Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Efficiently exposed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

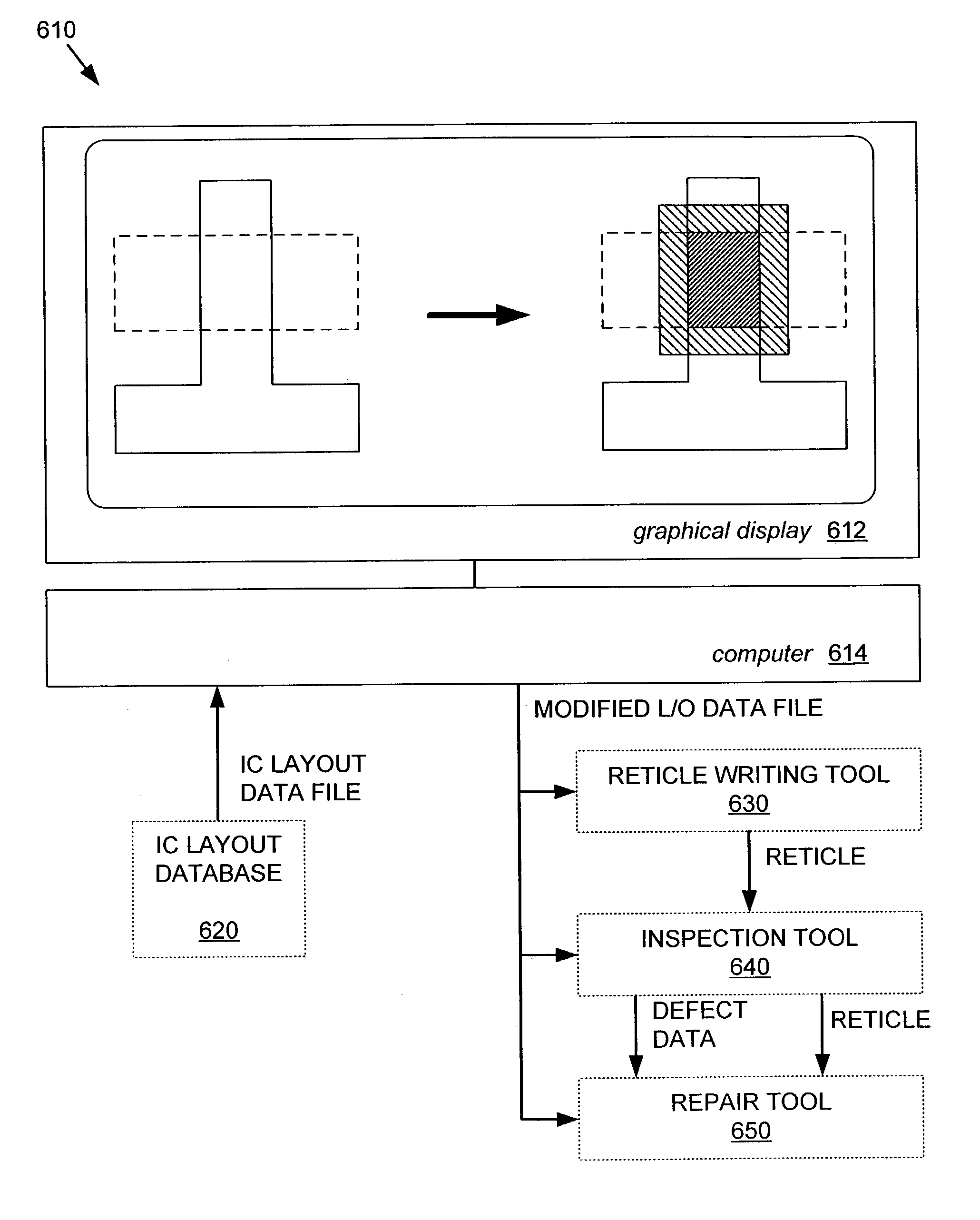

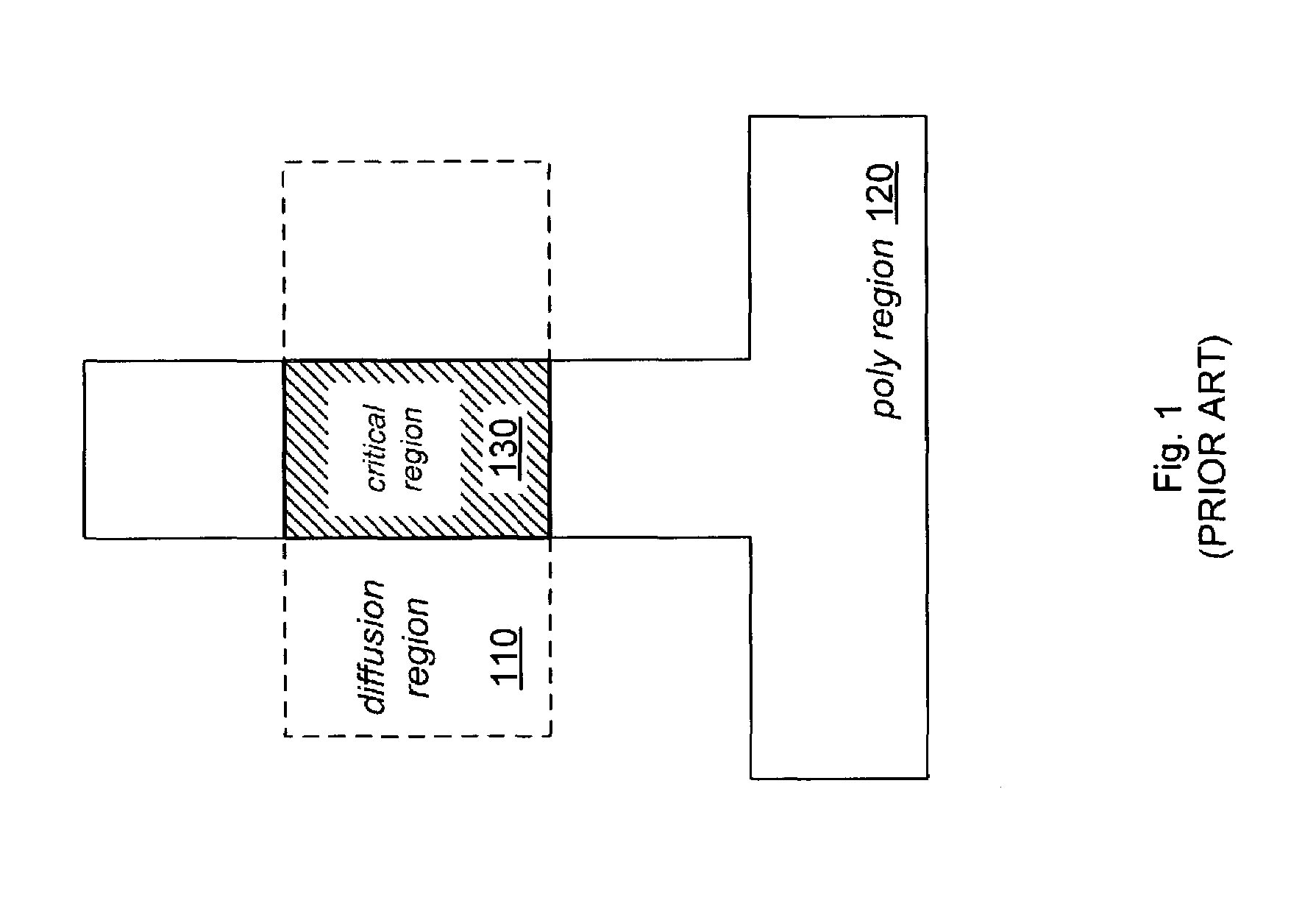

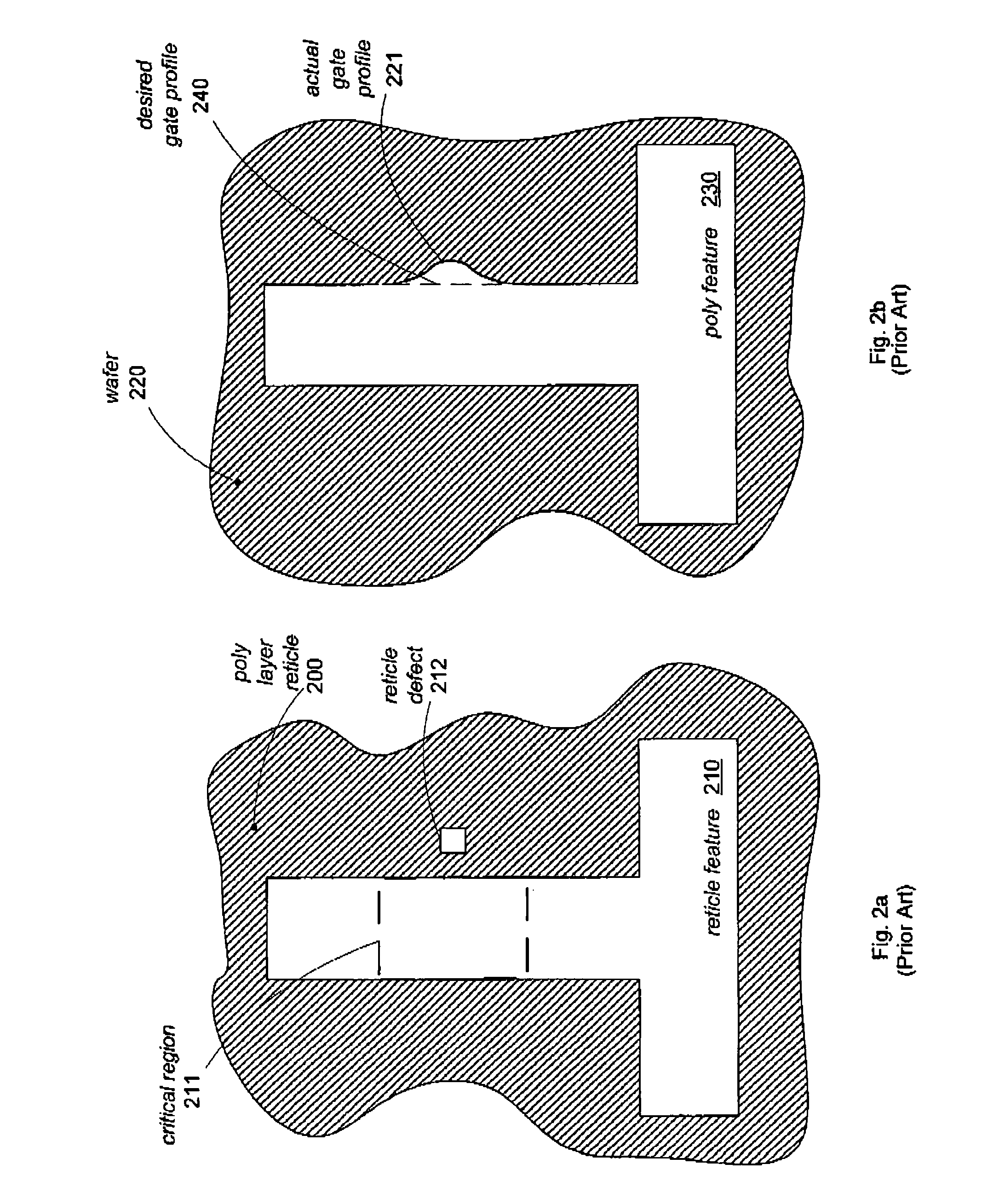

High yield reticle with proximity effect halos

InactiveUS6968527B2High degreeLow costElectric discharge tubesSemiconductor/solid-state device manufacturingGraphical displayData file

Owner:SYNOPSYS INC

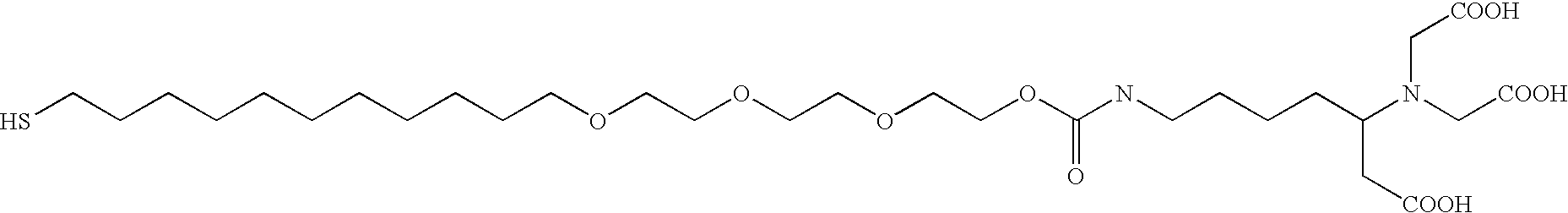

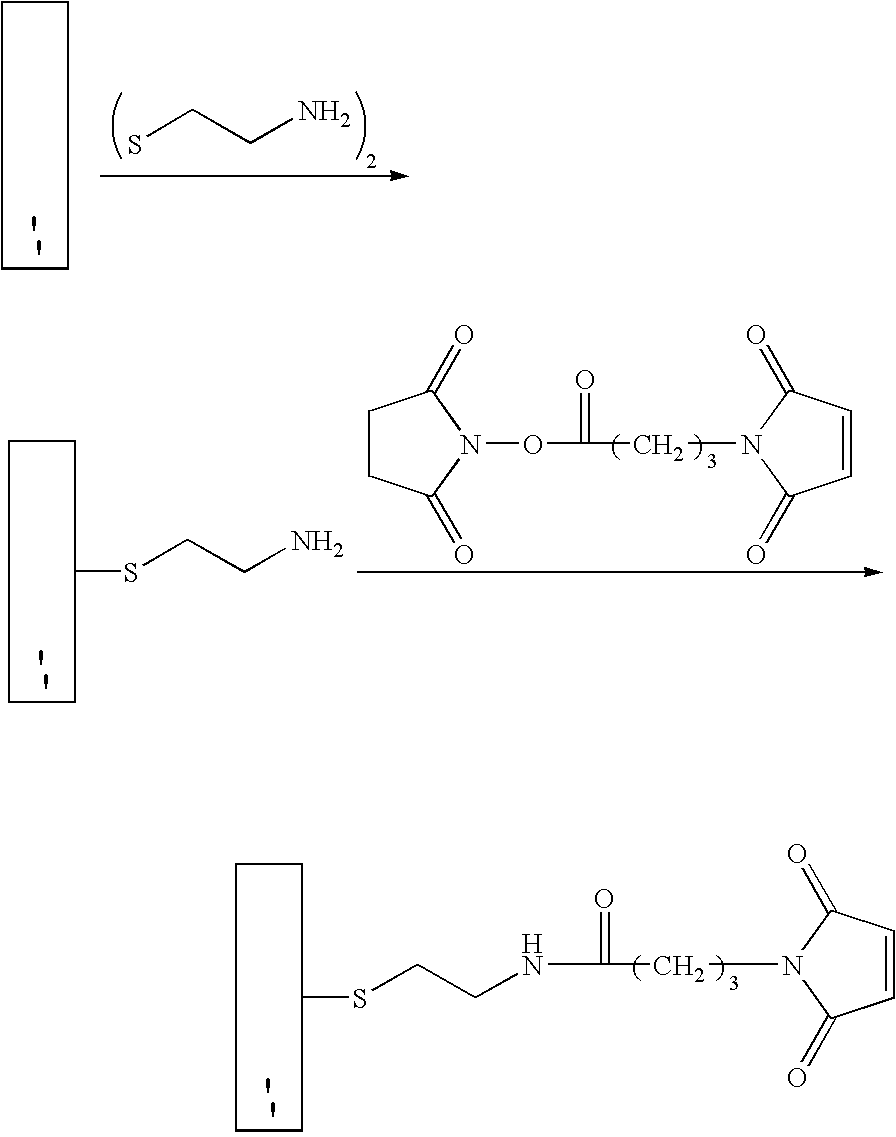

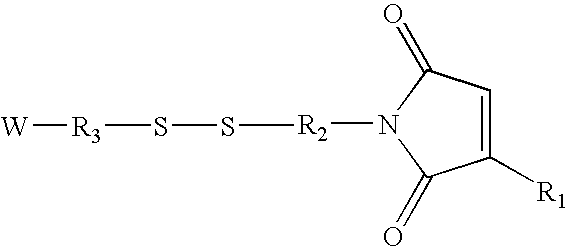

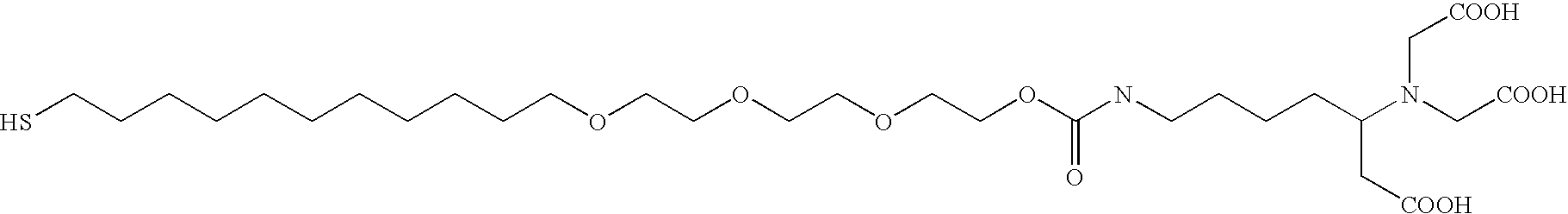

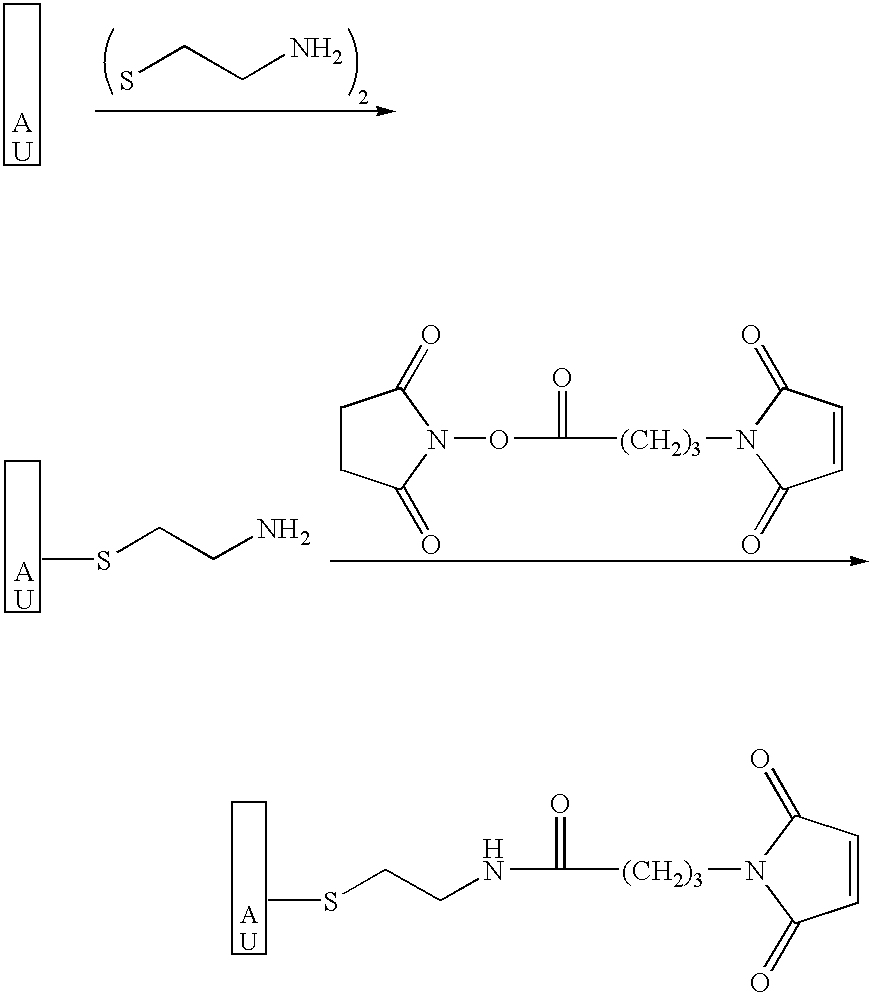

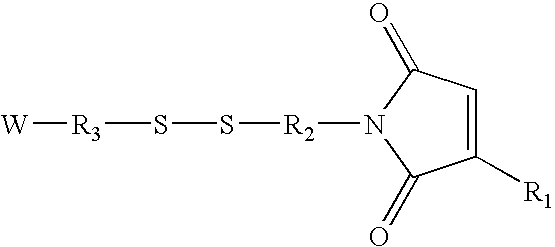

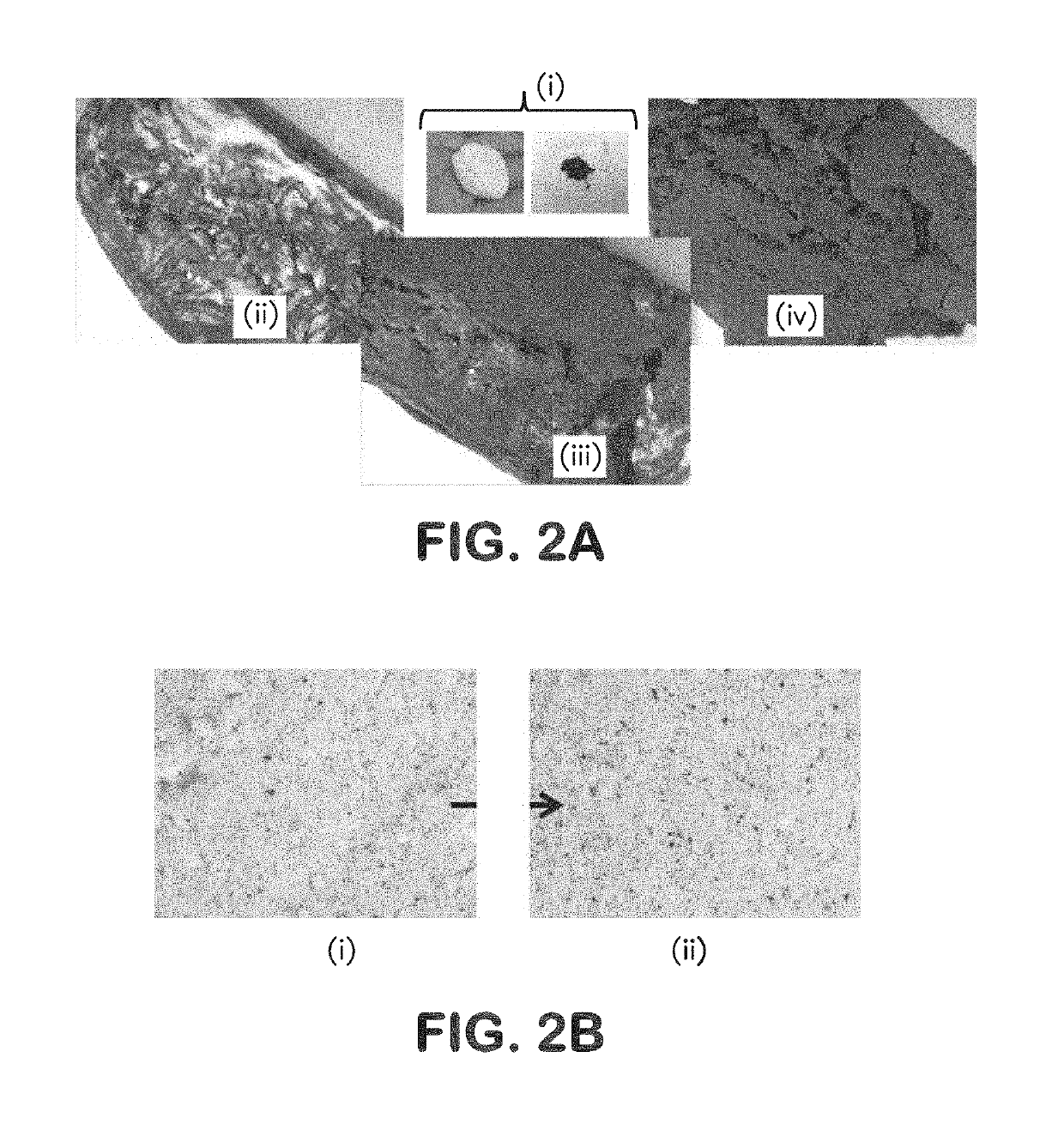

Methods of detecting immobilized biomolecules

InactiveUS6967074B2Efficiently exposedMaterial nanotechnologyImage enhancementBiological materialsMaterials science

