Stepped hot rolled strip production line laminar flow cooling control method

A technology of laminar flow cooling and control method, applied in the direction of temperature control, etc., can solve the problems of difficult large-scale and stable production of hot continuous rolling, and achieve the effects of strong practicability, stable operation, flatness and moderate hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

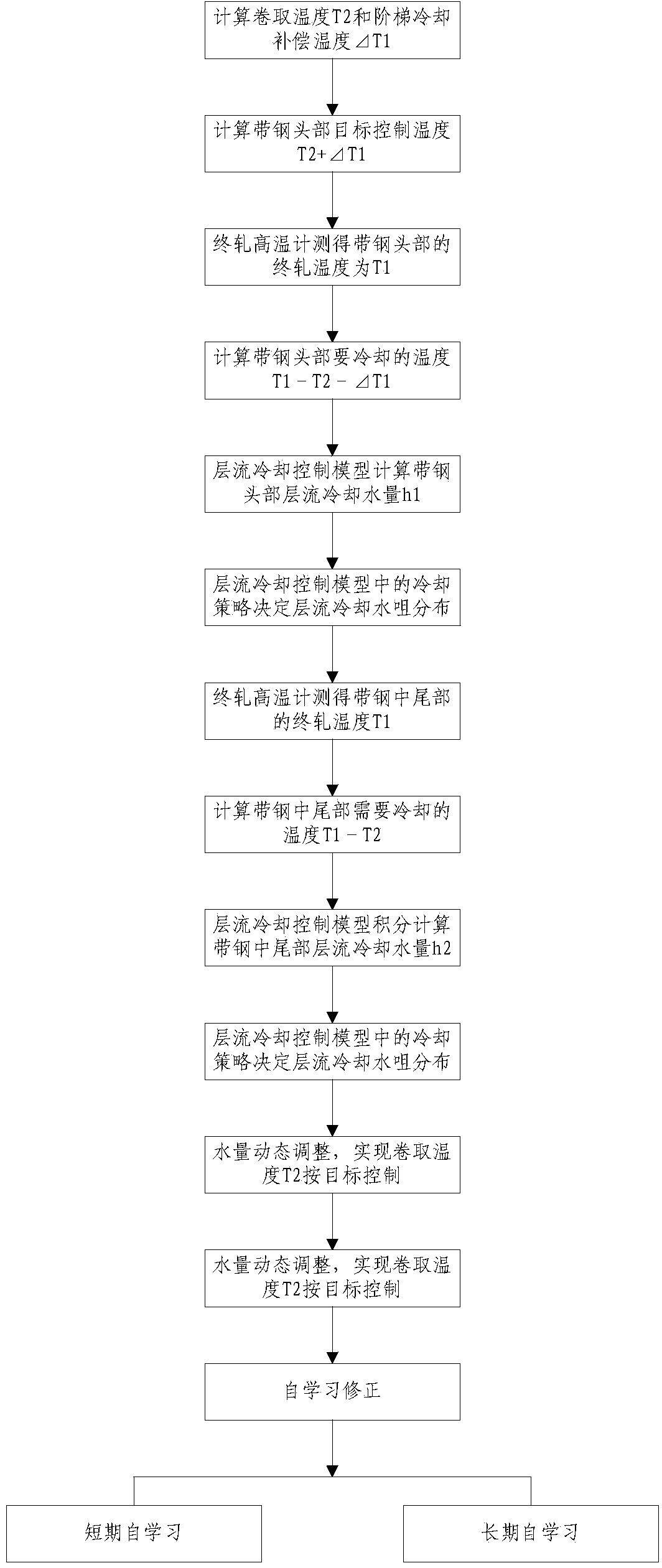

Method used

Image

Examples

Embodiment 1

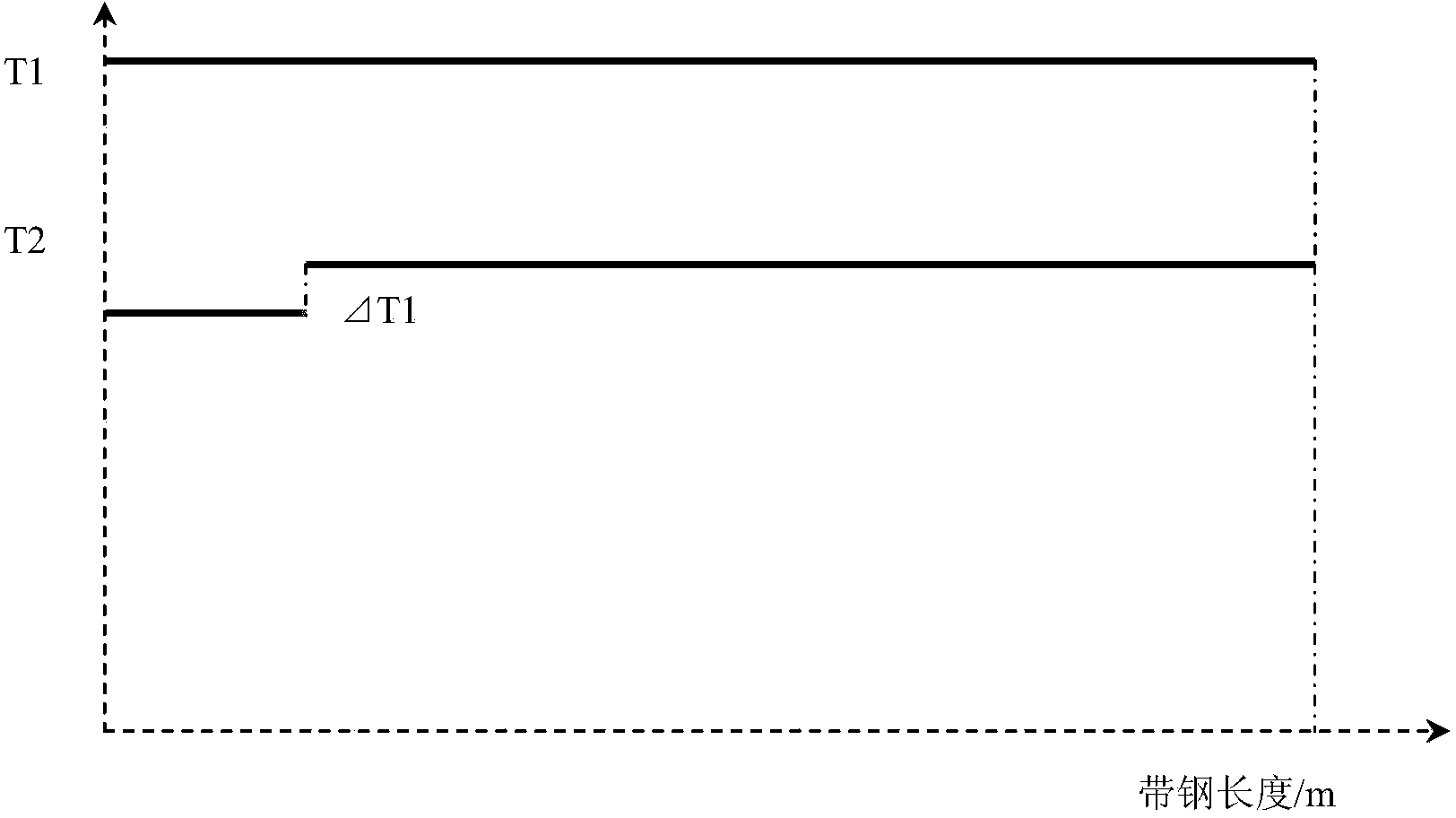

[0033] Steel type: SPHC, thickness 1.2mm, coiling temperature 660°C, step cooling compensation temperature -10°C, according to figure 2 The step cooling compensation temperature shown in above is executed, and the calculation starts at the head of the strip. The temperature is controlled at 650°C from 0 to 5m, and the target coiling temperature is controlled at 660°C after 5m. During the production process, the strip does not turn over on the roller table. Heaping and stacking of steel. After the strip steel is coiled, the inner ring of the steel coil does not have the head folding and the inner ring of the steel coil unwinding.

Embodiment 2

[0035] Steel type: SPHC, thickness 1.8mm, coiling temperature 640°C, step cooling compensation temperature -10°C, according to figure 2 The step cooling compensation temperature shown in above is executed, the strip head starts to be calculated, the temperature is controlled at 630°C at 0~1m, and the target coiling temperature is controlled at 640°C after 5m, during the production process, the strip does not turn over on the roller table Heaping and stacking of steel. After the strip steel is coiled, the inner ring of the steel coil does not have the head folding and the inner ring of the steel coil unwinding.

