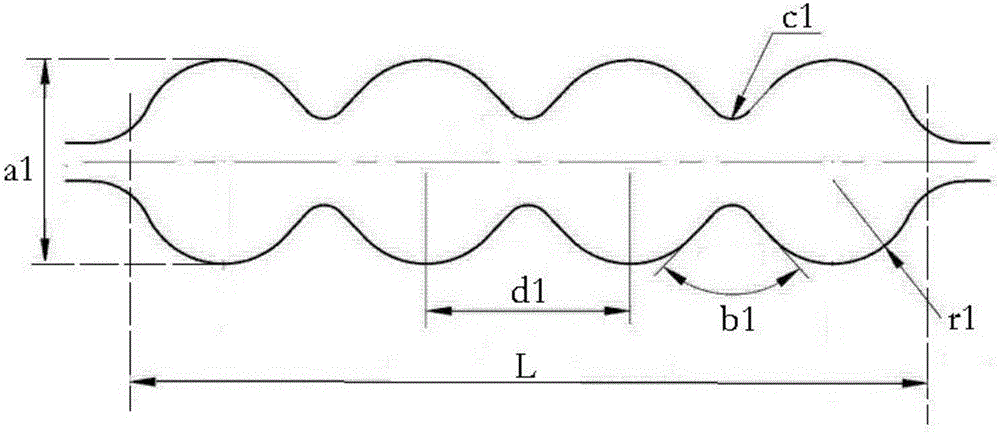

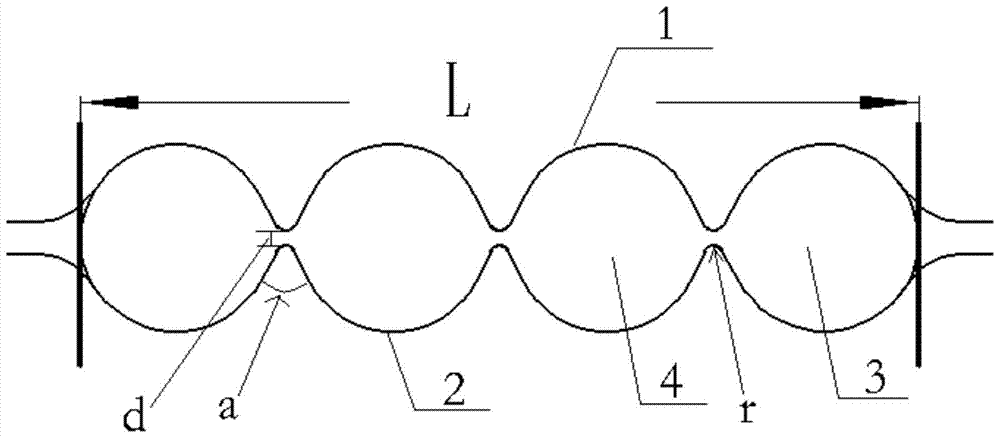

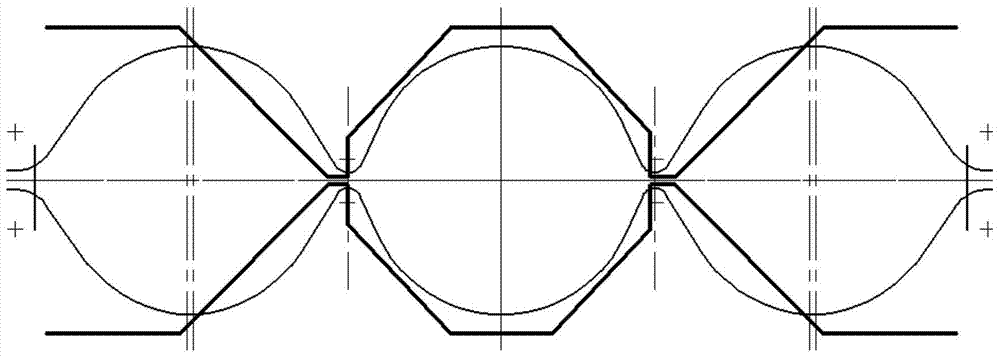

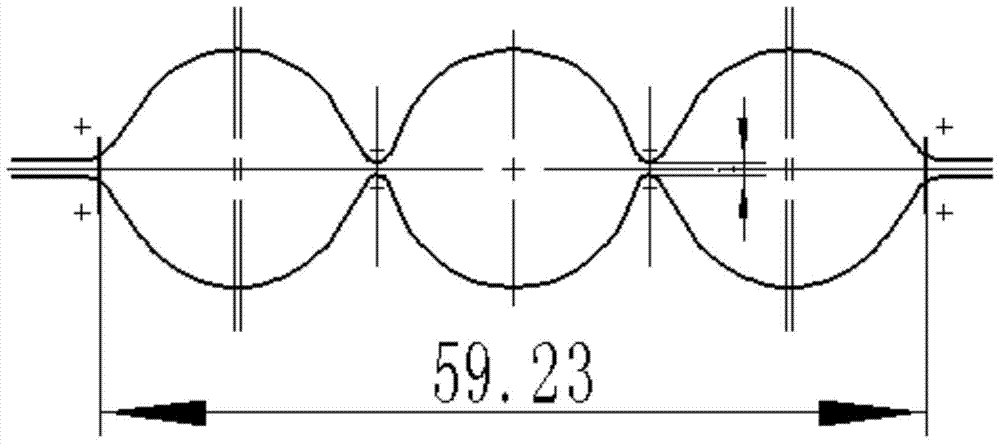

Slit-rolling groove

InactiveCN105080972AImprove mill productivityReduce material consumptionGuiding/positioning/aligning arrangementsRoll mill control devicesEllipseMiddle line

The invention discloses a slit-rolling groove. The slit-rolling groove comprises a pre-slitting groove K4, a slitting groove K3, an oval groove K2 and a final groove K1. The slit-rolling groove is characterized in that the height of the tank bottom of the pre-slitting groove K4 is 17.64mm, the roller wedge angle of the pre-slitting groove K4 is 88.5-89 degrees, and the circular arc radius of the wedge top of the pre-slitting groove K4 is 1.45-1.5mm; the height of the tank bottom of the slitting groove K3 is 14.5mm, the wedge angle of the slitting groove K3 is 50.5-51 degrees, and the circular arc radius of the wedge top of the slitting groove K3 is 0.6-0.9mm; the height of the tank bottom of the oval groove K2 is 8.5mm, and the height of the tank bottom of the final groove K1 is 11.2mm. Through the adoption of the slit-rolling groove disclosed by the invention, the good quality of products is guaranteed, the operation rate of a rolling machine is improved, the material consumption is reduced, the phenomenon of uneven slitting is avoided, midline folding is eliminated, the surface quality of finished products is improved, the size of finished products is stabilized, and the production efficiency is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

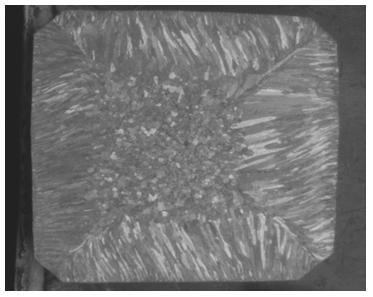

OCr17 continuous casting blank and production method thereof

The invention discloses an OCr17 continuous casting blank and a production method thereof. The continuous casting blank comprises the following chemical components in percentage by mass: 0.04-0.06% of C, 0.25-0.45% of Si, 0.40-0.55% of Mn, 0.035% or less of P, 0.030% or less of S, 16.50-16.75% of Cr, 0.60% or less of Ni, and the balance of Fe and inevitable impurities. The production method comprises the steps of: control of a continuous casting machine crystallizer water flow, a secondary cold water flow and crystallizer electromagnetic stirring parameters, slow cooling of the continuous casting blank and casting blank angle finishing chamfering plane width control. The method enables the surface pass percent of the continuous casting blank of rolled steel to reach above 99%, and guarantees elimination of surface and subsurface cracks of the continuous casting blank; and through angle finishing, the angle rolling broadening deformation is reduced, the angle temperature drop is reduced, the OCr17 wire folding and cracks are eliminated, the wire rod primary inspection pass percent is above 99%, and the acid washing secondary inspection pass percent is above 95%.

Owner:XINGTAI IRON & STEEL

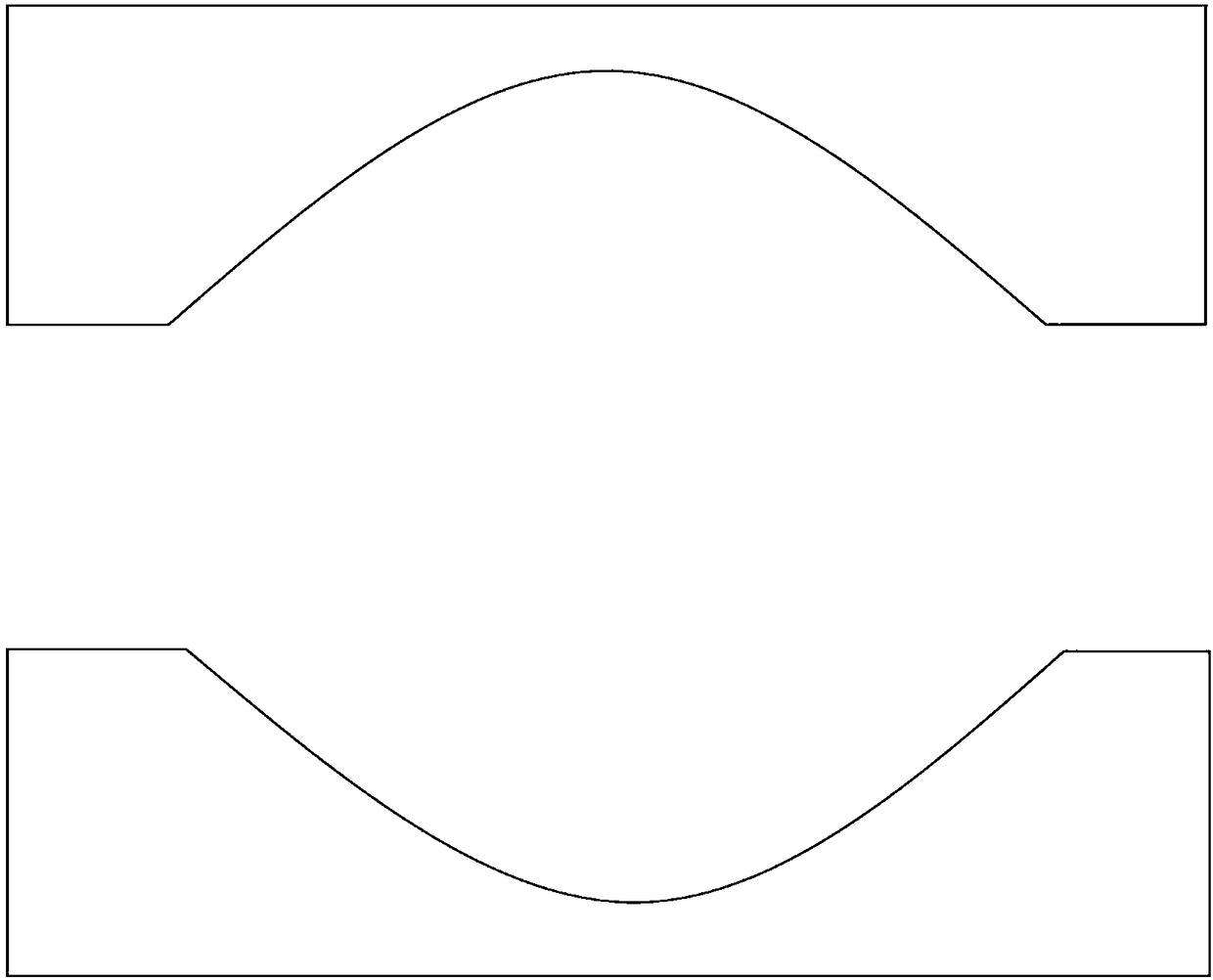

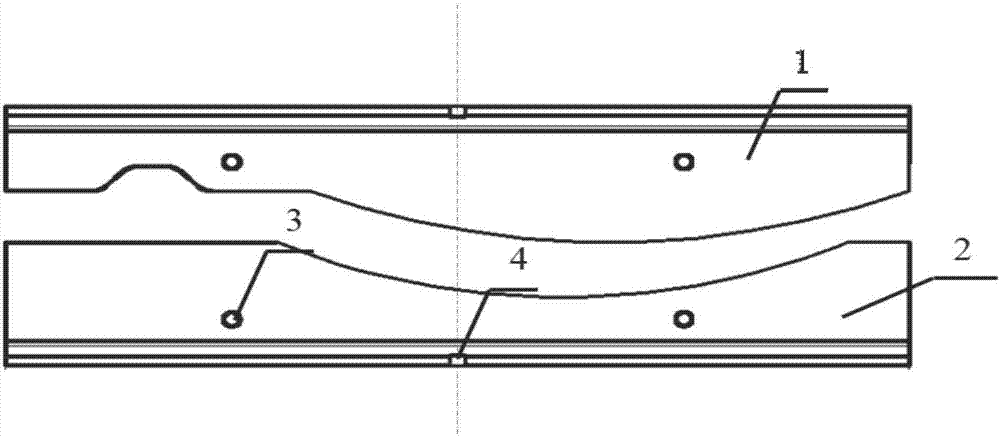

Variable-arc surface bending die

InactiveCN107983896AReduce the force loadExtended service lifeForging/hammering/pressing machinesEngineeringSurface shape

The invention discloses a variable-arc surface bending die. The variable-arc surface bending die comprises an upper die and a lower die, wherein one end of the upper die is an upper plane, and an upper arc surface which is connected with the upper plane is a preset shape. One end of the lower die is a lower plane matched with the upper plane, a lower arc surface which is connected with the lower plane is a preset shape, and the upper arc surface is separated from the circle center of the lower arc surface, so that a preset variable-arc surface space is formed after the upper die and the lowerdie are combined. According to the variable-arc surface bending die, the center position of the upper arc surface and the center position of lower arc surface are different, so that the preset variable-arc surface space is formed when the upper die and the lower mold die are combined, and thus the blank is formed into a preset variable-arc surface shape. The variable-arc-surface bending die is adopted, so that metal distribution in the final-pressing process of the subsequent raw blank forging is more reasonable. On the one hand, the defects of the folding and threading of forging are eliminated; and on the other hand, the stress load of the die is reduced, and the service life of the die is prolonged.