Owner:SURFACE LOGIX INC

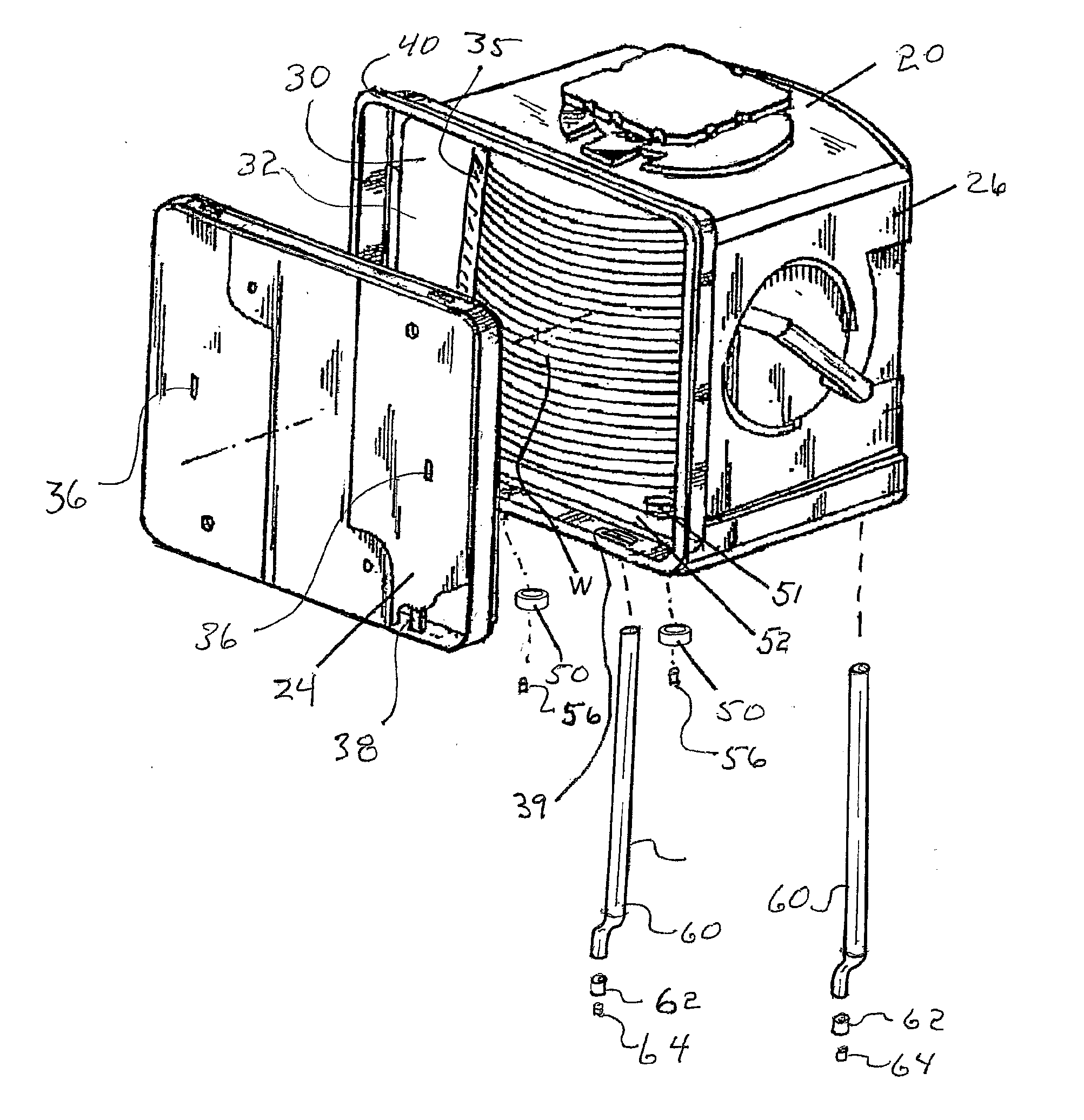

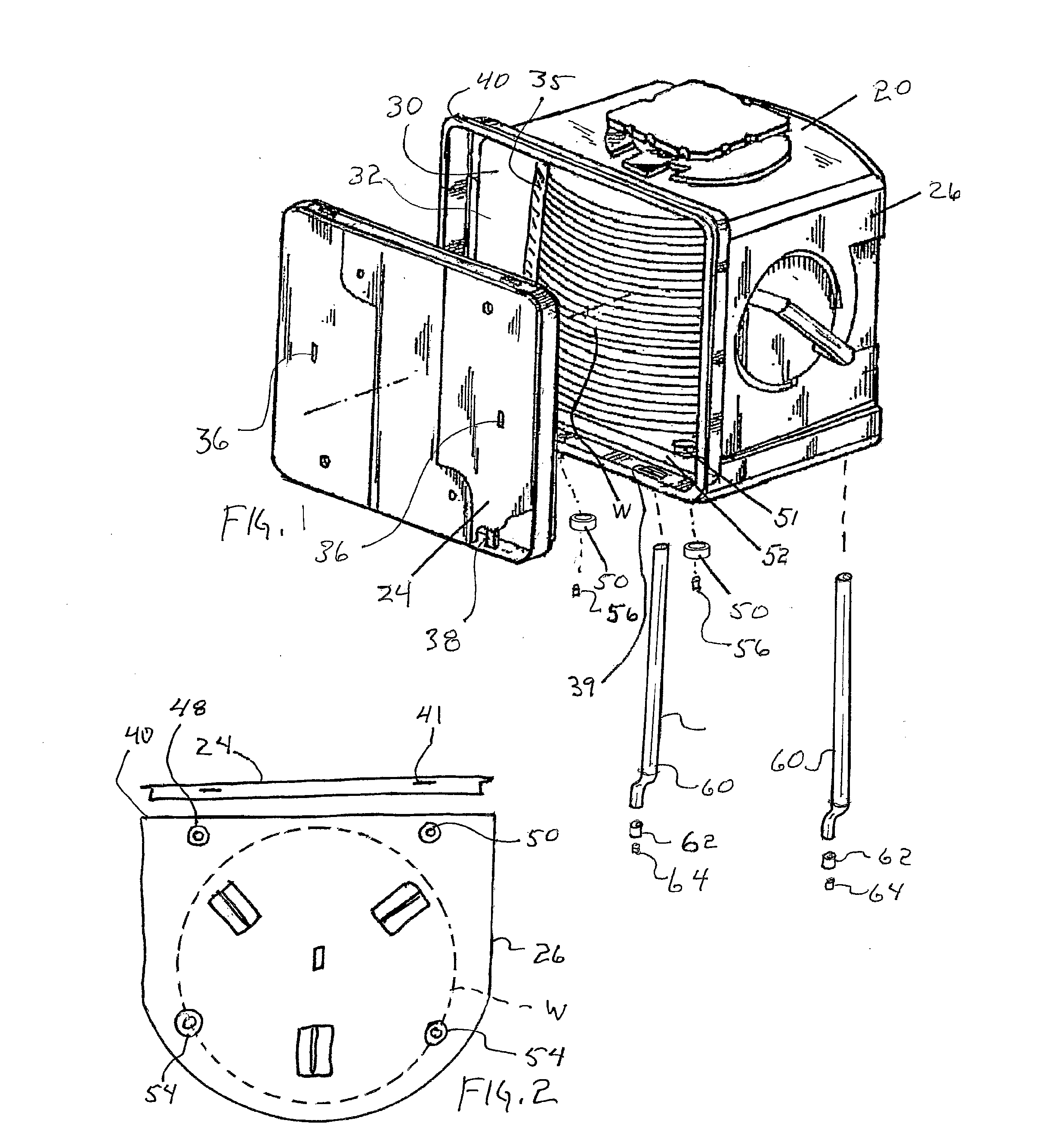

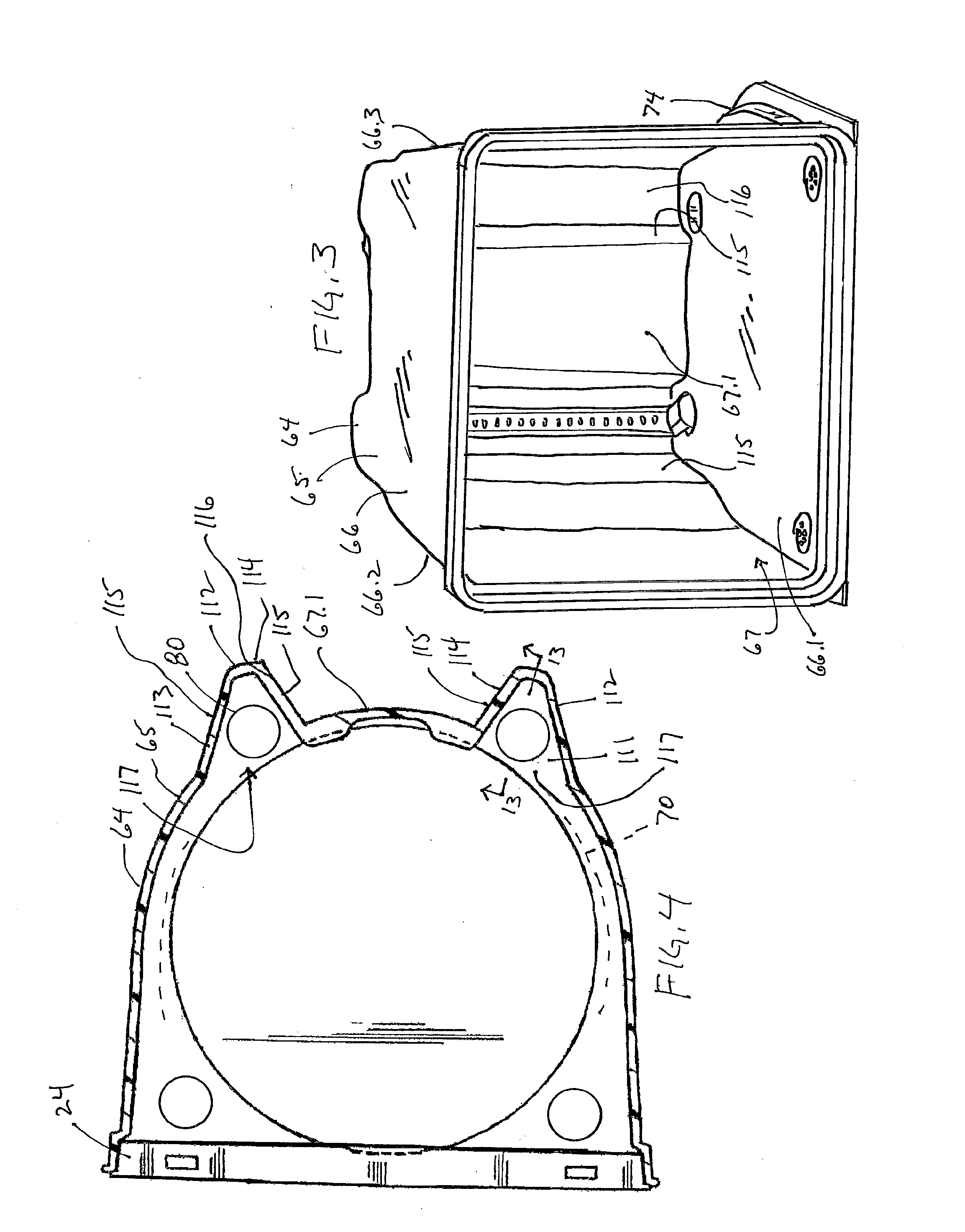

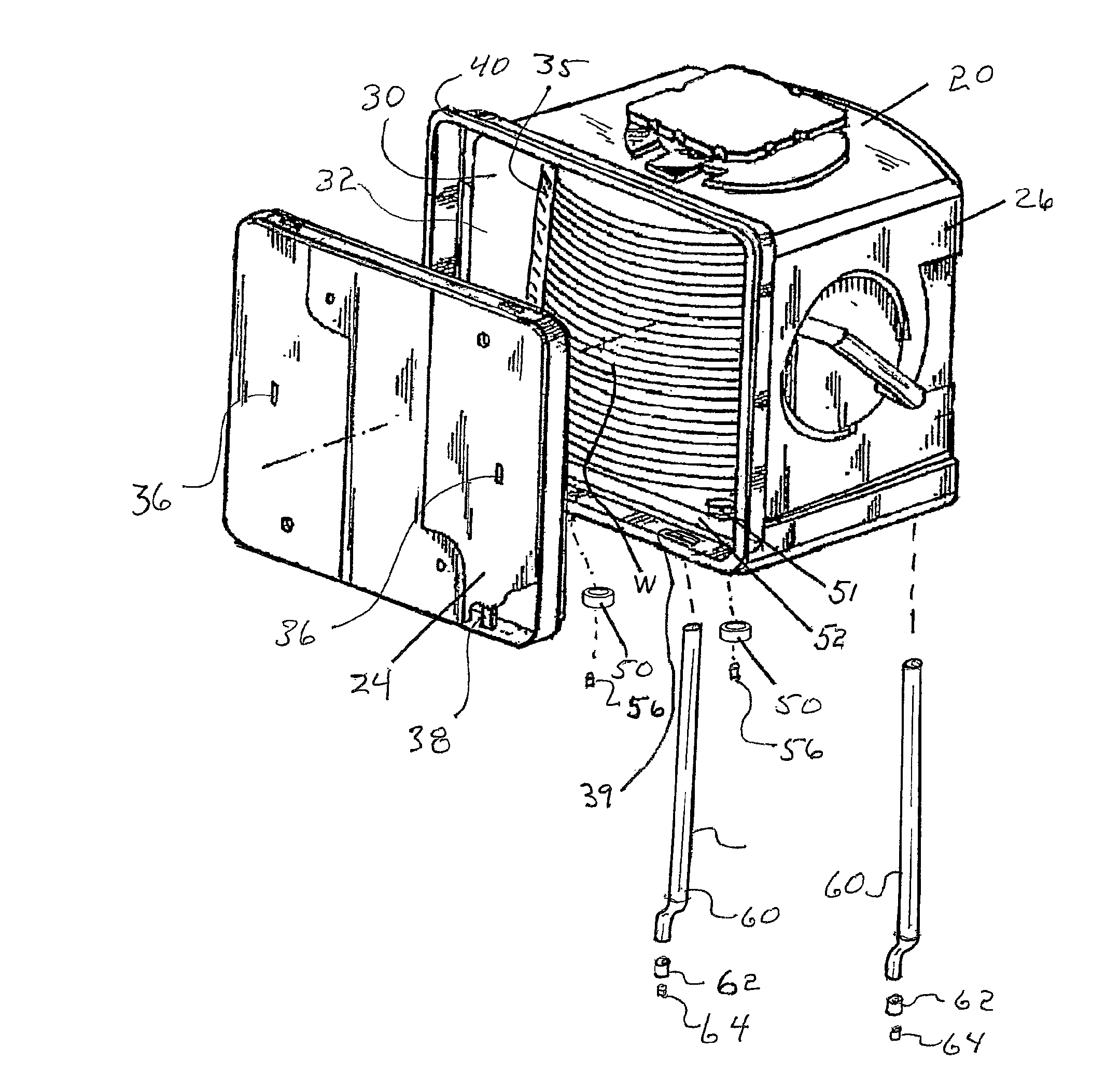

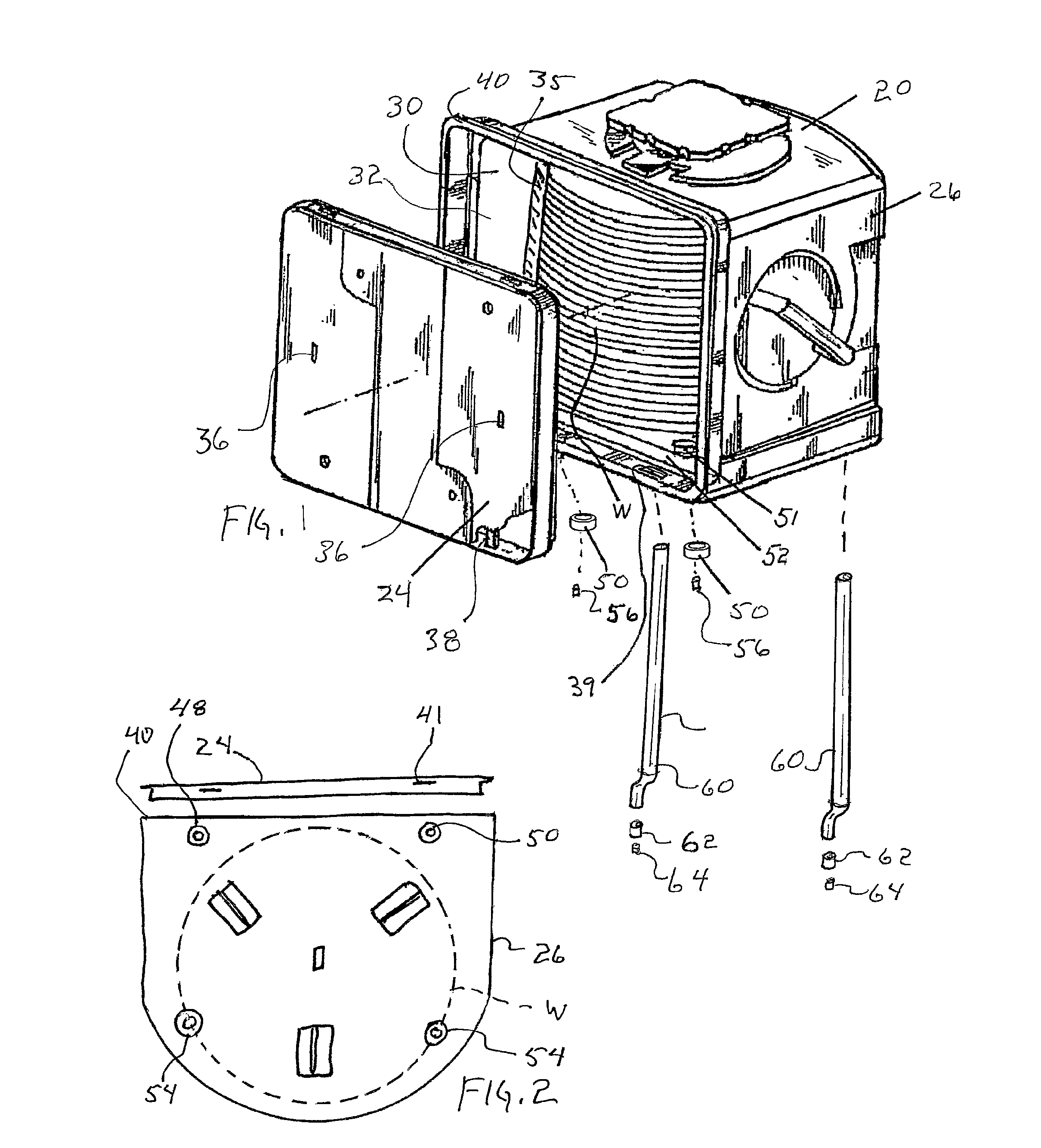

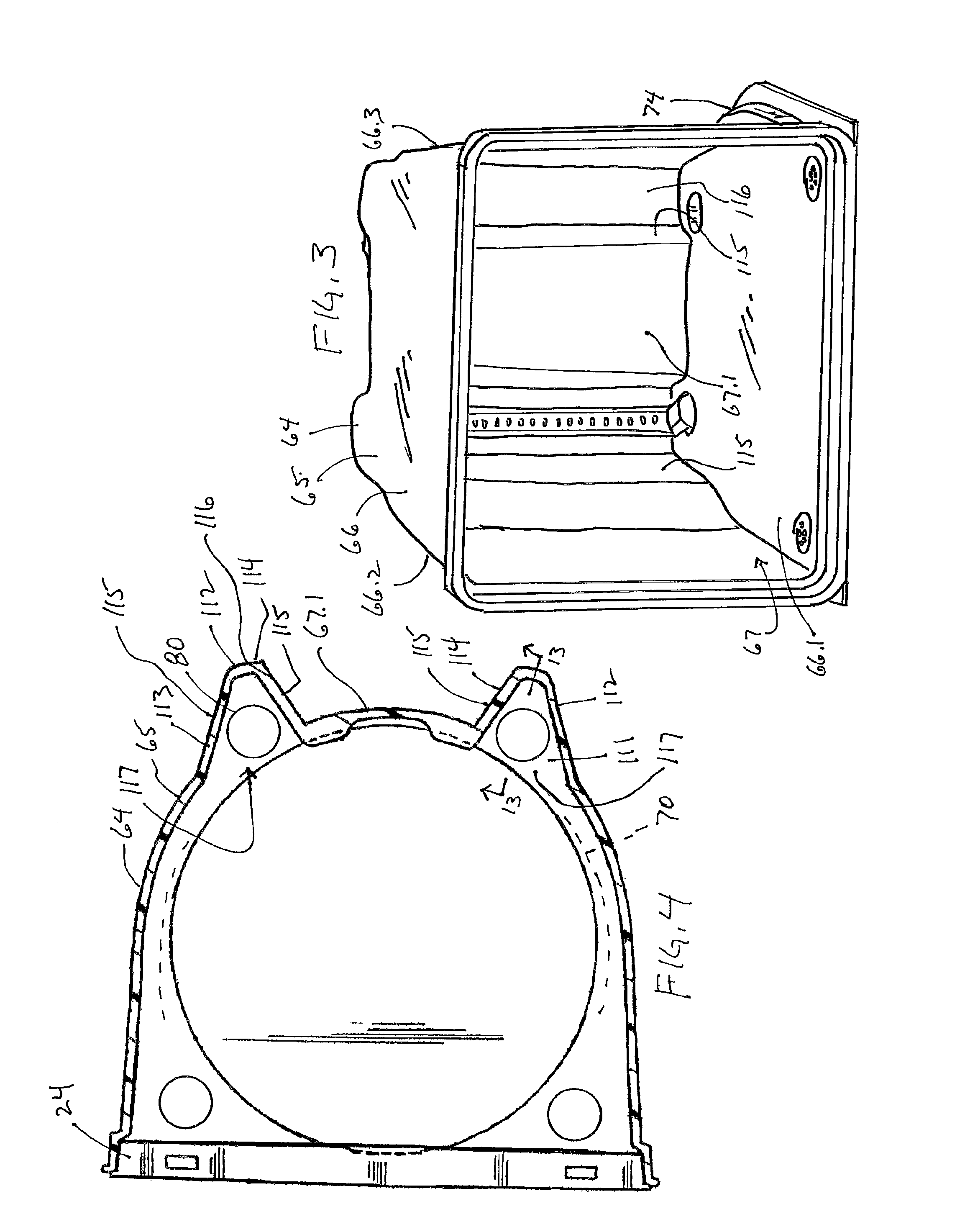

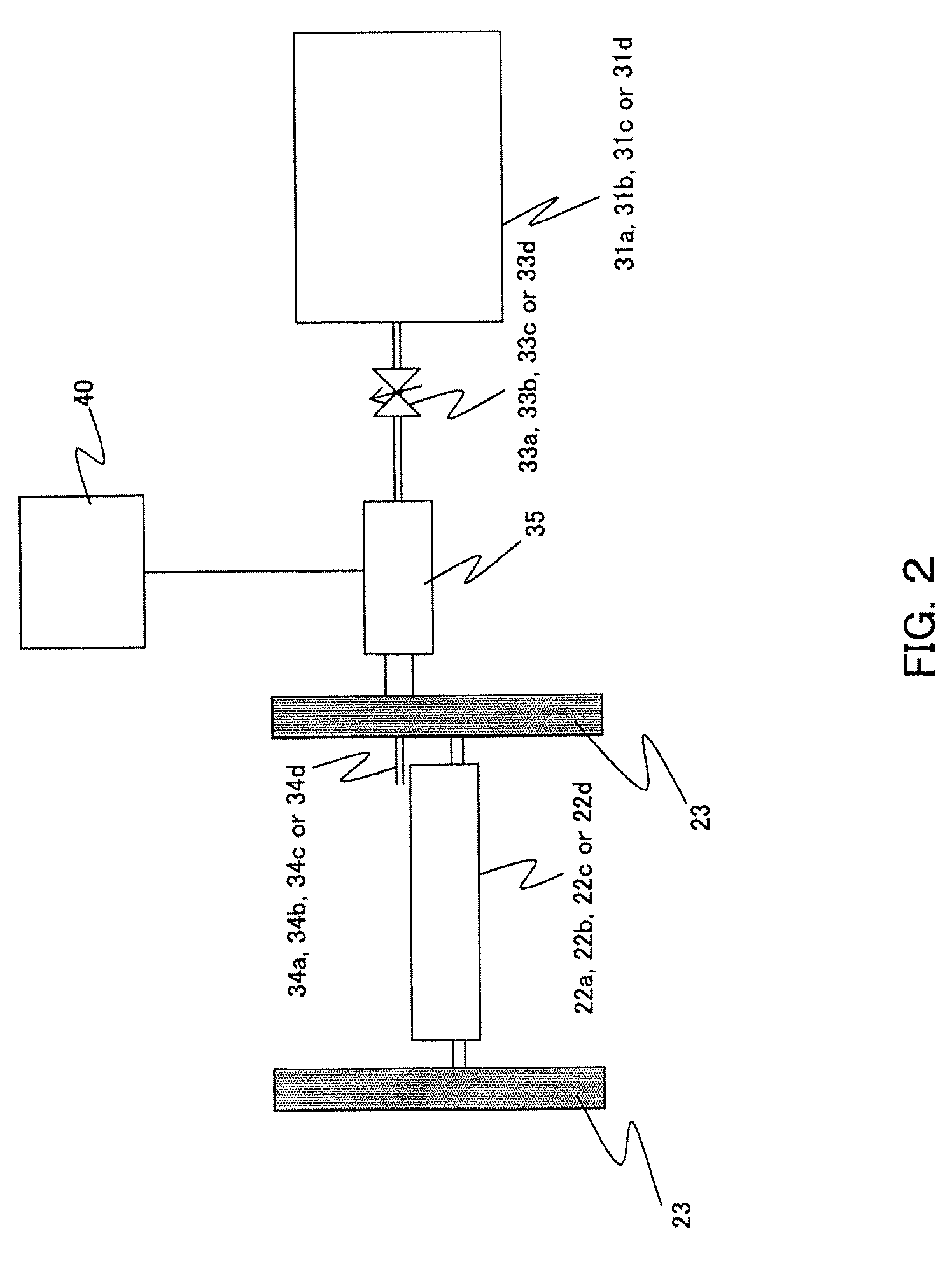

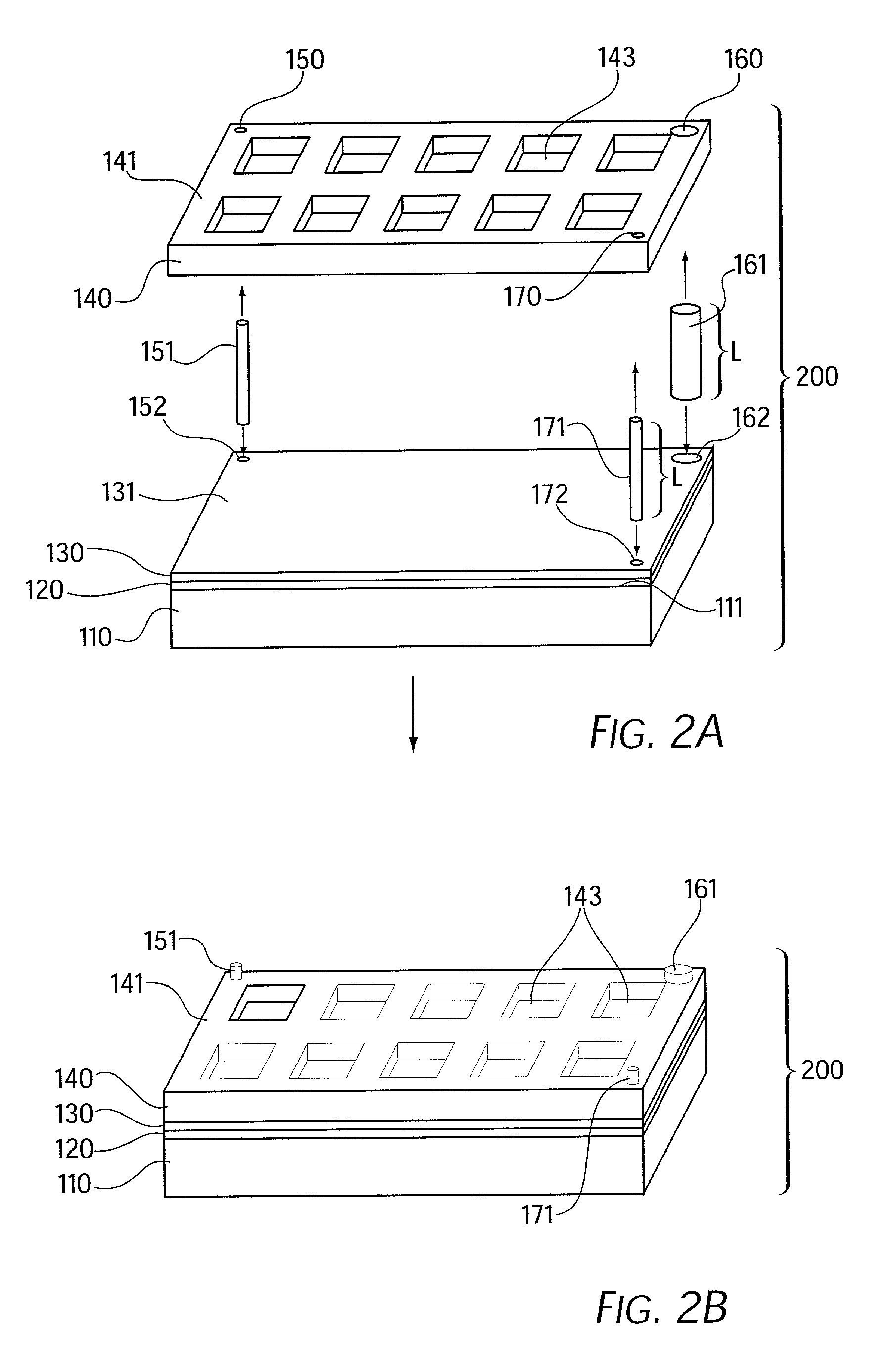

Wafer container with tubular environmental control components

ActiveUS20110114534A1Protected contentSuperior fluid flow characteristicSemiconductor/solid-state device manufacturingOther accessoriesFiltrationEngineering

A wafer container utilizes a rigid polymer tubular tower with slots and a “getter” therein for absorbing and filtering moisture and vapors within the wafer container. The tower preferably utilizes a purge grommet at the base of the container and may have a check valve therein to control the flow direction of gas (including air) into and out of the container and with respect to the tower. The tower is sealingly connected with the grommet. The tower may have a getter media piece rolled in an elongate circular fashion forming or shaped as a tube and disposed within the tower and may have axially extending. The media can provide active and / or passive filtration as well as having capabilities to be recharged. Front opening wafer containers for 300 mm sized wafers generally have a pair of recesses on each of the left and right side in the inside rear of the container portions. These recesses are preferably utilized for elongate towers, such towers extending substantially from a bottom wafer position to a top wafer position. In alternative embodiment, a tubular shape of getter material is exposed within the front opening container without containment of the getter other than at the ends. The tubular getter form is preferably supported at discrete locations to maximize exposure to the internal container environment. A blocker member can selectively close the apertures. An elastomeric cap can facilitate securement of the tubular component in the container portion.

Owner:ENTEGRIS INC

Methods of detecting immobilized biomolecules

InactiveUS20050100974A1Efficiently exposedImage enhancementMaterial nanotechnologyBiological materialsMaterials science

Devices and methods for performing assays on materials, particularly biological materials, are provided. The devices and methods make use of self-sealing members, which can be applied to a flat surface to form wells to facilitate immobilization of materials on the flat surface, then removed to yield a flat surface that facilitates the performance of processes on and / or detection of the immobilized material.

Owner:SURFACE LOGIX INC

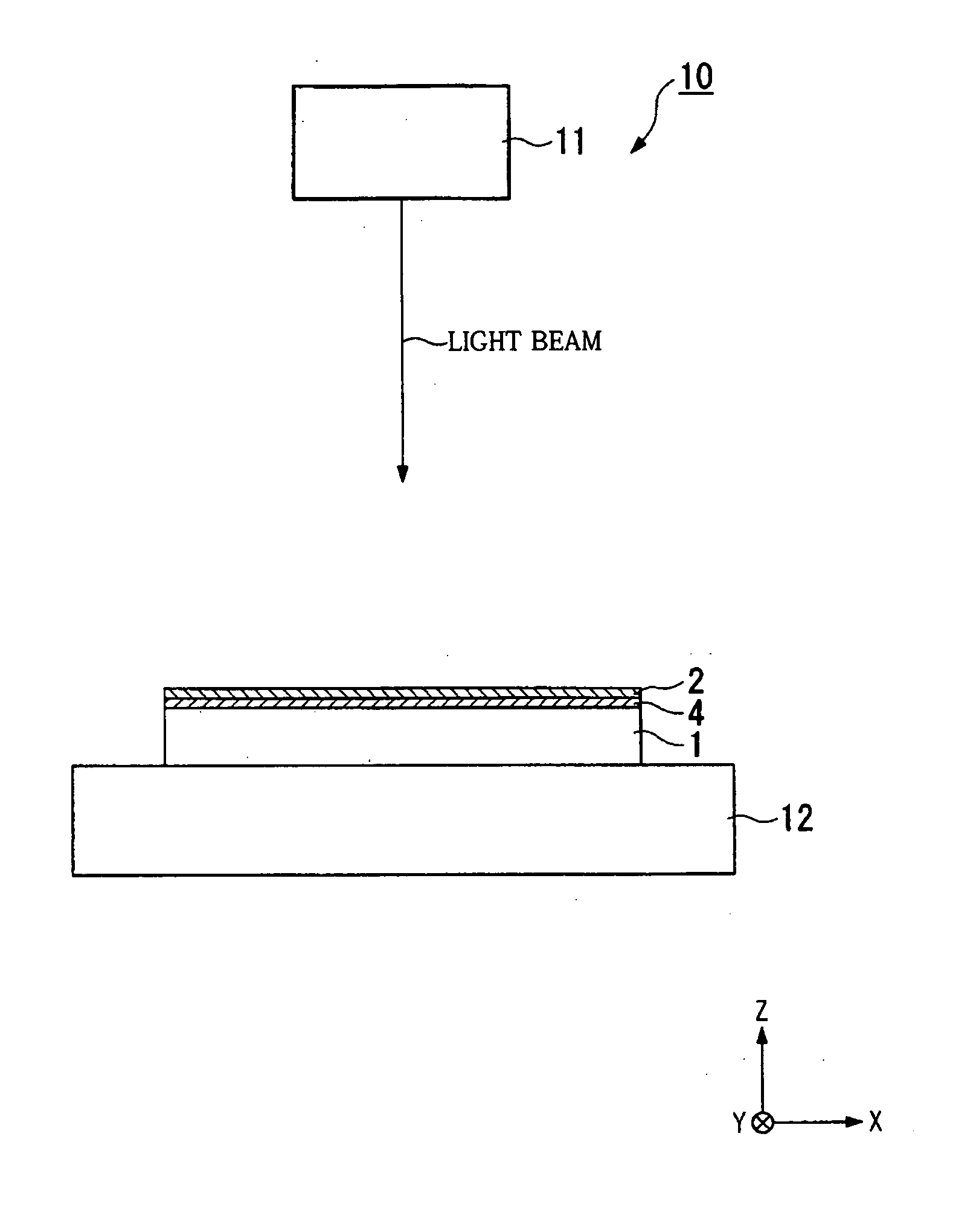

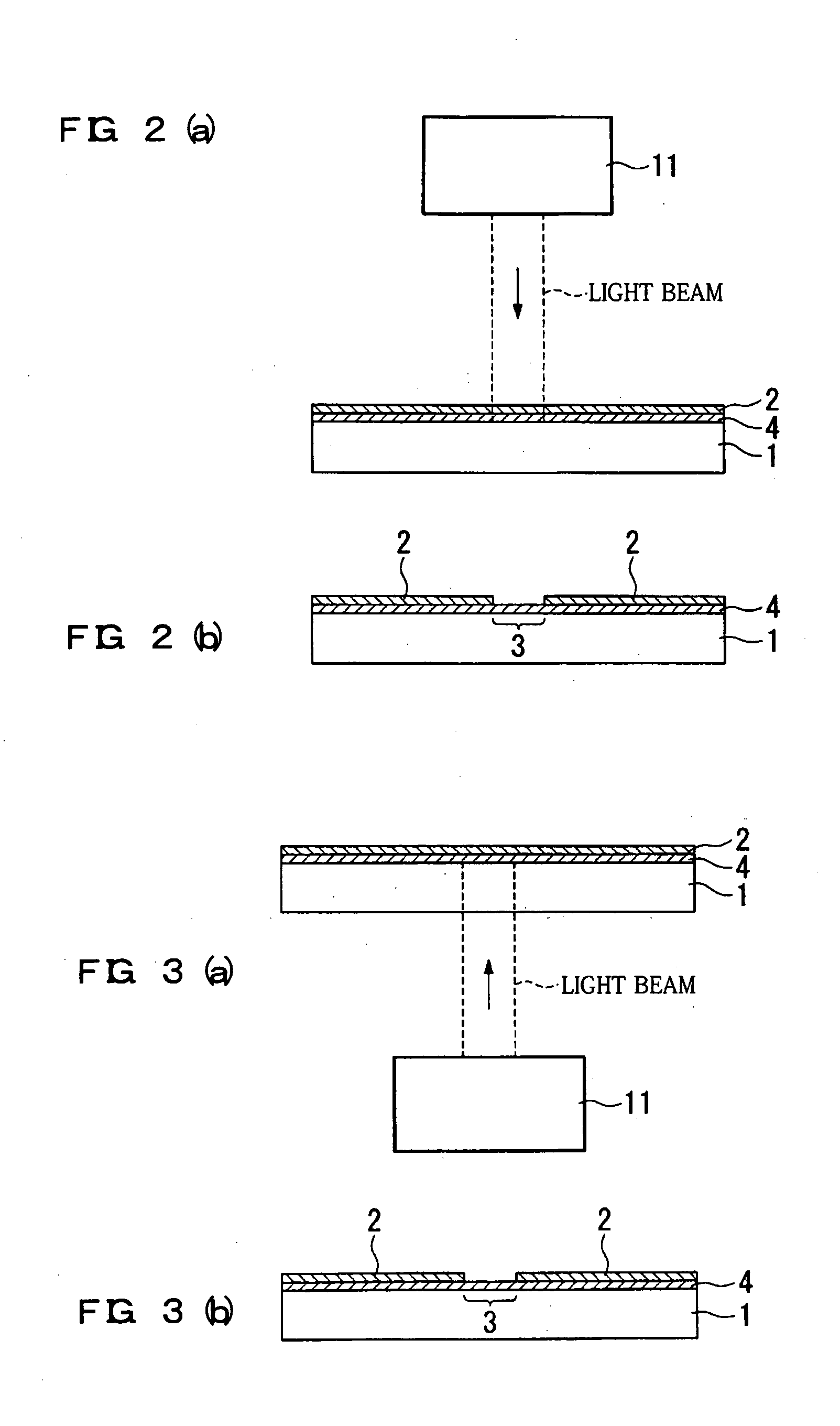

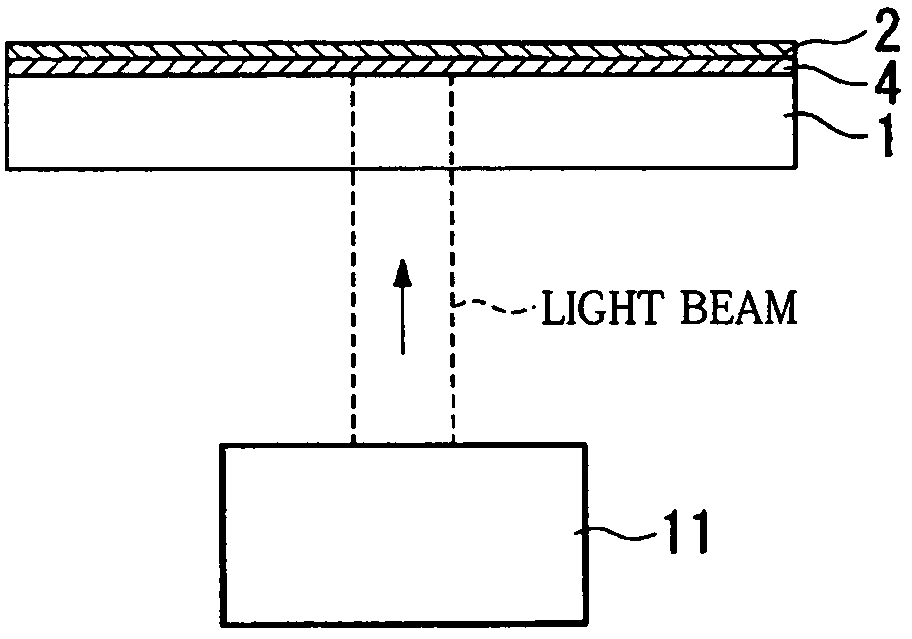

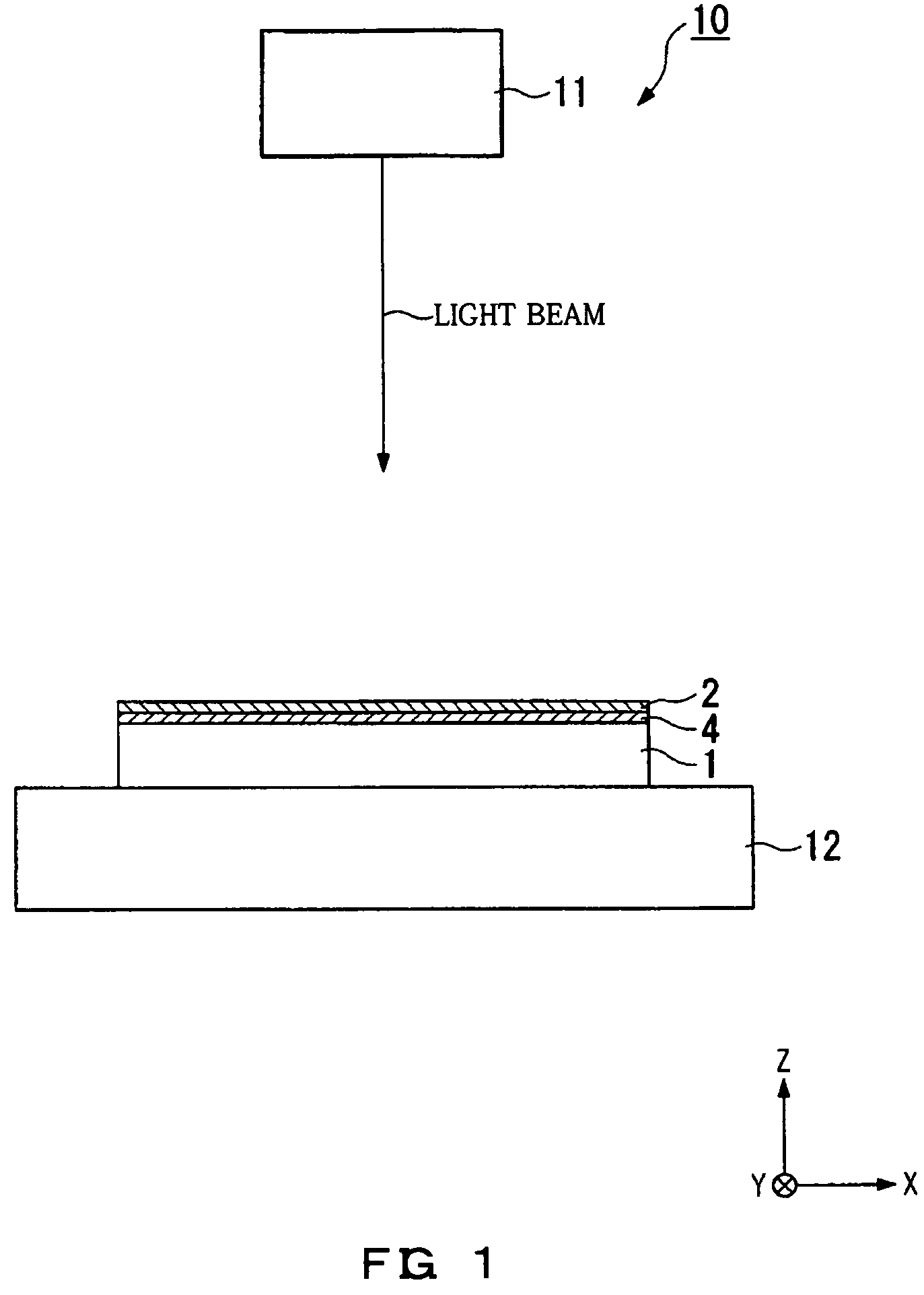

Pattern forming method, wiring pattern forming method, electro-optical device, and electronic apparatus

ActiveUS20050042430A1Simplified and inexpensive deviceValid conversionMaterial nanotechnologyElectric lighting sourcesThermal energyThin membrane

Aspects of the invention can provide a patterning forming method capable of patterning a thin film by a simple and inexpensive device. The thin film can be provided on a base member including a photothermal conversion material that converts optical energy into thermal energy and light is radiated onto the base member to remove the thin film corresponding to a light-radiated region, such that the thin film is patterned.

