Infant food & debris catcher

a technology for catching debris and food, which is applied in the field of infant food & debris catcher, can solve the problems of large waste of a large sheet, food, utensils and food containers spillage, sticky mess on the floor, etc., and achieve the effect of little ability and minimal disruption or distraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

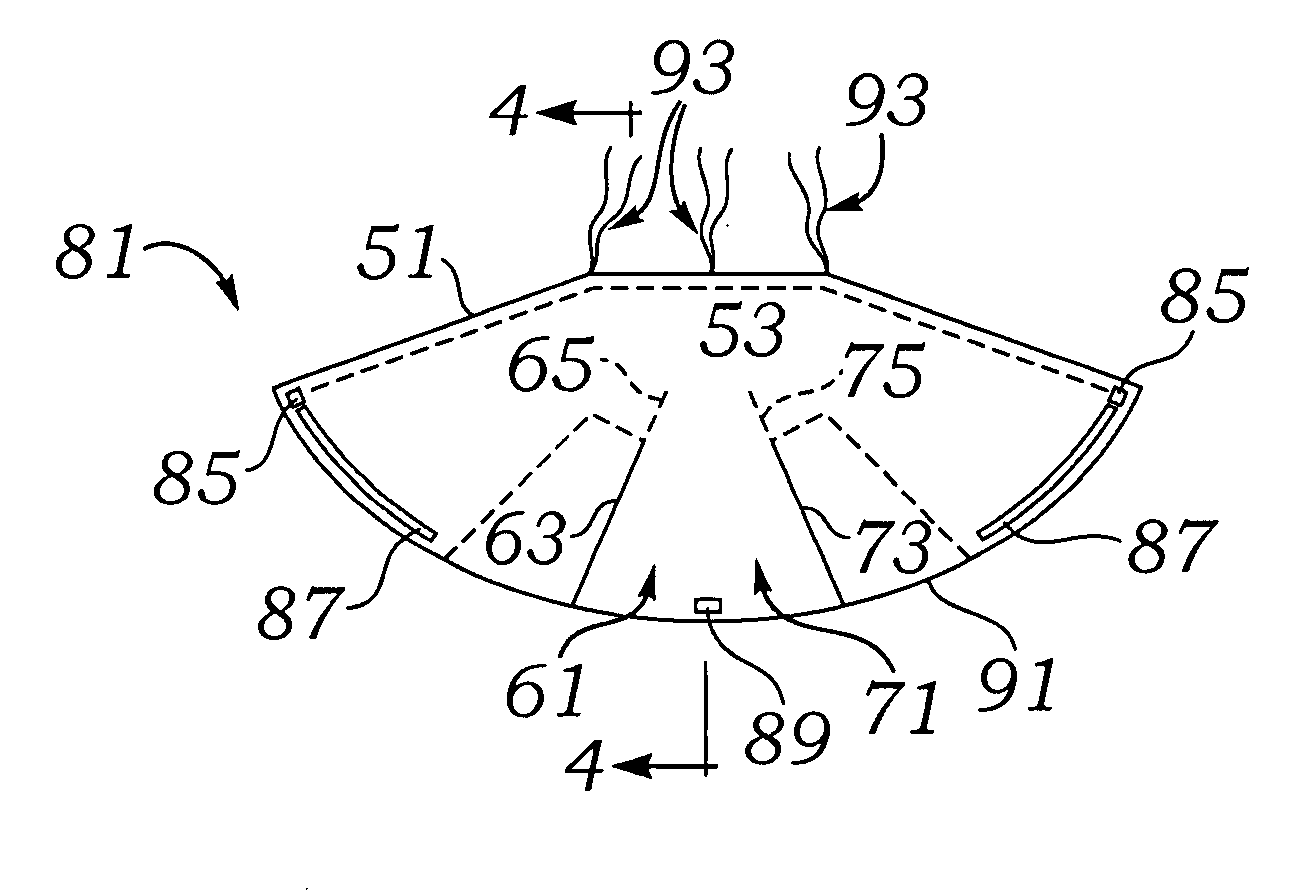

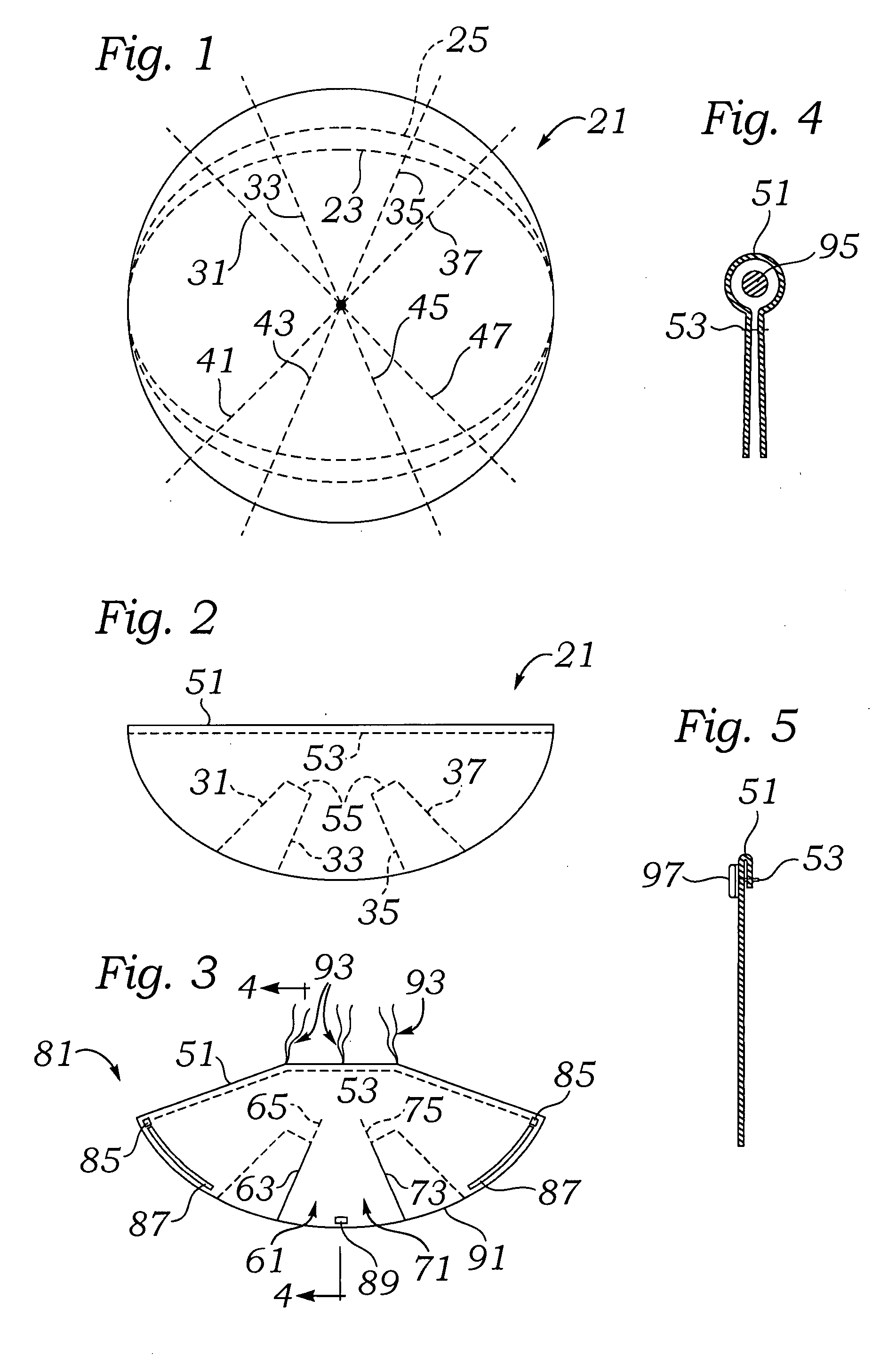

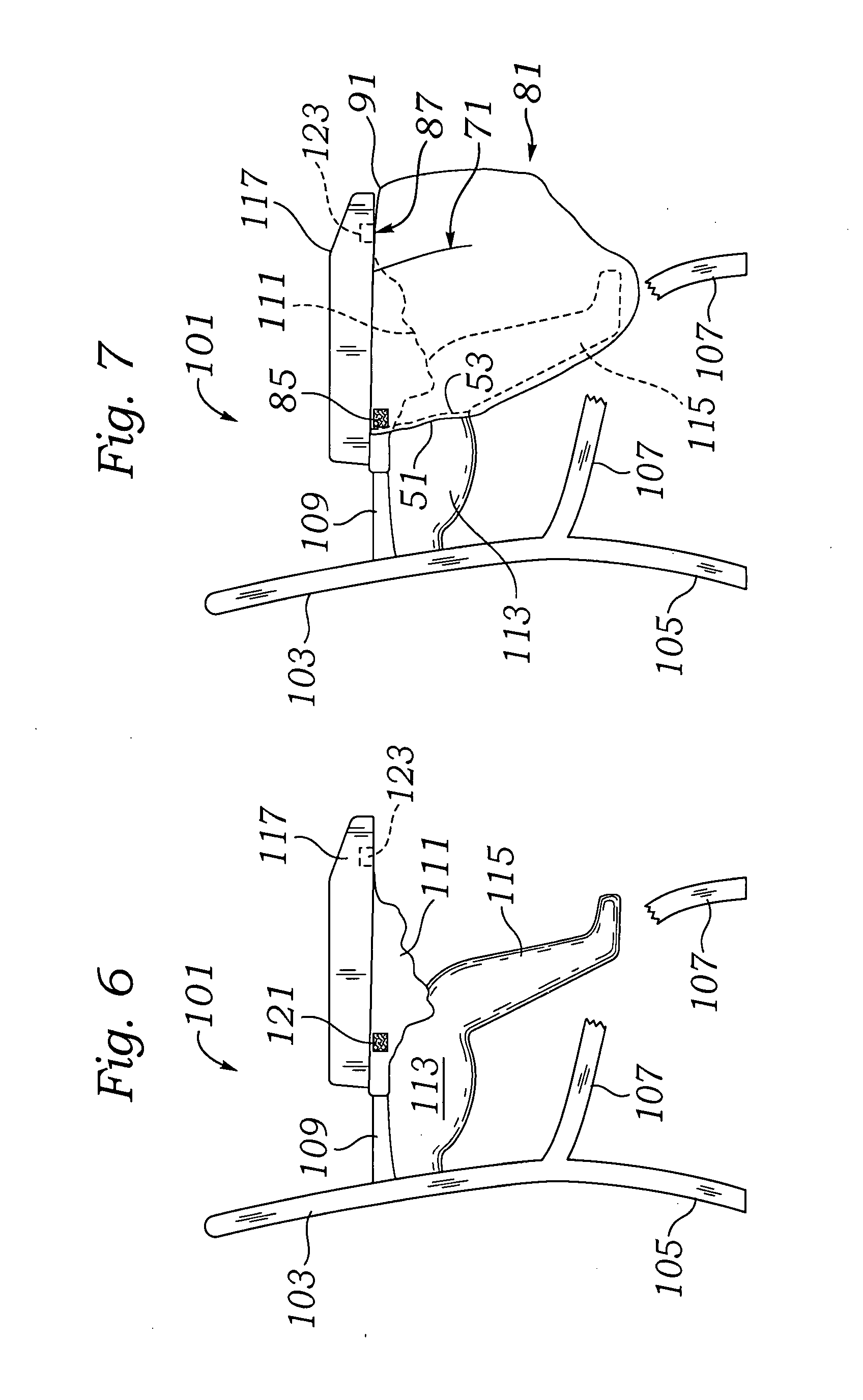

[0027]The description, construction and operation of the catcher of the invention will be best illustrated by beginning with the construction of the catcher. An expanse of material 21 is provided which may be cut to a circular shape or to an oval shape. Material 21 may preferably be made from polyurethane having a thickness of perhaps 3 mils. An alternative set of cutting lines are seen as cutting line 23 which may preferably form a blended radius for reduction of the effective radius by about 75% and a cutting line 25 which may preferably form a blended radius for reduction of the effective radius by about 83%.

[0028]A pair of dart cutting lines 31 and 33 and a pair of dart cutting lines 35 and 37 are shown on the upper half of the expanse of material 21. A pair of dart cutting lines 41 and 43 and a pair of dart cutting lines 45 and 47 are shown on the lower half of the expanse of material 21.

[0029]The expanse of material can be any size, but may have a maximum radius of about sixty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com