Owner:SOUTHWEST ALUMINUM GRP

Method for manufacturing S-shaped bent edge on heat-isolating protection metal component

Owner:CUI XUEJUN

Self-attaching female fasteners, method of forming same and strip of interconnected fasteners

A method of forming pierce and clinch nuts by rolling a section having the desired cross-section, punching equally spaced bores through the central pilot portion and then punching configured openings through the central pilot portion having convex arcuate surfaces and eliminating sharp corners. The strip of interconnected self-attaching fasteners may be installed directly from the strip in a panel, fed in bulk or separate fasteners interconnected by frangible connectors. The resultant self-attaching nut includes a central pilot portion having a bore through the top face, integral flange portions extending from opposed sides and the pilot portion includes convex arcuate faces reducing or eliminating stress cracking and propagation of stress cracks.

Owner:WHITESELL FORMED COMPONENTS

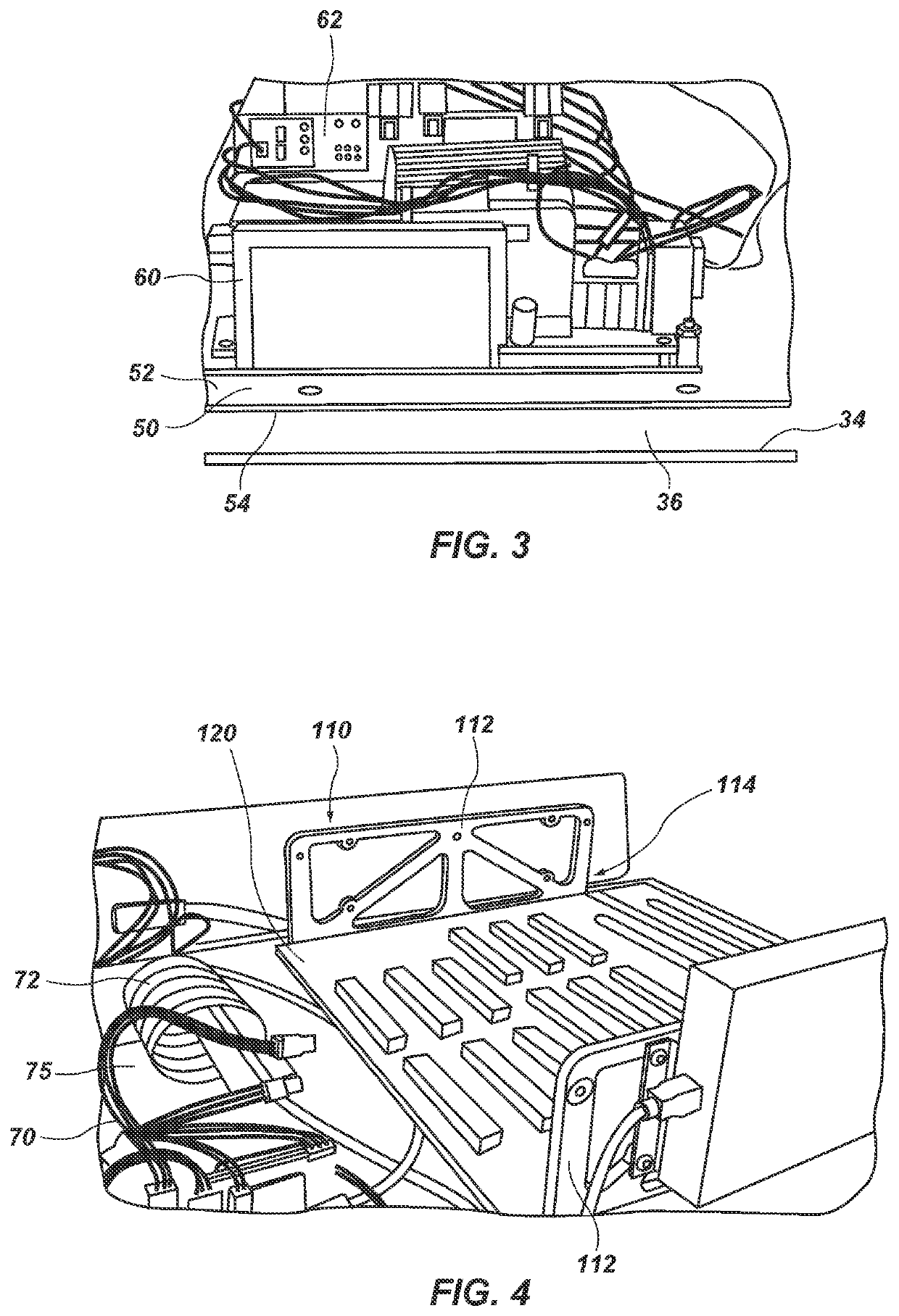

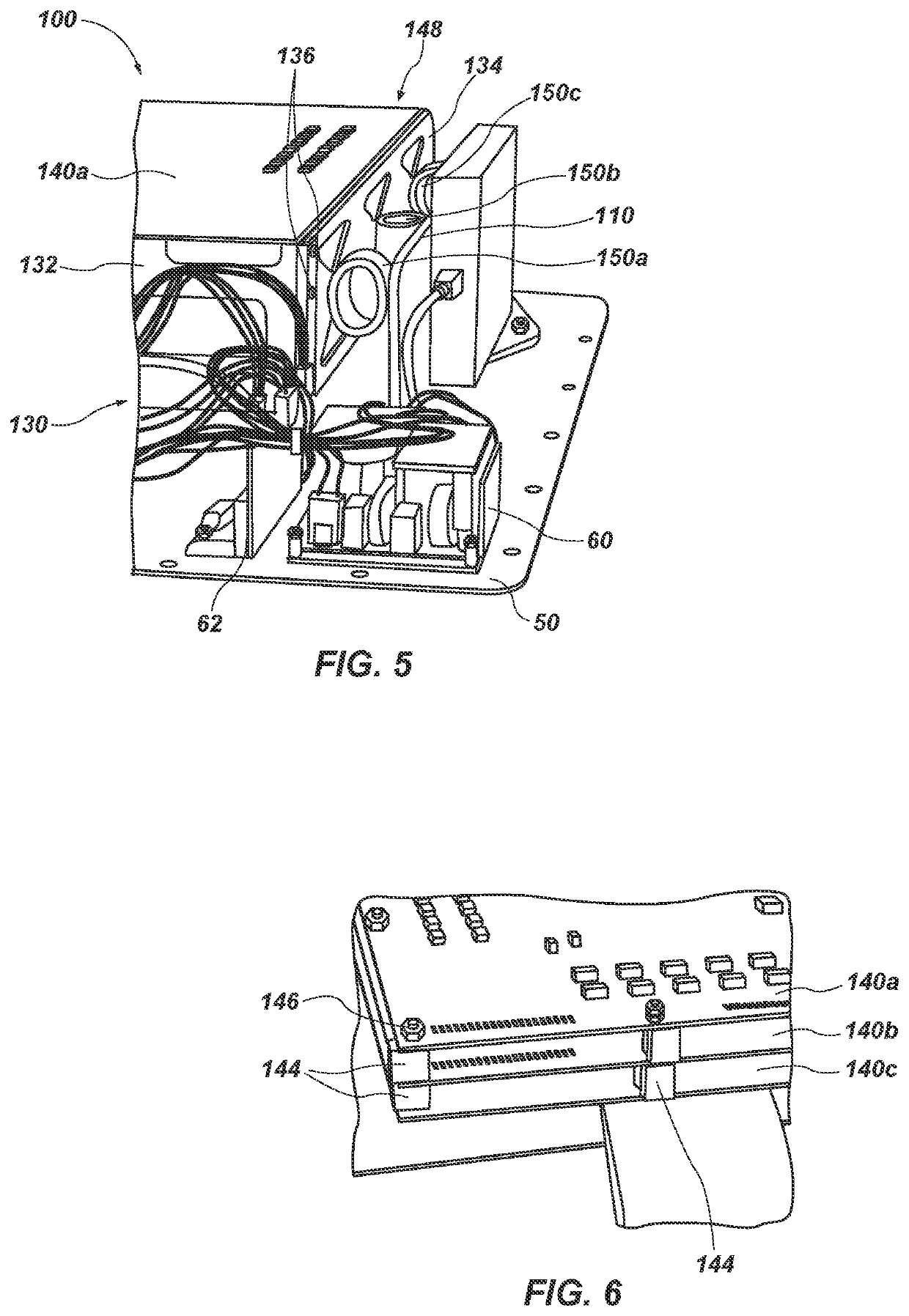

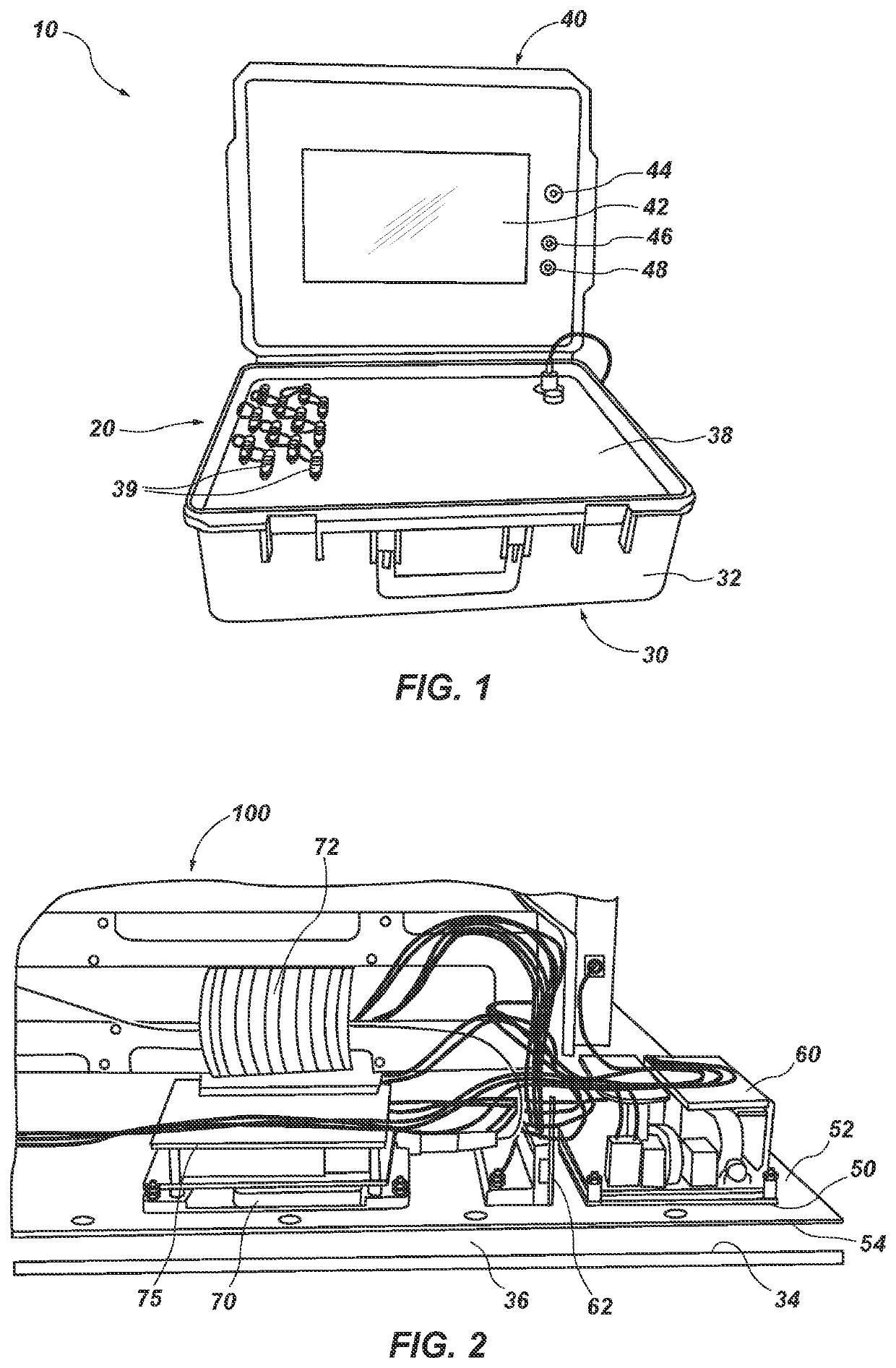

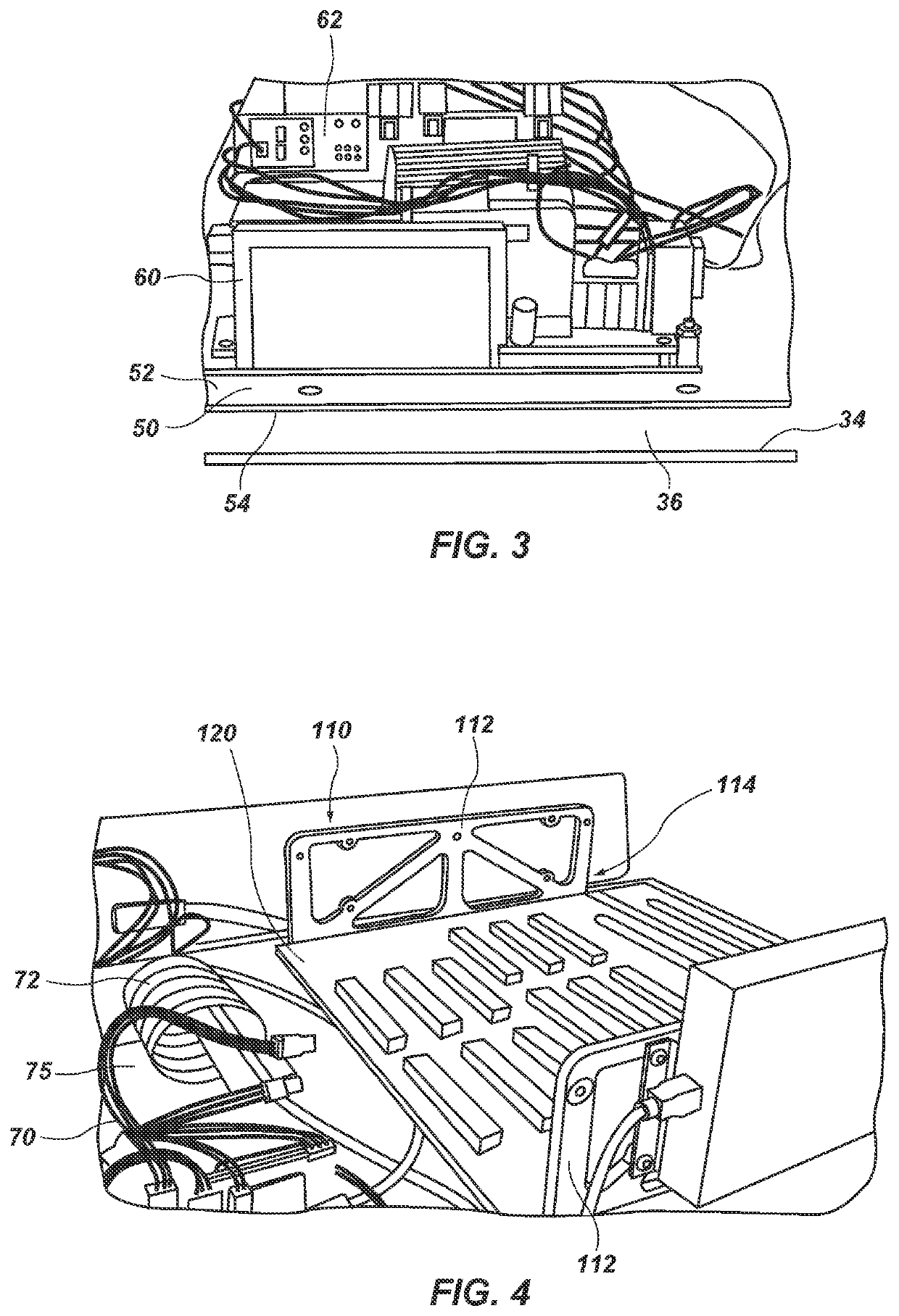

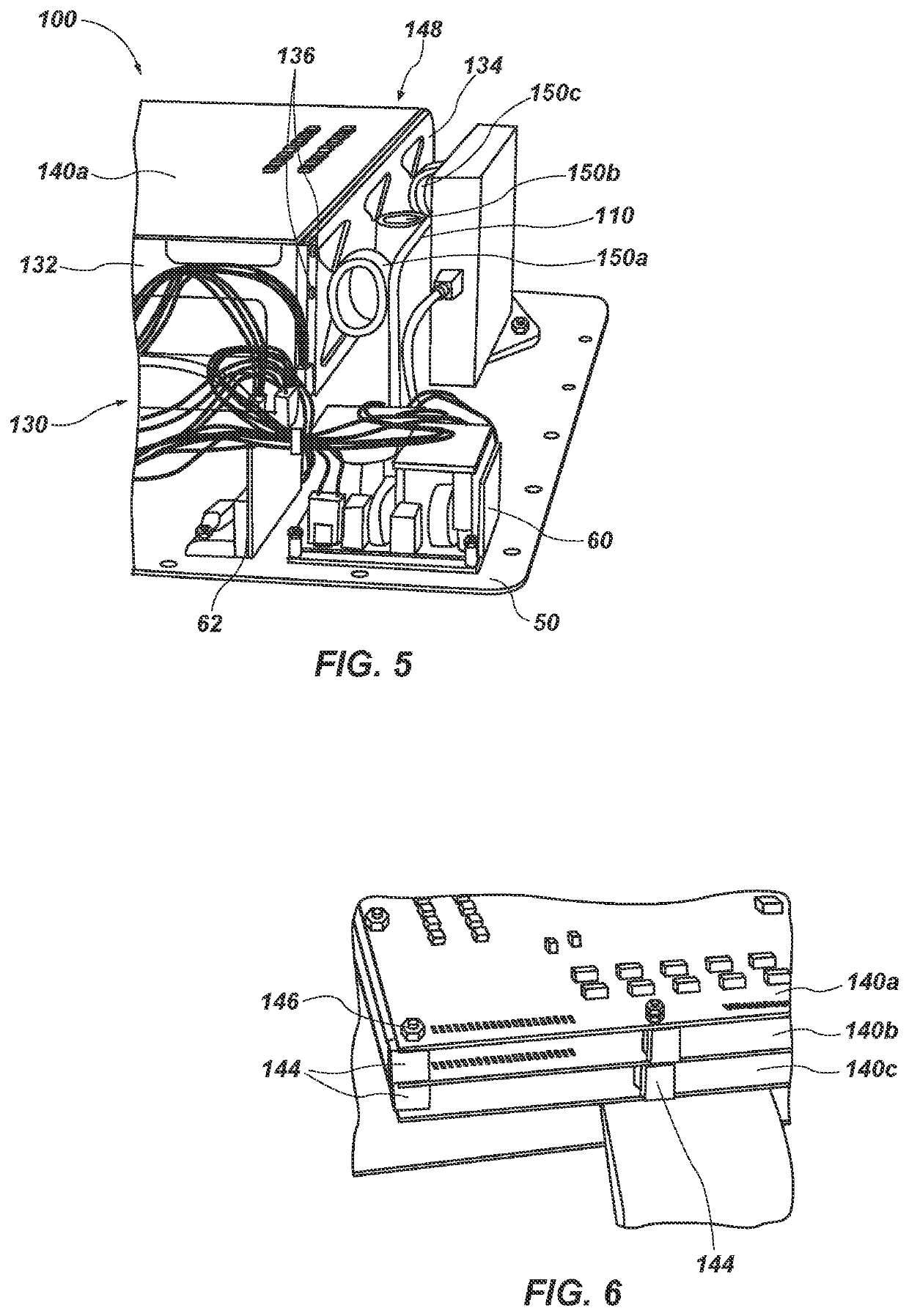

Portable intermittent fault detector

ActiveUS20210109163A1Reduce noiseForce is limitedElectric connection testingTesting electric installations on transportHeat managementDisplay device