Owner:INTELLECTUAL KEYSTONE TECH LLC

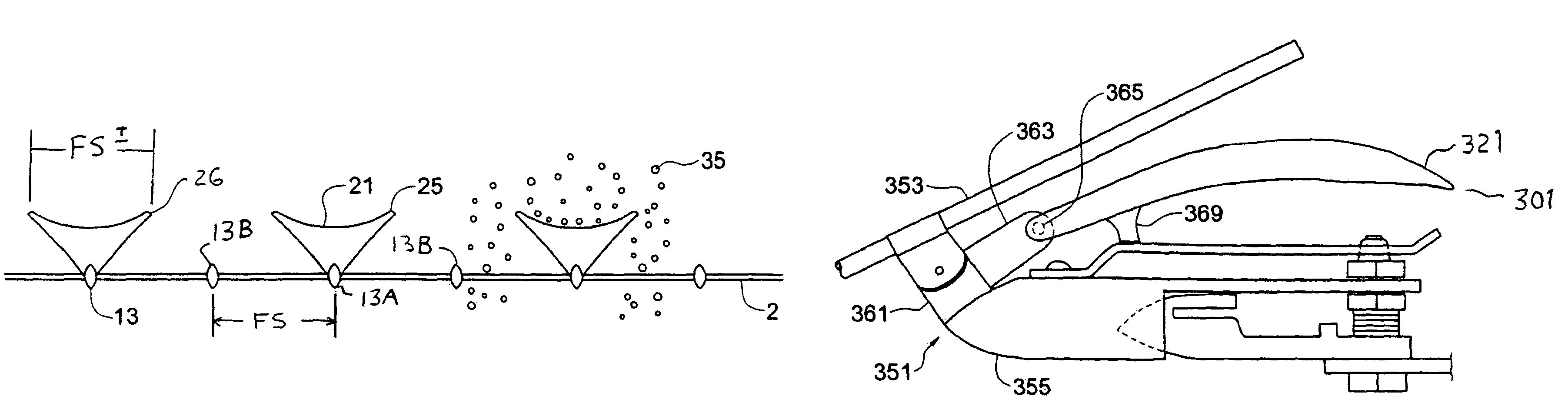

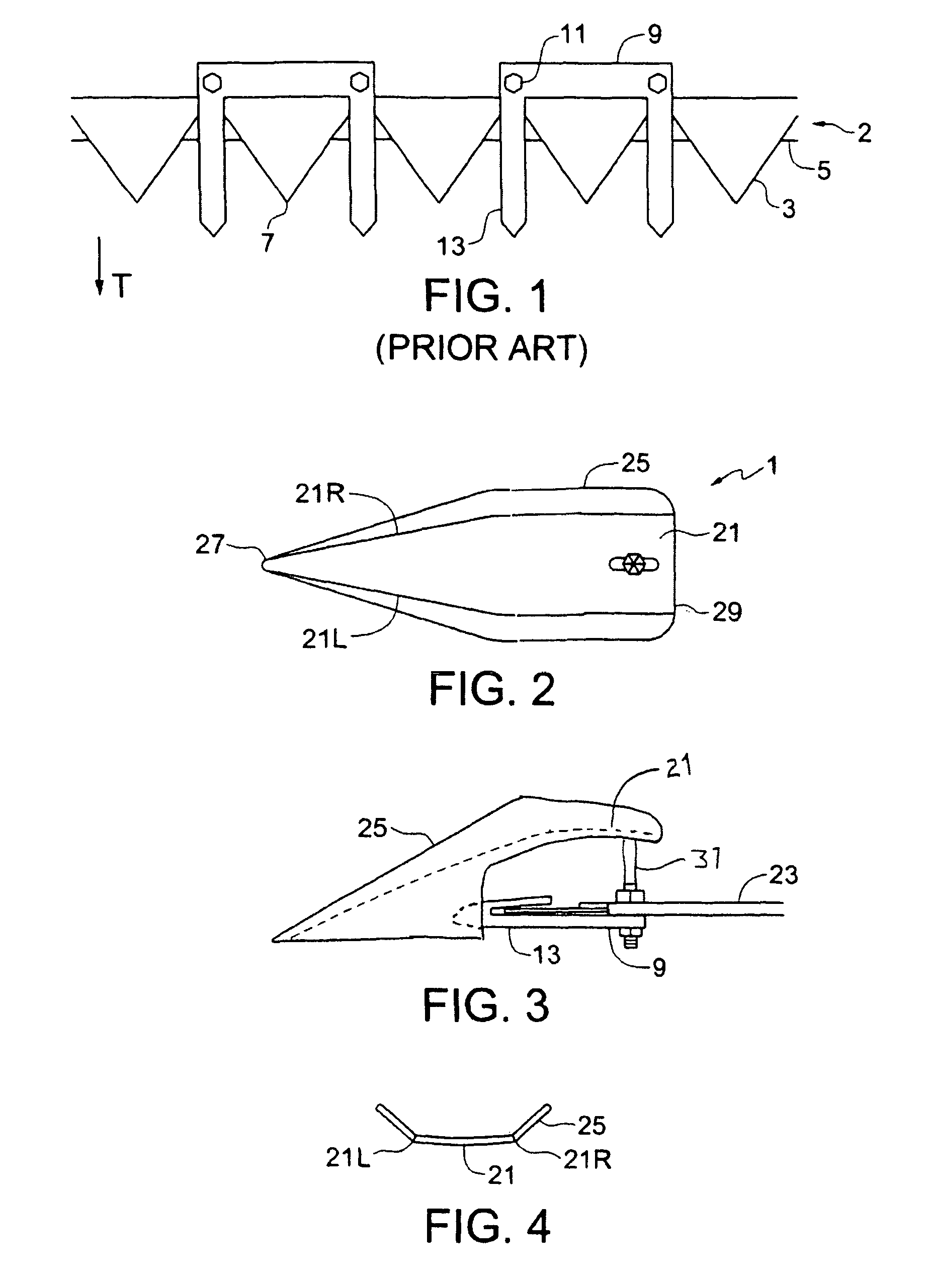

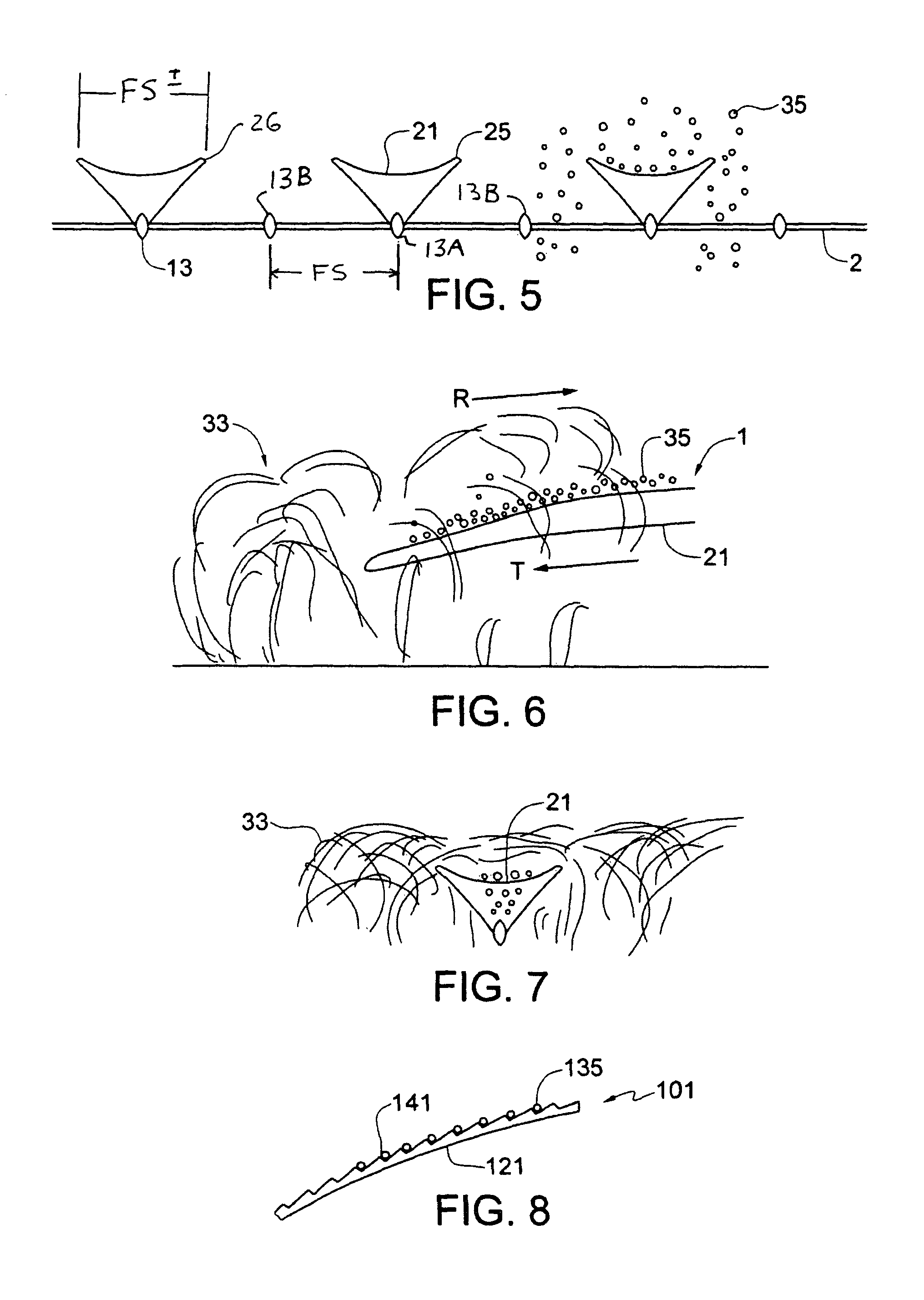

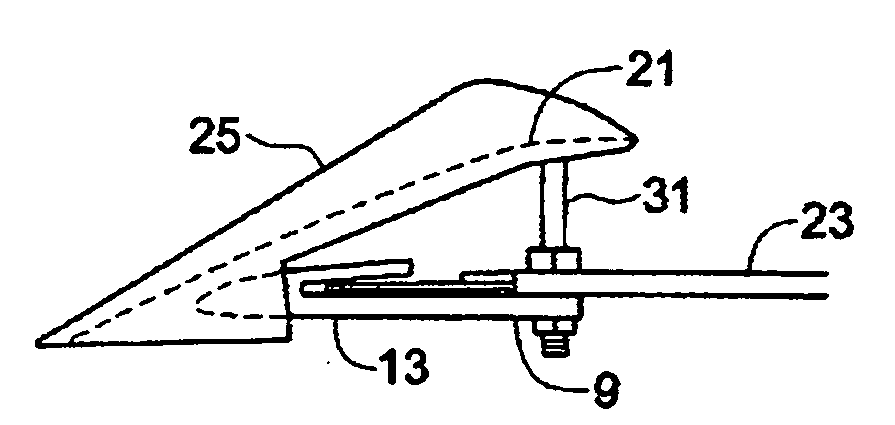

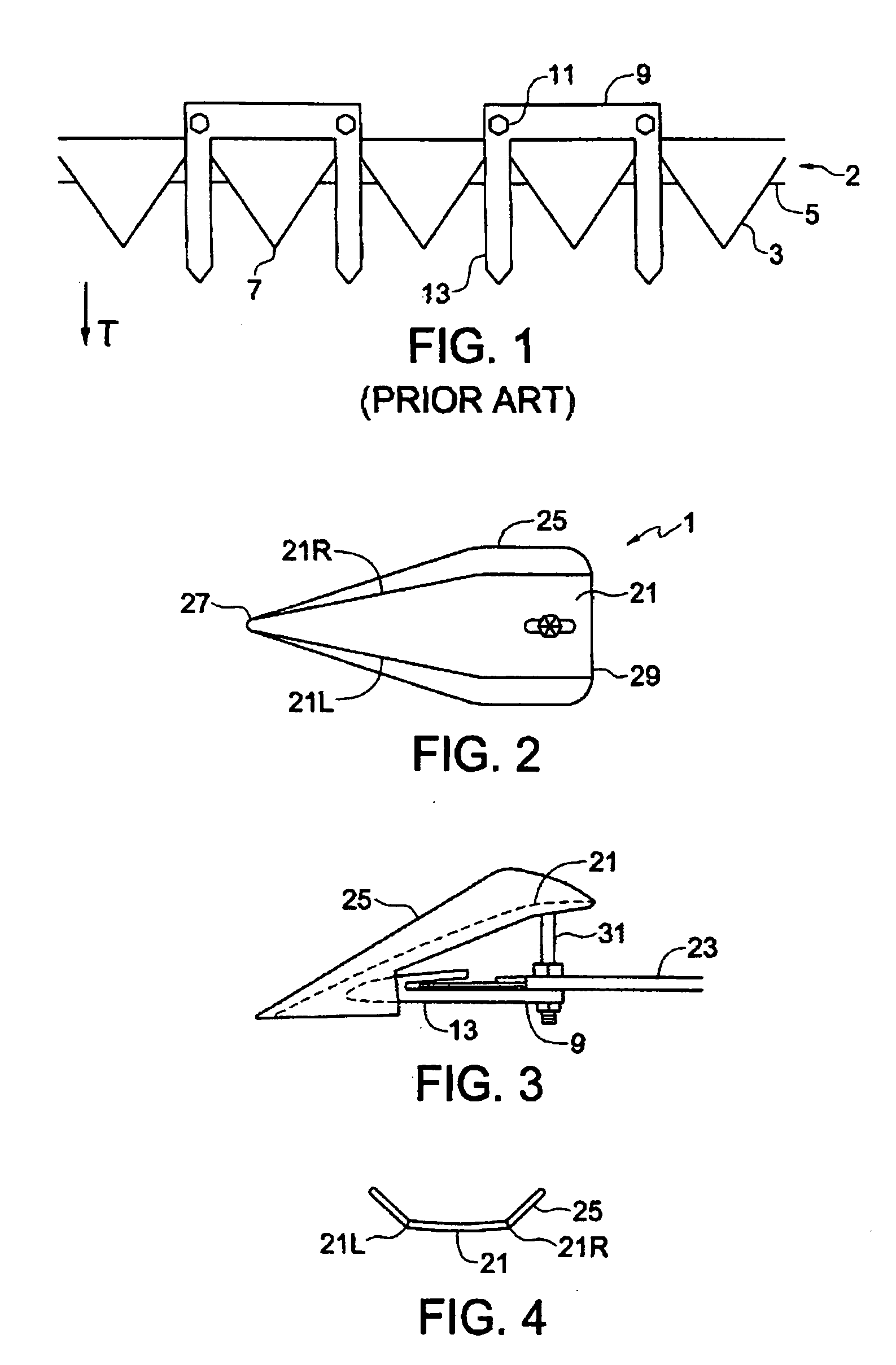

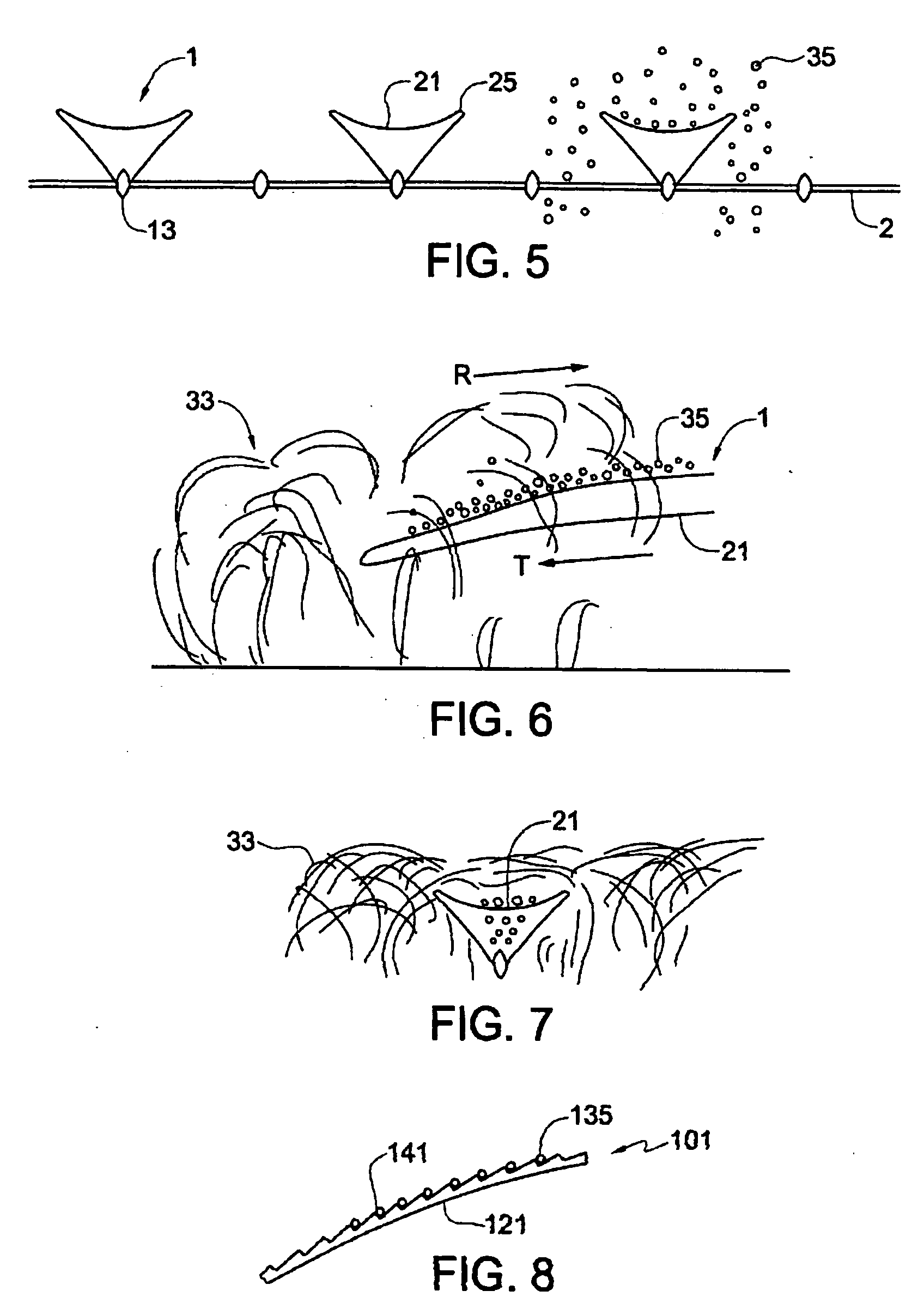

Crop lifter pans

ActiveUS8196381B2Efficiently exposedIncrease opportunitiesMowersAgricultural lifting devicesEngineeringFront edge

A seed pan apparatus for attachment to a cutting header having a knife and cooperating knife guards mounted along a lower front edge thereof includes a seed pan adapted at a front portion thereof for attachment to a guard finger such that when attached, the seed pan extends upward and rearward from a front portion of the seed pan forward of the guard finger over the guard finger and knife to a rear end thereof located rearward of the knife. Side walls extend upward from side edges of the seed pan, and side edges of the seed pan diverge from a front end to the rear end. The seed pan is configured such that when the seed pan is attached to the guard finger, side edges of the seed pan are located between the attached guard finger and an adjacent guard finger on each side.

Owner:101288550 SASKATCHEWAN LTD

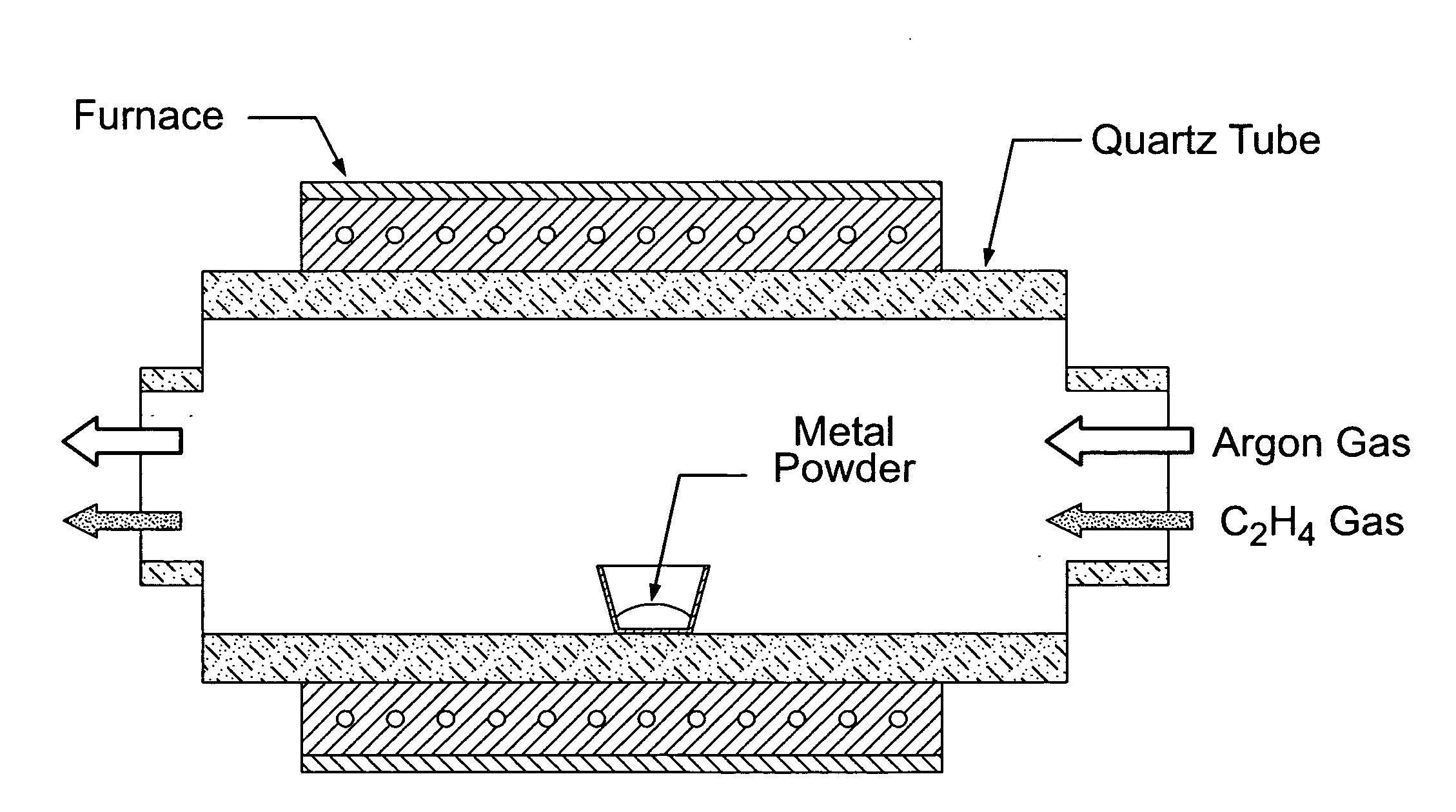

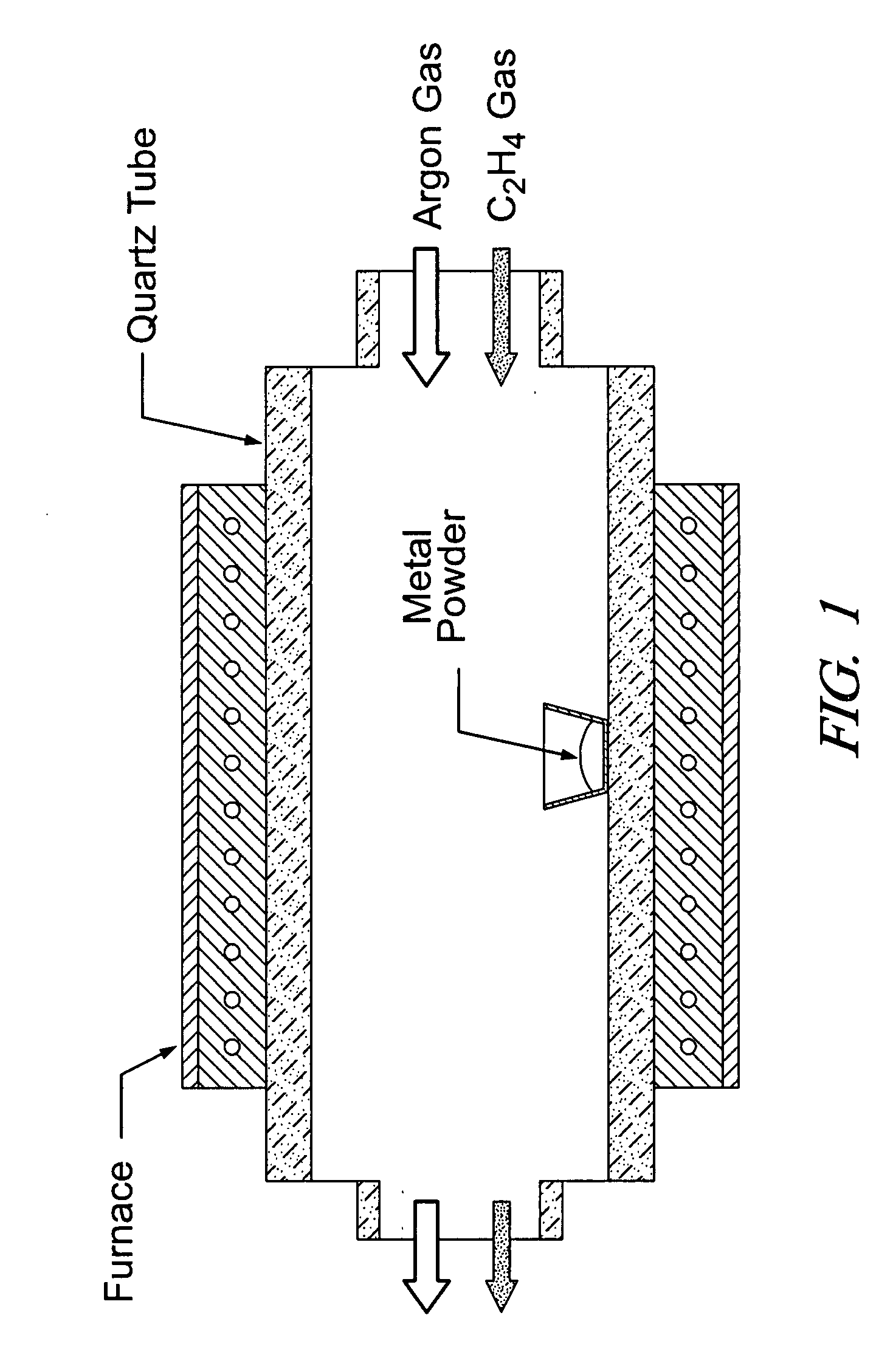

Nanowire supported catalysts for fuel cell electrodes

ActiveUS20090004552A1Effective carryEffective dispersionPretreated surfacesActive material electrodesPtru catalystCarbon fibers

Metal oxide nanowires and carbon-coated metal nanowires are effective as supports for particles of an expensive catalyst material, such as platinum metal group catalyst. Such supported catalysts are useful when included in an electrode on, for example, a proton exchange membrane in a hydrogen / oxygen fuel cell. For example, tin oxide nanowires are formed on carbon fibers of carbon paper and platinum nanoparticles are deposited on the tin oxide nanowires. The nanowires provide good surfaces for effective utilization of the platinum material.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

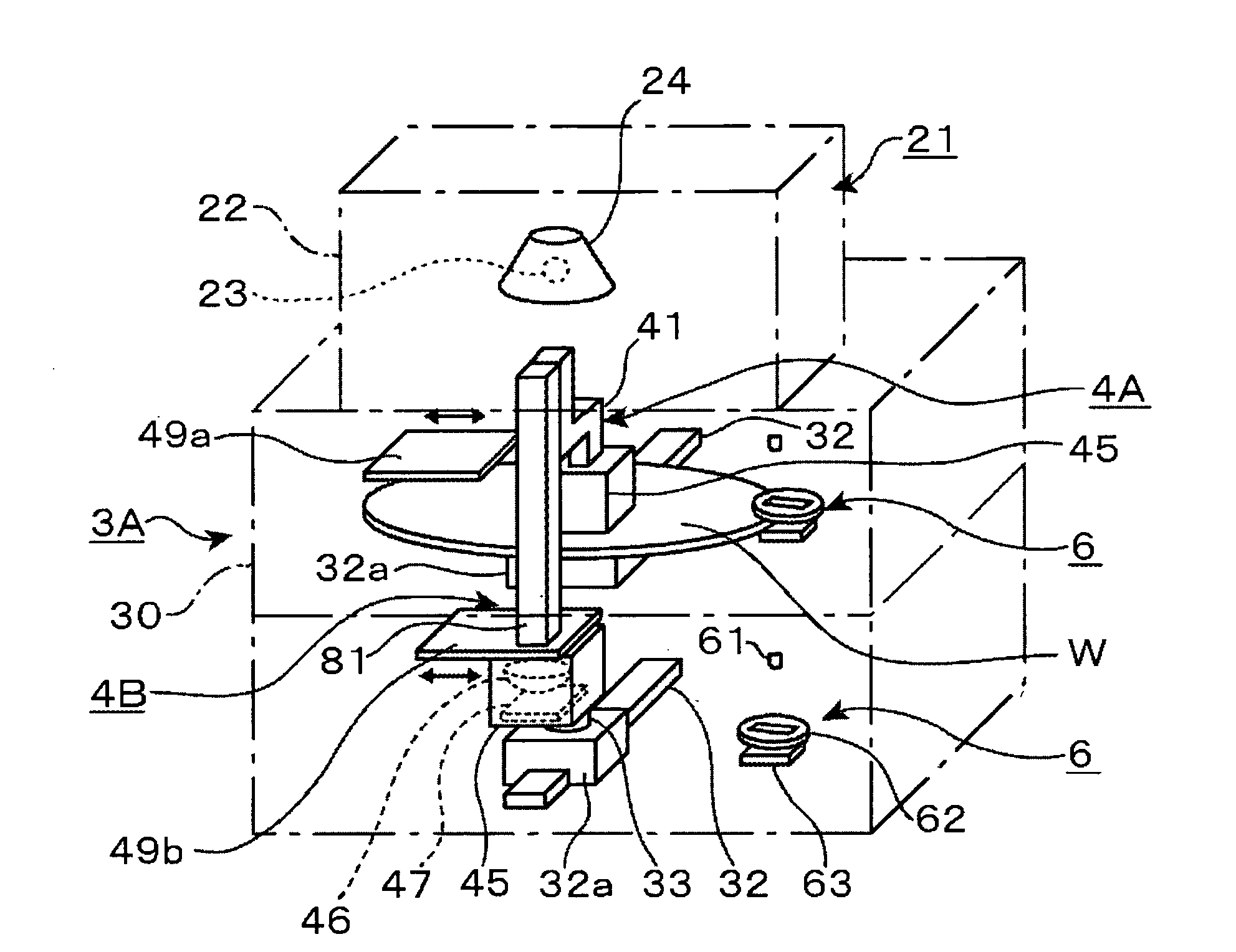

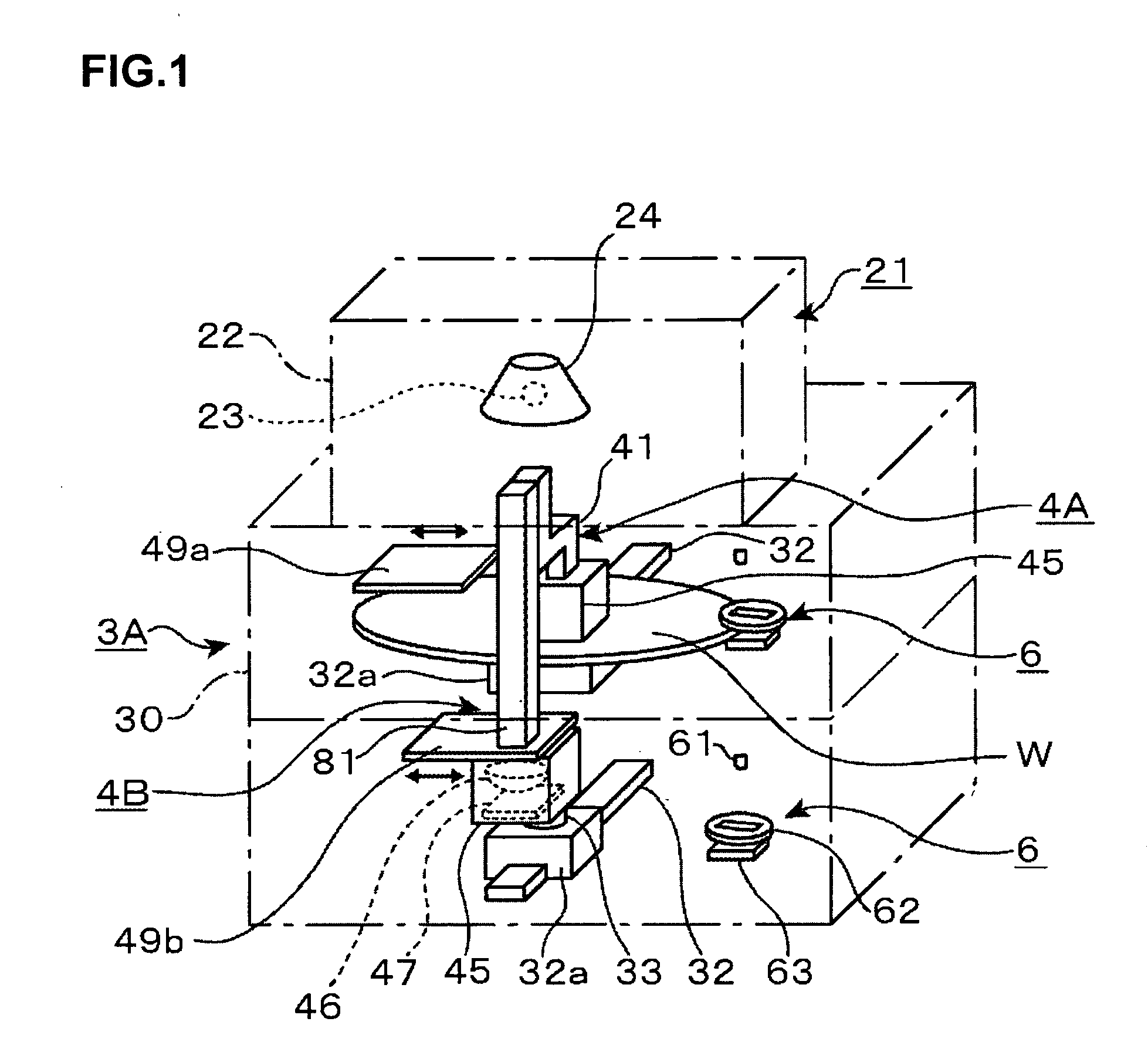

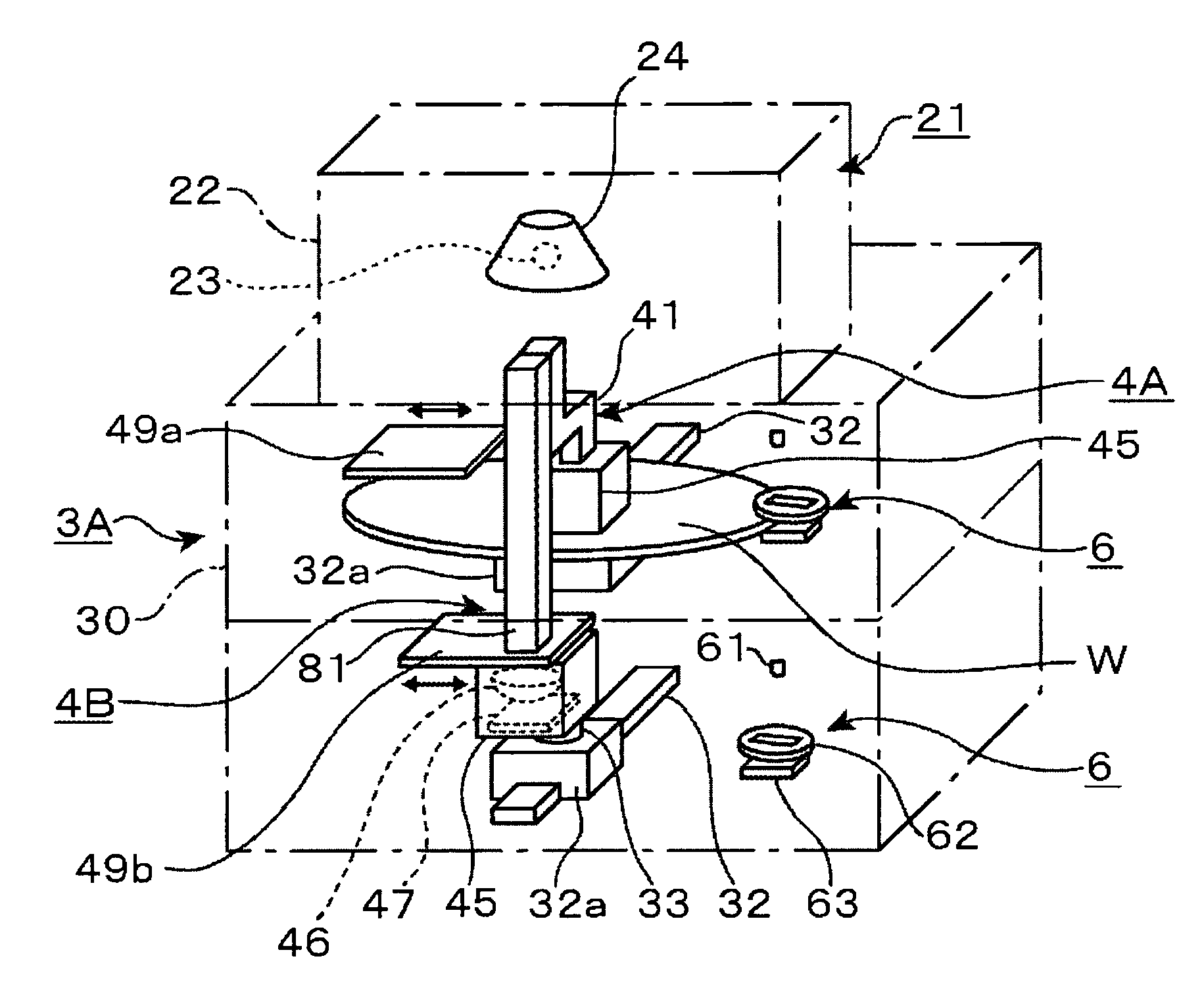

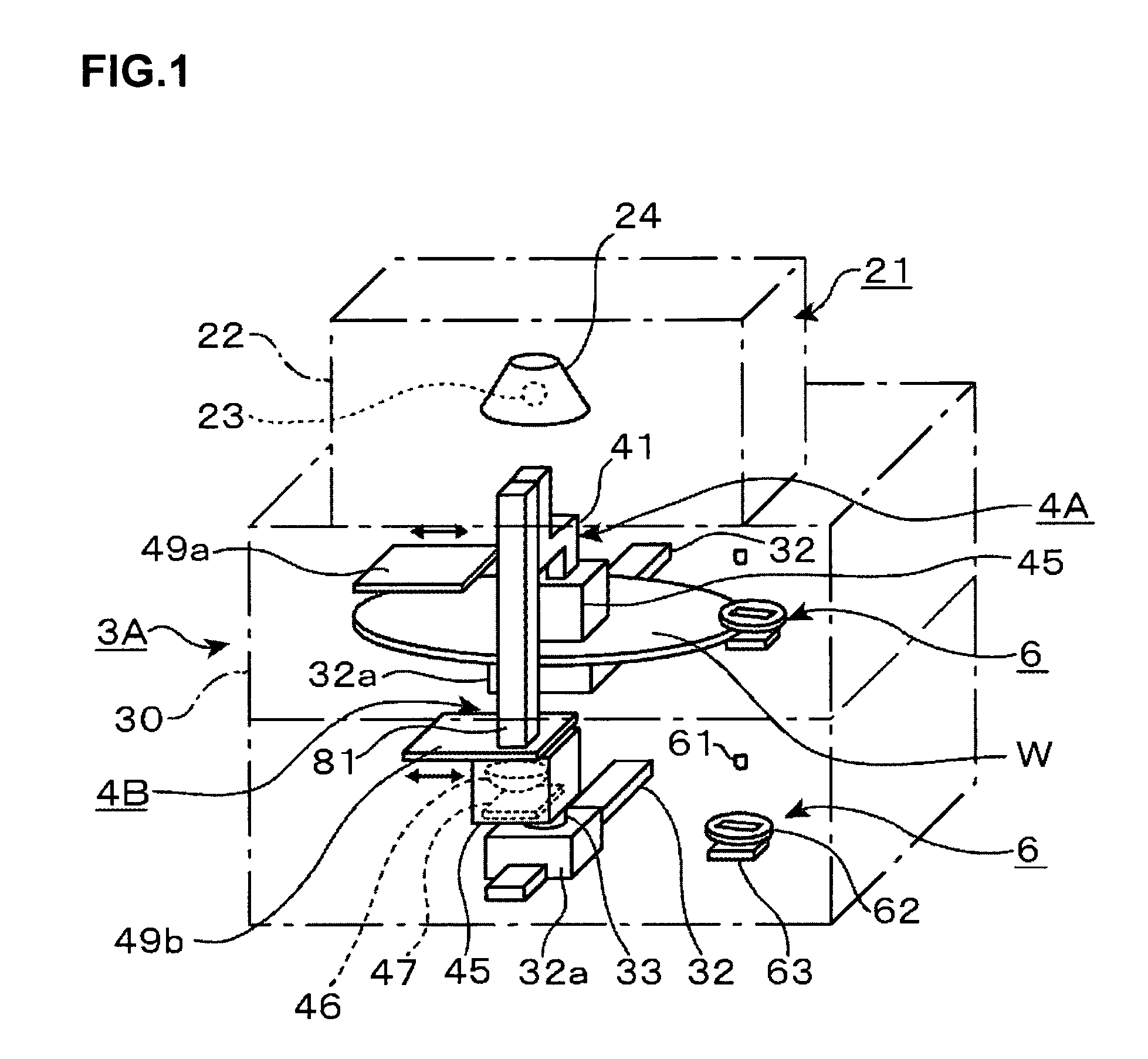

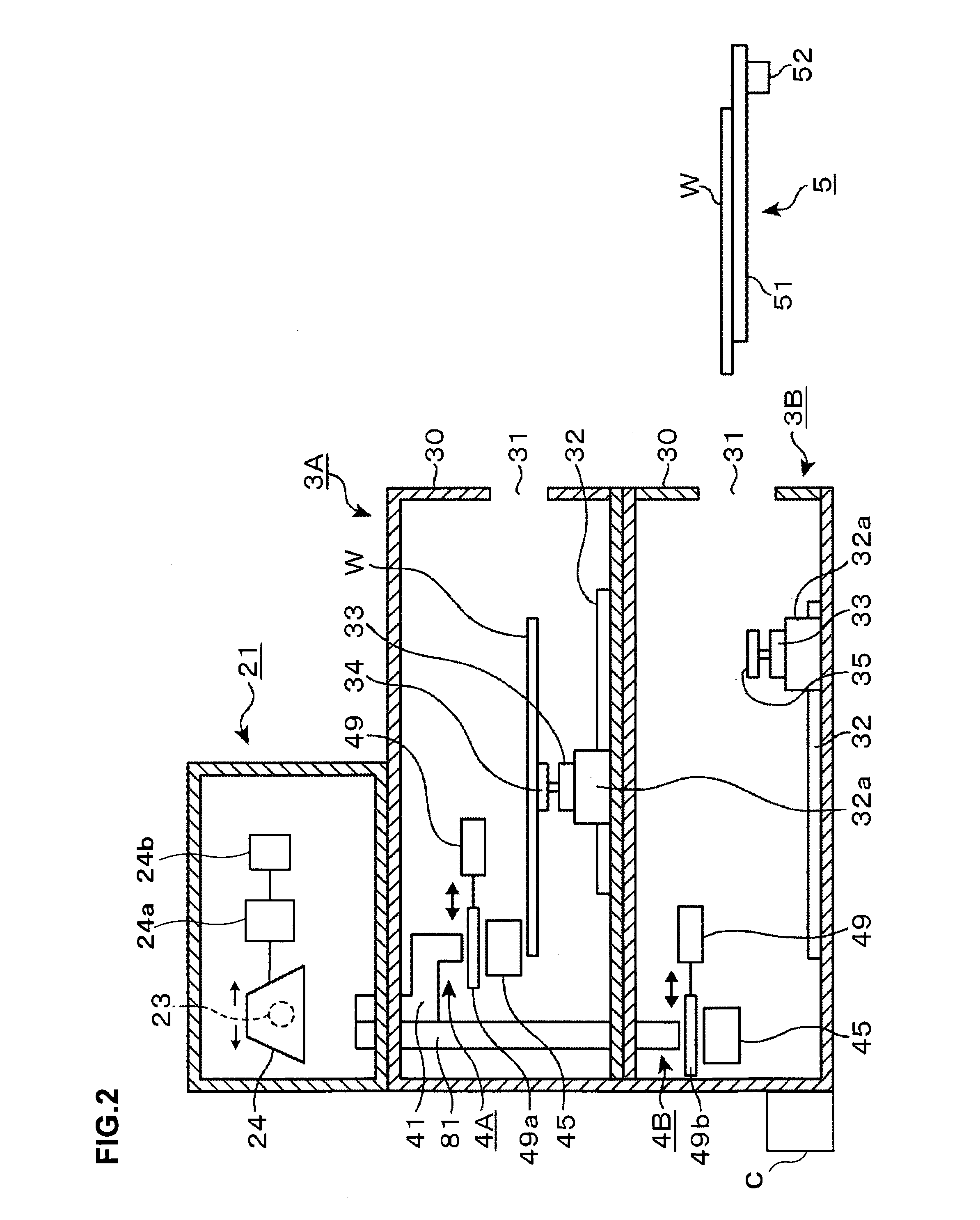

Edge exposure apparatus, coating and developing apparatus, and edge exposure method

ActiveUS20060250594A1High processing abilityIncrease in size of apparatusPhotomechanical apparatusInvestigating moving sheetsOptical pathEngineering

The present invention includes a first and a second optical path forming member arranged within a path of light beams from a light source; a first mounting table provided such that the edge portion of the substrate is located within an application region of the light beams from an outlet side of the first optical path forming member, and a second mounting table provided such that the edge portion of the substrate is located within an application region of the light beams from an outlet side of the second optical path forming member, each of the mounting tables being configured to be rotatable about a vertical axis while mounting the substrate thereon; and a light blocking means for blocking application of light from each of the first and second optical path forming members. A common light source can be used to perform edge exposure for the substrates on the first and second mounting tables, for example, at the same time, so that a high processing ability can be offered and an increase in size of the apparatus can be prevented.