Embodiment 3

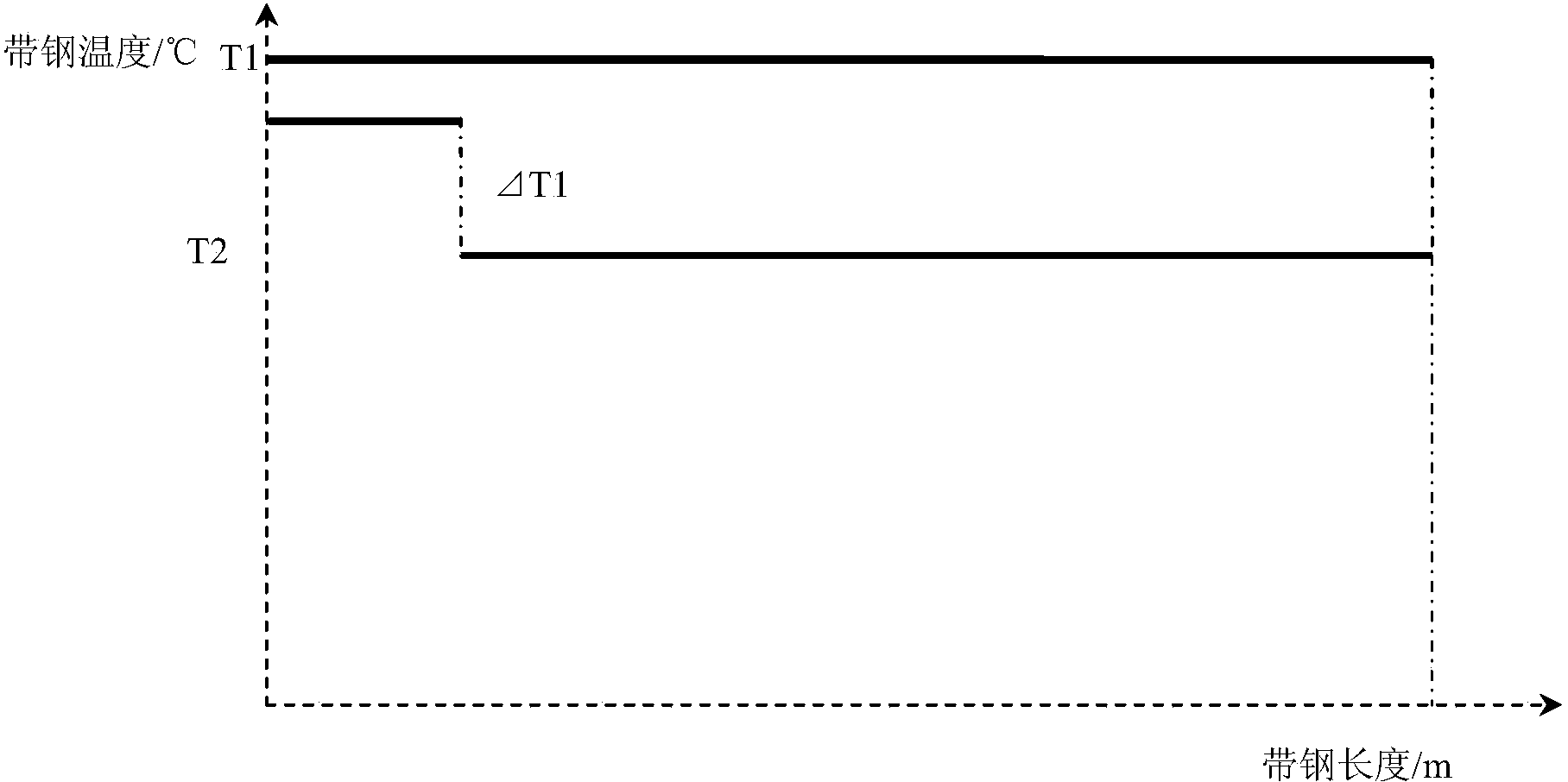

[0037] Steel type: Q215, thickness 1.1mm, coiling temperature 600°C, step cooling compensation temperature +50°C, press image 3 The step cooling compensation temperature shown in the above is executed, and the calculation starts at the head of the strip. The temperature is controlled at 650°C from 0 to 10m, and the target coiling temperature is controlled at 600°C after 10m. From the beginning, there is no phenomenon of stacking steel, and the inner ring of the steel coil does not have the head folding and the inner ring of the steel coil after the strip steel is coiled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com