A portable intermittent fault detector includes an enclosure that carries electronics and a display. The electronics are selected, arranged, and connected in a manner that minimizes noise, including noise that could interfere with an ability of the portable intermittent fault detector to detect intermittent faults in complex electrical systems. The portable intermittent fault detector also includes a passive heat management system hat conveys heat away from the electronics. In addition, a test module assembly of the portable intermittent fault detector includes an inner assembly with test module boards that are rigidly secured to one another and an outer support that carries the inner assembly in a manner that absorbs impacts and other forces on the portable intermittent fault detector.

Owner:UNIVERSAL SYNAPTICS CORP

Portable intermittent fault detector

ActiveUS11415639B2Reduce noiseForce is limitedElectric connection testingShort-circuit testingHeat managementDisplay device

Owner:UNIVERSAL SYNAPTICS CORP

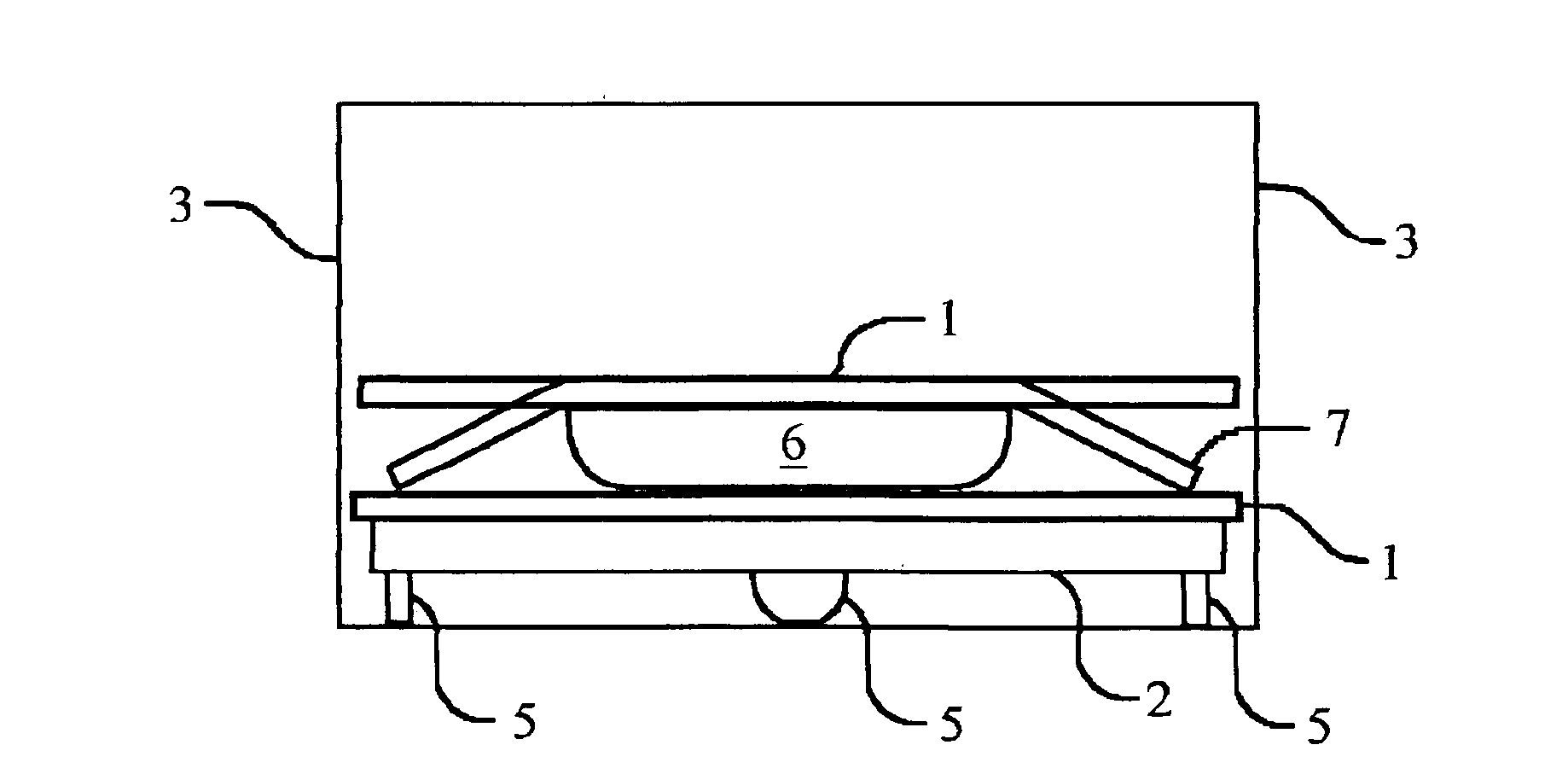

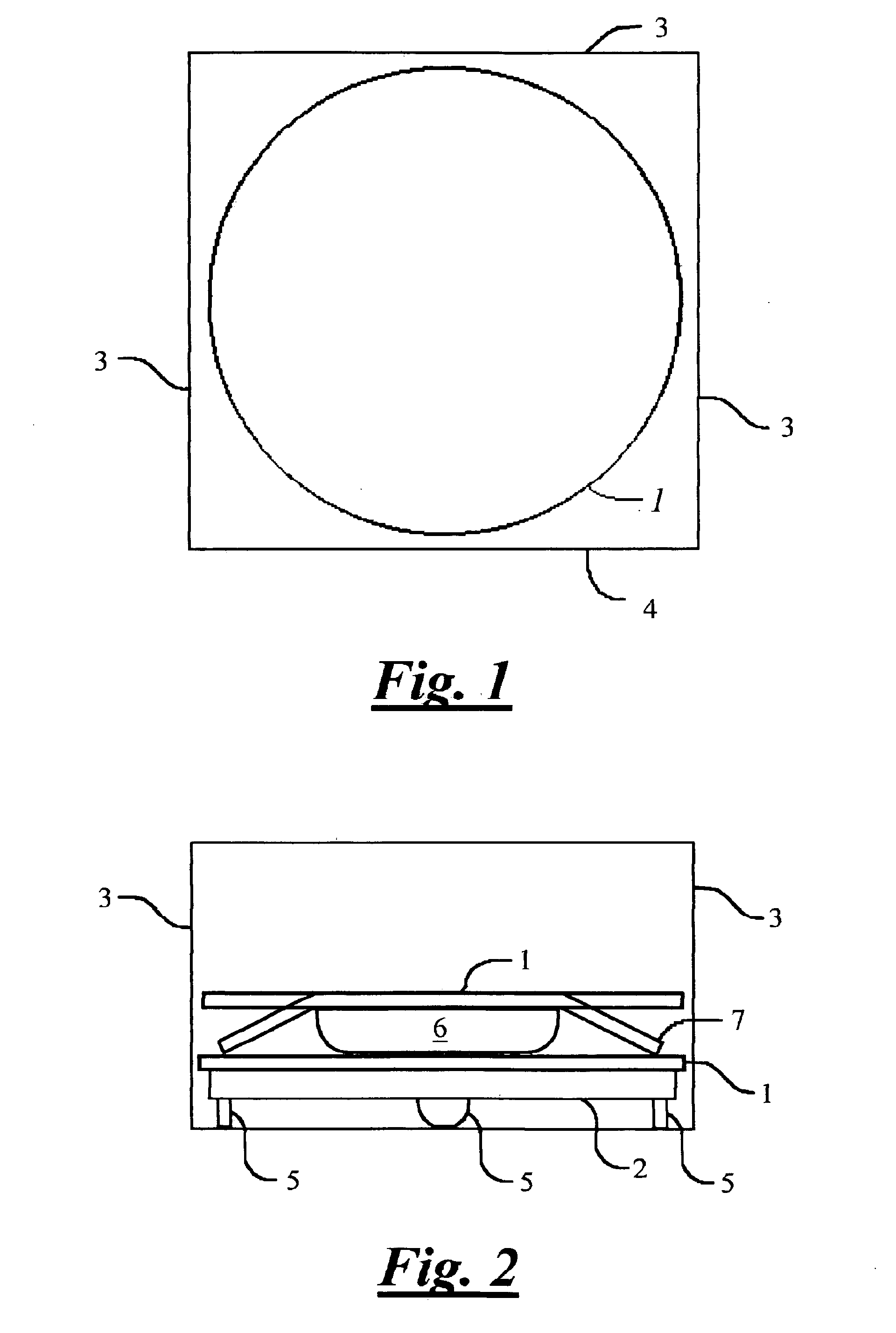

Disposable microwave protector

A disposable arcuate sheet of an air permeable, water absorbent and hypoallergenic garment interfacing fabric and method for using the sheet for protecting microwave ovens against food spills, splashes, spatters and spitting during rotation of a carousel. The disposable sheet being a single layer of conventional interfacing fabric provided in a unbroken and unfolded substantially round or circularly shaped flat pattern sized either to cover a rotating carousel of a square or rectangular microwave oven, or to cover a food container in the oven, without substantially interfering with the oven walls during rotation of the carousel.