Owner:TOKYO ELECTRON LTD

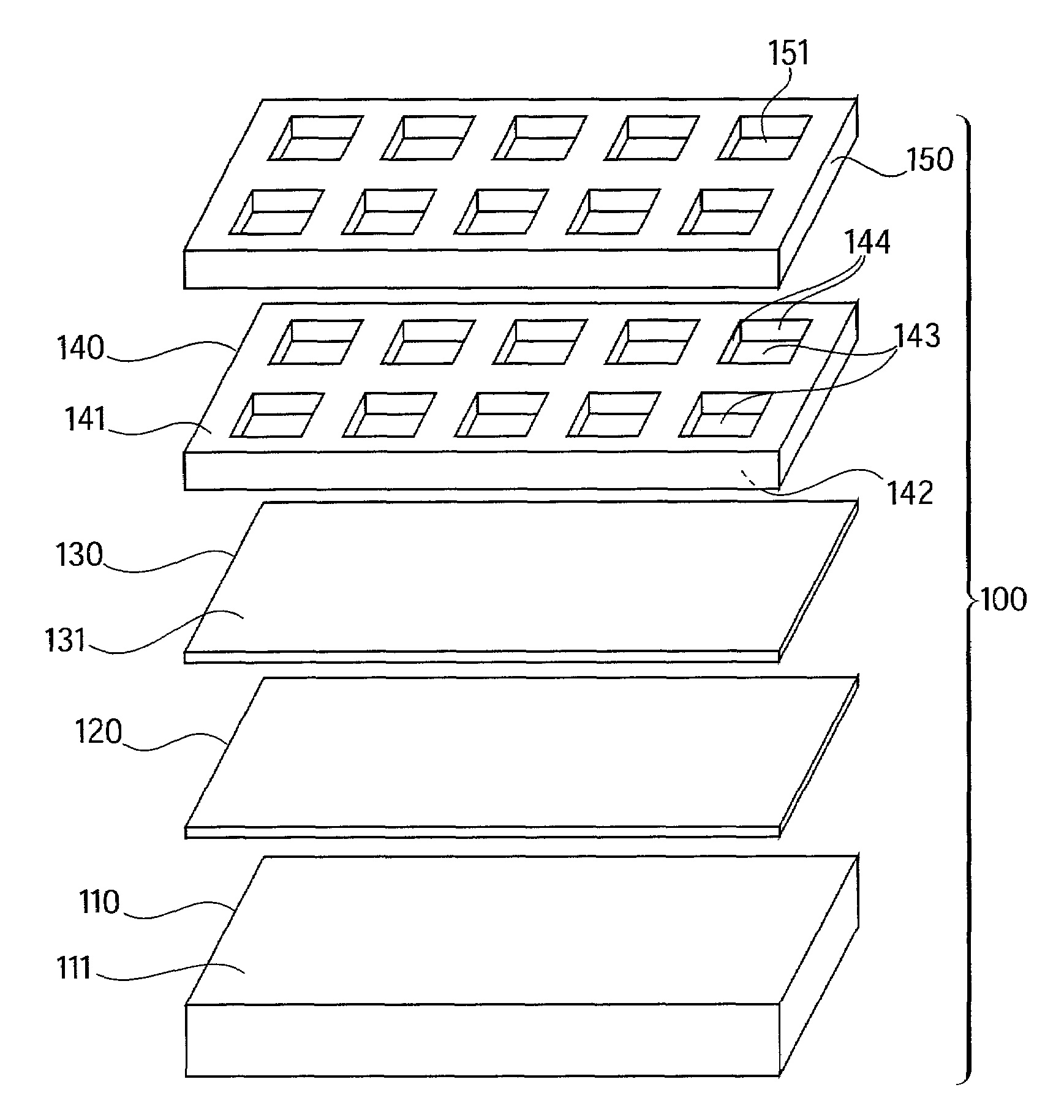

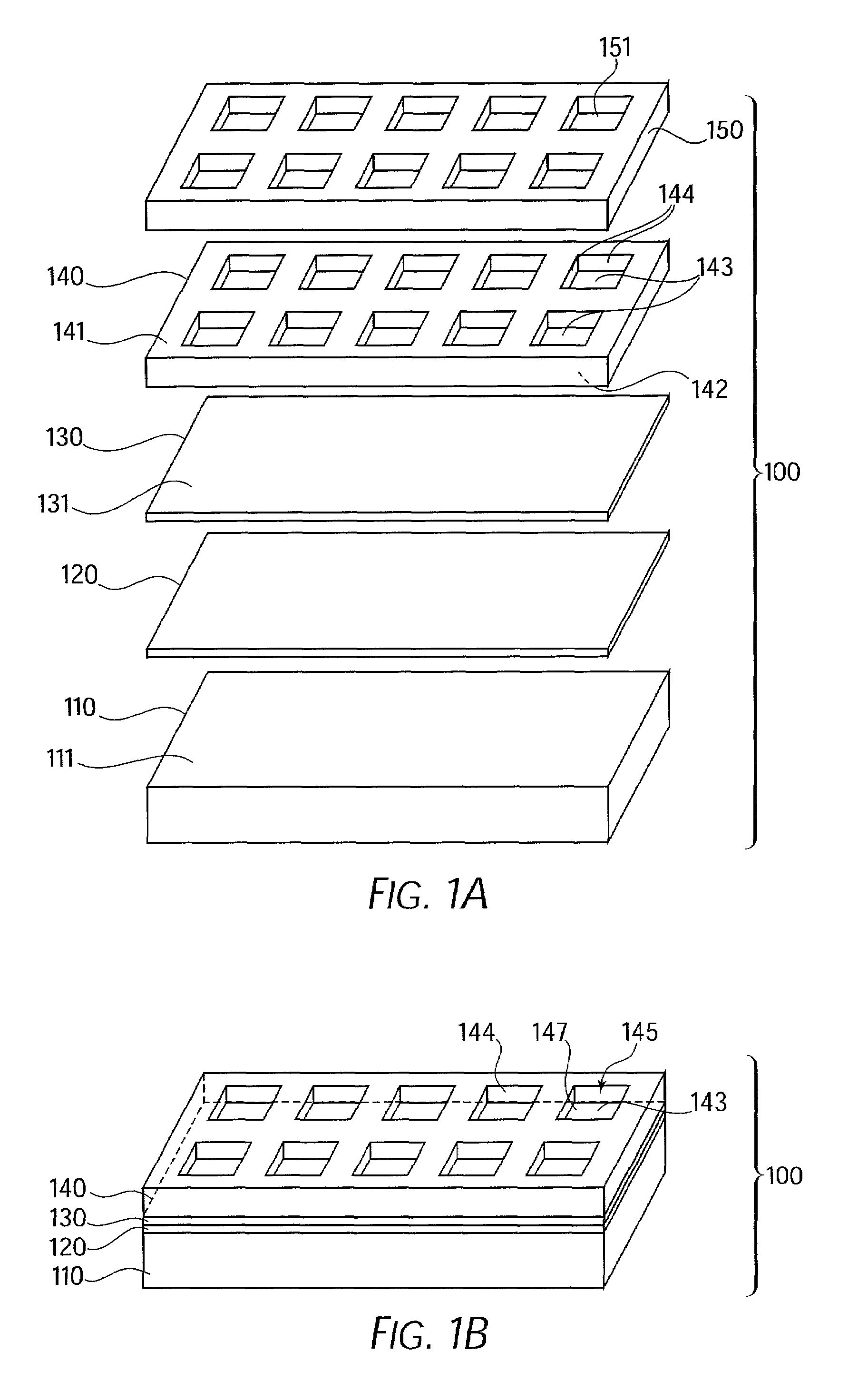

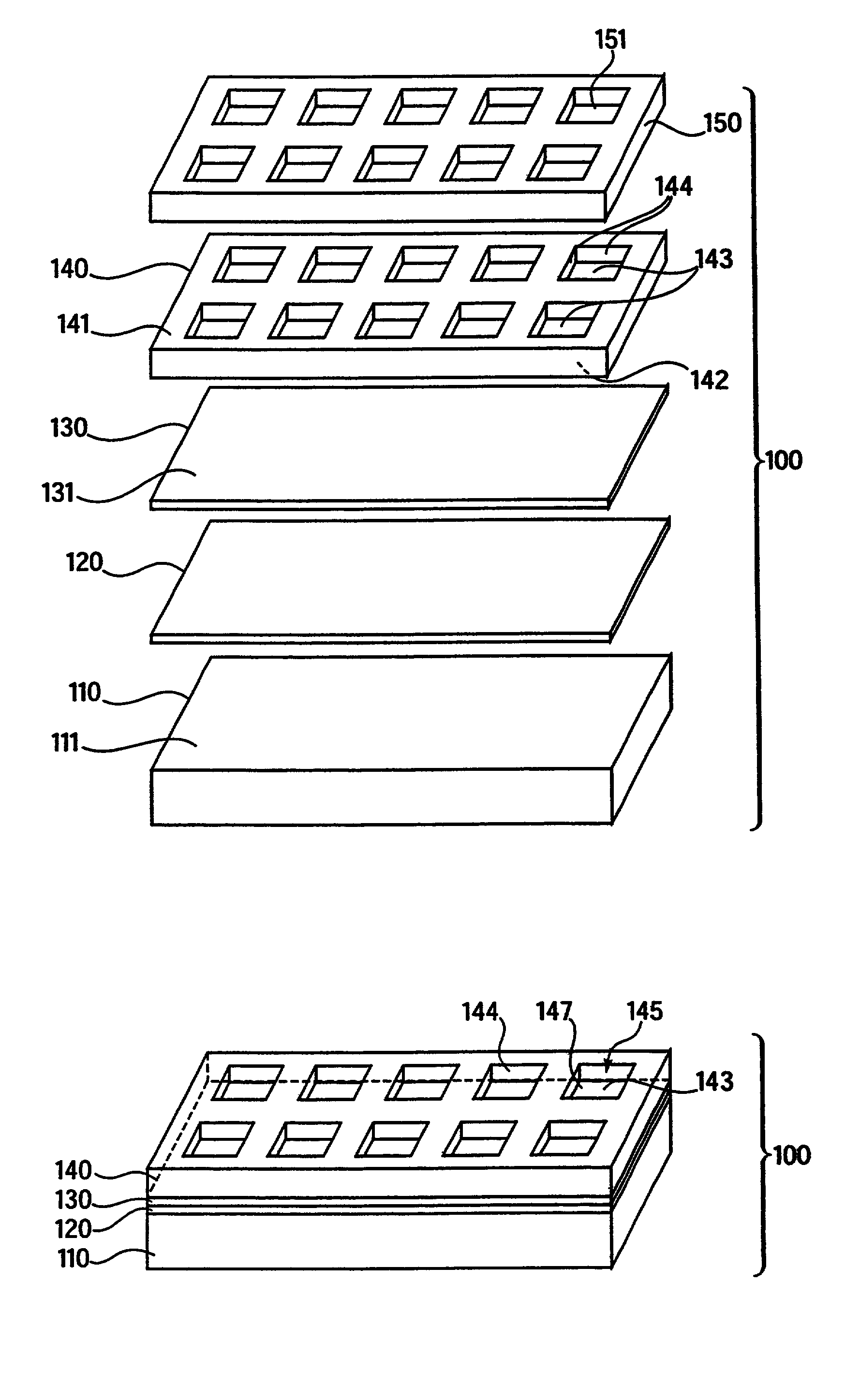

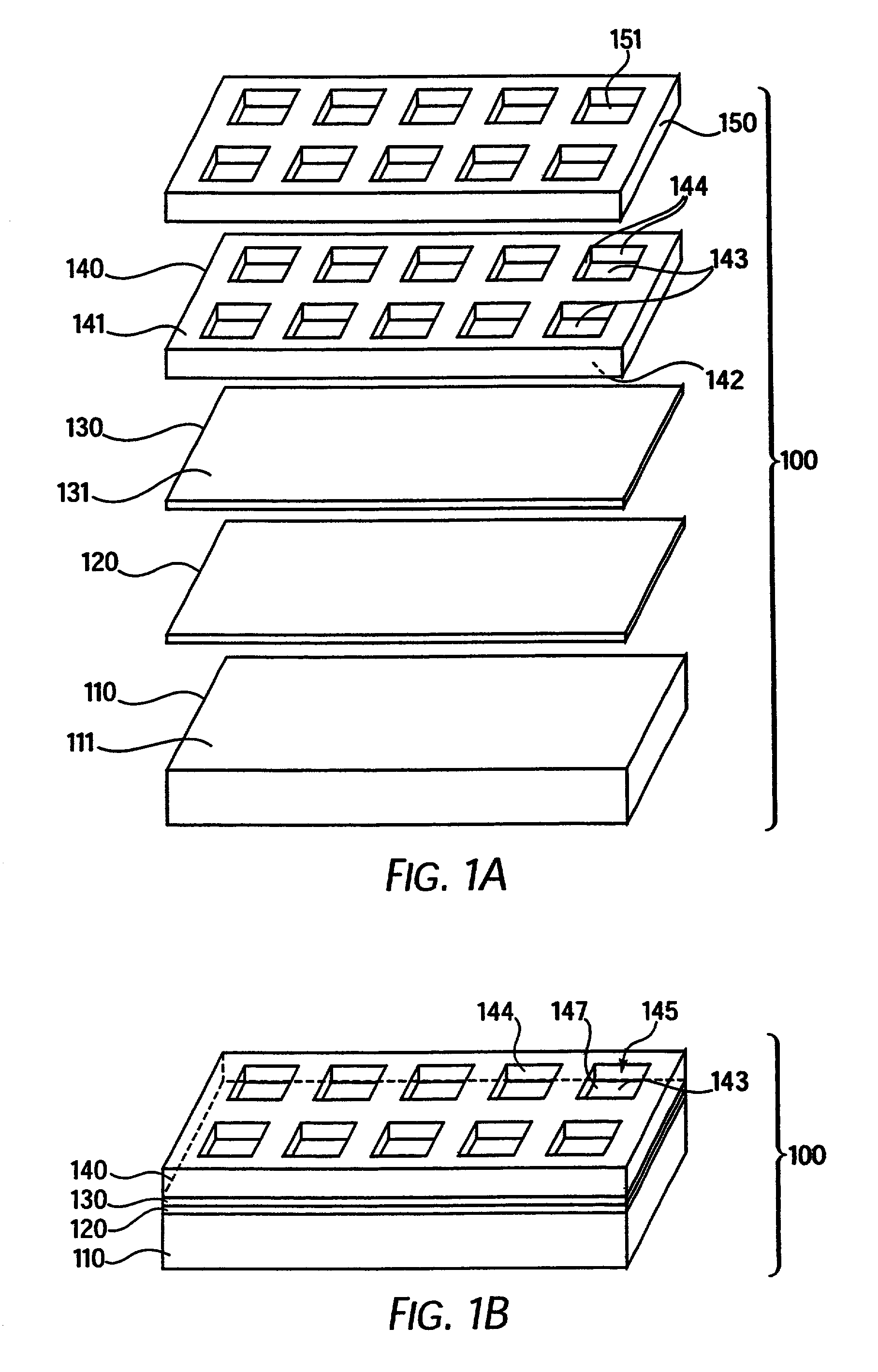

Wafer container with tubular environmental control components

ActiveUS8783463B2Protected contentSpeed up the flowSemiconductor/solid-state device manufacturingOther accessoriesFiltrationTower

A wafer container utilizes a rigid polymer tubular tower with slots and a “getter” therein for absorbing and filtering moisture and vapors within the wafer container. The tower preferably utilizes a purge grommet at the base of the container and may have a check valve therein to control the flow direction of gas (including air) into and out of the container and with respect to the tower. The tower is sealingly connected with the grommet. The tower may have a getter media piece rolled in an elongate circular fashion forming or shaped as a tube and disposed within the tower and may have axially extending. The media can provide active and / or passive filtration as well as having capabilities to be recharged. Front opening wafer containers for 300 mm sized wafers generally have a pair of recesses on each of the left and right side in the inside rear of the container portions. These recesses are preferably utilized for elongate towers, such towers extending substantially from a bottom wafer position to a top wafer position. In alternative embodiment, a tubular shape of getter material is exposed within the front opening container without containment of the getter other than at the ends. The tubular getter form is preferably supported at discrete locations to maximize exposure to the internal container environment. A blocker member can selectively close the apertures. An elastomeric cap can facilitate securement of the tubular component in the container portion.

Owner:ENTEGRIS INC

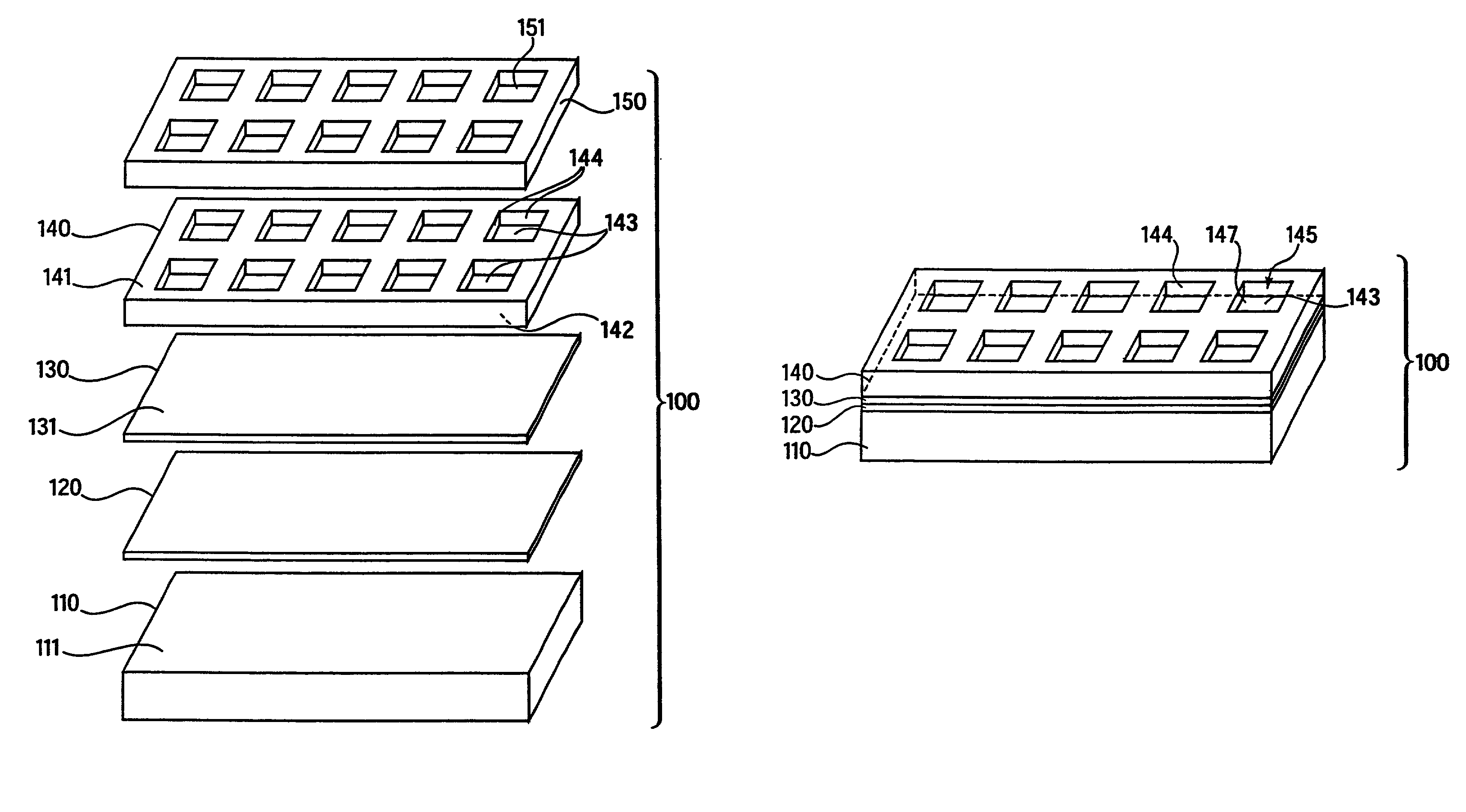

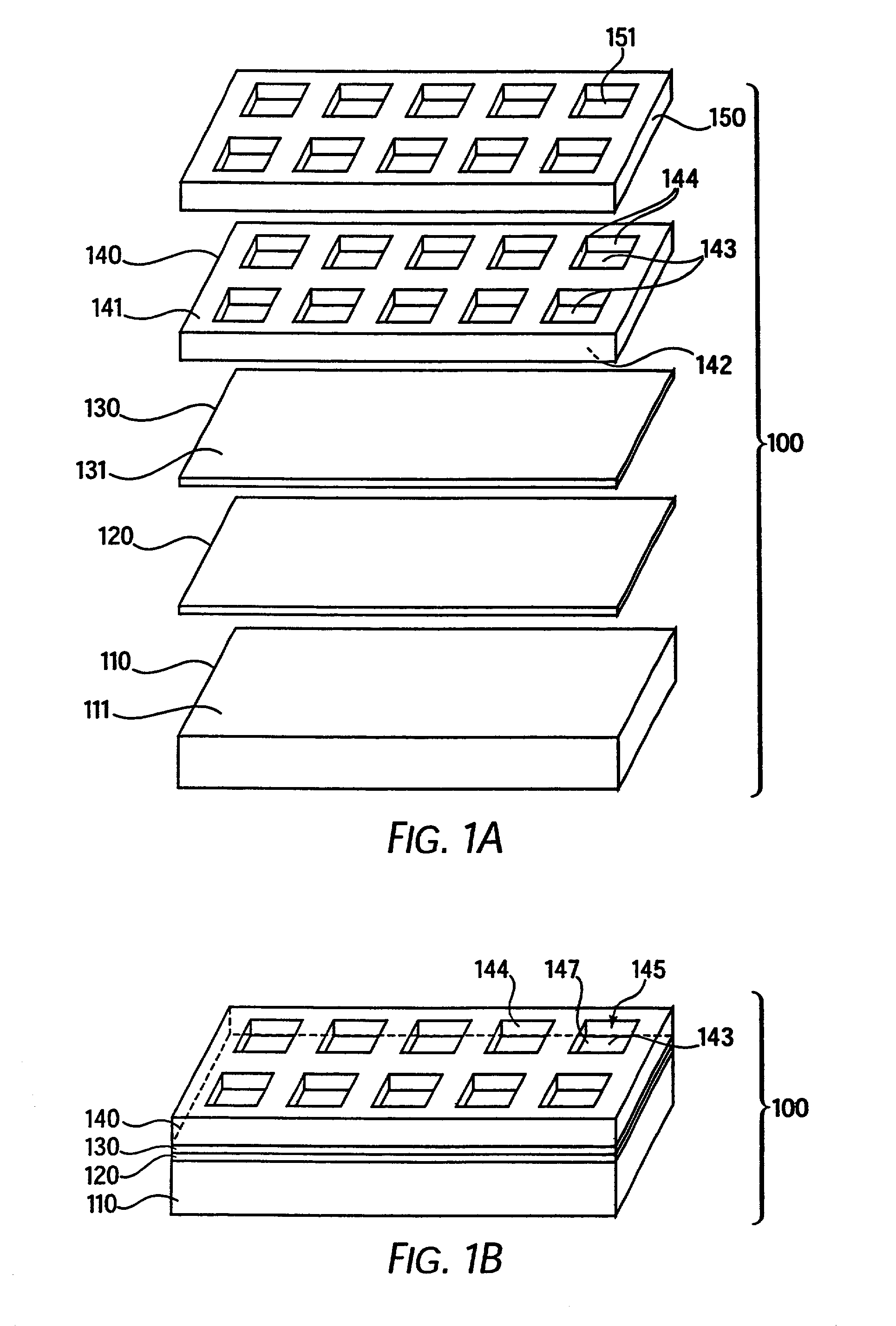

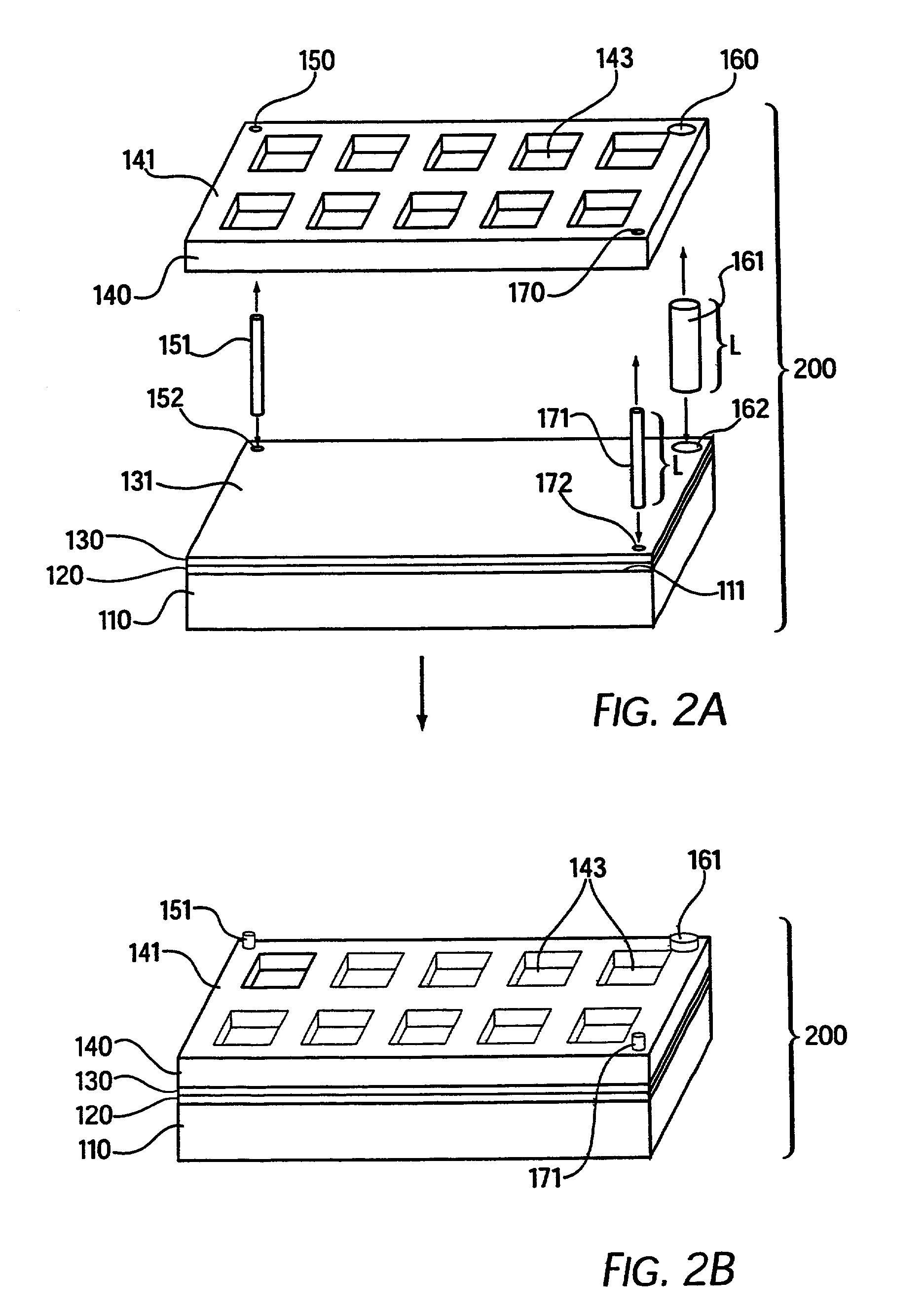

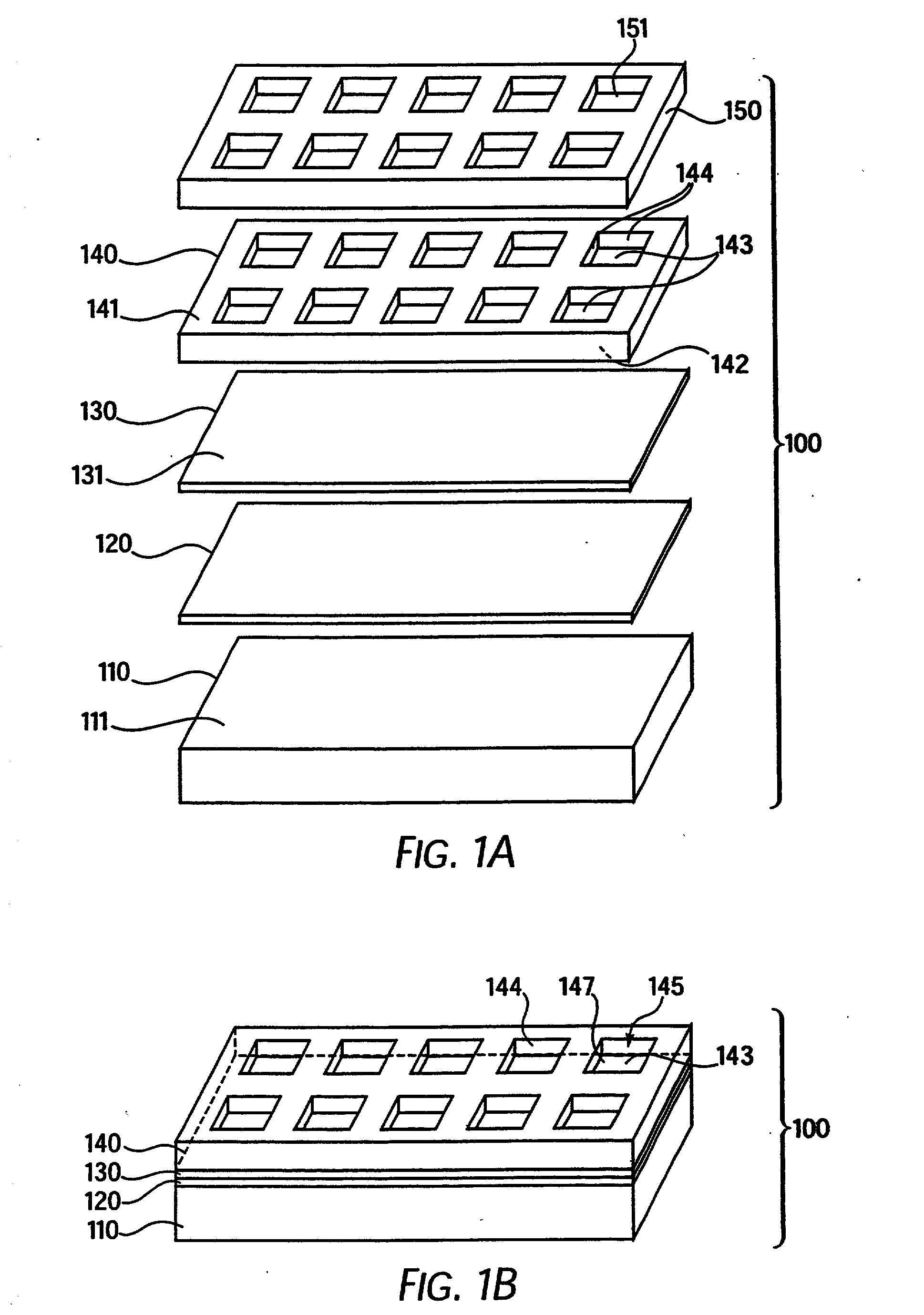

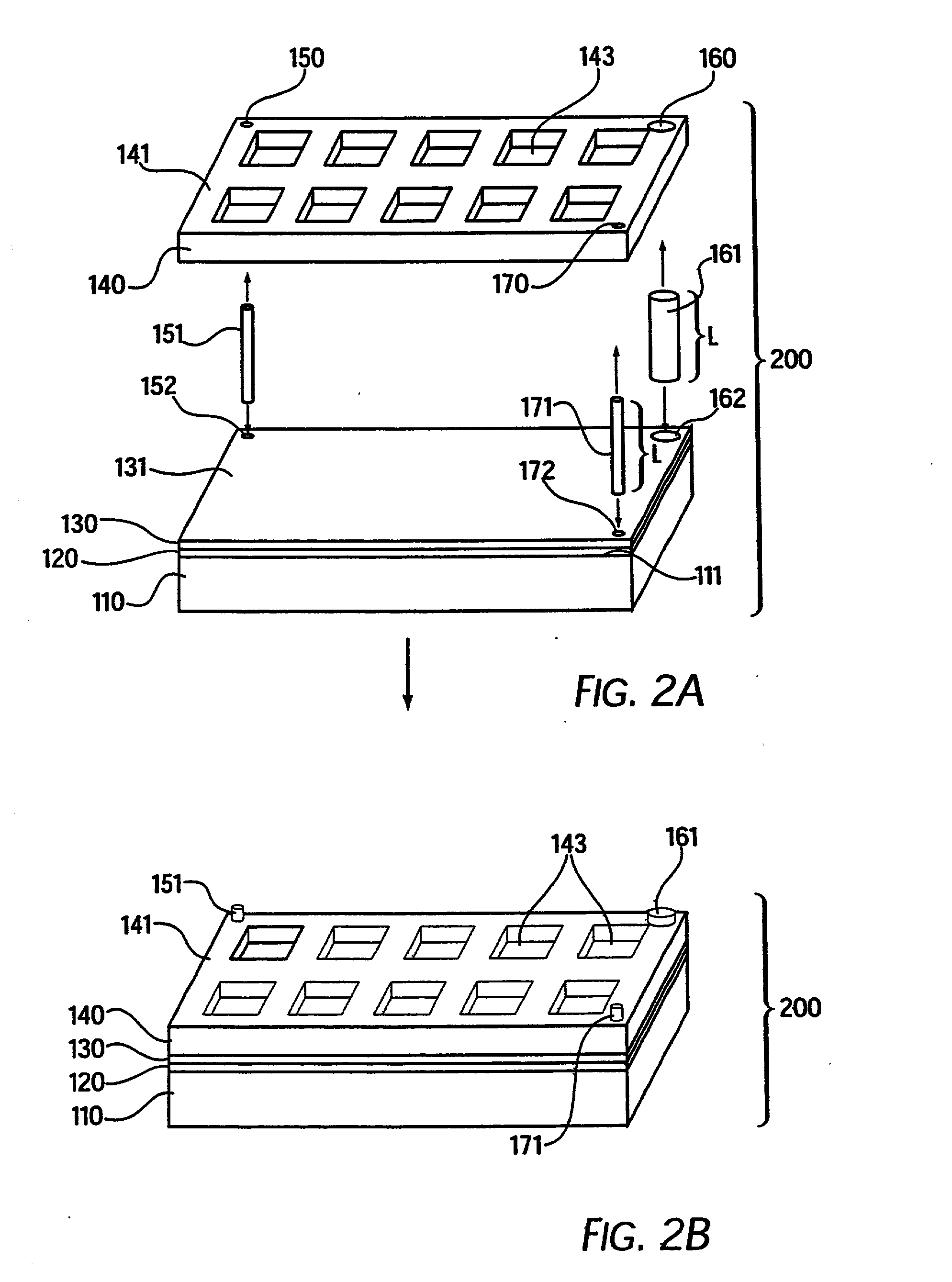

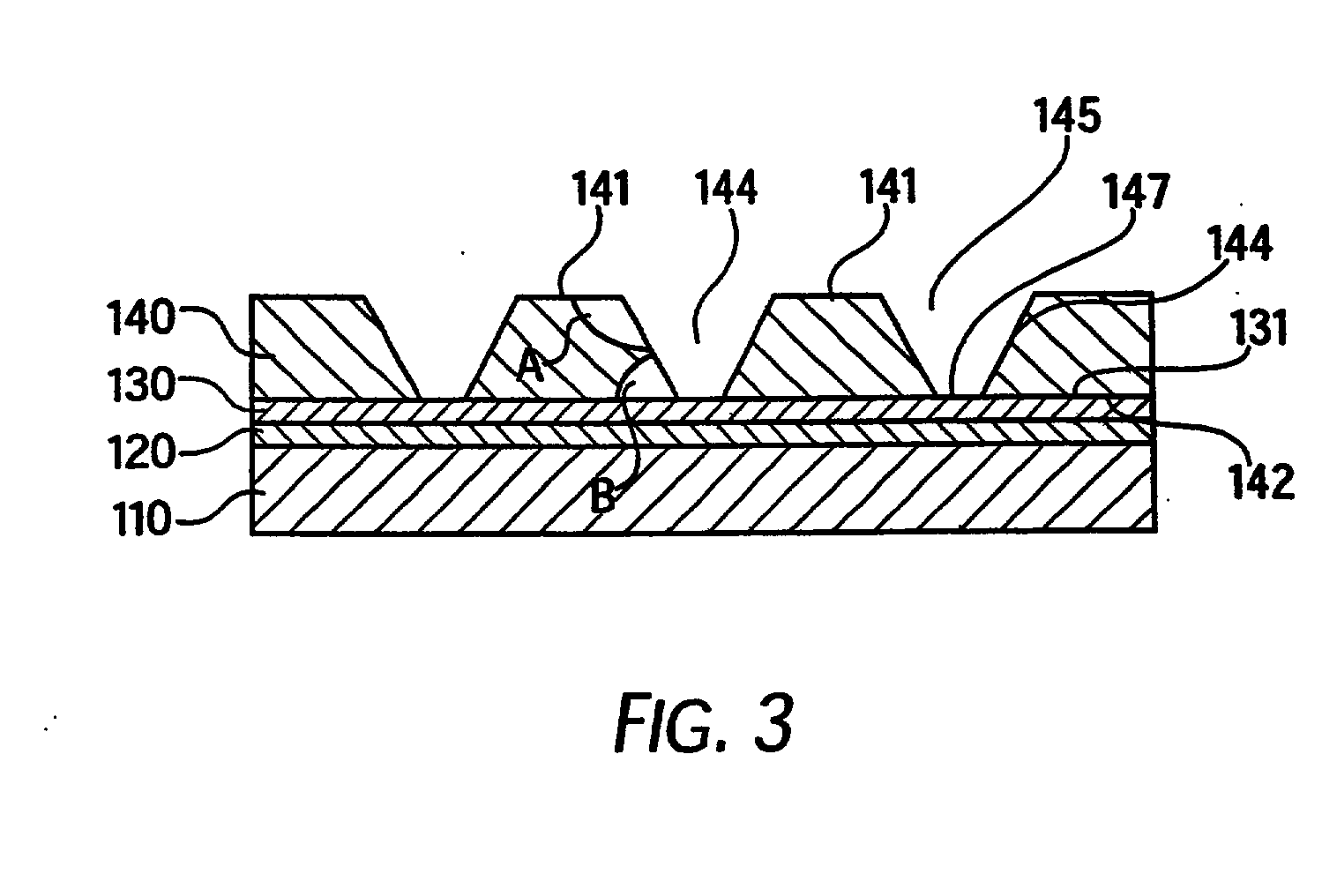

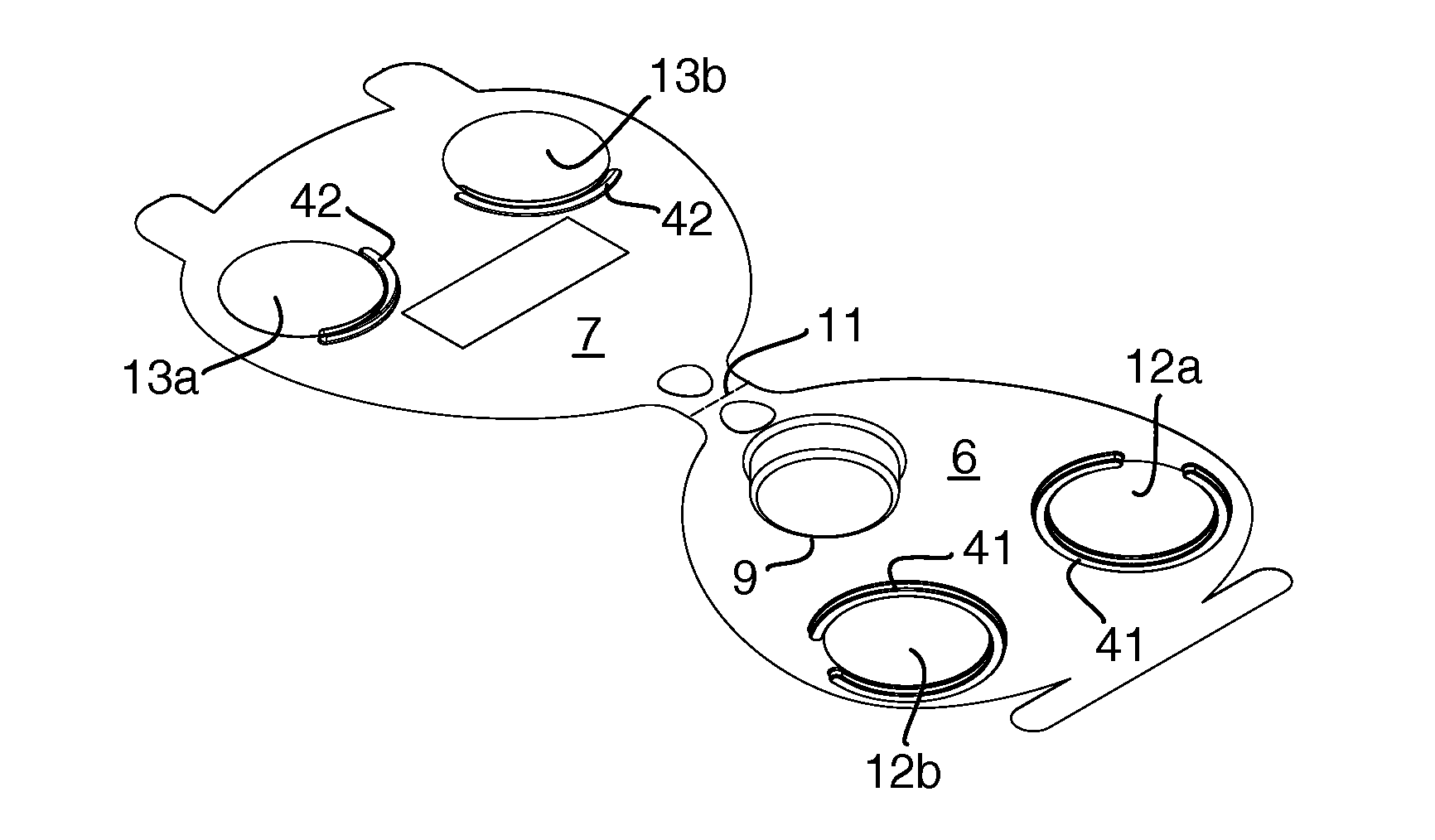

Peelable and resealable devices for biochemical assays

InactiveUS7371563B2Address limitationsEfficiently exposedImage enhancementMaterial nanotechnologyBiological materialsMaterials science

Devices and methods for performing assays on materials, particularly biological materials, are provided. The devices and methods make use of self-sealing members, which can be applied to a flat surface to form wells to facilitate immobilization of materials on the flat surface, then removed to yield a flat surface that facilitates the performance of processes on and / or detection of the immobilized material.

