Die and die forging method for improving multi-directional die forging die life

A technology of mold life and multi-directional die forging, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. Problems such as excessive flash, to achieve the effect of lowering the temperature, reducing the production cost and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

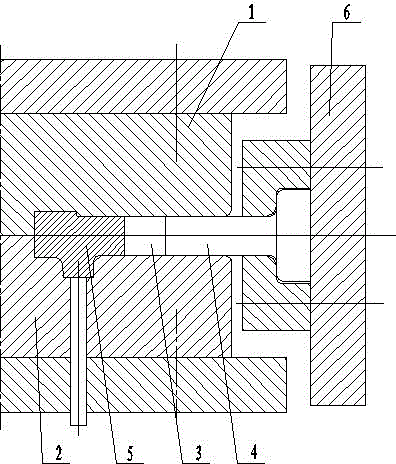

[0015] For specific implementation, see figure 1 , a die for improving the life of a multi-directional die forging die, comprising an upper die 1, a lower die 2 and a lateral punch, wherein the lateral punch includes a small punch 3 at the front end and a die base at the rear end 4. The front end of the small punch 3 is used to contact the part 5 and extrude the local shape of the part; The contact between the rear end and the front end of the mold base 4 is a plane butt or a concave-convex coupling that can prevent rotation. The length of the small punch 3 is 20-50cm.

[0016] When implementing this mold, the small punch uses H13 as the raw material, and the heat treatment hardness is 45-50HRC. Turn the steps and ensure that they can withstand the extrusion force required to form the part. The size of each cross-section of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com