Owner:NEWTON GLORIA

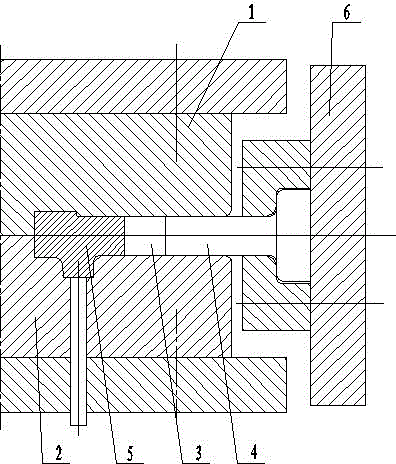

Die and die forging method for improving multi-directional die forging die life

InactiveCN103028689BExtend your lifeReduce manufacturing costForging/hammering/pressing machinesHigh volume manufacturingPower equipment

The invention discloses a mould and a die forging method thereof for prolonging the service life of a multidirectional die forged mould. The mould comprises an upper mould, a lower mould and a lateral male mould; the mould is characterized in that the lateral male mould comprises a small male mould which is located at the front end and a mould matrix which is located at the rear end; the front end of the small male mould is used for contacting a part and performing extrusion forming on the part to form a foot shape of the part; the rear end of the mould matrix is used for being fixed on a die holder or a piece of power equipment; and a contact place of the rear end of the small male mould and the front end of the mould matrix has a structure in a plane butting way or in the concave-convex coupling butting way which can prevent the small male mould from being rotated. The die forging method comprises the following steps that the mould is adopted; and during die forging, the small mould is changed to ensure the temperature of below 200 degrees centigrade. The mould and the die forging method have the advantages of capacities of prolonging the service life of the multidirectional die forged male mould and reducing wear of the mould, convenience in clamping, obviously improving the quality of the parts, greatly reducing production cost, greatly improving production efficiency, and realizing mass production of the parts by a multidirectional die forging process.