Owner:SURFACE LOGIX INC

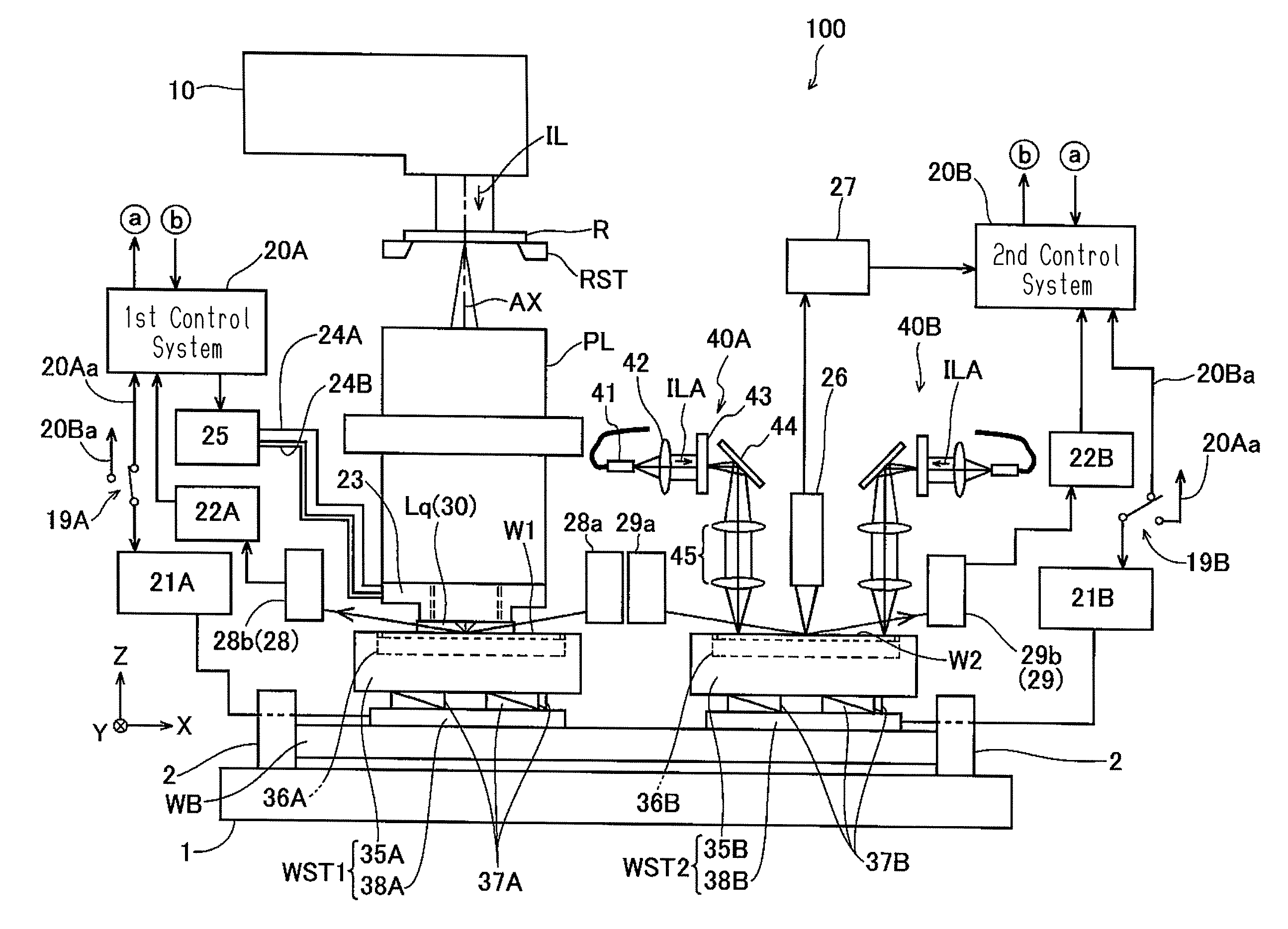

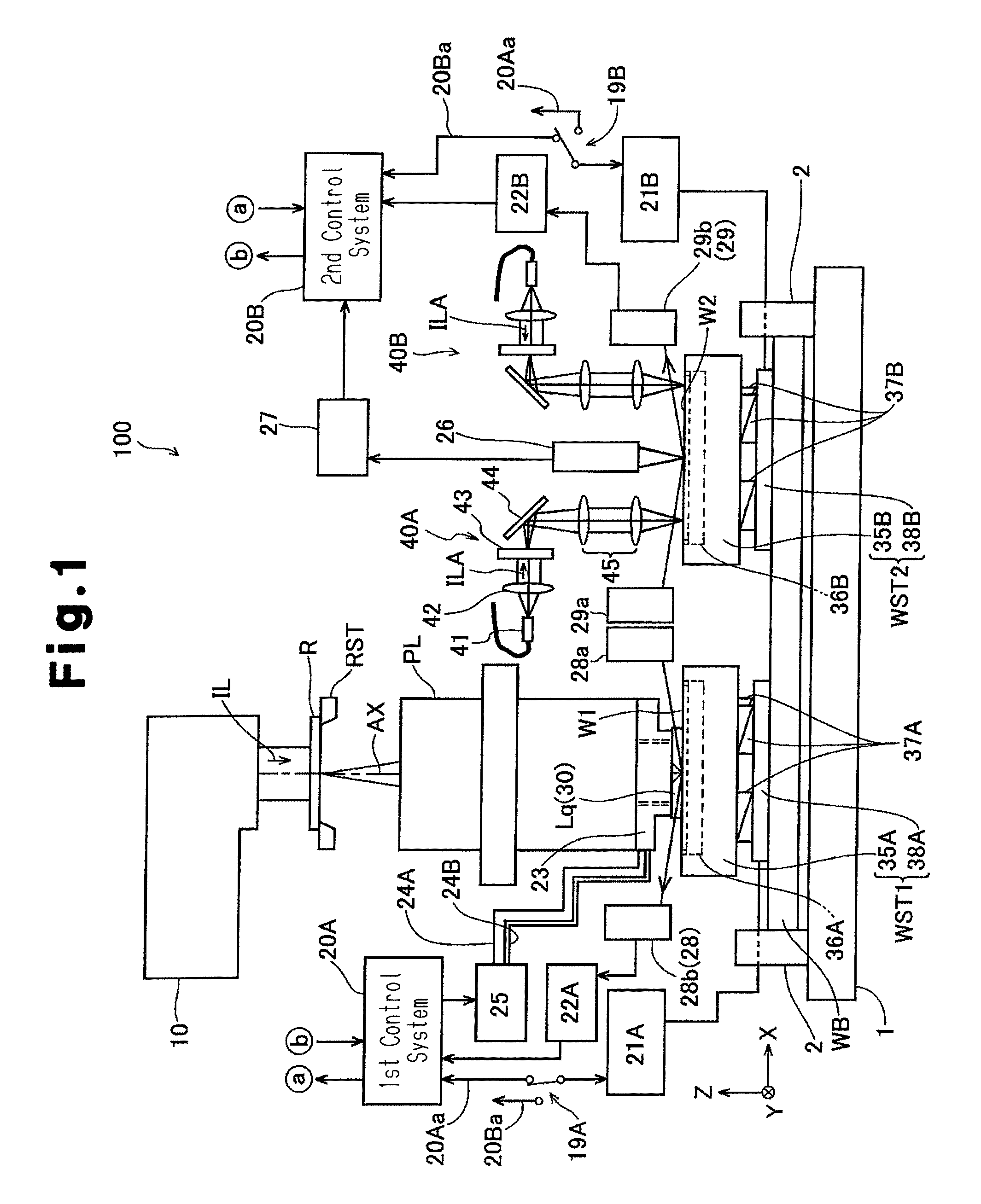

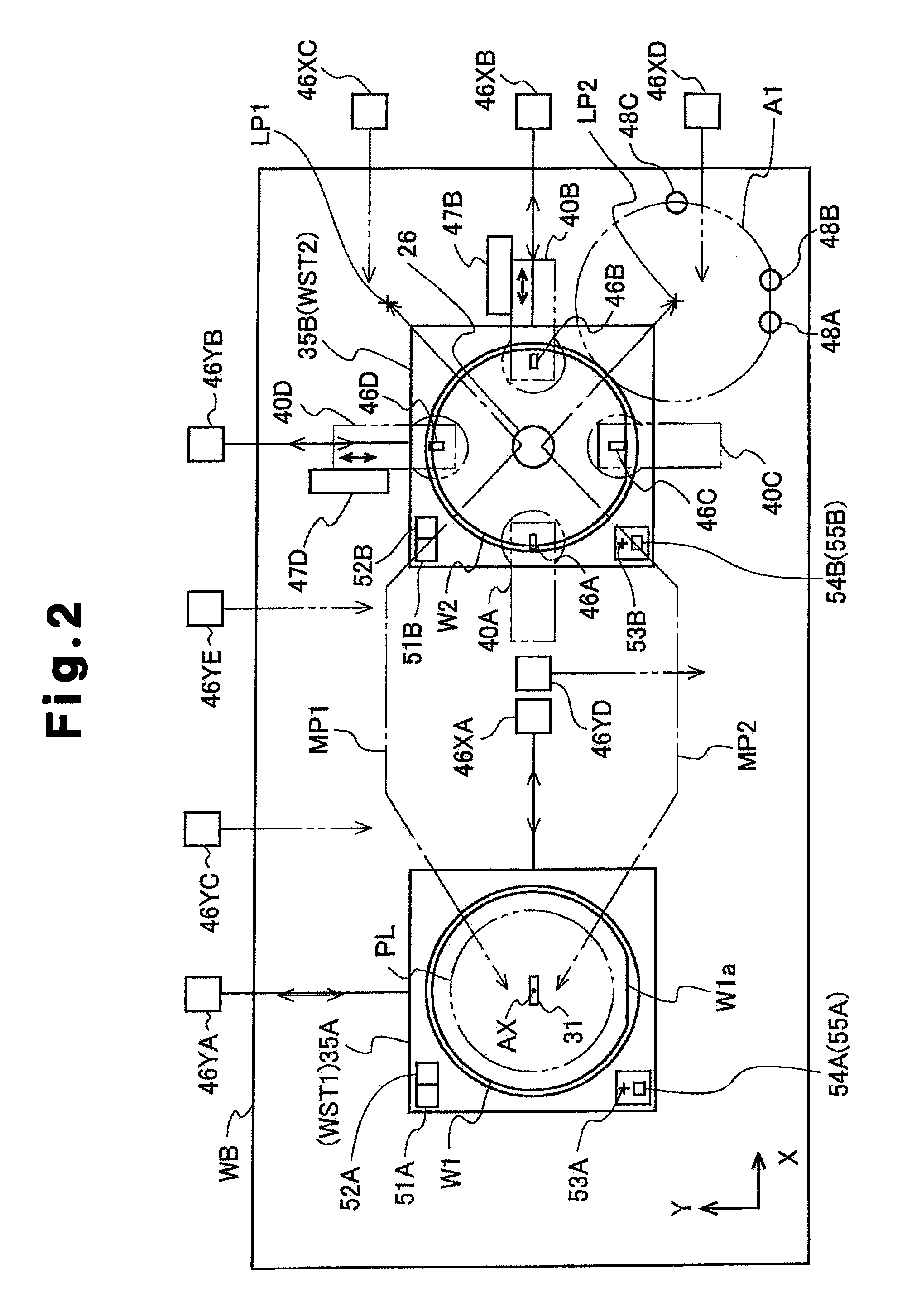

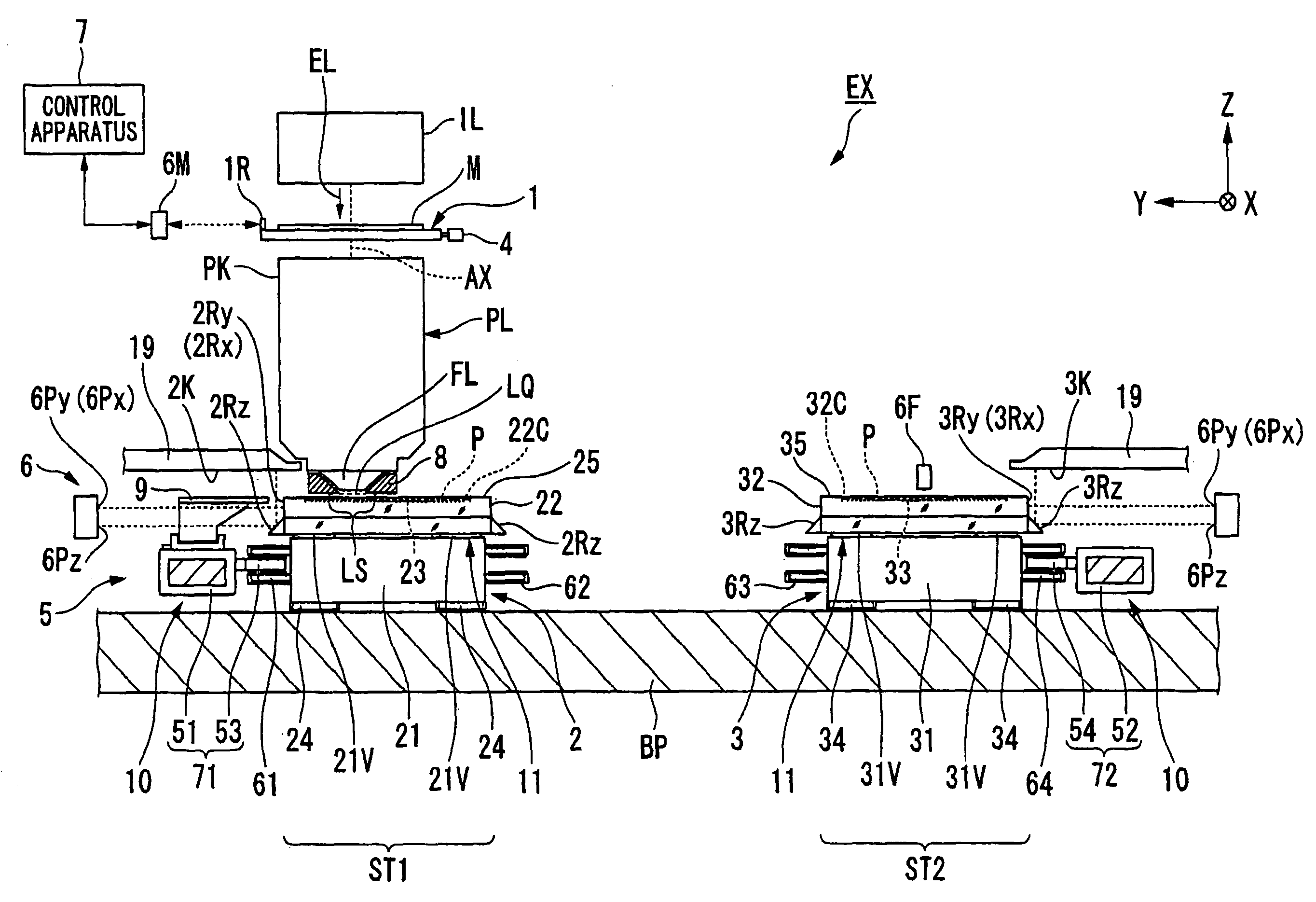

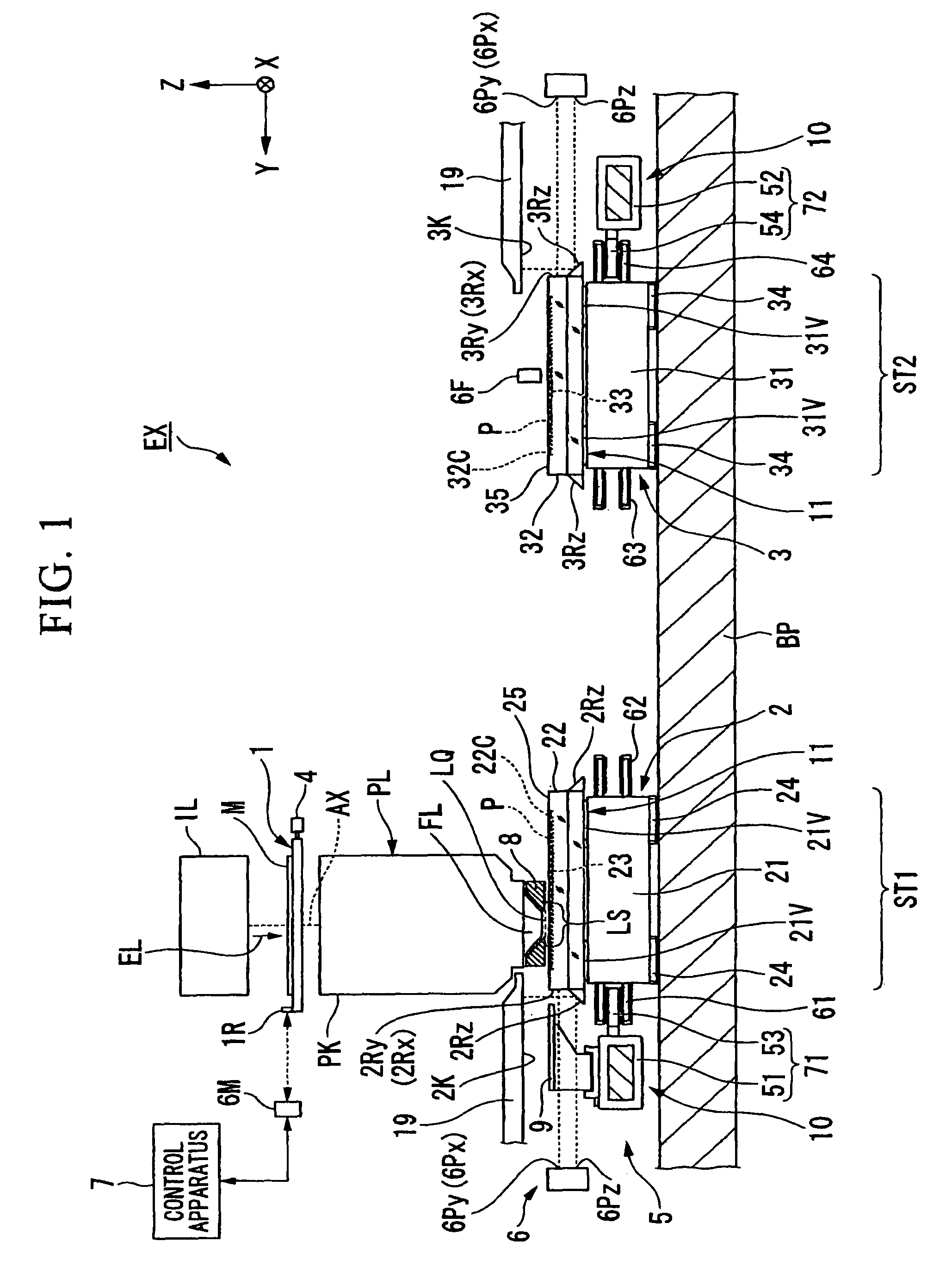

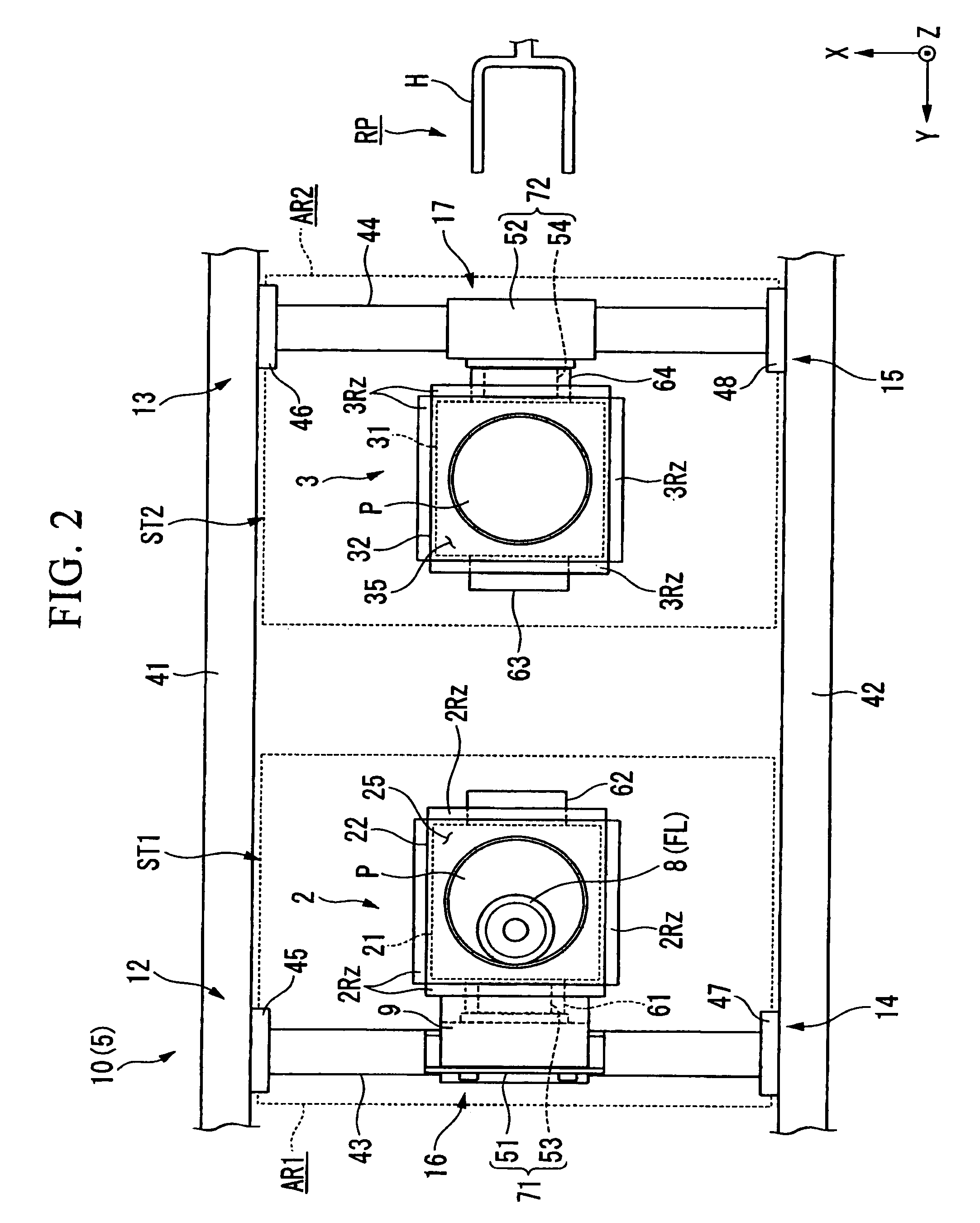

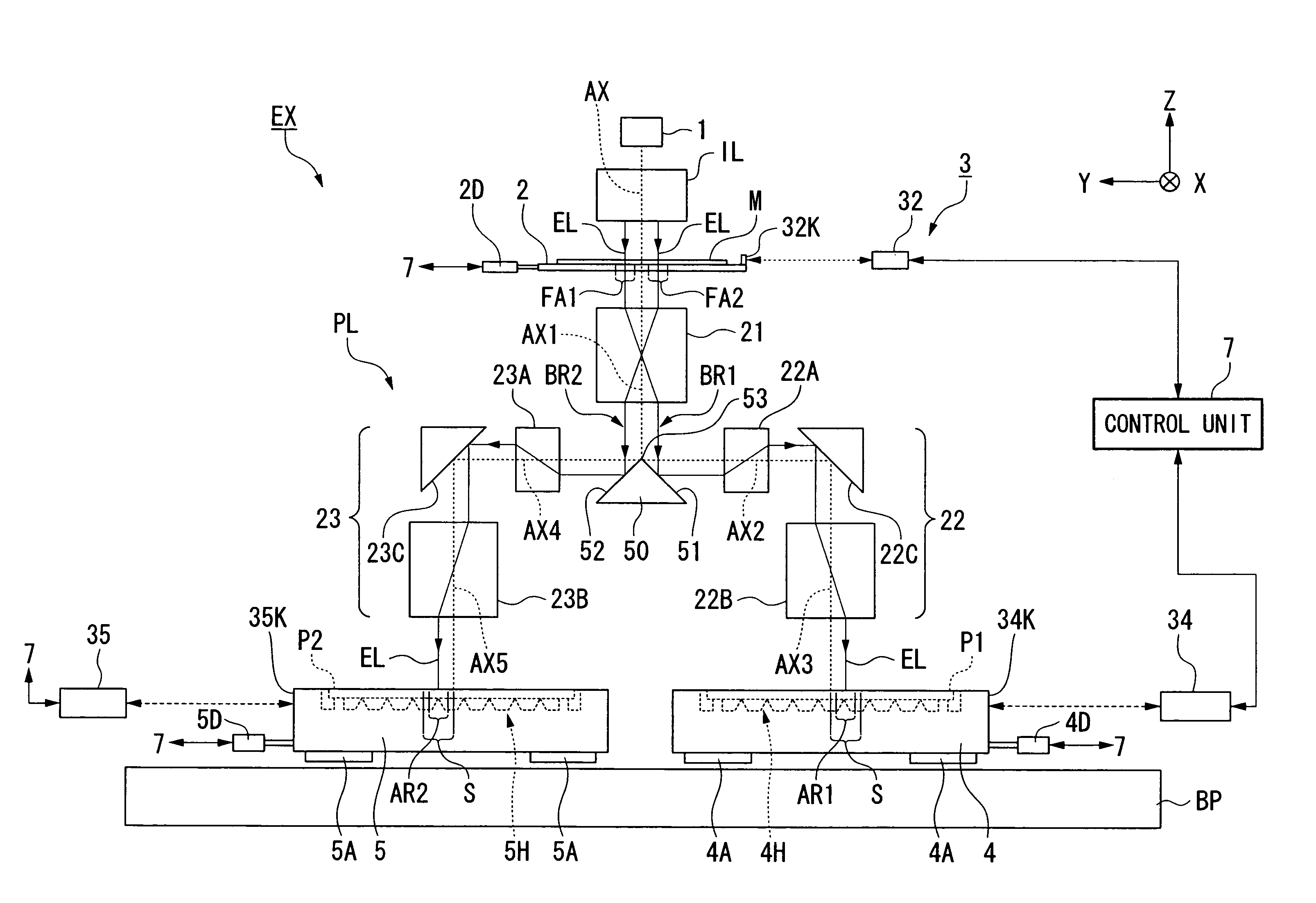

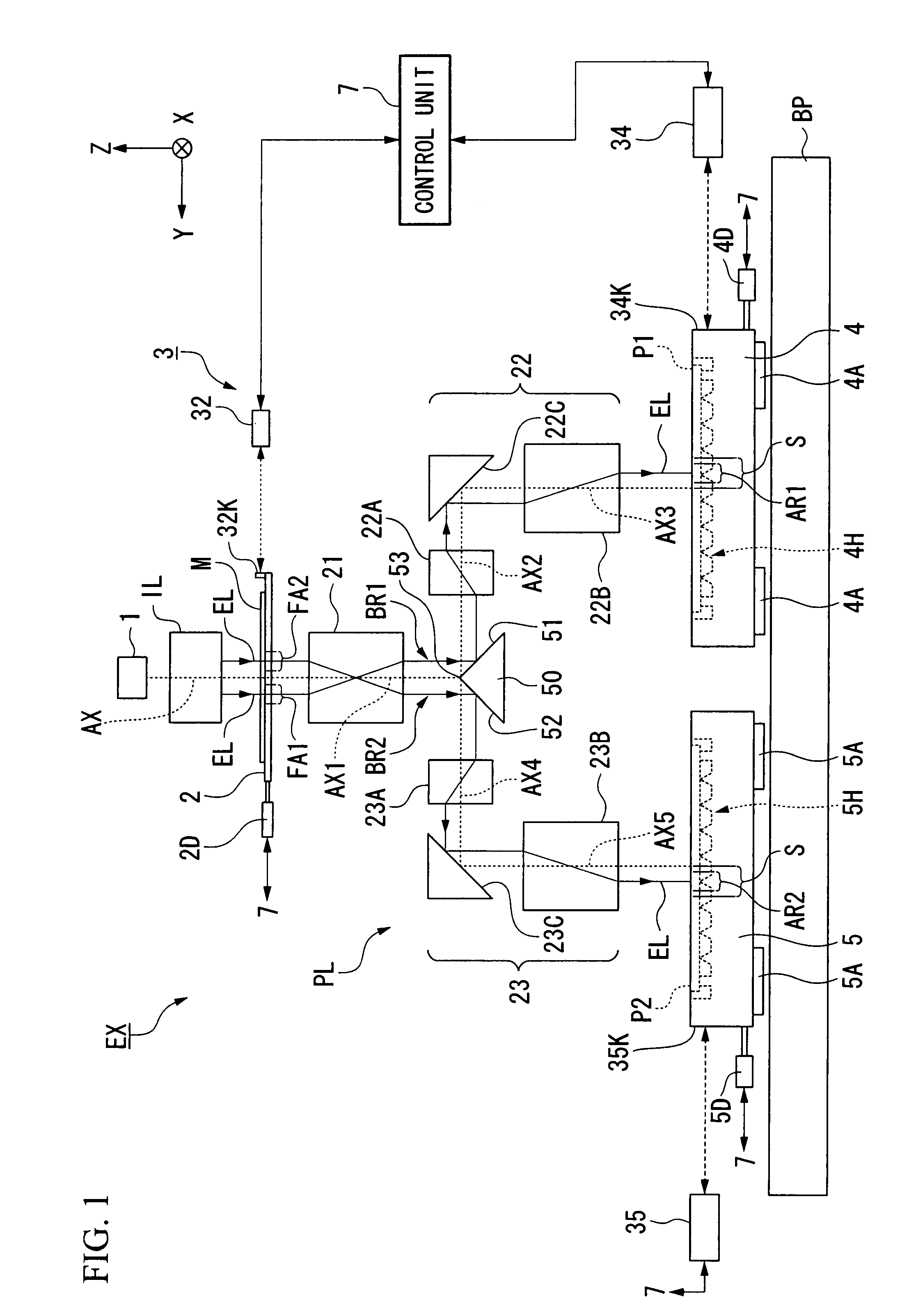

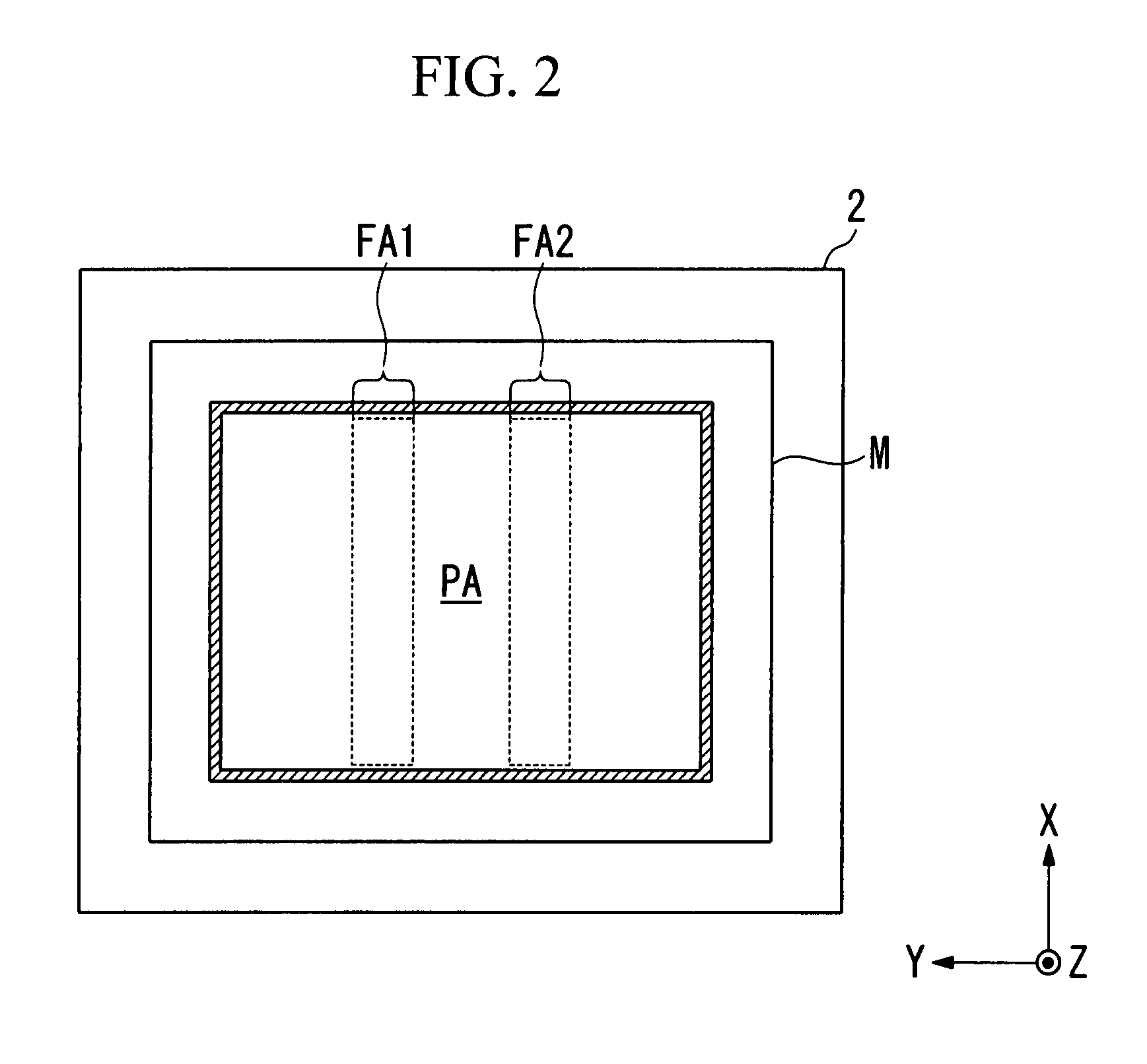

Exposure method, exposure apparatus, and method for manufacturing device

InactiveUS20090123874A1Efficiently exposedImprove throughputSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptoelectronicsPhysics

An exposure apparatus for efficiently exposing patterns onto corresponding regions of a substrate. The apparatus includes a first wafer stage, a second wafer stage, an alignment sensor which detects marks of wafers on the wafer stages, a projection optical system which irradiates a first region of a wafer with first exposure light, and an imperfect shot region exposure system which irradiates a second region of a wafer that differs from the first region with second exposure light. The imperfect shot region exposure system irradiates the second region of a wafer held on the second wafer stage with the second exposure light.

