Knotting machine

A knotting machine and frame technology, which is applied in the field of knotting machines, can solve the problems of corrosive damage to hands, low knotting efficiency, poor performance and operation stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

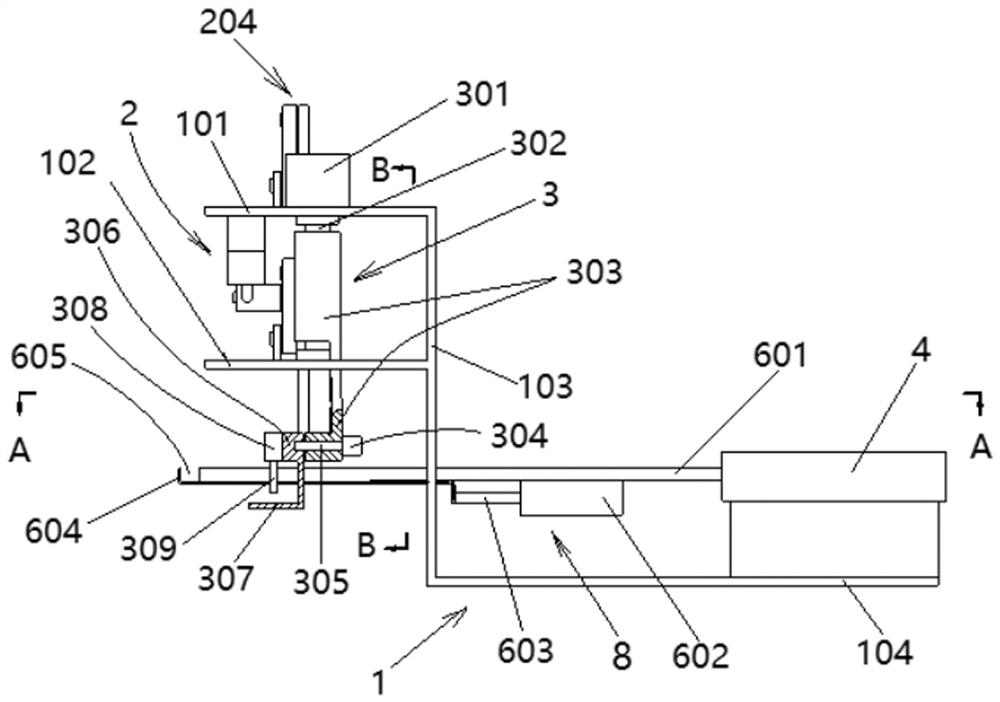

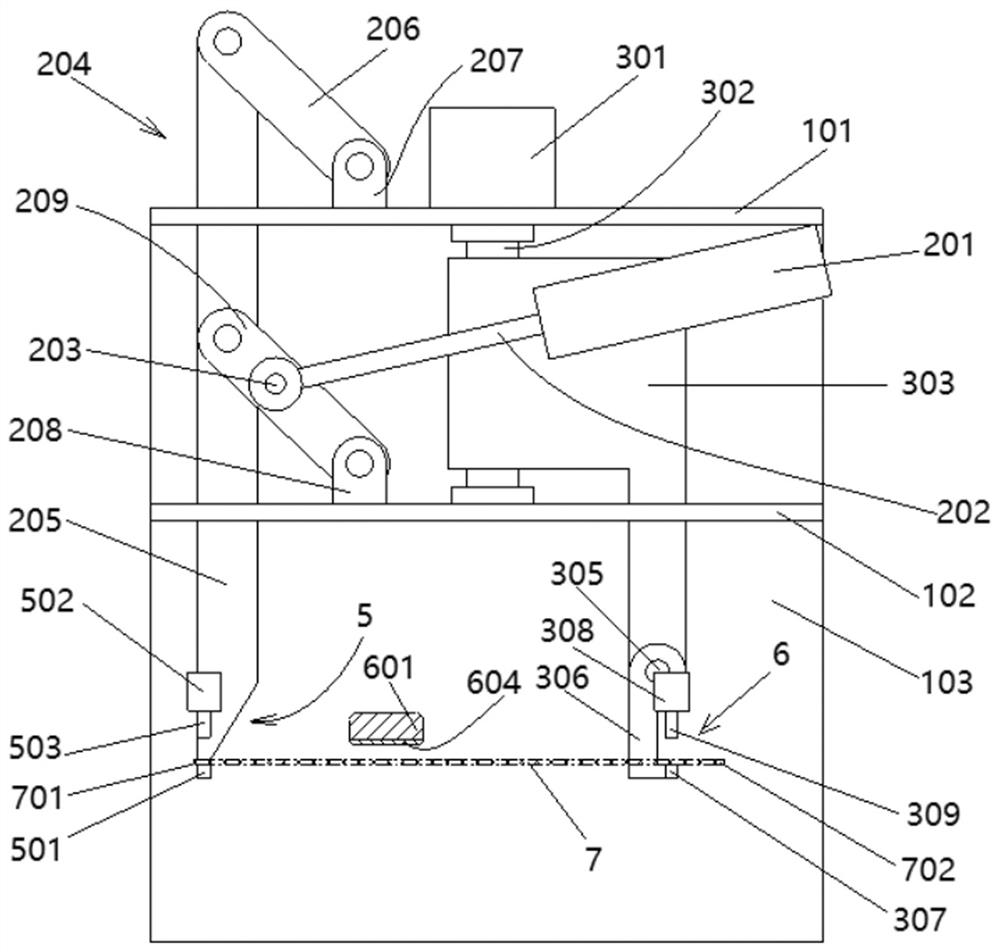

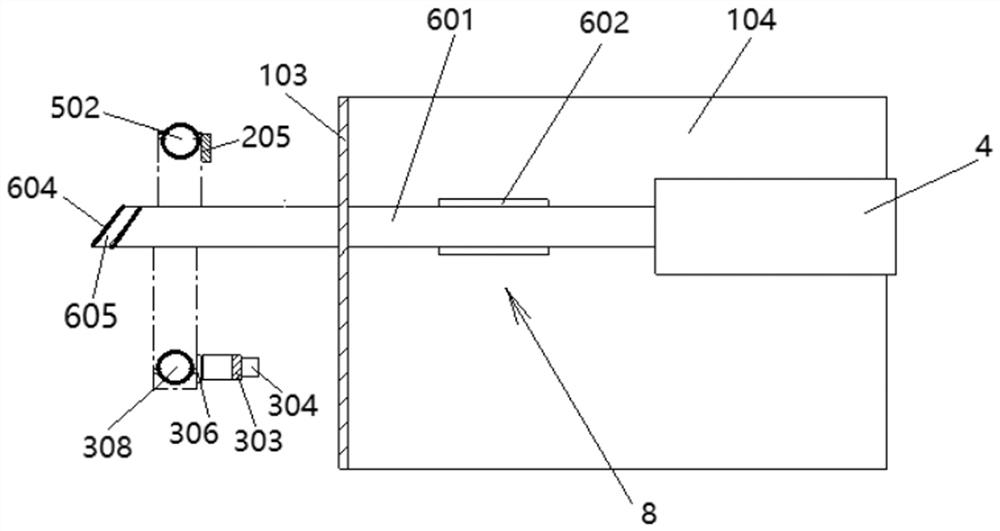

[0012] Embodiment 1: Set one end of the flexible food bar 7 (such as kelp, venetian knot, etc.) as the F end 701 , and the other end as the G end 702 .

[0013] First, the flexible strip food 7 is manually placed in the first clamping mechanism 5 and the second clamping mechanism 6, that is, the F end 701 of the flexible strip food 7 is placed on the first hem 501, and the G end 702 Place on the lower clamping bar 310, and the flexible strip food 7 is below the drawstring hook 604 (see figure 1 , figure 2 ), and then, open the first compression cylinder 502 in the first clamping mechanism 5 of the upper bending mechanism 2 and the second compression cylinder 311 in the second clamping mechanism 6 in the lower bending mechanism 3, The first pressing shaft 503 carried by the first pressing cylinder 502 is stretched and pressed to the first flange 501 to compress the F end 701 of the flexible strip food 7, and the second pressing shaft 503 carried by the second pressing cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com