Owner:CHONGQING JIANSHE IND GRP

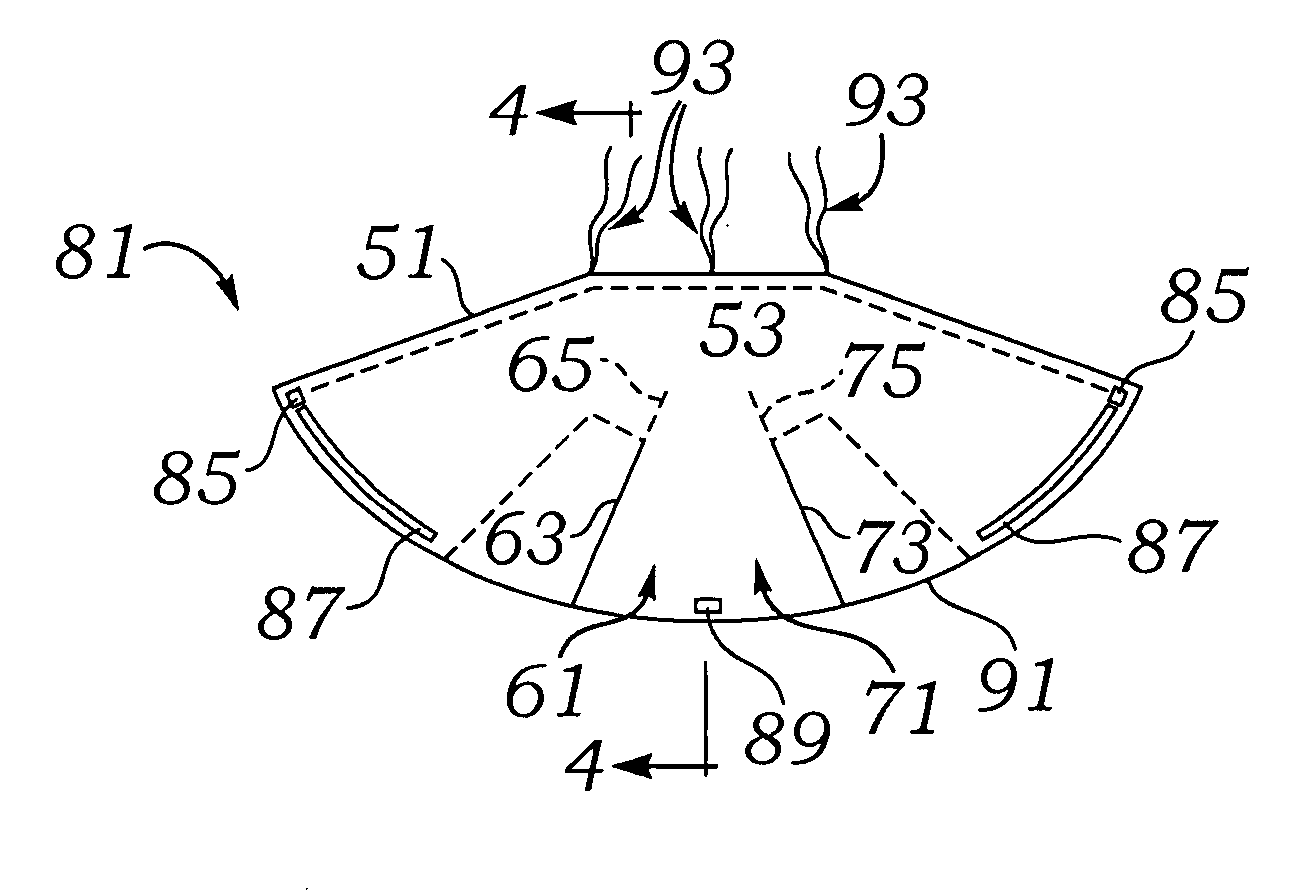

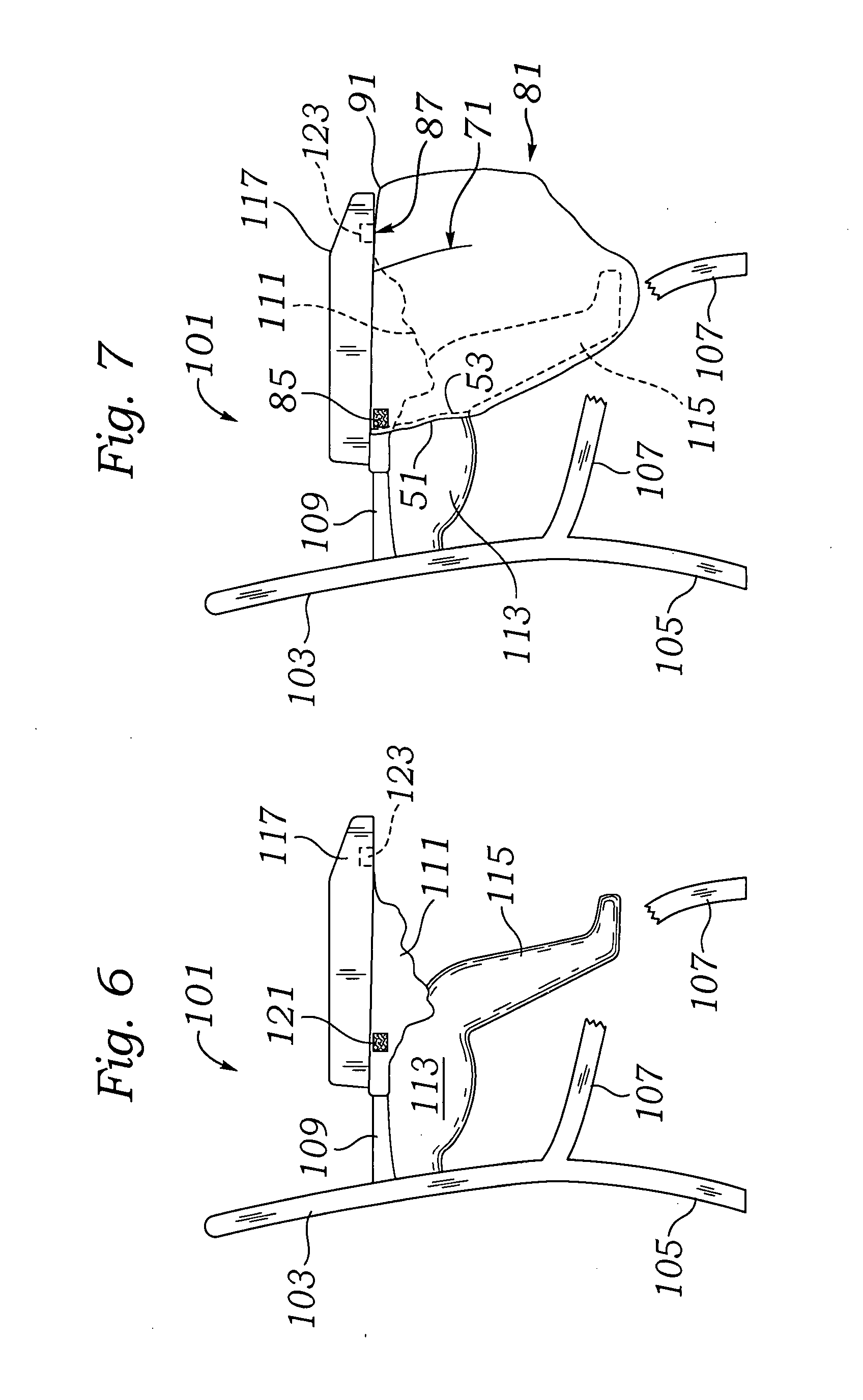

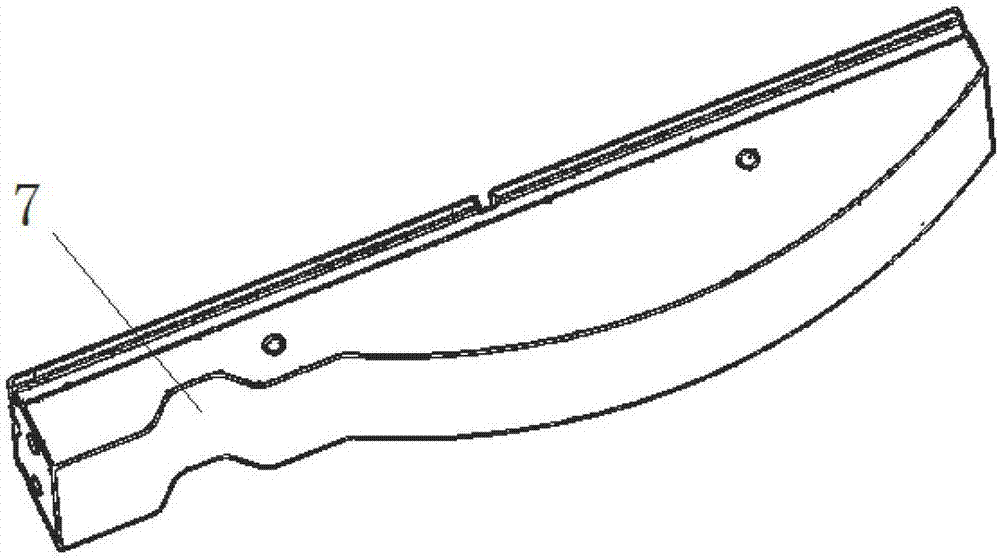

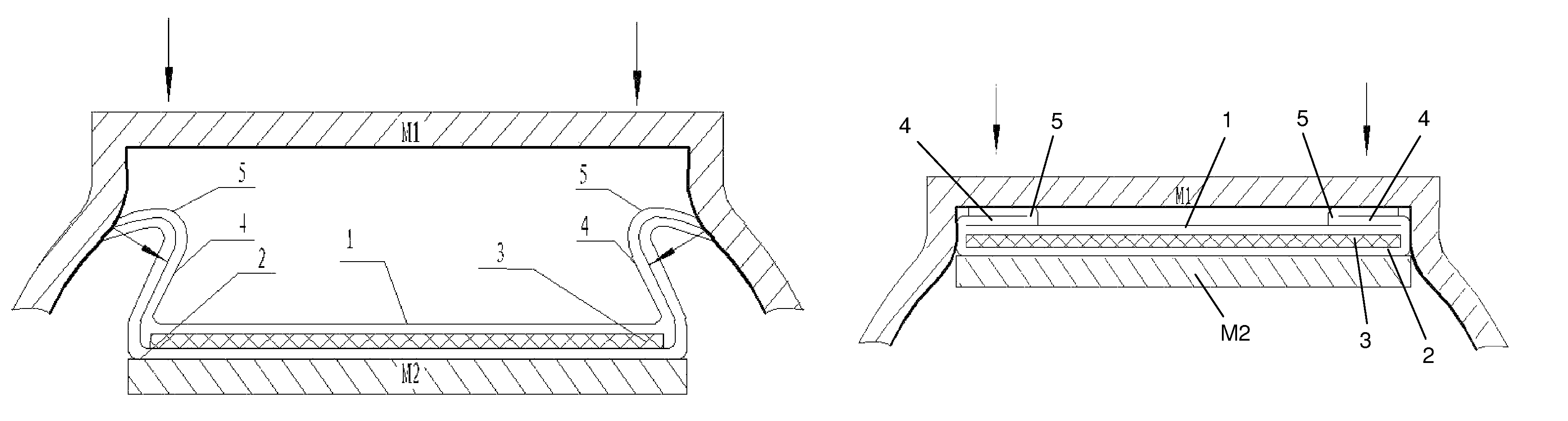

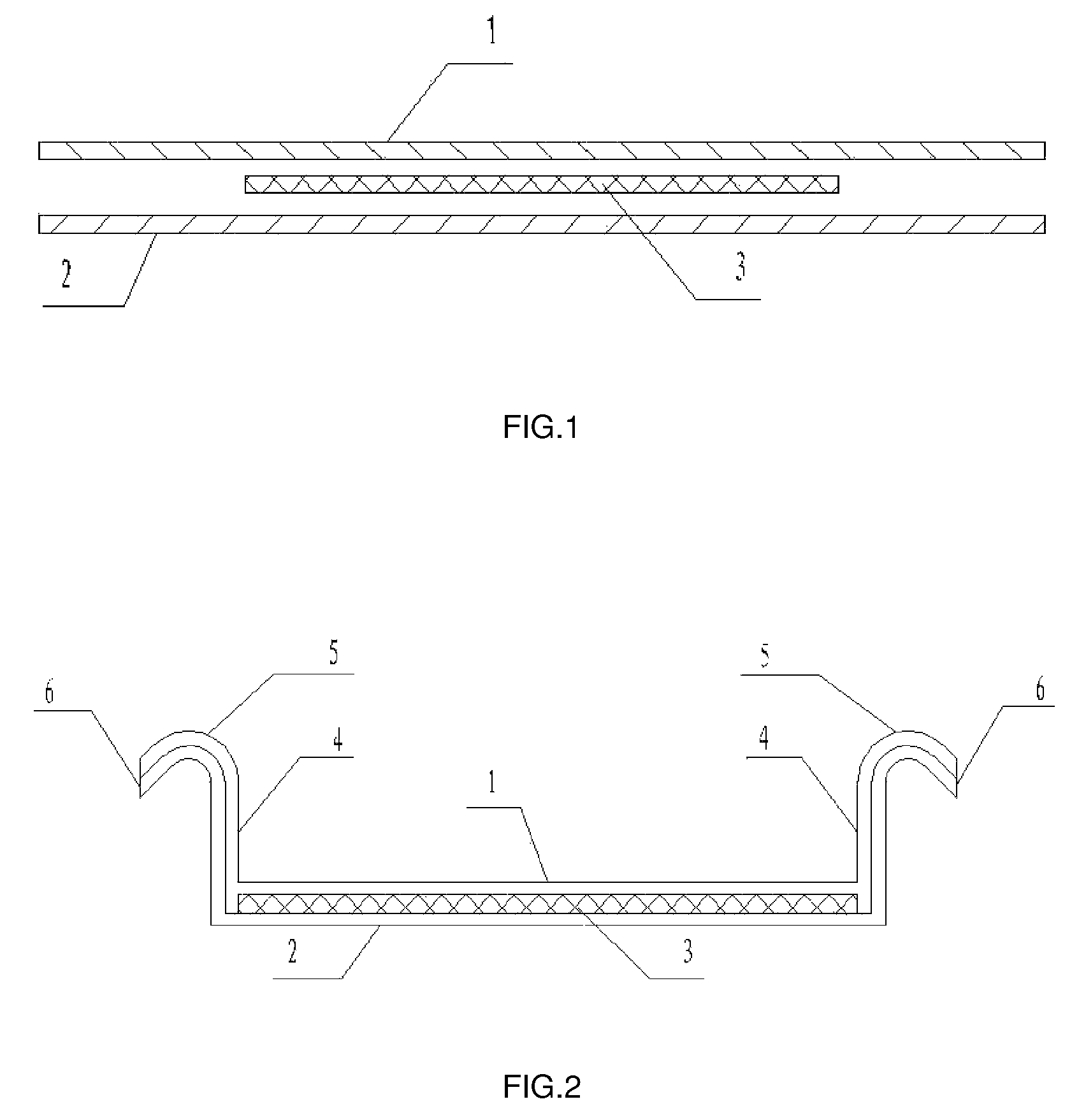

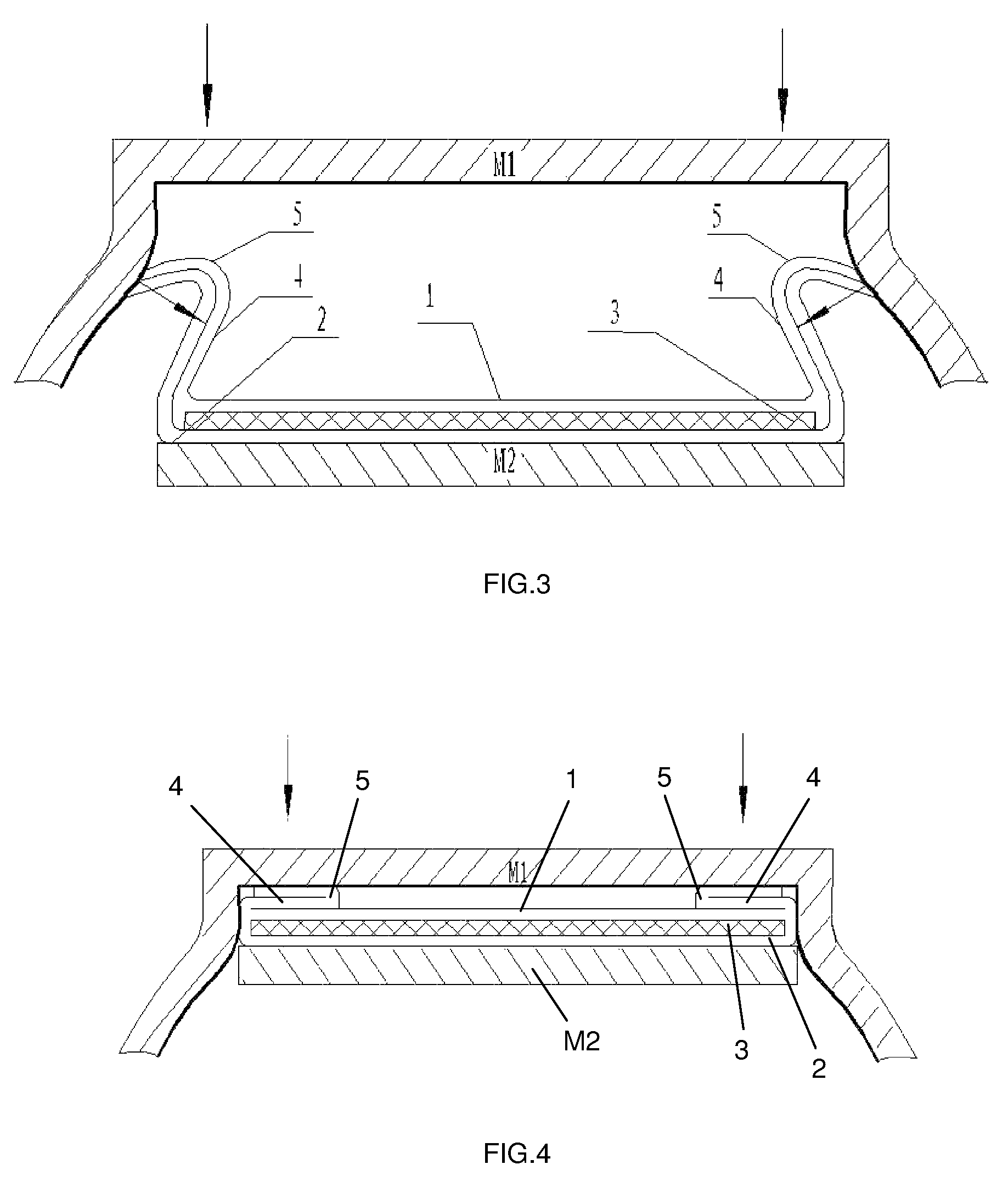

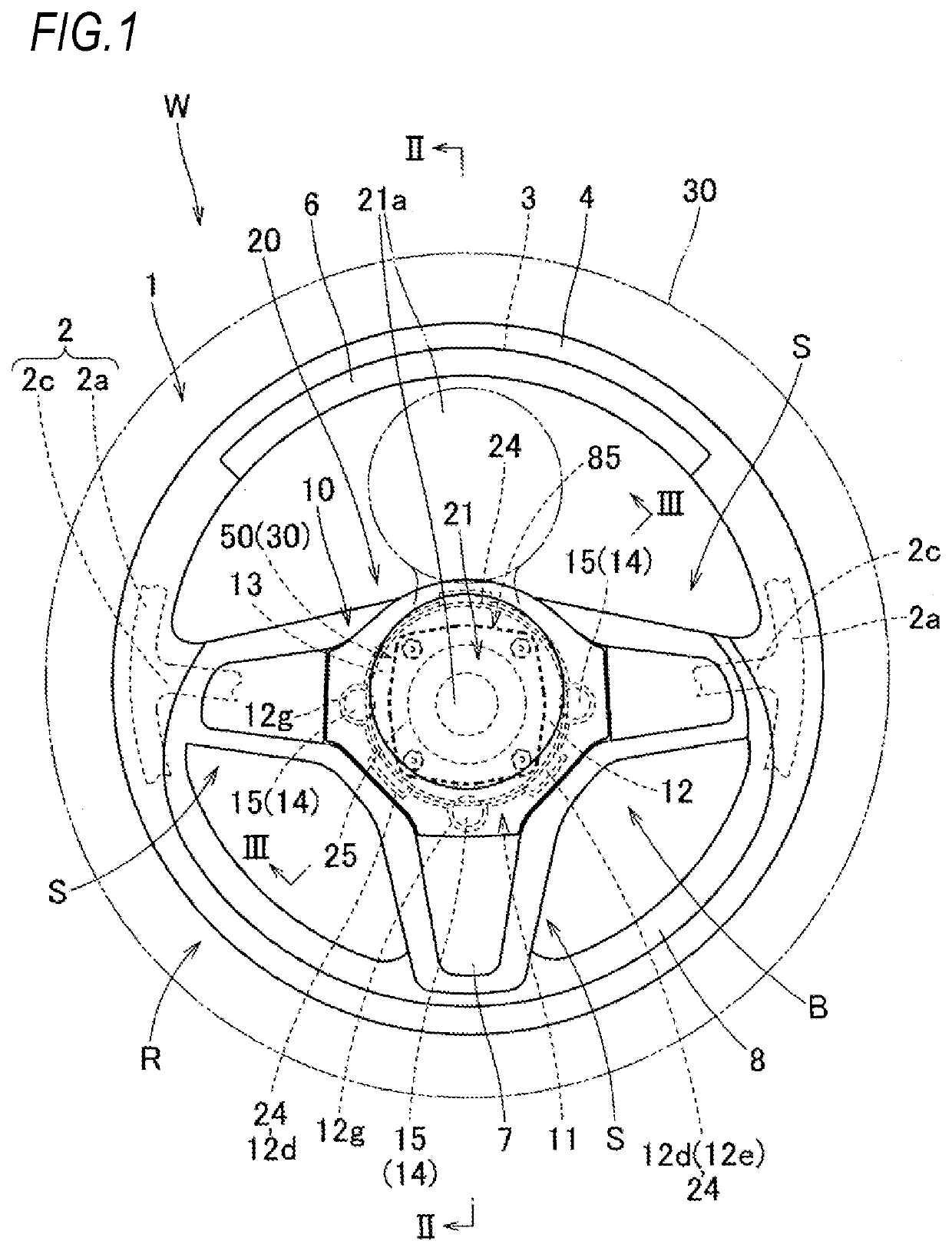

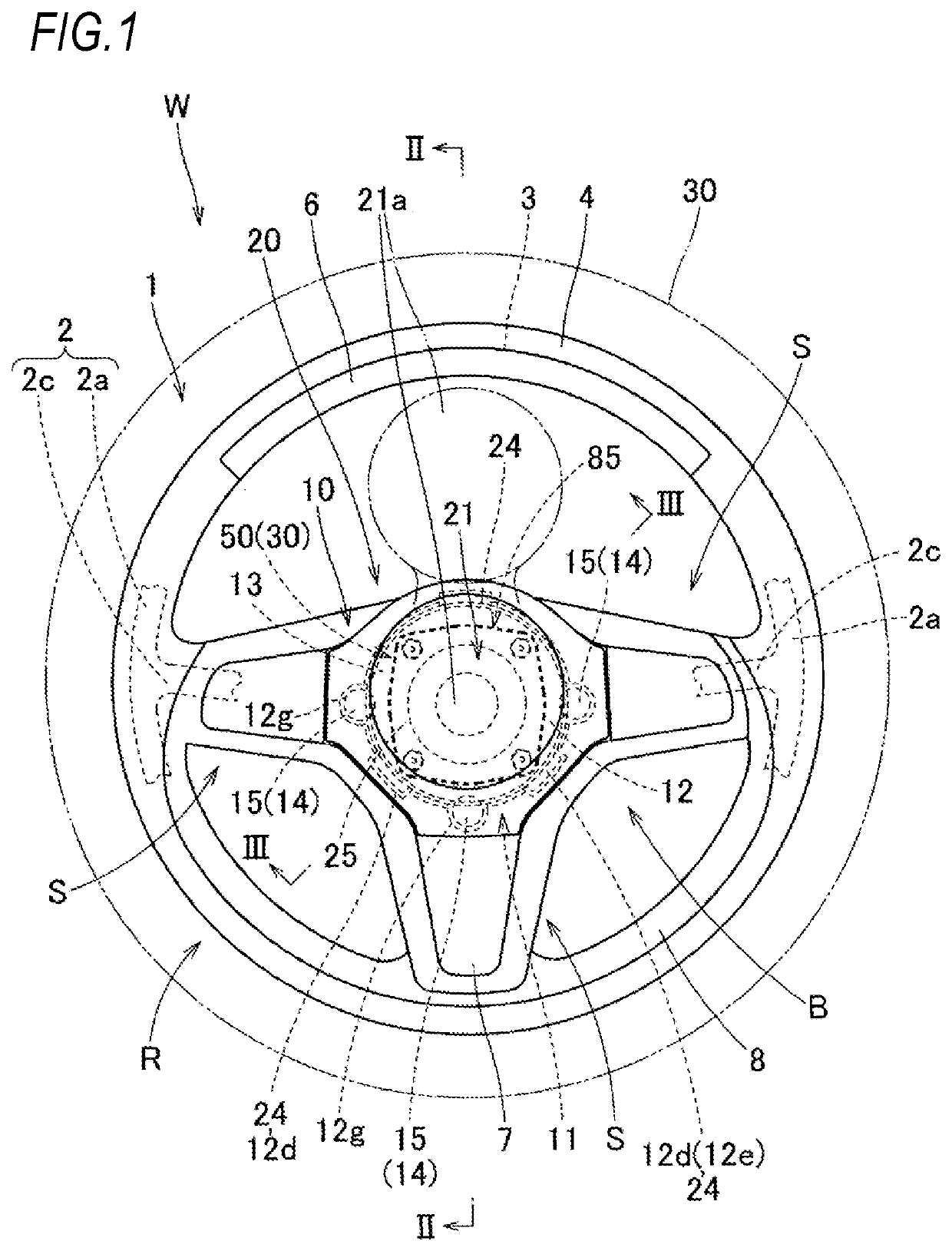

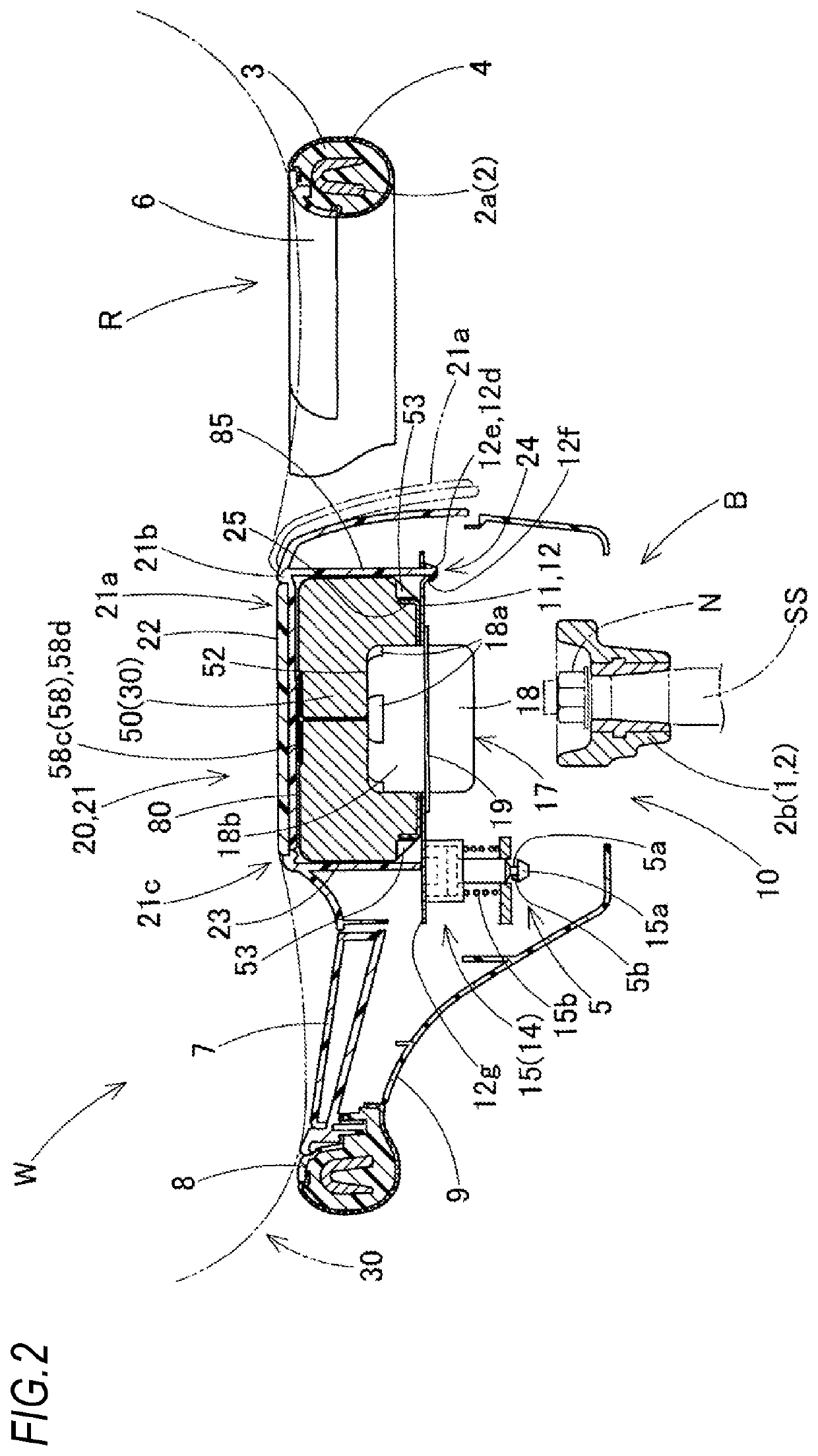

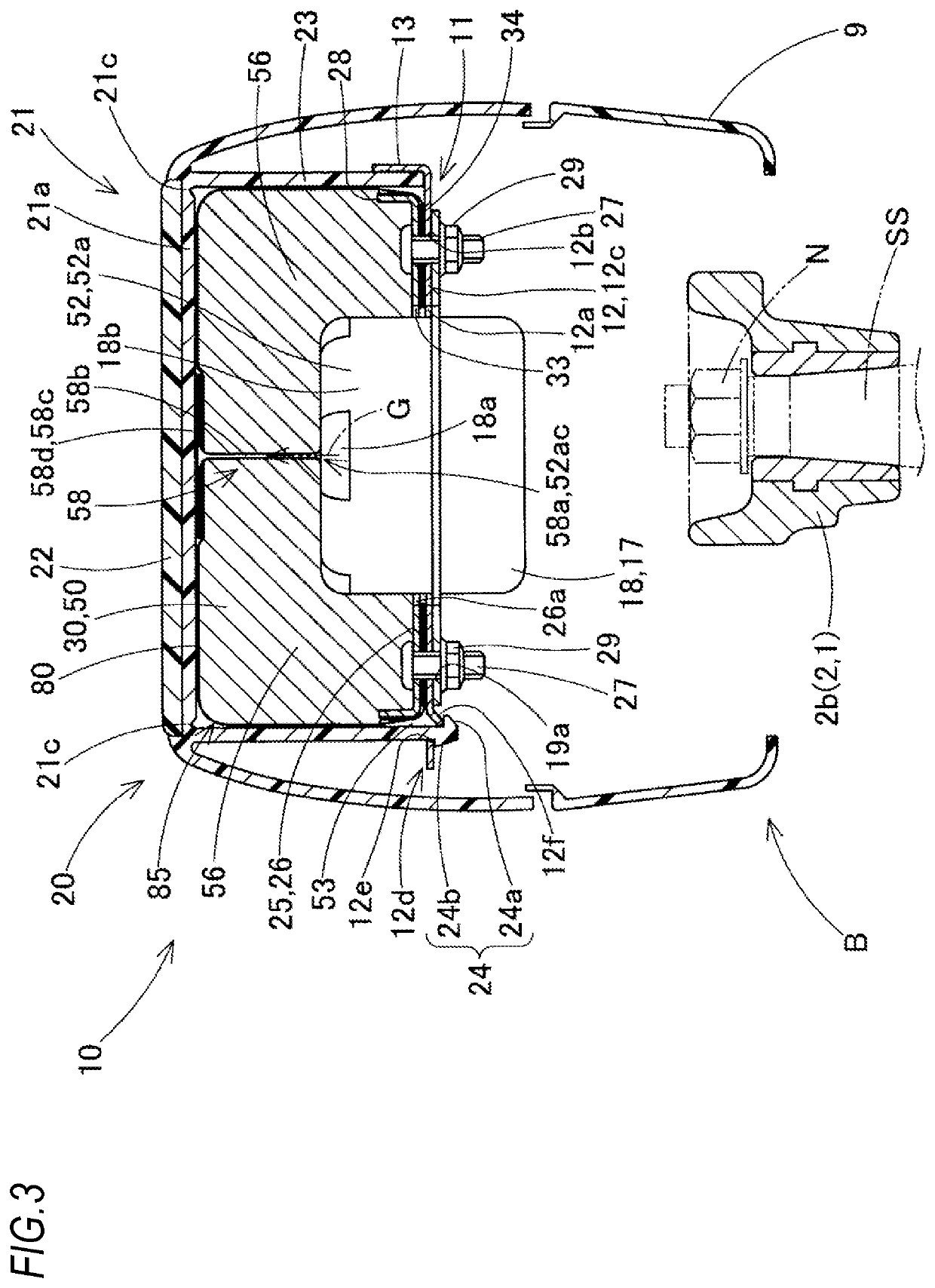

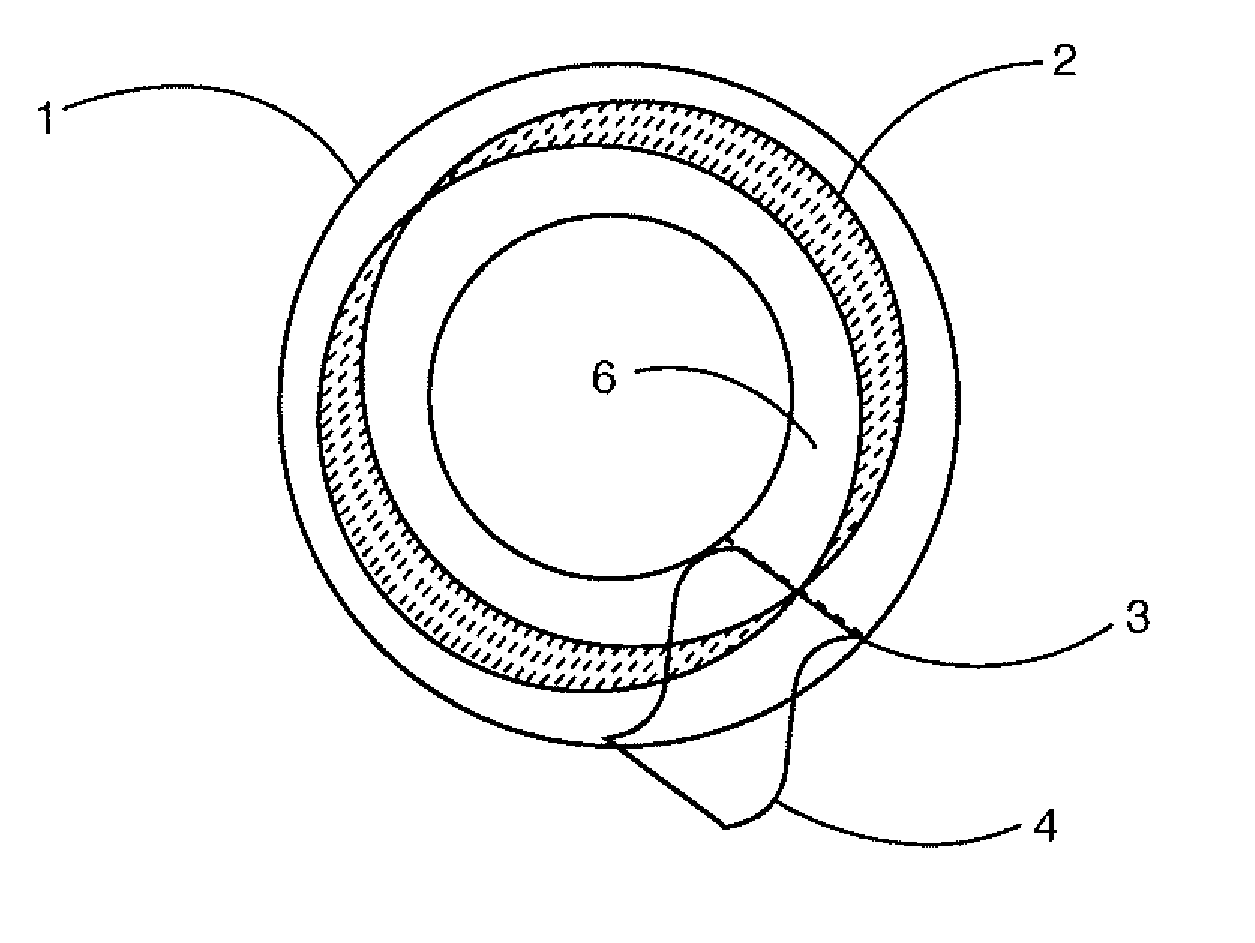

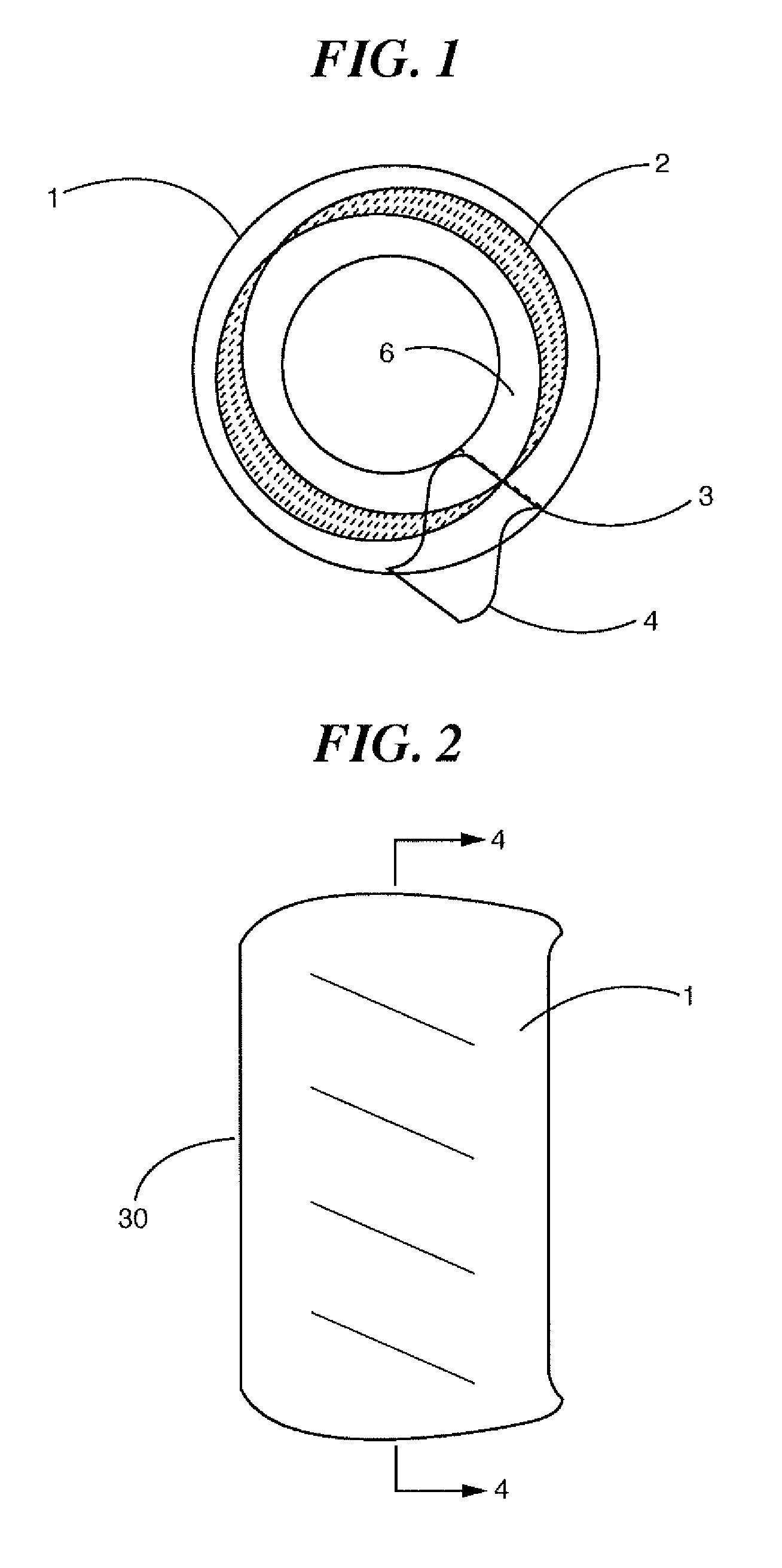

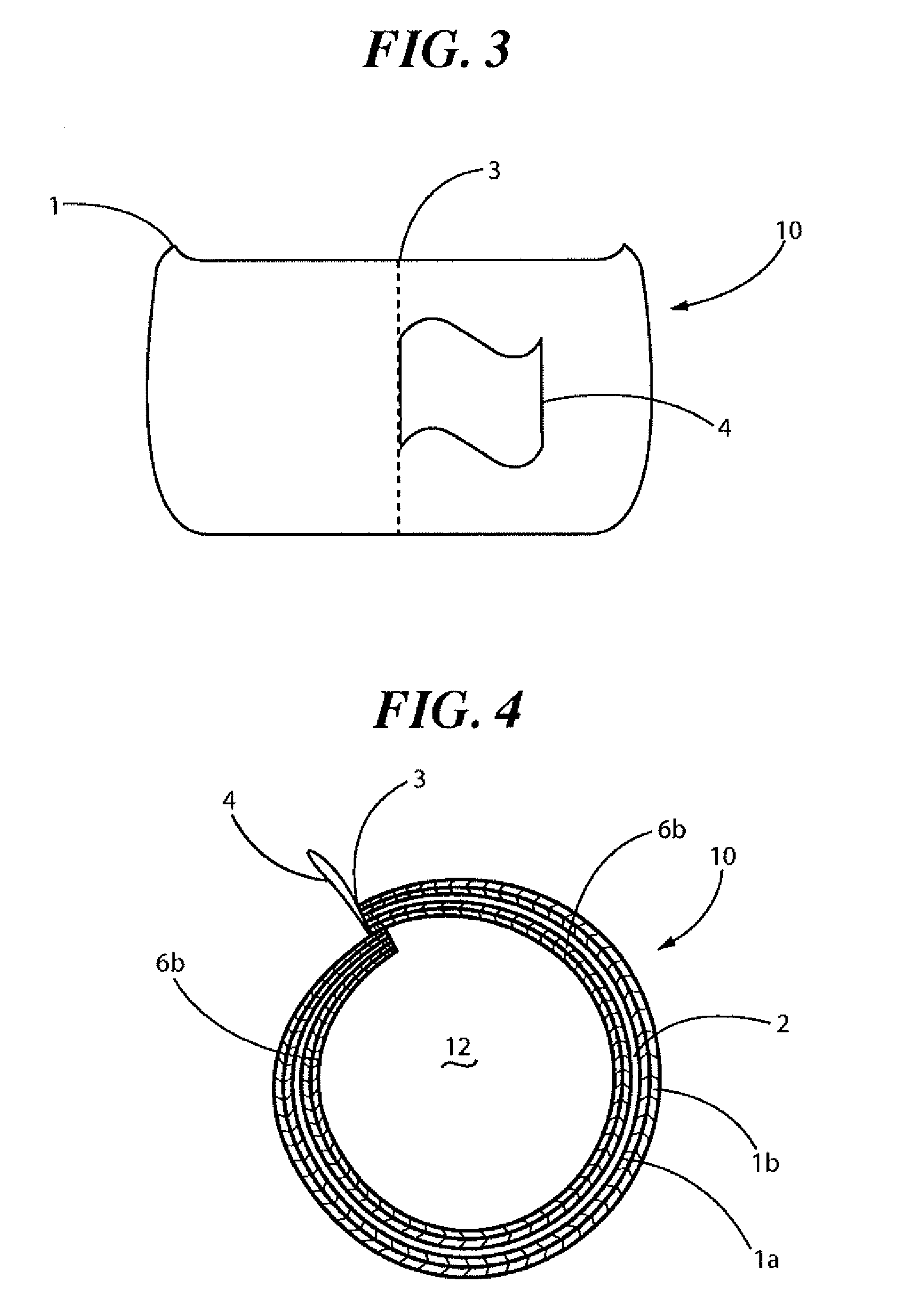

Completely folded body of airbag and folding method for same

ActiveUS20200346609A1Addressing slow performanceEliminate foldPedestrian/occupant safety arrangementAirbagGas supply

A completely folded body of an airbag, includes: an outer peripheral wall including a vehicle body side wall portion, and a receiving side wall portion. An outer peripheral edge side in a state where the receiving side wall portion is superimposed on the vehicle body side wall portion and is flatly deployed is subjected to radial folding and folded. An accommodation recess portion for accommodating an upper portion on a gas supply port side of an inflator is provided on a bottom surface. A radially-folded folded portion is disposed so as to surround a circumference of an intermediate portion from a base portion near the center of the ceiling surface of the accommodation recess portion in a linear supply path, for supplying the inflation gas from the inflator, to a tip portion disposed on an inner surface side near the center of the receiving side wall portion.