Owner:NIKON CORP

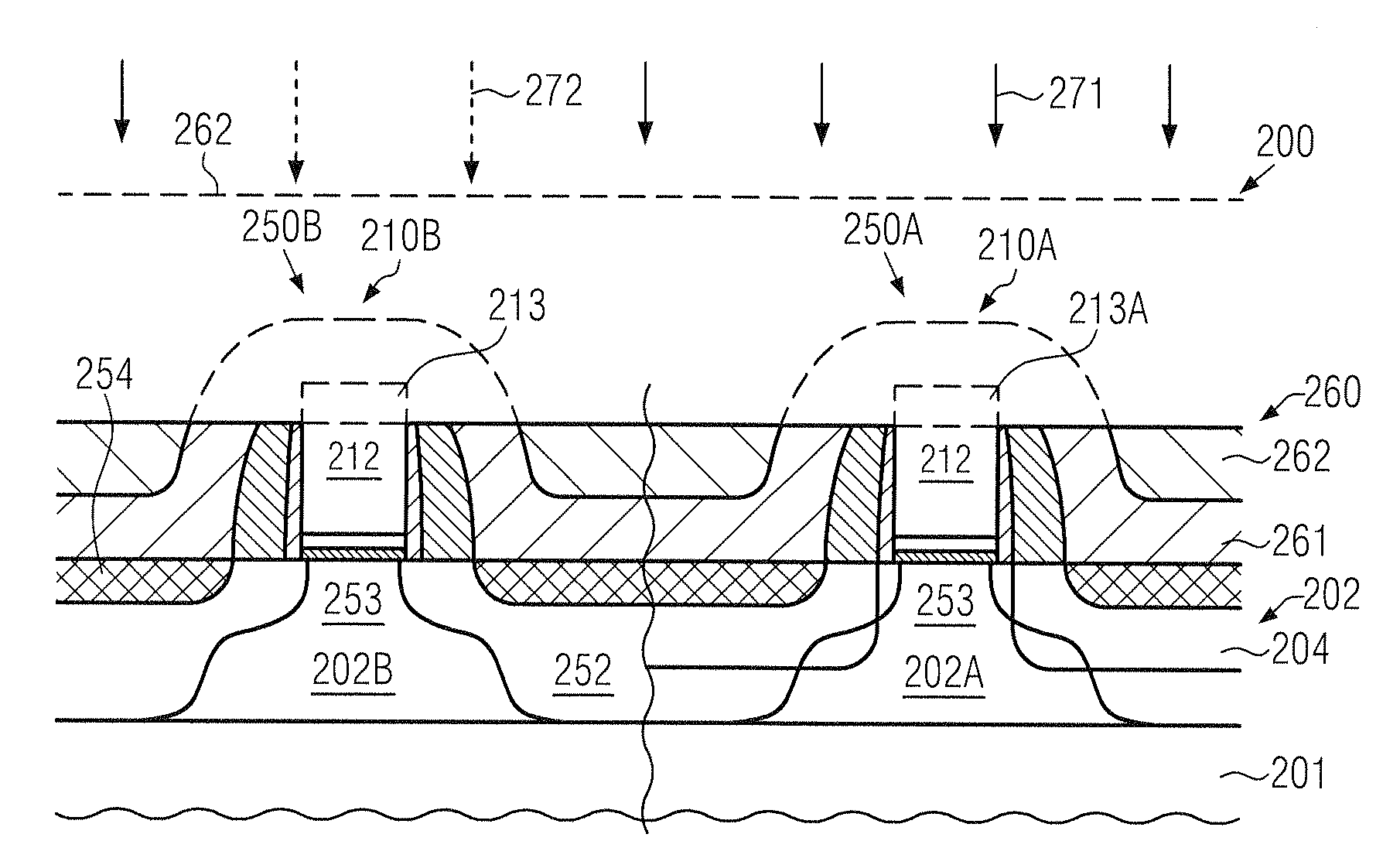

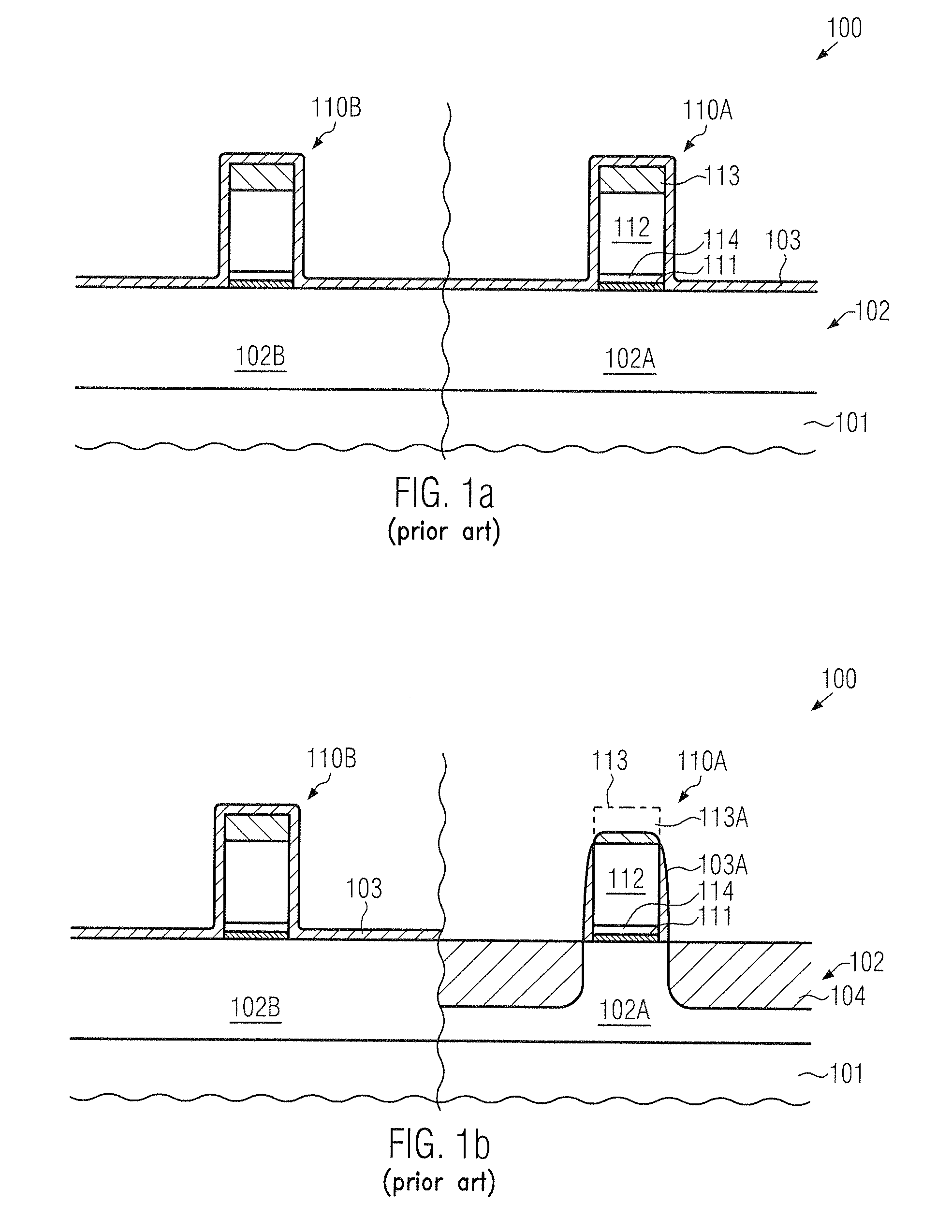

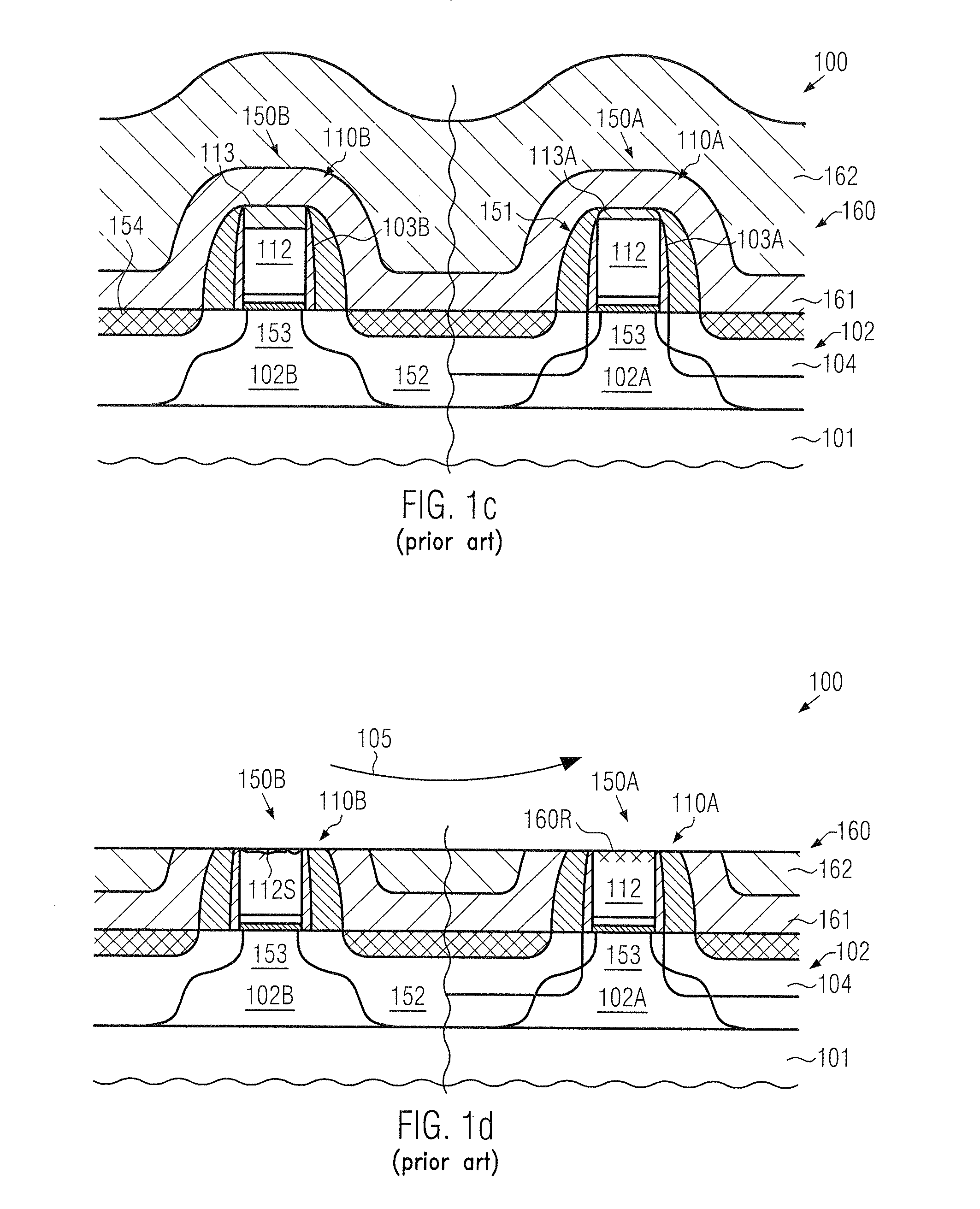

Replacement Gate Approach for High-K Metal Gate Stacks by Avoiding a Polishing Process for Exposing the Placeholder Material

InactiveUS20110244670A1Efficiently removeHighly conductiveSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMetal

In a replacement gate approach, the exposure of the placeholder material of the gate electrode structures may be accomplished on the basis of an etch process, thereby avoiding the introduction of process-related non-uniformities, which are typically associated with a complex polishing process for exposing the top surface of the placeholder material. In some illustrative embodiments, the placeholder material may be exposed by an etch process based on a sacrificial mask material.

Owner:GLOBALFOUNDRIES INC

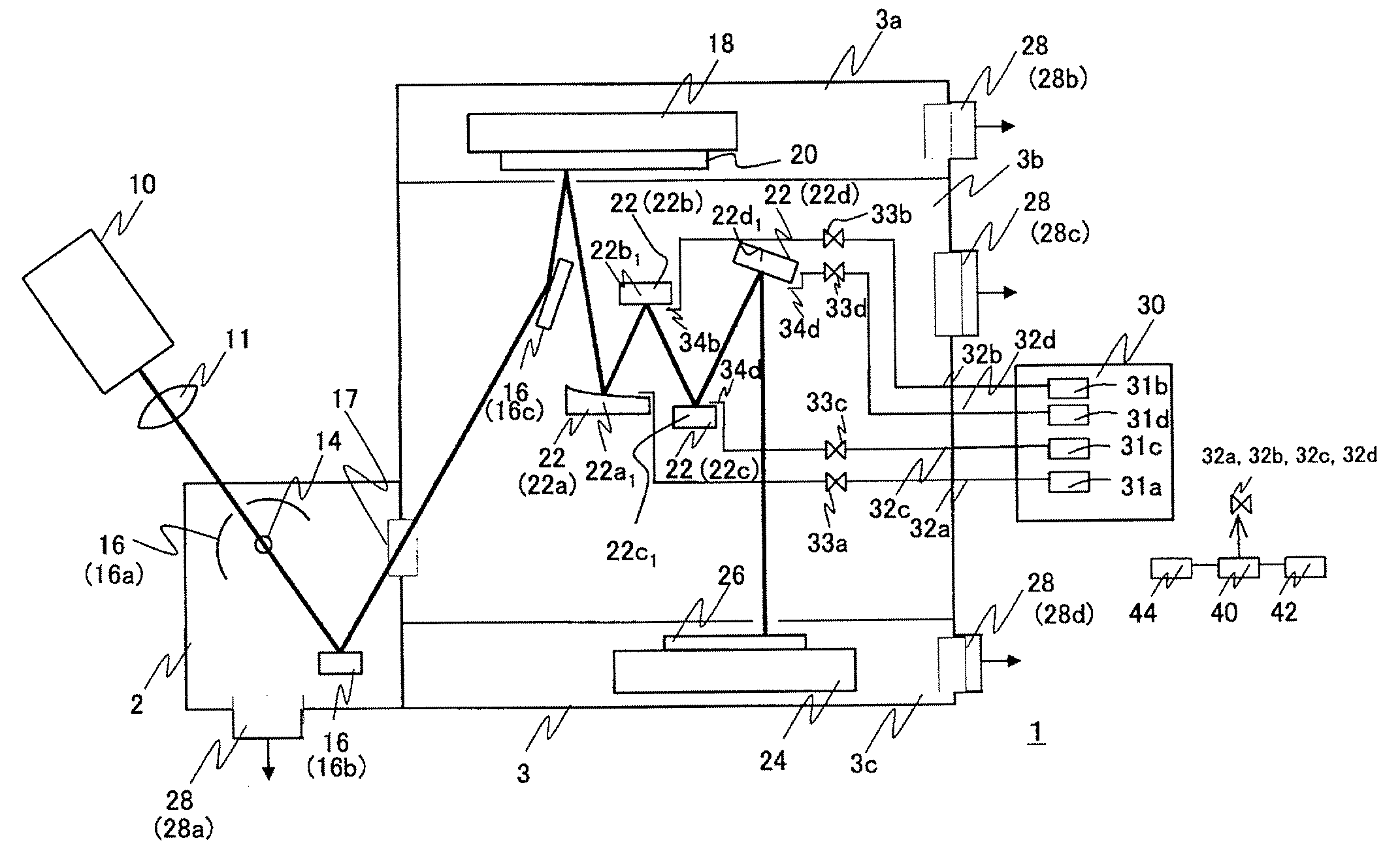

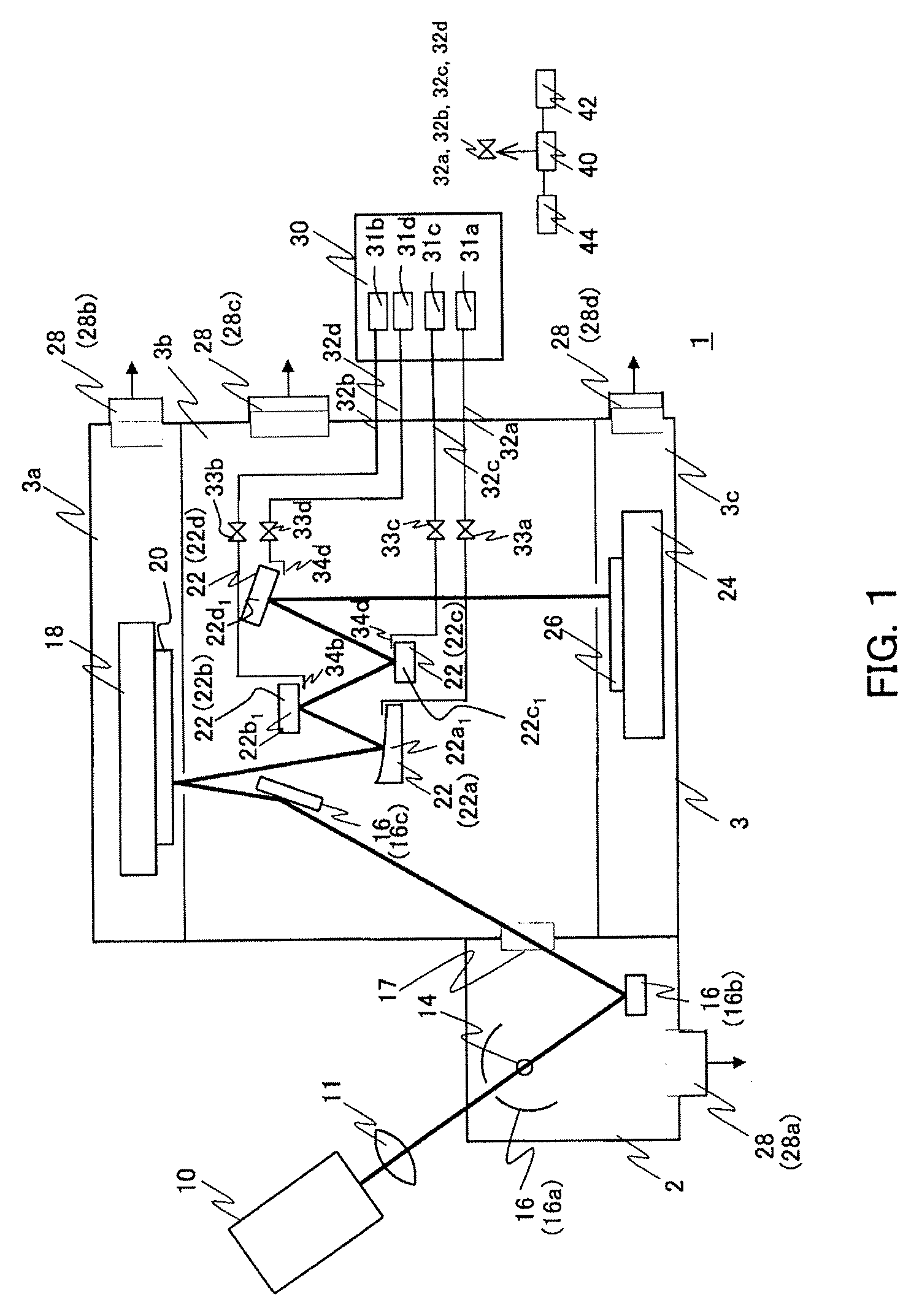

Exposure apparatus

InactiveUS20080304031A1Efficiently exposedInhibiting contamination of opticalPhotomechanical apparatusPhotographic printingPhysicsLight source

An exposure apparatus exposes a substrate using light from a light source having a wavelength of 20 nm or smaller, and includes plural optical elements, each of which is configured to reflect the light, plural vacuum chambers, each of which houses one or more of the plural optical elements, and a gas supplier configured to supply to each vacuum chamber independently a gas used to inhibit contaminations that could occur on the optical element housed in each vacuum chamber, wherein the gas supplier supplies different types of gases to the plural vacuum chambers according to an illuminance of an illumined region on the optical element housed in each vacuum chamber.

Owner:CANON KK

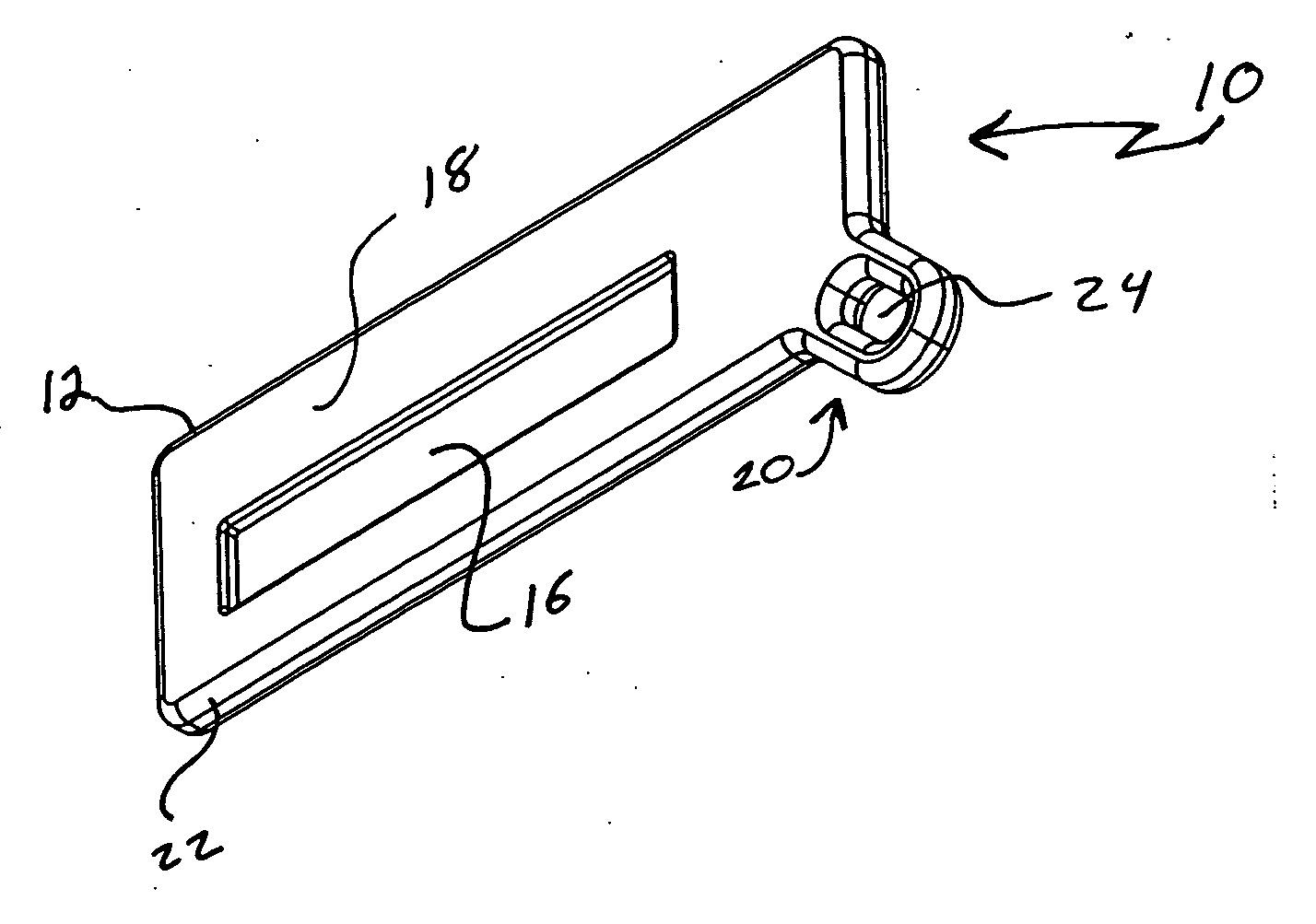

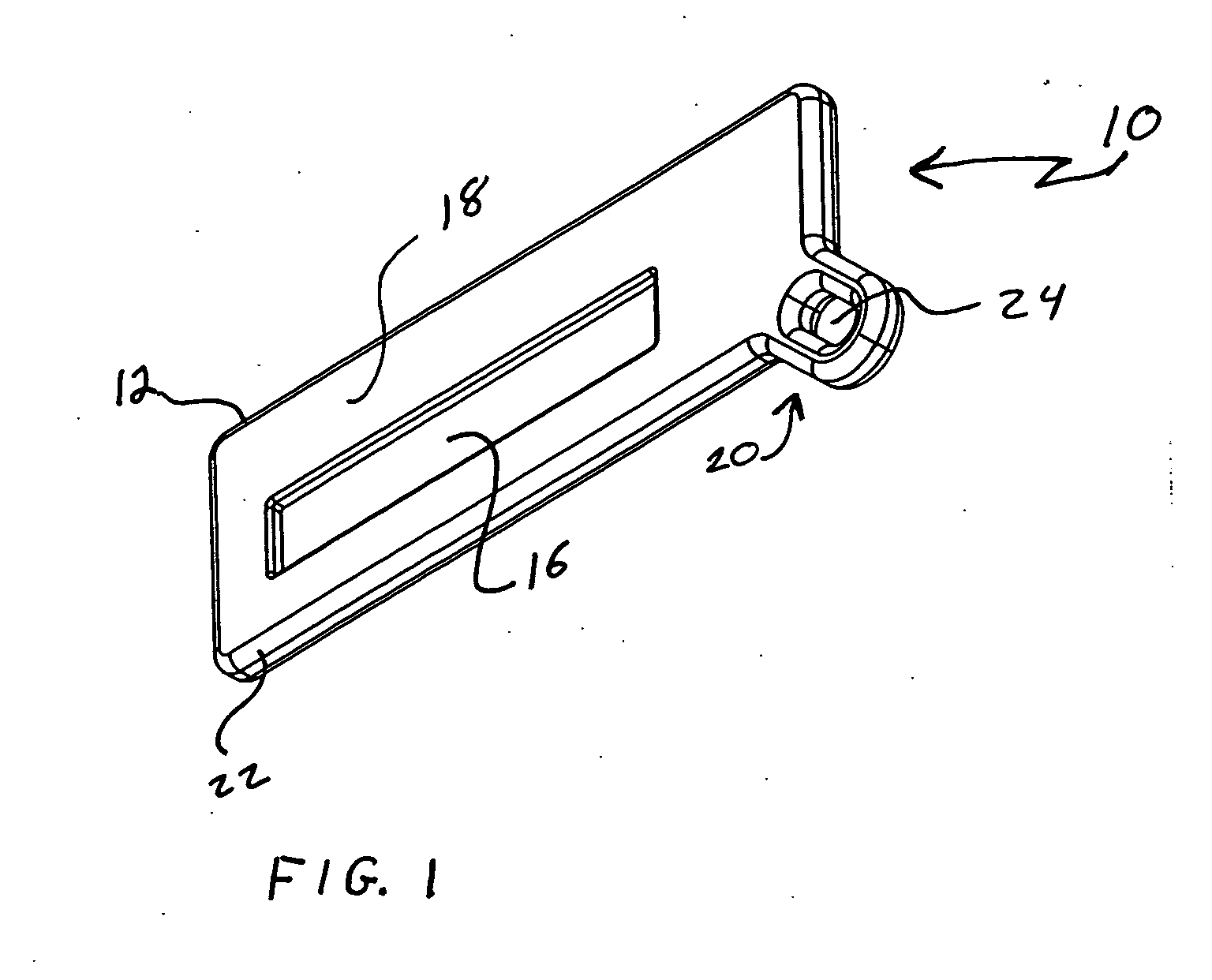

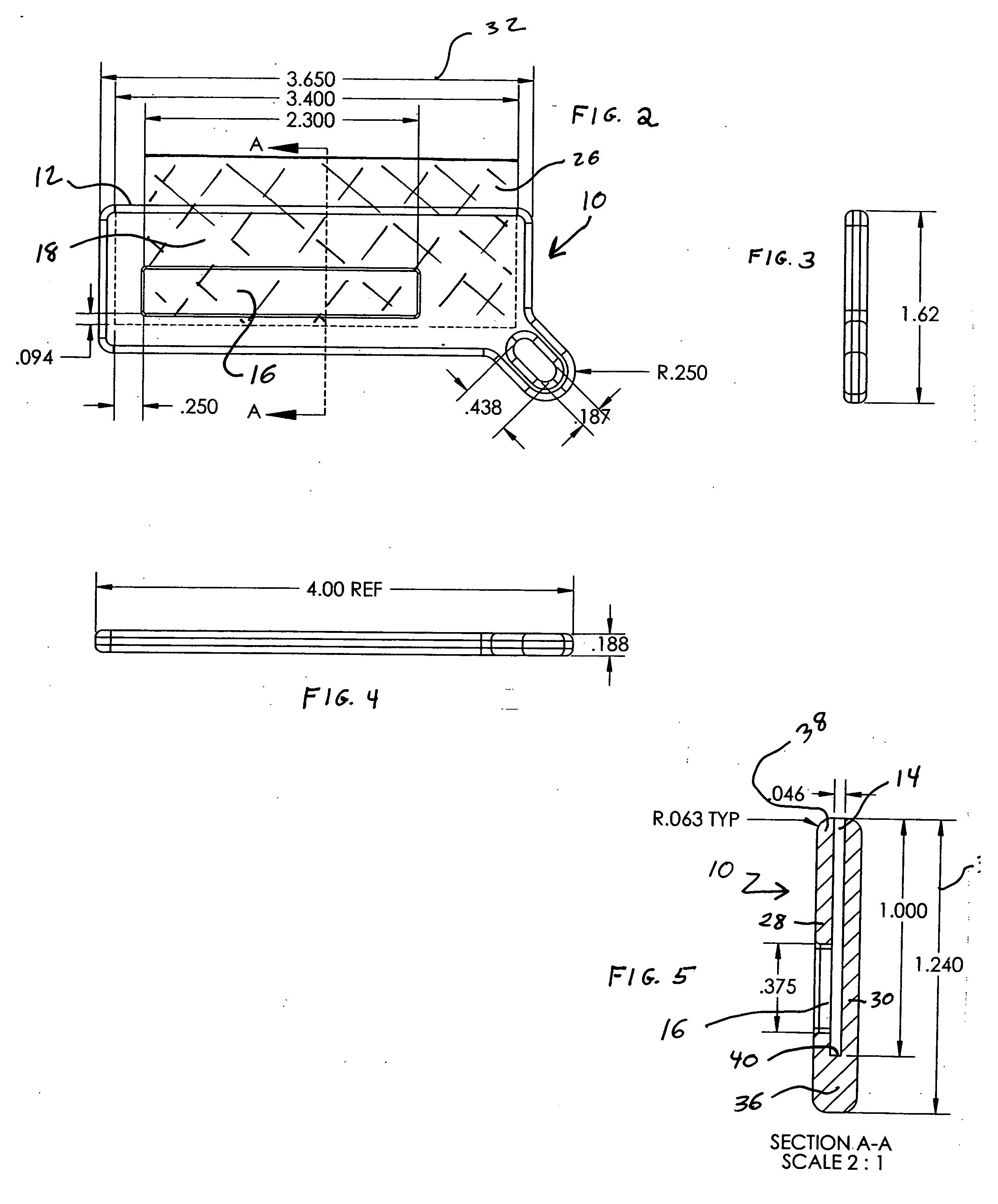

Debit or credit cardholder

There is provided a protective case for a plastic data card. This protective case includes a non-transparent housing having a first planar surface and a second planar surface both having a desired length and a desired height. The first planar surface and the second planar surface are joined together at a first end with a slit separating the first planar surface from the second planar surface. This slit extends inward from an opposing second end of said transparent housing. The slit terminates proximate the first end at a distance from the first end which is effective to position desired data on the plastic data card at an effective distance from the first end. A transparent window is formed in the first planar side and is effective to expose the desired data. The height of the second planar surface is effective to expose a magnetic stripe on the plastic data card.

Owner:HIGHER ONE

Methods of arraying biological materials using peelable and resealable devices

InactiveUS20050250097A1Address limitationsEfficiently exposedBioreactor/fermenter combinationsImage enhancementBiological materialsMaterials science

Devices and methods for performing assays on materials, particularly biological materials, are provided. The devices and methods make use of self-sealing members, which can be applied to a flat surface to form wells to facilitate immobilization of materials on the flat surface, then removed to yield a flat surface that facilitates the performance of processes on and / or detection of the immobilized material.

Owner:SURFACE LOGIX INC

Immersion exposure apparatus and immersion exposure method, and device manufacturing method

InactiveUS7872730B2Efficiently and satisfactorily exposedEfficiently exposedPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

An immersion type exposure apparatus comprises: an optical member from which an exposure beam is emitted; a first movable member that is movable while holding a substrate, in a predetermined region including a first region including a position facing the optical member and a second region different from the first region; a second movable member that is movable while holding the substrate independently from a first movable member, in a predetermined region including the first region and the second region; a first connection member that is releasably and alternately connected with the first movable member and the second movable member, and moves one movable member in the first region; a second connection member that is releasably and alternately connected with the first movable member and the second movable member, and moves the other movable member in the second region; and a third movable member that is provided on the first connection member and is movable to a position facing the optical member, and at least one of the first movable member, the second movable member, and the third movable member is moved to the position facing the optical member so that a beam path on the emitting side of the optical member is kept filled with a liquid.