Owner:TOYODA GOSEI CO LTD

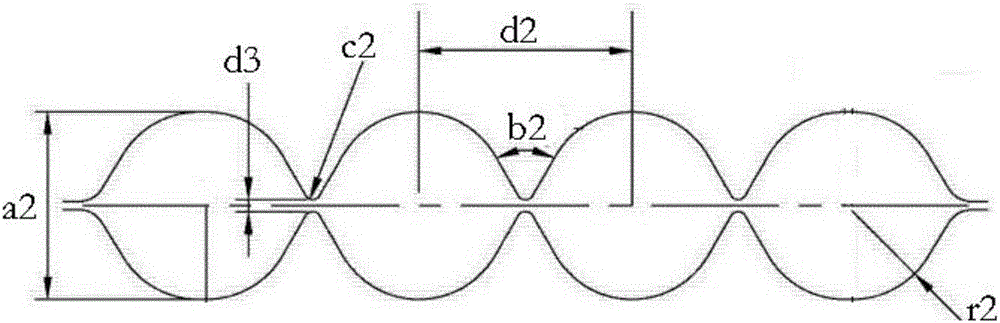

A split rolling process

ActiveCN105032936BReduce control difficultyImprove assembly qualityRoll mill control devicesRollsControl lineEngineering

The invention discloses a slitting and rolling process, which includes K6 flat roll rolling, K5 box-shaped fixed-width pass, K4 pre-slitting pass and K3 slitting pass, and is characterized in that the K3 slitting pass The roll used in the second place includes an upper rolling groove and a lower rolling groove. The upper rolling groove and the lower rolling groove are assembled up and down to form a complete cutting pass. The upper rolling groove and the lower rolling groove are provided with a number of grooves at the corresponding positions. A wedge top is formed between the upper rolling groove and the lower rolling groove to form a number of circular pass patterns arranged in parallel. The pass patterns are not closed in the horizontal direction and are connected to each other. It is a centerline hole, and the area of the sideline hole is greater than or equal to the area of the centerline hole. The slit rolling process of the present invention comprehensively considers the influence of rolling mill bounce, and the line difference can be effectively controlled when the area of the side line hole is greater than or equal to the area of the center line hole; the line difference can be controlled at 200mm by adjusting the area of the side line hole of the slit pass. Within , the negative bias difference can be controlled within 1.0%.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