Owner:NIKON CORP

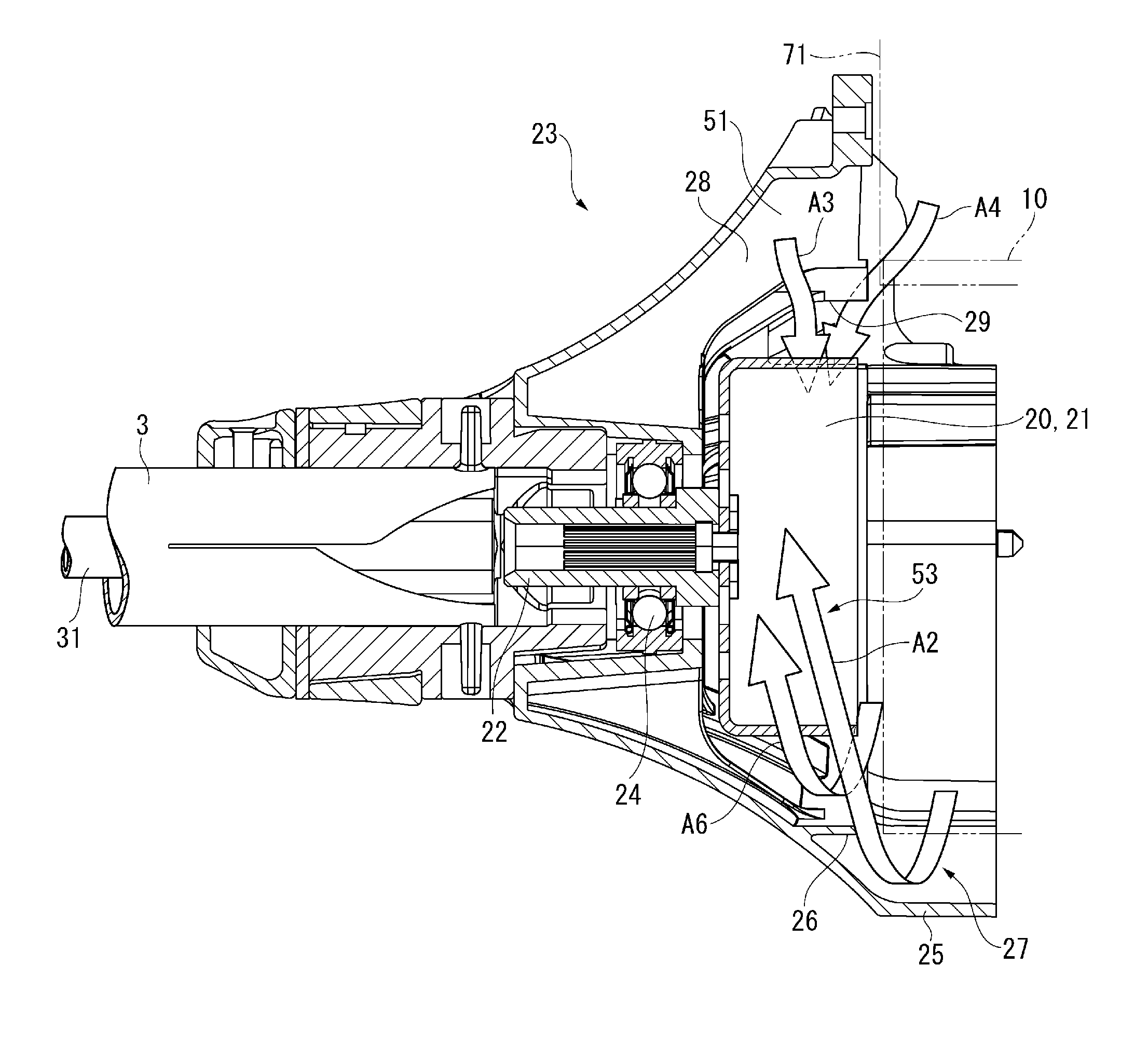

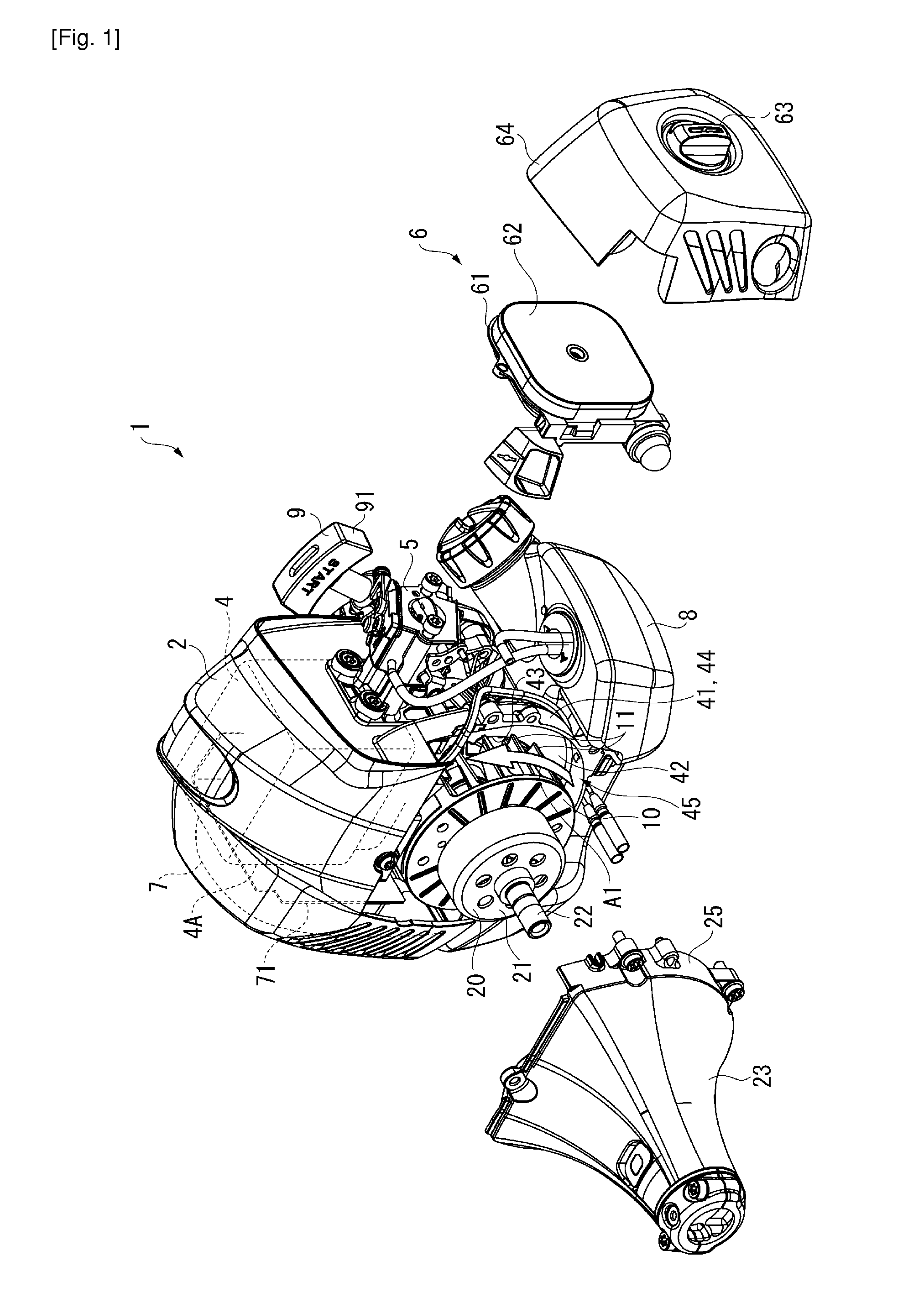

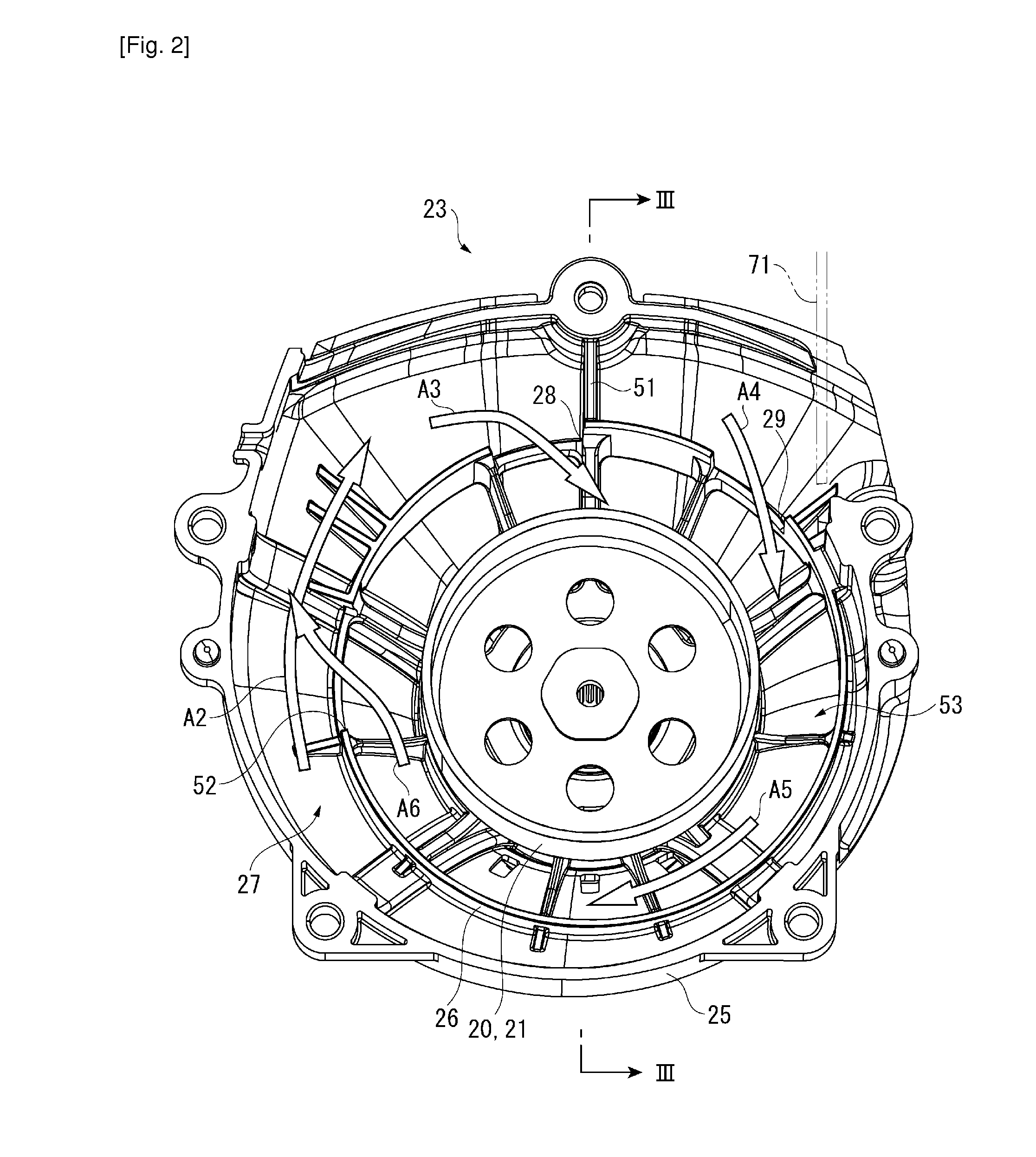

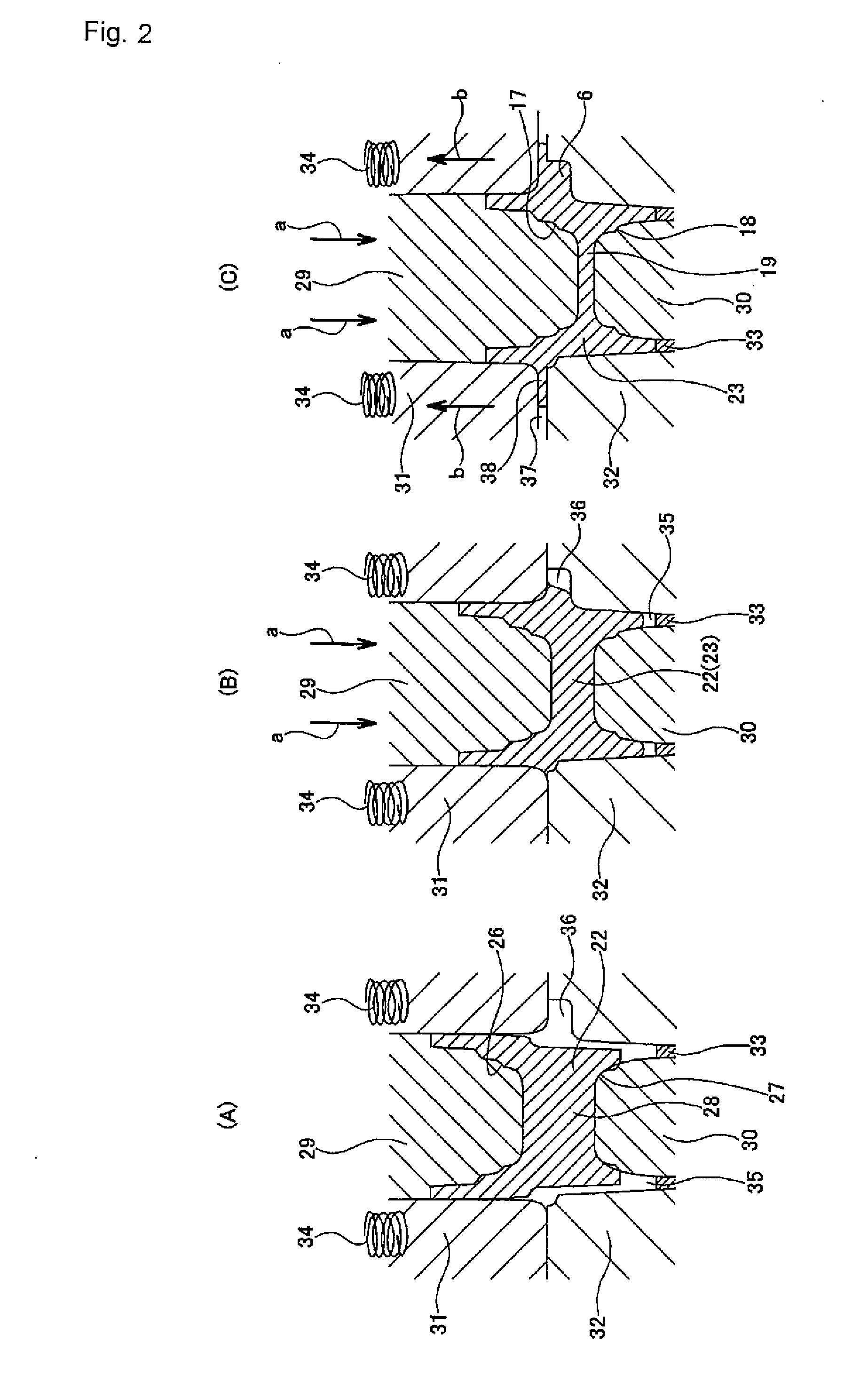

brushcutter

A brushcutter includes: a centrifugal clutch (20) that transmits a drive force of an engine from a crankshaft to a drive shaft; a clutch housing (23) covering the cooling fan and the centrifugal clutch, the clutch housing being made of a synthetic resin; and a bearing that is held inside the clutch housing (23) and supports a coupling shaft that couples the drive shaft and the centrifugal clutch (20). A volute-shaped air-flow space (27) defined including a rise wall (26) surrounding the centrifugal clutch (20) is provided inside the clutch housing (23) near an outer circumference of the centrifugal clutch (20). An inflow opening (28, 29) that lets a cooling air flowing in the air-flow space (27) flow into an inner air-flow space (53) and an outflow opening (52) that lets the cooling air flowing in the air-flow space (53) flow out to the air-flow space (27) are provided on the rise wall (26).

Owner:HUSQVARNA AB

Edge exposure apparatus, coating and developing apparatus, and edge exposure method

ActiveUS7573054B2Improve abilitiesIncrease in sizeInvestigating moving sheetsPhotomechanical apparatusLight beamEngineering

The present invention includes a first and a second optical path forming member arranged within a path of light beams from a light source; a first mounting table provided such that the edge portion of the substrate is located within an application region of the light beams from an outlet side of the first optical path forming member, and a second mounting table provided such that the edge portion of the substrate is located within an application region of the light beams from an outlet side of the second optical path forming member, each of the mounting tables being configured to be rotatable about a vertical axis while mounting the substrate thereon; and a light blocking means for blocking application of light from each of the first and second optical path forming members. A common light source can be used to perform edge exposure for the substrates on the first and second mounting tables, for example, at the same time, so that a high processing ability can be offered and an increase in size of the apparatus can be prevented.

Owner:TOKYO ELECTRON LTD

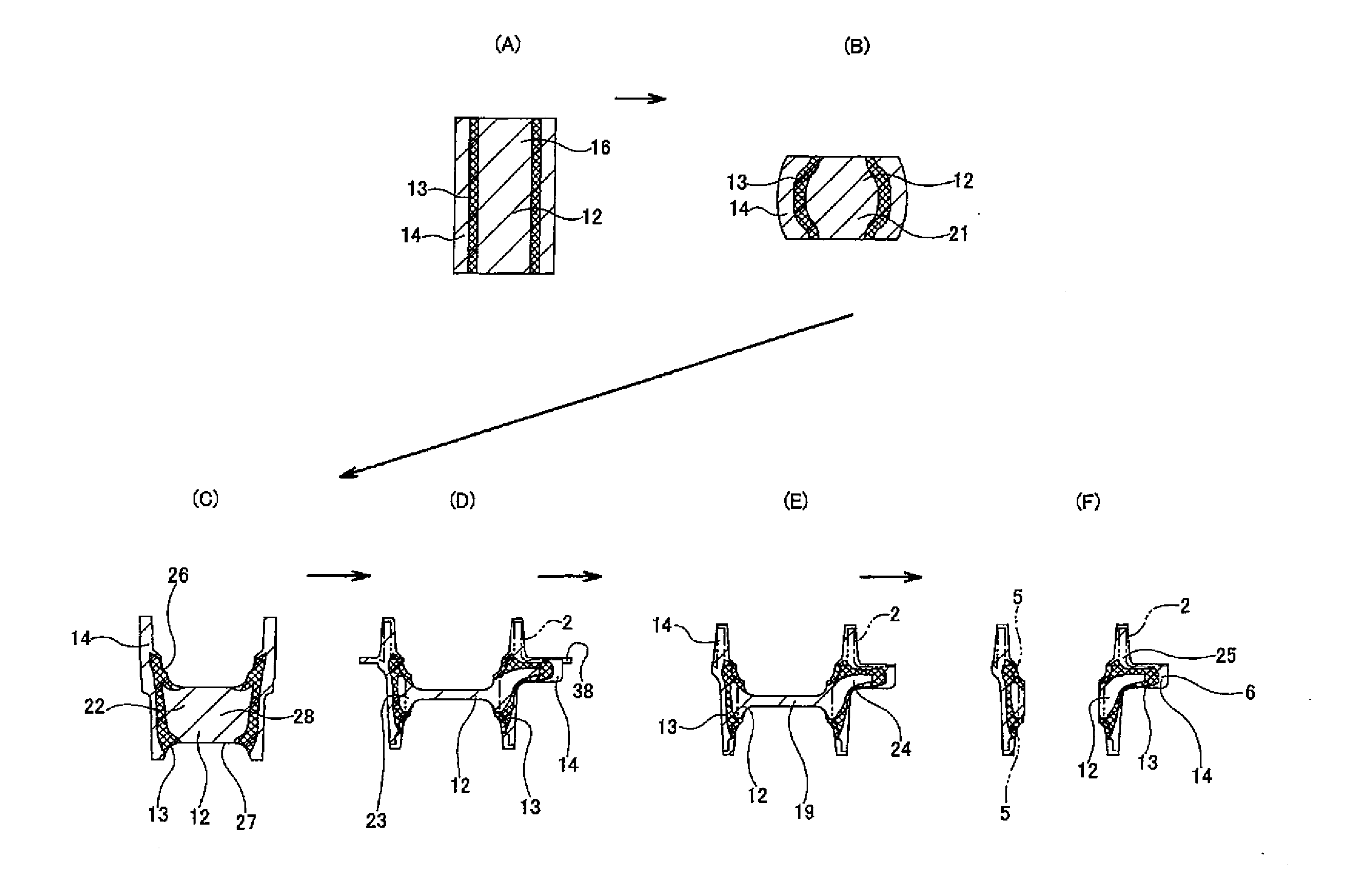

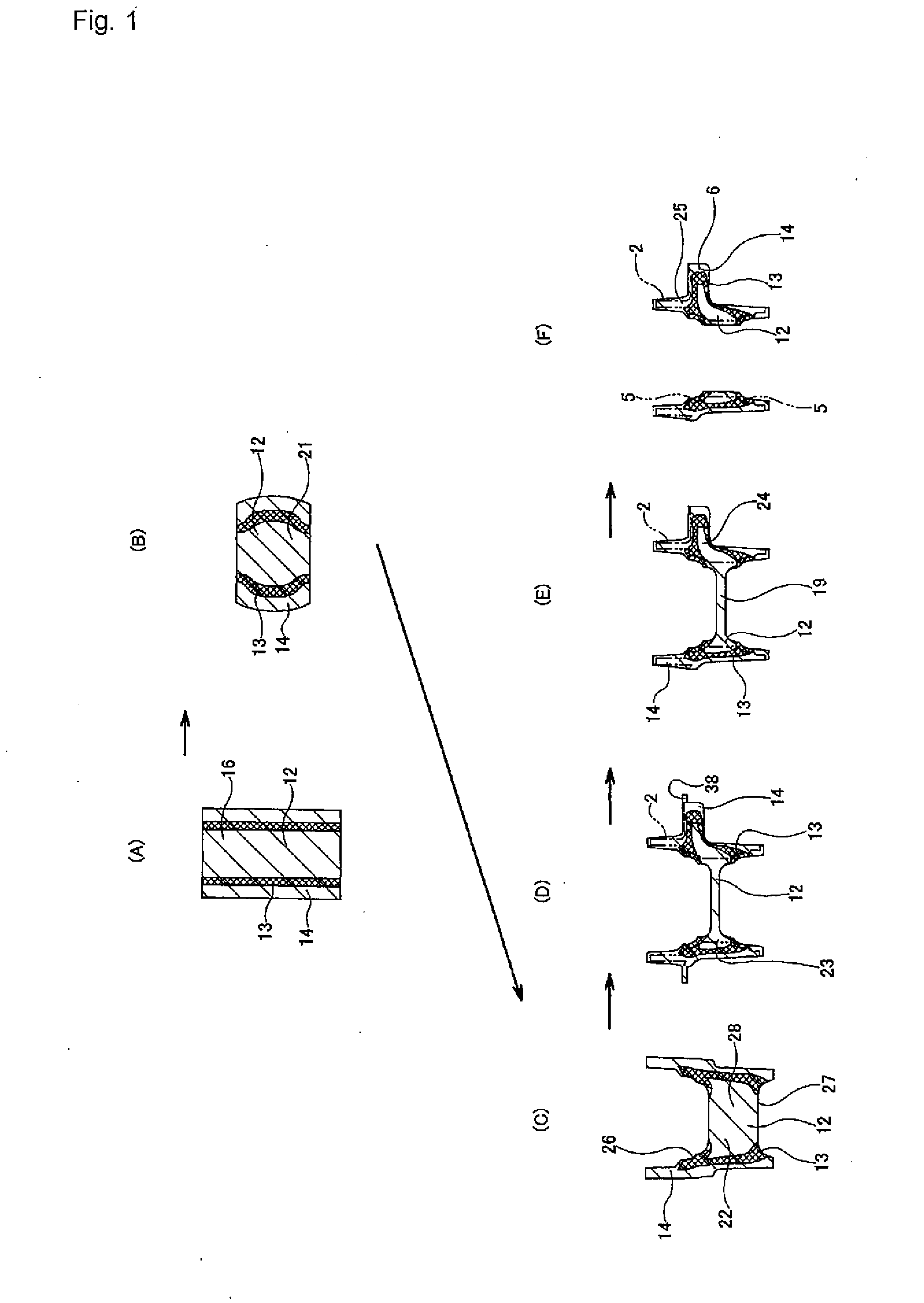

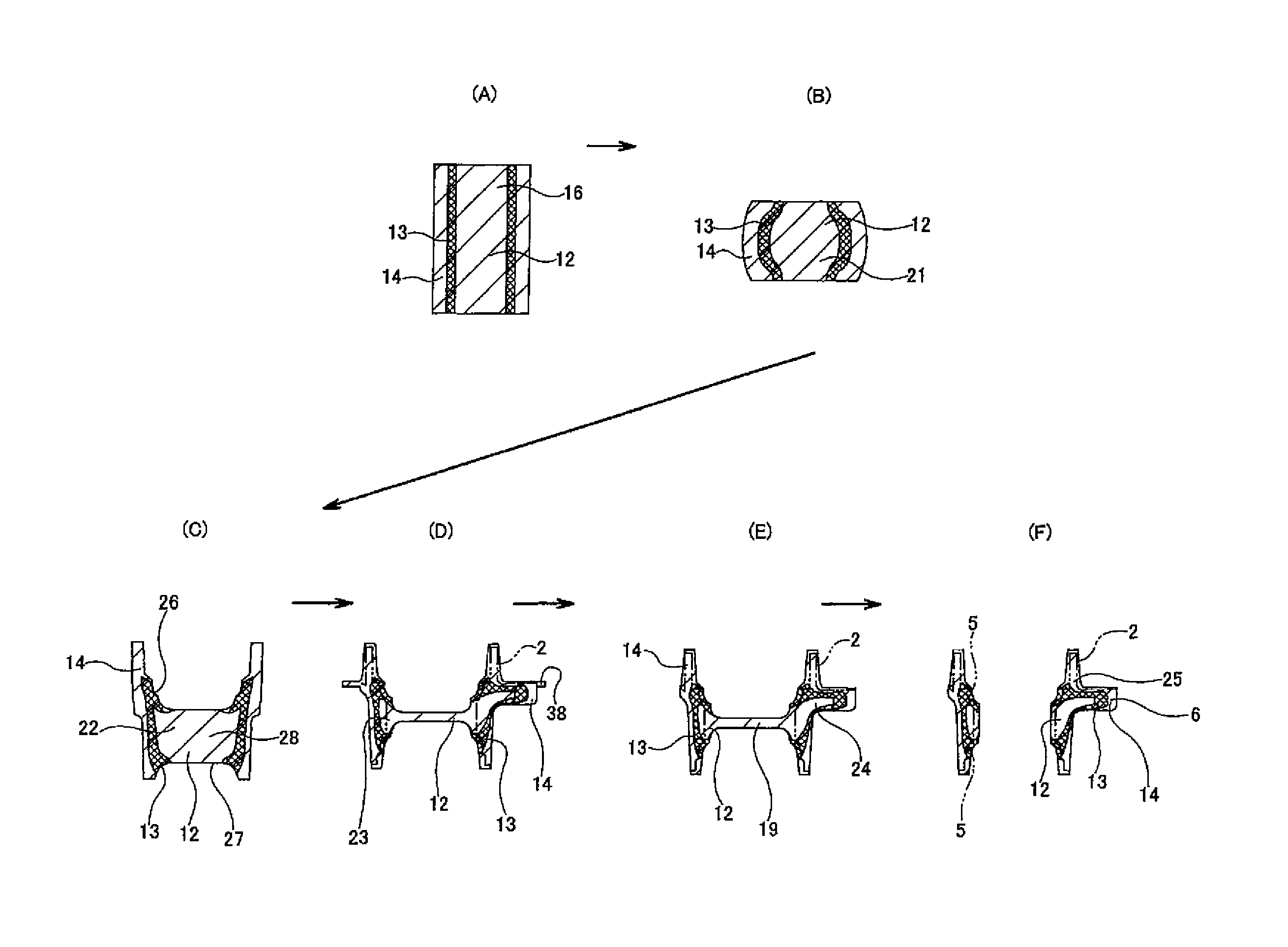

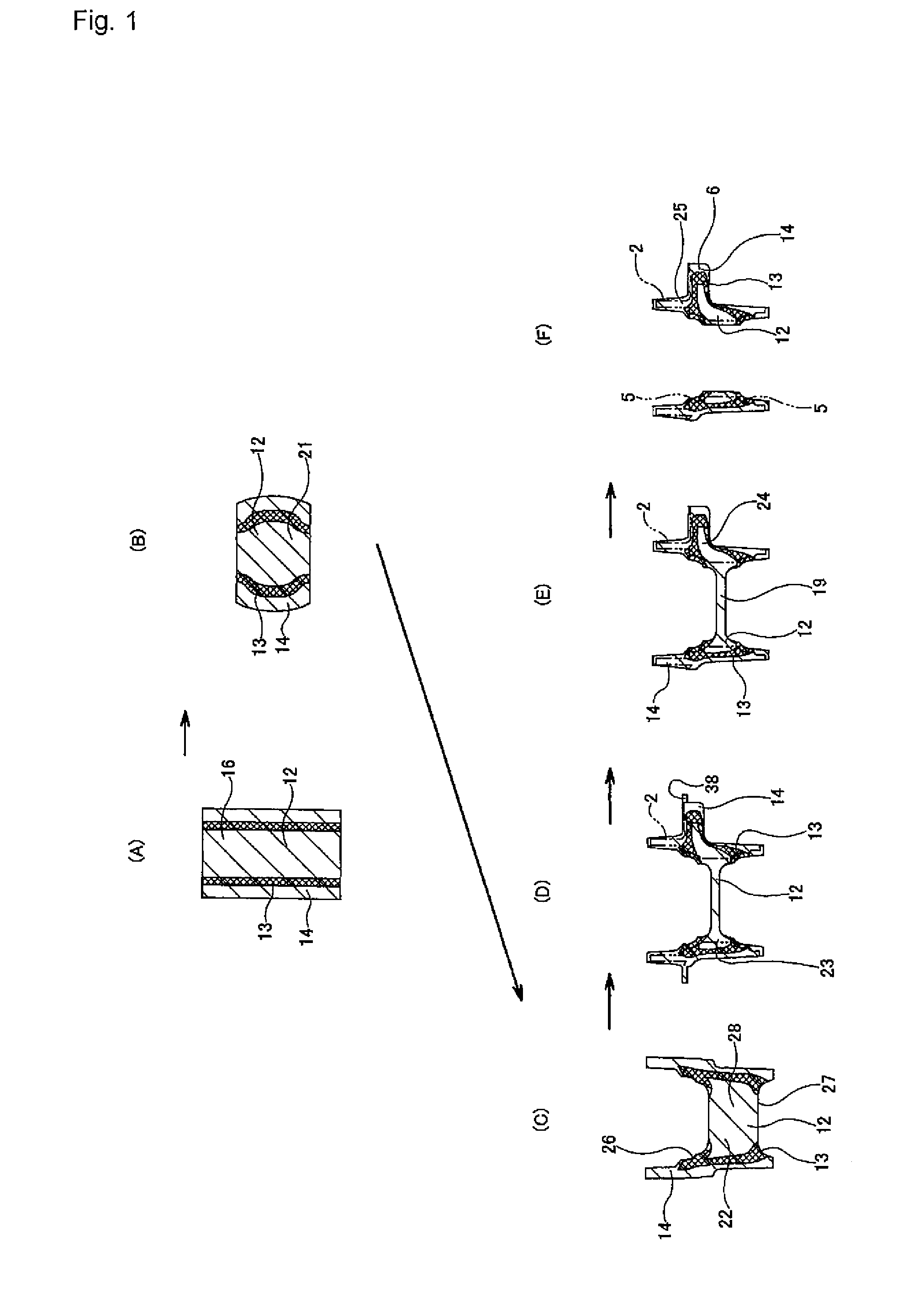

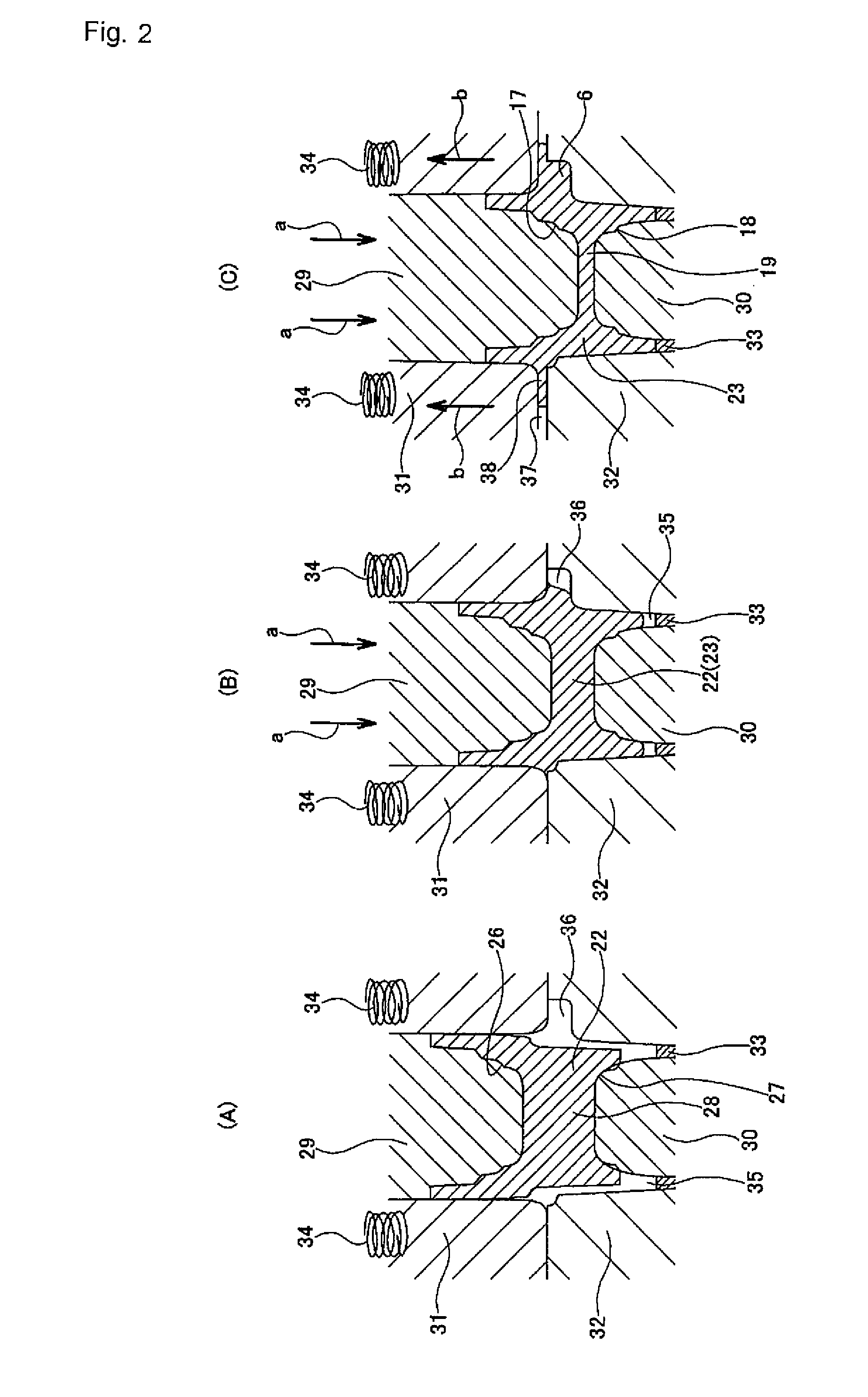

Method for manufacturing a bearing ring member

ActiveUS20100058591A1Increase freedomSimplify workRolling contact bearingsMetal-working apparatusEngineeringMechanical engineering

The present invention provides a manufacturing method of a bearing ring member such as an outer ring comprising an installation portion on the outer peripheral surface and a double row of outer-ring raceways on the inner peripheral surface, in which a raw material is processed to obtain a final stage intermediate member through a first upsetting process, a forward-backward extrusion process, a second upsetting process, a burr removing process, and a punching process, wherein a movable die which leaves a stationary die in the final step is used in the second upsetting process, and the excess metal material is moved toward outside in the radial direction to a portion which become the installation section and a burr formation section, exposing a high pure metal material at least in a portion where the load of rolling bodies acts so as to ensure the rolling fatigue life of the both of outer-ring raceways.

Owner:NSK LTD

Crop lifter pans

A seed pan apparatus for attachment to a cutting header hang a knife and cooperating knife guards mounted along a lower front edge thereof includes a seed pan adapted at a front portion thereof for attachment to the cutting header such that when attached to the cutting header, the seed pan extends upward and rearward from a guard finger of a knife guard over the knife to a rear end thereof located rearward of the knife. Side walls extend upward from side edges of the seed pan, and right and left side edges of the seed pan diverge from a front end thereof to the rear end thereof such that the rear end of the seed pan is wider than the front end thereof.

Owner:DIETRICH GMBH

Methods for processing biological materials using peelable and resealable devices

InactiveUS7351575B2Address limitationsEfficiently exposedBioreactor/fermenter combinationsMaterial nanotechnologyBiological materialsMaterials science

Devices and methods for performing assays on materials, particularly biological materials, are provided. The devices and methods make use of self-sealing members, which can be applied to a flat surface to form wells to facilitate immobilization of materials on the flat surface, then removed to yield a flat surface that facilitates the performance of processes on and / or detection of the immobilized material.

Owner:SURFACE LOGIX INC

Pattern forming method, wiring pattern forming method, electro-optical device, and electronic apparatus

ActiveUS7507519B2Simplified and inexpensive deviceValid conversionMaterial nanotechnologyElectric lighting sourcesThermal energyPhotothermal conversion

Aspects of the invention can provide a patterning forming method capable of patterning a thin film by a simple and inexpensive device. The thin film can be provided on a base member including a photothermal conversion material that converts optical energy into thermal energy and light is radiated onto the base member to remove the thin film corresponding to a light-radiated region, such that the thin film is patterned.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Methods of arraying biological materials using peelable and resealable devices

InactiveUS7001740B2Efficiently exposedMaterial nanotechnologyImage enhancementBiological materialsMaterials science

Devices and methods for performing assays on materials, particularly biological materials, are provided. The devices and methods make use of self-sealing members, which can be applied to a flat surface to form wells to facilitate immobilization of materials on the flat surface, then removed to yield a flat surface that facilitates the performance of processes on and / or detection of the immobilized material.