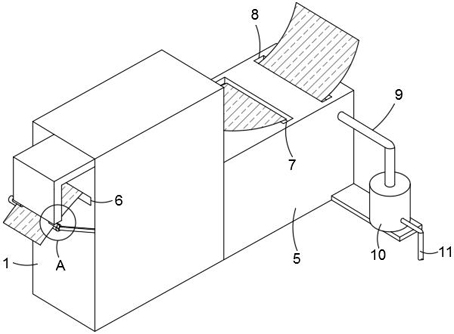

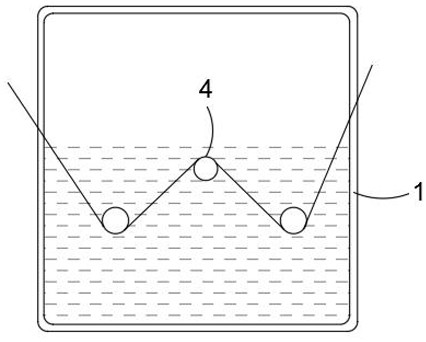

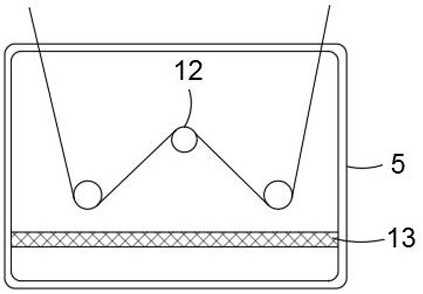

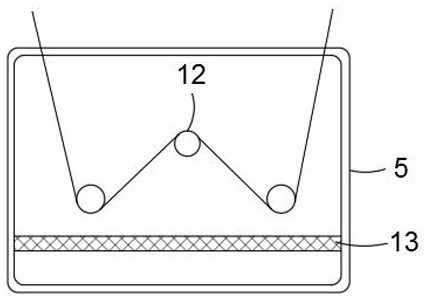

A hook and loop semi-finished product dyeing and drying device

ActiveCN113388986BAvoid the problem of secondary foldsEliminate wrinklesLiquid/gas/vapor removalTextile treatment machine arrangementsElectric machineryStructural engineering

The invention discloses a hook and loop semi-finished product dyeing and drying device, comprising a dyeing box and a drying box, a heating plate is installed in the drying box, and a purification mechanism is connected to the outer wall of the drying box; the dyeing box The end of the box is fixed with a right-angle plate, and a cavity is opened inside the right-angle plate, a gear one is installed in the cavity, a reset mechanism is connected between the gear one and the cavity, and a motor is fixed in the cavity. The driving end of the motor is fixedly connected with an incomplete gear that meshes with gear one, and guide rods are fixed on the inner walls of both sides of the lower end of the cavity. The present invention eliminates the folding of the Velcro through the reciprocating movement of the smoothing roller before the Velcro is dyed and dried, ensures the full contact of the Velcro with the dye solution and the hot air, ensures the effect of dyeing and drying, and greatly improves the drying process. The water vapor generated in the system is condensed and purified to avoid the problem of pollution.

Owner:南通卡芬迪家用纺织品有限公司

Semi-finished hook-and-loop fastener dyeing and drying device

ActiveCN113388986AAvoid the problem of secondary foldsEliminate wrinklesLiquid/gas/vapor removalTextile treatment machine arrangementsElectric machineWater vapor

The invention discloses a semi-finished hook-and-loop fastener dyeing and drying device. The device comprises a dyeing box and a drying box; a heating plate is installed in the drying box; a purification mechanism is connected to the outer wall of the drying box; a right-angle plate is fixed to the end part of the dyeing box; a cavity is formed in the right-angle plate; a first gear is installed in the cavity; a reset mechanism is connected between the first gear and the cavity; a motor is fixed in the cavity; the driving end of the motor is fixedly connected with an incomplete gear meshed with the first gear; and guide rods are fixed to the inner walls of the two sides of the lower end of the cavity. Before a hook-and-loop fastener is dyed and dried, folding of the hook-and-loop fastener is eliminated through reciprocating movement of a smoothing roller, so that it is guaranteed that the hook-and-loop fastener makes full contact with dye liquor and hot air flow, and the dyeing and drying effects are guaranteed; and water vapor generated in the drying process is condensed and purified, so that the problem of pollution is avoided.

Owner:南通卡芬迪家用纺织品有限公司

A kind of ocr17 continuous casting slab and production method thereof

The invention discloses an OCr17 continuous casting blank and a production method thereof. The continuous casting blank comprises the following chemical components in percentage by mass: 0.04-0.06% of C, 0.25-0.45% of Si, 0.40-0.55% of Mn, 0.035% or less of P, 0.030% or less of S, 16.50-16.75% of Cr, 0.60% or less of Ni, and the balance of Fe and inevitable impurities. The production method comprises the steps of: control of a continuous casting machine crystallizer water flow, a secondary cold water flow and crystallizer electromagnetic stirring parameters, slow cooling of the continuous casting blank and casting blank angle finishing chamfering plane width control. The method enables the surface pass percent of the continuous casting blank of rolled steel to reach above 99%, and guarantees elimination of surface and subsurface cracks of the continuous casting blank; and through angle finishing, the angle rolling broadening deformation is reduced, the angle temperature drop is reduced, the OCr17 wire folding and cracks are eliminated, the wire rod primary inspection pass percent is above 99%, and the acid washing secondary inspection pass percent is above 95%.

Owner:XINGTAI IRON & STEEL

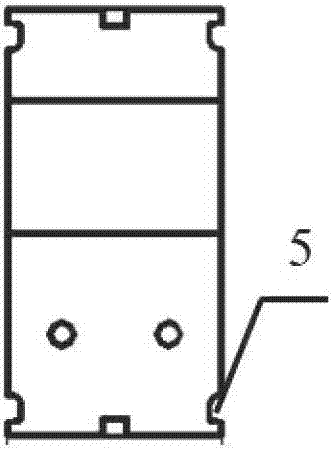

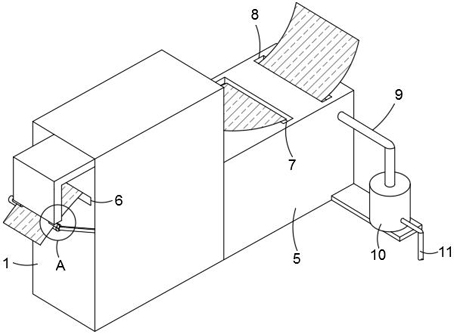

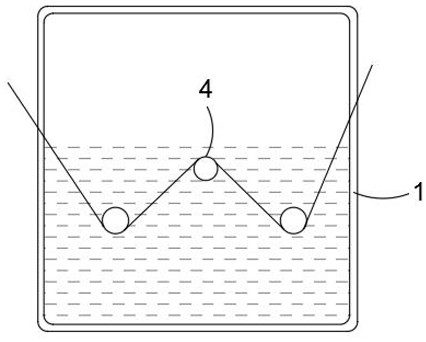

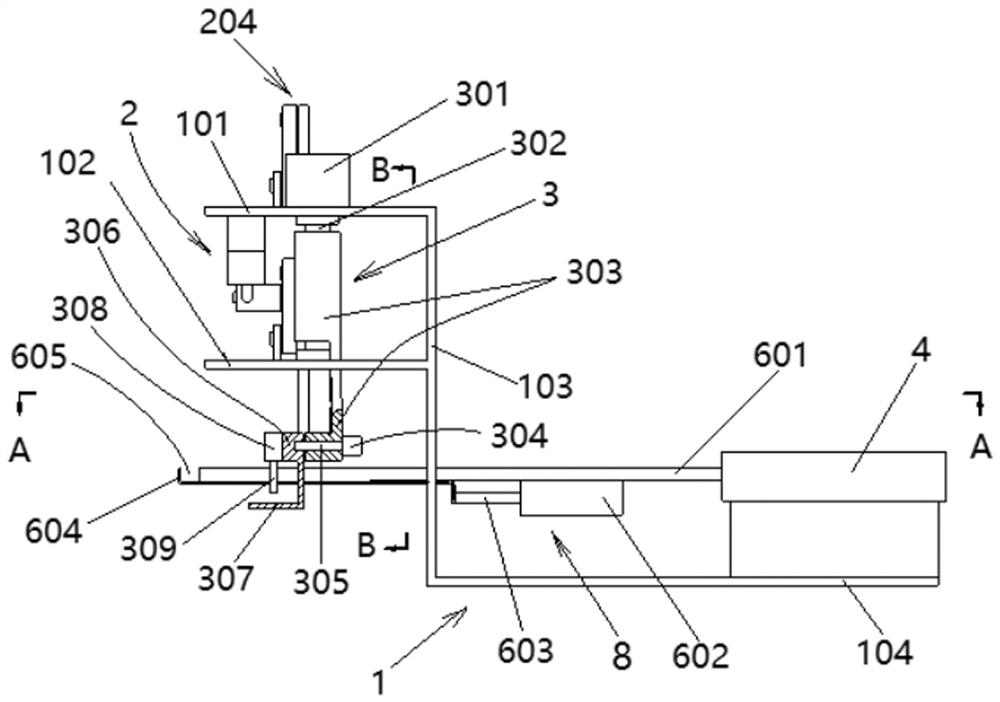

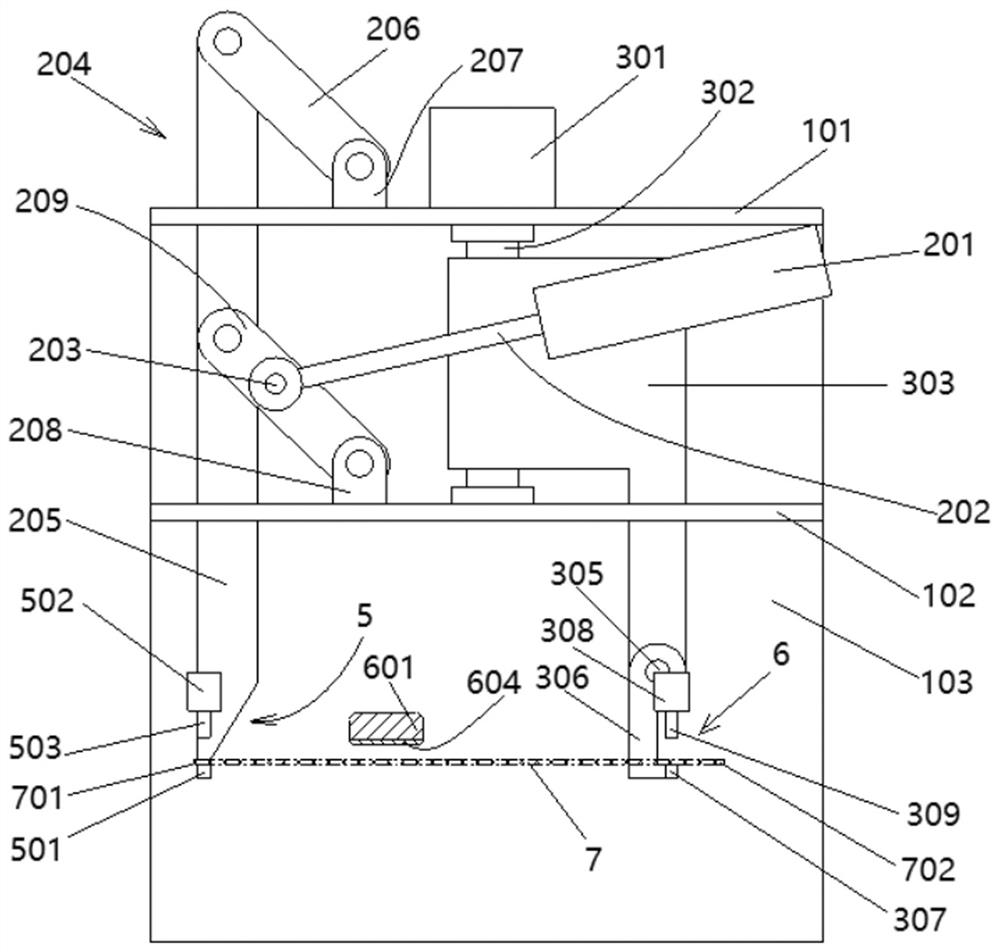

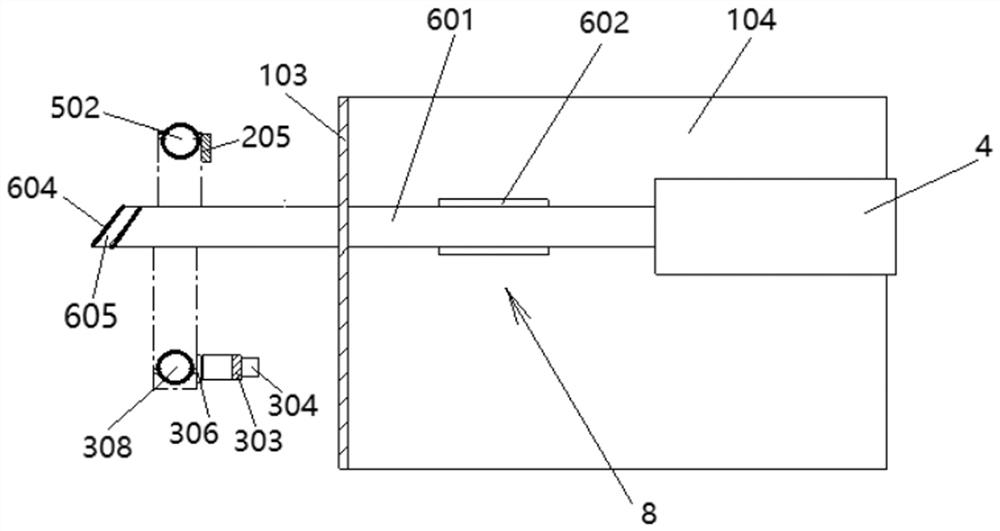

Knotting machine

The invention relates to the technical field of food machinery, in particular to a knotting machine which is widely used for knotting flexible strip-shaped food such as kelp and beancurd sheet knots. An upper bending mechanism 2, a lower bending mechanism 3 and a stretcher 4 are arranged on a rack 1, and the stretcher 4 is connected with a pulling mechanism 8. Compared with a knotting machine in the prior art, the knotting machine disclosed by the invention has the advantages that the accumulated monthly failure rate is lower than 5% when the knotting machine continuously works for 24 hours and stably runs, knotted flexible strip-shaped food (such as kelp and beancurd sheet knots) has triangular knots, clear edges and corners and vigorous texture, folds or crepes at the knots are eliminated, the soaking quality of the knots of the flexible strip-shaped food is not influenced, the performance is stable, and the knotting machine is suitable for popularization and application. The fault rate is low, the structure is simple and the cost performance is high.

Owner:上海嘉迪机械有限公司

Completely folded body of airbag and folding method for same

ActiveUS11155233B2Addressing slow performanceEliminate foldPedestrian/occupant safety arrangementAirbagGas supply

A completely folded body of an airbag, includes: an outer peripheral wall including a vehicle body side wall portion, and a receiving side wall portion. An outer peripheral edge side in a state where the receiving side wall portion is superimposed on the vehicle body side wall portion and is flatly deployed is subjected to radial folding and folded. An accommodation recess portion for accommodating an upper portion on a gas supply port side of an inflator is provided on a bottom surface. A radially-folded folded portion is disposed so as to surround a circumference of an intermediate portion from a base portion near the center of the ceiling surface of the accommodation recess portion in a linear supply path, for supplying the inflation gas from the inflator, to a tip portion disposed on an inner surface side near the center of the receiving side wall portion.

Owner:TOYODA GOSEI CO LTD

A Laminar Flow Cooling Control Method for a Stepped Hot Strip Steel Production Line

ActiveCN104307891BModerate shapeModerate hardnessTemperature control deviceProduction lineStrip steel

The invention discloses a stepped hot rolled strip production line laminar flow cooling control method. The method comprises the following steps: I, setting the temperature of the head of strip steel: calculating temperature to be cooled of the head of the strip steel by a laminar flow cooling control model through rolling temperature, stepped cooling compensation temperature and strip steel head finish rolling temperature; II, setting a strip steel head cooling scheme: calculating cooling water quantity of the laminar flow of the head of the strip steel by the laminar flow cooling control model according to the temperature to be cooled of the head of the strip steel and the speed of the strip steel, and then determining the cooling water nozzle distribution of the laminar flow according to a cooling strategy in the laminar flow cooling control model; III, setting the temperature of the tail part in the strip steel: calculating the temperature to be cooled of the tail part in the strip steel by the laminar flow cooling control model through the finish rolling temperature of the tail part in the strip steel; IV, setting the cooling scheme of the tail part in the strip steel. The method has the characteristics that the turn-up of the head of the strip steel on a track is prevented and folding and unwinding are prevented from occurring on the inner ring of a steel coil, and can be widely applied to the field of production of hot rolled strips.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com