Owner:SURFACE LOGIX INC

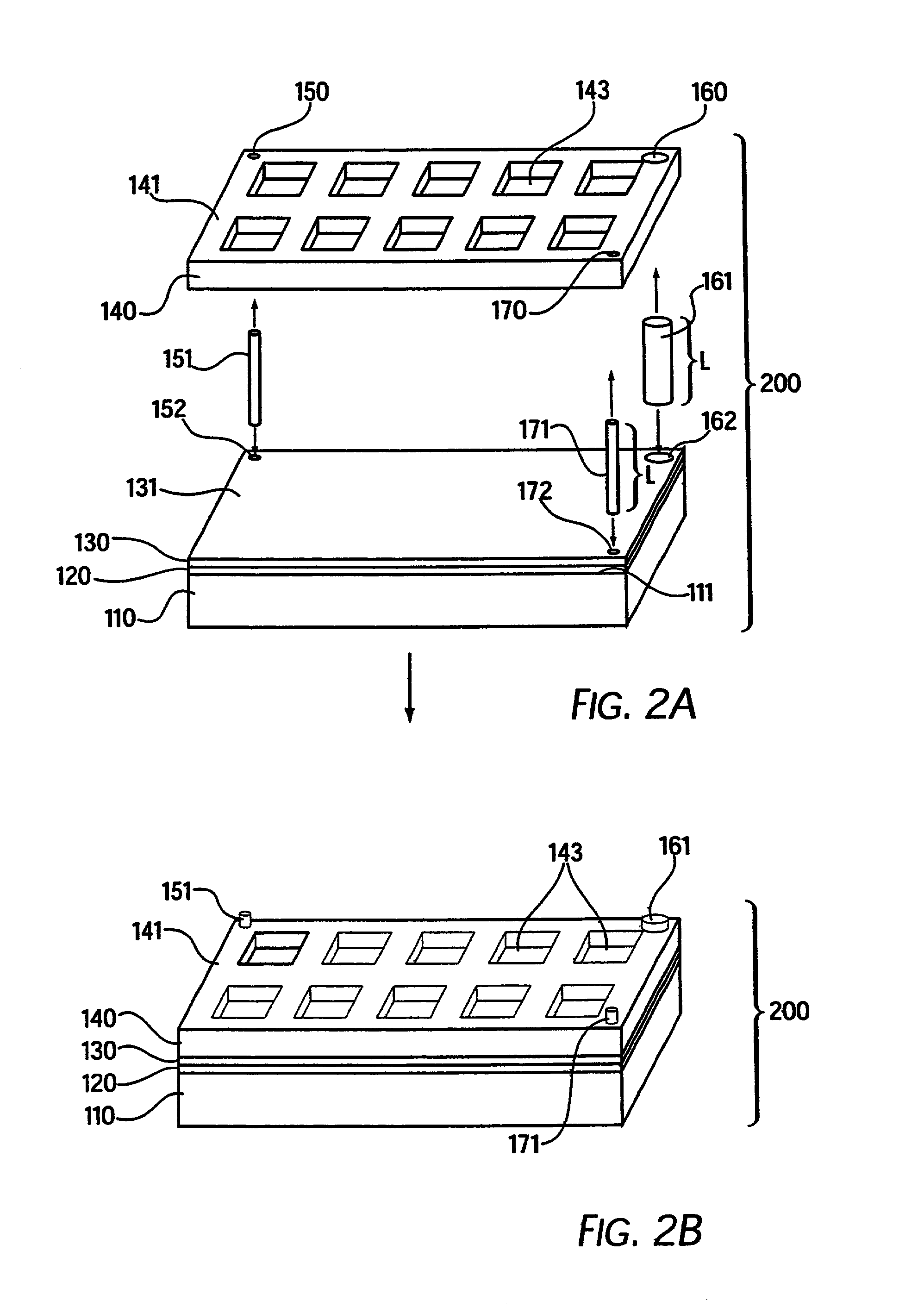

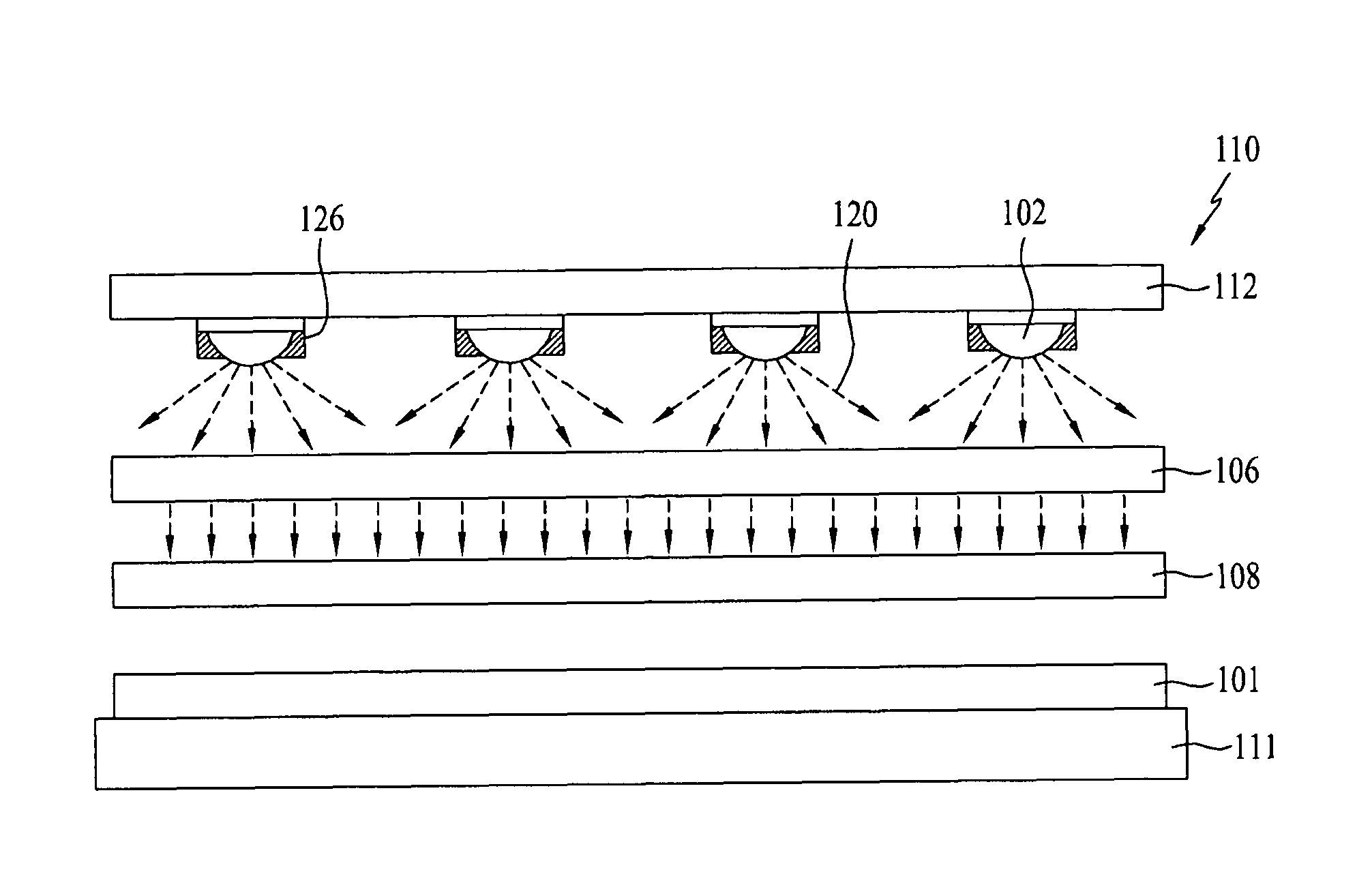

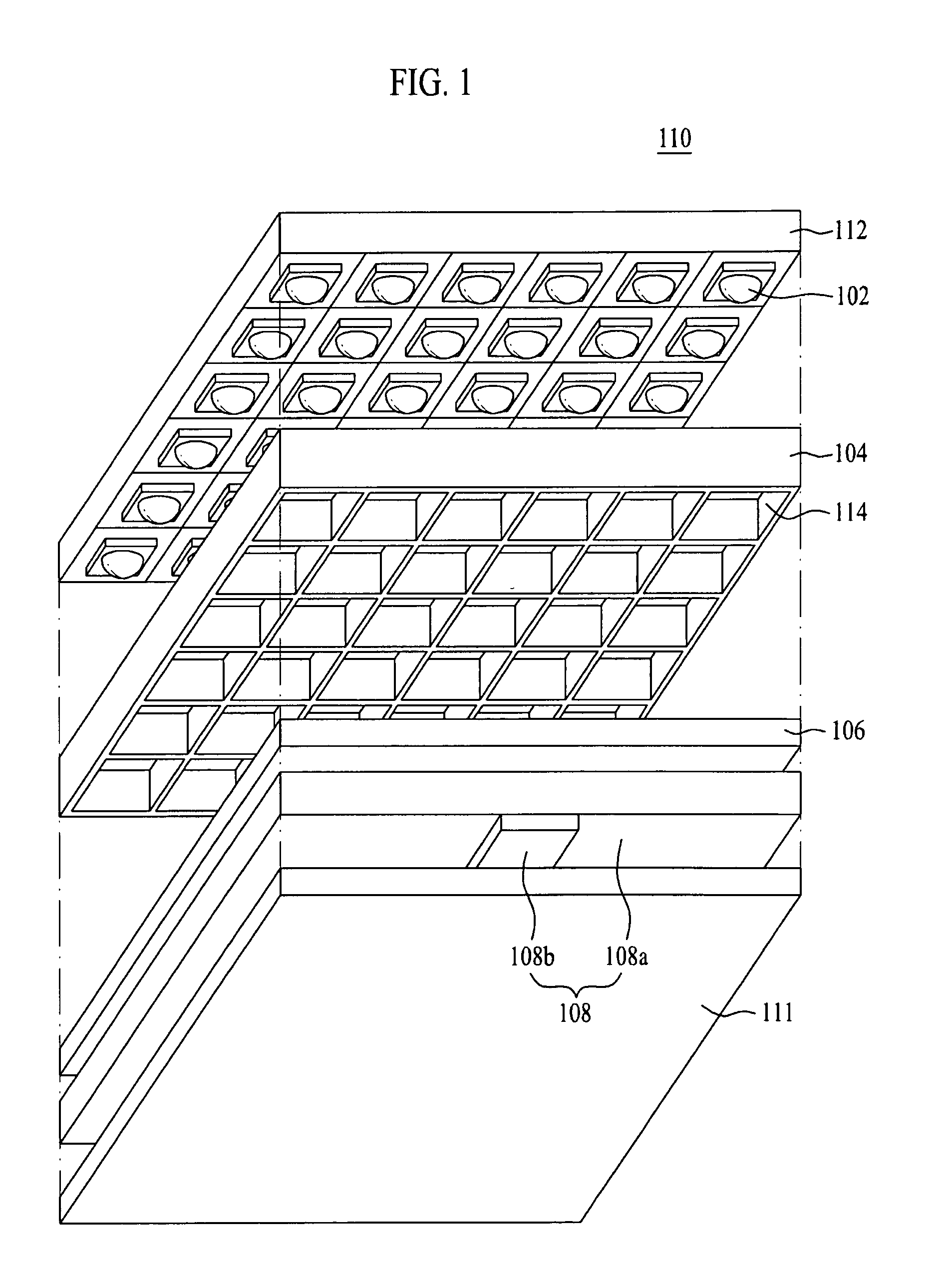

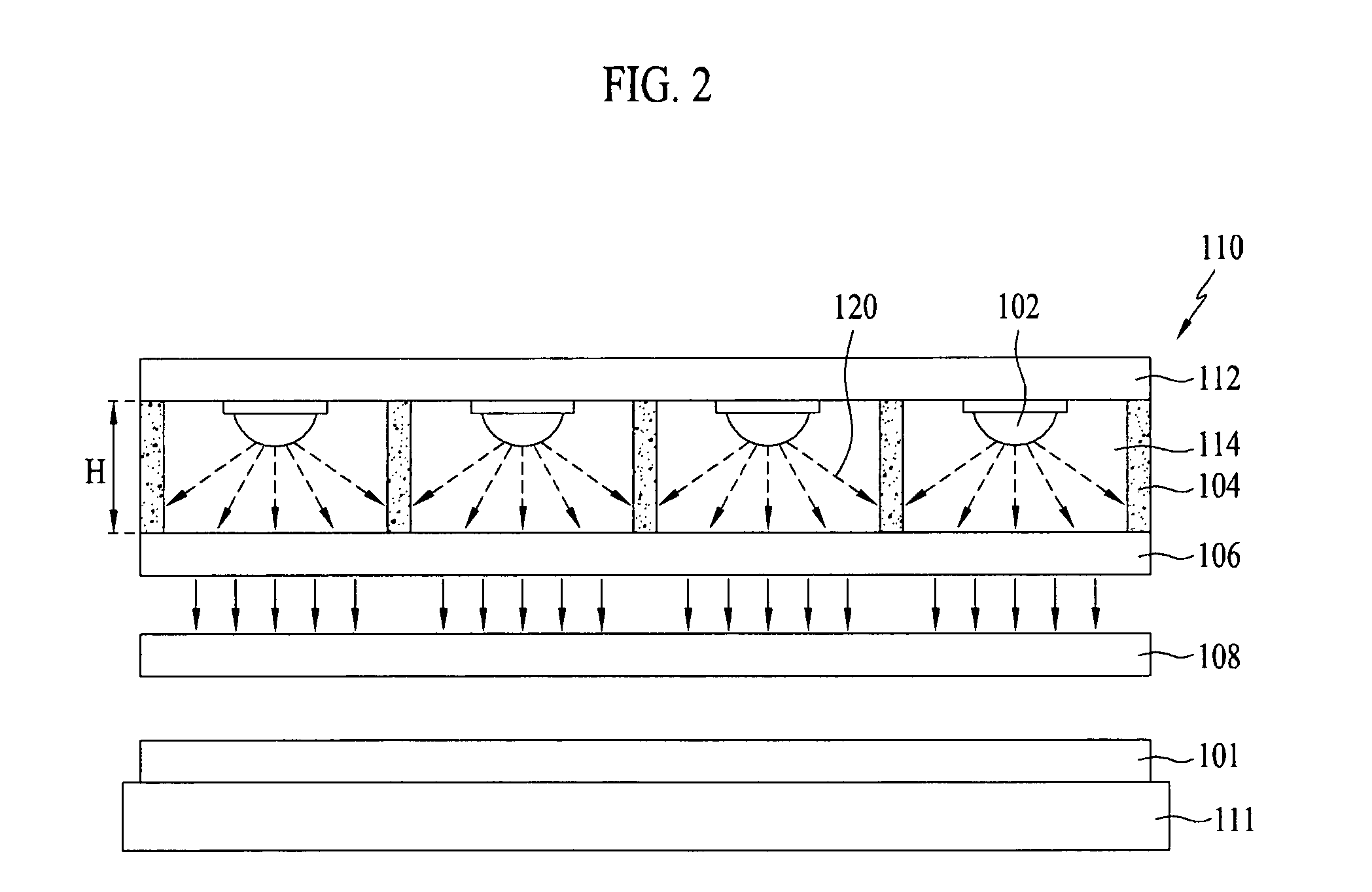

Exposure method and exposure apparatus for photosensitive film

ActiveUS8531647B2Low costEasy to operatePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringLight-emitting diode

An exposure apparatus for a photosensitive film includes: light-emitting diodes for generating rays to expose a photosensitive film; a light shield positioned between the light-emitting diodes to prevent noise; a stage for receiving a substrate having the photosensitive film thereon; and a parallelizer positioned between the light-emitting diodes and the stage for redirecting the rays from the light-emitting diodes to be perpendicularly incident upon the photosensitive film.

Owner:LG DISPLAY CO LTD

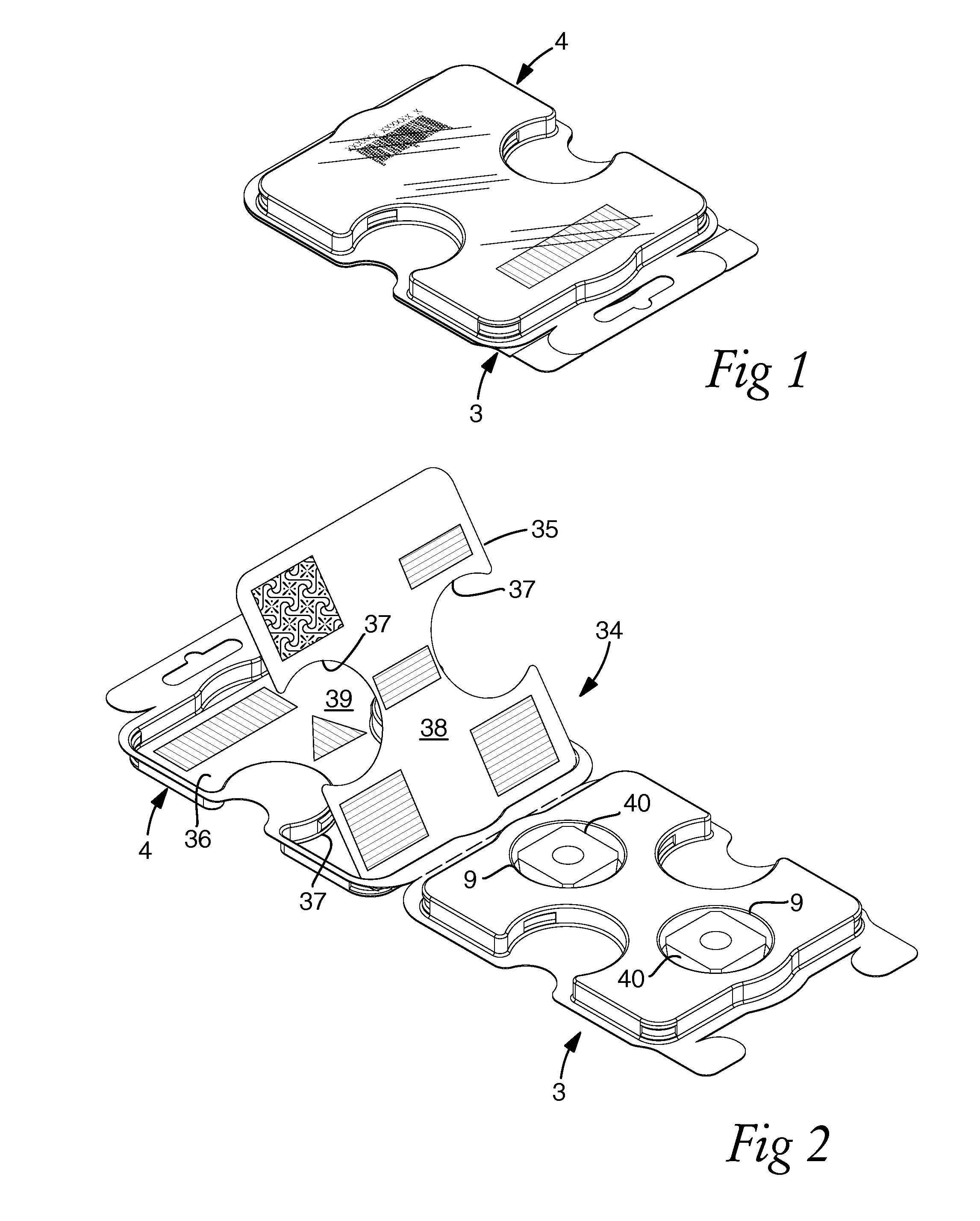

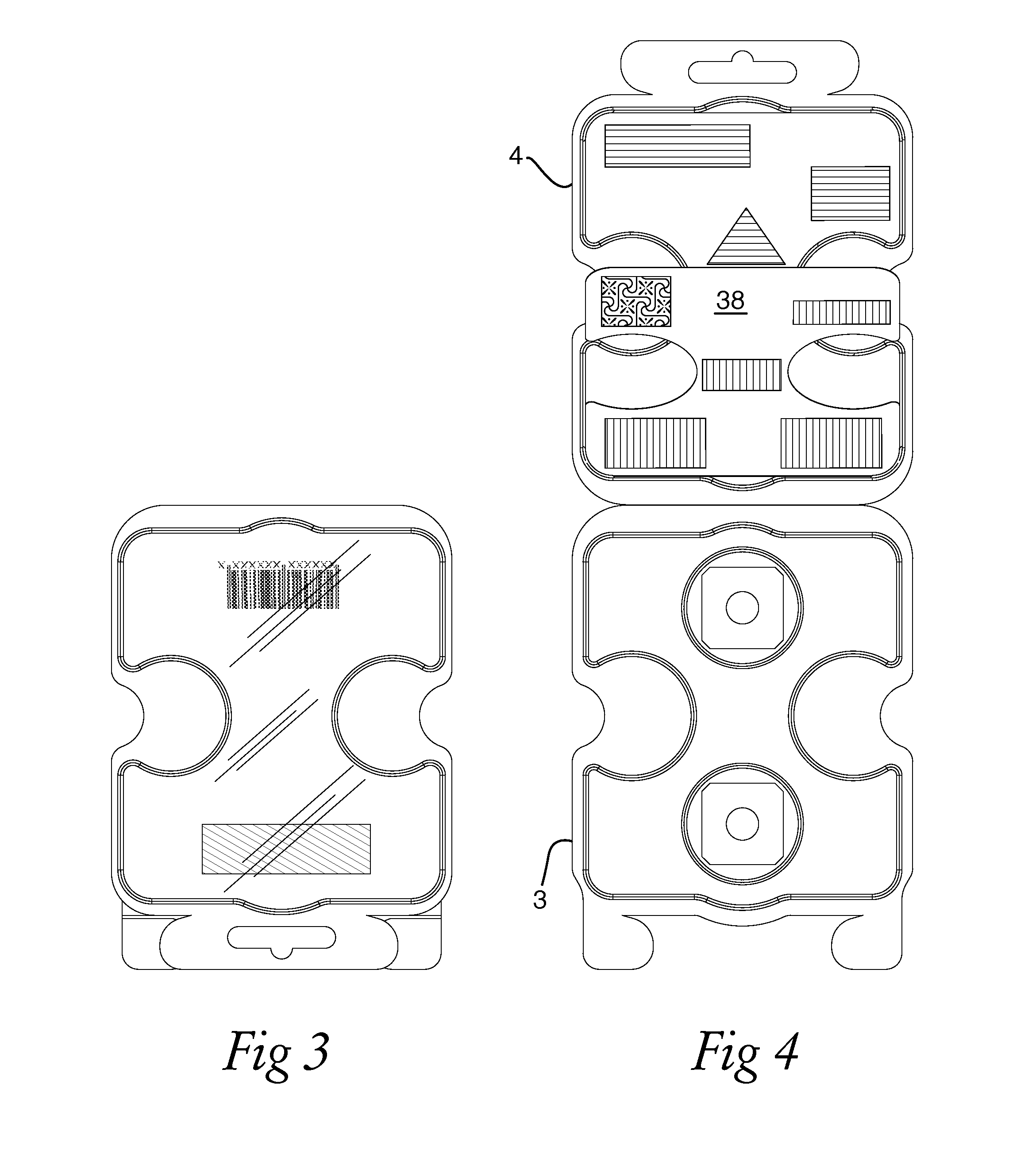

Package

ActiveUS20130292282A1Efficiently exposedEliminate disadvantagesPackaging vehiclesContainers for machinesSurface plateHinge angle

A package has two panels, one of which is a base part having at least one bubble that is intended for storage purposes. The bubble projects from an underside of the panel of the base part and opens into an opening in the upper side thereof. The other panel is a cover that is connected with the base part via a hinge in order to be rotatable between a raised position, in which the interior of the bubble is accessible, and a lowered position in which the panel of the cover covers the opening of the bubble. The panels of the base part and cover are each formed with two seats that in the lowered position of the cover are laterally and equidistantly separated from the bubble. The package allows exposure of information of one or two storage objects, while being stacked together with other packages in a compact pile.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Method for manufacturing a bearing ring member

ActiveUS8424205B2Increase freedomSimplify workRolling contact bearingsMetal-working apparatusPunchingForward backward

The present invention provides a manufacturing method of a bearing ring member such as an outer ring comprising an installation portion on the outer peripheral surface and a double row of outer-ring raceways on the inner peripheral surface, in which a raw material is processed to obtain a final stage intermediate member through a first upsetting process, a forward-backward extrusion process, a second upsetting process, a burr removing process, and a punching process, wherein a movable die which leaves a stationary die in the final step is used in the second upsetting process, and the excess metal material is moved toward outside in the radial direction to a portion which become the installation section and a burr formation section, exposing a high pure metal material at least in a portion where the load of rolling bodies acts so as to ensure the rolling fatigue life of the both of outer-ring raceways.

Owner:NSK LTD

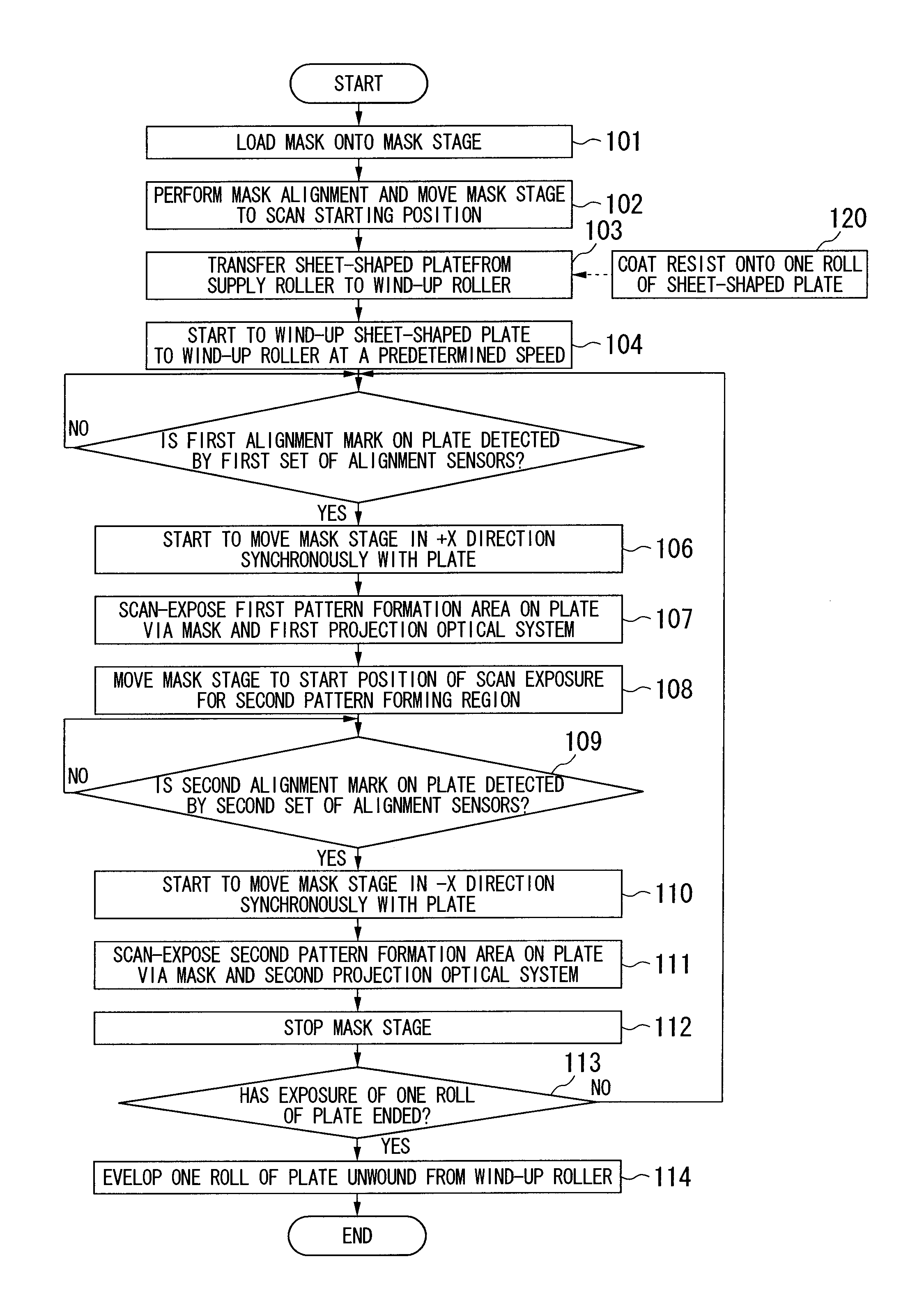

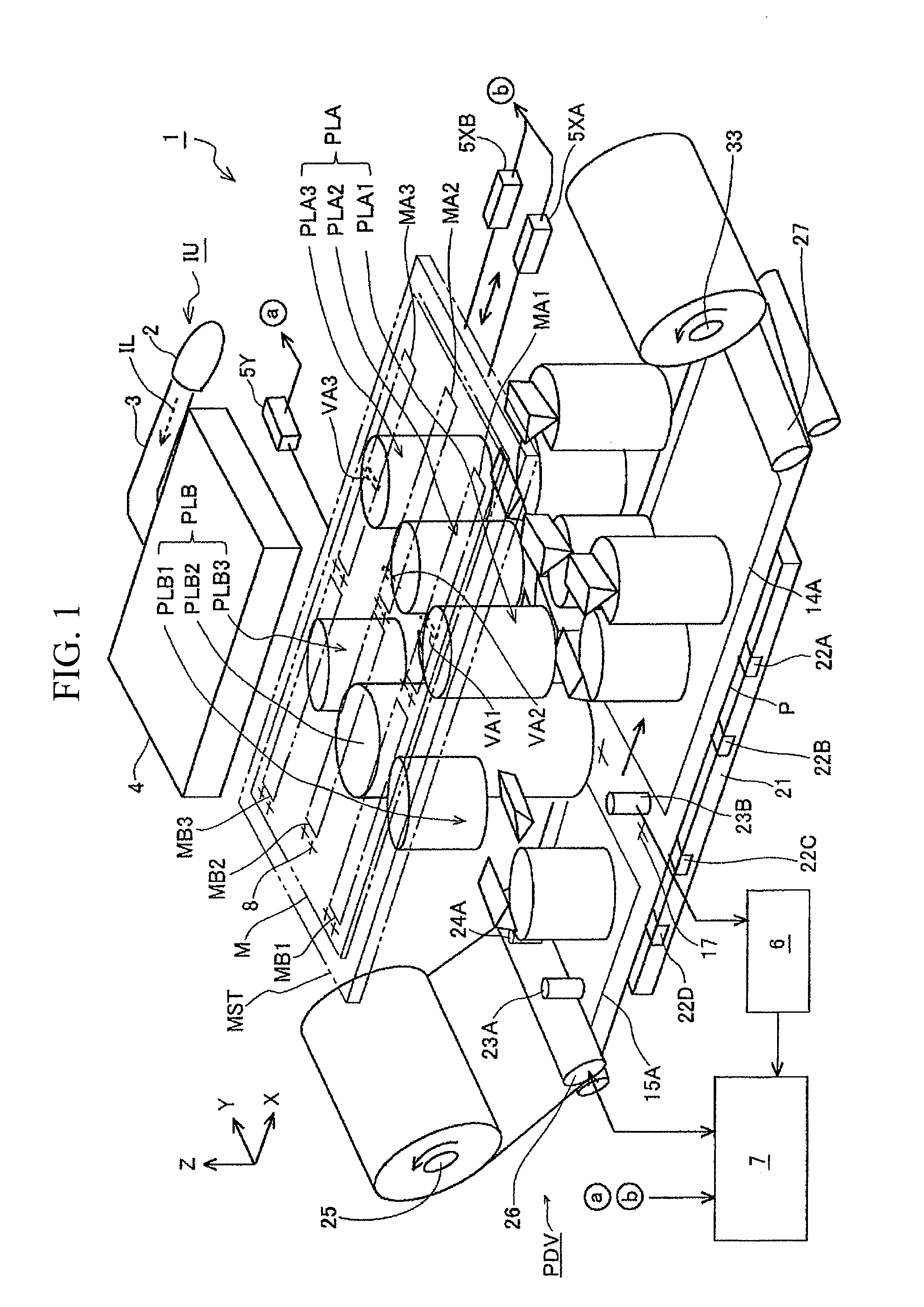

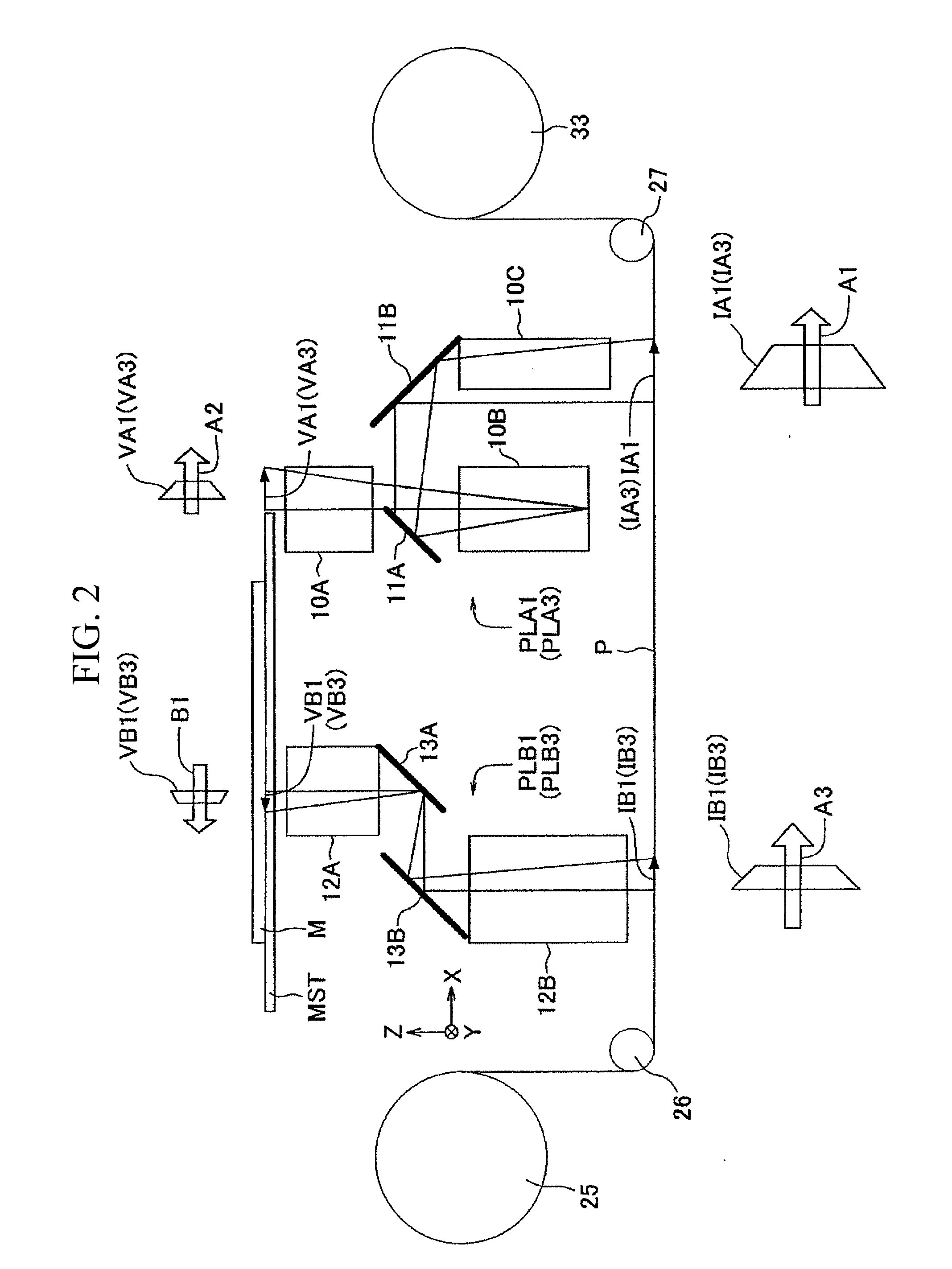

Exposure apparatus, exposure method and device fabricating method

InactiveUS20100290019A1Efficiently exposedEffective exposureResistance/reactance/impedencePhotomechanical exposure apparatusReciprocating motionEngineering

An exposure method for exposing a plate with an image of a pattern of a mask comprises: reciprocating the mask along X direction, synchronizing a movement of the mask and a movement of the plate to +X direction, projecting an image of a first pattern of the mask onto the plate as an erected image with respect to +X direction during a first period in which the mask that is reciprocating is moved in +X direction, and projecting an image of a second pattern of the mask onto the plate as an inverted image with respect to +X direction during a second period in which the mask that is reciprocating is moved in −X direction.

Owner:NIKON CORP

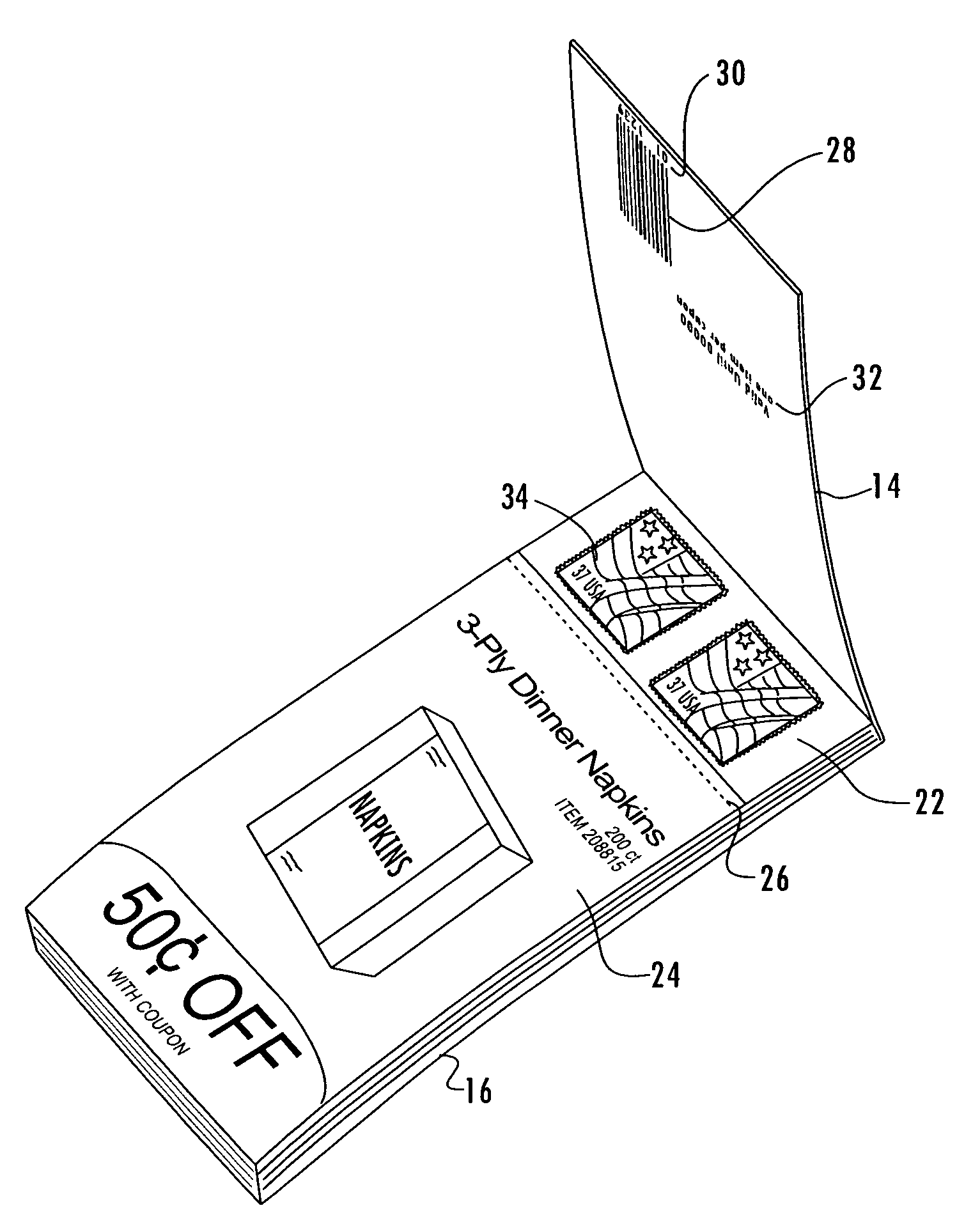

Combination stamp and advertising booklet

InactiveUS7513533B2Easy to placeImprove distributionStampsOther printing matterWorld Wide WebPostage Stamps

The present invention is directed toward a combination stamp and advertising booklet. Particularly, a combination postage stamp and advertising booklet having dimensions of paper currency so that it can be readily placed in the till of a checkout register for easy dispensing thereof by the cashier. Each page of the booklet may include one or more removably attached stamps and one or more forms of advertisement, thereby exposing the potential customer accessing the stamps to the advertising material located on the page and adjacent pages. This configuration minimizes the risk that the advertising material will be overlooked or discarded by the consumer.

Owner:POSTAGE STAMP ADVERTISING

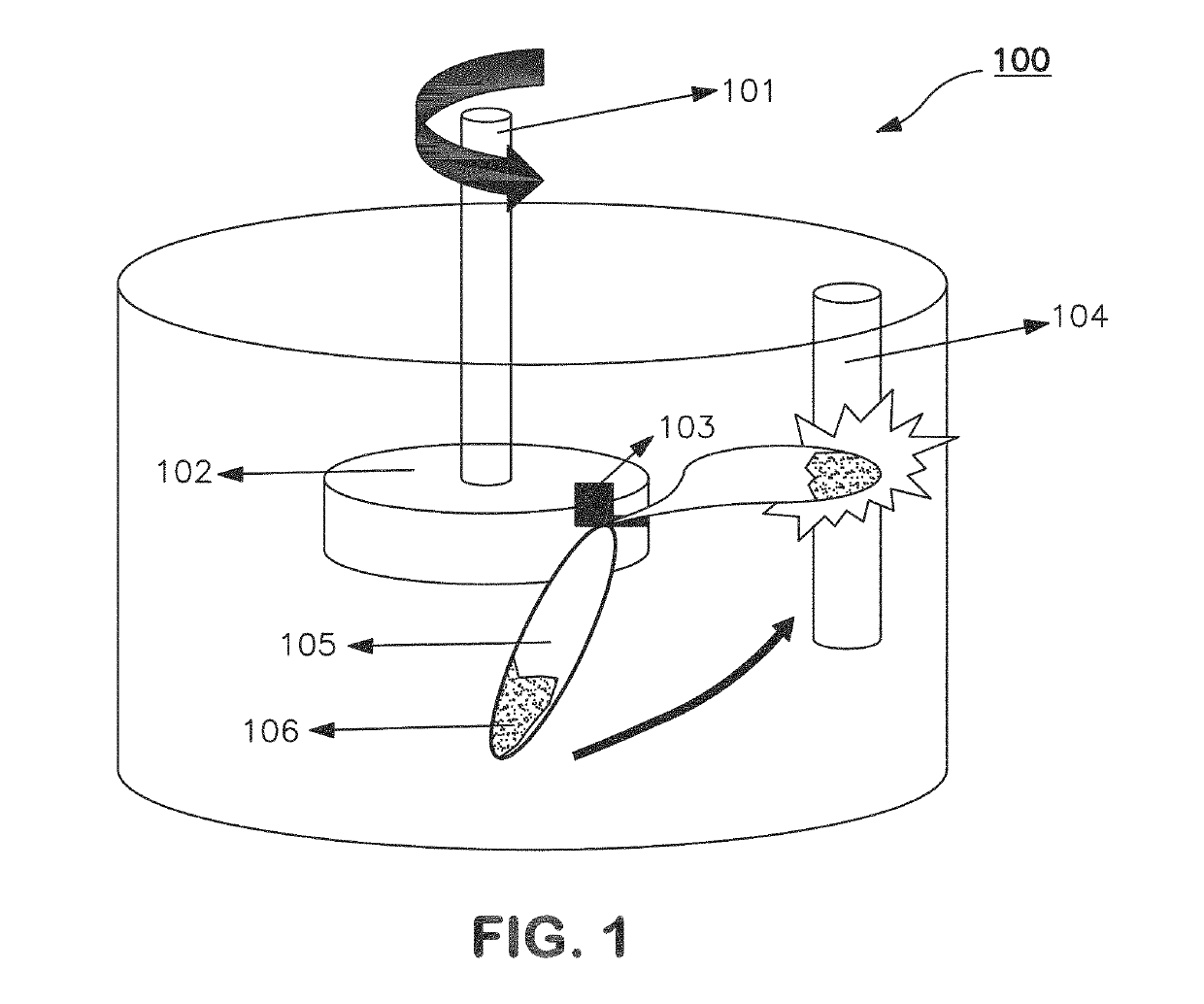

Apparatus and method for mixing and/or mulling a sample

InactiveUS10307751B2Improve sealingEfficiently exposedMolecular sieve catalystsAluminium silicatesGramEngineering

Disclosed herein are an apparatus and a method for mixing and / or mulling a sample, the apparatus comprising at least one container made of a flexible material and containing a sample, means for holding the container, and means for impacting the container, wherein the means for holding and the means for impacting are movable relative to each other, and wherein the means for holding, the means for impacting, and the container are arranged such that the means for impacting and the container can repeatedly collide, whereby an energy of collision can be imparted to the sample, thereby mixing and / or mulling the sample. Also disclosed is an assembly for performing high throughput experiments including the apparatus for mixing and / or mulling a sample and an extruder configured to receive a sample weighing less than 100 grams.

Owner:EXXON RES & ENG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com